3a (65)

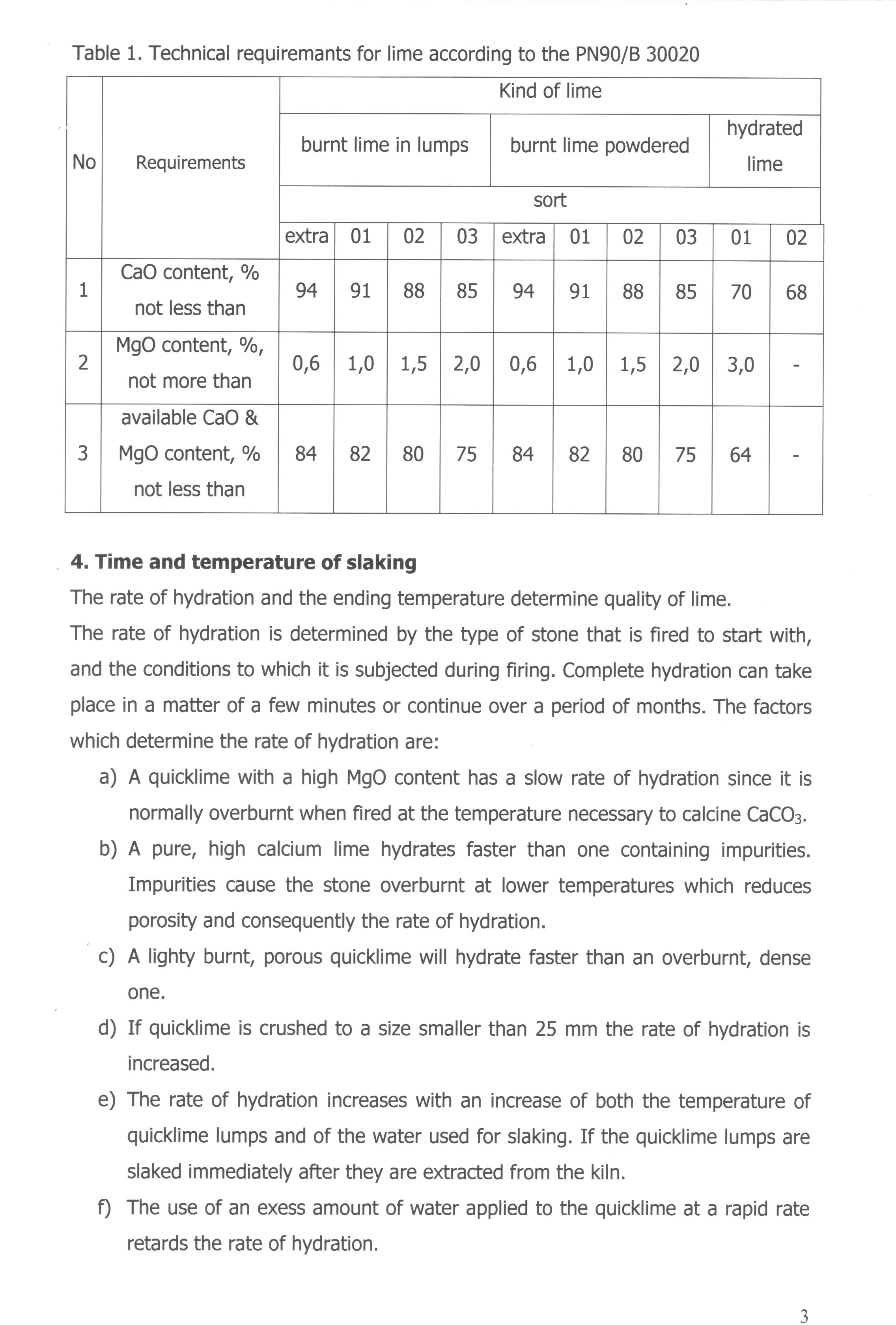

Table 1. Technical reguiremants for limę according to the PN90/B 30020

|

No |

Requirements |

Kind of limę | |||||||||

|

burnt limę in lumps |

burnt limę powdered |

hydrated limę | |||||||||

|

sort | |||||||||||

|

extra |

01 |

02 |

03 |

extra |

01 |

02 |

03 |

01 |

02 | ||

|

1 |

CaO content, % not less than |

94 |

91 |

88 |

85 |

94 |

91 |

88 |

85 |

70 |

68 |

|

2 |

MgO content, %, not morę than |

0,6 |

1,0 |

1/5 |

2,0 |

0,6 |

1,0 |

1,5 |

2,0 |

3,0 |

- |

|

3 |

available CaO & MgO content, % not less than |

84 |

82 |

80 |

75 |

84 |

82 |

80 |

75 |

64 |

- |

4. Time and temperaturę of slaking

The ratę of hydration and the ending temperaturę determine quality of limę.

The ratę of hydration is determined by the type of stone that is fired to start with, and the conditions to which it is subjected during firing. Complete hydration can take place in a matter of a few minutes or continue over a period of months. The factors which determine the ratę of hydration are:

a) A quicklime with a high MgO content has a slow ratę of hydration sińce it is normally overburnt when fired at the temperaturę necessary to calcine CaC03.

b) A pure, high calcium limę hydrates faster than one containing impurities. Impurities cause the stone overburnt at lower temperatures which reduces porosity and consequently the ratę of hydration.

c) A lighty burnt, porous quicklime will hydrate faster than an overburnt, dense one.

d) If quicklime is crushed to a size smaller than 25 mm the ratę of hydration is increased.

e) The ratę of hydration increases with an increase of both the temperaturę of quicklime lumps and of the water used for slaking. If the quicklime lumps are slaked immediately after they are extracted from the kiln.

f) The use of an exess amount of water applied to the quicklime at a rapid ratę retards the ratę of hydration.

3

Wyszukiwarka

Podobne podstrony:

67 The influence of anthropopressure... for pastures. According to H. Błaszczyk (1974), at the end o

unit6 to set up -to establish a treaty/agreement provides for ... economic accord to stand

1. The correct English spelling for the Hindi fępr^T, according to the

32 Rope-Sight. The rule for pncking changes in this way is to proceed according to the rules given f

Image (15) Reading 1 For questions 1-7, choose the answer (A, 8, C or D) which you think fits best a

fonetyka0001 fe mm INTONATION PRAGTICE TUTORIAL FOCUS / TONICITY Read thefollowing sentences accordi

00227 fa893f5d70e2a8634abfc718a817fdc 229Applications of the EWMA is scaled according to the percen

172 Aneta Wszelaki DIFFERENCES IN THE PREPARATION OF THE FINANCIAL STATEMENTS OF THE BANK ACCORDING

18 Małgorzata Bednarczyk, Ewa Wszendybył-Skulska According to the model presented in Figurę 2, the e

20 Paweł Antonowicz the effective CRM system must play various different functions. According to the

MODERNIZATION AND EXTENSION OF THE DAIRY FARM ACCORDING TO THE EUROPEAN STANDARDS Project initiato

RECONSTRACTION OF THE PIG COMPLEX ACCORDING TO THE EUROPEAN STANDARDS Project initiator Privately

Department and Clinic of Surgery Decreasing the number of Department was inforced according to the s

scratches and fingerprints on the disc surface. Over and above that, according to the specifications

The requirement for gaining access to the school is the certificate of completion of education in th

Comparison of Liąuid Propellant Rocket Engine Feed Systems - 1 - 11 According to the previously expo

więcej podobnych podstron