CCI20140507�11

lost in this way.

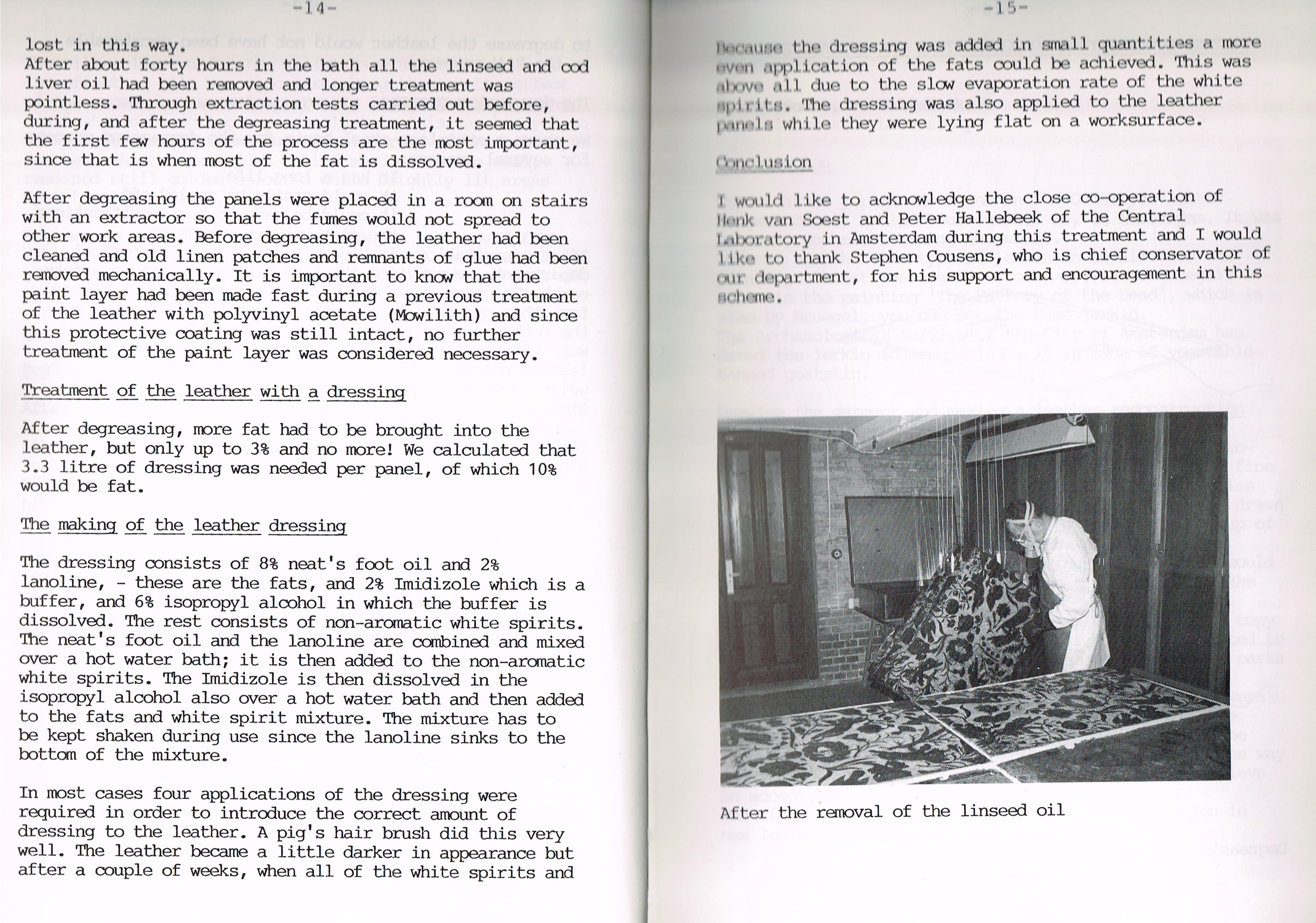

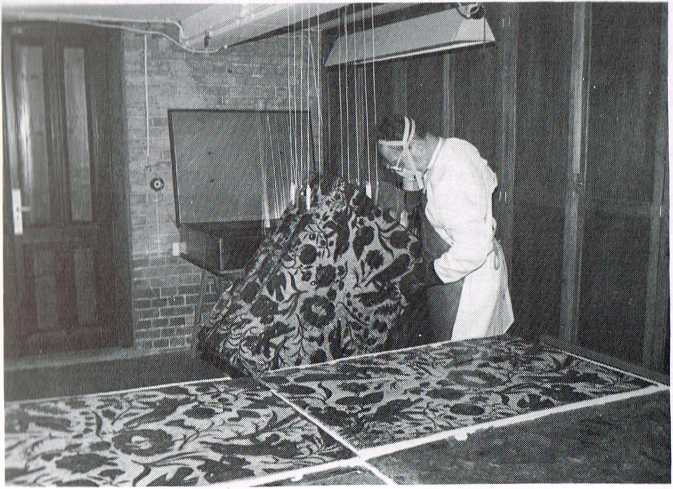

After about forty hours in the bath all the linseed and cod liver oil had been removed and longer treatment was pointless. Through extraction tests carried out before, during, and after the degreasing treatment, it seemed that the first few hours of the process are the most important, sińce that is when most of the fat is dissolved.

After degreasing the panels were placed in a room on stairs with an extractor so that the fumes would not spread to other work areas. Before degreasing, the leather had been cleaned and old linen patches and remnants of glue had been removed mechanically. It is important to know that the paint layer had been madę fast during a previous treatment of the leather with polyvinyl acetate (Mówilith) and sińce this protective coating was still intact, no further treatment of the paint layer was considered necessary.

Treatment of the leather with a dressing

After degreasing, morę fat had to be brought into the leather, but only up to 3% and no morę! We calculated that 3.3 litre of dressing was needed per panel, of which 10% would be fat.

The making of the leather dressing

The dressing consists of 8% neat's foot oil and 2% lanolinę, - these are the fats, and 2% Imidizole which is a buffer, and 6% isopropyl aloohol in which the buffer is dissolved. The rest consists of non-aromatic white spirits. The neat's foot oil and the lanolinę are combined and mixed over a hot water bath; it is then added to the non-aromatic white spirits. The Imidizole is then dissolved in the isopropyl alcohol also over a hot water bath and then added to the fats and white spirit mixture. The mixture has to be kept shaken during use sińce the lanolinę sinks to the bottom of the mixture.

In most cases four applications of the dressing were reąuired in order to introduce the correct amount of dressing to the leather. A pig's hair brush did this very well. The leather became a little darker in appearance but after a couple of weeks, when all of the white spirits and n<■< .miii' the dressing was addai in smali quantities a morę . 11 >| > l ication of the fats could te achieved. This was il»iv<< uli due to the siew evaporation ratę of the white "pliIlu. The dressing was also applied to the leather iiiiulu while they were lying fiat on a worksurface.

1 i nu I nul on i would ILke to acknowledge the close co-operation of III Mik van Soest and Peter Halleteek of the Central l.iterutory in Amsterdam during this treatment and I would III" to thank Stephen Cousens, who is chief conservator of

..... < li spartment, for his support and encouragement in this

in 'In>1110.

After the removal of the linseed oil

Wyszukiwarka

Podobne podstrony:

32 Rope-Sight. The rule for pncking changes in this way is to proceed according to the rules given f

m85$ Viking swords found in the Thames and River Witham: all belong to the period after c. 950. supp

File0053 The joy of t«t I cem talk about ko w people ust mobile pkones. Look at the photos in the te

BEADED AMULET PURSES • BEADING SUPPLIES 5How To Use This Book After choosing a project, first read t

DSC07405 Changes in the character and spatial distribution of vegetation communities that encompasse

l?970ad4d715496f98c05772ad3cc11f ‘Edward, no!’! screamed,but my voicewas lost in the roar of tl&nbs

WORLD STOCK EXCHANGES mu large Buildmgs Represent Appronimately $2 milion Billions hm been lost in t

Barth, John. Zagubiony w labiryncie śmiechu [Lost in the Funhouse], z przedmową. Wydawnictwo

EXPAND AND PRACTISE YOUR SKILLSTask 1 Talk about what is important in the chokc and applkation of ma

CCI20140507�29 -52- rules to advise the employees how to act in the storerooms and the collection wh

Fox, Norman ?ctus?valier B ‘ Down from the hills in the early dawn light King Ćonover had co

image001 Ingersoll bad gone out alone in the tractor, and tho ąuestion was: what

00268 ?a148167663d78e6679e602ee961c3b 270 Montgomery experiments are often used in the design and/o

więcej podobnych podstron