essentÊrving°22

ESSENTIAL W O O D C A R VIN G T E C H N IQ U E S

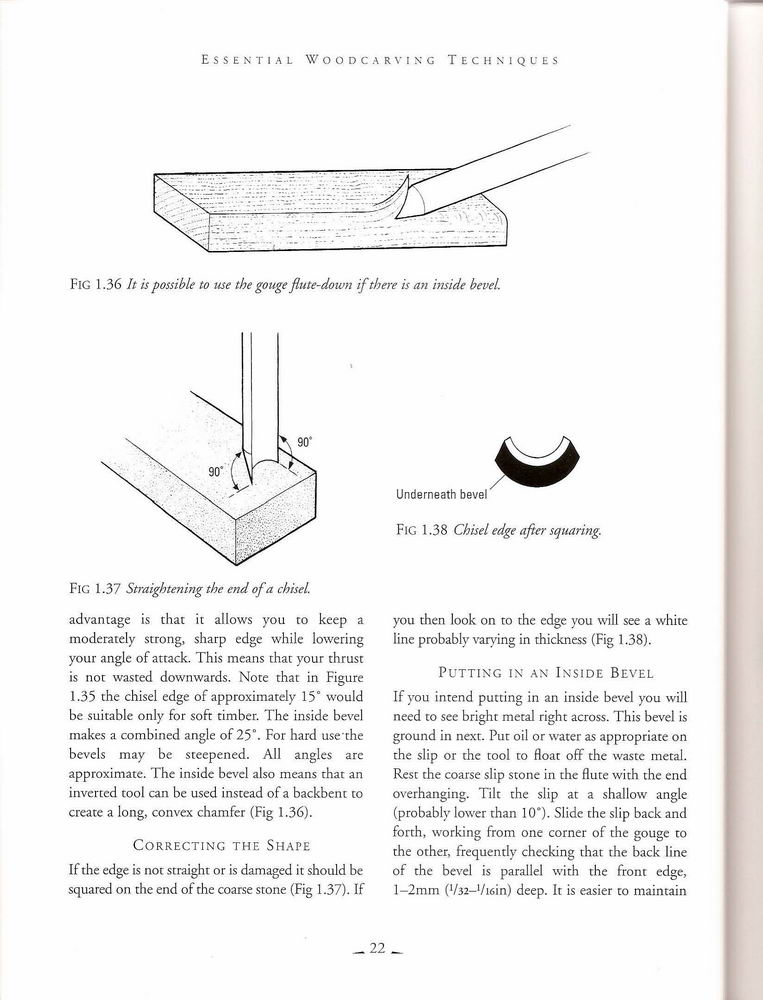

Fig 1.36 It is possible to use the gotige jlute-down if there is an inside bevei

Underneath bevel

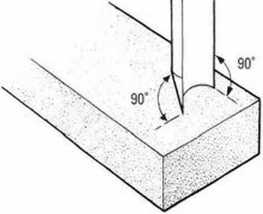

Fig 1.38 Chisel edge aftcr stjtiaring.

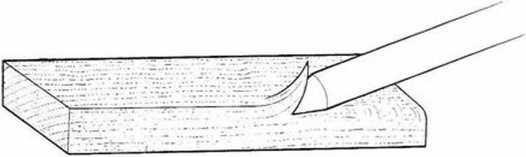

FlG 1.37 Straightening the end of a chisel.

advantage is chat it allows you to keep a moderately strong, sharp edgc while lowering your anglc of attack. This mcans that your chrust is not wasted downwards. Notę that in Figurę 1.35 the chisel edge of approximately 15° would be suitable only for soft timber. The inside bevel makes a combined angle of 25°. For hard usethe bevels may be steepened. Ali angles arc approximate. The inside bcvcl also means rhat an invcrtcd tool can be used instead of a backbent to create a long, convex chamfcr (Fig 1.36).

CORRECTING THE SHAPE

If the edge is not straighr or is damaged it should be squared on the end of the coarse stone (Fig 1.37). If you thcn look on to the edge you will see a white linÄ™ probably varving in thickness (Fig 1.38).

Putting in an Inside Bevel If you intend putting in an inside bevel you will need to see bright metal right across. This bevel is ground in next. Puc oil or water as appropriate on the slip or the tool to floac off the wastc metal. Rest the coarse slip stone in the flute with the end overhanging. Tilt che slip at a shallow angle (probably lower than 10*). Slide the slip back and forth, working from one corner of the gouge to the other, frequently chccking that the back linę of the bevel is parał lei with the front edge, l-2mm (1/32-,/ióin) deep. It is easier co maintain

_22_

Wyszukiwarka

Podobne podstrony:

essent?rving?77 C A R VI X G T RADITIONAL F O L 1 A G E Fig 6.8 Rococo frame showing leafedges to un

The goal of our thesis is to reflect on this legislative ban as it is seeing in France and in Quebec

68 Aleksandra Leśniewska3. Review of selected IT tools supporting the fitness club management It is

jff 119 GLOSSARY The use of Japanese terms has been kept to a minimum in this book. It is an imposit

• Andrzej Chodyński, Wojciech Huszlak • value, so that value to society also arises. It is an action

ERROR: The path /users/xxyyzz/Downloads/Cheatsheet.xlsx is invalid because it is not in the list of

KNOWLEDGE MANAGEMENT SYSTEMS IN POLISH HOSPITALS ... knowledge) and find it when it is necessary in

40 Mirosław Gerigk be applied. It is preferred to use the second approach. For the risk assessment a

gramatyka0003 Relative clauses - revision 1 Put in the missing relative pronoun, or — if it is poss

914 B. Rihn et al. It is now possible to use molecular biology techniÄ…ues with non-radioactive DNA l

IMGx52 2 76 The Origin of Ciirflisation The progress of the Total Culture System,

AIWA SIMPLY ADVANCEDNow recreating it is. Degree in engineering? Swiss bank account9 Ali you need to

WST ht/0.2 m not temporary. If it is possible to penetrate the stiff layer the test shall be continu

Advantages and disadvantages of digital education 25 (for this purpose it is recommended to use the

więcej podobnych podstron