essentÊrving°35

SELECT1NC AND B u Y I N G SflTABLE WOOI)

constantly growing. It is therefore wise to avoid brcathing chc dust of all woods.

The Chemical Make-up of Wood

The main constituents of wood materiał are principalły forms of cellulose and lignin. It is thc cellulose element that gives wood its main strcngths, while lignin confers stiffness.

Wood and Water: Shrinkage

AND SWELLING

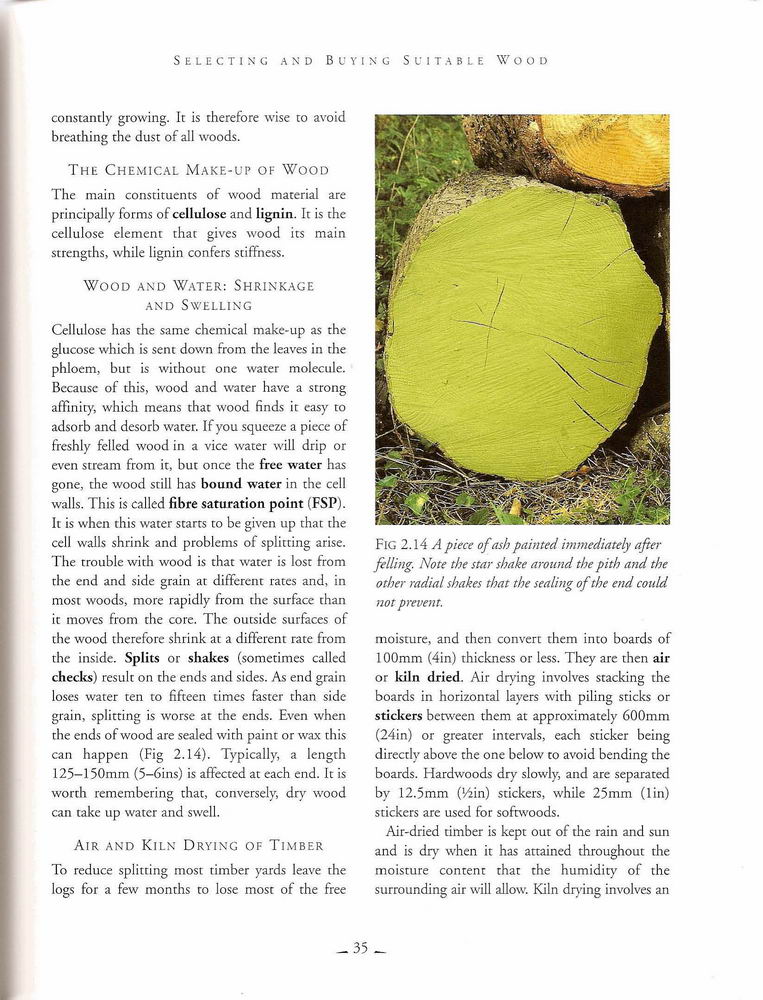

Cellulose has the same chcmical makc-up as thc glucose which is sent down from rhe leaves in the phloem, but is without one water molecule. Bccausc of this, wood and water havc a strong affinity, which means that wood finds it casy to adsorb and desorb water. If you squeeze a piece of freshly felled wood in a vice water will drip or even stream from it, but once the frcc water has gone, the wood still has bound water in the celi walls. This is callcd fibrÄ™ saturation point (FSP). It is whcn this water starts to be given up that the celi walls shrink and problems of splitting arise. The troublc with wood is that water is lost from the end and side grain at diffcrcnt ratcs and, in most woods, morÄ™ rapidly from thc surface than it moves from the core. The outside surfaces of the wood therefore shrink at a different ratÄ™ from the inside. Splits or shakes (sometimes called checks) result on the ends and sides. As end grain loses water ten to fifteen times fastcr than side grain, splitting is worse at thc ends. Evcn when the ends of wood are sealed with paint or wax this can happen (Fig 2.14). Typically, a lcngth 125-150mm (5-6ins) is affected at each end. It is worth remembering that, conversely, dry wood can take up water and swcll.

Air and Kiln Drying of Timber To reduce splitting most rimber yards leave rhe logs for a few months to lose most of rhe free

Fig 2.14 A piece ofash painted immediately afer felling. NotÄ™ the star sbake around the pith and the othcr radial shakes that the sealing of the end could not preoent.

moisture, and then convcrt them into boards of lOOmm (4in) thickness or less. Thcy are then air or kiln dried. Air drying involves stacking the boards in horizontal layers with piling sticks or stickers bctwecn them at approximatcly 600mm (24in) or greater intervals, each sticker being directly above the one below to avoid bending the boards. Hardwoods dry slowly, and are separared by 12.5mm (Viin) stickers, while 25mm (lin) stickers are used for softwoods.

Air-dried timber is kept out of the rain and sun and is dry when it has attaincd throughout the moisture content that the humidity of the surrounding air will allow. Kiln drying involves an

-35 -

Wyszukiwarka

Podobne podstrony:

essent?rving?37 SELECTING AND B V Y 1 N C» SUITABLE W O O I) carvc it immediatcly while green. This

essent?rving?33 Selecting and B l v i n g Sutable W o o d Hardwood cells pjfcre parenchyma (storage

Slajd14 5 Aplikacje GIS GIS is being applied in remarkable ways. To understand GIS and see why lt ma

914 B. Rihn et al. It is now possible to use molecular biology techniÄ…ues with non-radioactive DNA l

ipe 07 How Much Time and How Many Exercises It is much better to do exercises for a short period eac

UHAM094 WHERE CAN I GET HELP AND INFORMATION? * 77 this decision, and it is not appropriate to discu

CCF20100223�003 cavity than for Polish o, (2) it is morÄ™ open, i.e. the space between the back of th

Replication and Master or Slave Shutdowns It is safe to shut down a master server and restart it lat

Transactions and the count () function. When using MySQL Cluster Replication, it is not possible to

32 (236) Y E L L O W “But I mean to say that it is not easy to find a summer sun effect which is as&

9 9ąuilled Ietters "Say it with Quilling" — it is very simple to form letters. and. ofconr

więcej podobnych podstron