130859715

Mathematical model analysis of sample from...

where in formulas (10) and (11):

b, - damping coefficient of i-th element of the sample, N s m"1, k. - stiffness of i-th element of the sample, N m'1,

- h

h= — h0 = im - relative height i-th element of the sample,

K

» A

Ą = — Ą = lm2 - relative area i-th element of the sample, -,

4)

h - real height of i-th element of the sample, measured along the axis of driving force, m,

A - real surface perpendicular to the direction of the driving force of i-th element of the sample, m2.

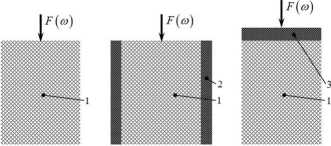

Possibilities of manufacturing different samples are presented in Fig. 4. Distribution of the skin on tested sample depends on whether it is cut or manufactured. Different samples allow to determine the materiał properties by the experimental methods for porous foam and skin.

Fig. 4. The possibilities of skin position in the sample Rys. 4. Możliwości rozmieszczenia lica próbki

Eąuations (3) for simplified samples presented in Fig. 4 are reduced eąuations as written below, respectively:

m,x, +6,x, + klxi = F (ot) (12)

(m, +m2)xl +(b{ +62)x, +(£, +k2)x{ =F{o)t) (13)

(14)

(15)

m33ć3 +b3 (x3 -x,) + ^3 (x, -x,) = F(ot)

m,x, + + kixl = 63 (x3 - x,) + k2 (x3 - x,)

m3 (x3 - 3ć,) + b3 (x3 - x,) + k2 (x3 - x,) = F ((ot)

(w, +w2)x, +(bl +b2)xl +(k{ +^2)x, =b3 (x3 -x,) + &3 (x3 -x,)

In generał, to determine the four parameters kl, k2=k3= k4 bx, and

b2=b3= b4 it is sufficient to study only two types of samples because the obtained transfer functions are complex numbers and each of them enables

Wyszukiwarka

Podobne podstrony:

Mathematical model analysis of sample from... b. The solution of the equations describing the model

Mathematical model analysis of sample from... The value we are interested in: X (s) = X,(s). can be

tity of infiltration water both from leaks in the aąueducts and sewers and from the discharge of was

jow06 04 ElUlntte Torcleos nunbora 1 and 2 of Pirat Loason, and nuobero 10 and 11 of your Ihlrd le

4ANALYSIS, TESTING JPRS-UMS-92-003 16 March 1992 elements from ethylene glycol model Solutions of ch

140 CZASOPISMA CHEMICZNE W POLSCE ABSTRACT The analysis of Chemical periodicals in Poland in 2004 ha

IMG@59 Zachowywanie wiary An analysis of ESS 2004/5 data by researchers at the Catholic University o

File0008 Hi! I m Martin l m 17 years old and Tm looking for e-mail friends of the same age from

D. Prokopowicz, S. Gwoździewicz, An analysis of the security of Information systems protection in th

WINKOWSKI, Józef (1934-). A mathematical model of action / Józef Winkowski. - Warszawa : Wydawnictwo

więcej podobnych podstron