372596180

168

RIKEN Accel. Próg. Rep. 24 (1990)

V-2-16. All-Metal Gate Valve with an RF Contact

S. Yokouchi, K. Yagi,* K. Yoshida, * T. Ohbayashi, * and S.H. Be

10->1-760 Torr

less (han IX 1 <H°Torr l/s

SUS304

Be-Cu

Alalloy

5~7 kgf/cm2G

150°C

JVIS 003 NB 100 Bakcable Flangc

GN21 5 Kgf/cm21

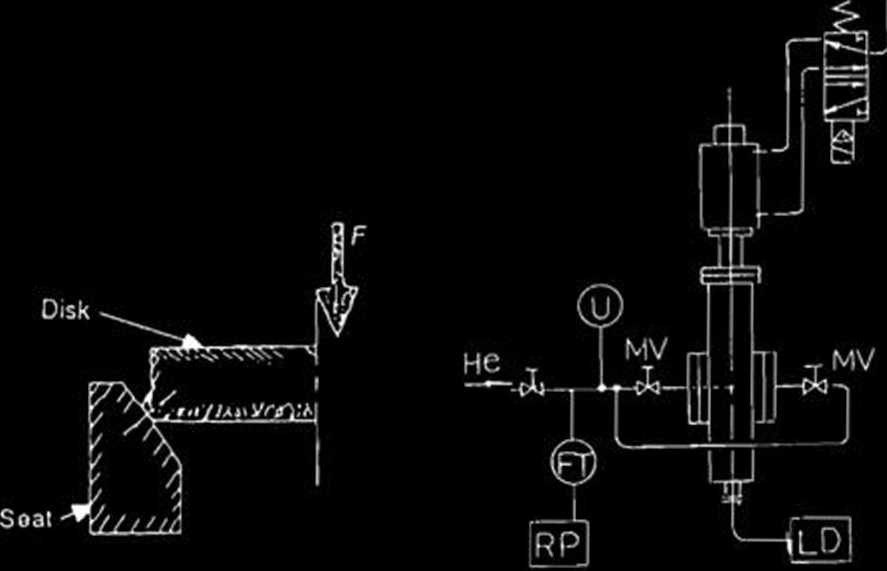

Fig. 3. Valve seal part. Fig. 4. Test system.

We manufactured an all-metal gate valve with an RF contact on trial. Table 1 gives main specifica-tions of the gate valve. The gate valve at the open position is shown in Fig. 1. The present valve body was madę of stainless-steel, but that to be used in the practical SR ring is madę of aluminum-alloy except a part of valve seats and disks. A techniąue is employed, which provides an enclosed evacuated space between double seals, thereby reducing the

Table 1. Main specification.

Pressure rangę Leak rato

body and valve seal parł* Materials

Main parts RF contact Others

Comprcsscd air pressure Bakcout temperaturę Flangc dimension

• Differcntial pressure on the valvc seal is 1 aim in either direction

Fig. 1. Outside view.

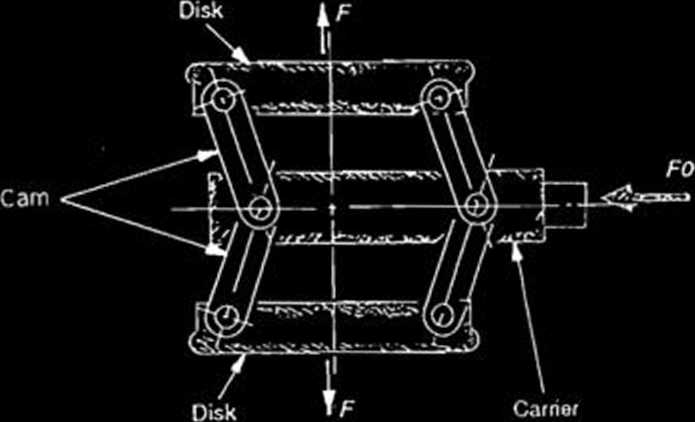

Fig. 2. Amplification mechanism of sealing force.

pressure difference across the seals and decreasing the leak ratę of the seals. In the open position, the RF contact which has the same geometry as the beam chamber can bring about a direct electrical connection between two body flanges. Applying the thrusting force of an actuator to cam parts, which are connected to a carrier and two disks by a link mechanism (see Fig. 2), the sealing force between the seats and disks coated with silver is amplified by F/F0>1. The further amplification of the sealing force is obtained by pushing the disks with a smali arc to tapered seats polished like a mirror (see Fig. 3). The deformation amount of the valve disks and seats due to the sealing force is within an elastic limit.

To investigate the leakage reliability at seals, we actuated the valve 1,000 times using the test system as shown in Fig. 4. The results show that the performance is not yet satisfied completely because there are a leak of the order of 10-8 Torr/s_1 over several times during actuations of these first 1,000 times. However, the present leak ratę can be reduced to less 1 X 10-10 Torr-/-s_1 by evacuating the enclosed space between double seals.

To improve fluctuation of the leak ratę to 1 x 10“10 Torr-/-s~\ we are planning an investigation of the relation between the sealing pressure and the leak ratę.

* Osaka Yacuum, Ltd.

Wyszukiwarka

Podobne podstrony:

RIKEN Accel. Próg. Rep. 24 (1990)111-1-20. Induced Fission Studied with a Multi-DimensionalLangevin

80 RIKEN Accel. Próg. Rep. 24 (1990)111-3-16. Development of an lon Beam Sputtering Method toPrepare

92 RIKEN Accel. Próg. Rep. 24 (1990)111-5. Instrumentation1. Design of a Microbeamline for a Compact

94 RIKEN Accel. Próg. Rep. 24 (1990)111-5-2. Design of a Decay Muon Channel Using an Axially Symmetr

102 RIKEN Accel Próg. Rep. 24 (1990)111-5-8. Performance of Isotopic Separation in RIPS T.Nakamura,

103 RIKEN Accel. Próg. Rep. 24 (1990)111-5-9. Test Experiment of the GARIS/IGISOL K. Morita, T. Nomu

105 RIKEN Accel. Próg. Rep. 24 (1990)111-5-10. Velocity Distribution of IGISOL lon Beams M. Koizumi,

108 RIKEN Accel. Próg. Rep. 24 (1990)111-5-12. Status Report of the RIKEN Swinger-Magnetic Analyzer

110 RIKEN Accel. Próg. Rep. 24 (1990)111-5-14. Test for Dispersive-Mode Beam Transportto the SMART

116 RIKEN Accel. Próg. Rep. 24 (1990)111-5-19. Responses of Large Position-Sensitive Detectorsto Hea

121 RIKEN Accel. Próg. Rep. 24 (1990)IM-5-23. A Test for SMART Neutron Detectors H. Orihara, K. Hata

RIKEN Accel. Próg. Rep. 24 (1990)111-5-25. High Speed Serial Data Link for PC-9801 J. Fujita > PC

129 RIKEN Accel. Próg. Rep. 24 (1990)IV-2. Cross Section Data for 68Ge ProductionY. Tendow, A. Hashi

132 RIKEN Accel. Próg. Rep. 24 (1990)IV-5. Cross Sections Calculated by an ALICE Codęin the A = 50 —

133 RIKEN Accel. Próg. Rep. 24 (1990)V. DEVELOPMENT OF ACCELERATOR FACILITIES1. lon Accelerator Deve

138 RIKEN Accel. Próg. Rep. 24 (1990)V-l-4. RIKEN (Japan)-RAL (U.K.) Collaboration on Muon Science R

więcej podobnych podstron