6585844938

Sweden

128

point bearing pil es is determined and the depth exceeds 20 - 25 m or the resistance of the upper part of the soil profile is high and the resis-tance increases gradually with depth. If the ro-tation prescribed for method A is used for method B the realibility of method B will increase in some degree.

The experience with the Swedish ram-sounding method is primarily based on method B which was originally developed for the purpose of estimat-ing the length of point bearing piles and of sheet piles. The same quality requirements are used at present for method A as for method B.

A penetration test is generałly interrupted when so called “rock indication" is obtalned, that is when the penetrometer "bounces" and the penetration is insignificant after one to three series of 50 blows each. (The penetration during each series should be measured carefully.) If the penetration res1 stance increases gradually with depth the test is terminated when the penetration resi stance exceeds 200 to 300 blows/20 cm wlthin a depth 1nterval of 0.6-1.0 m.More rigorous requirements are used when the transition from a loose to a hard layer is rapid 1n comparison with the case when the penetration resistance increases gradually with depth.

Light Hotor-Percussion Sounding

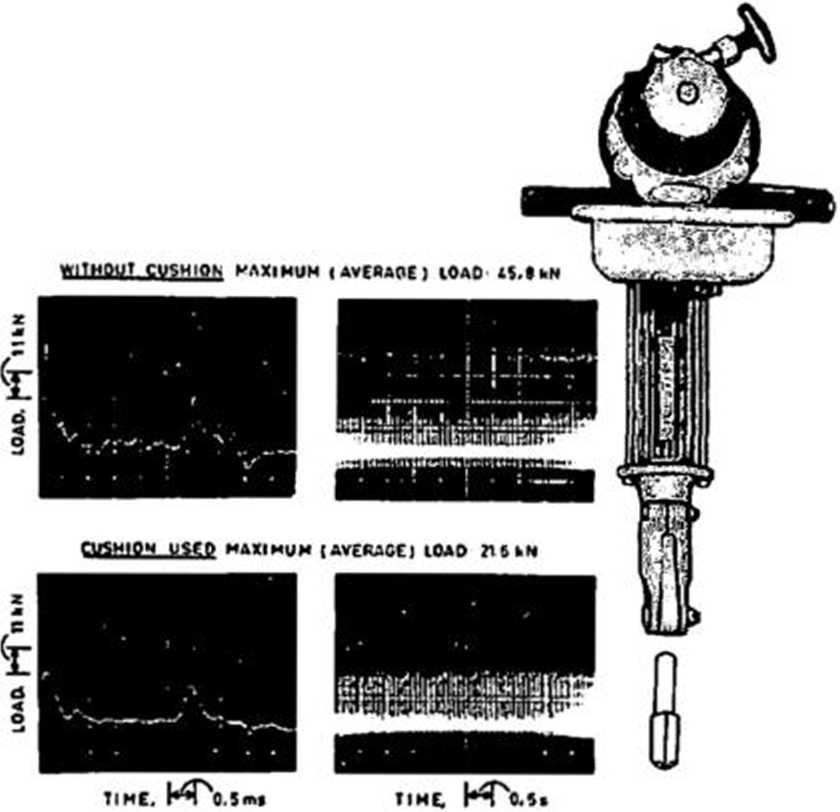

L1ght motor-percussion soundings are carried out with light rock drilling machines of type Cobra, Pionjb’r or Wacker. Rods with 22 or 25 mm diameter are used. The penetrometer is prov1ded with an enlarged square or round point. The s1de or the diameter of the point is usually 3 mm larger than the rods in use (see Fig. 21). The penetration resistance is recorded as the number of seconds reguired for 20 cm penetration (s/20 cm).

Fig. 21

Light motor-percussion machinę, type Wacker. Results from shock wave measurements with and without cushions.

Light motor-percussion sounding has been used only during the last few years as a soil inves-tigation method. This type of sounding will only g1ve a rough indication of the layer sequence sińce the machines mentioned above have not especially been designed for soli penetration testing but for use in hard rock. The test results are unreliable because the energy deli-vered by the machines (except the Wacker appa-ratus) varies with the blow frequency and with the penetration resistance. The driving force delivered by the machines is too high and 1ts duration is too short for soil exploration purposes. Also the frequency is too high, 1200-3000 blows/min. Earlier used Iow quality rods were not strong enough to resist the blows,which resulted in an abnormally high consumption of 22 mm weight sounding rods. That is the reason why 25 mm rods came into use.

Significant Information can be obtained with this method about, for example, “rock-free depth". This Information is important for exr cavations and for the driving of piles and sheet piles.If soil condltions are fayourable the test results can indicate the required lenqth of point bearing piles. It is also possible to obtain a rough indication about the content of boulders 1n the soil with this method. Light motor-percussion soundings are sometimes used in combinatlon with the Swedish weight sounding method in order to increase the penetration depth. In that case the weight sounding rods and a screw point are used.

Attempts have been madę to reduce the max1mum force from the rock drilling machines by placing a cushion on the anvil of the machinę, as reported by Dahlberg (1972)* Thereby the penetration ratę has increased in loose to medium dense soil, while the ratę has been reduced in hard soli. The cushion thus increases the difference in penetration resistance (s/20 cm) between loose and hard soil. Thereby the possi-bility to distinguish between layers with * different resistances is increased.The effect of damping on the shape of the shock wave is illustrated on the two diagrams on the left side in Fig. 21. The diagrams to the right show the maximum force in the rod during a number of blows del1vered by a Wacker machinę.

Soil-Rock Sounding

The main purpose of soil-rock sounding is to check the transition between soil and rock. $o1l-rock sounding is carried out, in principle, with the same equipment as that used for the drilling of borę holes in rock for blastlng.

With percussion drilling it is also possible to penetrate solls contalning boulders and to de-termine the quality of the underlaying rock.

In many cases the geological condltions are, however, such that special methods are needed. Frequently casing or wash drilling are requ1red. During drilling the penetration ratę is measured. The time in seconds per 20 cm penetration (s/20 cm) is an Indication of the hardness of the rock or the density of the soil. Rock drilling machines have generally been de-

Wyszukiwarka

Podobne podstrony:

Catherine Cooke The Hidden Temple (B) Arel is dead, and the kingdom should be at peace. But Queen

The Monarch and the Prime Minister in Great Britain •> The monarchy is hereditary, and the title

skanowanie0003 opisuje Mahometa w swojej książce zatytułowanej On Hero-es, Hero-Worship, and the Her

WHAT IS TELECOMMUNICATION AND THE TELECOM INDUSTRY? VALUCR5G: THE FUTURĘ FOR TELECOMSV* •»*«

PROTOTYPEWOOD PROTOTYPE The tire is removed and the inner tubę is stretched,

F00574 018 g002 o EXAMINATION OF THE ARTERIAL PULSE • The character of the pulse i

m POLITECHNIKA GDAŃSKAIntroduction An Embedded System (ES) is a Computer system with a dedicated fun

UHAM036 WHO HAS HEADACHES AND M IG RAI N ES? * 19 what is wrong with the vehicle. So when you see yo

UHAM041 24 * UNDERSTANDING HEADACHES AND M IG RAI N ES is in intensity rather than quality. In all o

ARCHMELOG and NOARCHIVELOG Modę One of the important decisions you nced to make as a DBA is to deter

img021 One may determine that the rea-son an individual is unstable in standing is in part due to hi

DSC00573 ^<i«a CMM. mAM7M &OOQ ^<i«a CMM. mAM7M &OOQ im <*Ł~. A-es* is»> 6t%

216 Z. Święcicka Abstract In project control precision it is very important in determining the plann

więcej podobnych podstron