28-1

Motronic Multiport Fuel

Injection (MFI) and ignition

system, general information

Ignition system, servicing

For information on servicing and repairing the

Multiport Fuel Injection (MFI) part of the Motronic

system

Repair Group 24

Note:

Only those components that are specifically

related to the ignition system are covered in this

repair group. For other components of the

Multiport Fuel Injection (MFI) and ignition

system

Repair Group 24

The Motronic Engine Control Module (J220) for

ignition and fuel injection is equipped with

Diagnostic Trouble Code (DTC) Memory.

Components marked with an asterisk (*) are

checked by the On Board Diagnostic (OBD)

program.

Before carrying out repairs or troubleshooting,

initiate the On Board Diagnostic program and

check for malfunctions stored in the Diagnostic

Trouble Code (DTC) Memory,

Repair Group

01

Electrical check of Motronic Multiport Fuel

Injection (MFI) and ignition system

Repair

Group 01

Safety rules

page 28-5

Technical data, Spark Plugs

page 28-6

28-2

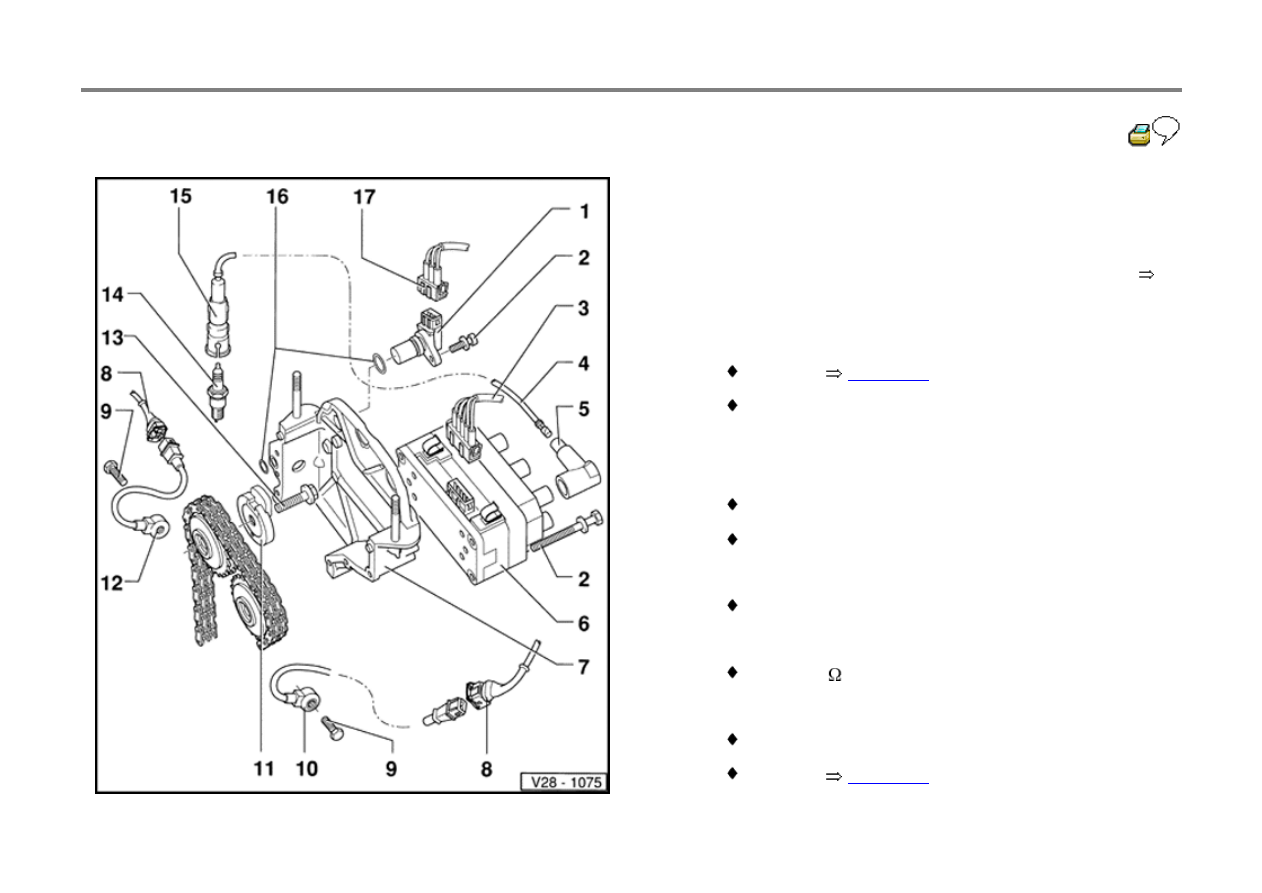

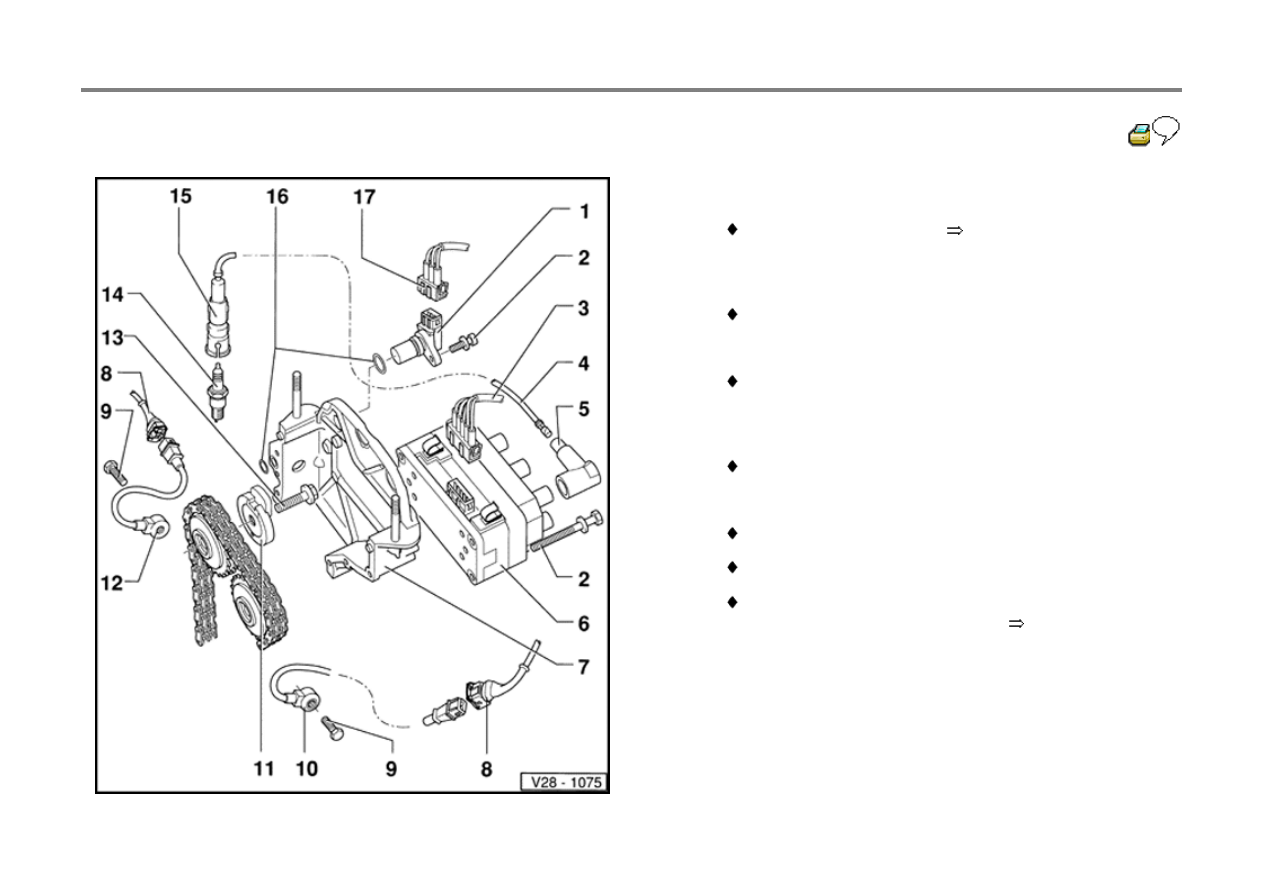

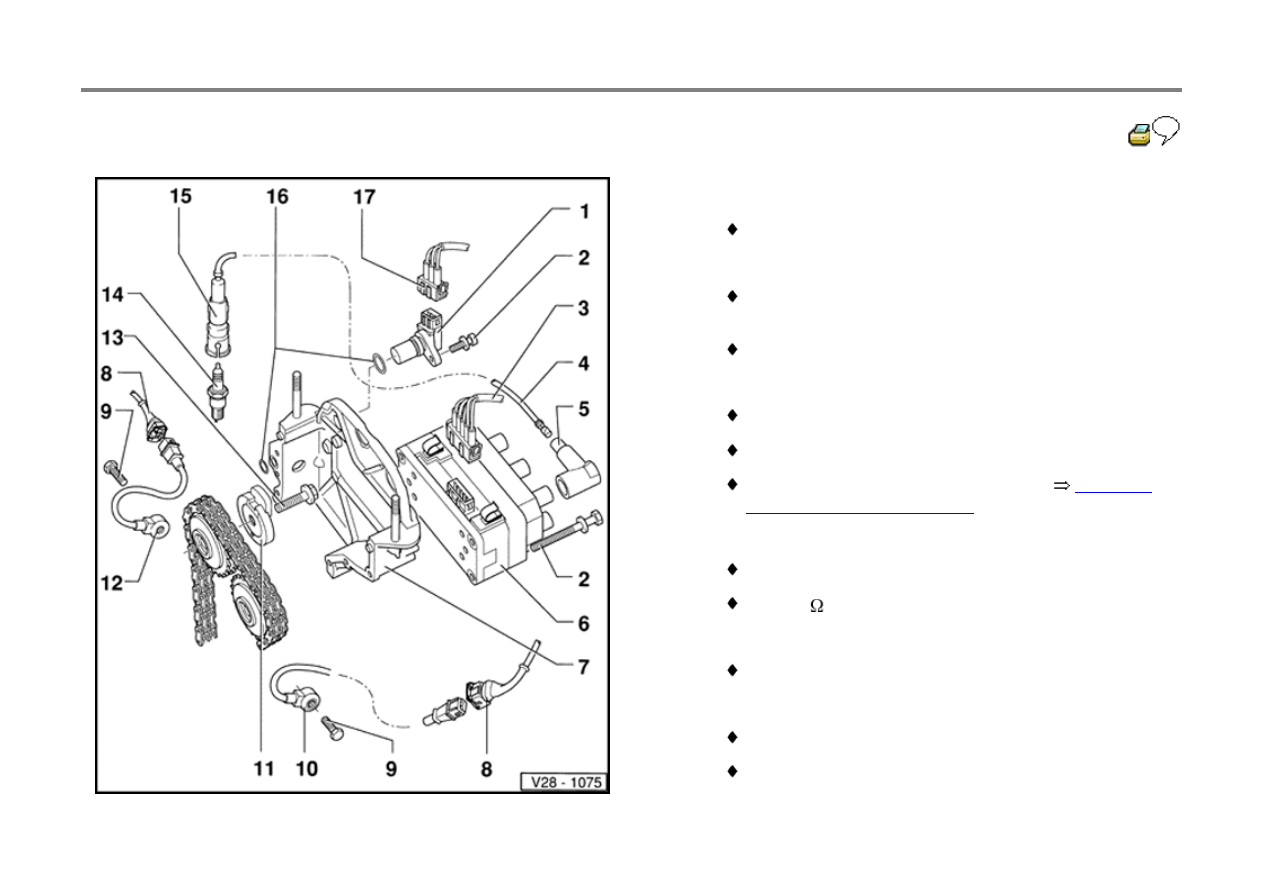

Motronic ignition system, components

Note:

Motronic Engine Control Module (J220) * with connector,

Repair Group 24

1 - Camshaft Position (CMP) Sensor (G40)*

Checking

page 28-7

Note spacers

2 - 10 Nm (7 ft lb)

3 - Connector

5-pin

For ignition coil (N152)

4 - Ignition cable

Check for continuity

5 - Suppressor

0.6 - 1.4 k

6 - Ignition coil (N152)*

With ignition cable identification, do not interchange

Checking

page 28-9

28-3

7 - Camshaft sprocket cover

Removing and installing,

Repair Manual, 2.8 Liter

General, Engine, Repair Group 15

8 - Connector

3-pin

9 - 20 Nm (15 ft lb)

Tightening torque influences function of knock

sensor

10 - Knock sensor 2 (G66)*

Mounting location: cylinder block intake side

11 - Sensor wheel

For Camshaft Position (CMP) Sensor (G40)

Contact surface on camshaft sprocket must be dry

If the sensor wheel has been removed, check

camshaft timing after installation

Repair Manual,

2.8 Liter General, Engine, Repair Group 13

28-4

12 - Knock Sensor 1 (G61)*

Mounting location: cylinder block exhaust side

13 - 100 Nm (74 ft lb)

Removing/installing: counter-hold with 24 mm

wrench on camshaft

Oil bolt head contact surface

14 - Spark plug

Tightening torque: 25 Nm (18 ft lb)

Remove and install with tool 3122B

Type and electrode gap specifications

Technical

data, spark plugs, page 28-6

.

15 - Spark plug connector

Use tool 3277 to disconnect and connect

4 to 6 K

16 - O-ring

Replace if damaged

17 - Harness connector

3-pin

For Camshaft Position (CMP) Sensor (G40), item -1-

28-5

Safety rules

CAUTION!

To prevent personal injury or damage to

sensitive electrical components:

Switch ignition OFF before connecting or

disconnecting components or test

equipment.

If engine must be cranked but not started (for

compression testing etc.) disconnect the 5-

pin connector from the Ignition Coil (N152)

DO NOTuse battery booster for longer than

one minute and DO NOT exceed 16.5 Volts.

DO NOT wash engine unlesss ignition is

switched OFF.

Switch OFF when arc or spot welding.

Connect or disconnect Battery only with

ignition switched OFF to prevent damage to

the Motronic Engine Control Module (ECM).

Before disconnecting the Battery, ALWAYS

ask for the correct radio code (if equipped

with anti-theft radio).

Note:

A variety of electrical connectors are used on this

vehicle. Always use VW 1594 adaptor kit to

connect test instruments to these connectors.

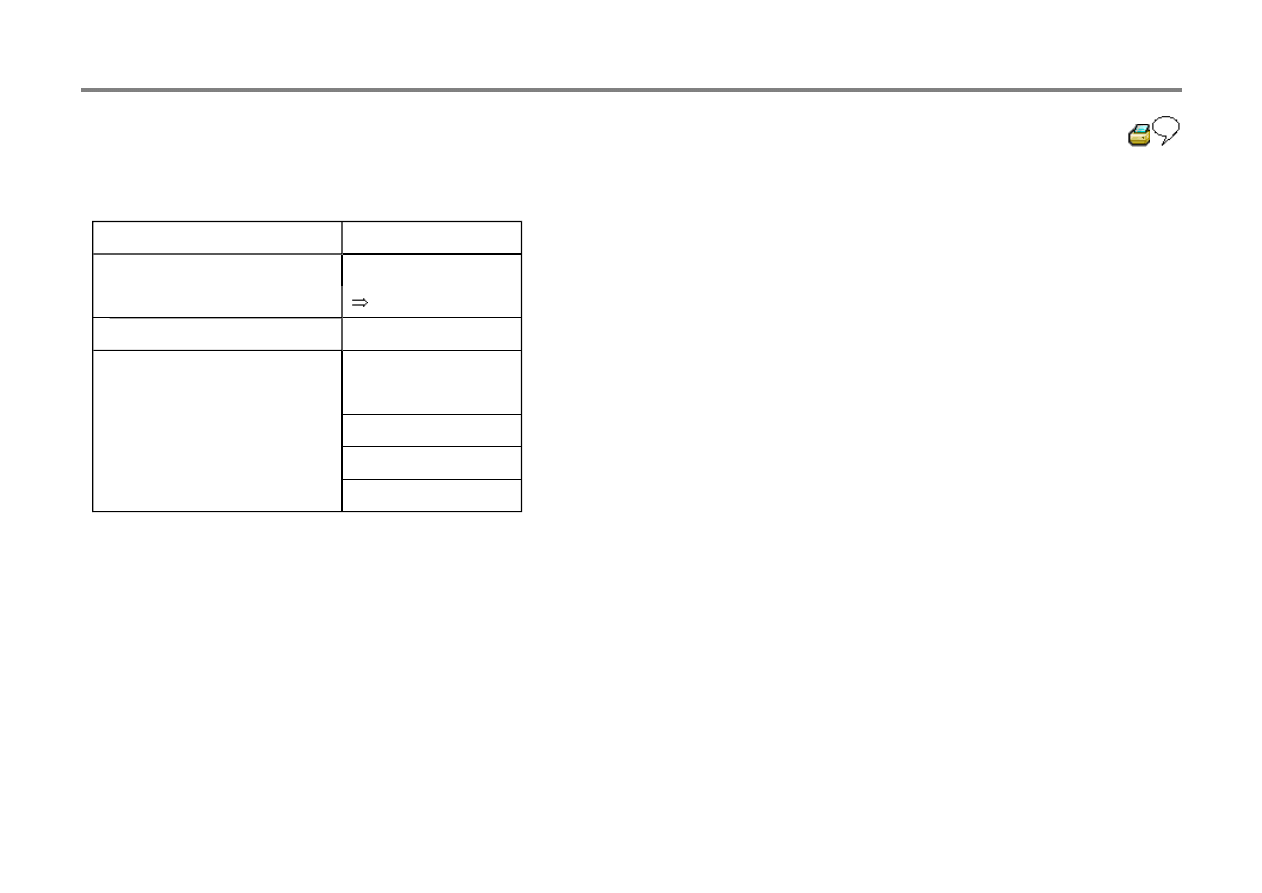

28-6

Technical data, Spark Plugs

Engine code

AAA

Ignition timing1)

Not adjustable

Checking

Repair Group 24

Firing order

1-5-3-6-2-4

Spark plugs1)

VW/Audi

101 000 035 AB

Manufacturer's designation

BKR 5 EKU

Electrode gap

0.7 mm (0.028 in.)2)

Tightening torque

25 Nm (18ftlb)

1)

Use tool 3277 to connect and disconnect spark plug connectors. Remove and install spark plugs with tool 3122B.

2)

Gap between Ground (GND) electrode and center electrode.

Wyszukiwarka

Podobne podstrony:

g3 mfi ign syst aba 93 95

g3 ign syst aaa 93 95

g3 mfi ign syst aaa 96 99

g3 mfi ign syst aba 96 99

ev ign syst aaf acu 95

93 95

93 95

93 95

93 95 (10)

93 95

93 95

93 95

93 95

93-95, 93

93 95

93 95

93 95 206 pol ed01 2008

więcej podobnych podstron