28-1

Motronic Multiport Fuel

Injection (MFI) and ignition

system

Ignition system, repairing

Notes:

Only components relating to the ignition system

are covered in this repair group. For other

components of the injection and ignition system

Repair Group 24.

The Motronic Engine Control Module (J220) for

the ignition and fuel injection system is

equipped with Diagnostic Trouble Code (DTC)

memory.

Components marked with an asterisk (*) are

checked by the On Board Diagnostic (OBD)

program.

Before repairing or troubleshooting, check

Diagnostic Trouble Code (DTC) Memory,

Repair Group 01.

Safety rules

page 28-5

Spark plugs, technical data

page 28-7

28-2

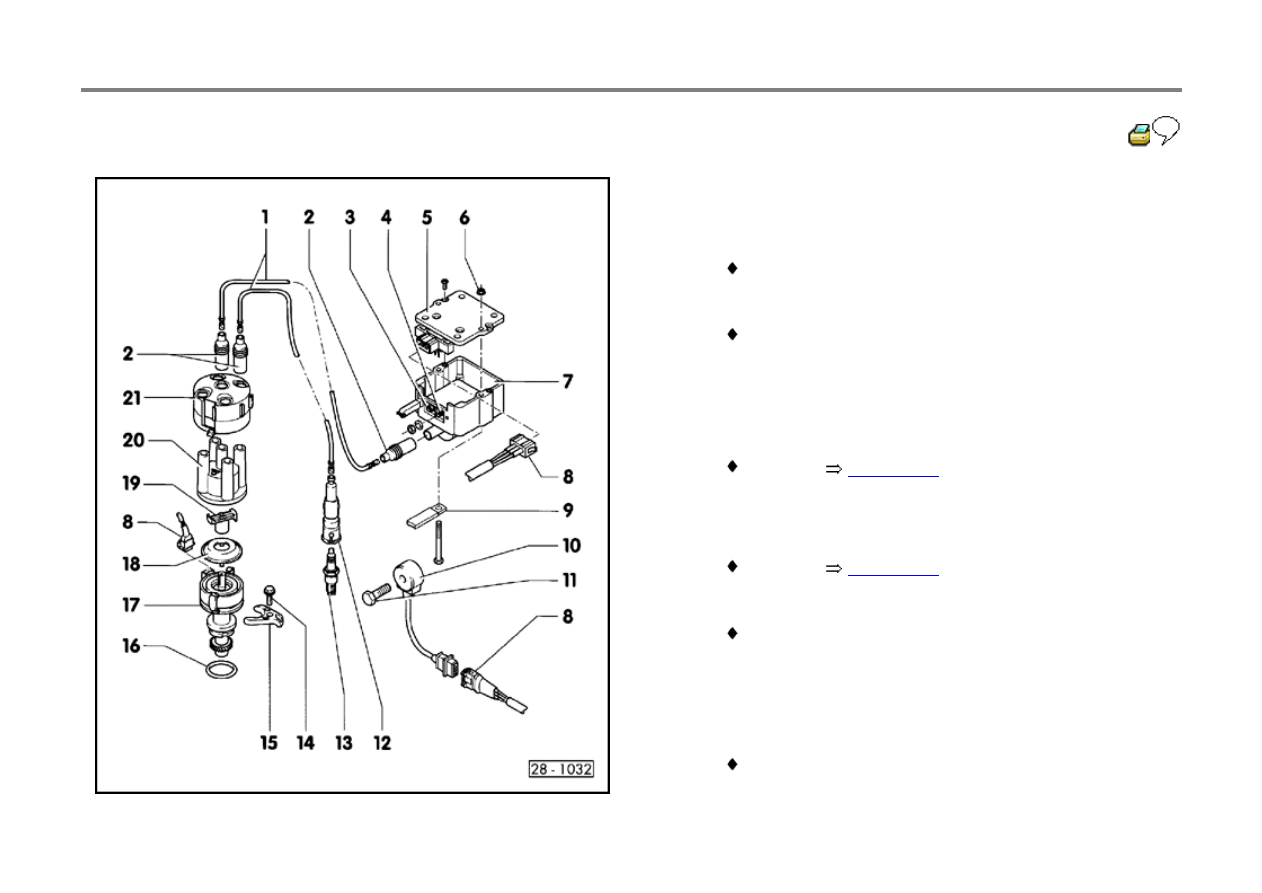

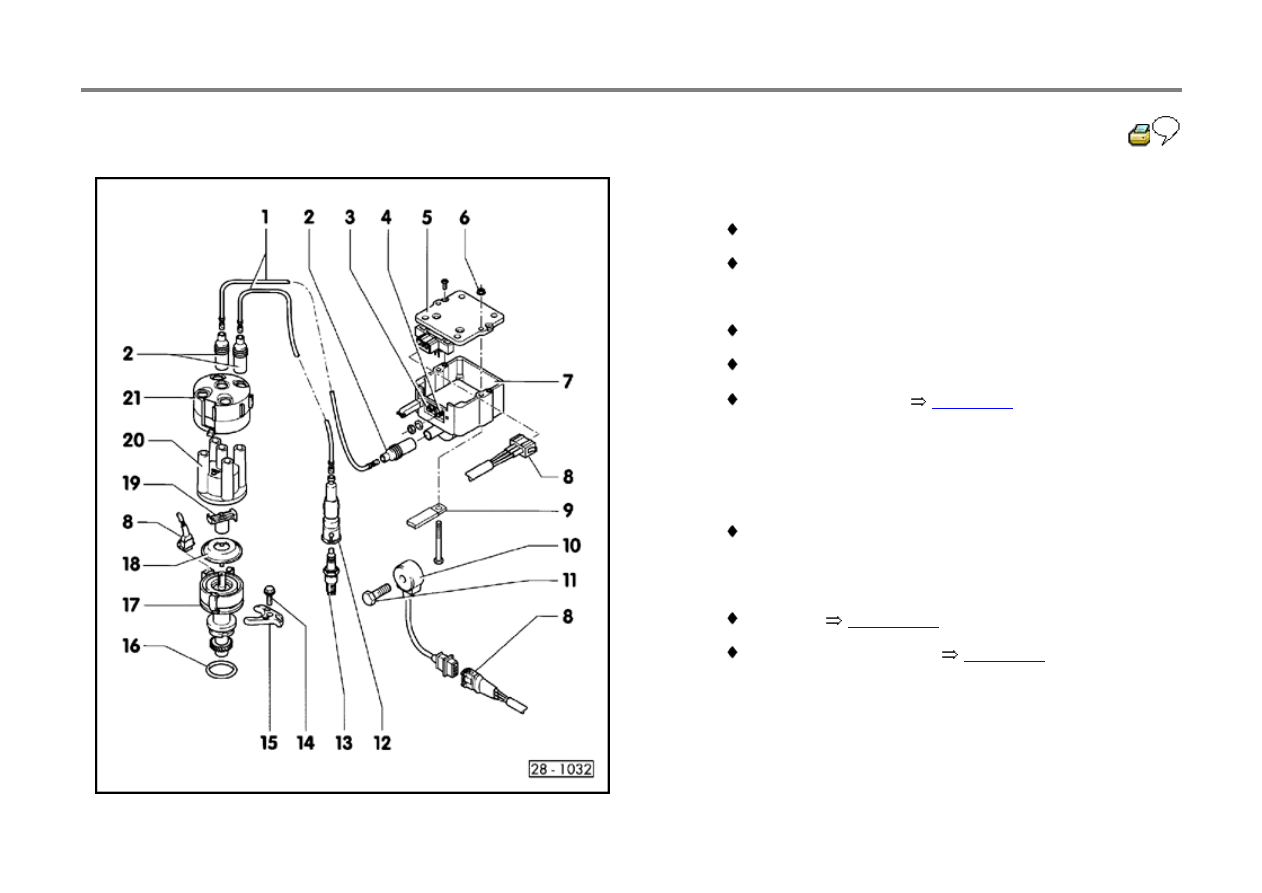

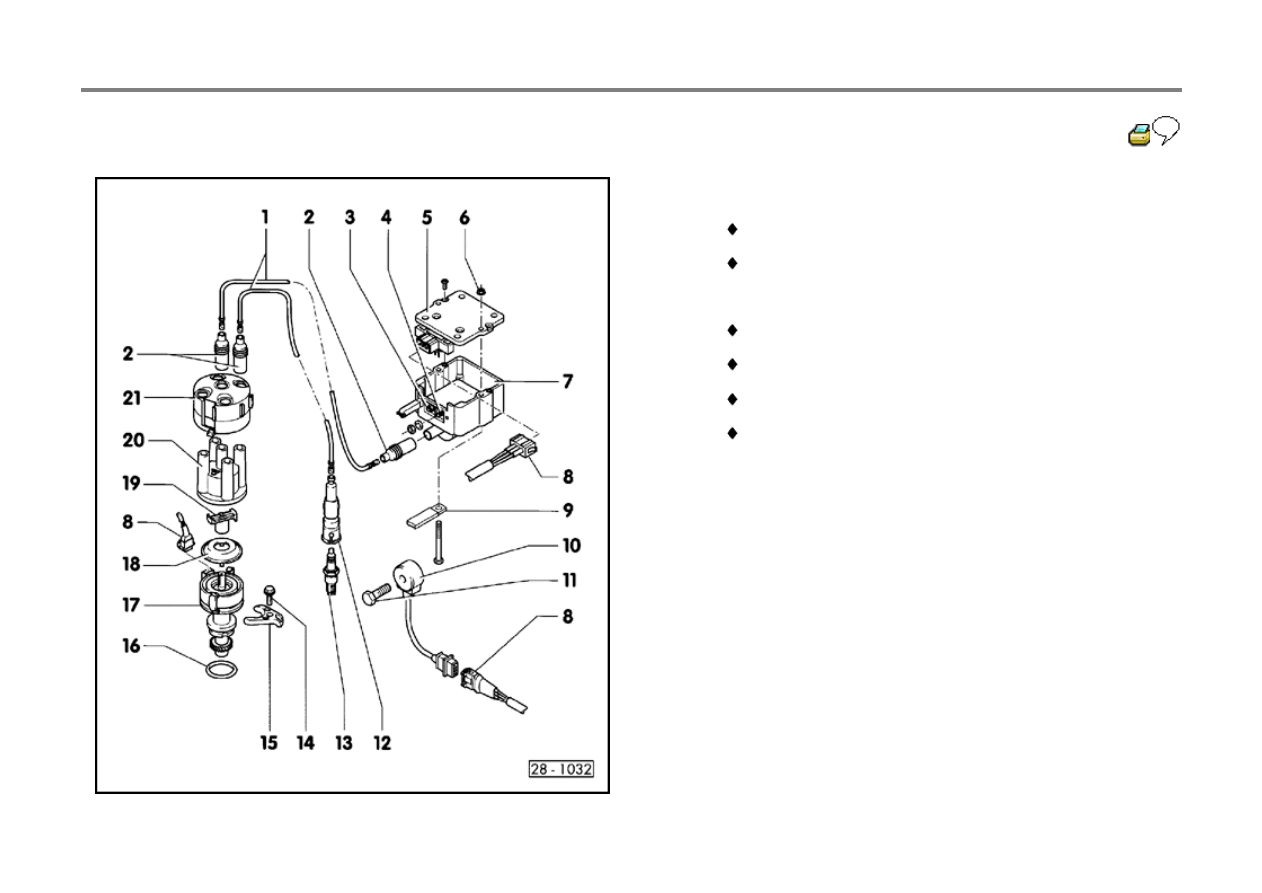

Ignition system, components

1 - Ignition wire

Check for continuity

2 - Interference suppression connector

Resistance 600 to 1400 Ohms

3 - Terminal 1

4 - Terminal 15

5 - Ignition Coil Power Output Stage (N157)*

Checking

page 28-15

6 - 10 Nm (7 ft lb)

7 - Ignition coil (N152)

Checking

page 28-14

8 - Connector

3-pin

9 - Ground (GND) strap

10 - Knock Sensor 1 (G61)*

11 - 20 Nm (15 ft lb)

Incorrect tightening torque affects function of Knock

Sensor

28-3

12 - Spark plug connector

Resistance 4000 to 6000 Ohms

Remove and install with VW 3277

13 - Spark plug

Tightening torque 30 Nm (22 ft lb)

Remove and install with 3122B

Type and spark gap

page 28-7

14 - 25 Nm (18 ft lb)

15 - Clamp

16 - O-ring

Always replace

17 - Ignition Distributor with Camshaft Position (CMP)

Sensor (G40)*

Checking

page 28-13

Removing and installing

page 28-8

18 - Dust cap

28-4

19 - Rotor for Ignition Distributor

Identification: R1

Resistance: 600 to 1400 Ohms

20 - Distributor cap

Check for cracks, traces of current leaks

Check for wear on contacts

Clean before installing

Check carbon brushes for wear and freedom of

movement

21 - Interference suppression cap

28-5

Safety rules

CAUTION!

To prevent personal injury or damage to

sensitive electrical components:

Switch ignition OFF before connecting or

disconnecting components or test

equipment.

Connect or disconnect Battery only with

ignition switched OFF to prevent damage to

the Engine Control Module (ECM).

If engine must be cranked but not started (for

compression testing, etc.) disconnect

Ignition Coil Power Output Stage (N157).

DO NOT use battery booster for longer than

one minute and DO NOT exceed 16.5 volts

(v).

DO NOT wash engine unless ignition is

switched OFF.

Switch ignition OFF when arc or spot

welding.

Before towing vehicles with suspected

malfunctioning ignition system, disconnect

terminal 1 (green) on Ignition Coil (N152).

When installing noise suppressors, ONLY

use 1000 Ohm for high tension wires and

5000 Ohm for spark plug connectors

DO NOT replace distributor rotor marked R1

with different type.

If vehicle is heated (paint booth), DO NOT

start engine until cooled to room

temperature.

28-6

Note:

A variety of electrical connectors are used on this

vehicle. Always use VW 1594 adaptor kit to

connect test instruments to these connectors.

CAUTION!

Before disconnecting a Battery, ALWAYS ask

for the correct radio activation code (vehicles

equipped with anti-theft radio).

28-7

Spark plugs, technical data

Engine code

ABA

Ignition timing

Cannot be

adjusted

Idle speed

Checking

Repair Group 24

Firing order

1-3-4-2

Spark plugs (remove and

install using tool 3122B)

Bosch FR 8 DS

Part number

101 000 044 AA

Electrode gap

0.6 mm (0.024)

maximum

Tightening torque

30 Nm (22 ft lb)

28-8

Ignition distributor, removing/installing

Note:

For injection timing and knock regulation, the

Motronic Engine Control Module (J220) needs

the TDC cylinder 1 signal from the Camshaft

Position Sensor (G40).

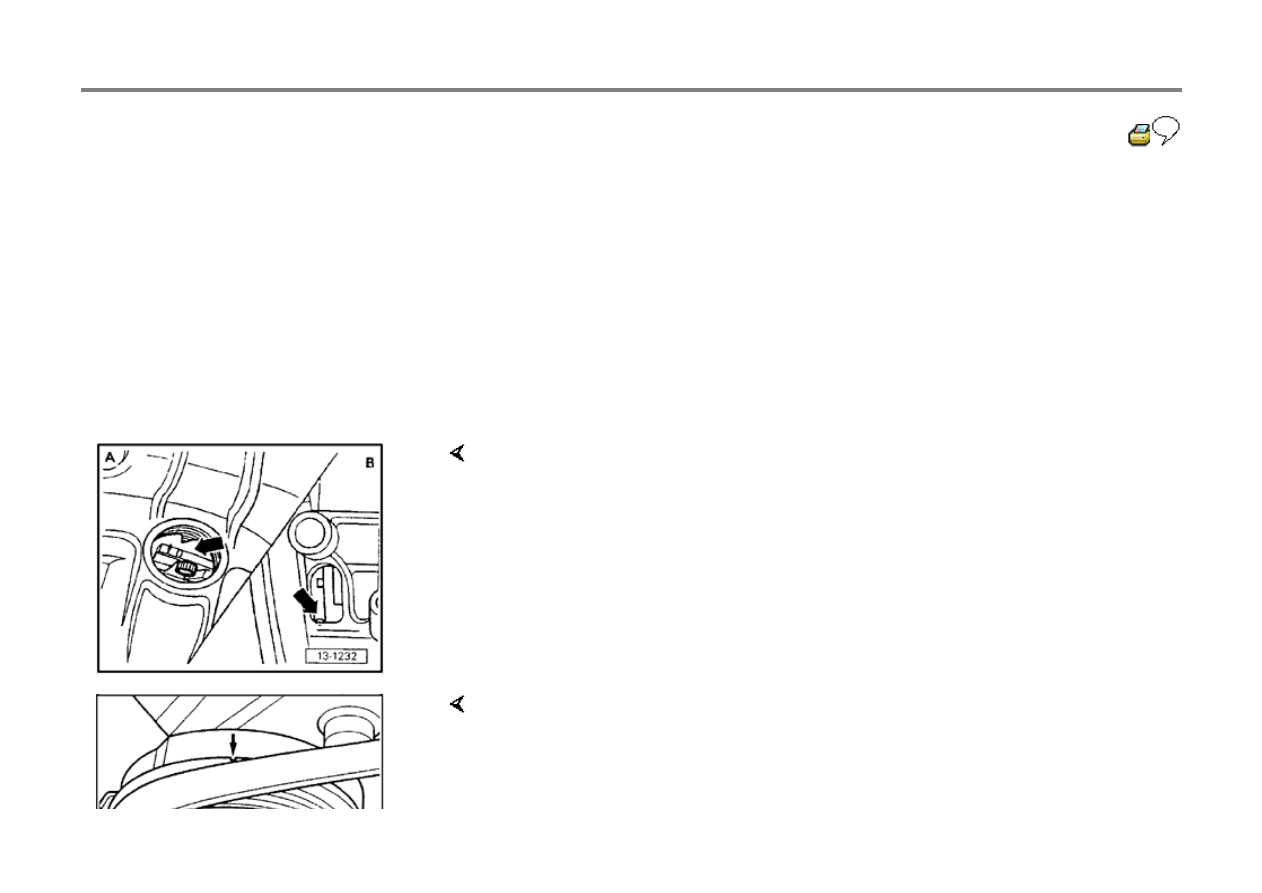

TDC cylinder 1, checking

Engine installed:

Engine removed:

- Move flywheel (-A-) or drive plate (-B-) to cylinder 1 TDC marking -arrow-.

- Set vibration damper to cylinder 1 TDC marking -arrow-.

28-9

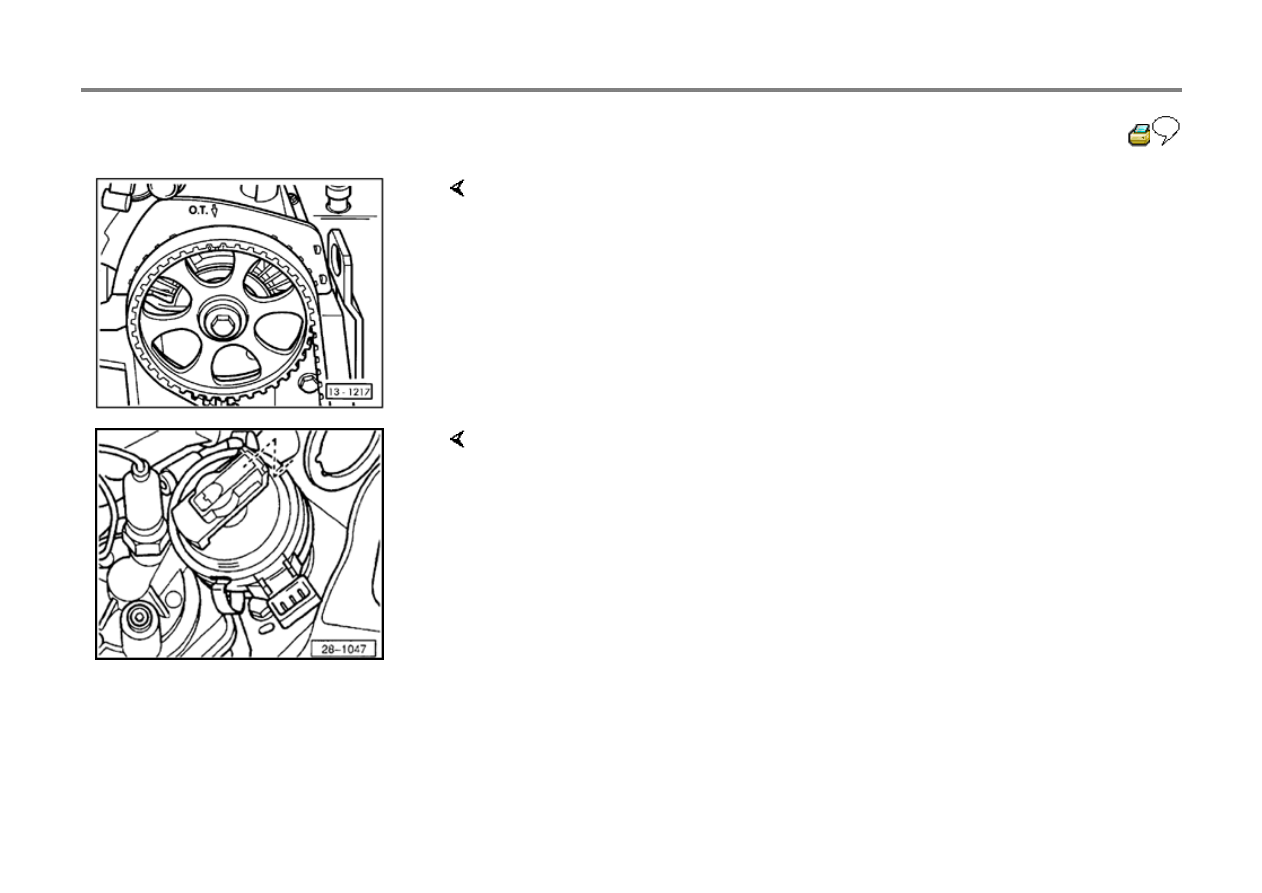

- Marking on camshaft drive belt sprocket must line up with marking on toothed

belt cover.

- Rotor must line up with mark on distributor housing or notch in rim of Camshaft

Position Sensor dust cover.

28-10

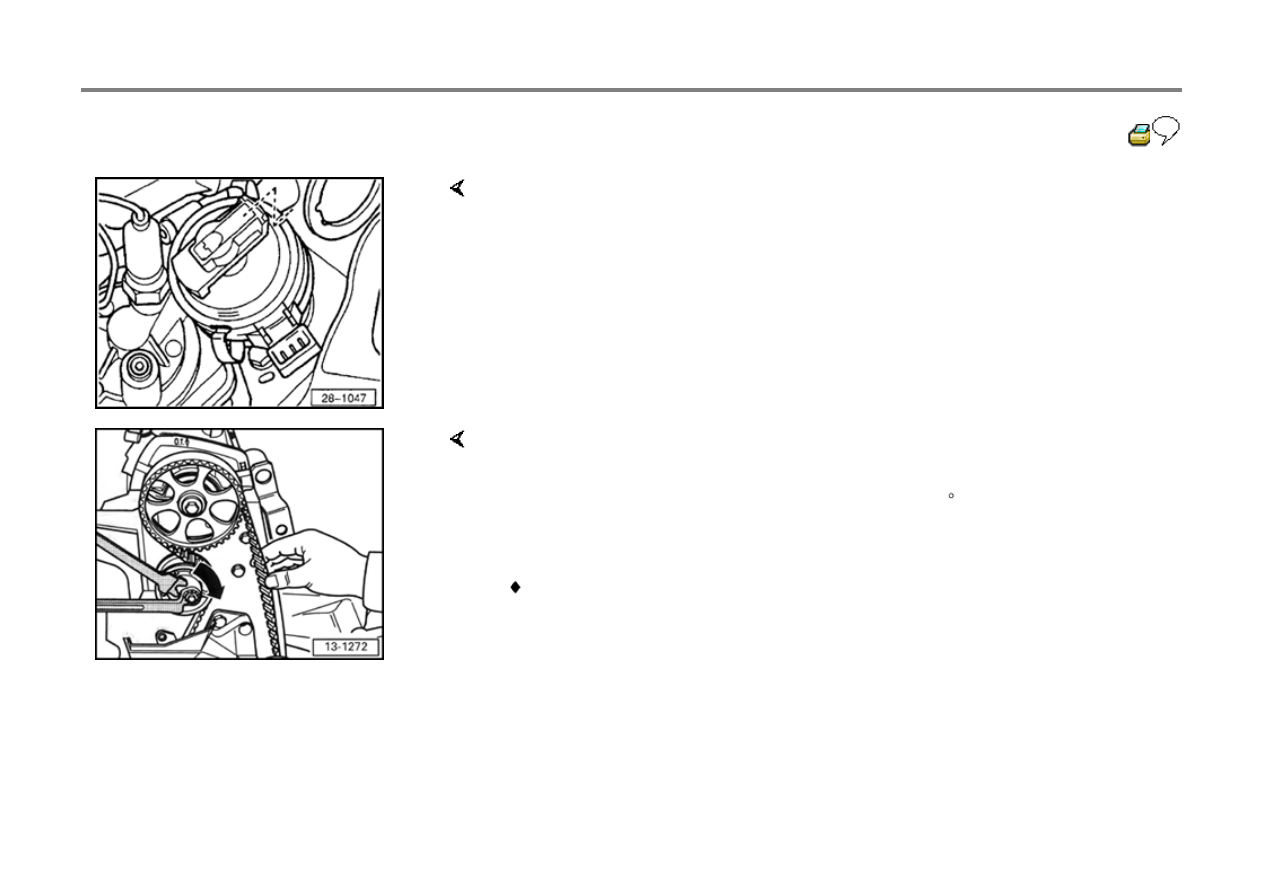

Removing

Crankshaft and camshaft in cylinder 1 TDC

position

- Remove distributor.

Installing

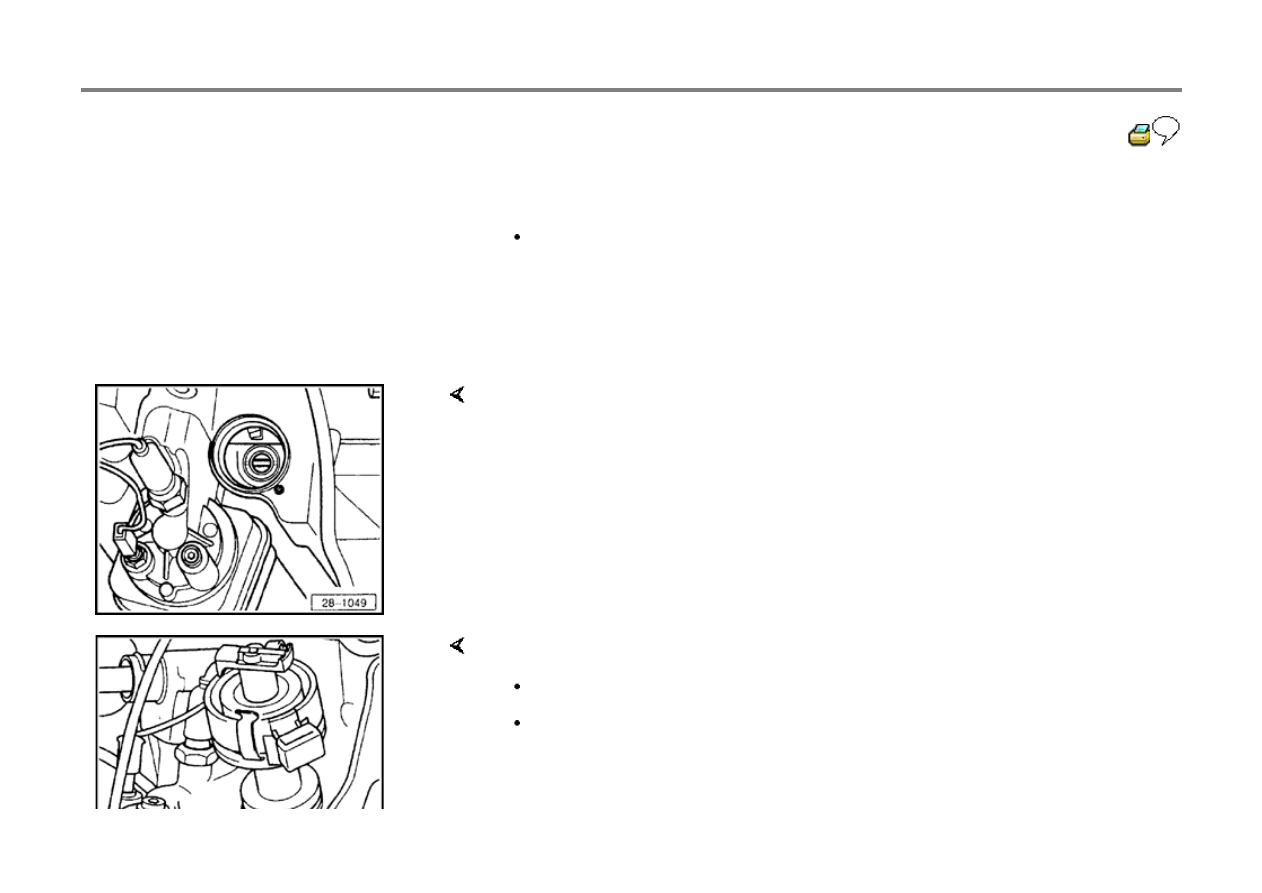

- Before installing the ignition distributor, position slot on oil pump shaft parallel to

crankshaft.

- Install Ignition Distributor.

To remove, hold distributor rotor as shown.

Pins on Ignition Distributor must point toward hold for mounting screw -arrow-.

28-11

If markings do not match:

- With the Ignition Distributor installed, marking on housing must line up with

marking on distributor rotor or with notch on rim of dust cover for Camshaft

Position Sensor.

- Tighten mounting screw for Ignition Distributor.

Tightening torque: 25 Nm (18 ft lb)

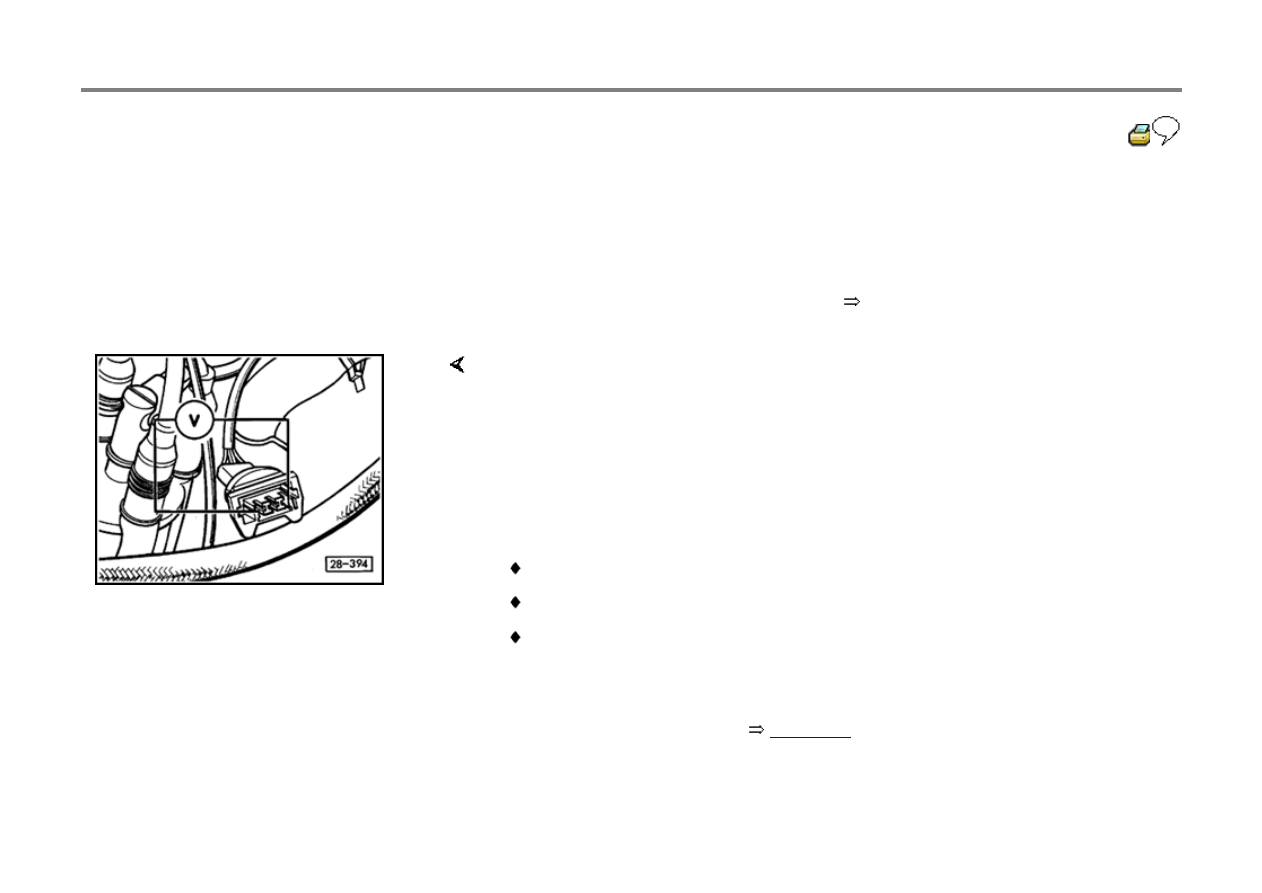

- Loosen belt tensioner and remove drive belt from camshaft sprocket.

- Turn intermediate shaft sprocket with drive belt in direction of arrows until

marking on distributor rotor lines up with marking for cylinder 1 on distributor

housing (drive belt slips over crankshaft drive belt sprocket).

28-12

Note:

For easier installation of drive belt, only tighten belt tensioner nut approx. one turn.

- Marking on Ignition Distributor must line up with marking on distributor rotor or

with notch on rim of dust cover for Camshaft Position Sensor.

- Position drive belt on pulley and camshaft drive belt sprocket.

- Tighten drive belt by turning belt tensioner in direction of arrow with V159

spanner.

- Drive belt is correctly tensioned if it can be twisted 90 with thumb and

forefinger halfway between camshaft and intermediate shaft sprockets.

- Tighten nut on belt tensioner.

Tightening torque: 45 Nm (33 ft lb)

- Rotate crankshaft two full revolutions and re-check adjustment.

- Check markings on Ignition Distributor and rotor.

- Install upper part of belt guard.

- Clean Ignition Distributor cap and check for cracks before installing.

28-13

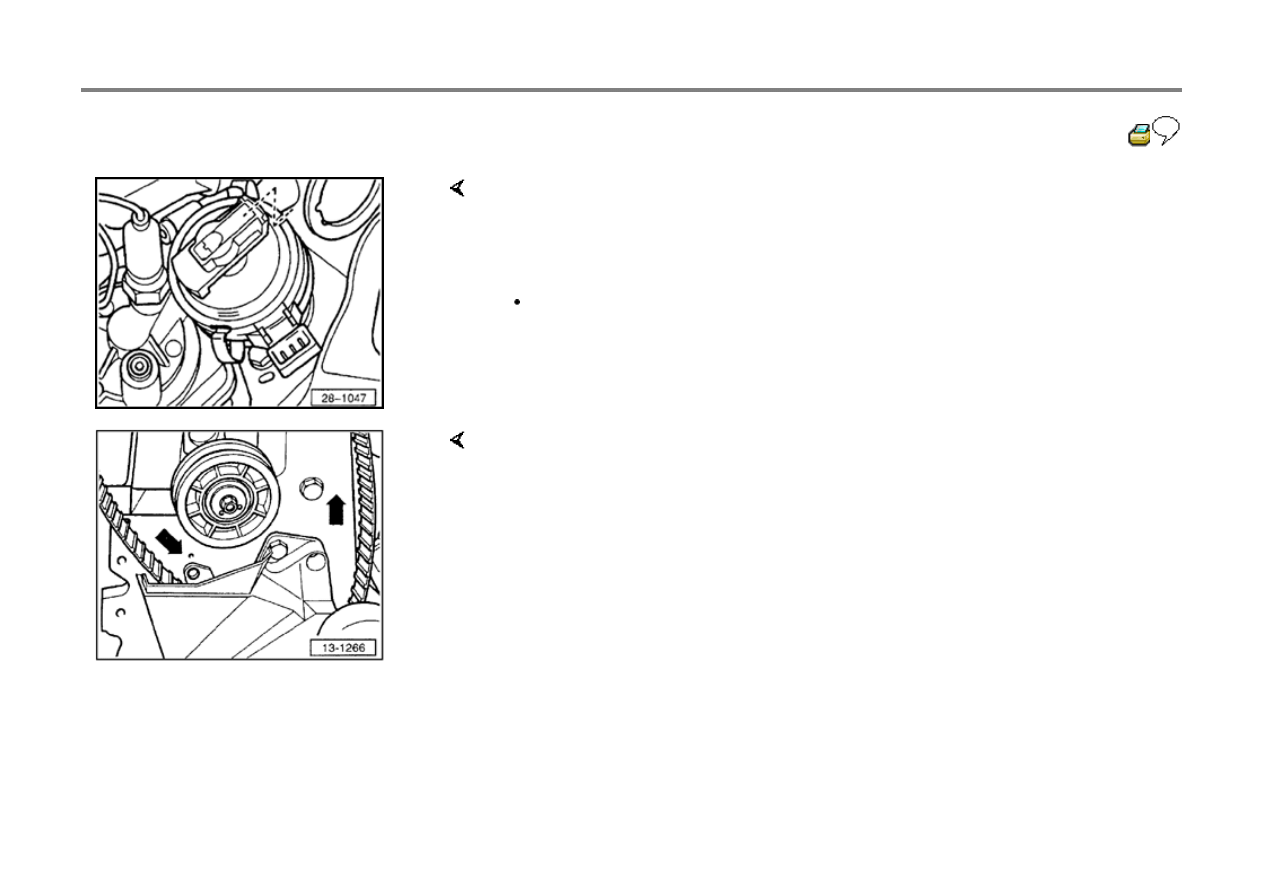

Camshaft Position Sensor, checking

Camshaft Position Sensor malfunctions are

recognized by On Board Diagnostic (OBD).

- Carry out electrical testing, test step 21,

Repair Group 01

Specified values:

If OK:

If NOT OK:

- Disconnect harness connector on Camshaft Position Sensor at Ignition

Distributor.

- Connect Fluke 83 multimeter with adapter cables from VW 1594 to measure

voltage across outer terminals of connector.

- Switch ignition ON.

Up to 10.93 production, 49-states: 10 Volts min.

Up to 10.93 production, California: 5 Volts min.

From 10.93 production, all vehicles: 5 Volts min.

- Replace Ignition Distributor,

page 28-8

.

- Replace Motronic Engine Control Module (J220),

Repair Group 24

28-14

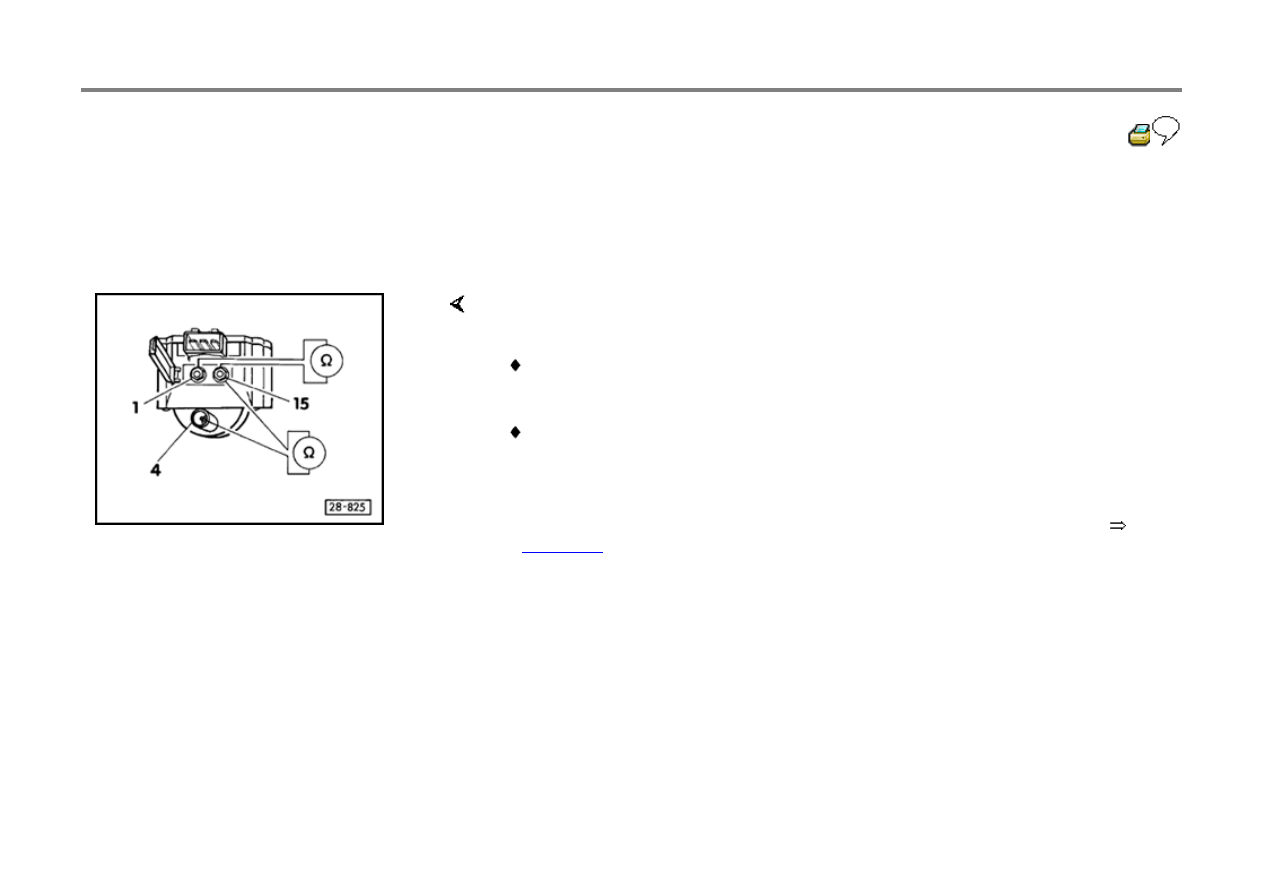

Ignition coil, checking

- Disconnect harness connector and ignition wire

from Ignition Coil (N152).

If NOT OK:

- Check primary resistance between terminals -1- and -15- using Fluke 83

multimeter (or equivalent).

Specified value: 0.5 to 0.7 Ohms.

- Check secondary resistance between terminals -4- and -15-.

Specified value: 3000 to 4000 Ohms

- Remove Ignition Coil and disconnect Ignition Power Output Stage (N157)

page 28-2

, item 5.

- Repeat test.

28-15

Ignition Coil Power Output Stage,

checking

Requirements

Camshaft Position Sensor (G40) OK

Engine Speed (RPM) Sensor (G28) OK

Electrical testing, test step 22 OK, checking

Repair Group 01

Ignition Coil (N152) OK

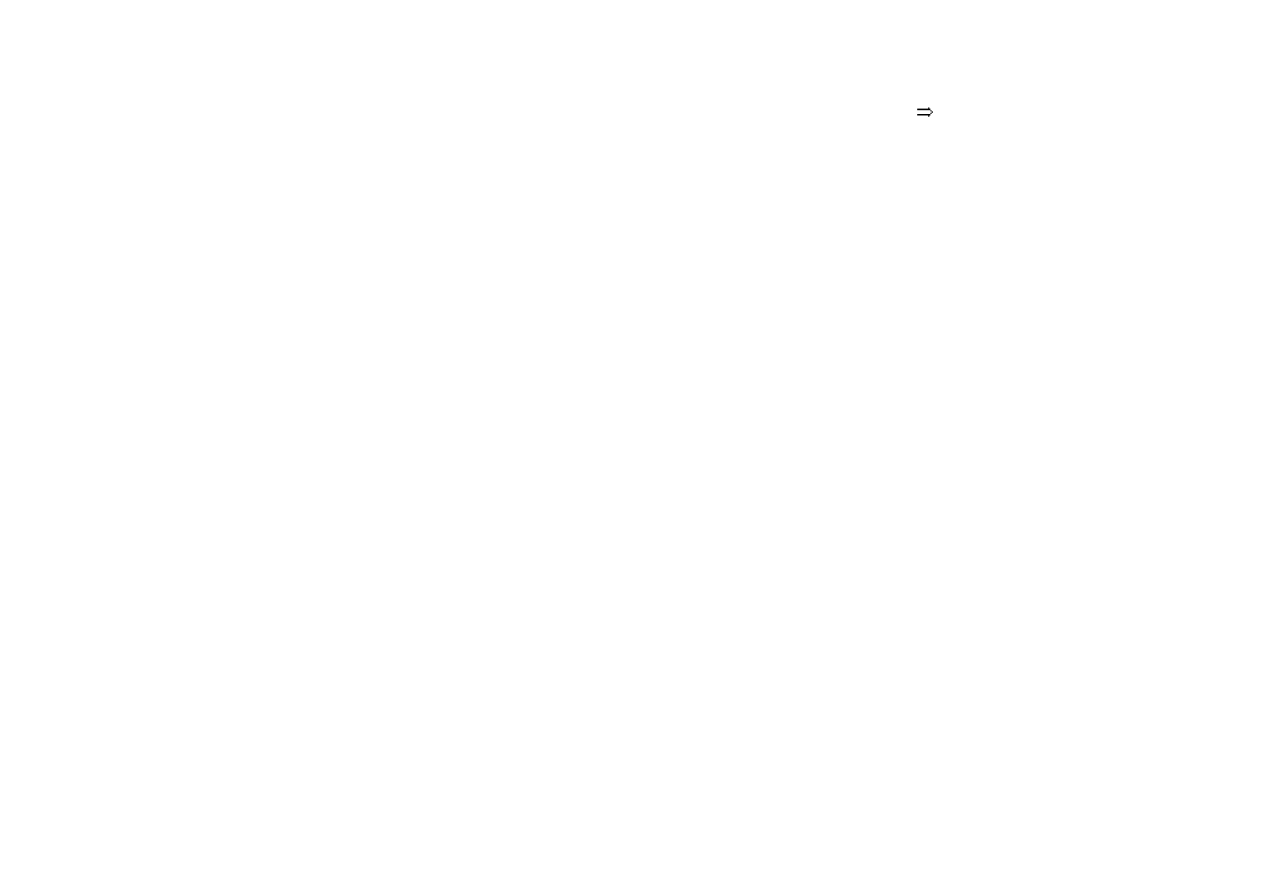

Voltage supply, checking

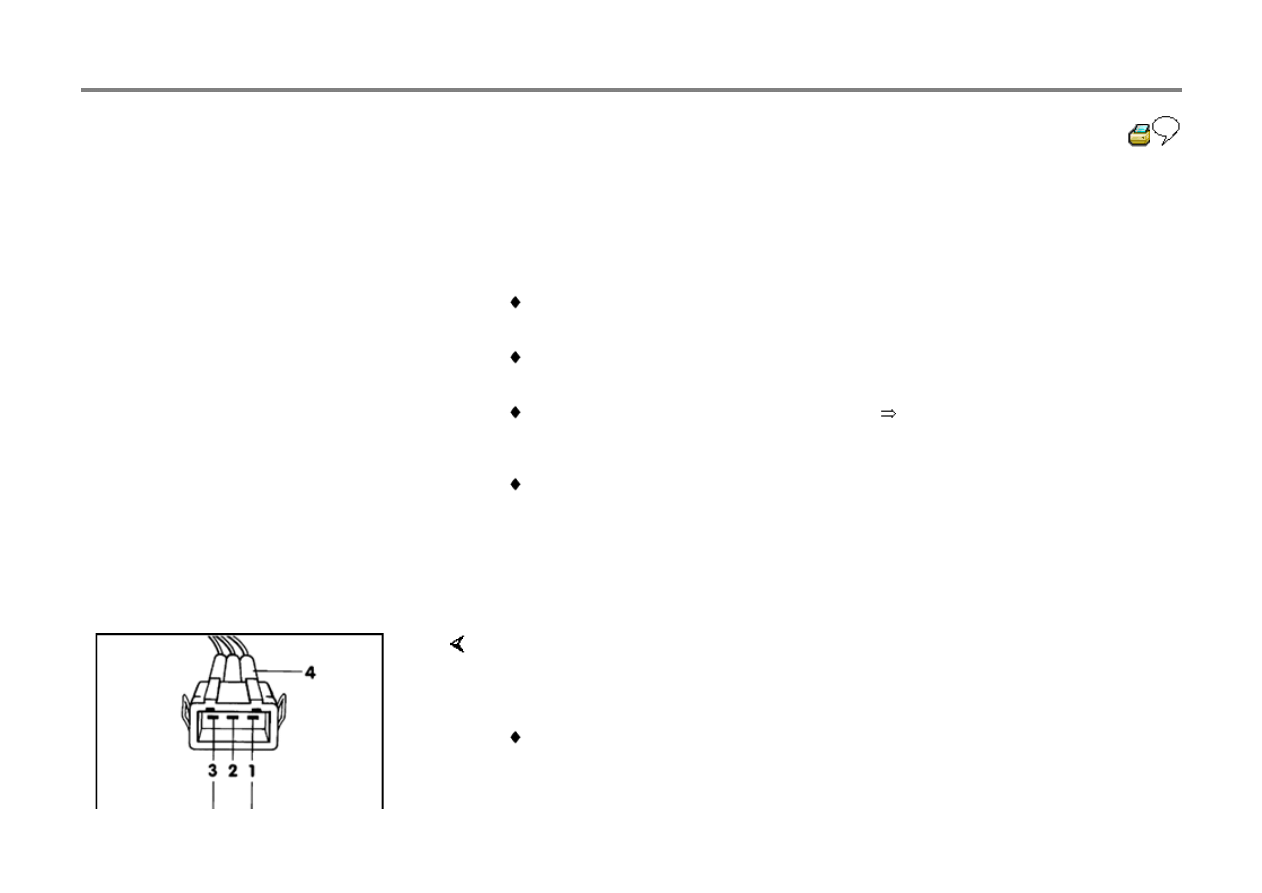

- Disconnect ignition wire and 3-pin connector

from Ignition Coil (N152).

- Connect Fluke 83 multimeter with adapter cables from VW 1594 to measure

voltage at terminals -1- and -3- of disconnected connector.

- Switch ignition ON.

Specified value: Battery Positive Voltage (B+)

- Switch ignition OFF.

28-16

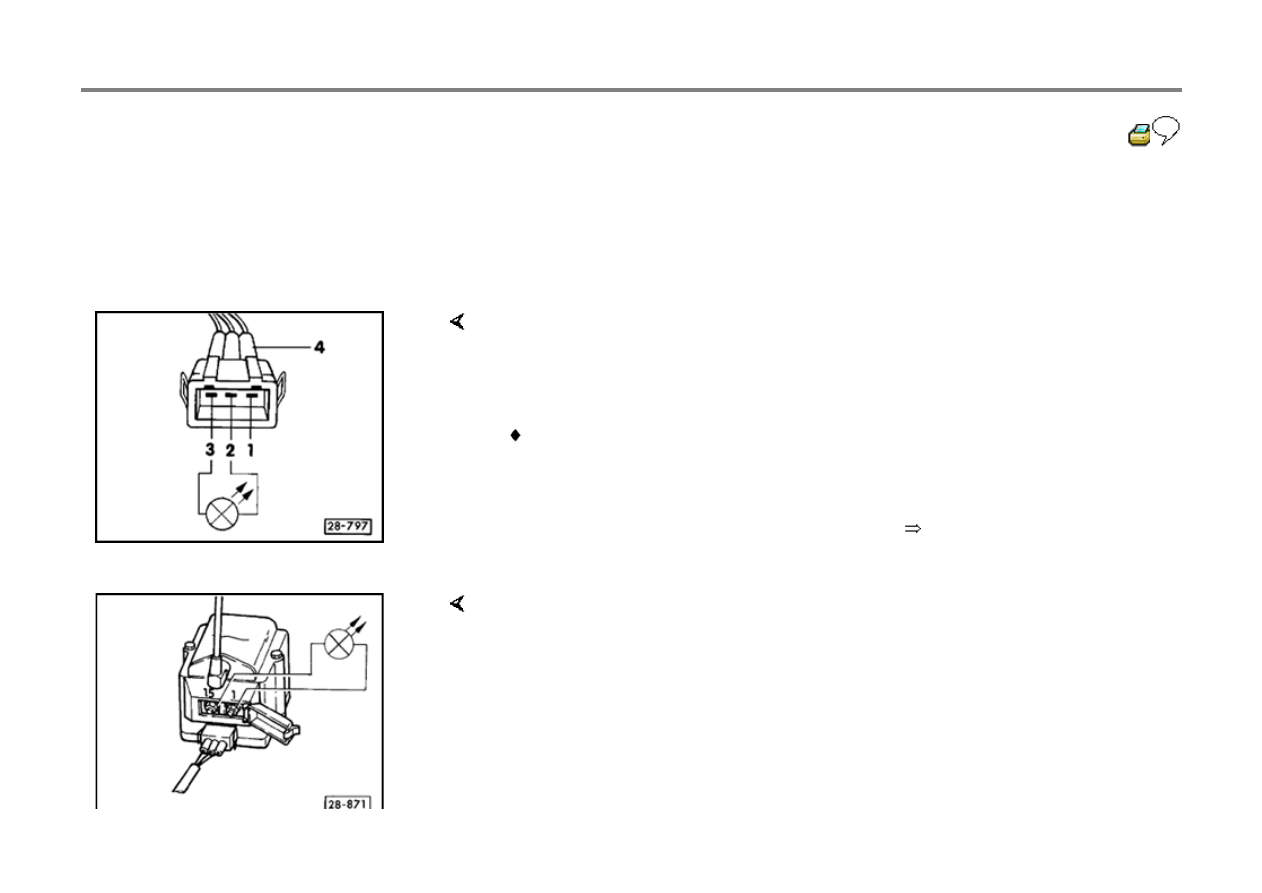

Control, checking

- Disconnect harness connectors from the Fuel

Injector for cylinders 1 and 4 and remove fuse

18 (S18).

If NO:

- Connect US 1115 LED tester to connector terminals -2- and -3- using adapter

cables from VW 1594 adaptor kit and VW 1594/15.

- Operate Starter and check ignition signal from Motronic Engine Control Module

(ECM).

LED should flicker

- Replace Motronic Engine Control Module J220,

Repair Group 24

- Connect 3-pin connector and ignition wire on Ignition Coil.

WARNING!

During the following test DO NOT touch the Ignition Coil or test leads

terminals.

- Connect LED tester with adapter cables to terminals -1- and -15- on Ignition Coil.

28-17

- Operate Starter.

LED should flicker

If NO:

- Replace Ignition Coil Power Output Stage.

- Connect connector to Fuel Injectors.

- Reinstall fuse 18 (S18).

Wyszukiwarka

Podobne podstrony:

g3 mfi ign syst aaa 93 95

g3 mfi ign syst aba 96 99

g3 ign syst aaa 93 95

g3 mfi ign syst aaa 96 99

ev ign syst aaf acu 95

93 95

93 95

93 95

93 95 (10)

93 95

93 95

93 95

93 95

93-95, 93

93 95

93 95

93 95 206 pol ed01 2008

więcej podobnych podstron