28-22

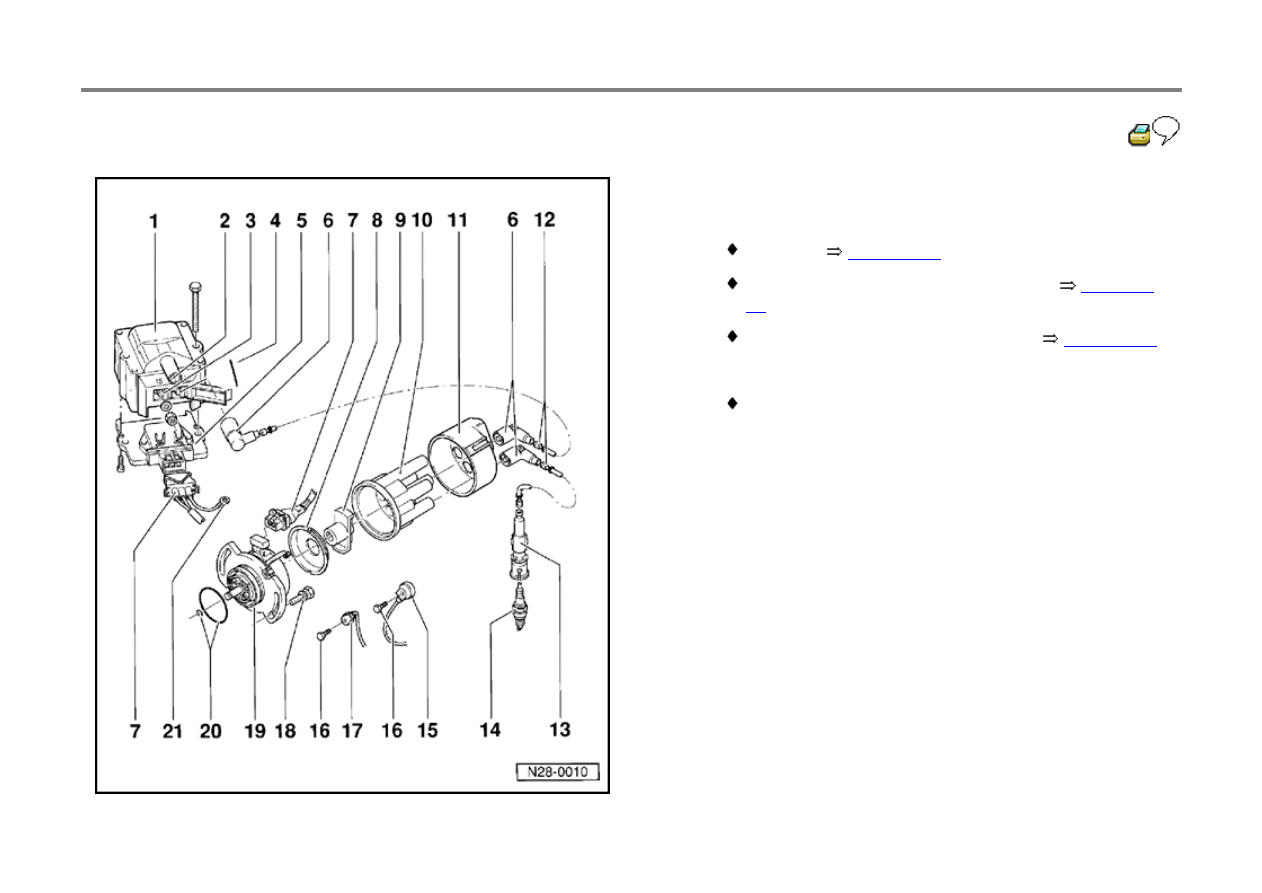

Digifant Ignition system,

component overview

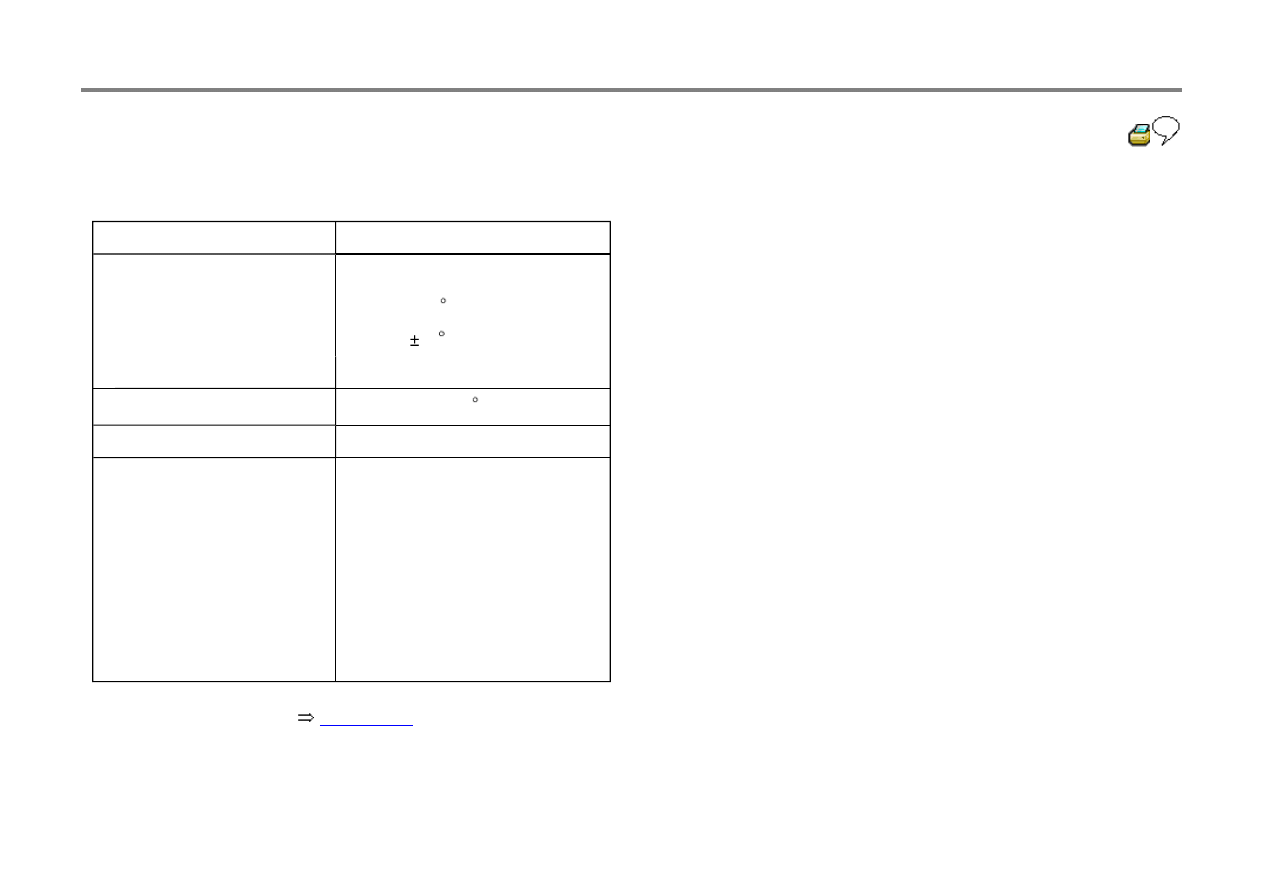

Vehicles starting m.y. 1995

Notes:

Repair Manual , Fuel Injection & Ignition,

Repair Group 24

Only information specific to the ignition system

is covered in this Repair Group. For Fuel

injection system information:

The Fuel Injection and Ignition system Engine

Control Module is equipped with On Board

Diagnostic capability.

Components marked with an * are checked via

the On Board Diagnostic system.

Before performing repairs and/or

troubleshooting, check the Diagnostic Trouble

Code *(DTC) memory

Page 01-53

.

Safety precautions

Page 28-27

Checking and adjustment data, spark plugs

Page 28-28

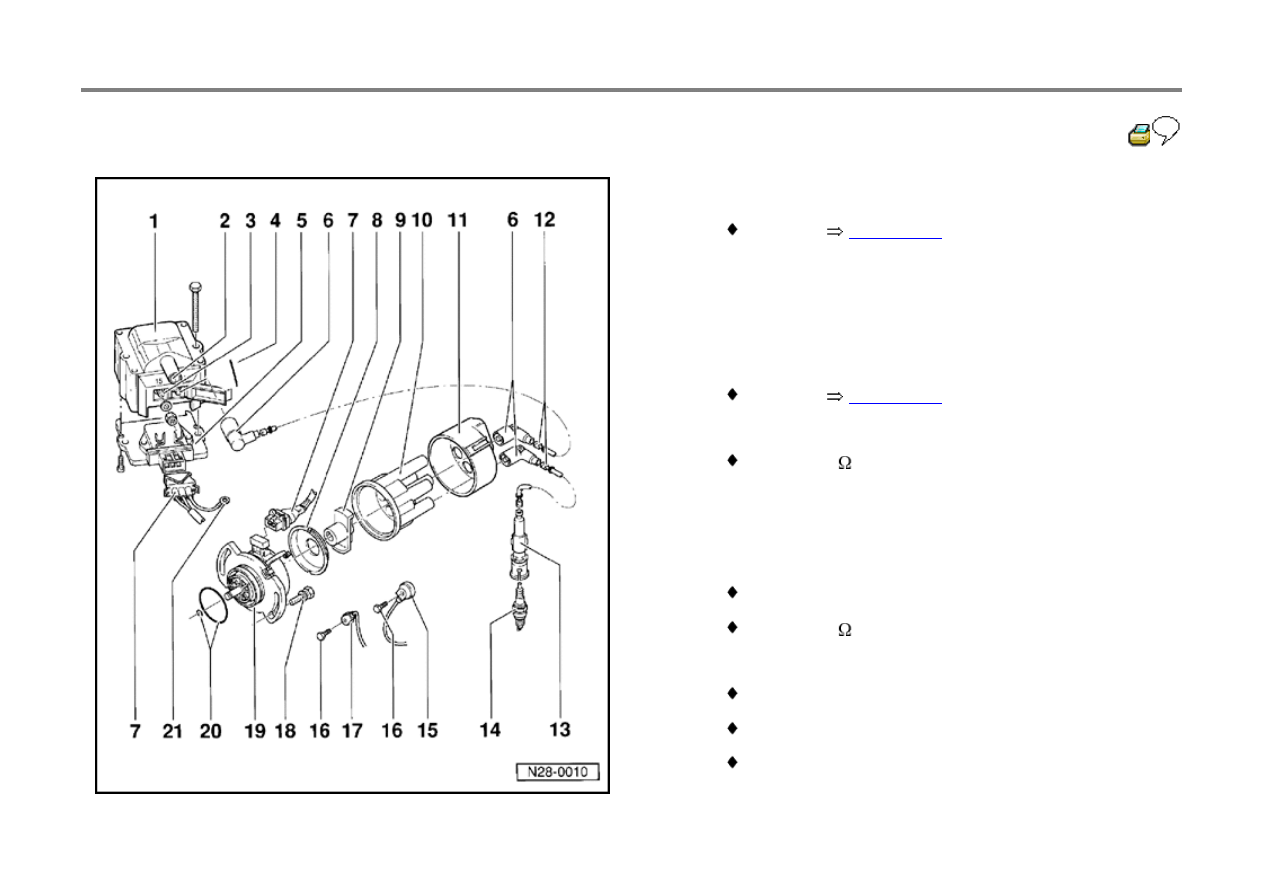

28-23

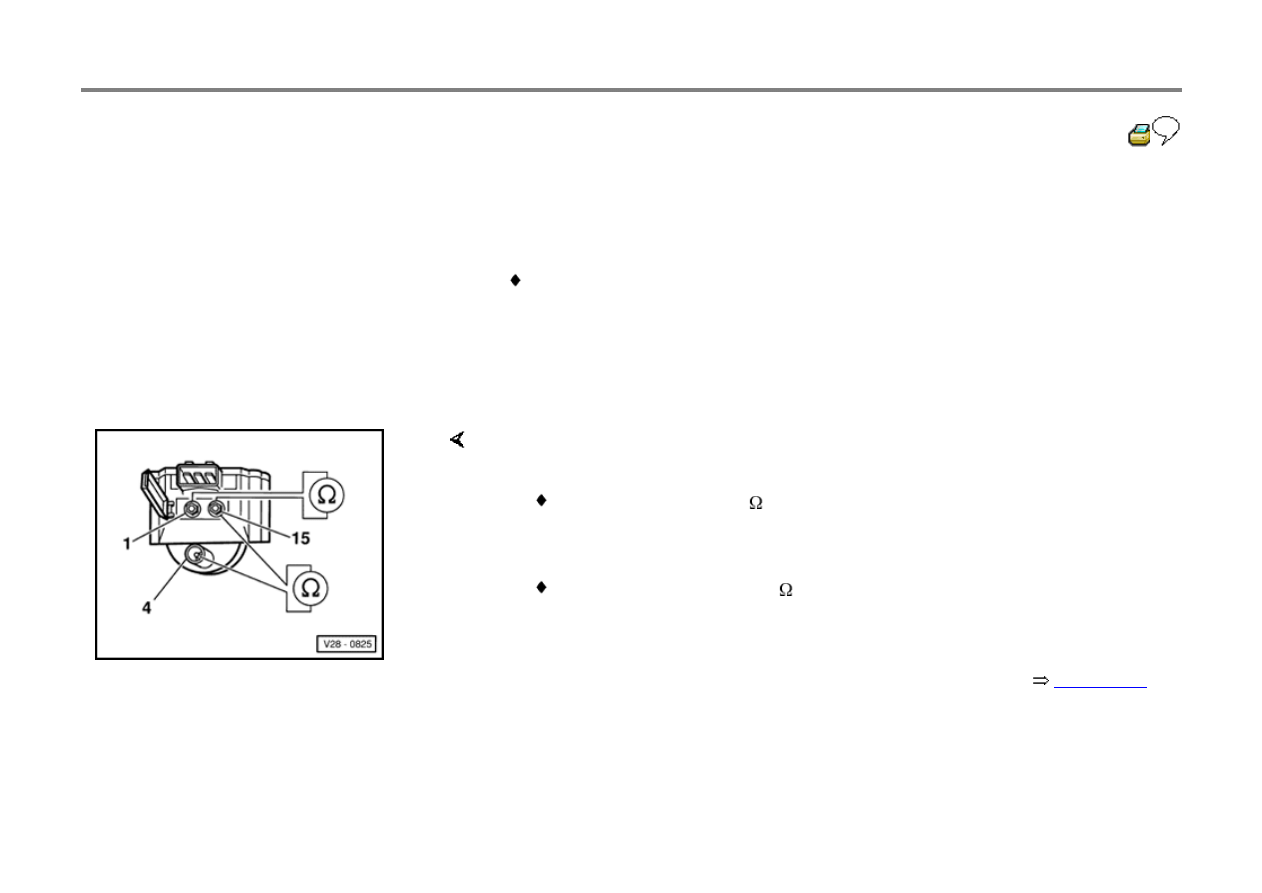

1 - Ignition coil -N152-

checking:

Page 28-36

2 - Terminal 4

3 - Terminal 15

4 - Terminal 1

5 - Ignition coil power output stage -N157-

checking:

Page 28-37

6 - RFI Suppressor

0.6 to 1.4 k

7 - Connector

8 - Dust cap

9 - Rotor

marking: R1

0.6 to 1.4 k

10 - Distributor cap

check for cracks and signs of arcing (carbon tracks)

check electrode wear

clean before fitting

check carbon brush for wear and freedom of

movement

28-24

11 - RFI shield

12 - High tension cable

check for continuity

13 - Spark plug connector

4000 to 6000

14 - Spark plug

30 Nm (22 ft lb)

type and electrode gap

Page 28-28

15 - Knock sensor 2 -G66-**

on left in direction of travel

on engine block

16 - 20 Nm (15 ft lb)

tightening torque influences the function of the knock

sensor

17 - Knock sensor 1 -G61-*

on right in direction of travel

on engine block

18 - 10 Nm (7 ft lb)

28-25

19 - lgnition Distributor with Camshaft Position sensor

G40

installing:

Page 28-29

ignition timing, checking and adjusting:

Page 28-

31

Camshaft Position sensor. checking:

Page 28-35

20 - O-ring

replace if damaged

21 - Ground strap

28-26

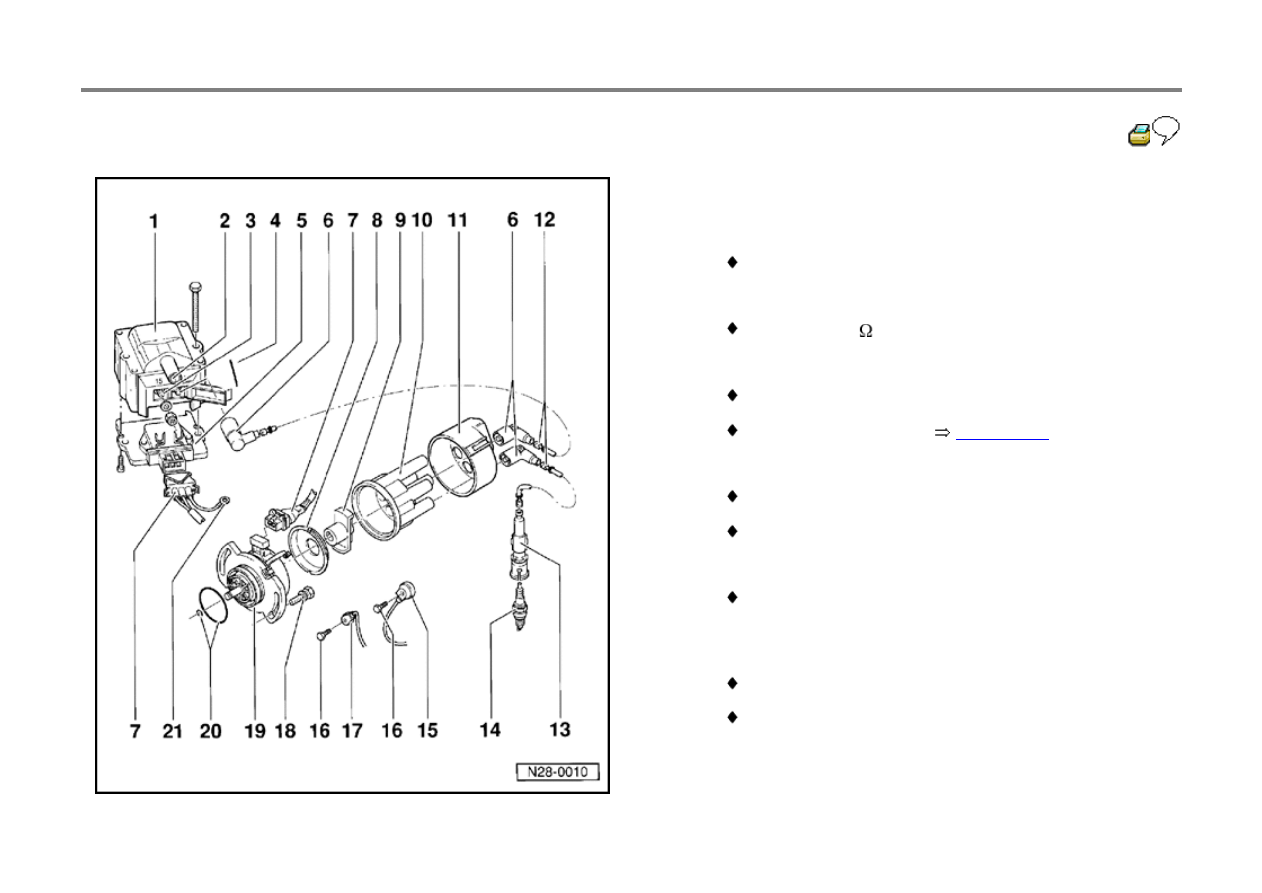

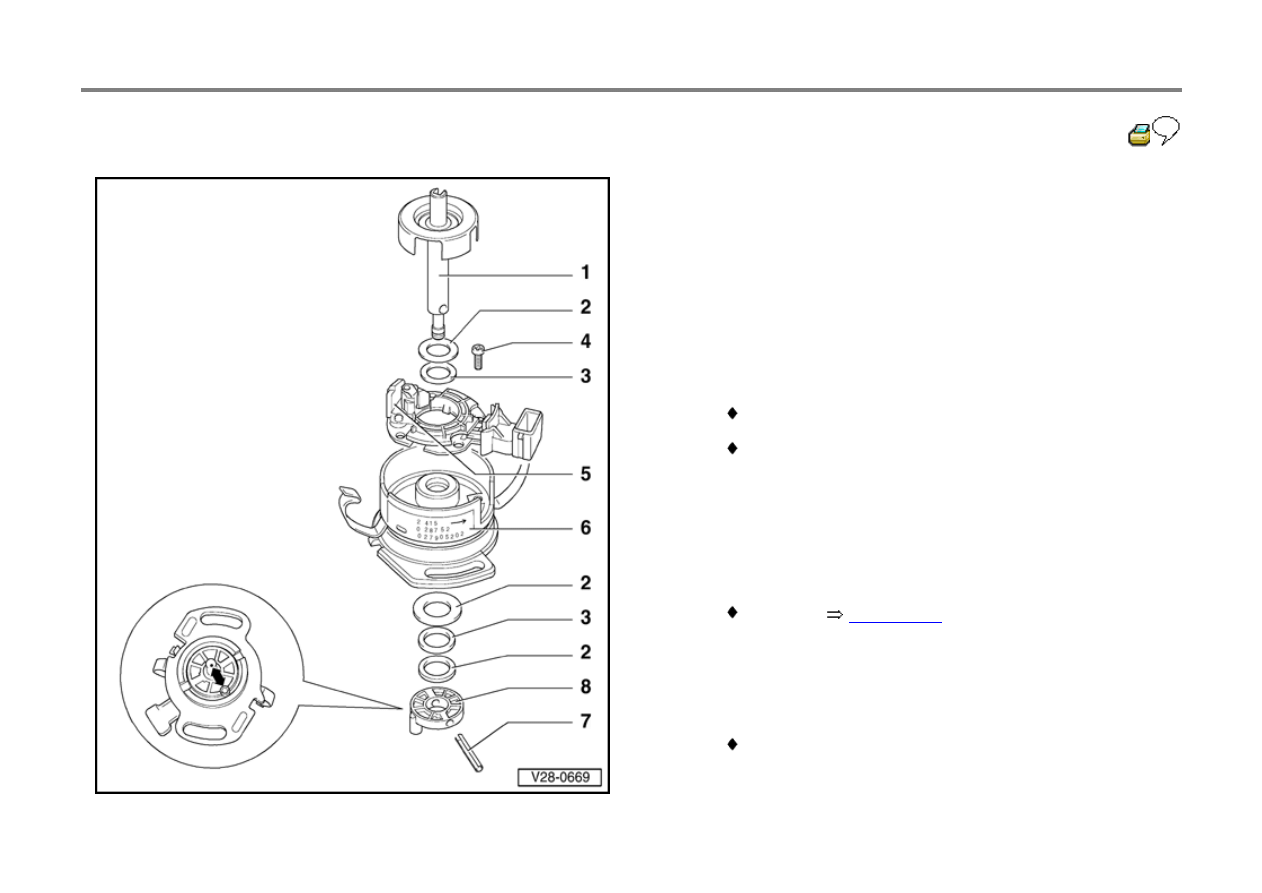

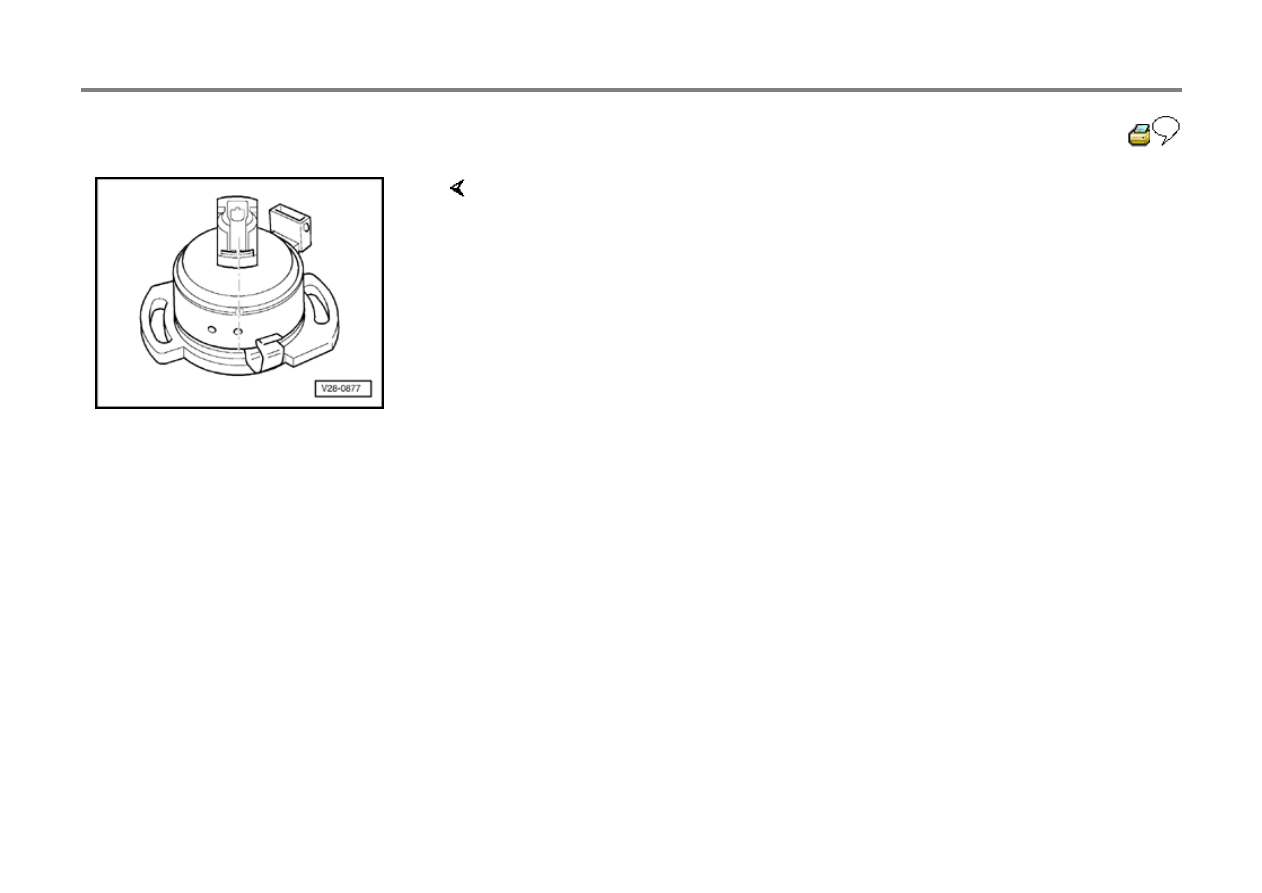

Ignition distributor, disassembling and

assembling

Note:

When assembling, ensure that coupling /item 8) can be

moved slightly on the pin (item 7) and distributor shaft (item

1) play is not restricted.

1 - Distributor shaft

with Camshaft Position sensor trigger wheel

pull out after removing spring pin (item 7)

2 - Shim(s)

3 - Plastic washer

4 - 3 Nm (127 in. Ib)

5 - Camshaft Position sensor -G40-

checking:

Page 28-35

6 - Distributor housing

7 - Spring pin

8 - Coupling

before removing, mark position of drive dog to shaft

(item 1)

28-27

Safety precautions

To prevent injuries to persons and/or damage to

the fuel injection and ignition system

components, observe the following points:

Do not touch or disconnect ignition wires when

the engine is running or cranking at starter

speed.

The ignition must be switched off when

disconnecting or connecting injection and

ignition system component wiring as well as

test instrument cables.

If the engine requires cranking at starter speeds

but without starting, e.g. when checking

compression: Disconnect the harness

connector from the Engine Speed sensor

(below bracket on left side of cylinder head).

Do not connect a capacitor (of any description)

to the ignition coil terminal 1 (-).

Do not replace the 1000

(identification: R1)

distributor rotor with a different type even for

Radio Frequency Interference (RFI)

suppression.

For RFI suppression purposes only, high

tension leads must have a resistance of 1000

and spark plug connectors must have a

resistance of 5000

.

28-28

Test data, spark plugs

Engine code

ACU

Ignition timing

1)

Checking value

3 to 8 before TDC

Adjusting value

6 1 before TDC

Engine speed

2000 to 2500 rpm

Ignition timing at 2200 rpm

4)

23 to 33 BTDC

Firing order

1-2-4-5-3

Spark plugs

Manufacturers gap: designation:

101 000 026 AA

3)

101 000 005 AE

101 000 001 AE

101 000 007 AB

N9 BMC

3)

0.6 mm max.

2)

W 8 DTC 0.7 to 0.9 mm

14-8 DTU 0.7 to 0.9 mm

N 7 BYC 0.7 to 0.9 mm

Tightening torque

25 Nm (18 ft lb)

l)

Checking and adjusting

Page 28-31

2)

Gap between the ground electrode and center electrode

3)

Especially recommended for short journeys

4)

Ignition timing point, checking

28-29

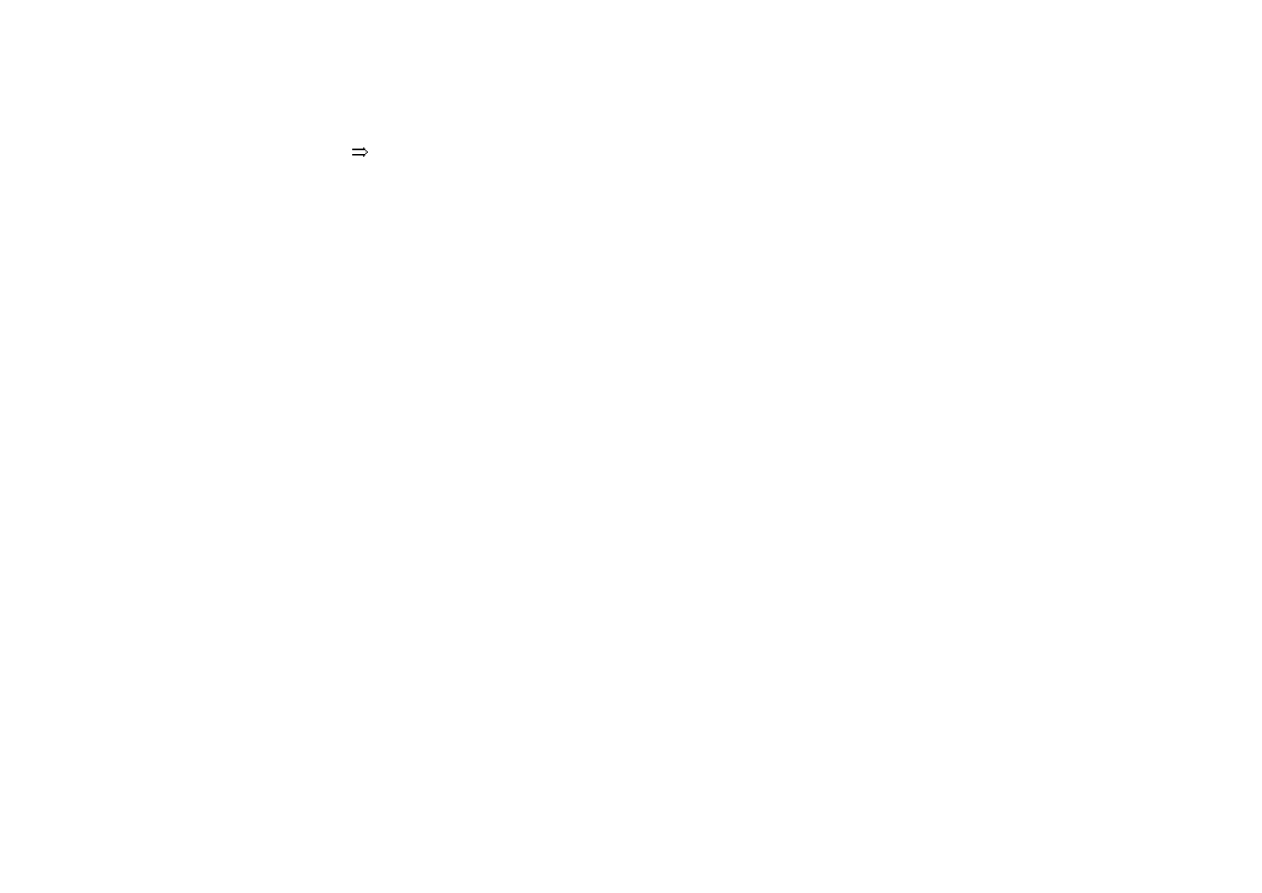

Ignition distributor, installing

Engine installed

- Set flywheel -A- or drive plate -B- to TDC for cyl.

1

Engine removed

- Align marking on vibration damper -C- with marking on lower toothed belt guard -

arrow-

- Align marks on camshaft sprocket with mark on rear toothed belt guard -arrow-

28-30

- Position distributor rotor to point to cyl. 1 mark on housing

- Install ignition distributor

- Before installing, clean distributor cap and check for cracks and signs of tracking,

replace if necessary

- Check and adjust ignition timing

28-31

Ignition timing, checking and adjusting

Special tools, testers and auxiliary items

VAG 1367 Engine Tester using inductive pick-

up VAG 1 367/8

VAG 1551 Scan Tool using adaptor cable VAG

1551/1

Test conditions

Engine oil temperature 80 C (176 F)

minimum

VAG 1551 Scan Tool connected

Test sequence

Note:

On some vehicles a TDC sensor is fitted as

standard. Use adapter cable VAG 1367/9 to

connect to a TDC sensor.

- Connect VAG 1367 Engine Tester using the VAG 1367/8 inductive pickup

Note:

If the engine stalls, after restarting it can automatically run for up to 4 minutes at an

increased speed. In which case do not continue until the speed drops off.

- Start engine and let idle (idle speed not to exceed 1500 rpm)

- Operate Scan Tool taking the displayed information into account

- Press 1 button to select "Rapid data transfer"

28-32

- Press 0 and 1 buttons to select address word

01: "Engine electronics"

- Press Q button to enter input

- Press

button

- Press 0 and 4 buttons to select Function 04:

"Basic setting"

- Press Q button to enter input

Note:

The Digifant Engine Control Module will be

matched to the engine at idle speed, in the basic

setting.

Basic setting

HELP

Input display group number XX

Display will appear as shown

- Press 0 and 1 buttons to select "Display group number"

- Press Q button to enter input

Basic setting 1

1

2

3

4

Display will appear as shown, (1 to 4 = Display zones)

Do not continue with check until

Engine temperature exceeds 85 C (display zone 2)

All setting conditions have been fulfilled Specification: 00000000 (display zone

4)

page 01-78.

- Check ignition timing between 2000 and 2500 rpm

Checking value: 3 to 8 before TDC (fluctuating)

28-33

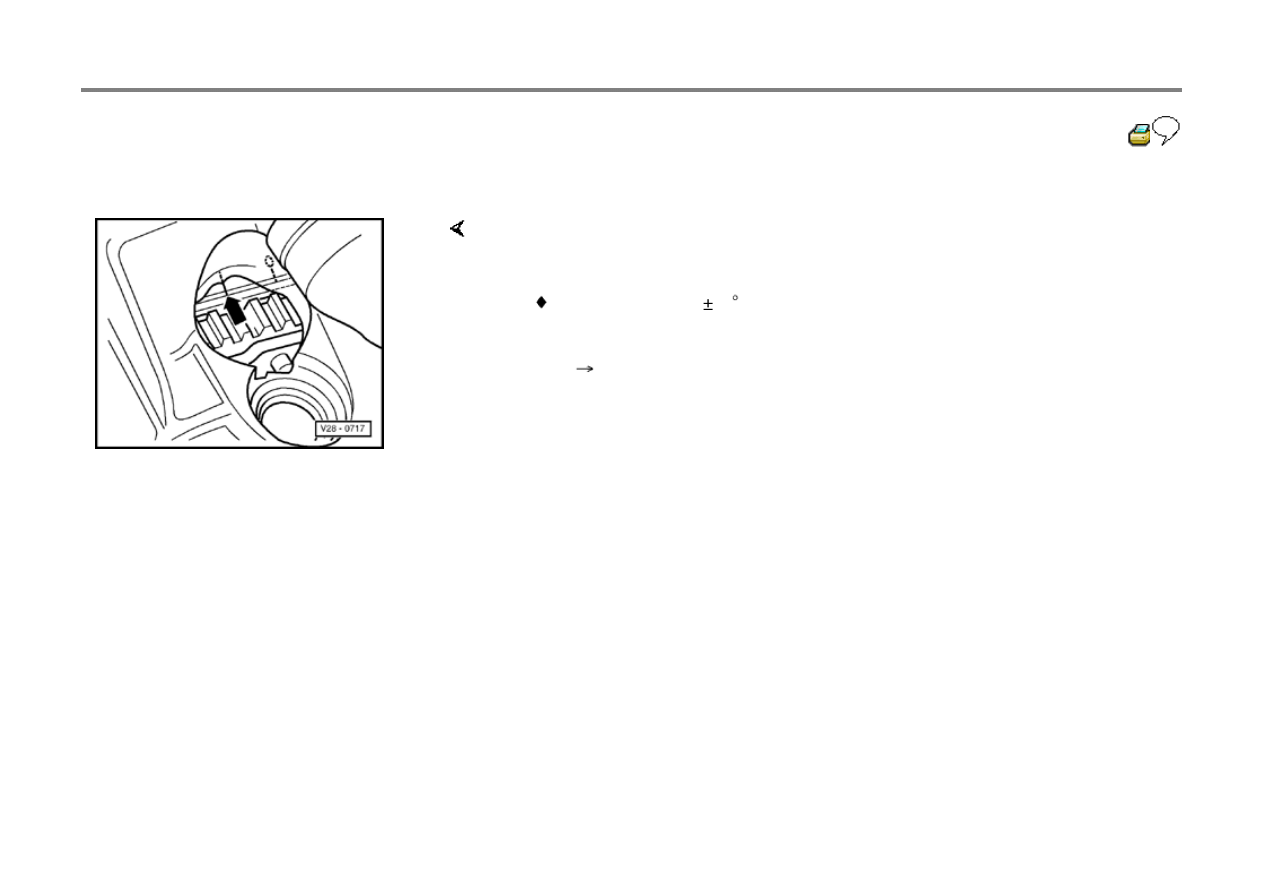

Using a stroboscope:

- Point strobe at ignition timing mark

- If necessary, adjust ignition timing by turning the distributor

Adjusting value: 6 1 before TDC

- Allow engine to idle for at least 1 minute

- Press

button

- Press 0 and 6 buttons to select Function 06: "End data output"

- Press Q button to enter input

28-34

Ignition timing point, checking

Special tools, testers and auxiliary items

VAG 1367 Engine Tester and inductive pick-up

VAG 1367/8

Test conditions

Ignition timing OK

No malfunctions stored in DTC memory

Engine oil temperature at least 80 C (176 F)

minimum

Test sequence

Note:

On some vehicles a TDC sensor is installed as

standard. Use adaptor cable VAG 1367/9 to

connect the TDC sensor.

- Connect VAG 1367 Engine Tester using VAG 1367/8 inductive pickup

- Start engine and let idle

If timing does not advance

- Set Engine Tester to 2200 rpm

- Slowly raise engine speed to slightly above 2200 rpm until ignition timing

(advance angle) is displayed

specification: 23 to 33 before TDC

- Perform electrical checks, if necessary, replace ECM -J169-

Page 01-83

28-35

Camshaft Position sensor, checking

Special tools, testers and auxiliary items

Fluke 83 multimeter

VW 1594 adaptor kit

VAG 1527B LED tester

Adaptor cable VAG 1315A/4

Test conditions

DTC code "Camshaft Position sensor -G40-"

recognized by On Board Diagnostic

Test sequence

Repair Group 01

Page 01-87

- Perform electrical check, test step 12

Voltage supply, checking

If specifications are obtained

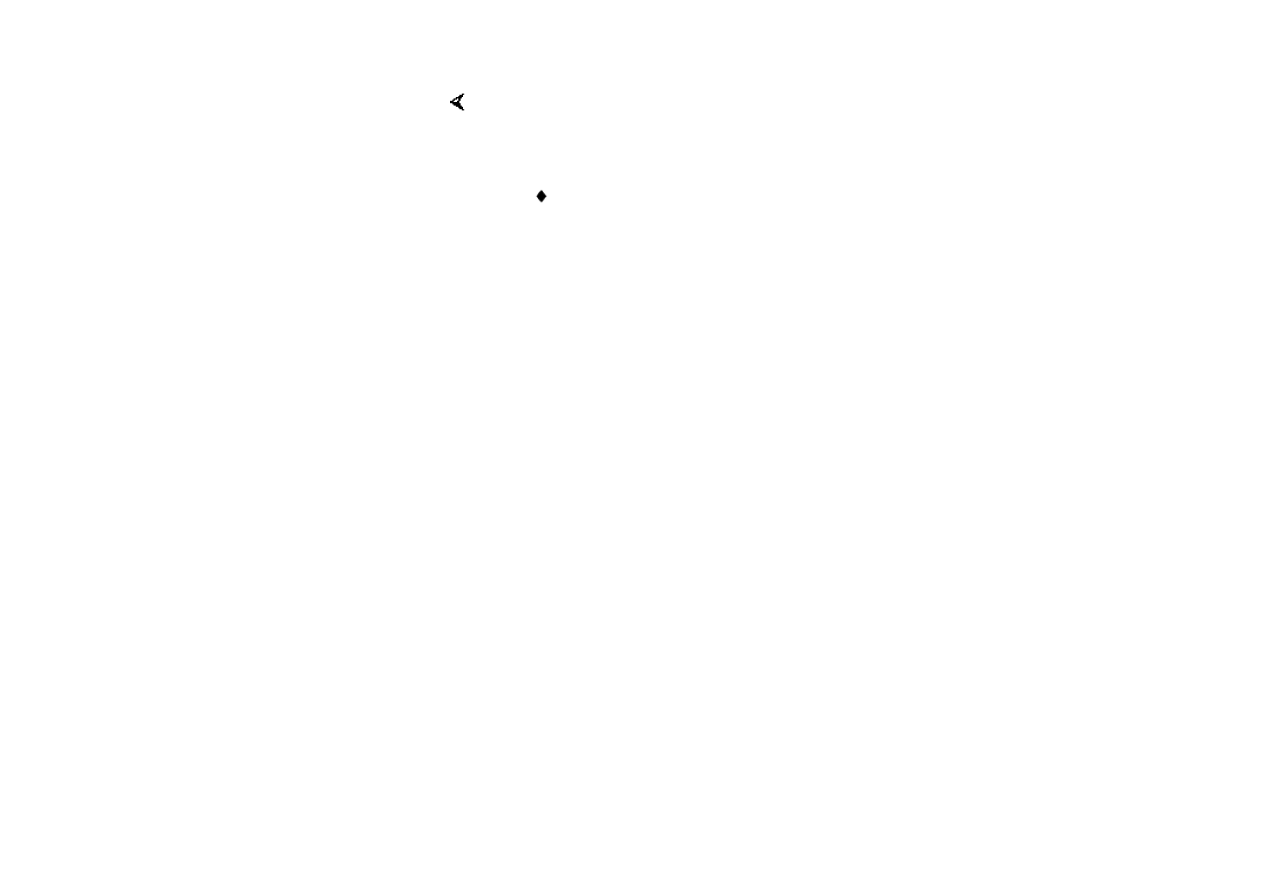

- Disconnect 3-pin harness connector from Camshaft Position sensor -G40-

- Connect multimeter between terminals 1 and 3 of harness connector using VW

1594 adaptor leads

- Switch ON ignition

Specification: At least 10 Volts

- Switch OFF ignition

- Replace Camshaft Position sensor

Page 28-26

, item 5

28-36

Ignition coil, checking

Special tools, testers and auxiliary items

Fluke 83 multimeter

Test sequence

- Disconnect coil wire from ignition coil and

harness connector from power output stage

If specifications not obtained

- Check primary resistance by connecting multimeter between ignition coil

terminals 1 and 15

Specification: 0.5 to 0.7

- Check secondary resistance by connecting multimeter between ignition coil

terminals 4 and 15

Specification: 3000 to 4000

- Remove ignition coil and disconnect power output stage -N157-

Page 28-23

,

item 5

- Repeat check

28-37

Ignition coil power output stage,

checking

Special tools, testers and auxiliary items

Fluke 83 multimeter

VW 1594 adaptor kit

VAG 1527B LED tester

Test conditions

Camshaft Position sensor OK

Repair Group 01, page 01-85

Electrical check, test step 9 OK, checking

Ignition coil OK

Voltage supply, checking

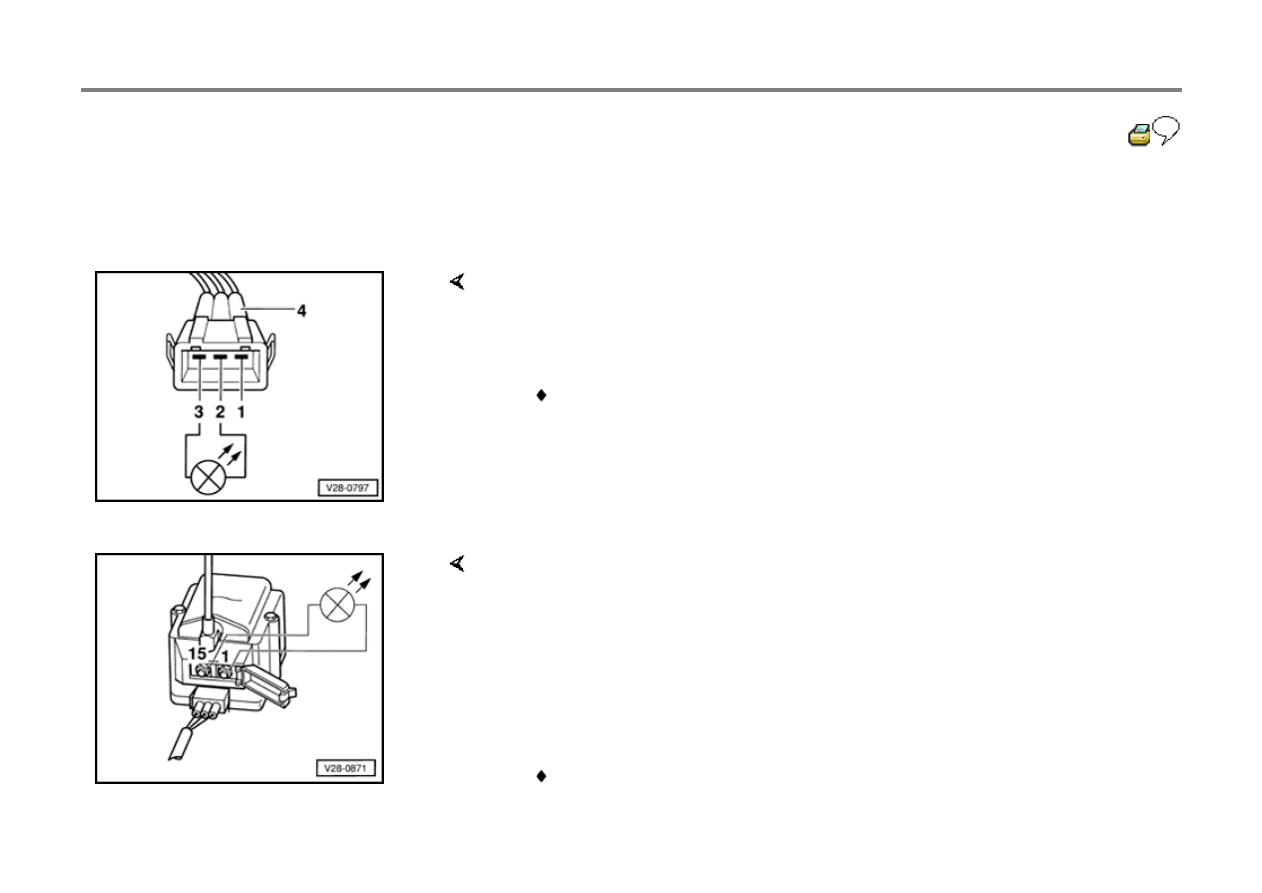

- Disconnect ignition coil 3-pin harness

connector

- Connect multimeter between terminals 1 and 3 of the harness connector using

jumper leads from the VW 1594 adaptor kit

- Switch ON ignition

Specification: Approx. battery Voltage

- Switch OFF ignition

28-38

Activation, checking

- Remove fuse 18

If the LED does NOT flicker

- Connect VAG 1527B LED tester between terminals 2 and 3 of ignition coil

harness connector using jumper wires and adaptor VW 1594/15 from VW 1594

adaptor kit

- Operate starter and observe ignition signal from ECM

LED must flicker

- Replace Digifant ECM -J169-

- Reconnect ignition coil harness connector and coil wire

CAUTION!

During the following check, do not touch the ignition coil terminals or test

cables!

- Connect LED tester between terminals 1 and 15 of ignition coil using jumper

wires from VW 1594 adaptor kit

- Switch ON ignition

LED must light up for 1 to 2 seconds

- Operate starter

LED must flicker

- Replace ignition coil power output stage, if necessary

Wyszukiwarka

Podobne podstrony:

g3 ign syst aaa 93 95

g3 mfi ign syst aaa 93 95

g3 mfi ign syst aba 93 95

g3 mfi ign syst aba 96 99

g3 mfi ign syst aaa 96 99

Proj syst log wykl 6

syst tr 1 (2)TM 01 03)13

Dyrektywa Dzwigowa 95 16 WE Czesc 1

94, 95

Program Progr Syst i Wspolb2011

Lepiej usługiwać innym niż sobie, Kazania Słowa Bożego, Jacek Filończyk, 02 Usprawiedliwienie przez

pomoc SYST[1].INF, Szkoła

Cechy org jako syst społ

Obwód zasilania 15 (IGN 1) skrzynka bespieczników w kabinie

A New American Acupuncture Acu Nieznany

IR(95) 1927 pl

DYREKTYWA 2006 95 WE dotycząca sprzętu elektrycznego

więcej podobnych podstron