TIN(IV) CHLORIDE–ZINC CHLORIDE

1

Tin(IV) Chloride–Zinc Chloride

1

SnCl

4

–ZnCl

2

(SnCl

4

)

[7646-78-8]

Cl

4

Sn

(MW 260.51)

InChI = 1/4ClH.Sn/h4*1H;/q;;;;+4/p-4/f4Cl.Sn/h4*1h;/q4*-1;m

InChIKey = HPGGPRDJHPYFRM-LUCXXLOKCB

(ZnCl

2

)

[7646-85-7]

Cl

2

Zn

(MW 136.29)

InChI = 1/2ClH.Zn/h2*1H;/q;;+2/p-2/f2Cl.Zn/h2*1h;/q2*-1;m

InChIKey = JIAARYAFYJHUJI-ATOKYBHQCC

(catalyst for bond formation between silyl nucleophiles and

carbonyl groups or enones

1

)

Physical Data:

SnCl

4

: mp −33

◦

C; bp 114.1

◦

C; d 2.226 g cm

−

3

;

ZnCl

2

: mp ca. 290

◦

C; bp 732

◦

C.

Solubility:

both reagents react violently with water. SnCl

4

: sol

cold H

2

O; dec hot H

2

O; sol alcohol, ether, CCl

4

, benzene,

toluene, acetone. ZnCl

2

: sol H

2

O (432 g/100 g at 25

◦

C, 614

g/100 g at 100

◦

C); 2% HCl (4 g/1 mL); alcohol (1 g/1.3 mL);

glycerol (1 g/2 mL); freely sol acetone.

Form Supplied in:

blend not commercially available. Anhydrous

SnCl

4

: colorless liquid; 1 M soln CH

2

Cl

2

or heptane; widely

available. Anhydrous ZnCl

2

: white, odorless granules, lumps,

or rods; 1 M soln in Et

2

O, 0.5 M soln in THF; widely available.

Purification:

SnCl

4

: heat to reflux with mercury or P

2

O

5

for sev-

eral hours, then distil under reduced nitrogen pressure into re-

ceiver with P

2

O

5

. Redistil. Typical impurities: hydrates. ZnCl

2

:

heat to reflux in dioxane (100 g/800 mL) with zinc dust (10 g),

filter hot, and cool to precipitate ZnCl

2

. Crystallize from diox-

ane. Impurities: H

2

O, zinc oxychloride.

Handling, Storage, and Precautions:

both reagents are hygro-

scopic and should be stored in a glove box or over P

2

O

5

to

minimize exposure to moisture. Containers should be flushed

with N

2

or Ar and tightly sealed. Perform all manipulations un-

der N

2

or Ar. Solvating SnCl

4

with H

2

O is highly exothermic.

Use in a fume hood.

Introduction. The Tin(IV) Chloride–Zinc Chloride blend

1

is one of many Lewis acid blends, such as Sn(OTf)

2

–Bu

3

SnF,

2

SnCl

4

–Sn(OTf)

2

,

3

SbCl

5

–Sn(OTf)

2

,

4

TMSCl–SnCl

2

,

5

TrCl–SnCl

2

(Tr = trityl),

6

SnO–TMSOTf,

7

and GaCl

3

–AgClO

4

,

8

which are effective catalysts in carbon–carbon bond forming

reactions. The active catalyst is believed to be

+

ZnCl–SnCl

5

−

which is formed prior to the addition of organic reactants. Single

Lewis acids (SnCl

4

, TiCl

4

, etc.) promote these reactions, but do

not catalyze them.

9

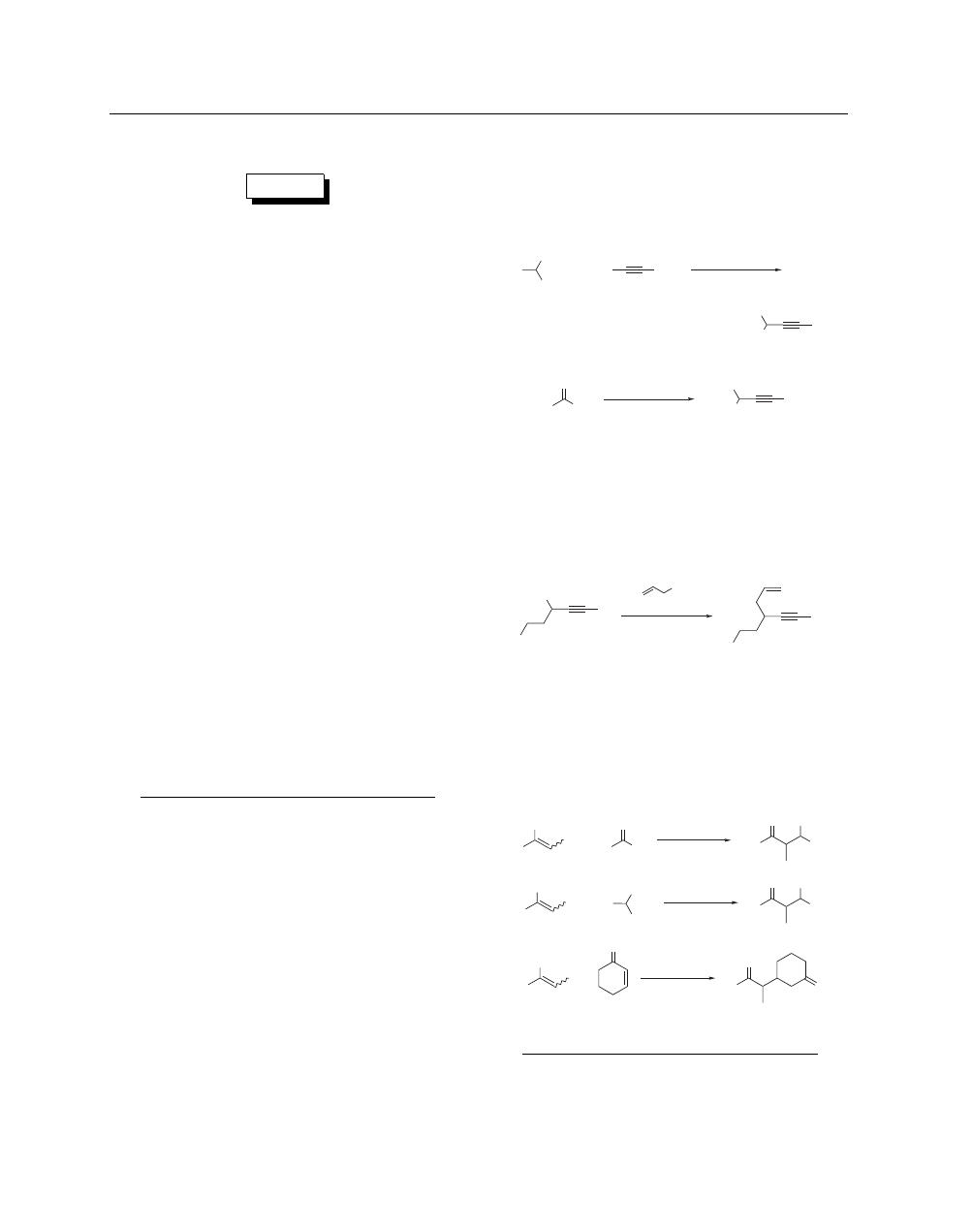

Ethynylation of Acetals and Aldehydes.

1

The SnCl

4

–ZnCl

2

blend is the most useful catalyst (10 mol %) for the preparation of

secondary propargylic ethers from 1-trimethylsilyl-1-alkynes and

acetals (eq 1).

1

Conventional promoters such as TrCl–SnCl

2

and

TMSCl–SnCl

2

are not effective, and Sn

II

–Sn

IV

, Sn

II

–Ti

IV

, and

Zn

II

–Ti

IV

blends provide lower yields. Moderate yields (29–53%)

are obtained for acetals with large alkoxy groups (R

2

); however,

cyclic acetals, such as 1,3-dioxolane, do not react. Aromatic and

conjugated dimethyl acetals provide dipropargyl derivatives as

side products. Ethynylation of aldehydes is accomplished by form-

ing intermediate hemiacetal-like compounds from aldehydes and

alkoxytrimethylsilanes in the presence of the Lewis acid blend.

These intermediates then undergo reaction with 1-trimethylsilyl-

1-alkynes to form the desired secondary propargylic ethers (eq 2).

R

1

OR

2

OR

2

R

3

TMS

R

1

R

2

O

R

3

+

10% SnCl

4

–ZnCl

2

CH

2

Cl

2

, rt

(1)

(1)

13–85%

R

1

R

2

O

R

3

1. cat. SnCl

4

–ZnCl

2

2. R

2

OTMS

3. (1)

(2)

R

1

H

O

0–78%

Allylation

of

Secondary

Propargylic

Ethers

and

Aldehydes.

1

Propargylic ethers are allylated by Allyltrimethyl-

silane in the presence of the SnCl

4

–ZnCl

2

blend (eq 3). Thus

acetals can be transformed to 1,5-enynes in one pot with

sequential nucleophilic additions. The blend also catalyzes

the allylation of aldehydes by allyltrimethylsilane, yielding

homoallylic alcohols in good yields (61–74%).

MeO

Ph

cat. SnCl

4

–ZnCl

2

(3)

Ph

TMS

Ph

Ph

56%

Aldol and Michael Reactions.

1

The SnCl

4

–ZnCl

2

blend is

an effective catalyst in the aldol reaction of silyl enol ethers with

aldehydes (eq 4), acetals (eq 5), or ketones. The product anti/syn

ratios are variable (32:69 to 89:11). The blend also catalyzes the

Michael addition of silyl enol ethers with α,β-unsaturated ketones

(eq 6), yielding alkylation products (84–100%) with anti selectiv-

ity (anti/syn = 55:45 to 87:23)

SnCl

4

–ZnCl

2

Ph

OTMS

Ph

H

O

Ph

Ph

O

OH

+

(4)

99%

SnCl

4

–ZnCl

2

Ph

OTMS

Ph

OMe

OMe

Ph

Ph

O

OMe

+

(5)

99%

+

(6)

Ph

OTMS

Ph

O

SnCl

4

–ZnCl

2

O

O

87%

Related Reagents. Tin(IV) Chloride; Zinc Chloride.

1.

(a) Hayashi, M.; Inubushi, A.; Mukaiyama, T., Bull. Chem. Soc. Jpn. 1988,

61

, 4037. (b) Hayashi, M.; Inubushi, A.; Mukaiyama, T., Chem. Lett. 1987,

1975.

Avoid Skin Contact with All Reagents

2

TIN(IV) CHLORIDE–ZINC CHLORIDE

2.

(a) Mukaiyama, T.; Uchiro, H.; Kobayashi, S., Chem. Lett. 1989, 1001.

(b) Kobayashi, S.; Mukaiyama, T., Chem. Lett. 1989, 297. (c) Kobayashi,

S.; Uchiro, H.; Fujishita, Y.; Shiina, I.; Mukaiyama, T., J. Am. Chem. Soc.

1991, 113, 4247.

3.

Mukaiyama, T.; Shimpuku, T.; Takashima, T.; Kobayashi, S., Chem. Lett.

1989, 145.

4.

Kobayashi, S.; Tamura, M.; Mukaiyama, T., Chem. Lett. 1988, 91.

5.

(a) Iwasawa, N.; Mukaiyama, T., Chem. Lett. 1987, 463. (b) Mukaiyama,

T.; Wariishi, K.; Saito, Y.; Hayashi, M.; Kobayashi, S., Chem. Lett. 1988,

1101.

6.

(a) Mukaiyama, T.; Kobayashi, S.; Tamura, M.; Sagawa, Y., Chem. Lett.

1987, 491. (b) Mukaiyama, T.; Sugumi, H.; Uchiro, H.; Kobayashi, S.,

Chem. Lett. 1988

, 1291.

7.

Mukaiyama, T.; Uchiro, H.; Kobayashi, S., Chem. Lett. 1990, 1147.

8.

Mukaiyama, T.; Ohno, T.; Nishimura, T.; Suda, S.; Kobayashi, S., Chem.

Lett. 1991

, 1059.

9.

(a) Mukaiyama, T.; Narasaka, K.; Banno, K., Chem. Lett. 1973, 1011. (b)

Mukaiyama, T., Angew. Chem., Int. Ed. Engl. 1977, 16, 817. (c) Narasaka,

K.; Soai, K.; Aikawa, Y.; Mukaiyama, T., Bull. Chem. Soc. Jpn. 1976, 49,

779.

Stephen Castellino

Rhône-Poulenc Ag. Co., Research Triangle Park, NC, USA

David E. Volk

North Dakota State University, Fargo, ND, USA

A list of General Abbreviations appears on the front Endpapers

Wyszukiwarka

Podobne podstrony:

benzyl chloride eros rb050

oxalyl chloride eros ro015

copper II chloride eros rc214

lithium chloride eros rl076

palladium II chloride eros rp007

phenylzinc chloride eros rp148

iron III chloride eros ri054

aluminum chloride eros ra079

mercury II chloride eros rm031

allyl chloride eros ra046

hydrogen chloride eros rh035

iron II chloride eros ri055

benzyl chloride eros rb050

oxalyl chloride eros ro015

copper II chloride eros rc214

vanadium II chloride eros rv002

pyridinium chloride eros rp287m

więcej podobnych podstron