Cold-connection techniques replace soldering

in this quick and easy necklace.

by Wendy Witchner

E

ditor’s Note: Wendy Witchner embraces a motor-home lifestyle so she can travel

around the country selling her wire and metal jewelry at shows. Because she lives and

works in the same space, she uses cold-connection techniques that require a limited

number of tools. Witchner shares some of her secrets with you in this project, so if you

have limited workspace or just want to work with cold connections, you’ll benefit from

her experience.

—Dori Olmesdahl

A r t J e w e l r y • M a y 2 0 0 5

1

metal

beginner

Twisted

glory

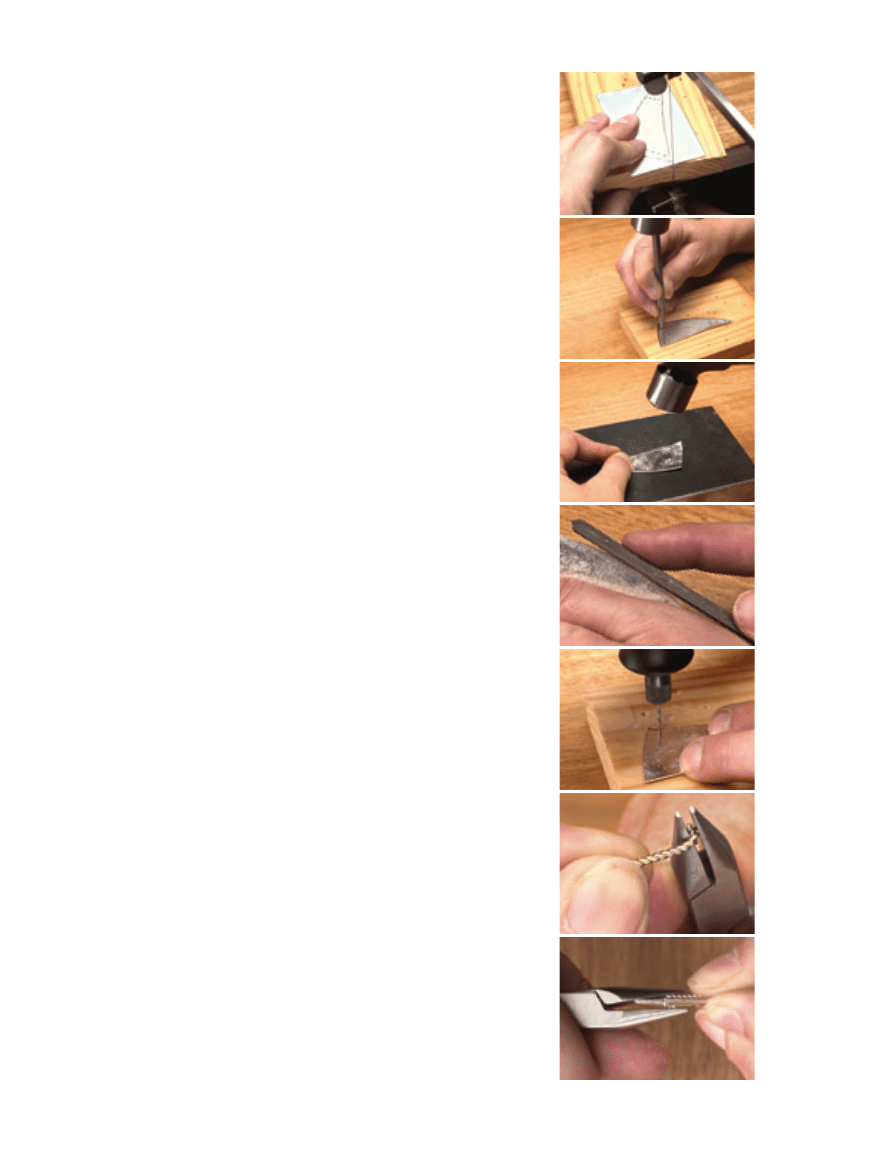

Trace the template. Place a piece of Glad® Press ’n Seal™ over the

template on page 4 and trace the shape and the dots. Position the

Press ’n Seal template on the silver sheet and gently press it so it

adheres to the silver.

[1] Cut out the shape. Rest the silver sheet against a bench pin and

use a jeweler’s saw fitted with a 2/0 blade to cut around the outside

edge of the shape. Hold the saw frame and blade perpendicular to the

plane of the silver sheet and use a gentle up-and-down motion to

guide the saw. The blade only cuts metal on the down stroke; do not

apply too much pressure or the blade will jam or break. Think of using

a pressure so light that the weight of the saw pulls the blade through

the silver—your hand just keeps the saw perpendicular and moves it

upward at the end of each stroke.

[2] Mark the drill holes. Place the pendant right side up on a steel

bench block. Position a center punch on mark A and hold it

perpendicular to the metal. Strike the top of the punch with a hammer

to make a slight indentation. If you use too much pressure, the metal

sheet will start to curl upward. Repeat with marks B–M.

[3] Apply texture. Remove the Press ’n Seal from the metal shape.

Place the metal face up on a steel block. Use a hammer with a pattern

incised into the head (see “Make a Texture Hammer,” page 4) or use

another tool to texture the front of the pendant.

[4] File the edges. Use a flat or half-round file to file the edges

smooth. Push the file away from you so it glides along the edge of the

piece and lift off on the return stroke. Do not file using a back-and-

forth motion.

Add a patina. If desired, apply liver of sulfur to the silver elements,

including all the parts of the pendant, the neckwire, and the wire used

to join the elements. Follow the manufacturer’s directions. Rinse, dry,

and use a lathe with a buffing wheel or bristle disks to buff the

pendant. Buff the wire by running it through a rouged polishing cloth.

Never try to buff wire on a polishing wheel.

[5] Drill the holes. Start drilling a hole in the dent you made with

the center punch. Use a drill press or power drill with a #63 drill bit to

make holes I–K. Use a #51 drill bit to make all the other holes.

[6–7] Attach the twisted wire. Use a wire cutter to cut a piece of

twisted wire that is 2

1

⁄

4

inches (5.7cm) long. Use chainnose pliers to

grasp the wire about

1

⁄

8

inch (3.18mm) from one end. Use your fingers

to bend the long end of the wire so it forms a right angle.

Working from the textured side of the pendant, press the short end

of the wire through hole A. Use chainnose pliers to simultaneously

apply pressure from both sides to press the wire flat against the silver

sheet. Grasp the opposite end of the wire with chainnose pliers across

from hole B and bend it at a right angle. Press the wire through the

hole. If needed, trim the end to

1

⁄

16

inch (1.59mm). As you did before,

use the pliers to press the wire against the metal. Repeat with holes

C–D, E–F, and G–H.

A r t J e w e l r y • M a y 2 0 0 5

2

2

3

4

1

5

6

7

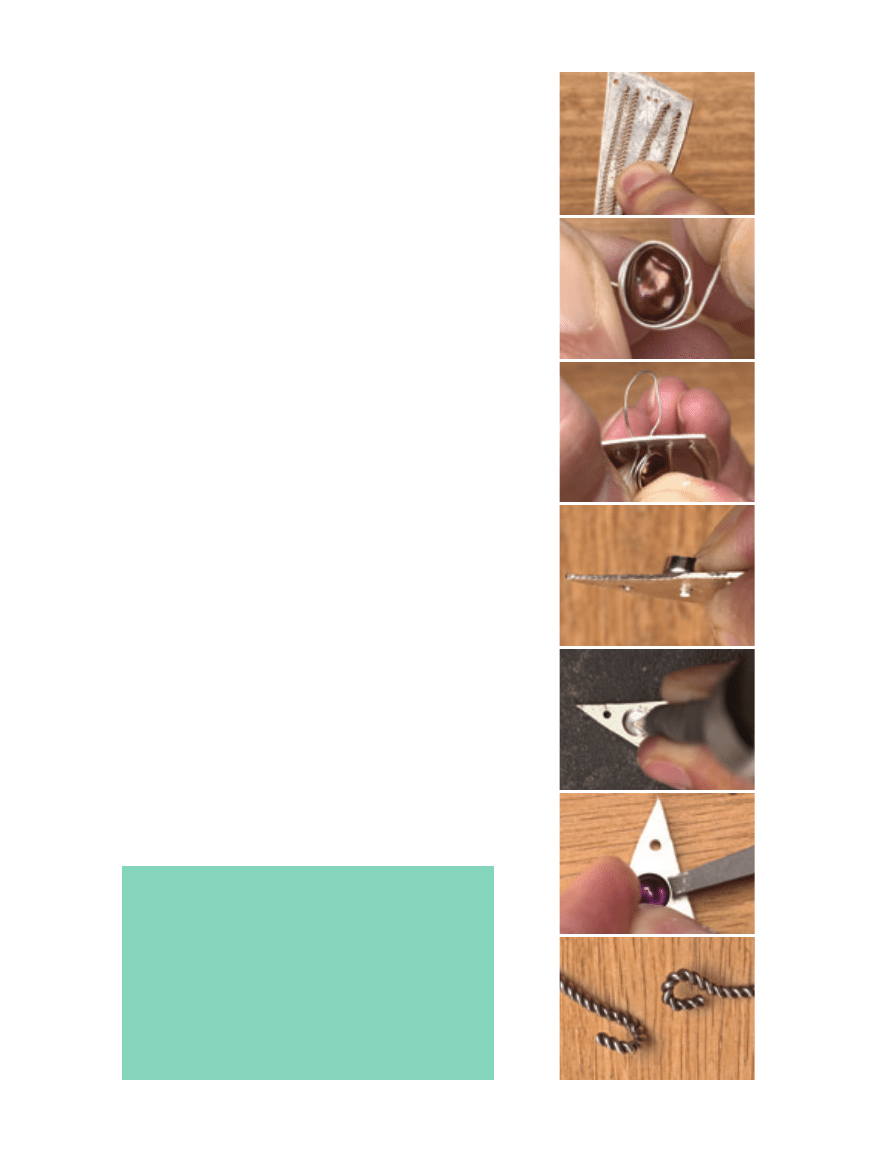

[8] Position the wires. Working from the front of the pendant,

use a finger to separate a set of wires so they curve away from

each other near the center of the pendant. Place the pendant face

up on a steel bench block. Hold the wires apart and use a hammer

to strike the two wires near one end of the pendant and then at

the other end. This keeps the wires in place. Repeat with the

remaining wires.

[9–10] Add the pearl. Slide about 3 inches (7.6cm) of 22-gauge

wire through the hole in the pearl. While holding one end, wrap the

other end around the pearl two or three times. Working from the

front of the pendant, slide the longer tail through hole I and then

slide it through hole J so both tails are on the front of the pendant.

Pull this tail so the pearl sits tightly on the pendant. Use wire cutters

to trim the wires and press them in toward the face of the pendant.

[11–13] Attach the bezel. Place the bezel cup on a steel bench

block with the bezel’s lip facing up. Use a center punch and

hammer to make a slight indentation in its center. Use a drill press

or power drill to make a hole with a #63 bit.

Use a flat jeweler’s file to level off one end of the 20-gauge

round wire. Use flush-cut wire cutters to trim the other end to

1

⁄

8

inch (3.18cm). This piece will be used as a rivet. Align the hole in

the bezel cap over hole K on the pendant. Press the rivet through

the holes so a little wire extends from each side [11]. Place the

pendant on a steel bench block, and flatten the rivet with a

hammer and nail set [12].

Place the cabochon in the bezel and use a bezel pusher to press

the sides of the bezel against the cabochon [13]. After the first

press, work from the alternate side. Using a clock analogy, if your

first press was at 9:00, the second would be at 3:00, the third at

12:00, and the fourth at 6:00. Continue in this manner until the

bezel is smooth and securely holds the cabochon.

[14] Shape the neck wire. Use a roundnose pliers to grasp one

end of the 16-gauge wire about

1

⁄

2

inch (1.3cm) from the tip. Use

nylon-coated pliers to bend the wire around the jaw of the

roundnose to form a U shape. Repeat at the other end of the wire,

but once you make the U shape, use nylon-coated pliers to press

the short end toward the neck wire. Use the same pliers to twist

one end so it is almost perpendicular to the other. Use a metal file

to smooth the tips of both.

A r t J e w e l r y • M a y 2 0 0 5

3

9

10

11

8

12

13

14

note

Twisted wire is made by twisting two round

wires together. The gauge of the wire is

usually described by the gauge of the

individual wires and not the diameter of the

resulting piece. Sixteen-gauge twisted wire

is fabricated from two 16-gauge round

wires, which form a strand with a diameter

equivalent to that of 10-gauge round wire.

on twisted wire

A

M

L

K

J

I

H

G

F

E

D

C

B

Opening

and closing

jump rings

[1] Hold the jump

ring with two pairs

of chainnose pliers.

[2] To open the ring,

bring one pair of

pliers toward you

and push the other

away in a rotating

motion.

[3] Grasp the open

jump ring with one

pliers for ease of

maneuvering.

Reverse the steps to

close the ring.

To make your own texture hammer, use a 1–2mm

diamond-tipped drill bit to incise a random pattern onto

the head of a steel utility hammer. For another option, use

a hacksaw or other saw to score grooves onto the head’s

surface. Whatever tool you have that will fashion metal

may be used to make specific textures.

If you do not want to texture the head of a hammer,

you can make random dents in the silver sheet with a

regular utility hammer

or another type of

texture tool such as a

metal stamp.

materials

■

Utility hammer

tools

■

Power drill with

1–2mm diamond-

tipped drill bit

Make a texture hammer

A r t J e w e l r y • M a y 2 0 0 5

4

■

Sterling-silver sheet: 1

×3 inches (2.5×7.6cm)

■

Sterling-silver wire: 10 inches (25.4cm),

20-gauge, twisted, dead-soft

■

Sterling-silver wire: 6 inches (15.2cm),

22-gauge, round

■

Pearl, 8mm, flat-sided

■

Sterling-silver bezel cup, 6mm round

■

Sterling-silver wire; 1 inch (2.5cm),

20-gauge, round

■

Cabochon, 6mm round, calibrated

■

Sterling-silver wire: 19 inches (48.3cm),

16-gauge, twisted, half hard

■

2 sterling-silver jump rings: 5mm round,

16-gauge

■

Liver of sulfur (optional)

tools & supplies

■

Bench pin

■

Jeweler’s saw frame, 2/0 blade

■

Steel bench block

■

Center punch

■

Hammer

■

Texture hammer, metal stamp, or other

metal-texturing tool

■

Flat or half-round metal file

■

Buffing wheel or bristle disks (optional)

■

Polishing cloth with rouge

■

Drill press or power drill, #51 and #63 bits

■

Ring clamp

■

Flush wire cutters

■

Chain-, round-, and flatnose pliers

■

Nail set

■

Bezel pusher

■

Nylon-coated flatnose pliers

■

Glad® Press ’n Seal™

materials

2

3

1

When the ends are complete, shape the wire

into a circle by pressing it around a necklace

mandrel or coffee can.

Connect the pendant to the neck wire. Open a

jump ring (see the sidebar “Opening and Closing

Jump Rings,” page 4). Slide the open ring through

hole L, and then over the neck wire. Close the jump

ring. Repeat with another jump ring and hole M.

Z

Witchner’s pattern template is marked with letters

that correspond to specific points, as indicated in the

project’s instructions.

Make jewelry

that makes a

statement . . .

your statement

Looking for projects that use different

materials such as metalwork, wirework,

stone, glass, polymer, and enamel? Then

Art Jewelry

is the magazine for you!

Discover the secrets you need to create

breathtaking pieces that express your own

distinctive style like never before! Whether

you want to learn a new technique, try a

different material, or get ideas for your

own jewelry projects, there’s something for

you in

Art Jewelry!

Order online at

Enter code: I4XZ1

or call 800-533-6644

Monday-Friday, 8:30 a.m. - 5:00 p.m. Central Time.

Outside the U.S. and Canada, call 262-796-8776, ext. 661.

I4XZ1

Subscribe

Today!

05X1017

Wyszukiwarka

Podobne podstrony:

connections pre intermediate minimock test 0 4 b

Pryda Timber Connectors Catalogue March 2007

Toys The The Cold Gun

23 299 318 Optimizing Microstructure for High Toughness Cold Work Steels

Ch17 Screw Connections

Artistic Wire Green or Magenta Single Spiral Bead Necklace & Earrings

ar 156 connect 60360892 05 2004

Field of Glory Errata

fiat multipla Nawigator connect nav 60360855 09 2004

Butterworth Finite element analysis of Structural Steelwork Beam to Column Bolted Connections (2)

deer connectdot august5

kawa cold, Kobiece różnosci- przepisy, zbiory przepisów

Portal of Glory

ar 147 connect nav 60389170 05 2008

connection

sprawko tworzywa cold box

Kill The Cold

4 2 4 5 Packet Tracer Connecting a Wired and Wireless LAN Instructions

więcej podobnych podstron