Function Block Reference Manual

APP-RTT-B-GB

Sucosoft S

40

Application Software

Closed-Loop Control Toolbox, Basic Version

03/99 AWB 2700-1365 GB

1st published 1999, edition 03/99

© Moeller GmbH, Bonn

Author:

Rainer Tenhagen

Production: Ingo Meyer

Translators: Baker & Harrison, Terence Osborn

1

03/

99 AW

B

2700-

1365 G

B

Contents

1 Basic Information and Technical Data

General 3

Philosophy of the RTT

Technical data and other technical information 7

Additional tools for the RTT

3 Pulse Duration Modulator (PDM)

4 Miscellaneous Function Blocks

Two-point interpolation (scaling)

2

03/

99 AW

B

2700-

1365 G

B

3

03/

99 AW

B

2700-

1365 G

B

1

Basic Information and Technical Data

General

The basic version of the closed-loop control toolbox

(RTT) is a tool for programming with Sucosoft S 40 to

the IEC 1131-3 standard. Once installed, the toolbox

provides 9 function blocks under the menu item

“Symbols/User-defined function blocks”, each in

German and English. The basic version of the

toolbox covers the basic requirements for closed-

loop control such as a PID controller in conjunction

with a pulse duration modulator.

Should the user require further functions, the full

versions of the RTT are available in German and

English. The full versions contain approximately

100 function blocks from the following areas:

Mathematical and logical function blocks

Trigonometric functions

Exponentiation, root extraction

Interpolation

Basic blocks of closed-loop control

Integrator

DT1 system

Sinus oscillation

Hysteresis

Basic Information and

Technical Data

4

03/

99 AW

B

2700-

1365 G

B

Controllers

PID controller

PID split-range controller (heating/cooling)

Autotuning controller

PD three-step controller

Two-step controller

Three-step controller

Pulse duration modulation (PDM)

Conventional PDM

Dynamic PDM

Split-range PDM

Noise-shape PDM (suitable only for solid states)

Signal filters, processing and limitation

Tolerance limit monitors

Limit monitors

PT1 filters

PT3 filters

System simulation

Oscillatory PTn system simulation

Fuzzy systems

Fuzzy function blocks with 2 to 4 input variables

and 2, 3 or 5 terms per input variable

Which PLCs can be used with the RTT?

The RTT can be used on all PLCs that can be

programmed with Sucosoft S 40, e. g. PS 4-201,

PS 416 and PS 4-341.

Philosophy of the RTT

5

03/

99 AW

B

2700-

1365 G

B

Philosophy of the RTT

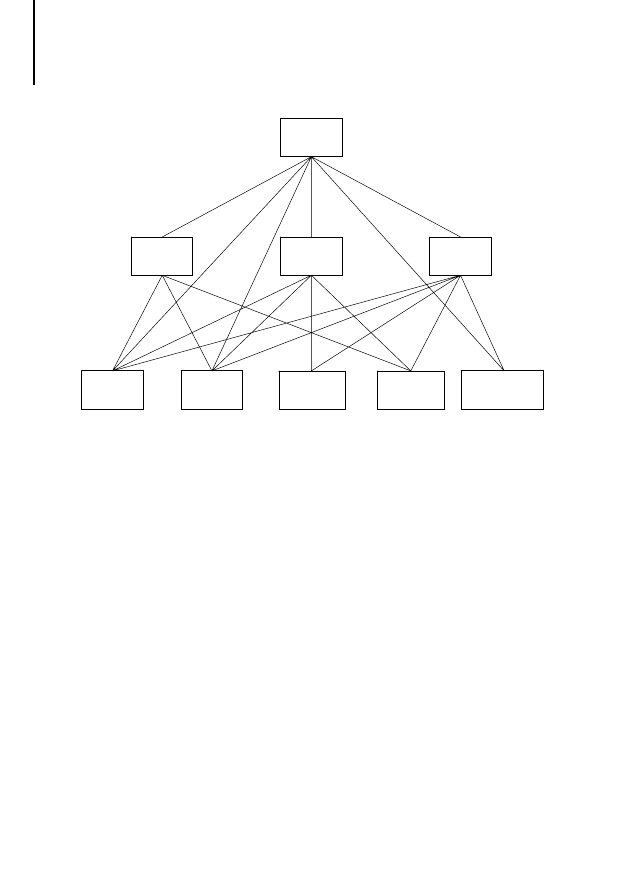

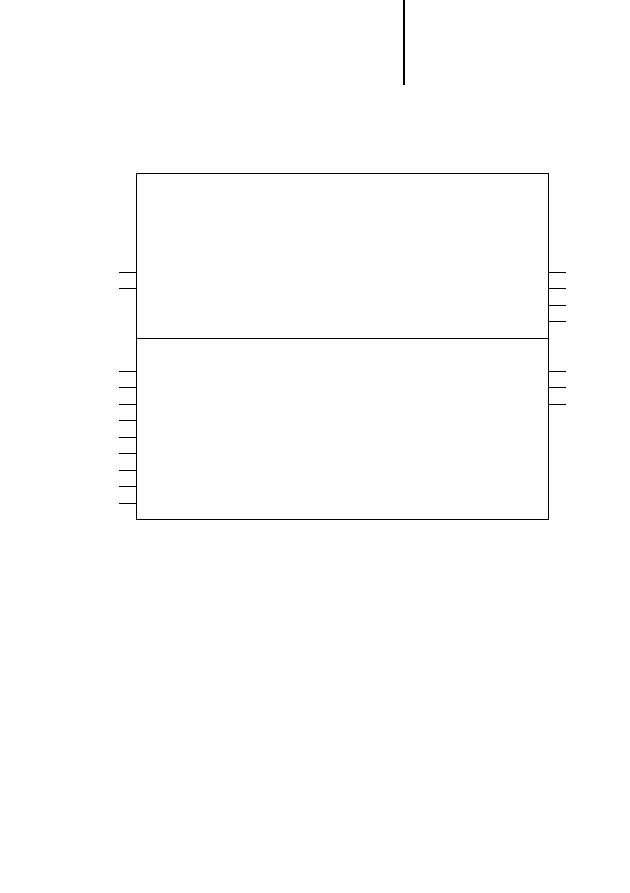

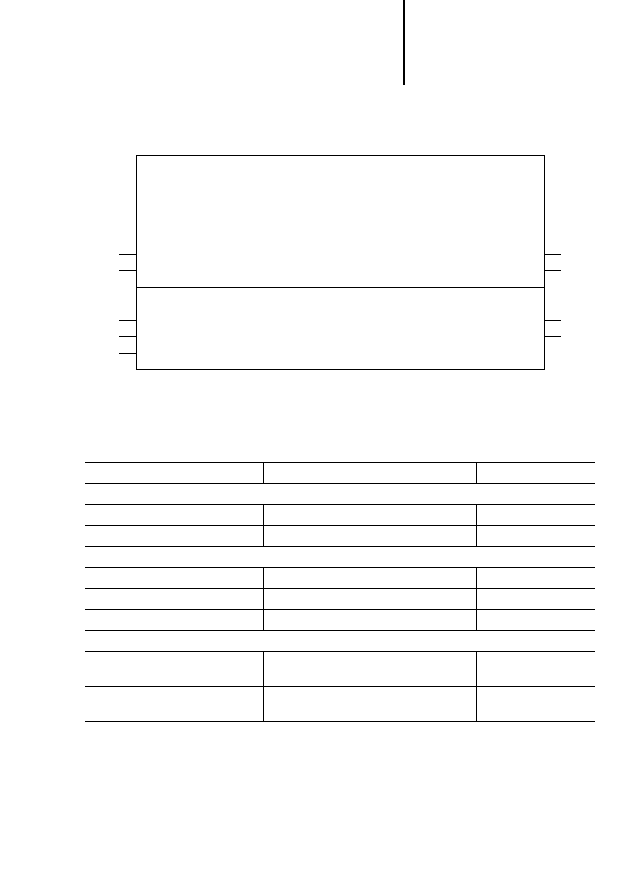

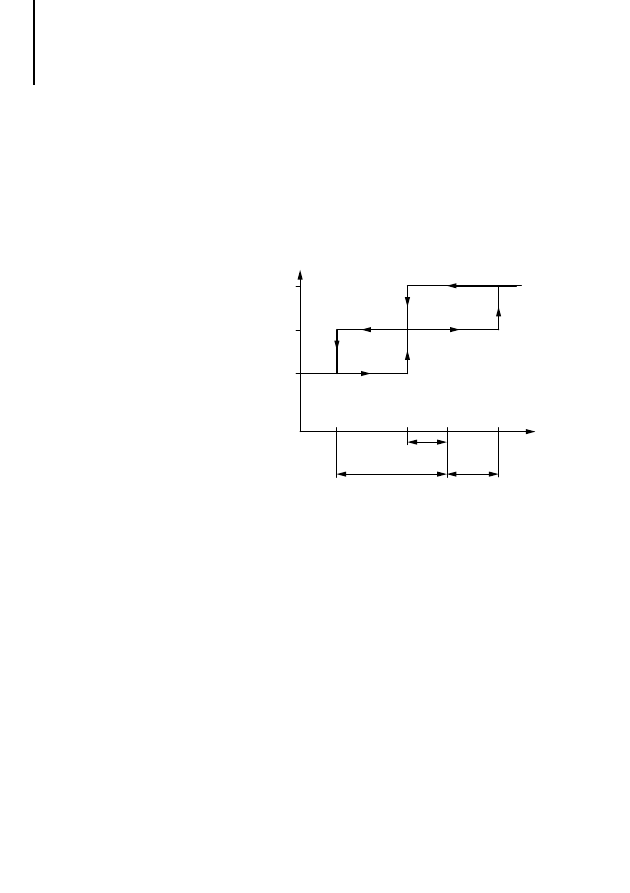

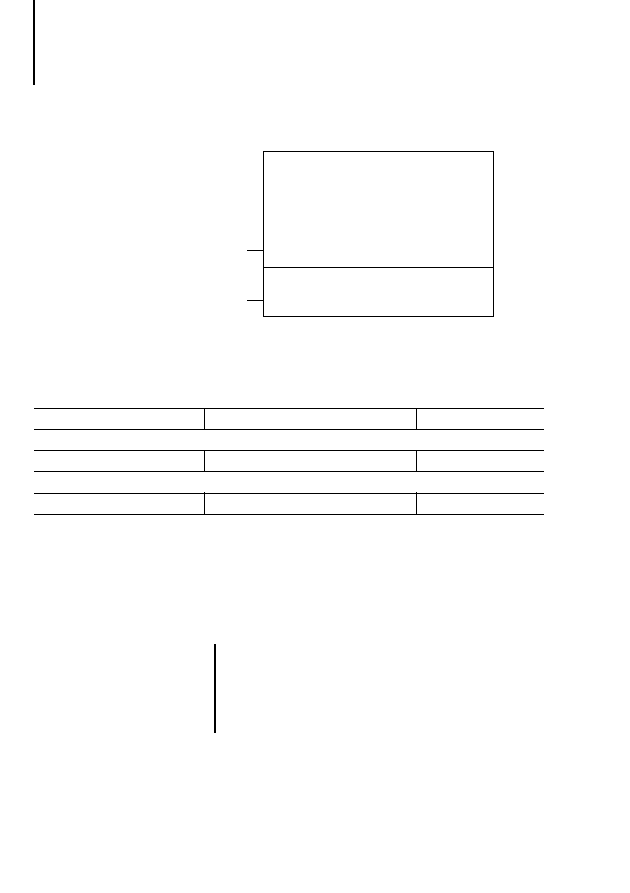

Hierarchical structure of the toolbox

The RTT is modular in structure and consists of

several hierarchical levels (see Figure 1). The function

blocks of the 1st level have basic functions such as

limiters or mathematical functions. Function blocks

of the 2nd level provide basic functions for closed-

loop control such as integrators or differentiating

elements. The 3rd level covers higher functions for

closed-loop control. In the example of the PID

controller (see Figure 1), you can see how function

blocks of the higher levels can access function

blocks of the lower levels.

The hierarchical, modular structure of the RTT

affords the following advantages:

Self-contained functions can be selectively

tested and optimized.

Since function blocks of the upper levels may

access function blocks of the lower levels

multiple times, relatively small code sizes arise in

comparison with non-modular programs.

Complex algorithms can be implemented very

quickly by combining the modular functions.

Because only tested function blocks are used, the

number of programming errors is relatively low.

Basic Information and

Technical Data

6

03/

99 AW

B

2700-

1365 G

B

Figure 1: Hierarchical arrangement of RTT function blocks

in multiple levels in the example of the PID controller

Self-explanatory variable and block names

The chosen variable and function block names of the

RTT are described in detail and are self-explanatory

so that programmers can use the RTT without

lengthy familiarisation. Most of the function blocks

can be integrated into the user program and

assigned parameters without the aid of the

documentation.

Parameter assignment instead of programming

Using the RTT means that the user’s task is one of

assigning parameters rather than creating a program.

This considerably reduces programming effort.

Level 3

Level 2

Level 1

D controller

Type conversion

Multiplication

I controller

Clock

generator

Addition

Limitation

P controller

PID

controller

Technical data and other

technical information

7

03/

99 AW

B

2700-

1365 G

B

Utilisation effort as low as possible, functionality

as high as possible

The effort of utilising the RTT function blocks should

be as low as possible for the user. As much

functionality as possible should be processed

automatically within the function block. The PID

controller, for example, has the follows functions:

anti-windup procedure

effective D computation (differentiation)

standardised control response

automatic definition of internal scanning time by

integrator and differentiator

smooth acceptance of manual setpoint

Technical data and

other technical

information

General information on code sizes and cycle time

requirements of RTT function blocks

Code is generated only once for each declared

function block. Where function blocks are instanced

(declared again with other instance names), only one

additional data field is created for each instance.

Because of the considerable code sizes in some

cases, the cycle time requirement of the RTT function

blocks is relatively large if PS 4-200 series PLCs are

used. A PID controller, for example, requires

approx. 10 ms PLC cycle time. If, for example,

30 control zones are necessary, long PLC cycle

times arise and/or the maximum cycle time is

exceeded.

Basic Information and

Technical Data

8

03/

99 AW

B

2700-

1365 G

B

In such cases, the program can be segmented so

that the controller is called for one zone only per PLC

cycle. The cycle time requirement when using a

PS 416 or PS 4-300 PLC is approx. 15 to 20 times

smaller.

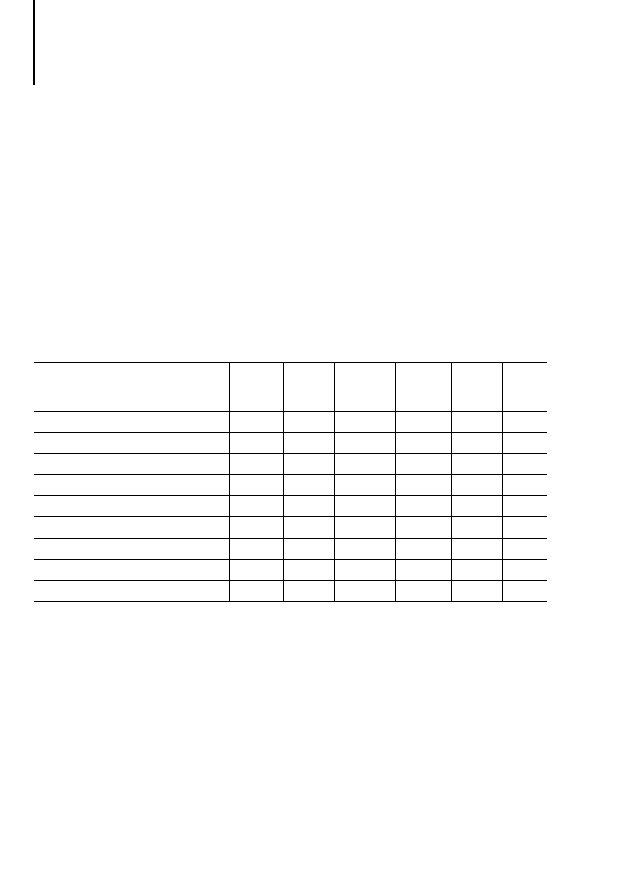

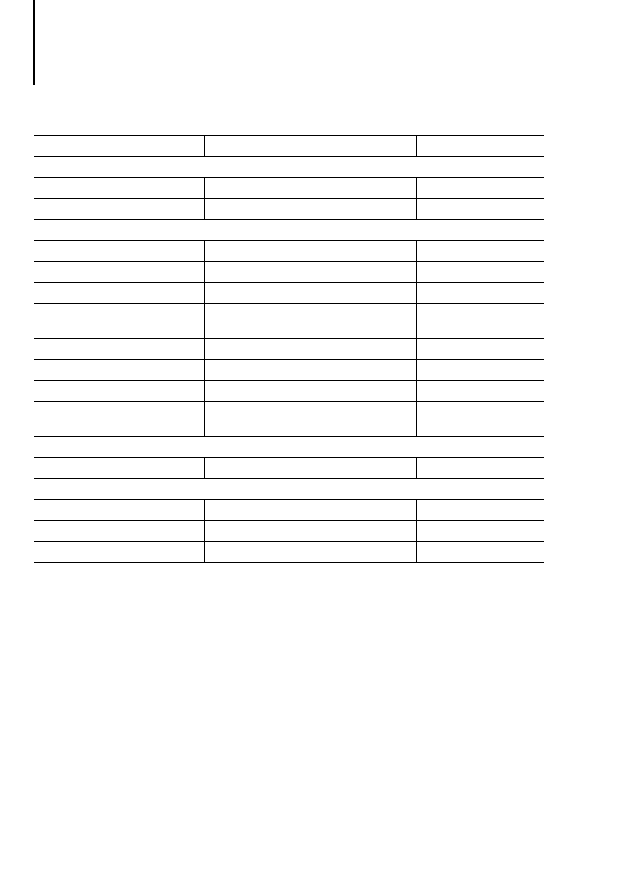

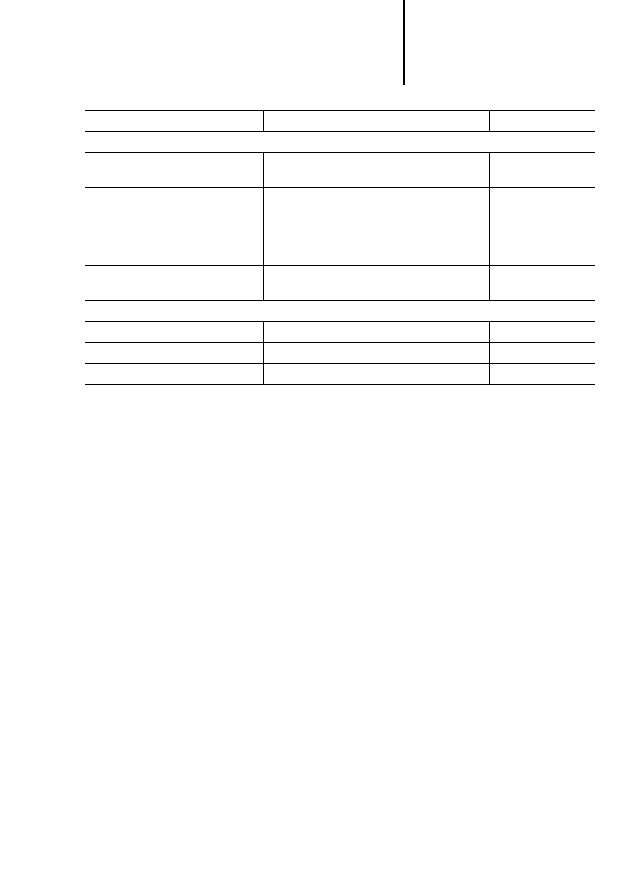

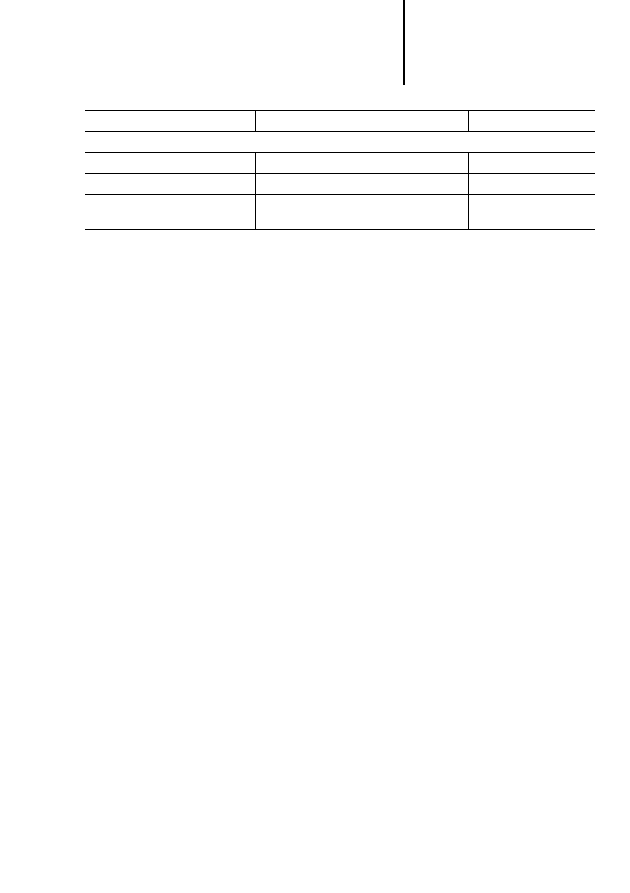

Technical data

The data apply to the PS 4-200 PLC types (subject to

change). The code sizes for the PS 416 and

PS 4-300 PLC types are approx. 20 % larger and the

cycle time requirement is approx. 15 to 20 times

smaller.

*

Function block stores data until the next call.

Multiple instancing is therefore required if the

function block is used multiple times.

Function block name

Code

size

[bytes]

Data

size

[bytes]

Function

sub-

blocks

Instances Instance

depth

Cycle

time

[ms]

U_2_STEP_CONTROLLER*

758

132

2

2

1

1.29

U_3_STEP_CONTROLLER*

1058

144

2

2

1

2.11

U_IP2_INT_INTERPOLATION

3690

88

4

4

1

10.51

U_PD_THREE_STEP_CONTROLLER*

14754

431

17

29

3

8.19

U_PID_CONTROLLER*

17016

419

14

28

3

12.4

U_PT1_FILTER*

6674

152

11

12

2

1.77

U_PDM_CONTACTOR*

3582

68

4

4

1

0.43

U_RMS_RAMP*

10098

121

9

9

2

11.01

U_CYCS_CYCLETIME_SETPOINT_VALUE

418

104

2

2

1

0.73

Additional tools for the RTT

9

03/

99 AW

B

2700-

1365 G

B

Additional tools for

the RTT

Visualisation and parameter assignment tool

A visualisation and parameter assignment tool is a

useful addition to the RTT. Please refer to the

relevant readme file for more detailed information.

Visualisation:

A marker word area of the PLC can be read via the

Sucom A interface or EPC card (maximum 32 words).

The data can be processed as follows:

Numerical display

Graphic display (visualisation)

Storage in a file

Parameter assignment:

A marker word area of the PLC can be written via the

Sucom A interface or EPC card (maximum 32 words).

This function can be used for assigning parameters

to closed-loop controllers, for example.

10

03/

99 AW

B

2700-

1365 G

B

11

03/

99 AW

B

2700-

1365 G

B

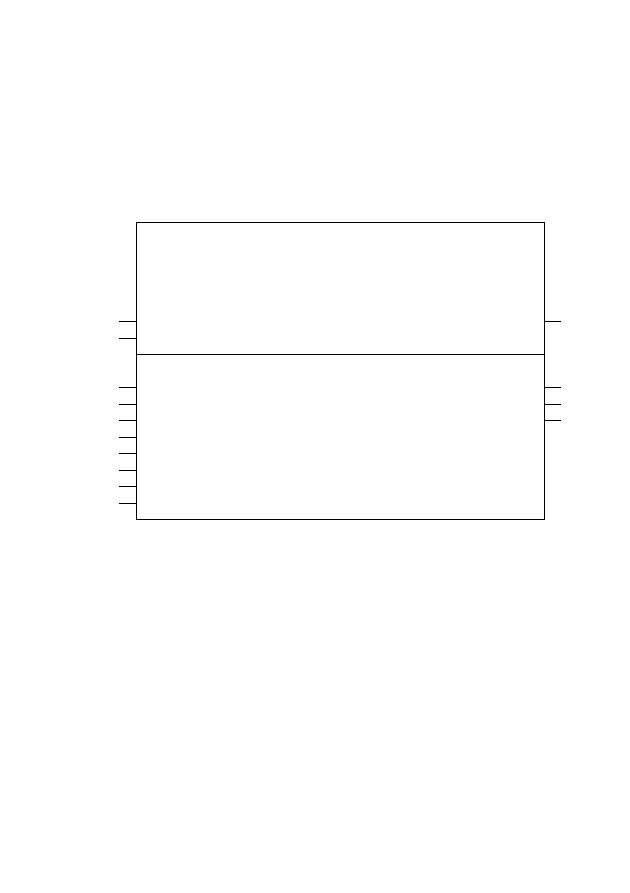

2

Controllers

PID controller

U_PID_controller

PID controller

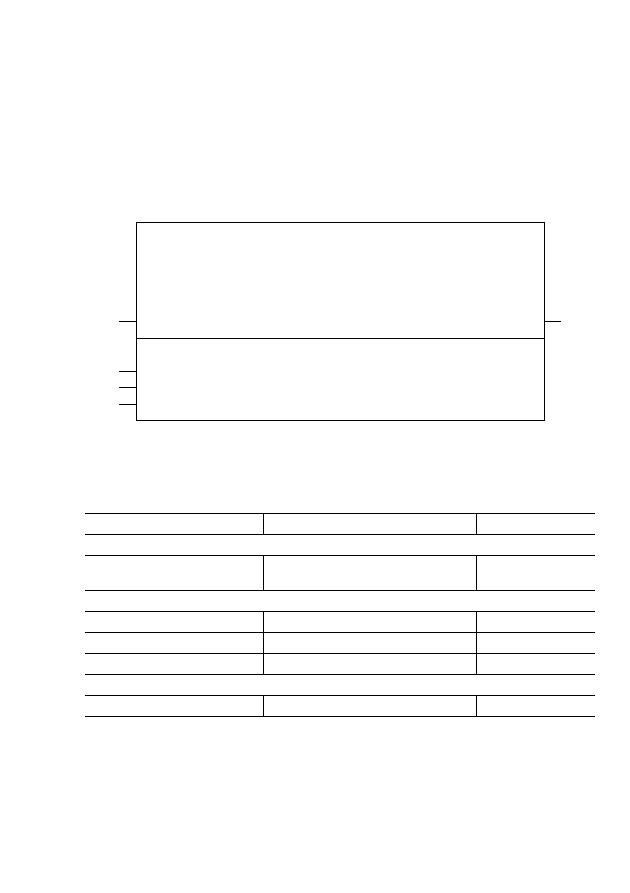

Prototype of the function block

U_PID_controller

Inputs

Outputs

UINT

Setpoint_value_12Bit_UINT

Manipulated_variable_12Bit_UINT

UINT

UINT

Actual_value_12Bit_UINT

Parameters

Monitor outputs

BOOL

P_activate_BOOL

Manipulated_variable_P_13Bit_INT

INT

BOOL

I_activate_BOOL

Manipulated_variable_I_13Bit_INT

INT

BOOL

D_activate_BOOL

Manipulated_variable_D_13Bit_INT

INT

BOOL

Accept_manual_manipulated_variable_BOOL

UINT

Proportional_rate_P_percent_UINT

UINT

Reset_time_10ths_UINT

UINT

Derivate_action_time_10ths_UINT

UINT

Manual_manipulated_variable_12Bit_UINT

Controllers

12

03/

99 AW

B

2700-

1365 G

B

Meaning of the operands

Description

The components of the controller can be individually

activated (= enables the controller) or deactivated

with the BOOL variables “P_activate_BOOL”,

“I_activate_BOOL” and “D_activate_BOOL”. A reset

is automatically started when I or D components are

deactivated. The parameter assignment of the

controller is effected by means of the standard

variables proportional_rate [%], reset_time [0.1 s]

and derivate_action_time [0.1 s].

Designation

Meaning

Value range

Inputs

Setpoint_value_12Bit_UINT

Setpoint value

0 to 4095

Actual_value_12Bit_UINT

Actual value

0 to 4095

Parameters

P_activate_BOOL

Activates P component

0/1

I_activate_BOOL

Activates I component

0/1

D_activate_BOOL

Activates D component

0/1

Accept_manual_manipulated_

variable_BOOL

“Smooth” acceptance of manual

manipulated variable

0/1

Proportional_rate_P_percent_UINT Proportional rate Kp [%]

0 to 65535

Reset_time_10ths_UINT

Reset timeTn [0.1 s]

0 to 65535

Derivate_action_time_10ths_UINT

Derivative action time [0.1 s]

0 to 65535

Manual_manipulated_variable_

12Bit_UINT

Manual manipulated variable

0 to 4095

Outputs

Manipulated_variable_12Bit_UINT

Manipulated variable (analog, 12 bits)

0 to 4095

Monitor outputs

Manipulated_variable_P_13Bit_INT P manipulated variable component

–4095 to 4095

Manipulated_variable_I_13Bit_INT

I manipulated variable component

–4095 to 4095

Manipulated_variable_D_13Bit_INT D manipulated variable component

–4095 to 4095

PID controller

13

03/

99 AW

B

2700-

1365 G

B

The controller outputs the analog value

“manipulated_variable_12Bit_UINT”. The PID

components of the manipulated variable (from which

the total manipulated variable is obtained by addition)

are available as separate monitor outputs to allow

selective (remote) diagnosis of the control response.

Manual operation:

An “override” of the controller in manual operation

can be done with the corresponding BOOL and UINT

variables. If the status of

“accept_manual_manipulated_variable_BOOL”

goes to “1”, the controller outputs the variable

“manual_manipulated_variable_12Bit_UINT” to

“manipulated_variable_12Bit_UINT”. If the status of

“accept_manual_manipulated_variable_BOOL”

changes back to “0”, the controller accepts the

manual manipulated variable and continues the

control operation smoothly with this manipulated

variable.

Example program:

In the example program “zone2”, a PID controller is

called with the parameters:

Proportional rate = 1.2

Reset time = 30 s

Derivative action time = 3 s

Controllers

14

03/

99 AW

B

2700-

1365 G

B

Use of the function block

“U_PID_controller” in the program “zone2”

PROGRAM zone2

VAR

pid_controller_zone2 : U_PID_CONTROLLER;

setpoint_value_zone2 : UINT :=2500;

actual_value_zone2 : UINT;

enable_pid_controller : BOOL :=0;

enable_manual_manipulated_variable : BOOL := 0;

manual_manipulated_variable : UINT :=1000;

manipulated_variable_zone2 : UINT;

manipulated_variable_P_zone2 : INT;

manipulated_variable_I_zone2 : INT;

manipulated_variable_D_zone2 : INT;

END_VAR

CAL pid_controller_zone2(

setpoint_value_12Bit_UINT :=setpoint_value_zone2,

actual_value_12Bit_UINT :=actual_value_zone2,

P_activate_BOOL :=enable_pid_controller,

I_activate_BOOL :=enable_pid_controller,

D_activate_BOOL :=enable_pid_controller,

accept_manual_manipulated_variable_BOOL :=enable_manual_manipulated_variable,

proportional_rate_percent_UINT :=120,

reset_time_10ths_UINT :=300,

derivate_action_10ths_UINT :=30,

manual_manipulated_variable_12Bit_UINT :=manual_manipulated_variable_zone2

|

manipulated_variable_zone2 :=manipulated_variable_12Bit_UINT,

manipulated_variable_P_zone2 :=manipulated_variable_P_13Bit_INT,

manipulated_variable_I_zone2 :=manipulated_variable_I_13Bit_INT,

manipulated_variable_D_zone2 :=manipulated_variable_D_13Bit_INT

)

END_PROGRAM

PD three-step controller

15

03/

99 AW

B

2700-

1365 G

B

PD three-step

controller

U_PD_three_step_controller

PD controller with three-step action for

“opening” and “closing” valves

Prototype of the function block

U_PD_three_step_controller

Inputs

Outputs

UINT

Setpoint_value_12Bit_UINT

Open_BOOL

BOOL

UINT

Actual_value_12Bit_UINT

Close_BOOL

BOOL

Manipulated_variable_open_12Bit_UINT

UINT

Manipulated_variable_close_12Bit_UINT

UINT

Parameters

Monitor outputs

BOOL

P_activate_BOOL

Manipulated_variable_bipolar_13Bit_INT

INT

BOOL

D_activate_BOOL

Manipulated_variable_P_13Bit_INT

INT

BOOL

Accept_manual_manipulated_variable_BOOL

Manipulated_variable_D_13Bit_INT

INT

UINT

Proportional_rate_P_percent_UINT

UINT

Proportional_rate_D_percent_UINT

UINT

Derivate_action_time_10ths_UINT

UINT

Length_of_period_PDM_ms_UINT

UINT

Minimum_switch_on_time_PDM_ms_UINT

INT

Manual_manipulated_variable_13_Bit_INT

Controllers

16

03/

99 AW

B

2700-

1365 G

B

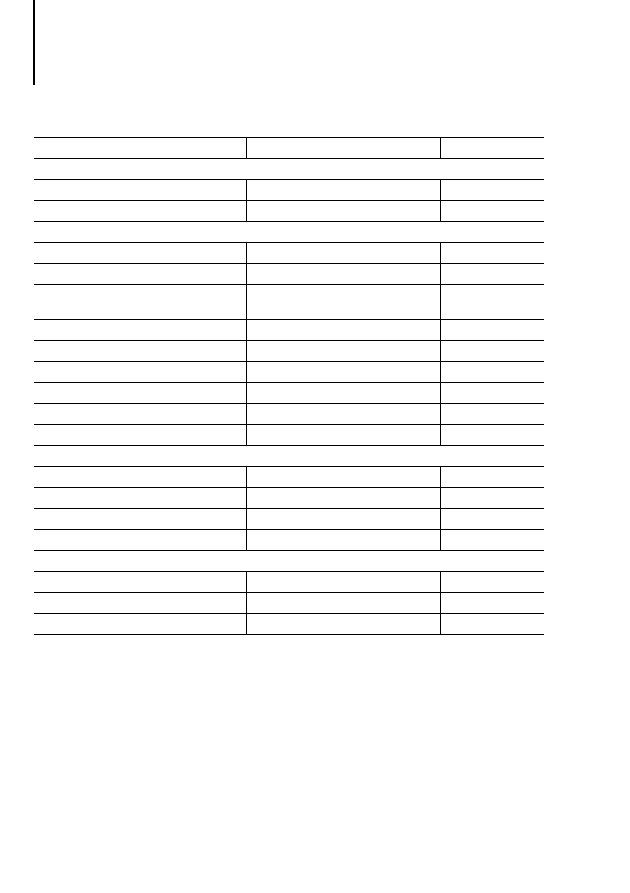

Meaning of the operands

Designation

Meaning

Value range

Inputs

Setpoint_value_12Bit_UINT

Setpoint value

0 to 4095

Actual_value_12Bit_UINT

Actual value

0 to 4095

Parameter

P_activate_BOOL

Activates P component

0/1

D_activate_BOOL

Activates D component

0/1

Accept_manual_manipulated_variable_BOOL Smooth acceptance of manual

manipulated variable

0/1

Proportional_rate_P_percent_UINT

P component proportional rate [%]

0 to 65535

Proportional_rate_D_percent_UINT

D component proportional rate [%]

0 to 65535

Derivate_action_time_10ths_UINT

Derivative action time [0.1 s]

0 to 65535

Length_of_period_PDM_ms_UINT

Length of period PDM [ms]

0 to 65535

Minimum_switch_on_time_PDM_ms_UINT

Minimum switch-on time PDM [ms]

0 to 65535

Manual_manipulated_variable_13_Bit_INT

Manual manipulated variable

–4095 to 4095

Outputs

Open_BOOL

Opens a valve, for example

0/1

Close_BOOL

Closes a valve, for example

0/1

Manipulated_variable_open_12Bit_UINT

Analog manipulated variable “open”

0 to 4095

Manipulated_variable_close_12Bit_UINT

Analog manipulated variable “close”

0 to 4095

Monitor outputs

Manipulated_variable_bipolar_13Bit_INT

Bipolar manipulated variable

–4095 to 4095

Manipulated_variable_P_13Bit_INT

P manipulated variable component

–4095 to 4095

Manipulated_variable_D_13Bit_INT

D manipulated variable component

–4095 to 4095

PD three-step controller

17

03/

99 AW

B

2700-

1365 G

B

Description

The controller is suitable for “integrating systems”,

i. e. systems without self-regulation where an I

component is unnecessary, e. g. for flow control with

a valve, whereby the following actions are possible:

open

close

pause (neither open nor close)

The P and D components of the controller can be

individually activated (= enables the controller) or

deactivated by the BOOL variables

“P_activate_BOOL” and “D_activate_BOOL”. A reset

of the D component is automatically started when

the D component is deactivated.

If “accept_manual_manipulated_variable_BOOL”

goes to “1”, the controller outputs

“manual_manipulated_variable_12Bit_INT” to

“manipulated_variable_12Bit_UINT”.

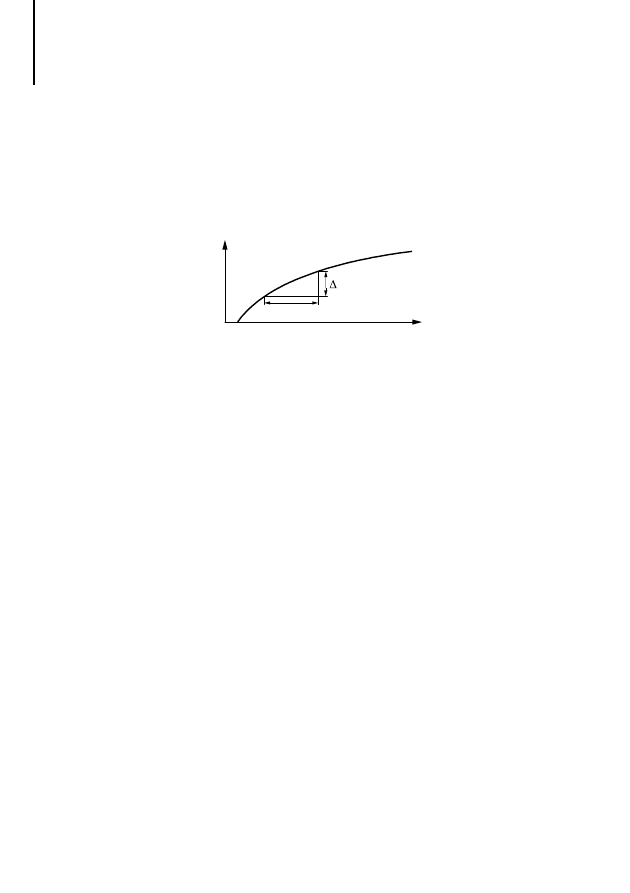

Parameter setting for the controller is done with the

variables proportional_rate_P_percent_UINT [%],

proportional_rate_D_percent_UINT [%] and

derivate_action_time_10ths_UINT [0.1 s]. For the

calculation of the D manipulated variable

component, a scanning time (

∆

t) is defined with the

derivative action time (see Figure 1). The actual value

changes are multiplied with the D proportional rate

parameter.

Controllers

18

03/

99 AW

B

2700-

1365 G

B

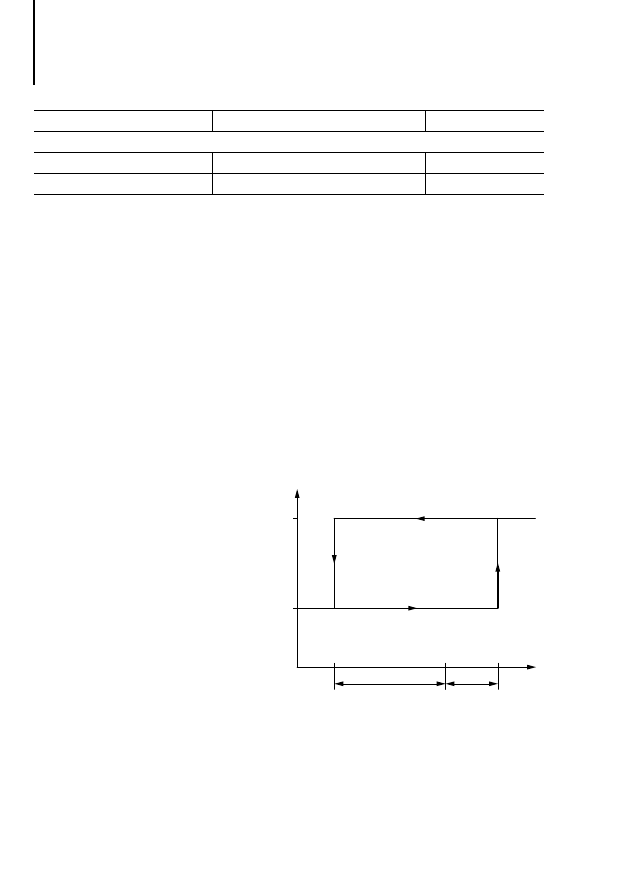

The following equation applies:

D manipulated variable component = D proportional

rate

⫻

∆

X

∆

X = current_actual_value –previous_actual_value

~ derivate_action_time

=> D manipulated variable component ~ derivative

action time

⫻ D proportional rate

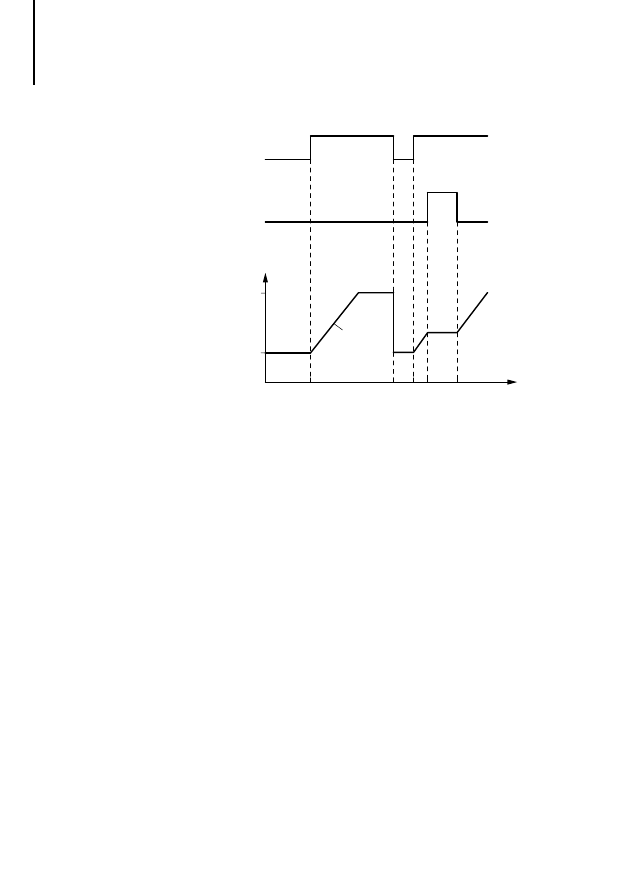

Figure 2: Relationship of actual value changes to

derivative action time T

V

Example:

Derivative action time T

V

= 10 s

Proportional rate D = 500 %

Over a period of 10 s, the actual value has changed

by 100 increments

=> D manipulated variable = 100

⫻ 5 = 500

If you reduce derivate_action_time by a factor of 2

(5 s) and increase the D component rate by a factor

of 2 (1000 %), then the result in the above example is

an identical D manipulated variable, as follows:

=> D manipulated variable = 50

⫻ 10 = 500

The following points should be noted:

The smaller the derivative action time chosen, the

smaller the maximum change in the actual value

within this time.

=> The resolution of the D value calculation

decreases. => The D manipulated variable

become discontinuous.

The smaller the derivative action time chosen, the

faster must a current D value be calculated.

=> The D value calculation is delayed by the

derivative action time.

X

T

t

v

x

PD three-step controller

19

03/

99 AW

B

2700-

1365 G

B

For the digital outputs, “open_BOOL” and

“close_BOOL”, you must specify the period length and

minimum switch-on time of a pulse duration modulator

(PDM). The controller still provides the analog values

“manipulated_variable_close_12Bit_UINT” and

“manipulated_variable_close_12Bit_UINT” as output

variables. The PD components of the manipulated

variable (from which the total manipulated variable is

obtained by addition) are available as separate monitor

outputs to allow selective (remote) diagnosis of the

control response.

Minimum switch-on time

The ratio of “Period length/minimum switch-on time”

(“P/M”) determines which percentage manipulated

variables are not effective. As low a minimum switch-on

time as possible should be selected so that the “P/M”

is as high as possible. If, however, a very short switch-

on time is still not effective with the connected

actuators, these short switch-on phases should be

suppressed in order to save the hardware. The period

length should not be set too low.

Example:

The assignment of parameters to proportional_rate_D

and derivate_action_time causes the change in the

control deviation that establishes itself within 2000 s to

be factorised by 5 when calculating the D manipulated

variable component. The P manipulated variable

component is calculated from the control variance

multiplied by 0.8. The resulting “total manipulated

variable” (manipulated_variable_ bipolar_13Bit_INT)

acts as input signal of a pulse duration modulator with

a period length of one minute and a minimum switch-

on time of 3 s.

The ratio of “Period length/Minium switch-on

time” must not be too low since relatively large

manipulated variables may be suppressed.

H1365g.fm Seite 19 Mittwoch, 29. November 2000 3:08 15

Controllers

20

03/

99 AW

B

2700-

1365 G

B

Use of the function block

“U_PD_three_step_controller”

in the program “valve1“

PROGRAM valve1

VAR

valve_1 : U_PD_three_step_controller;

setpoint_value_valve1 : UINT :=2000;

actual_value_valve1 AT %IAW0.0.0.4 : WORD;

enable_controller_valve1 : BOOL;

enable_manual_variable_valve1 : BOOL;

manual_manipulated_variable_valve1 : INT :=1500;

open_valve1 AT %Q0.0.0.0.0 : BOOL;

close_valve1 AT %Q0.0.0.0.1 : BOOL;

END_VAR

ld

actual_value_valve1

WORD_TO_UINT

st

valve_1.actual_value_12Bit_UINT

CAL valve_1(

setpoint_value_12Bit_UINT :=setpoint_value_valve1,

actual_value_12Bit_UINT :=,

P_activate_BOOL :=enable_controller_valve1,

D_activate_BOOL :=enable_controller_valve1,

accept_manual_manipulated_variable_BOOL :=enable_manual_variable_valve1,

proportional_rate_P_percent_UINT :=80,

proportional_rate_D_percent_UINT :=500,

derivate_action_time_10ths_UINT :=20000,

length_of_period_PDM_ms_UINT :=60000,

minimum_switch_on_timePDM_ms_UINT :=3000,

manual_manipulated_variable_13_Bit_INT :=manual_manipulated_variable_valve1

|

open_valve1 :=open_BOOL,

close_valve1 :=close_BOOL,

:=manipulated_variable_open_12Bit_UINT,

:=manipulated_variable_close_12Bit_UINT,

:=manipulated_variable_bipolar_13Bit_INT,

:=manipulated_variable_P_13Bit_INT,

:=manipulated_variable_D_13Bit_INT

)

END_PROGRAM

Two-step controller

21

03/

99 AW

B

2700-

1365 G

B

Two-step controller

U_2_step_controller

Two-step controller

Prototype of the function block

Meaning of the operands

U_2_step_controller

Inputs

Outputs

INT

Setpoint_value_INT

Control_signal_bottom_BOOL

BOOL

INT

Actual_value_INT

Control_signal_top_BOOL

BOOL

Parameters

Monitor outputs

BOOL

Activate_BOOL

Lower_switchover_point_INT

INT

INT

Switchover_point_offset_bottom_INT

Upper_switchover_point_INT

INT

INT

Switchover_point_offset_top_INT

Designation

Meaning

Value range

Inputs

Setpoint_value_INT

Setpoint value

–16383 to 16383

Actual_value_INT

Actual value

–16383 to 16383

Parameters

Activate_BOOL

Activates the controller

0/1

Switchover_point_offset_bottom_INT Relative offset of bottom switchover point

–16383 to 16383

Switchover_point_offset_top_INT

Relative offset of top switchover point

–16383 to 16383

Outputs

Control_signal_bottom_BOOL

Control signal for undershoot of bottom

switchover point

0/1

Control_signal_top_BOOL

Control signal for overshoot of top

switchover point

0/1

Controllers

22

03/

99 AW

B

2700-

1365 G

B

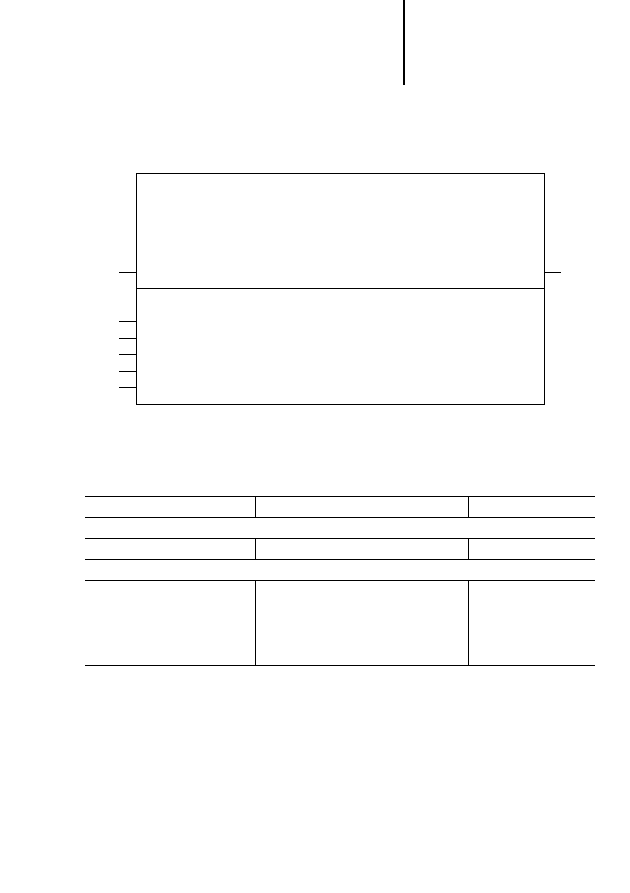

Description

The function block is activated with

“activate_BOOL=1” (= enables the controller). On

deactivation, the value “0” is output by both control

signal outputs. The function block calculates the

lower and upper switchover points by adding the

setpoint value and the respective switchover point

offsets (see Figure 3).

If the upper switchover point is exceeded,

“control_signal_top_BOOL” goes to “1” and if the

lower switchover point is undershot,

“control_signal_bottom_BOOL” goes to “1”. The

other control signal in each case goes to “0”.

Figure 3: Switchover of the 2-step controller with

hysteresis

Monitor outputs

Lower_switchover_point_INT

Lower switchover point

–32768 to 32767

Upper_switchover_point_INT

Upper switchover point

–32768 to 32767

Designation

Meaning

Value range

Setpoint

Actual

value

Control_signal_top

Control_signal_bottom

Lower switchover

point

Switchover point [SPOFF]

offset bottom

SPOFF top

Upper switchover

point

Two-step controller

23

03/

99 AW

B

2700-

1365 G

B

Example:

The following switchover points are assigned for the

2-step controller with the parameters shown below:

Lower switchover point = 2000 – 200 = 1800

Upper switchover point = 2000 + 300 = 2300

Use of the function block

“U_2_step_controller” in the program “two_step”

PROGRAM two_step

VAR

Two_step_controller: U_2_step_controller;

setpoint : INT :=2000;

actual AT %IAW0.0.0.4 : WORD;

enable_controller : BOOL;

digital_output_0_0 AT %Q0.0.0.0.0 : BOOL;

digital_output_0_1 AT %Q0.0.0.0.1 : BOOL;

END_VAR

ld

actual

WORD_TO_INT

st

Two_step_controller.actual_value_INT

CAL Two_step_controller(

setpoint_value_INT :=setpoint,

actual_value_INT :=,

activate_BOOL :=enable_controller,

switchover_point_offset_bottom_INT :=-200,

switchover_point_offset_top_INT :=300

|

digital_output_0_0 :=control_signal_bottom_BOOL,

digital_output_0_1 :=control_signal_top_BOOL,

:=lower_switchover_point_INT,

:=top_switchover_point_INT)

END_PROGRAM

Controllers

24

03/

99 AW

B

2700-

1365 G

B

Three-step controller

U_3_step_controller

Three_step controller

Prototype of the function block

Meaning of the operands

U_3_step_controller

Inputs

Outputs

INT

Setpoint_value_INT

Control_signal_bottom_BOOL

BOOL

INT

Actual_value_INT

Control_signal_Mitte_BOOL

BOOL

Control_signal_top_BOOL

BOOL

Parameters

Monitor outputs

BOOL

Activate_BOOL

Lower_switchover_point_INT

INT

INT

Switchover_point_offset_ bottom_INT

Intermediate_switchover_point_INT

INT

INT

Switchover_point_offset_middle_INT

Upper_switchover_point_INT

INT

INT

Switchover_point_offset_top_INT

Designation

Meaning

Value range

Inputs

Setpoint_value_INT

Setpoint value

–16383 to 16383

Actual_value_INT

Actual value

–16383 to 16383

Parameters

Activate_BOOL

Activation of controller

0/1

Switchover_point_offset_bottom_INT Relative offset of lower switchover point

–16383 to 16383

Switchover_point_offset_middle_INT Relative offset of intermediate switchover point –16383 to 16383

Switchover_point_offset_top_INT

Relative offset of upper switchover point

–16383 to 16383

Three-step controller

25

03/

99 AW

B

2700-

1365 G

B

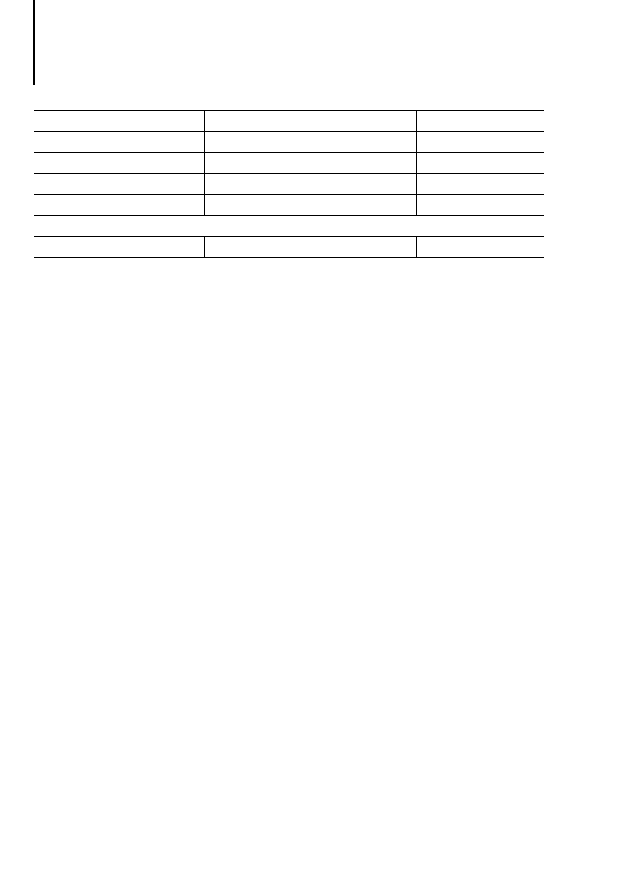

Description

The function block is activated with

“activate_BOOL=1” (= enables the controller). On

deactivation, the value “0” is output by the three

control signal outputs. The function block calculates

the lower, intermediate and upper switchover points

by adding the setpoint value and the respective

switchover point offsets (see Figure 4).

If the top switchover point is overshot,

“control_signal_top_BOOL” goes to “1” and if the

lower switchover point is undershot,

“control_signal_bottom_BOOL” goes to “1”.

Outputs

Control_signal_bottom_BOOL

Control signal for undershoot of lower

switchover point

0/1

Control_signal_middle_BOOL

Control signal for overshoot of intermediate

switchover point and

“control_signal_bottom_BOOL=1 or

undershoot of intermediate switchover point

and “control_signal_top_BOOL=1”

0/1

Control_signal_top_BOOL

Control signal for overshoot of upper

switchover point

0/1

Monitor outputs

Lower_switchover_point_INT

Lower switchover point

–32768 to 32767

Intermediate_switchover_point_INT

Intermediate switchover point

–32768 to 32767

Upper_switchover_point_INT

Upper switchover point

–32768 to 32767

Designation

Meaning

Value range

Controllers

26

03/

99 AW

B

2700-

1365 G

B

“control_signal_middle_BOOL” goes to “1” in the

following cases:

The intermediate switchover point is exceeded

and “control_signal_bottom_BOOL=1”

The intermediate switchover point is undershot

and “control_signal_top_BOOL=1”

The other control signals in each case go to “0”.

Figure 4: Switchover of 3-step controller with hysteresis

Example:

The following switchover points are assigned for the

3-step controller with the parameters shown below:

Lower switchover point = 2000 – 200 = 1800

Intermediate switchover point= 2000 – 50= 1950

Upper switchover point = 2000 + 100 = 2100

Actual

value

SPOFF

middle

Control_signal_middle

Control_signal_bottom

Control_signal_top

Setpoint

Lower switchover

point

Middle switchover

point

Upper switchover

point

Switchover point [SPOFF]

offset bottom

SPOFF

top

Three-step controller

27

03/

99 AW

B

2700-

1365 G

B

Use of the function block

“U_3_step_controller” in the program “threestep”

PROGRAM threestep

VAR

three_step_controller : U_3_step_controller;

setpoint : INT :=2000;

actual AT %IAW0.0.0.4 : WORD;

enable_controller : BOOL;

digital_output_0_0 AT %Q0.0.0.0.0 : BOOL;

digital_output_0_1 AT %Q0.0.0.0.1 : BOOL;

digital_output_0_2 AT %Q0.0.0.0.2 : BOOL;

END_VAR

ld

actual

WORD_TO_INT

st

three_step_controller.actual_value_INT

CAL three_step_controller(

setpoint_value_INT :=setpoint,

actual_value_INT :=,

activate_BOOL :=enable_controller,

switchover_point_offset_bottom_INT :=-200,

switchover_point_offset_middle_INT :=-50,

switchover_point_offset_top_INT :=100

|

digital_output_0_0 :=control_signal_bottom_BOOL,

digital_output_0_1 :=control_signal_middle_BOOL,

digital_output_0_2 :=control_signal_top_BOOL,

:=lower_switchover_point_INT,

:=intermediate_switchover_point_INT,

:=top_switchover_point_INT)

END_PROGRAM

28

03/

99 AW

B

2700-

1365 G

B

29

03/

99 AW

B

2700-

1365 G

B

3

Pulse Duration Modulator (PDM)

PDM

U_PDM_contactor

Pulse duration modulator suitable for contactors

Prototype of the function block

Meaning of the operands

U_PDM_contactor

Inputs

Outputs

UINT

Manipulated_variable_12Bit_UINT

Output_BOOL

BOOL

Parameters

BOOL

Activate_BOOL

UINT

Length_of_period_ms_UINT

UINT

Minimum_switch_on_time_ms_UINT

Designation

Meaning

Value range

Inputs

Manipulated_variable_12Bit_UINT

12-bit input variable of the PDM

(usually the output variable of a controller)

0 to 4095

Parameters

Activate_BOOL

Enables the PDM

0/1

Length_of_period_ms_UINT

Period length [ms]

0 to 65535

Minimum_switch_on_time_ms_UINT Minimum switch-on time [ms]

0 to 65535

Outputs

Output_BOOL

Digital output of the PDM

0/1

Pulse Duration Modulator

(PDM)

30

03/

99 AW

B

2700-

1365 G

B

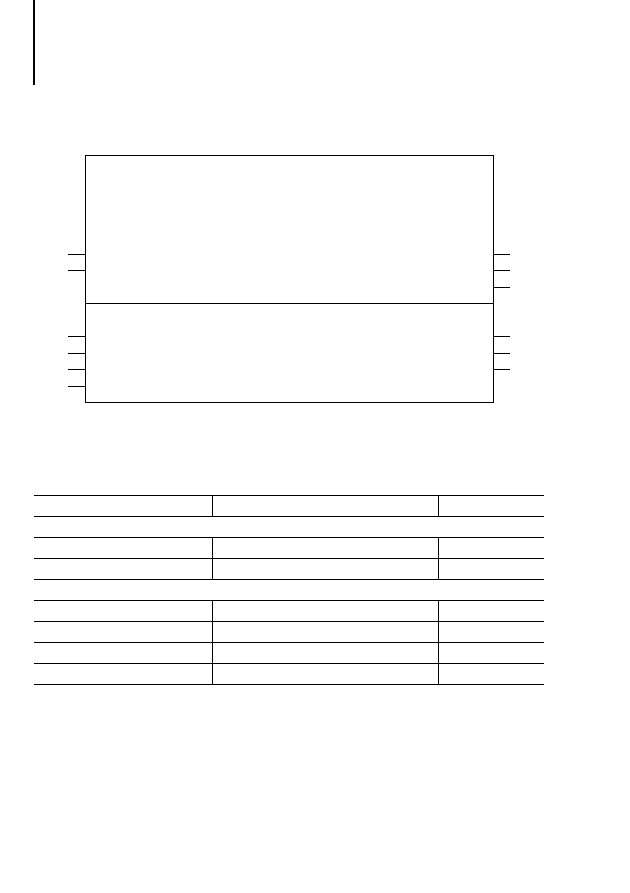

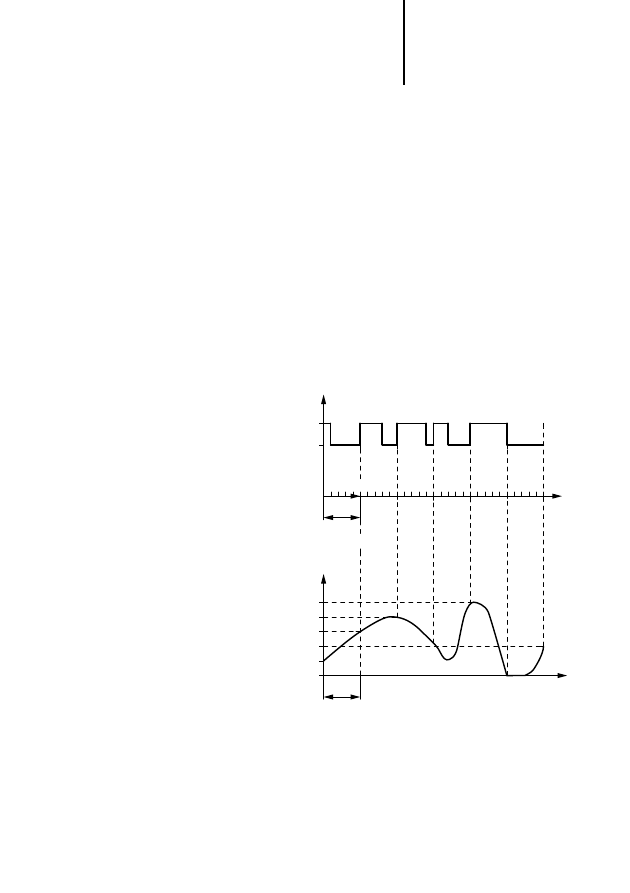

Description

The function block “U_PDM_contactor” is suitable

for connecting to mechanically switched contactors.

The PDM is normally logically combined with the

12-bit manipulated variable (4095 = 100 %) of a

controller. The variable “manipulated_variable

_12Bit_UINT” is provided for this reason in the input

section.

When “activate_BOOL=1”, the PDM is started and

one pulse duration is output with “output_BOOL=1”

(see Figure 5) if the specified minimum switch-on

time is exceeded. When “activate_BOOL=0”, the

output signal is set to zero and a reset of the current

actions is performed. In the event of reactivation, a

new period length starts. The period length and

minimum switch-on time can be specified in ms. The

maximum value of 65535 thus corresponds to a time

of 65.535 s..

Minimum switch-on time

The ratio of “Period length/minimum switch-on time”

(“P/M”) determines which percentage manipulated

variables are not effective. As low a minimum switch-

on time as possible should be selected so that the

“P/M” is as high as possible. If, however, a very short

switch-on time is still not effective with the

connected actuators, these short switch-on phases

should be suppressed in order to save the hardware.

The period length should not be set too low.

The ratio of “Period length/Minium switch-on

time” must not be too low since relatively large

manipulated variables may be suppressed.

PDM

31

03/

99 AW

B

2700-

1365 G

B

Examples:

Heater/Contactor

=> Minimum switch-on time = 1 s

=> Period length = 40 s

=> Manipulated variables less than 2.5 % are

suppressed

Heater/Solid state relay

=> Minimum switch-on time = 0 s

=> Period length = 20 s

=> No manipulated variables suppressed

Fan/contactor or solid state relay

=> Minimum switch-on time = 2 s

=> Period length = 40 s

=> Manipulated variables less than 5 % suppressed

Figure 5: Pulse duration modulation in dependency on the

manipulated variable of a controller

1

0

20 40 60 80 100

[%]

t [s]

t [s]

0

20

40

60

80

100

PWM

Output

PWM

period length

Manipulated

variable [%]

PWM

period length

Pulse Duration Modulator

(PDM)

32

03/

99 AW

B

2700-

1365 G

B

Example:

In the example program, a pulse duration modulator

is connected to a PID controller of the same zone by

connecting the 12-bit manipulated variable of the

controller to the input of the PDM. The period length

is set to 60 s and the minimum switch-on time is set

to 3 s.

Use of the function block

“U_PDM_contactor” in the program “zone1pdm”

PROGRAM zone1pdm

VAR

puls_duration_modulator : U_PDM_CONTACTOR ;

manipulated_variable_PID_controller1 : UINT ;

enable_zone1 AT %I0.0.0.0.0 : BOOL ;

digital_output_zone1 AT %Q0.0.0.0.0 : BOOL ;

END_VAR

CAL pulse_duration_modulator(

manipulated_variable_12Bit_UINT

:=manipulated_variable_PID_controller1

activate_BOOL :=enable_zone1,

length_of_period_PDM_ms_UINT :=60000,

minimum_switch_on_time_PDM_ms_UINT :=3000

|

digital_output_zone1 :=output_BOOL

)

END_PROGRAM

33

03/

99 AW

B

2700-

1365 G

B

4

Miscellaneous Function Blocks

PT1 signal smoothing

filter

U_PT1_filter

PT1 filter for signal smoothing

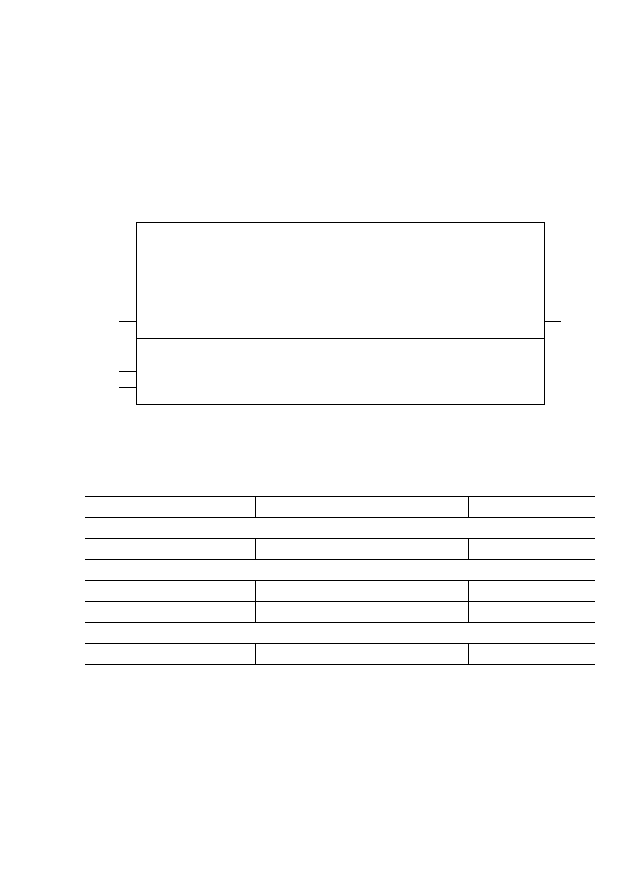

Prototype of the function block

Meaning of the operands

U_PT1_filter

Inputs

Outputs

UINT

Input_value_12Bit_UINT

Delay_value_12Bit_UINT

UINT

Parameters

BOOL

Activate_BOOL

UINT

Delay_time_Tg_10thsec_UINT

Designation

Meaning

Value range

Inputs

Input_value_12Bit_UINT

Input value

0 to 4095

Parameters

Activate_BOOL

Activates the function block

0/1

Delay_time_Tg_10thsec_UINT

Delay time Tg

0 to 65535

Outputs

Delay_value_12Bit_UINT

PT1-delayed output value

0 to 4095

Miscellaneous Function

Blocks

34

03/

99 AW

B

2700-

1365 G

B

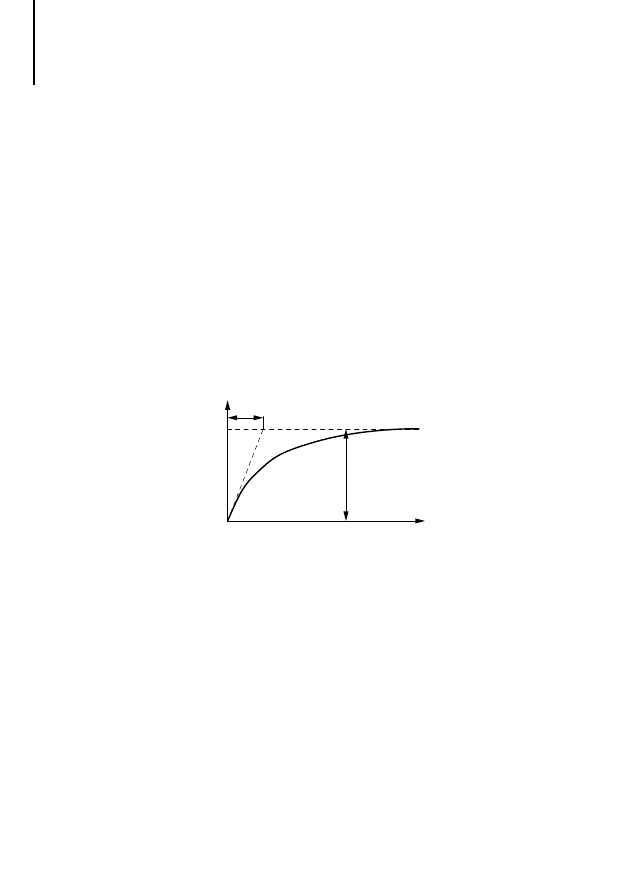

Description

The function block can be used to smooth noisy

signals. The time period over which the smoothing

process takes place is set with

“delay_time_Tg_10thsec_UINT” (see Figure 6). The

delay time should not be set longer than necessary

since the signals will be delayed more than is

necessary for smoothing (unavoidable side-effect of

signal smoothing). The function block is started with

“activate_BOOL=1”. A reset is effected with

“activate_BOOL=0”. In order to accelerate the PT1

startup behaviour, the first call of the function block

after a reset (or the first PLC cycle) causes

“delay_value_12Bit_UINT” to be initialised with the

input value (the PT1 delay does not start at zero).

Figure 6: PT1 delay of the filter in dependence on T

g

and

the input step X

e

Example:

In the example program “pt1smooth”, the “noisy”

actual value is smoothed over a time period of half a

second.

X

e

x

t

g

T

PT1 signal smoothing filter

35

03/

99 AW

B

2700-

1365 G

B

Use of the function block

“U_PT1_filter” in the program “pt1smooth”

PROGRAM pt1smooth

VAR

pt1_filter : U_pt1_filter ;

actual_value_high_noise at %IW0.0.0.0 : UINT ;

actual_value_smoothed: UINT ;

END_VAR

CAL pt1_filter(

input_value_12Bit_UINT :=actual_value_high_noise,

activate_BOOL :=1,

delay_time_Tg_10thsec_UINT :=5

|

actual_value_smoothed :=delay_value_12Bit_UINT

)

END_PROGRAM

Miscellaneous Function

Blocks

36

03/

99 AW

B

2700-

1365 G

B

Ramp function

U_RMS_ramp

Ramp with millisecond input value

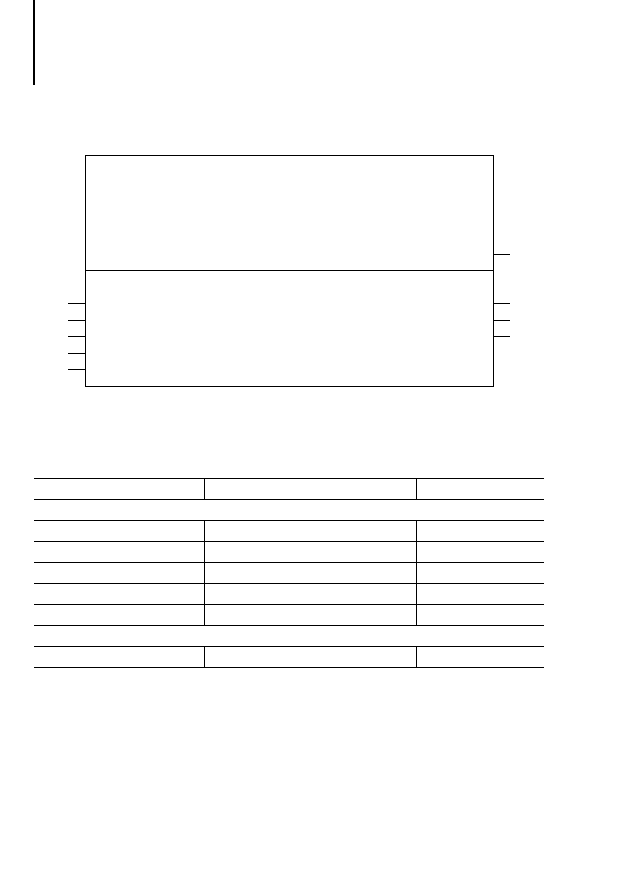

Prototype of the function block

Meaning of the operands

U_rms_ramp

Outputs

Ramp_value_INT

INT

Parameters

Monitor outputs

BOOL

Activate_BOOL

End_value_attained_BOOL

BOOL

BOOL

Interrupt_BOOL

Ramp_sequence_time_ms_UINT

UINT

INT

Start_value_INT

Ramp_time_overshoot_ms_UINT

UINT

INT

End_value_INT

UINT

Ramp_time_ms_UINT

Designation

Meaning

Value range

Parameters

Activate_BOOL

Activates ramp generation

0/1

Interrupt_BOOL

Interrupts ramp generation

0/1

Start_value_INT

Start value of ramp

–32768 to 32767

End_value_INT

End value of ramp

–32768 to 32767

Ramp_time_ms_UINT

Ramp time from start value to end value

0 to 65535

Outputs

Ramp_value_INT

Ramp value

–32768 to 32767

Ramp function

37

03/

99 AW

B

2700-

1365 G

B

Description

When the function block is enabled by a rising edge

on “activate_BOOL”, it generates a ramp specified

by a start value, an end value and a ramp time

specified in ms (see Figure 7). The parameters are

accepted with the rising edge on “activate_BOOL”.

The ramp is interrupted if “interrupt_BOOL=1”.

When the end of the ramp is reached, a BOOL

variable is set on the monitor output. The variable

“ramp_sequence_time_ms_UINT” specifies the

amount of the specified ramp time that has elapsed.

An overshoot of the specified ramp time

(the maximum is the PLC cycle time) is indicated by

the variable “ramp_time_overshoot_ms_UINT”.

Monitor outputs

End_value_attained_BOOL

Message: End of ramp has been reached

0/1

Ramp_sequence_time_ms_UINT

Currently expired ramp time

0 to 65535

Ramp_time_overshoot_ms_UINT

Amount of time by which the specified ramp

time has been exceeded

0 to 65535

Designation

Meaning

Value range

Miscellaneous Function

Blocks

38

03/

99 AW

B

2700-

1365 G

B

Figure 7: Generation of ramps in conjunction with the

command bits “activate” and “interrupt”

Example program:

The example program generates a ramp which has

two sections with different slopes. In the first ramp

phase, the ramp increases from 500 to 4000 with

a ramp time of 20 s. In the second ramp phase,

the ramp increases from 4000 to 6000 with a ramp

time of 5 s.

t

End value

Start value

Ramp value

Activate

Interrupt

Ramp function

39

03/

99 AW

B

2700-

1365 G

B

Use of the function block

“U_rms_ramp” in the program “ramps”

PROGRAM Ramps

VAR

RMS_RAMP : U_RMS_RAMP ;

Reset_BOOL at %I0.0.0.0.0 : BOOL ;

Initialize_ramp1_BOOL : BOOL ;

Initialize_ramp2_BOOL : BOOL ;

End_value_reached_ramp1_BOOL : BOOL ;

Ramp_value_1_2_INT : INT ;

Rising_edge_end_value_ramp1 : R_TRIG ;

Rising_edge_reset : R_TRIG ;

END_VAR

CAL Rising_edge_reset(

CLK :=Reset_BOOL

)

ld

Rising_edge_reset.Q

jmpcn

NO_RESET

ld

1

st

Initialize_ramp1_BOOL

stn

End_value_reached_ramp1_BOOL

NO_RESET:

ld

Initialize_ramp1_BOOL

jmpcn

INITIALIZE_RAMP1

ld

0

st

RMS_RAMP.activate_BOOL

Cal

RMS_RAMP

ld

500

st

RMS_RAMP.Start_value_INT

ld

4000

st

RMS_RAMP.End_value_INT

ld

20000

st

RMS_RAMP.Ramp_time_ms_UINT

ld

1

st

RMS_RAMP.activate_BOOL

ld

0

st

Initialize_ramp1_BOOL

INITIALIZE_RAMP1:

Miscellaneous Function

Blocks

40

03/

99 AW

B

2700-

1365 G

B

ld

Initialize_ramp2_BOOL

jmpcn

INITIALIZE_RAMP2

ld

0

st

RMS_RAMP.activate_BOOL

Cal

RMS_RAMP

ld

4000

st

RMS_RAMP.Start_value_INT

ld

6000

st

RMS_RAMPE.End_value_INT

ld

5000

st

RMS_RAMPE.Ramp_time_ms_UINT

ld

1

st

RMS_RAMP.activate_BOOL

ld

0

st

Initialize_ramp2_BOOL

INITIALIZE_RAMP2:

CAL RMS_RAMP

ld

RMS_RAMP.End_value_attained_BOOL

s

End_value_reached_ramp1_BOOL

CAL Rising_edge_end_value_ramp1(

CLK :=End_value_reached_ramp1_BOOL

)

ld

Rising_edge_end_value_ramp1.Q

st

Initialize_ramp2_BOOL

ld

RMS_RAMP.Ramp_value_INT

st

Ramp_value_1_2_INT

END_PROGRAM

Two-point interpolation

(scaling)

41

03/

99 AW

B

2700-

1365 G

B

Two-point interpolation

(scaling)

U_IP2_INT_interpolation

Interpolation with 2 X/Y interpolation points

and integer values

Prototype of the function block

Meaning of the operands

U_IP2_INT_interpolation

Inputs

Outputs

INT

X_INT

Y_INT

INT

Parameters

BOOL

Suppress_extrapolation_BOOL

INT

X1_INT

INT

X2_INT

INT

Y1_INT

INT

Y2_INT

Designation

Meaning

Value range

Inputs

X_INT

Known x value

–32768 to 32767

Parameters

Suppress_extrapolation_BOOL

For x values outside the interpolation limits,

the following can be set:

0/1

0 =>

1 =>

Extrapolation

Extrapolation is suppressed.

The interpolation limits are output

Miscellaneous Function

Blocks

42

03/

99 AW

B

2700-

1365 G

B

Description

Between the X/Y interpolation points, a linearly

interpolated Y value is calculated for the X value

present at the input. Outside the X/Y interpolation

points, a linearly extrapolated Y value is calculated if

“suppress_extrapolation_BOOL=0”. If

“suppress_extrapolation_BOOL=1”, the Y

interpolation limits are output instead.

Example program:

For the input parameters shown in the example

program below, the input value

“analog_value_4_till_20_mA :=1500” results in the

output value “actual_value :=852”.

X1_INT

X value 1

–32768 to 32767

X2_INT

X value 2

–32768 to 32767

Y1_INT

Y value 1

–32768 to 32767

Y2_INT

Y value 2

–32768 to 32767

Outputs

Y_INT

Interpolated (or extrapolated) Y value

–32768 to 32767

Designation

Meaning

Value range

Two-point interpolation

(scaling)

43

03/

99 AW

B

2700-

1365 G

B

Use of the function block

“U_IP2_INT_interpolation”

in the program “scaling1”

PROGRAM scaling1

VAR

scaling : U_IP2_INT_INTERPOLATION ;

analog_value_4_till_20_mA AT %IAW0.0.0.4 : WORD ;

actual_value : INT ;

END_VAR

ld

analog_value_4_till_20_mA

WORD_TO_INT

st

scaling.X_INT

CAL scaling(

X_INT :=,

suppress_extrapolation_BOOL :=1,

X1_INT :=819,

X2_INT :=4095,

Y1_INT :=0,

Y2_INT :=4095

|

actual_value :=Y_INT)

END_PROGRAM

Miscellaneous Function

Blocks

44

03/

99 AW

B

2700-

1365 G

B

PLC cycle time setpoint

value

(equidistant PLC cycle

times)

U_CYCS_cycletime_setpoint_value

Specify a (constant) required cycle time

Prototype of the function block

Meaning of the operands

Description

The function block enables you to specify a set cycle

time. This cycle time is used if the maximum cycle

times of the user program are smaller than this.

U_CYCS_cycletime_setpoint_value

Inputs

UINT

Cycletime_ms_UINT

Parameters

BOOL

Activate_BOOL

Designation

Meaning

Value range

Inputs

Cycletime_ms_UINT

Required cycle time to be established

1 to 250

Parameters

Activate_BOOL

Activates the function block

0/1

If the PLC cycle time exceeds the specified cycle

time, this does not have any consequences

(the PLC does not switch to Halt).

It merely means that the set cycle time cannot

be achieved.

PLC cycle time setpoint

value (equidistant PLC

cycle times)

45

03/

99 AW

B

2700-

1365 G

B

Example program:

In the example program below, the instructions and

function block calls result in an average cycle time of

approx. 22 ms (± 4 ms). Setting the cycle time to

30 ms then results in a constant cycle time.

Use of the function block

“U_CYCS_cycletime_setpoint_value”

in the program “ms_30”

PROGRAM ms30

VAR

setpoint_cycle_time : U_CYCS_cycletime_setpoint_value ;

END_VAR

(*The calling of other function blocks causes average PLC cycle times of a maximum of

26 ms. The function block “U_CYCS_cycletime_setpoint_value” should be called at the end

of the program*)

CAL setpoint_cycle_time(

activate_BOOL :=1,

cycletime_ms_UINT :=30)

END_PROGRAM

46

03/

99 AW

B

2700-

1365 G

B

47

03/

99 AW

B

2700-

1365 G

B

Index

F

Function blocks

U_2_step_controller ................................................... 21

U_3_step_controller ................................................... 24

U_CYCS_cycletime_setpoint_value ........................... 44

U_IP2_INT_interpolation ............................................. 41

U_PD_three_step_controller ....................................... 15

U_PDM_contactor ...................................................... 29

U_PID_controller ........................................................ 11

U_PT1_filter ................................................................ 33

U_RMS_ramp ............................................................. 36

I

Interpolation ................................................................... 41

M

Mindesteinschaltdauer ................................................... 30

P

PID controller ................................................................. 11

PT1 filter ......................................................................... 33

Pulse duration modulation ............................................. 29

R

Ramp .............................................................................. 36

S

Scaling ........................................................................... 41

Signal smoothing ........................................................... 33

T

Three-step action ........................................................... 15

Three-step controller ..................................................... 24

Two-step controller ........................................................ 21

Document Outline

- Contents

- 1 Basic Information and Technical Data

- 2 Controllers

- PID controller

- PROGRAM zone2

- VAR pid_controller_zone2 : U_PID_CONTROLLER; setpoint_value_zone2 : UINT :=2500; actual_value_zon...

- CAL pid_controller_zone2( setpoint_value_12Bit_UINT :=setpoint_value_zone2, actual_value_12Bit_UI...

- END_PROGRAM

- PROGRAM valve1

- VAR valve_1 : U_PD_three_step_controller; setpoint_value_valve1 : UINT :=2000; actual_value_valve...

- ld actual_value_valve1 WORD_TO_UINT st valve_1.actual_value_12Bit_UINT CAL valve_1( setpoint_valu...

- END_PROGRAM

- 3 Pulse Duration Modulator (PDM)

- 4 Miscellaneous Function Blocks

- PT1 signal smoothing filter

- Ramp function

- Two-point interpolation (scaling)

- PLC cycle time setpoint value (equidistant PLC cycle times)

- PROGRAM ms30

- VAR setpoint_cycle_time : U_CYCS_cycletime_setpoint_value ; END_VAR

- (*The calling of other function blocks causes average PLC cycle times of a maximum of 26 ms. The ...

- CAL setpoint_cycle_time( activate_BOOL :=1, cycletime_ms_UINT :=30)

- END_PROGRAM

- Index

Wyszukiwarka

Podobne podstrony:

[ebook] Assembler Intel Architecture Optimization Reference Manual [pdf]

PostHaste for GibbsCAM Format Reference Manual 50408g

Bash Reference Manual [EN]

PostHASTE for GibbsCAM 2005 Format Reference Manual

( SPC ) STASTICAL PROCESS CONTROL REFERENCE MANUAL

The GNU C Reference Manual

Lean Excel Top Functions Quick Reference Guide with 500 Examples! by Scott Ratliff

PostHASTE Formatting Reference Manual

operator reference manual kongsberg maritime sdp

alesis dm5 instrukcja reference manual 163339

Modern Electornic Circuits Reference Manual John Markus

OpenGL Reference Manual

PS4 Sucosoft S40 Library Manager h1366g

C Reference Manual

więcej podobnych podstron