SAFETY HANDBOOK

B--80687EN/03

E

FANUC LTD, 1996

Table of Contents

B--80687EN/03

i

GENERAL PRECAUTIONS

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1

FANUC ROBOT SYSTEM

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 PURPOSE OF ROBOT

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 CONFIGURATION OF ROBOT SYSTEM

5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 WORKING PERSON

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Robot Training

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

ROBOT SYSTEM DESIGN

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 GENERAL

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 PLACEMENT OF EQUIPMENT

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 POWER SUPPLY AND PROTECTIVE EARTH CONNECTION

11

. . . . . . . . . . . . . . . . . . . . . .

2.4 OTHER PRECAUTIONS

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 END EFFECTOR, WORKPIECE AND PERIPHERAL EQUIPMENT

14

. . . . . . . . . . . . . . . . . .

Chapter 3

SAFETY DEVICES

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 EMERGENCY STOP

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 MODE SELECT SWITCH

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Operating Modes

20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DEADMAN SWITCH

20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 SAFEGUARDS

21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Safety Fence

21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Safety Gate and Plugs

21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Other Protection Devices

22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 THE SAFETY SEQUENCE FOR FENCE ENTRY

23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 ROBOT STOP VARIATION

25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

GENERAL CAUTIONS

27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 INSTALLATION

27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 COMMISSIONING AND FUNCTIONAL TESTING

27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Designation of the Restricted Space

27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Restriction of Personnel

28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Safety and Operational Verification

28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Robot System Restart Procedures

28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PROGRAMMING

29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Prior to Programming

29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

B--80687EN/03

ii

4.3.2 During Programming

29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Returning to Automatic Operation

29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PROGRAM VERIFICATION

30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 TROUBLE SHOOTING

30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 SAVING PROGRAMMED DATA

30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 AUTOMATIC OPERATION

30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 MAINTENANCE

31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 OTHER CAUTIONS

32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

DAILY MAINTENANCE

33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 MECHANICAL UNIT

33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Before Powering On

33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 After Automatic Operation

33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CONTROL UNIT

34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

CONTACTS

35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

MANUFACTURER LABEL

37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

CAUTION LABELS

43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

GENERAL CAUTIONS

B--80687EN/03

4

In this chapter, the requirements for safety during the following situations.

D

Installation (1.1)

D

commissioning and functional testing (1.2)

D

programming (1.3)

D

program verification (1.4)

D

trouble shooting (1.5)

D

saving programmed data (1.6)

D

automatic operation (1.7)

D

maintenance (1.8)

D

other cautions (1.9)

The user must ensure that the safeguarding methods are provided, utilized,

and maintained for each operation associated with the robot system and in

particular for personnel other than those utilizing the teach pendant or

enabling device.

The user must ensure that a teach pendant not connected to the robot

controller must be inaccessible.

Note that the motors of the robot may have heated just after its movement.

Please be careful not to touch them, if possible. If it is needed to touch the

motors for maintenance, etc., care should be taken in touching them.

The robot system must be installed in accordance with FANUC’s

requirements. The safeguarding methods must be identified by the hazard

analysis and the risk assessment. The user must review the safety

requirements to ensure that the appropriate safeguards are applied and

operational prior to use in production.

During the testing of robots or robot systems after installation or

relocation, the following procedures must be followed. These procedures

are also applied to robots or robot systems after modifications (e.g.

changes in hardware or software, replacement of parts, adjustments) and

after maintenance or repairs that can adversely affect their operation.

When the safeguarding methods are not in place prior to commissioning

and functional testing, interim means of designating the restricted space

must be in place before proceeding.

1.1

INSTALLATION

1.2

COMMISSIONING AND

FUNCTIONAL TESTING

1.2.1

Designation of the

Restricted Space

B--80687EN/03

5

1. GENERAL CAUTIONS

During the commissioning and functional testing, personnel must not be

allowed in the safeguarded space until the safeguards are functional.

At the initial start--up, the following procedure must be included (but not

limited to). Before applying power, verify that

D

the robot has been properly mechanically mounted and is stable,

D

the electrical connections are correct and that the power (i.e. voltage,

frequency, interference levels) is within specified limits,

D

the other utilities (e.g. water, air, gas) are properly connected and

within specified limits,

D

the peripheral equipment is properly connected,

D

the limiting devices that establish the restricted space (when utilized)

are installed,

D

the safeguarding means are applied, and

D

the physical environment is as specified (e.g. lighting and noise levels,

temperature, humidity, atmospheric contaminants).

After applying power, verify that

D

the start, stop, and mode selection (including key lock switches)

control devices function as intended,

D

each axis moves and is restricted as intended,

D

emergency stop circuits and devices are functional,

D

it is possible to disconnect and isolate the external power sources,

D

the teach and playback facilities function correctly,

D

the safeguards and interlocks function as intended,

D

other safeguarding is in place (e.g. barriers, warning devices),

D

in reduced speed, the robot operates properly and has the capability to

handle the product or workpiece, and

D

in automatic (normal) operation, the robot operates properly and has

the capability to perform the intended task at the rated speed and load.

A procedure for the restart of the robot system after hardware, software or

task program modification, repair, or maintenance must include but not

necessarily be limited to the following:

D

check any changes or additions to the hardware prior to applying

power;

D

functionally test the robot system for proper operation.

1.2.2

Restriction of

Personnel

1.2.3

Safety and Operational

Verification

1.2.4

Robot System Restart

Procedures

B--80687EN/03

6

1. GENERAL CAUTIONS

Whenever possible, programming must be performed with all persons

outside the safeguarded space. When it is necessary to perform

programming with personnel inside the safeguarded space, the following

safety procedures are necessary.

The programmer must be trained on the type of robot used in the actual

robot system and must be familiar with the recommended programming

procedures including all of the safeguarding methods.

D

The programmer must visually check the robot system and safeguarded

space to ensure that extraneous conditions which can cause hazardous

do not exist.

D

Where required for programming, the teach pendant must be tested to

ensure proper operation.

D

Any faults or failures must be corrected prior to entering the

safeguarded space.

Before entering the safeguarded space, the programmer must ensure that all

necessary safeguards are in place and functioning.

The programmer must set the operating mode T1 (or T2) from AUTO prior

to entering the safeguarded space.

During programming, only the programmer must be allowed in the

safeguarded space and the following conditions must be met.

D

The robot system must be under the sole control of the programmer

within the safeguarded space. (When T1 or T2 mode is selected, the

robot can be moved only by the teach pendant.)

D

The controls of the teach pendant must be used as intended.

D

The robot system must not respond to any remote commands or

conditions that would cause hazardous conditions.

D

Movement of other equipment in the safeguarded space which can

present a hazard must either be prevented or under the sole control of

the programmer. When under control of the programmer, it must

require deliberate action on the part of the programmer separate from

the action to initiate robot motion.

D

All robot system emergency stop devices must remain functional.

The programmer must return the suspended safeguards to their original

effectiveness prior to initiating automatic operation of the robot system.

1.3

PROGRAMMING

1.3.1

Prior to Programming

1.3.2

During Programming

1.3.3

Returning to Automatic

Operation

B--80687EN/03

7

1. GENERAL CAUTIONS

When visual examination of the robot system response to the task program

is necessary as part of the verification procedure, it should be made with all

persons outside the safeguarded space. When it is necessary to perform

program verification with personnel inside the safeguarded space, the

following must apply.

D

Program verification must initially be performed at reduced speed.

D

When it is necessary to examine the movement of the robot at full

(operational) speed, the following requirements must apply:

--

suspension of the reduced speed by the operation mode switch (T2

mode) must be done by the programmer only;

--

an enabling device or a device with an equivalent safety level must

be used by personnel within the safeguarded space;

--

safe working procedures are established to minimize the exposure

of personnel to hazards within the safeguarded space.

Trouble shooting must be performed from outside the safeguarded space.

When this is not practicable, and the design of the robot system has taken

into account the necessity of performing trouble shooting from within the

safeguarded space, the following requirements must apply:

D

personnel responsible for trouble shooting are specifically authorized

and trained for these activities;

D

personnel entering the safeguarded space must use the teach pendant

(deadman switch) to allow motion of the robot;

D

safe working procedures are established to minimize the exposure of

personnel to hazards within the safeguarded space.

Whenever possible, a record of the task programs together with any

modifications should be maintained.

Programmed data can be stored on a floppy disk. The floppy disk must be

stored in a suitably protected environment when not in use.

Please refer to ”Setup and Operations Manual” for storing a data to a

floppy disk.

Automatic operation must only be permissible when

D

the intended safeguards are in place and functioning,

D

no personnel are present within the safeguarded space, and

D

proper safe working procedures are followed.

1.4

PROGRAM

VERIFICATION

1.5

TROUBLE SHOOTING

1.6

SAVING

PROGRAMMED DATA

1.7

AUTOMATIC

OPERATION

B--80687EN/03

8

1. GENERAL CAUTIONS

The robot system must have an inspection and maintenance program to

ensure continued safe operation of the robot system. The inspection and

maintenance program must take into account the robot and robot system

manufacturer’s recommendations.

Personnel who perform maintenance or repair on robots or robot system

must be trained in the procedures necessary to perform safely the required

tasks.

Personnel who maintain and repair robot systems must be safeguarded

from hazards.

Where possible, maintenance must be performed from outside the

safeguarded space by placing the robot arm in a predetermined position.

The following is the safety procedure of entering into safeguarded space

for maintenance when it is necessary to perform maintenance within the

safeguarded space.

Procedure 1

Entering safeguarded space for maintenance

1 Stop the robot system.

2 Shut off the power of the robot system, and lock the main breaker to

prevent powering on during maintenance working, by mistake.

If you have to enter the safeguarded space while power is available to

the robot system, you must do the following things prior to entering

the safeguarded space:

--

check the robot system to determine if any conditions exist that are

likely to cause malfunctions,

--

check if the teach pendant works correctly, and

--

if any damage or malfunction is found, complete the required

corrections and perform retest before personnel enter the

safeguarded space.

3 Enter the safeguarded space (see 3.5 ”The Safety Sequence for Fence

Entry”).

4 After the maintenance working, check if the safeguard system is

effective. If it has been suspended to perform the maintenance

working, return their original effectiveness.

1.8

MAINTENANCE

Step

B--80687EN/03

9

1. GENERAL CAUTIONS

D

Some robot models have some axes without brakes which prevents

moving during their power being cut off. So their axes without brakes

may be moved by the force of gravity when:

--

cut off the power of the robot, and

--

stop the robot by an emergency stop.

Please be careful of their movement, especially for their wrist joints,

in the above operations. For details, refer to the maintenance manual

for each robot model.

1.9

OTHER CAUTIONS

2

ROBOT SYSTEM DESIGN

B--80687EN/03

9

In this chapter, requirements for robot system design are described.

--

Placement of Equipment

--

Power Supply and Protective Earth Connection

--

Other Precautions

In addition, the basic requirements for end effector, workpiece, and

peripheral equipment are outlined in 2.5.

About safety fence, safety gate and other protection devices, please refer to

3.4 and 3.5.

The robot system must be designed, constructed, and implemented so that

in case of a foreseeable failure of any single component, whether electrical,

electronic, mechanical, pneumatic, or hydraulic, safety functions are not

affected or when they are, the robot system is left in a safe condition

(”Failure to safety”).

The application of the electrical equipment of the robot system must be

accordance with EN60204--1.

Please make sure the following requirements are all satisfied for each

component of a robot system.

D

Appropriate safety fence/guard must be placed according to EN775

and Annex I of Machine Directive. Please refer to section 3.4 and 3.5

for the requirement of the safety fence/guard and protection devices.

D

The risk assessment must determine the additional space required

beyond the restricted space to define the safeguarded space.

D

The operator panel must be located at a safe place:

--

outside the safety fence, and cannot be reached from inside the

safety fence,

--

where it can be easily seen, and easily operated by the operator,

--

where the operator can operate it without hesitation or loss of time

and without ambiguity, and

--

where no dangerous situation is created by operating it.

D

Large space must be secured around each component enough for the

maintenance and inspection of the system.

2.1

GENERAL

2.2

PLACEMENT OF

EQUIPMENT

B--80687EN/03

10

2. ROBOT SYSTEM DESIGN

D

A stable scaffold must be provided, wherever necessary, for the

maintenance and inspection of the system.

D

The space inside the safety fence, especially for maintenance and

inspection, must be designed to protect the operator from falling off or

slipping off the step.

D

The robot system must be secured on a stable floor. Especially the

robot mechanical unit must be attached to the floor according to the

instructions in the maintenance manual.

D

Robot systems must be designed to avoid trapping and collision

between the moving parts of the robot and other fixed or moving

objects.

D

The layouts must be designed in such a way that between moving parts

of the robot and objects in the environment (e.g. pillars of the

structure, ceiling joists, fences, supply leads) sufficient clearance is

available.

This rule does not apply to associated equipment in order to allow it to

perform its task.

D

When a limitation of the restricted space, by limiting the range of

motion of the primary axes, is required by the plan, limiting devices

must be provided. They must comply with one of the following.

--

Mechanical stops which are capable of stopping the robot at any

adjusted position when it is carrying its rated load at maximum

velocity.

--

Alternative methods of limiting the range of motion may be

provided only if they are designed, constructed, and installed to

achieve the same level of safety as the mechanical stops.

This may include using the robot controller and limit switches

according to IEC204--1.

Note that the limiting devices must be correctly adjusted and secured.

D

When it is intended that operators will perform manual operations

associated with the robot, such as loading and unloading of parts, this

must be taken into account in the arrangement of the robot system,

either by providing loading devices so that the operator cannot access

the hazardous area, or by providing appropriate safeguards for the

manual activity.

B--80687EN/03

11

2. ROBOT SYSTEM DESIGN

D

The power supply and the grounding must be connected according to

maintenance manual.

--

R--J controller

: B--67995E

--

R--J2 controller

: B--80525E--1

--

R--J2 Mate controller

: B--80465EN--1

--

R--J3 controller

: B--80945EN--1

D

Unsafe conditions must be avoided in the event of a power down,

power recovery after a power down or supply voltage fluctuations.

Unsafe conditions to be avoided are;

--

Dropping workpiece or any material,

--

Safety equipment not functioning, etc..

D

The robot system must have means to isolate its power sources. These

means must be located in such a way that no person will be exposed to

hazardous and the must have a lockout/tagout capability.

D

Shut down (removal of power) to the robot system or any associated

equipment must not result in a hazardous condition.

D

All environmental conditions must be evaluated to ensure

compatibility of the robot and the robot system with the anticipated

operational conditions.

These conditions include, by are not limited to, explosive mixtures,

corrosive conditions, humidity, dust, temperature, electromagnetic

interference (EMI), radio frequency interference (RFI), and vibration.

D

The control position where the operator stands must be predetermined.

The control position must satisfy the following conditions.

--

The operator can easily operate the panel or the teach pendant.

--

The operator can easily make sure that nobody is inside the safety

fence.

--

The operator can easily verify the operation of the system.

--

The operator can immediately stop the entire or partial system in

the event a malfunction of the system or any dangerous condition.

2.3

POWER SUPPLY AND

PROTECTIVE EARTH

CONNECTION

2.4

OTHER PRECAUTIONS

B--80687EN/03

12

2. ROBOT SYSTEM DESIGN

D

The following safety measure must be used if the operator cannot

easily verify nobody is inside the safety fence, or as required by the

risk--assessment result.

--

A visible/audible warning (complying EN standards) is used

before robot starts moving.

--

A measure for the person inside the fence to stop the robot system

or a measure for the person to evacuate outside the fence.

D

The manual intervention and reset procedure to restart the robot system

after an emergency stop must take place outside the restricted space.

D

A warning device must be such that the operator and people in

dangerous area can easily recognize it.

D

The area must be appropriately lighted, especially for maintenance and

inspection.

The lighting must not create a new dangerous situation (e.g. dazzled).

D

It is recommended that adjustment, oiling, and other maintenance work

can be performed from outside the dangerous area while the system is

stopping.

If it is not feasible, a method to perform these operation safely must be

established.

D

If the robot and the peripheral equipment synchronously move in the

robot system, an appropriate measure must be provided to avoid unsafe

condition by stopping the entire system in the event any of the

equipment stops due to malfunction.

D

Any robot that can be controlled from a remote location must be

provided with an effective means that must prevent hazardous

conditions of the robot being initiated from any other location.

D

For robot systems that can be operated from a remote location (e.g.

over a communications network), a means must be provided (e.g. a key

operated switch) to ensure that no commands can initiate hazardous

conditions from the remote location when in local control.

B--80687EN/03

13

2. ROBOT SYSTEM DESIGN

D

It is recognized that for certain phases of the robot system life (e.g.

commissioning, process changeover, cleaning, and maintenance) it

may not be possible to design completely adequate safeguards to

protect against every hazard or that contain safeguards may be

suspended.

Under these conditions, appropriate safe working procedures must be

used.

D

A robot system manufacturer must provide an operation manual

according to EN775 10.2 ”Robot system documentation to be supplied

by the robot system manufacturer”.

D

The requirements in the Machinery directive appendix #1 and EN775

must be considered when a robot application system is designed.

B--80687EN/03

14

2. ROBOT SYSTEM DESIGN

It is the responsibility of the robot system manufacturer to perform the risk

assessment of the end effector, workpiece and the peripheral equipment.

This section outlines the basic requirement for the risk assessment of these

components.

D

End effectors must be designed and constructed, or safeguarded, so

that

--

power failure does not cause release of the load or result in a

hazardous condition, and

--

the static and dynamic forces created by the load and the end

effector together are within the load capacity and dynamic

response of the robot.

D

If it is equipped with a tooling that can function with several different

conditions (speed, etc.), the selection of the condition must be safely

and securely done.

D

The material and its shape must cause no dangerous situation, or safety

measures must be provided.

D

If the workpiece is extreme high or low temperature, safety measures

must be provided to avoid personnel from touching or getting too close

to it.

D

The material and shape must cause no dangerous situation.

D

If any component has possibility to break down during operation, it

must be placed so that it will not scatter in the event it breaks down.

D

Pipes (for liquid/gas) must have enough strength for its internal /

external pressure.

D

Pipes must be secured and protected from the external pressure or

tension.

D

Measures must be provided to avoid dangerous situation due to sudden

movement of the pipe or the high speed flow of material in the event a

pipe is broken.

2.5

END EFFECTOR,

WORKPIECE AND

PERIPHERAL

EQUIPMENT

End Effector

Workpiece

Peripheral Equipment

(including end effector)

B--80687EN/03

15

2. ROBOT SYSTEM DESIGN

D

If a pneumatic device is used, an air valve which shuts off the air

supply to the robot must be installed.

D

If other power source than the electricity (e.g. pneumatic, water, heat)

is used in the system, appropriate risk--assessment must be performed,

and appropriate safety measures must be provided.

D

Safety measures must be provided to avoid swapping of components

that causes unsafe conditions, by

--

design to avoid swapping,

--

indication of necessary information on the parts.

D

Safety measures must be provided to avoid inferior contacts, by

--

design to avoid inferior contacts,

--

displaying the information on the connectors, pipes, cables.

D

Safety measures must be provided to avoid unsafe condition by

touching an extremely high/low temperature parts (if any).

D

Safety measures must be provided to avoid fire or explosion through

sufficient amount of investigation.

D

Vibration and sound noise must be kept minimum considering the

effect to the environment.

D

If a laser equipment is used, the following must be considered.

--

avoid unexpected emission of laser light

--

direct/indirect emission of light must give no harm to the health

--

laser light must give no harm to health during maintenance /

adjustment.

B--80687EN/03

16

2. ROBOT SYSTEM DESIGN

3

SAFETY DEVICES

B--80687EN/03

17

This robot has following emergency stop devices.

D

two emergency stop buttons

( installed on the operator’s panel and the teach pendant)

D

external emergency stop (input signal)

When emergency stop button are pushed, the robot stops immediately in

any cases.

The external emergency stop input signal is input from peripheral devices

(e.g. safety fence , gate).

The signal terminal is inside the operator’s box.

MODE SELECT SWITCH is installed on the operator’s panel. You can

select one of the operation modes using this switch. The selected operation

mode can be locked by removing its key.

When the mode is changed by this switch, the robot system stops and a

message is shown in teach pendant LCD.

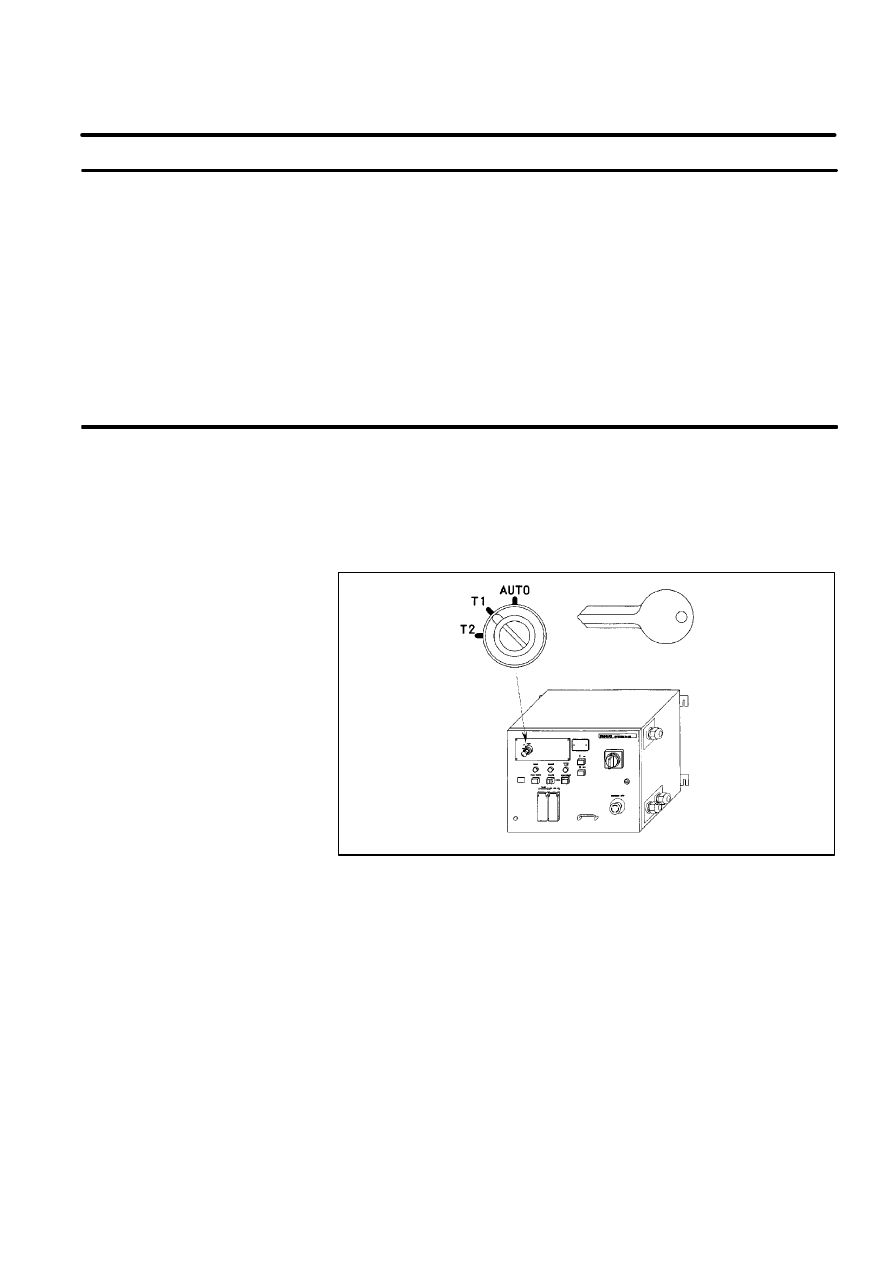

Figure 1. Mode Select Switch(R--J2 i cabinet)

3.1

EMERGENCY STOP

3.2

MODE SELECT

SWITCH

B--80687EN/03

18

3. SAFETY DEVICES

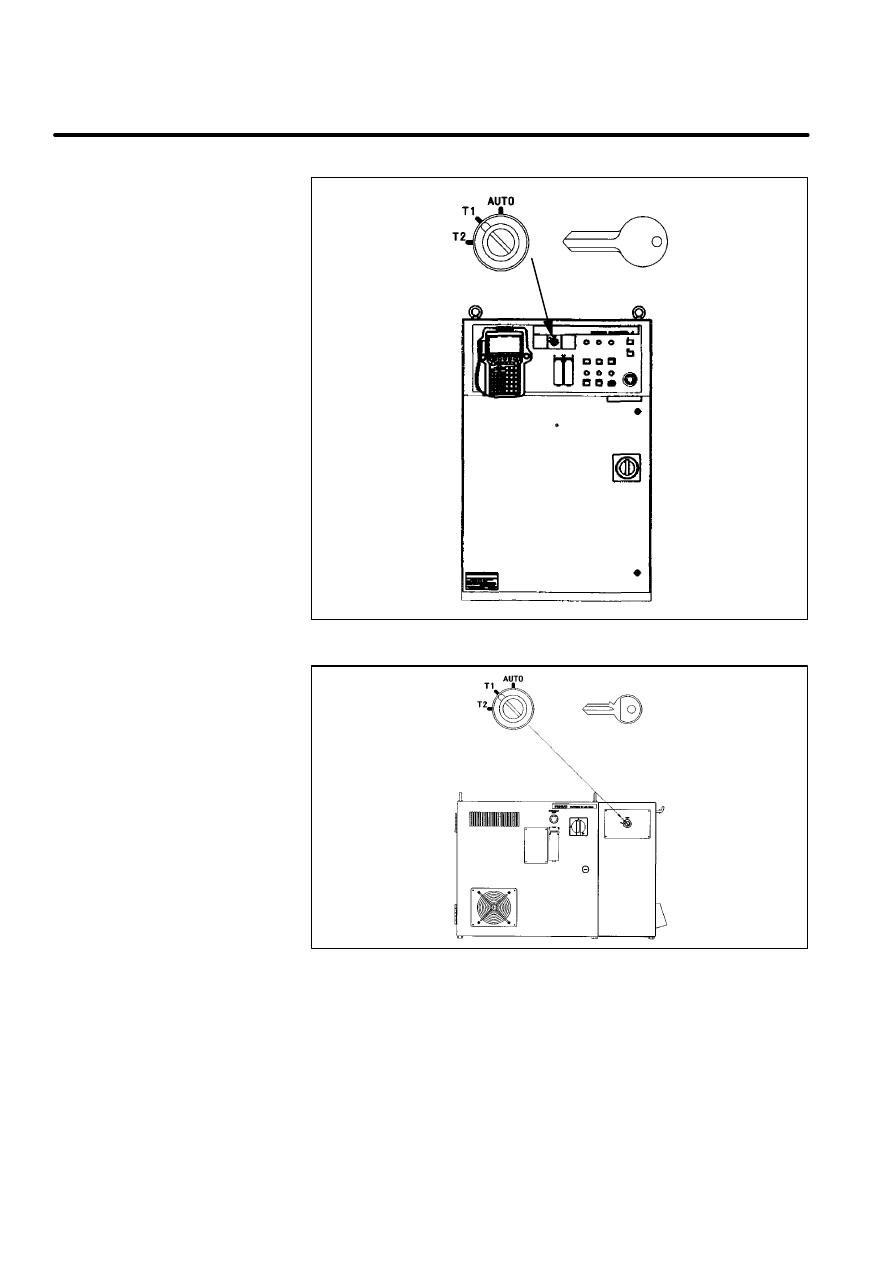

Figure 2. Mode Select Switch(R--J2 B cabinet)

Figure 3. Mode Select Switch(R--J2 Mate)

B--80687EN/03

19

3. SAFETY DEVICES

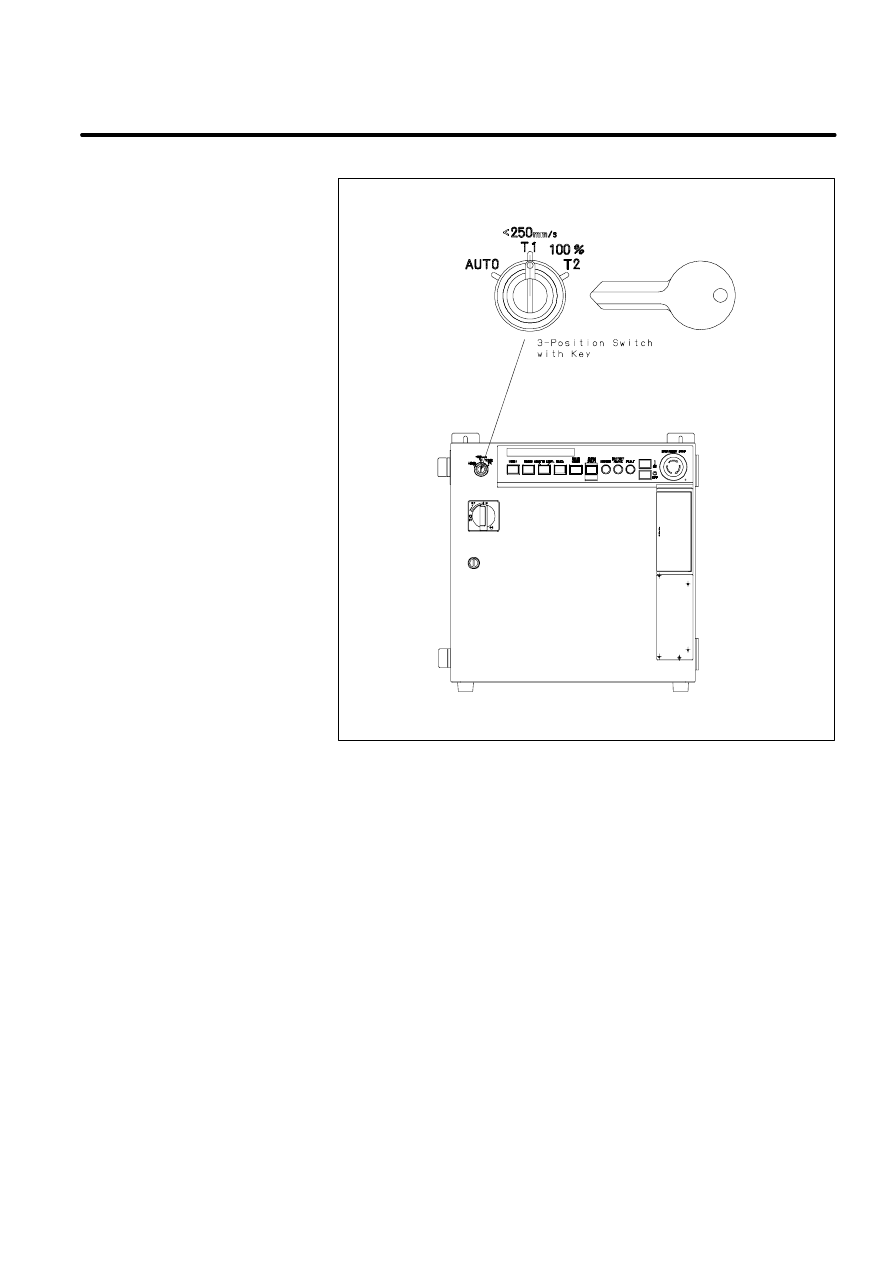

Figure 4. Mode Select Switch(R--J3 i cabinet)

B--80687EN/03

20

3. SAFETY DEVICES

There are three operating modes.

D

The operator’s panel/box becomes enable.

D

The robot program can be started by the operator’s panel/box start

button or peripheral device I/O.

D

Safety fence is enabled.

D

The robot can be operated at the specified maximum speed.

D

Program can be activated from the teach pendant only.

D

The robot cannot be operated at speeds higher than 250mm/sec.

D

Safety fence is disabled.

D

Program can be activated from the teach pendant only.

D

The robot can be operated at the specified maximum speed.

D

Safety fence is disabled.

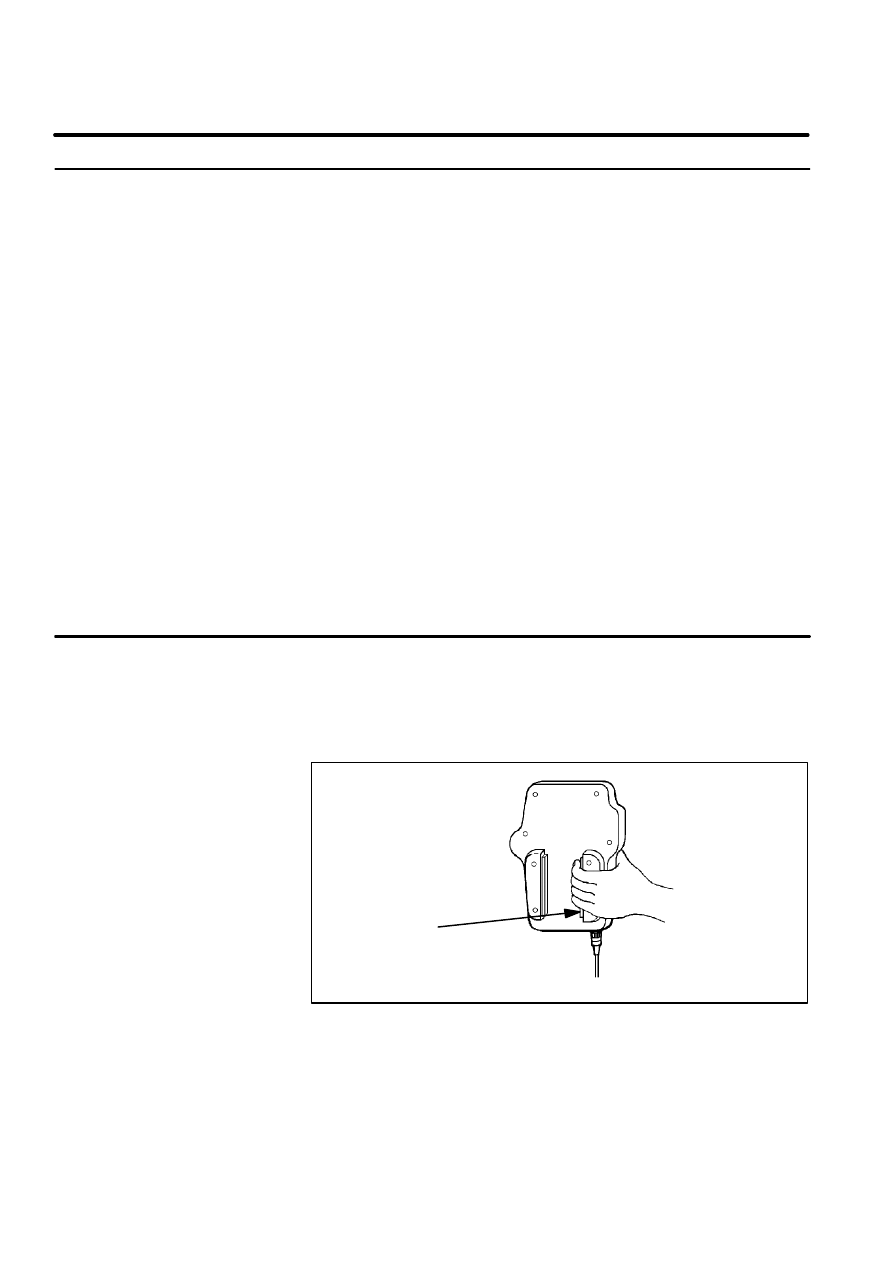

DEADMAN SWITCH is used as an enabling device.

When the teach pendant is enabled, this switch allows robot motion only

while deadman switch is gripped. If you release this switch, the robot stops

immediately.

Figure 5. Deadman Switch

DEADMAN SWITCH

3.2.1

Operating Modes

AUTO: Automatic Mode

T1: Test Mode 1

T2 :Test Mode 2

3.3

DEADMAN SWITCH

B--80687EN/03

21

3. SAFETY DEVICES

The safeguards consists of :

D

safety fence (fixed guard),

D

safety gate (with interlocking devices),

D

safety plug and socket, and

D

other protection devices.

These safety devices must be complied with the EN775 standard.

This section describes the basic requirements for these devices.

Please refer to EN775 standard for detail.

Note that these safety devices must be fitted to the robot system by the

system house, etc..

The requirements for Safety Fence are as follows.

D

The fence is constructed to withstand foreseeable operational and

environmental forces.

D

The fence is free of sharp edges and projection and is not themselves a

hazard.

D

The fence prevent access to the safeguarded space except through

openings associated with interlocking devices.

D

The fence is permanently fixed in position and only be removable with

the aid of a tools.

D

The fence cause minimum obstruction to the view of the production

process.

D

The fence is located at an adequate distance from the maximum space.

D

The fence should be connected to PE(protective Earth) to prevent the

electric shock with accident.

Please refer to EN294, EN349, prEN547 and related standards for detail.

The requirements for Safety Gate are as follows.

D

The gate prevents the robot system from automatic operation until the

gate is closed.

D

The closure of the gate is not the control to restart automatic operation.

This must be a deliberate action at a control station.

D

The gate has plug and socket for interlock.

D

The plug and socket must be selected appropriate things for safety.

3.4

SAFEGUARDS

3.4.1

Safety Fence

3.4.2

Safety Gate and Plugs

B--80687EN/03

22

3. SAFETY DEVICES

This gate must be the one either it remains locked closed until the risk of

injury from the hazard has passed (interlocking guard with guard locking)

or opening the guard while the robot system is working gives a stop or

emergency stop instruction (interlocking guard).

Please refer to prEN1088 and related standards for detail of interlocking

system.

Care should be taken to ensure that actuation of an interlock installed to

protect against on hazard (e.g. stopping hazardous motion of the robot

system) does not create a different hazard (e.g. the release of hazardous

substances into the work zone).

Protection devices must be designed and incorporated into the control

system so that:

D

moving parts cannot start up while they are within the operator’s reach,

D

the exposed person cannot reach moving parts once they have started

up,

D

they can be adjusted only by means of an intentional action, such as

the use of a tool, key, etc.,

D

the absence or failure of one of their components prevents starting or

stops the moving parts.

If some presence sensing devices are used for safety purposes, they must

comply with the following.

D

A presence sensing device must be installed and arranged so that

persons cannot enter and reach into a hazardous area without activating

the device or cannot reach the restricted space before the hazardous

conditions have ceased. Barriers used in conjunction with the presence

sensing device may be required to prevent persons from bypassing the

device.

D

Their operation must not be adversely affected by any of the

environmental conditions for which the system was intended.

D

When a presence sensing device has been activated, it may be possible

to restart the robot system from the stopped position provided that this

does not create other hazards.

D

Resumption of robot motion must require the removal of the sensing

field interruption. This must not be the control to restart automatic

operation.

3.4.3

Other Protection

Devices

B--80687EN/03

23

3. SAFETY DEVICES

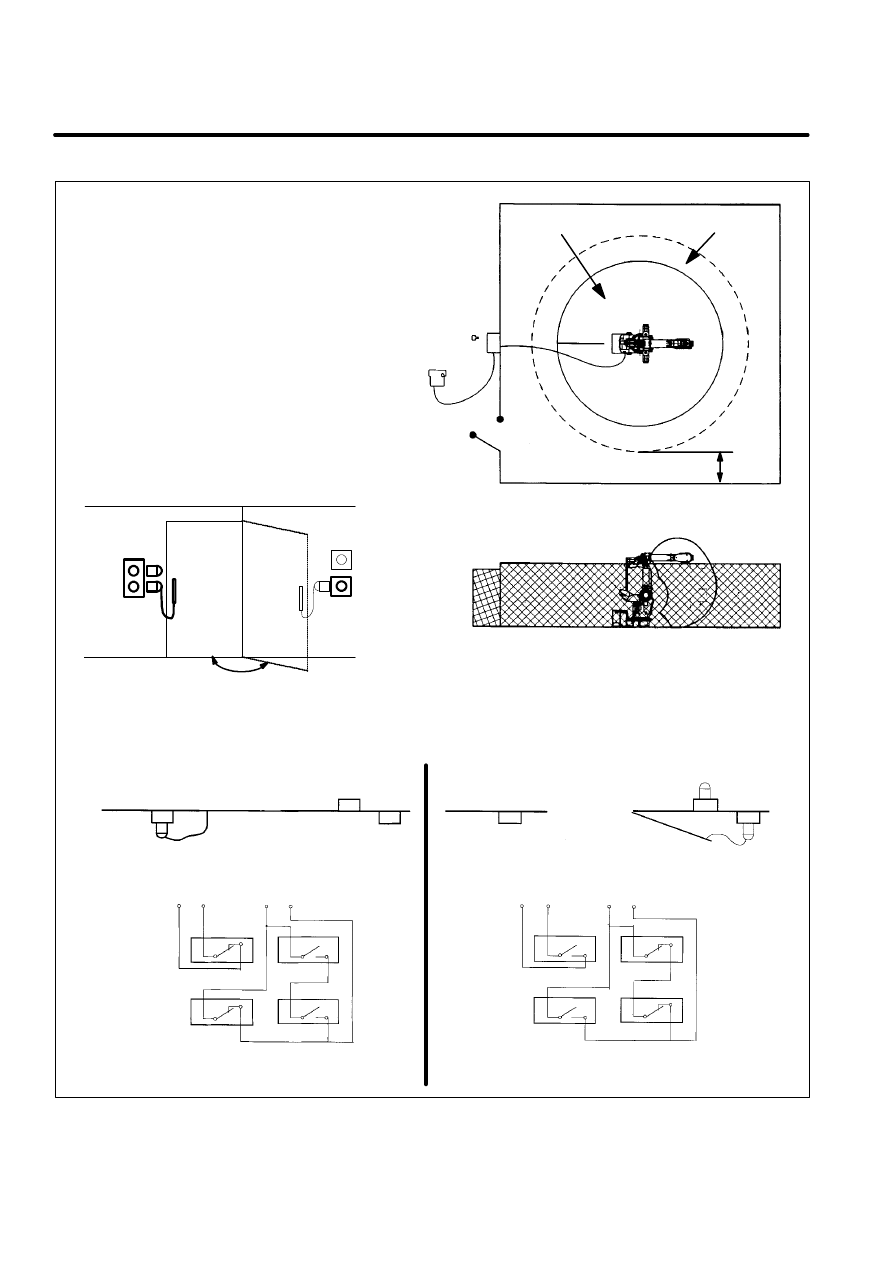

This section describes the safety procedure of entering into the safety

fence.

Note that only a programmer or a maintenance person can enter into the

safety fence. A general person CANNOT enter into the safety fence.

Procedure 2

Entering into the SAFETY FENCE

H

The robot is moving automatically (in AUTO mode).

5 Stop the robot.

You can stop the robot:

--

by press emergency switch of operator’s panel or teach pendant

--

by press HOLD button

--

by change to enable with teach pendant enable switch

--

by open SAFETY GATE (pull safety plug)

--

by change mode with operation mode key switch

6 Change the operating mode to T1 or T2 from AUTO.

7 Remove key of operating mode switch for mode lock.

8 Remove the plug2 from socket2.

Open the gate of the safety fence, and put the plug2 to socket4.

9 Remove the plug1 from socket1

10 Enter inside of the safety fence, and put the plug1 to socket3.

Please refer to Figure 6 for details of safety fence and safety plug

configurations.

WARNING

The key of operating mode key switch and the safety plug1

must be carried into the safety fence. The safety plug1

must be put to the socket3 inside fence.

3.5

THE SAFETY

SEQUENCE FOR

FENCE ENTRY

Condition

Step

B--80687EN/03

24

3. SAFETY DEVICES

Figure 6. SAFETY FENCE and SAFETY GATE example

Operator’s box

and

mode switch key

Teach pendant

Safety Gate

Safeguard distance

Ristriction space

Maximum space

Safety Fence

Safety Gate

Safety Fence

Safety Gate

Socket 1

Socket 2

plug 1

plug 2

Socket 3

Socket 4

Socket 3

Socket 4

Safety Gate

Safety Fence

Socket 1

Socket 2

plug 1

plug 2

Socket 1

Socket 2

Safety Fence

Safety Gate

Socket 3

Socket 4

plug 1

plug 2

AUTO mode

FENCE1 FENCE2

EMGIN1 EMGIN2

Socket 1

Socket 2

Socket 3

Socket 4

PLUG1

PLUG2

FENCE1 FENCE2

EMGIN1 EMGIN2

T1 / T2 mode

Socket 1

Socket 2

Socket 3

Socket 4

PLUG1

PLUG2

Close

Open

Safety Fence

B--80687EN/03

25

3. SAFETY DEVICES

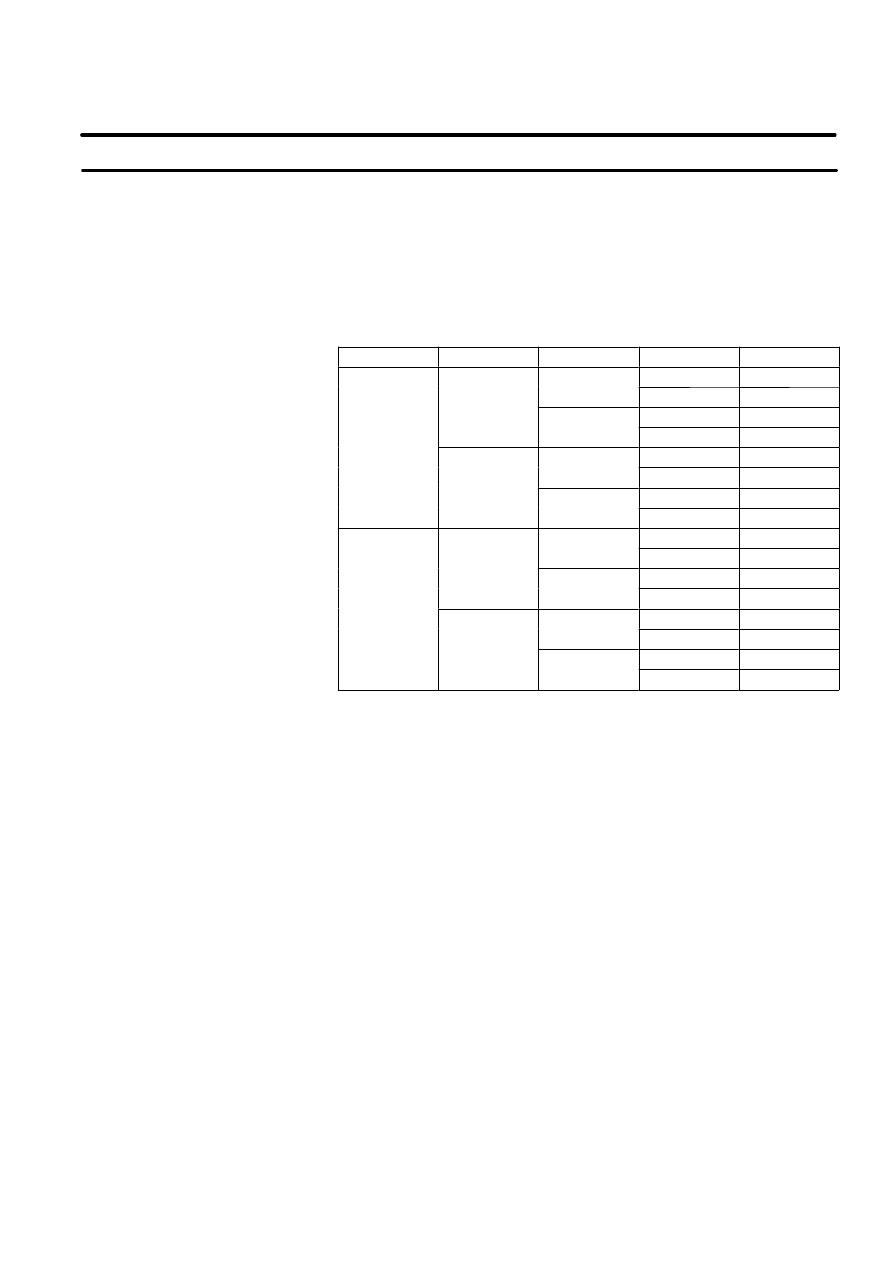

When emergency stop switch on operator’s panel/box or teach pendant is

pressed, the robot stops immediately.

In other cases (excluding emergency stop switch being pressed), there are

following situations when an emergency stop condition is created by the

combination of operation mode selection, teach pendant enable/disable,

deadman switch, and safety fence open/close.

Table 1. Robot Stop Variations

Mode

TP--Enable

Dead--man

Fence

Status

Auto

enable

grip

open

EMG--stop

g p

close

available

release

open

EMG--stop

close

EMG--stop

disable

grip

open

EMG--stop

g p

close

available

release

open

EMG--stop

close

available

T1/T2

enable

grip

open

available

g p

close

available

release

open

EMG--stop

close

EMG--stop

disable

grip

open

n.a

g p

close

n.a

release

open

EMG--stop

close

EMG--stop

EMG--stop:

Emergency stop

available:

Robot is available

n.a:

Robot is not available

3.6

ROBOT STOP

VARIATION

B--80687EN/03

26

3. SAFETY DEVICES

4

DAILY MAINTENANCE

B--80687EN/03

27

Clean each part, and visually check component parts for damage before

daily system operation.

Check the following items as the occasion demands.

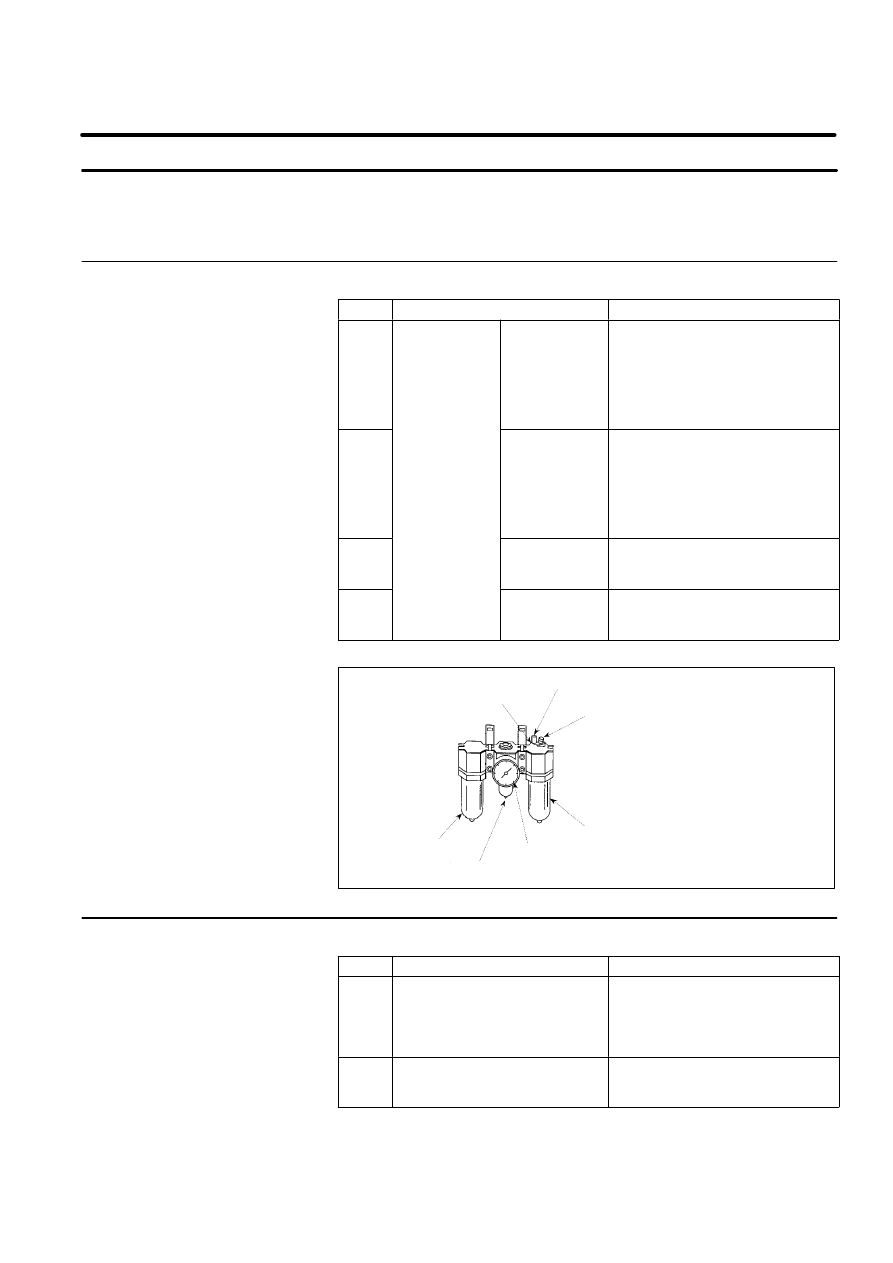

item

check item

check points

1

when air control

set is combined

Air pressure

Check air pressure using the

pressure gauge on the air regulator

as shown in Figure 7. If it does not

meet the specified pressure of 5 -- 7

kgf/cm2(0.49 to 0.69MPa), adjust it

using the regulator pressure setting

handle.

2

Oiler oil mist

quantity

Check the drop quantity during wrist

or hand motion. If it does not meet

the specified value (1 drop/10 --

20sec), adjust it using the oiler

control knob. Under normal usage

the oiler becomes empty in about 10

to 20 days under normal operation.

3

Oiler oil level

Check to see that the oiler level is

within the specified level shown in

Figure 7.

4

Leakage from

hose

Check the joints, tubes, etc. for

leaks. Repair leaks, or replace parts,

as required.

Figure 7. Air control set

Adjusting knob

Oiler mist amount check

Oil inlet

Oiler

Filter

Pressure gauge

Regulator pressure setting handle

item

check item

check points

5

Vibration, abnormal noises, and

motor heating

Check whether the robot moves

along and about the axes smoothly

without unusual vibration or sounds.

Also check whether the temperature

of the motors are excessively high.

6

Changing repeatability

Check to see that the stop positions

of the robot has not deviated from

the previous stop positions.

4.1

MECHANICAL UNIT

4.1.1

Before Powering On

4.1.2

After Automatic

Operation

B--80687EN/03

28

4. DAILY MAINTENANCE

item

check points

check item

7

Peripheral device for

Check whether the peripheral

devices operate

8

proper operation

properly according to commands

from robot.

Brakes for each axis

Check that the end effector drops

within 0.2mm

Before operating the system each day, clean each part of the system and

check the system parts for any damage or cracks.

Also check the following:

D

Before service operation

--

Check the cable connected to the teach pendant for excessive

twisting.

--

Check the controller and peripheral devices for abnormalities.

D

After service operation

--

At the end of service operation, return the robot to the proper

position, then turned off the controller.

--

Clean each part, and check for any damage or cracks.

--

If the ventilation port and the fan motor of the controller is dusty,

wipe off the dust.

4.2

CONTROL UNIT

1

B--80687EN/03

FANUC is not and does not represent itself as an expert in safety systems,

safety equipment, or the specific safety aspects of your company and/or its

workplace.

It is the responsibility of the owner, employer, or user to take all necessary

steps to guarantee the safety of all personnel in the workplace.

The appropriate level of safety for your application and installation can

best be determined by safety system professionals.

FANUC therefore, recommends that each customer consult with such

professionals in order to provide a workplace that allows for the safe

application, use, and operation of FANUC system.

Additionally, as the owner, employer, or user of a robotic system, it is your

responsibility to arrange for the training of the operator of a robot system

to recognize and respond to known hazards associated with your robotic

system and to be aware of the recommended operating procedures for your

particular application and robot installation.

FANUC therefore, recommends that all personnel who intend to operate,

program, repair, or otherwise use the robotics system be trained in an

approved FANUC training course and become familiar with proper

operation of the system.

Persons responsible for programming the system--including the design,

implementation, and debugging of application programs must be familiar

with the recommended programming procedures for your application and

robot installation.

It is recognized that the operational characteristics of robots can be

significantly different from those of other machines and equipment.

Robot are capable of high energy movements through a large volume

beyond the base of robots.

This handbook provides some hints and guidelines for the robot system

safety design.

The system designer is responsible for designing the robot system to

comply with Annex I of Machine Directive, EN775, and EN292 standards.

GENERAL PRECAUTIONS

B--80687EN/03

2

1. ENTER YOUR CHAPTER TITLE HERE

5

FANUC ROBOT SYSTEM

B--80687EN/03

3

FANUC Robot series can be used for the following applications.

D

Arc Welding

D

Spot Welding

D

Handling

D

Deburring

D

Assembling

D

Sealing

D

Cleaning

D

Spraying

Required functionality for these application is implemented by selecting an

appropriate TOOL software. Please inquire FANUC sales representatives

for available options.

If you are using the robot for an application other than listed above, please

make sure with FANUC sales representatives for the feasibility.

5.1

PURPOSE OF ROBOT

B--80687EN/03

4

5. FANUC ROBOT SYSTEM

Please do NOT use the robot for any of the following usage.

Inappropriate usage of robots may cause not only damage to the robot

system, but also serious injury or even death of the operator and the people

in the premises.

D

Use of robot in flammable atmosphere

D

Use of robot in explosive atmosphere

D

Use of robot in radio active environment

D

Use of robot in water or any kind of liquid

D

Use of robot for the purpose of transferring human or animals

D

Use of robot as a step (climbing upon the robot)

D

Use of robot under conditions not in accordance with FANUC

recommended installation or usage

FANUC is not responsible for any damage caused by misuse of the robots.

B--80687EN/03

5

5. FANUC ROBOT SYSTEM

The following elements has been verified their safety.

D

Robot

D

Robot controller and Teach pendant

The following elements must be prepared by the user according to system

configuration.

D

Safeguard

D

Interlocked gate and Interlocking device

FANUC Robot has an interface to connect interlocking devices.

However, the following elements are not considered, due to wide variety of

its design and safety measures.

D

End effector

D

Workpiece

D

Other peripheral equipment

The designer of a robot application system must design the robot system

according to EN775 and Annex I of Machine Directive.

5.2

CONFIGURATION OF

ROBOT SYSTEM

B--80687EN/03

6

5. FANUC ROBOT SYSTEM

The personnel can be classified as follows.

General person :

D

Power ON/OFF for robot controller

D

Start of robot program with operator’s panel

Operator/Programmer :

D

Operate for Robot

D

Teaching inside safety fence

Maintenance person :

D

Operate for Robot

D

Teaching inside safety fence

D

Maintenance (adjustment, replacement)

D

The general person cannot work inside the safety fence.

D

The operator, programmer and maintenance person can work inside the

safety fence. The workings inside safety fence are lifting, setting,

teaching, adjusting, maintenance, etc..

D

To work inside the fence, the person must be trained for the robot.

Table 2 lists the workings of outside the fence. In this table, the symbol

”o” means the working allowed to be carried out by the personnel.

Table 2. List of workings outside the fence

General

person

Operator /

Programmer

Maintenance

person

Power ON/OFF for Robot controller

o

o

o

Select operating mode (AUTO, T1, T2)

o

o

Select Remote/Local mode

o

o

Select robot program with teach pendant

o

o

Select robot program with external device

o

o

Start robot program with operator’s panel

o

o

o

Start robot program with teach pendant

o

o

Reset alarm with operator’s panel

o

o

Reset alarm with teach pendant

o

o

Set data on the teach pendant

o

o

Teaching with teach pendant

o

o

Emergency stop with operator’s panel

o

o

Emergency stop with teach pendant

o

o

Emergency stop with safety fence open

o

o

Maintain for operator’s panel

o

Maintain for teach pendant

o

5.3

WORKING PERSON

B--80687EN/03

7

5. FANUC ROBOT SYSTEM

In operating, programming and maintenance, the operator / programmer

and maintenance person take care of their safety using the following safety

protectors, for example.

D

Use adequate clothes, uniform, overall for operation

D

Put on the safety shoes

D

Use helmet

The programmer and maintenance person must be trained for the robot

operating and maintenance.

The required items are:

D

Safety,

D

Practice of jog feed,

D

Practical training of manual operation and teaching of robot,

D

Programming practice, teaching and playback practice,

D

Practice of automatic operation,

D

Explanation of configuration and function of robot,

D

Explanation and practice of setting up frame,

D

Explanation of outline of programming and program example,

D

Explanation of automatic operation,

D

Explanation of interface between robot and peripheral device,

D

Explanation and practice of check item when trouble occur,

D

Explanation of periodical inspection and exchange of consumable,

D

Explanation and practice of basic operation,

D

Explanation and practice of display for maintenance,

D

Explanation and practice of handling of floppy cassette,

D

Explanation and practice of initial setting,

D

Explanation and practice of controller,

D

Explanation and practice of checking item on trouble,

D

Explanation and practice of troubleshooting by error code,

D

Explanation and practice of servo system,

D

Explanation and practice of mastering, and

D

Explanation and practice of dis--assemble and assemble.

Some training courses for these items for the maintenance person or

system engineer are provided in the robot school and each technical service

center.

Please refer to Appendix B for contacts.

5.3.1

Robot Training

B--80687EN/03

8

5. FANUC ROBOT SYSTEM

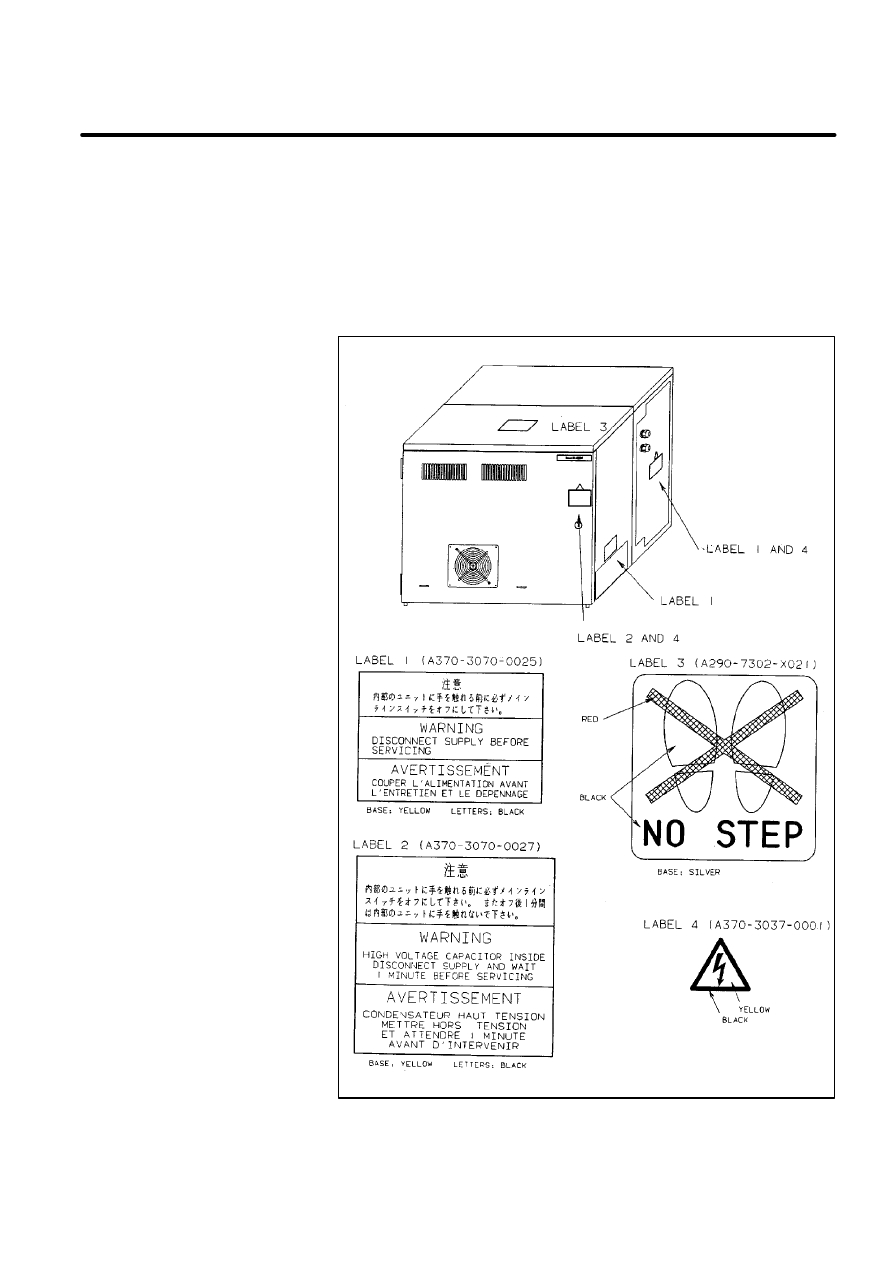

A

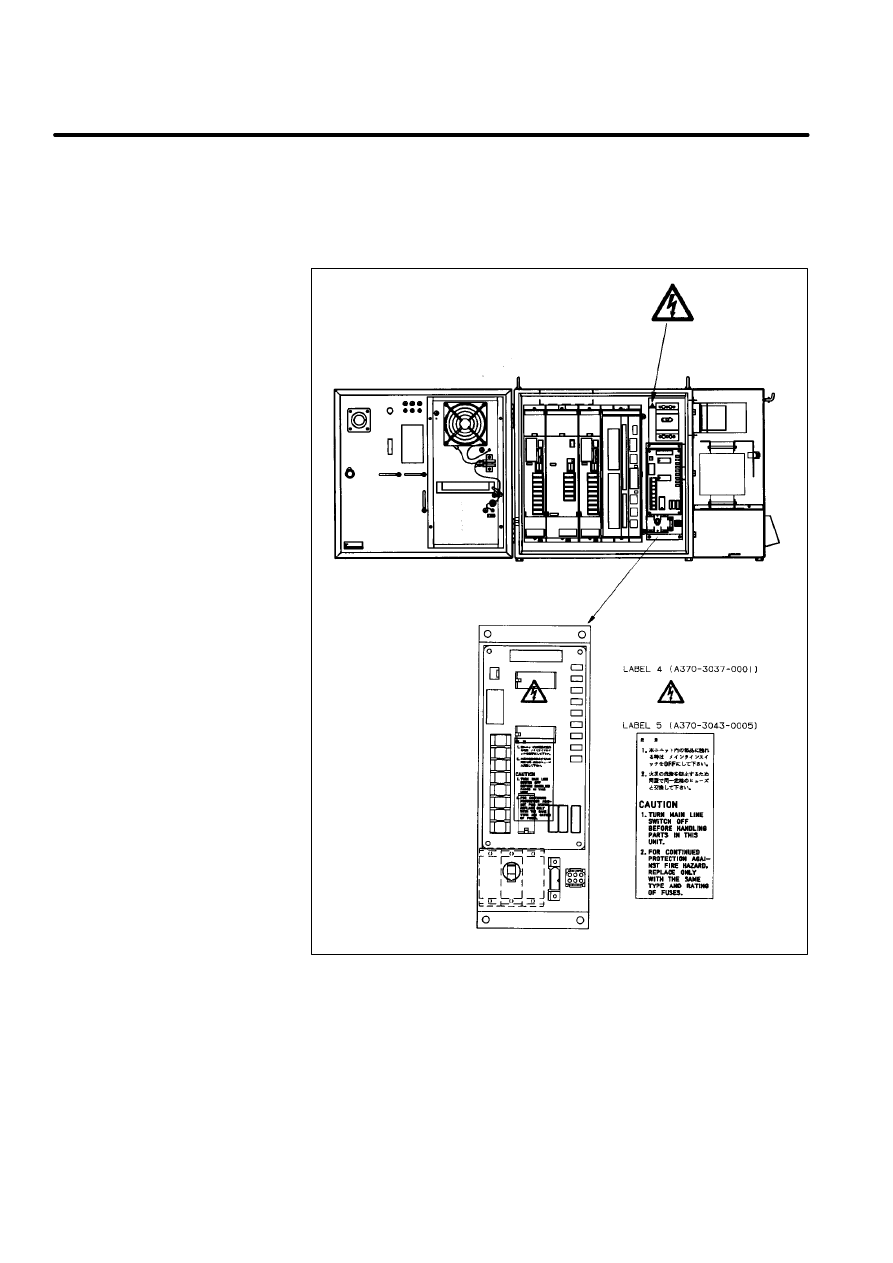

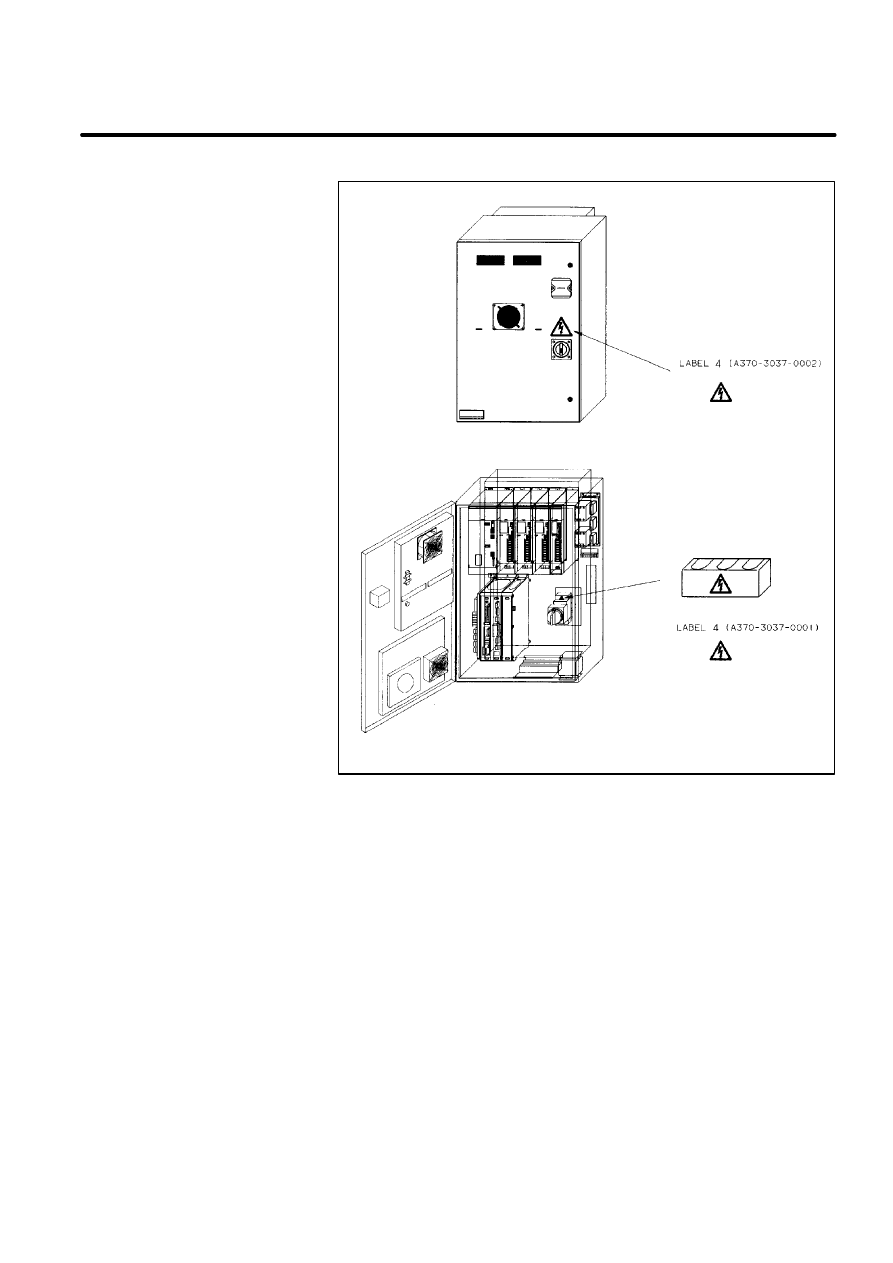

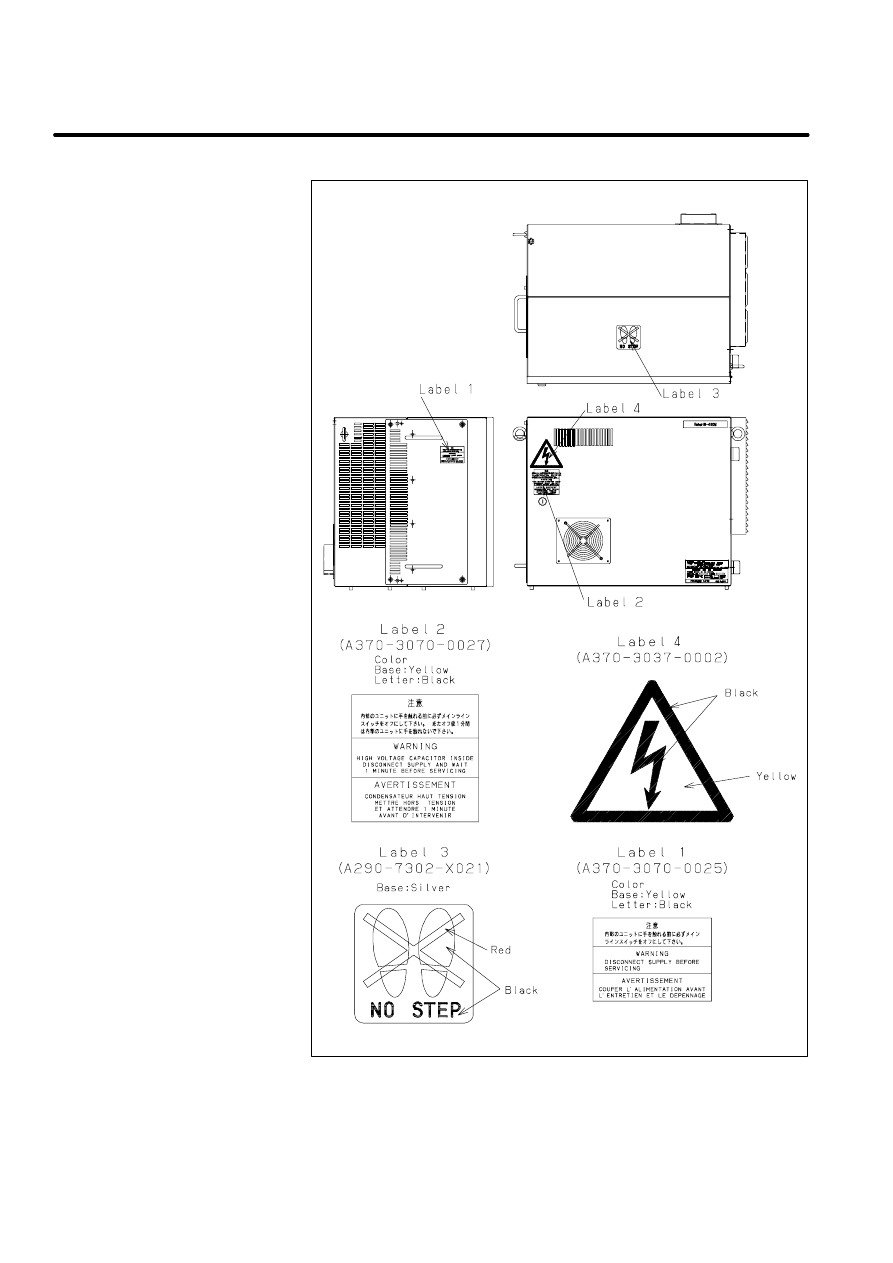

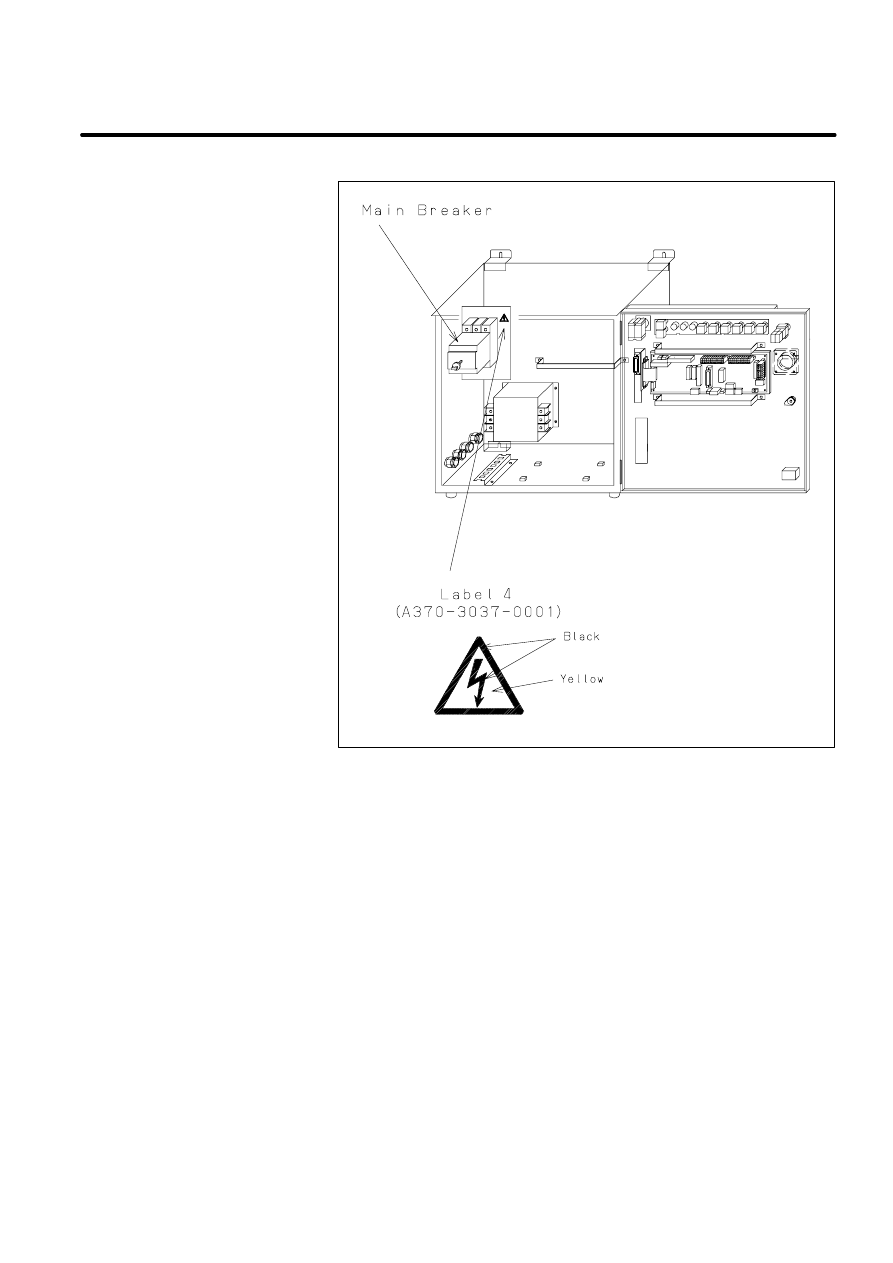

CAUTION LABELS

9

B--80687EN/03

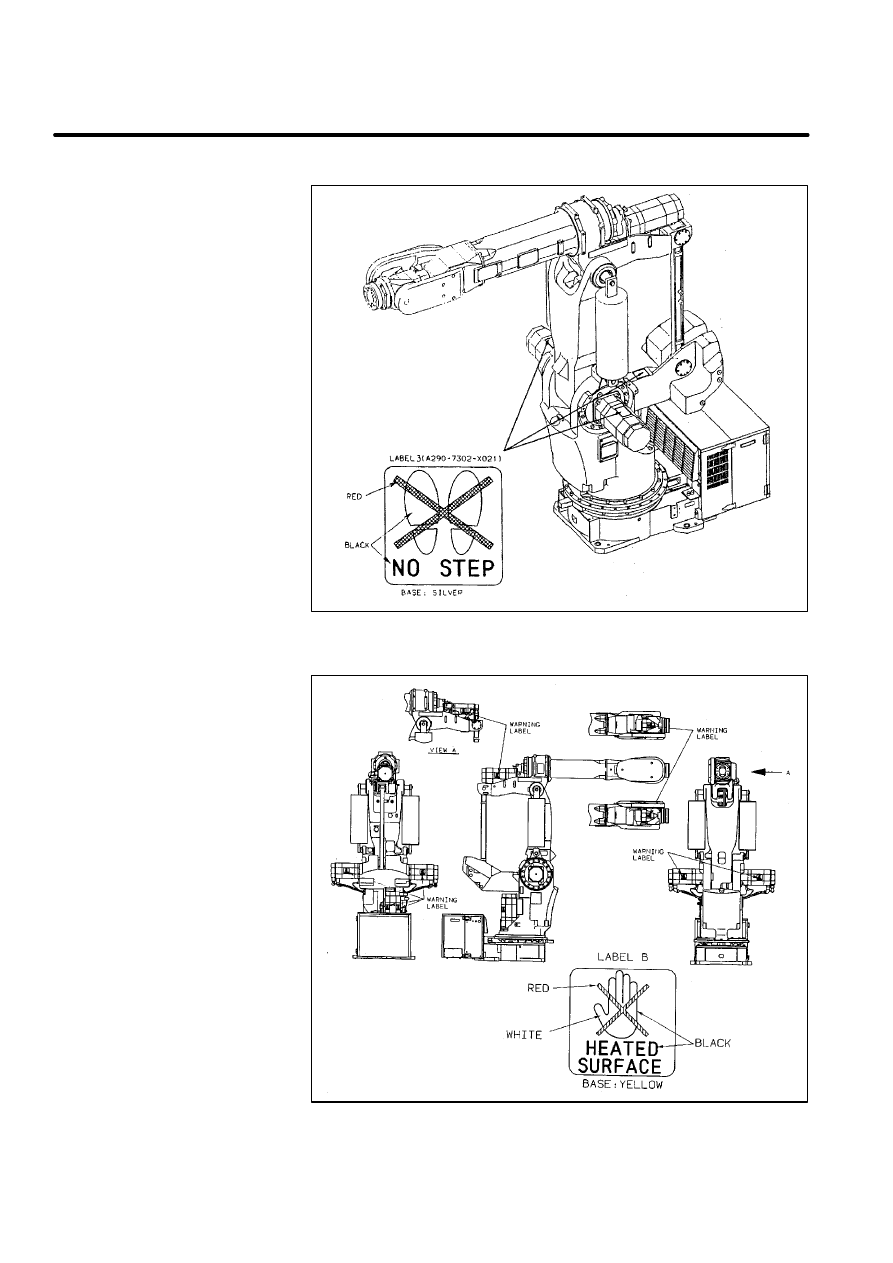

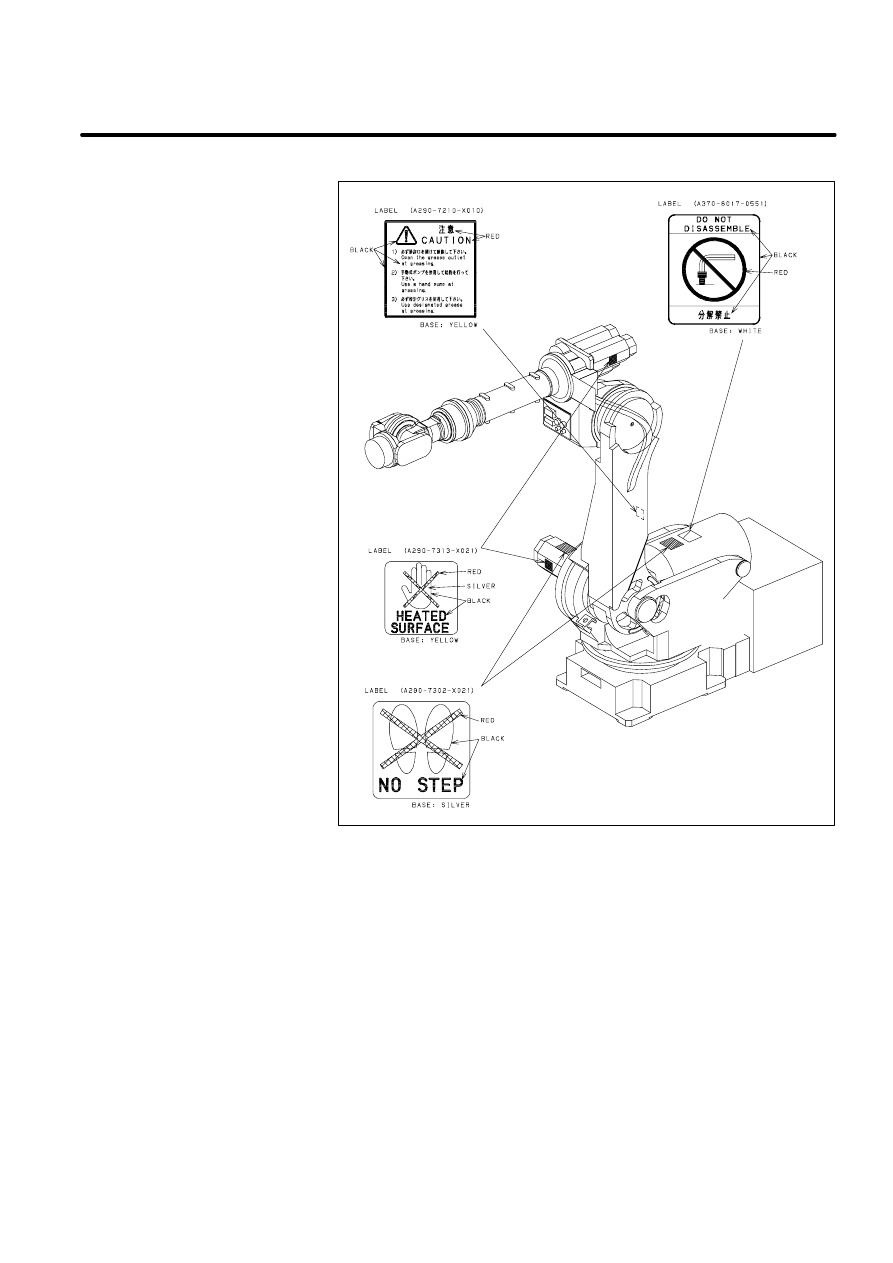

There are six kinds of caution labels fixed to the robot as follows.

D

Label 1: says ”WARNING, disconnect supply before servicing”.

D

Label 2: says ”WARNING, high voltage capacitor inside disconnect

supply and wait 1 minute before servicing.

D

Label 3: says ”Don’t step on the robot”.

D

Label 4: says ”DANGER, connection of power supply”.

Caution label

(Controller)

[R--J2 i cabinet]

10

A. CAUTION LABELS

B--80687EN/03

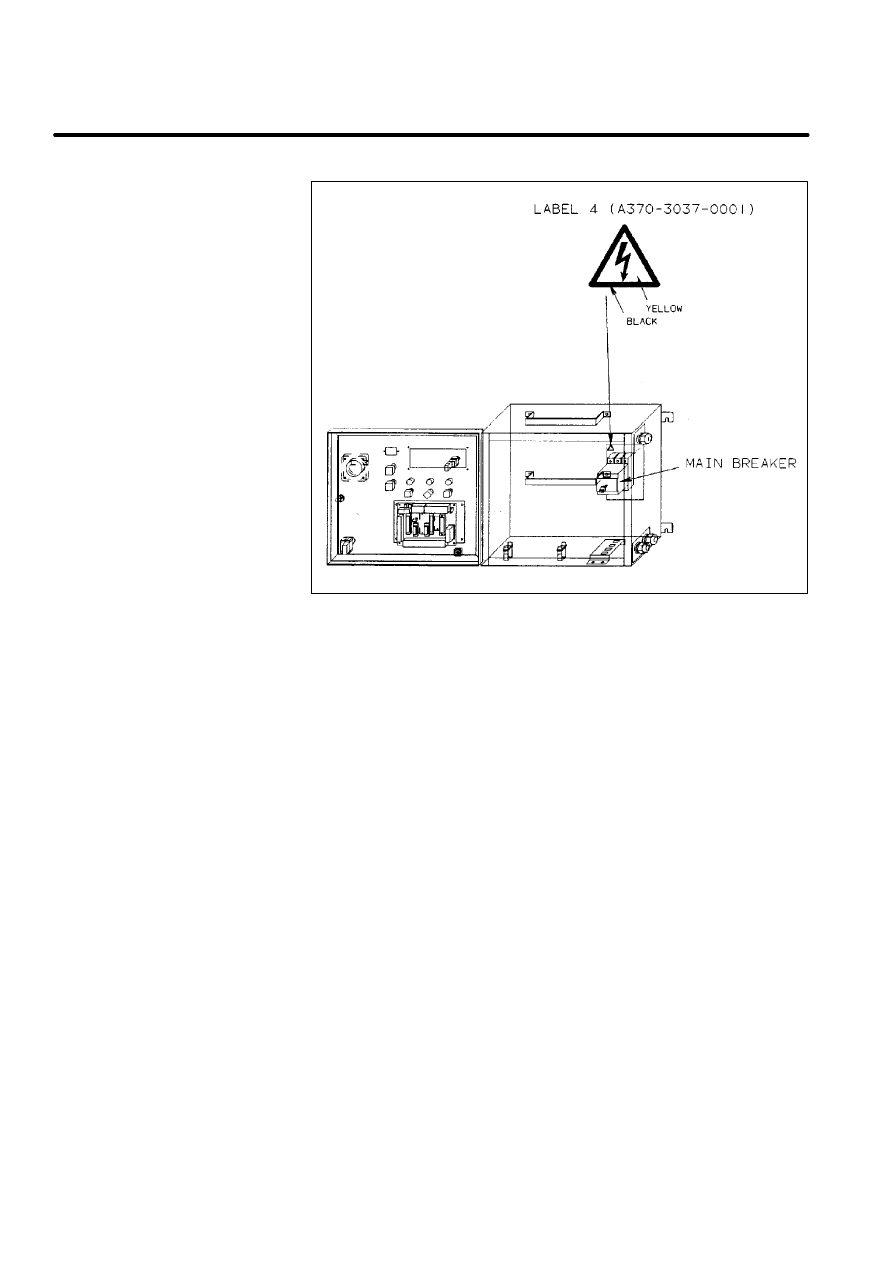

Caution label

(Operator’s box)

[R--J2 i cabinet]

B--80687EN/03

11

A. CAUTION LABELS

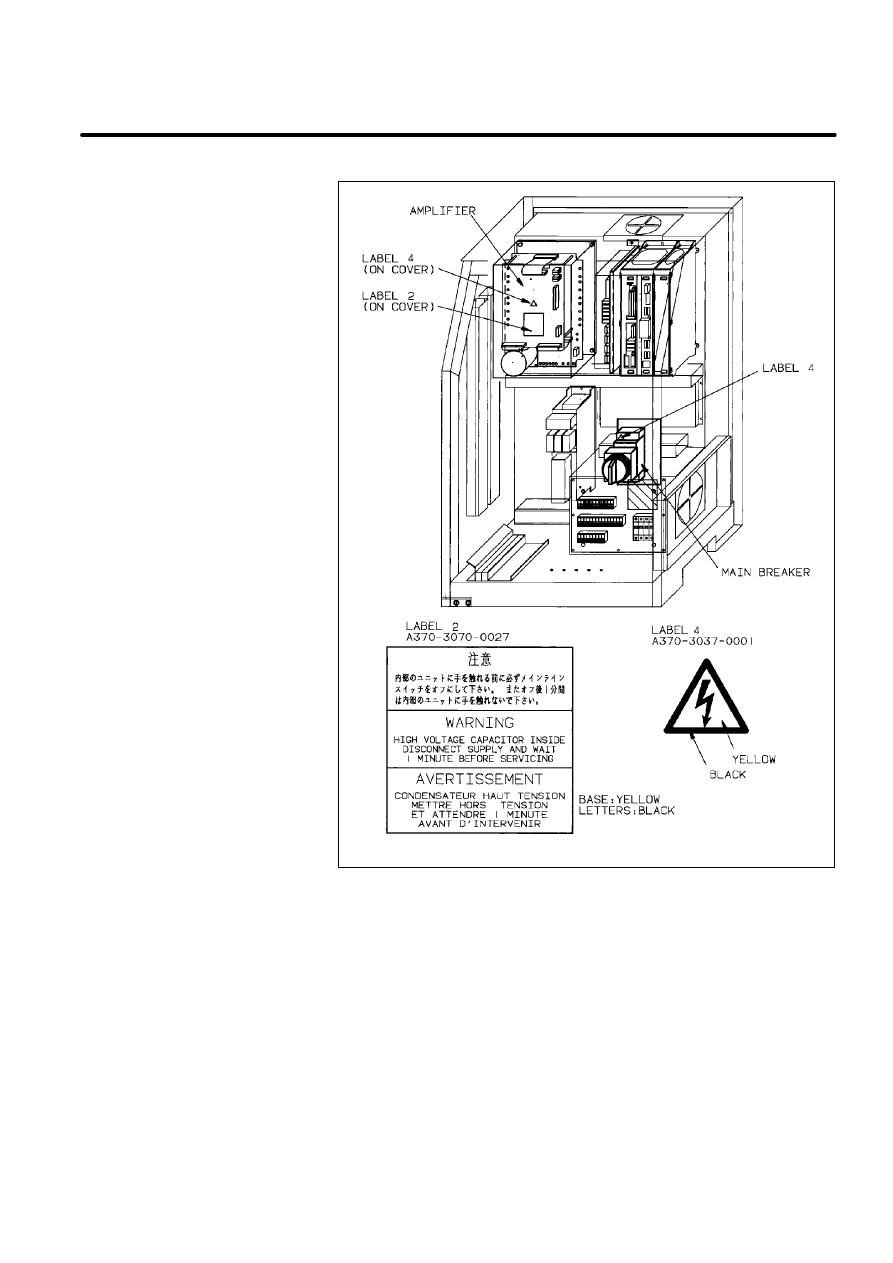

Caution label

(Controller)

[R--J2 B cabinet]

12

A. CAUTION LABELS

B--80687EN/03

D

Label 5: says ”CAUTION,

1. Turn main line switch off before handling parts in this unit.

2. For continued protection against fire hazard. Replace only with the

same type and rating of fuses.

Caution label

(Controller)

[R--J2 Mate]

B--80687EN/03

13

A. CAUTION LABELS

Caution label

(Controller)

[R--J2 for M--410i]

14

A. CAUTION LABELS

B--80687EN/03

Caution label

(Controller)

[R--J3 i--cabinet]

B--80687EN/03

15

A. CAUTION LABELS

Caution label

(Operation box)

[R--J3 i--cabinet]

16

A. CAUTION LABELS

B--80687EN/03

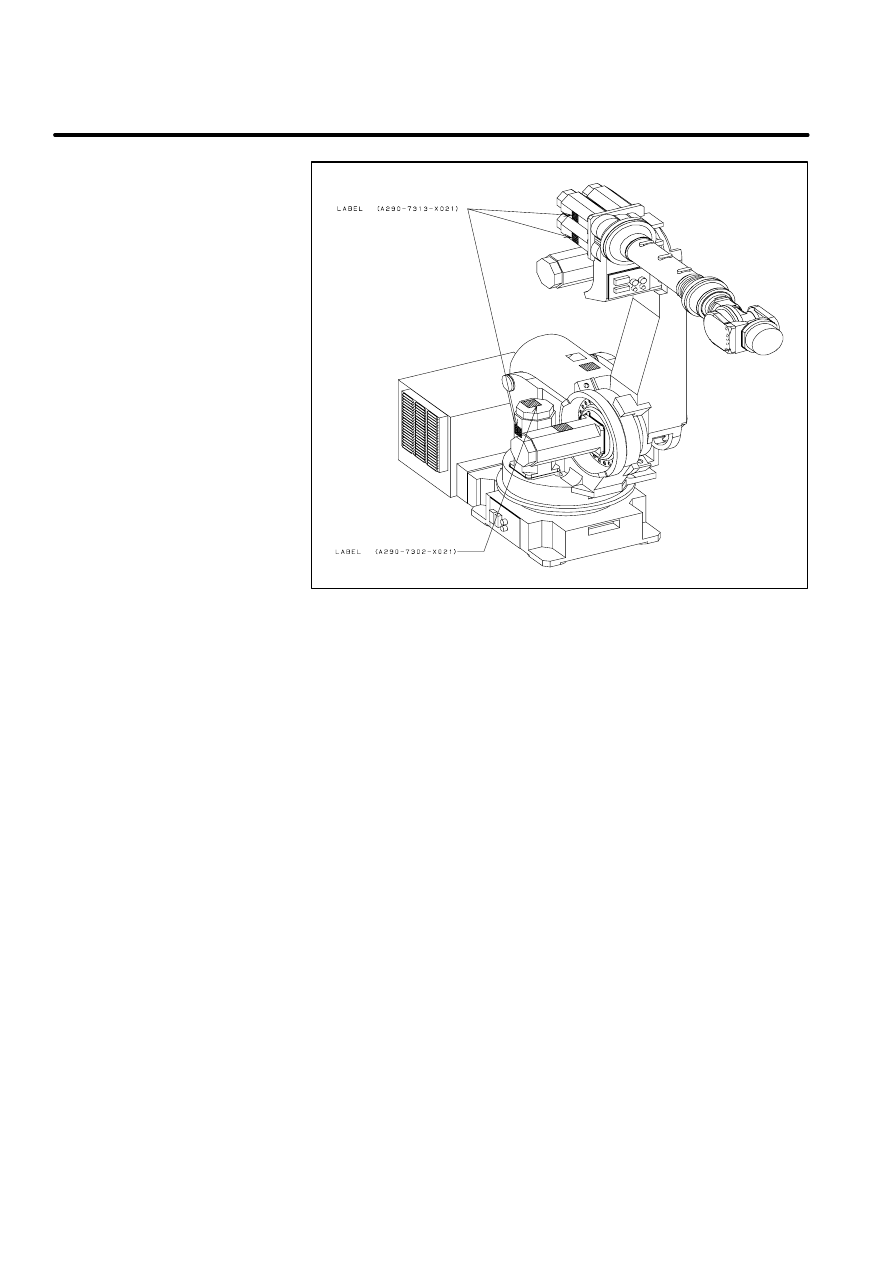

D

Label 6: says ”Don’t touch this heated surface”.

Caution label

(Mechanical unit)

[Example:S--420iF]

B--80687EN/03

17

A. CAUTION LABELS

8

7

6

3

Caution label

(Mechanical unit)

[Example:S--430iF]

18

A. CAUTION LABELS

B--80687EN/03

6

6

B

CONTACTS

19

B--80687EN/03

ADDRESS

PHONE

FANUC LTD

Oshino--mura, Yamanashi Prefecture

401--0597, Japan

TEL:81--555--84--5555

FAX:81--555--84--5512

FANUC Robotics N.A.

3900 West Hamlin Road,

Rechester Hills,

Michigan 48309--3253

Industrial

TEL:1--248--377--7582

FAX:1--248--377--7365

Automotive

TEL:1--248--377--7090

FAX:1--248--377--7365

Hot Line

(24hour service)

TEL:1--248--377--7159

FAX:1--248--377--7463

Training Department

TEL:1--248--377--7234

FAX:1--248--377--7367

FANUC Robotics West

15602 Mosher Avenue Tustin, California

92680

TEL:1--714--258--7075

FAX:1--714--258--7080

FANUC Robotics Central

2831 East Remper Road Cincinatti, Ohio

45241--4840

TEL:1--513--771--8844

FAX:1--513--771--5827

FANUC Robotics Ltd.

Canada

6395 Kestrel Road Mississauga, Ont. L5T

125 Canada

TEL:1--905--670--5755

FAX:1--905--670--4046

FANUC Robotics Mexico

Guadalupe I.Ramirez #715 Col. San Juan

Tepepan, Xochimilco Mexico D.F.

TEL:52--5--653--6506

FAX:same as above

20

B. CONTACTS

B--80687EN/03

PHONE

ADDRESS

FANUC Robotics Europe

S.A.

Zone Industrielle L--6468 Echternach,

Grand--Duche de Luxembourg

TEL:352--7277771

FAX:352--727777403

FANUC Robotics

Deutschland GmbH

Bernhauser Strasse 22, D--73765

Neuhausen, Germany

TEL:49--7158--187--250

FAX:49--7158--187--253

FANUC Robotics France

SARL

Z.I. du Bois--Chaland C.E. 2904--lisses

F--91029, Evry Cedex, France

TEL:33--1--69897000

FAX:33--1--69897001

FANUC Robotics UK Ltd.

Seven Stars Industrial Estate Wheler Road

GB--Coventry CV3 4LB, UK

TEL:44--203--639669

FAX:44--203--304333

FANUC Robotics Italia

s.r.l.

Vialle delle Industrie 12 I--20020

Arese(Mi), Italy

TEL:39--2--93581518

FAX:39--2--93581598

FANUC Robotics Iberica S.L.

Avda. de la Fama no.127 E--08940

Cornella, Spain

TEL:34--93--4743767

FAX:34--93--4744410

C

MANUFACTURER LABEL

21

B--80687EN/03

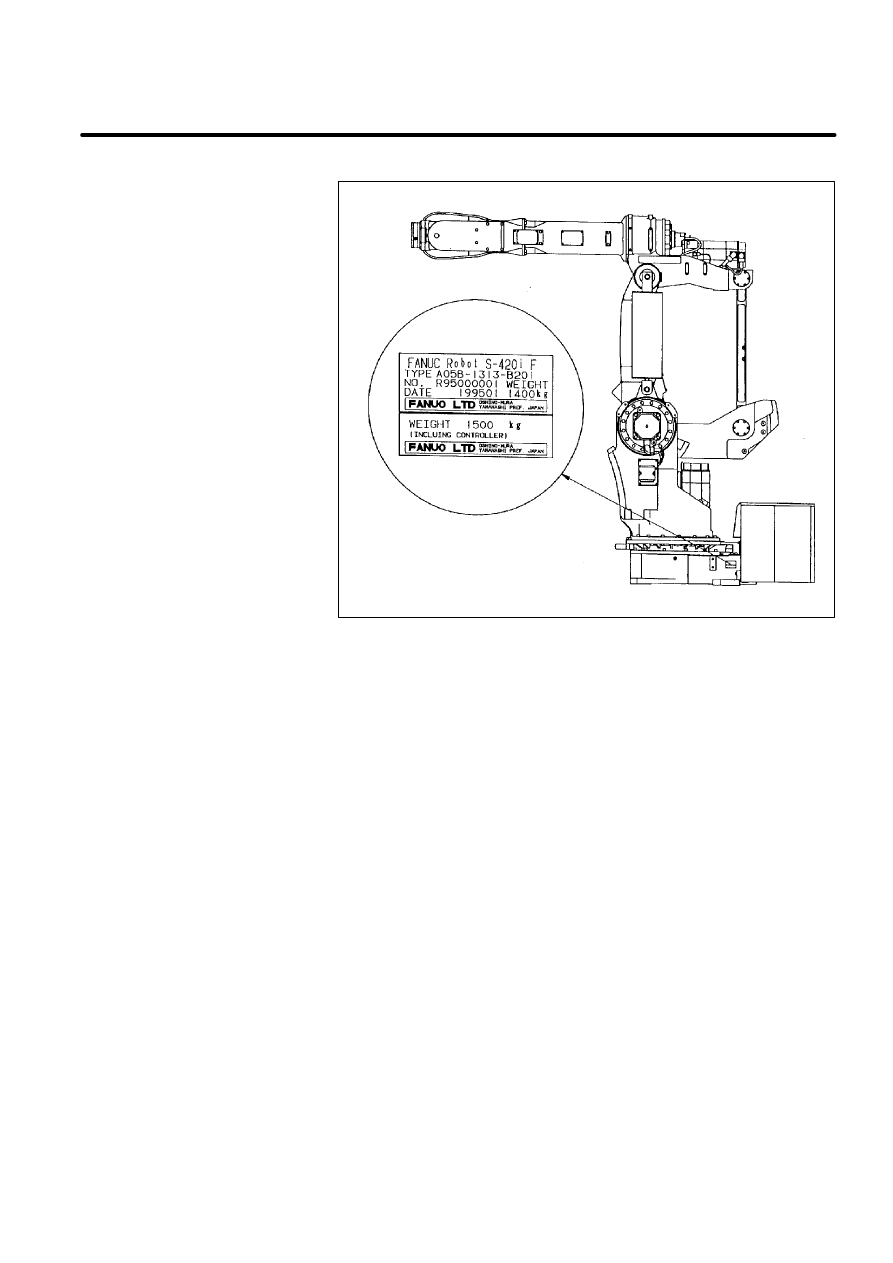

Manufacturer label

(Mechanical unit)

[Example:S--420iF]

22

C. MANUFACTURER LABEL

B--80687EN/03

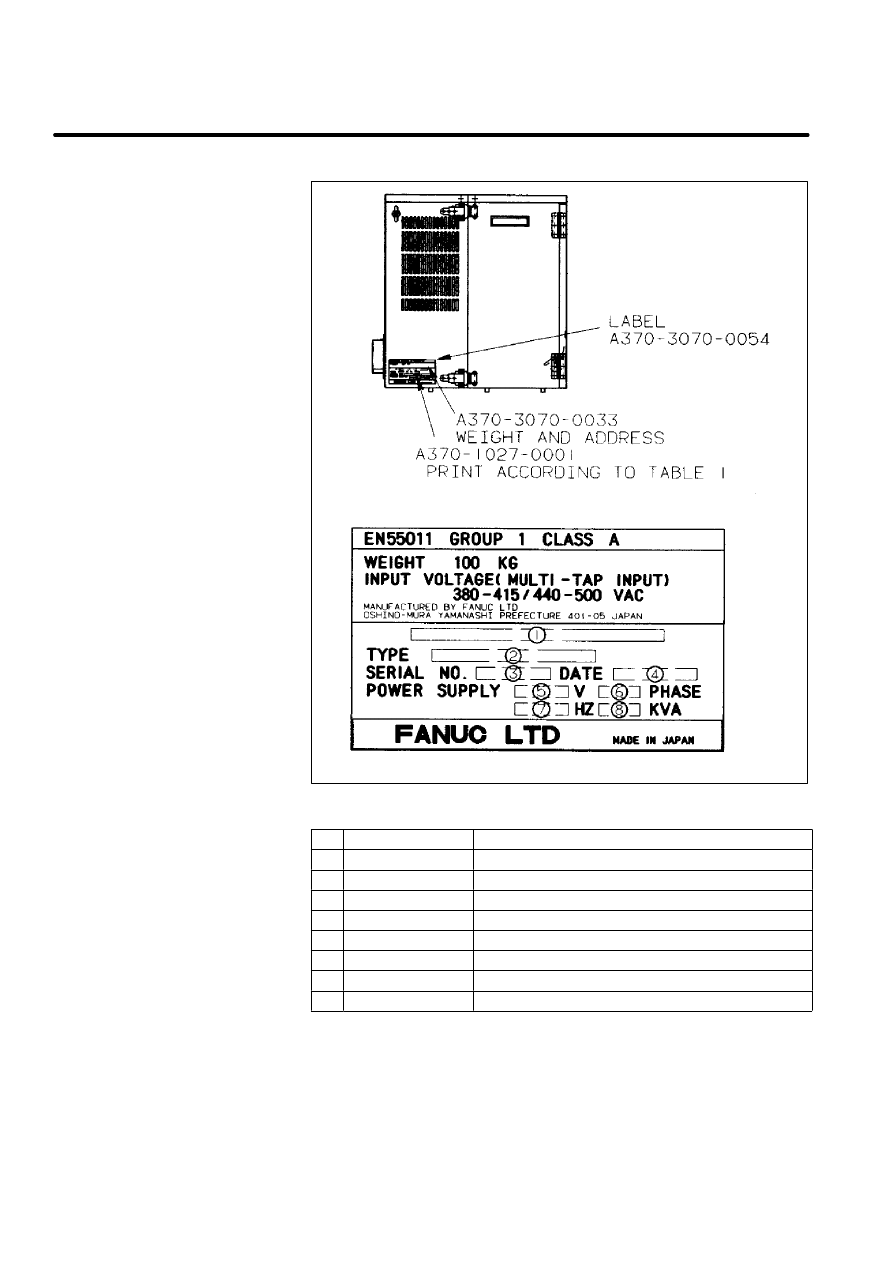

Table 1. Letters

No.

Contents

Letters

1

--

FANUC SYSTEM R--J2

2

TYPE

A05B--2350--B007

3

SERIAL NO.

Print serial No.

4

DATE

Print production year and month

5

V

Ordered voltage

6

PHASE

3

7

HZ

50/60

8

KVA

12

Manufacturer label

(R--J2 controller i cabinet)

[Example:For S--420iF

integrate type]

B--80687EN/03

23

C. MANUFACTURER LABEL

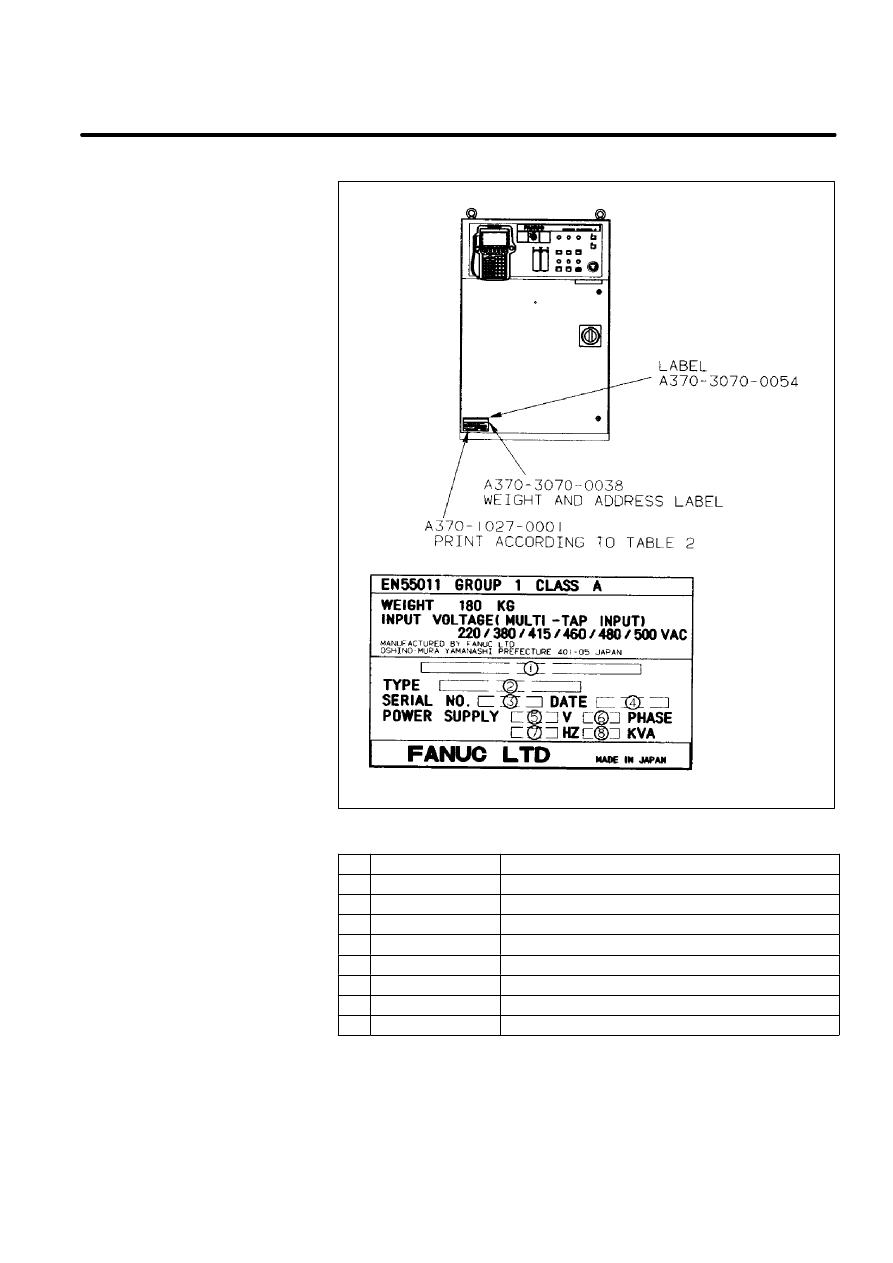

Table 2. Letters

No.

Contents

Letters

1

--

FANUC SYSTEM R--J2

2

TYPE

A05B--2351--B006

3

SERIAL NO.

Print serial No.

4

DATE

Print production year and month

5

V

Ordered voltage

6

PHASE

3

7

HZ

50/60

8

KVA

12

Manufacturer label

(R--J2 controller B cabinet)

[Example:For S--420iF]

24

C. MANUFACTURER LABEL

B--80687EN/03

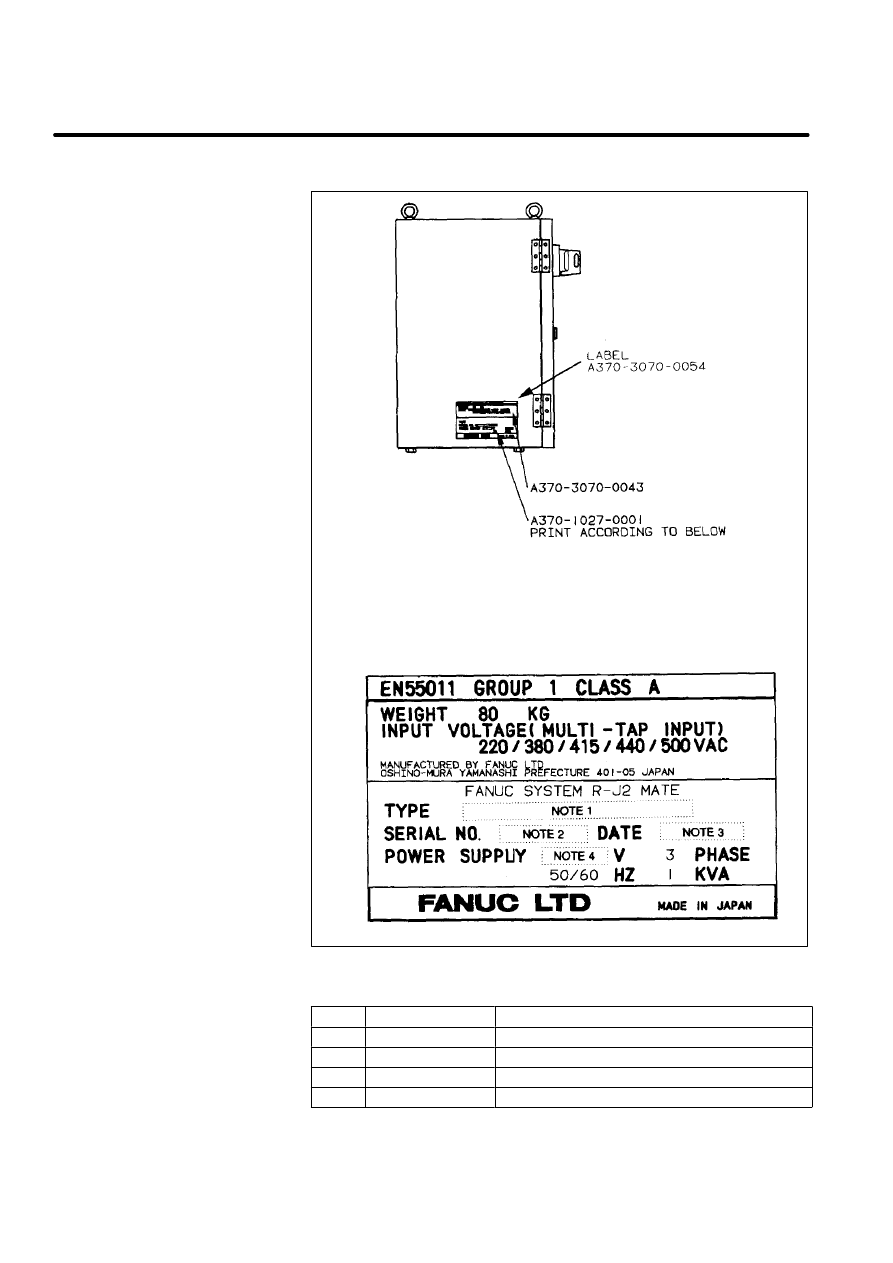

Table 3. Letters

Note

Contents

Letters

1

TYPE

A05B--2330--B012

2

SERIAL NO.

Print serial No.

3

DATE

Print production year and month

4

V

Ordered voltage

Manufacturer label

(R--J2 Mate controller)

[Example:

For LR Mate 100i]

B--80687EN/03

25

C. MANUFACTURER LABEL

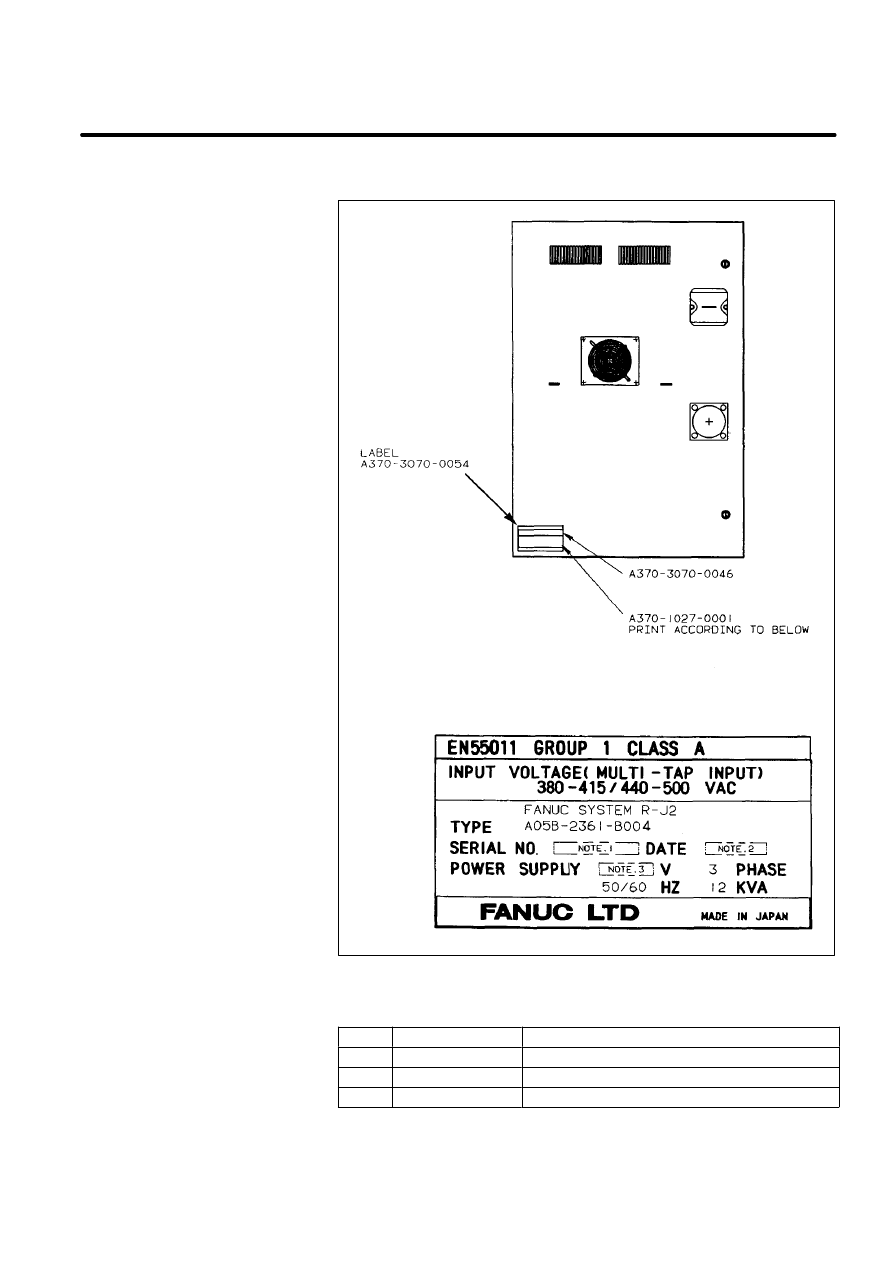

Table 4. Letters

Note

Contents

Letters

1

SERIAL NO.

Print serial No.

2

DATE

Print production year and month

3

V

Ordered voltage

Manufacturer label

(Mechanical unit)

[Example:S--420iF]

26

C. MANUFACTURER LABEL

B--80687EN/03

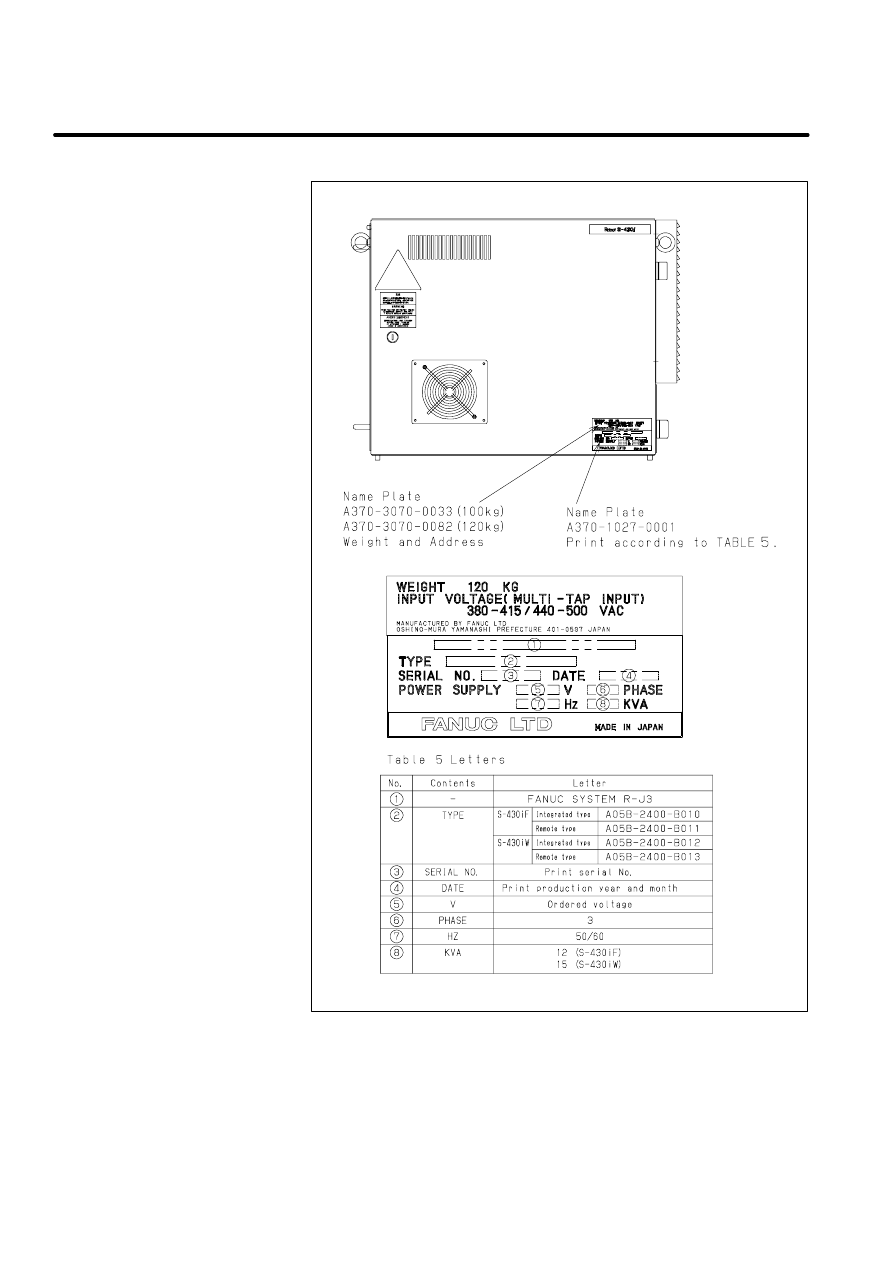

Manufacturer label

(R--J3 controller i cabinet)

[Example:for S--430i]

Revi

si

o

n

Reco

rd

FANUC

R

obot

S

A

FE

TY

HANDBO

O

K

(B

--80687E

N)

03

Aug.

,’

98

Addi

tion

of

R-

-J

3

i--

cabi

net

.

02

Jul

.,

’96

Addi

tional

descr

ip

tions

of

B-

-c

abi

net

.

01

Feb.

,’

95

E

ditio

n

Dat

e

Cont

ent

s

E

ditio

n

Dat

e

Cont

ent

s

Index

B--80687EN/03

i--1

≪A≫

After automatic operation, 33

Automatic operation, 30

≪B≫

Before powering on, 33

≪C≫

Commissioning and functional testing, 27

Configuration of robot system, 5

Control unit, 34

≪D≫

Daily maintenance, 33

Deadman switch, 20

Designation of the restricted space, 27

During programming, 29

≪E≫

Emergency stop, 17

End effector, workpiece and peripheral equipment, 14

≪F≫

FANUC robot system, 3

≪G≫

General cautions, 27

General precautions, 1

≪I≫

Installation, 27

≪M≫

Maintenance, 31

Mechanical unit, 33

Mode select switch, 17

≪O≫

Operating modes, 20

Other cautions, 32

Other precautions, 11

Other protection devices, 22

≪P≫

Placement of equipment, 9

Power supply and protective earth connection, 11

Prior to programming, 29

Program verification, 30

Programming, 29

Purpose of robot, 3

≪R≫

Restriction of personnel, 28

Returning to automatic operation, 29

Robot stop variation, 25

Robot system design, 9

Robot system restart procedures, 28

Robot training, 7

≪S≫

Safeguards, 21

Safety and operational verification, 28

Safety devices, 17

Safety fence, 21

Safety gate and plugs, 21

Saving programmed data, 30

≪T≫

The safety sequence for fence entry, 23

Trouble shooting, 30

≪W≫

Working person, 6

July., 1996

FANUC LTD

Printed in Japan

Document Outline

- SAFETY HANDBOOK

- Table of Contents

- 1 GENERAL CAUTIONS

- 2 ROBOT SYSTEM DESIGN

- 3 SAFETY DEVICES

- 4 DAILY MAINTENANCE

- 5 FANUC ROBOT SYSTEM

- A CAUTION LABELS

- B CONTACTS

- C MANUFACTURER LABEL

- Index

Wyszukiwarka

Podobne podstrony:

Safety Handbook [B 80687EN 09]

03 E83 Safety Systems

03 safety chain solution Safe Stop0

03 Aramaic (Beyond Babel A Handbook of Biblical Hebrew and Related Languages)

03 Sejsmika04 plytkieid 4624 ppt

03 Odświeżanie pamięci DRAMid 4244 ppt

podrecznik 2 18 03 05

od Elwiry, prawo gospodarcze 03

Probl inter i kard 06'03

TT Sem III 14 03

03 skąd Państwo ma pieniądze podatki zus nfzid 4477 ppt

03 PODSTAWY GENETYKI

Wyklad 2 TM 07 03 09

03 RYTMY BIOLOGICZNE CZŁOWIEKAid 4197 ppt

więcej podobnych podstron