43

Drying of Coal

Jerzy Pikon´ and Arun S. Mujumdar

CONTENTS

43.10 Mechanical Thermal Expression Process.......................................................................................... 1014

43.11 Conclusion ........................................................................................................................................ 1014

Nomenclature ............................................................................................................................................... 1015

Bibliography ................................................................................................................................................. 1016

43.1 INTRODUCTION

Coal drying is of much theoretical and economic

importance. Coal is a valuable fuel and raw material

for many chemical synthesis processes that are

becoming more and more important considering the

increasing price of crude oil. Drying of coal is carried

out to increase its calorific value and facilitate its

transport. Wet coal is difficult to load or unload

from railway cars owing to freezing, which is a

problem in colder climates. The presence of moisture

causes a reduction in friability of coal, makes it

difficult to control blending operations, worsens the

quality of grinding (if coal is ground), and impedes

separation and classification as well as the pneumatic

transport of pulverized coal. Friable coal suitable for

combustion in modern steam boilers is obtained only

when the moist coal is dried. Coal must also be dried

for the following processes: (a) briquetting; (b) cok-

ing; (c) gasification; (d) low-temperature carboniza-

tion; (e) liquid fuel synthesis, and others. The final

moisture content requirement of coal is different

depending on the process in which it is used. The

following is a summary of approximate ranges of

moisture content of coal required for various

processes.

ß

2006 by Taylor & Francis Group, LLC.

Hard coal:

.

Coking processes (based on the ramming

method), 8 to 12%

.

Coking processes (based on the charring

method), <8%

.

Briquetting processes, <4%

.

Low-temperature carbonization process, ~0%

.

Hydrogenation process, ~0%

.

Coal combustion process in the pulverized fuel-

fired furnace, <2%

.

Brown coal:Briquetting process, 8 to 18%

.

Gasification process, 5 to 15%

.

Low-temperature carbonization process, <15%

.

Hydrogenation process, ~0%

.

Coal combustion process in the pulverized fuel-

fired furnace, 12 to 15%

Coal drying and preheating are of particular import-

ance in coke production because at a relatively small

investment cost (for the installation of dryers) it is

possible to increase the production capacity of the

coke ovens by about 30 to 50% in preheating and

about 10 to 15% in drying. The preheating of coal in

dryers makes it possible to utilize in the mixture a

greater proportion of gas coals, which give coke char-

acterized by better mechanical strength, very low

grainability, and homogeneous graining. The mois-

ture content is very important in determining the

usability of coal for further technological processing.

In coal, the moisture may be present in the form of

surface or hygroscopic moisture. Surface moisture is

not dependent on the coal type because it depends on

the classification and washing processes performed in

the coal mine and on the soaking process during

transport and storage. The evaporation of surface

moisture takes place in the first drying period at a

constant drying rate.

Hygroscopic moisture depends on the rank of

coal; it decreases with the age of coal. The evapor-

ation of hygroscopic moisture takes place in the sec-

ond drying period at a falling drying rate.

43.2 TYPICAL DESIGNS OF DRYERS USED

FOR COAL DRYING

Both direct and indirect dryers are in use for coal

drying. Combustion gases or steam may be used as

the heating medium. Steam-heated dryers (e.g., drum,

tray, and tube dryers) are used mainly for drying of

brown coals in the coal briquetting process. Fre-

quently, coal drying is carried out in convection

dryers, e.g.,

.

Rotary dryers

.

Pneumatic dryers

.

Fluid-bed dryers with spouted bed

.

Vibratory fluid-bed dryers

.

Shaft dryers

.

Mill-type dryers

43.2.1 R

OTARY

D

RYERS

In many industrial plants, rotary dryers are used for

the drying of coal and coal muds. Generally these

dryers operate in the cocurrent mode to avoid the

possibility of ignition. The drying medium is hot air

or combustion gases derived from natural gas or coal

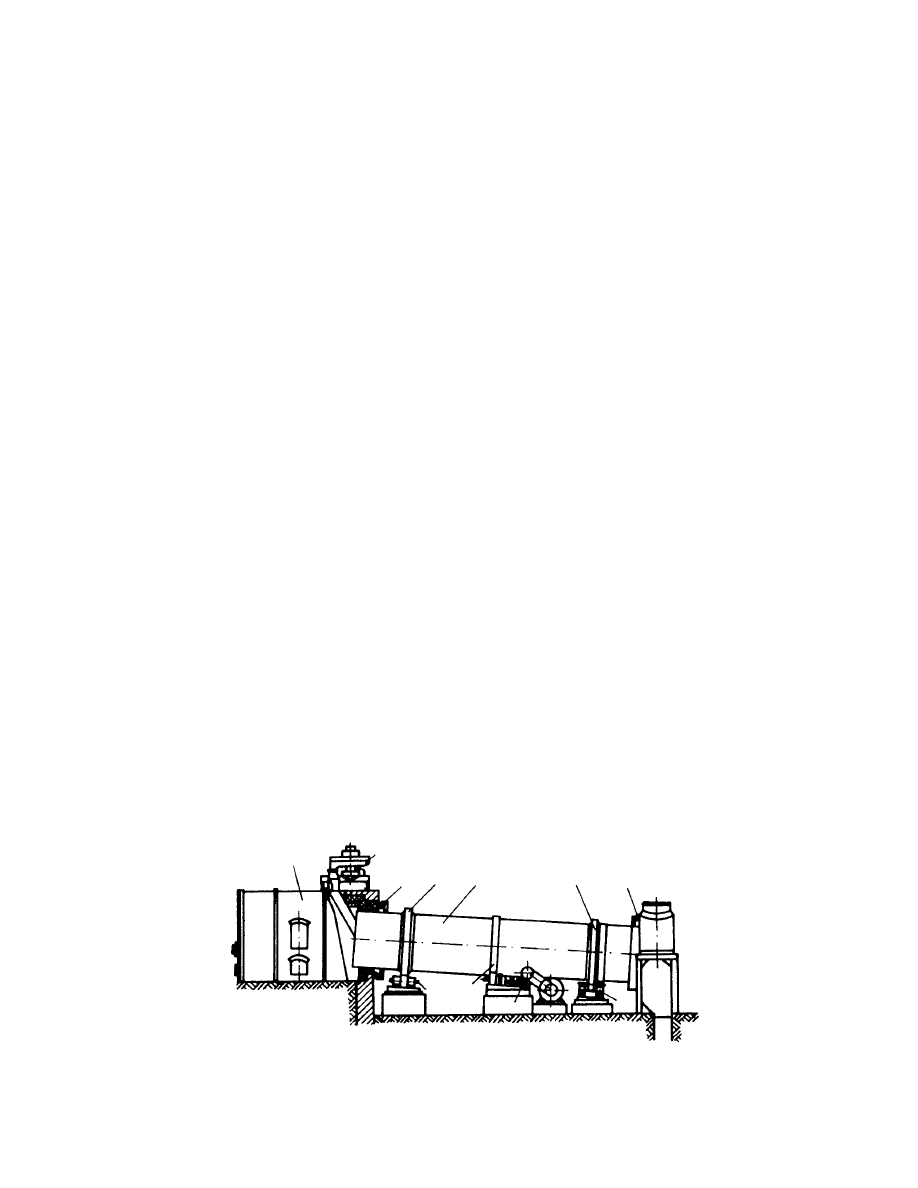

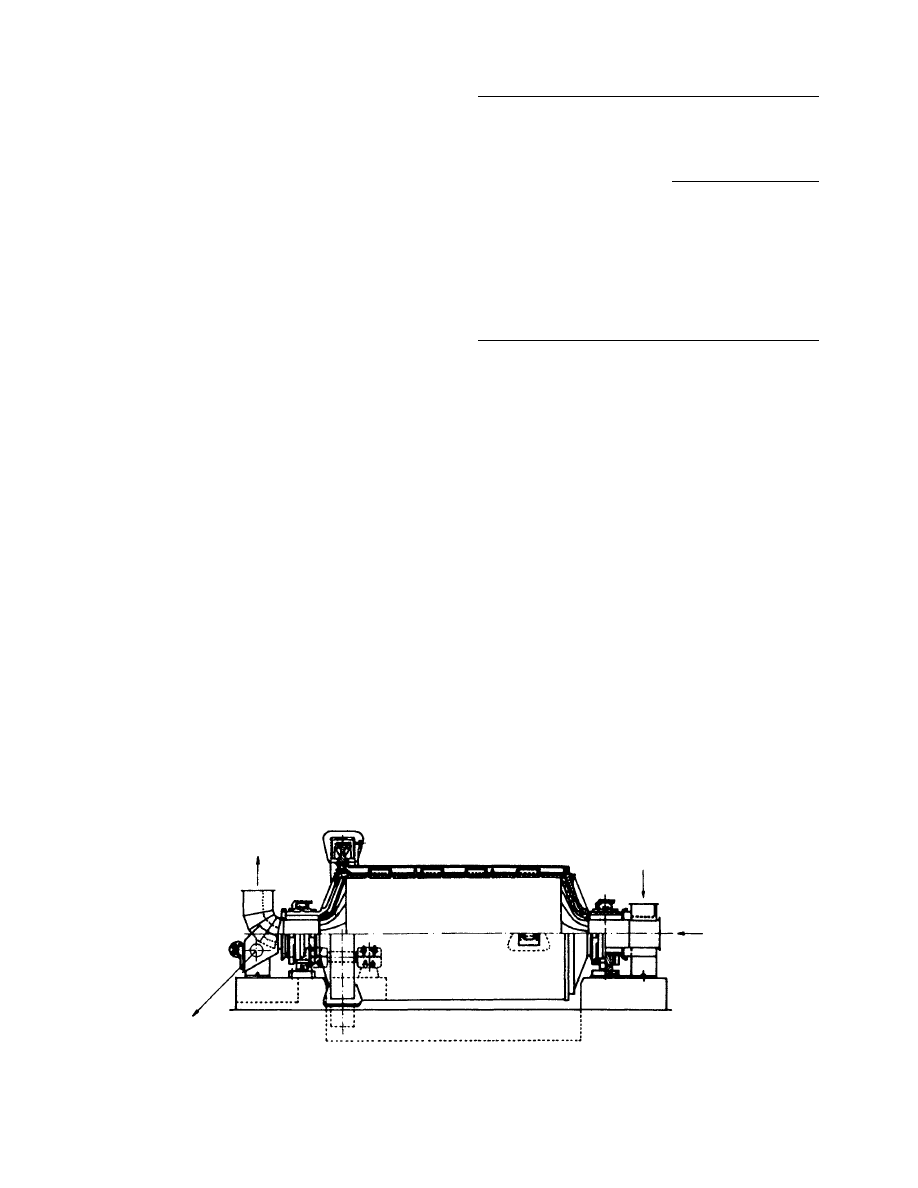

combustion. A typical rotary dryer is shown schemat-

ically in Figure 43.1. The main component of this

dryer is the steel shell (3) lined with a refractory lining

and set up on rollers (7) by means of bandages

(hoops, 10) located on the shell. The shell is rotated

typically using a toothed gear (5). The shell is set up

obliquely with a slope of 2 to 58 to the horizontal.

Inside the shell, there are lifters fastened to the inner

surface of the drum. During operation, these lifters

lift the coal granules and shower them gradually in-

side the shell in the stream of the flowing heating gas.

Various lifter s are shown in

.

1

2

9

10

3

10

9

8

5

6

7

4

FIGURE 43.1 Schematic of a rotary dryer.

ß

2006 by Taylor & Francis Group, LLC.

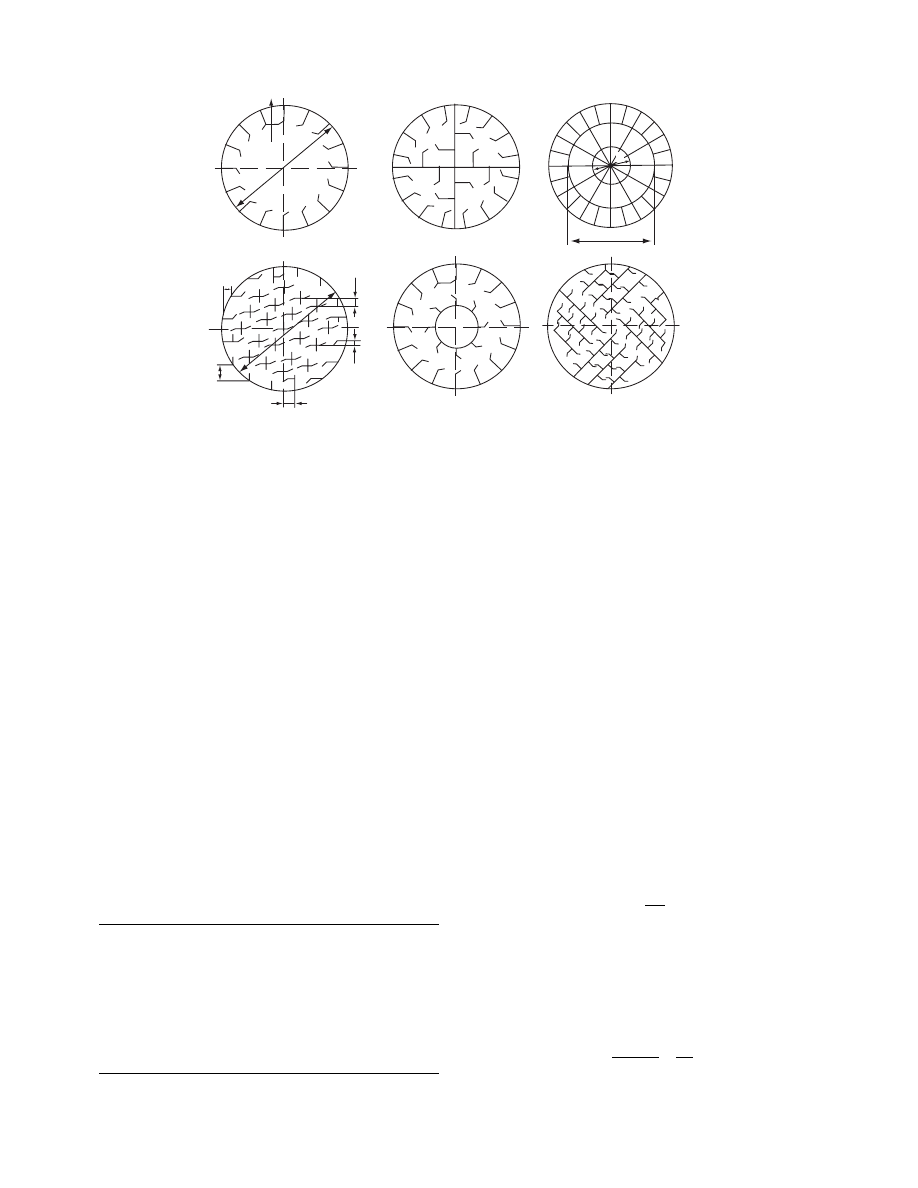

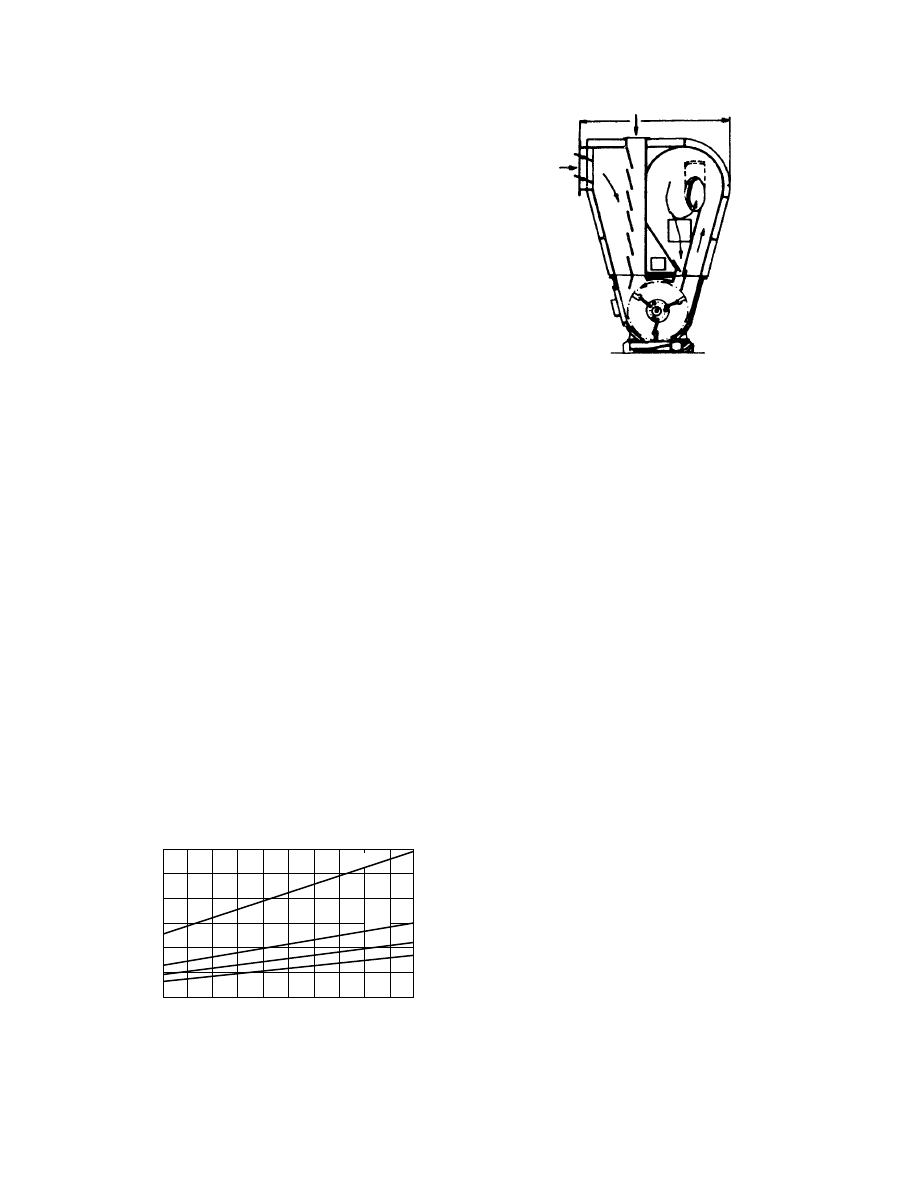

For drying of big lumps of coal that stick to the

shell wal l, type a devices may be used . For lumpy

coals of low friab ility, type b devices may be us ed.

For fine r coal granule s of high fria bility, the lifting–

mixing devices are made in the form of separat e cell s

(type f ). For superfine coals (dust ), a system of c losed

cells (type c ) is used. The en ds of the dryer shell are

sealed labyri nthinel y to the inlet and outlet head s.

The co mbustion g ases leavi ng the dryer carry co al

dust, whi ch may be up to 15% of the co al fed to the

dryer. Hence the dryer exhaust is direct ed to cyclon es

or elect rostatic precipi tators to separat e the entrained

dust. The final loss of coal doe s not exce ed 0.5 to

1.5%, de pending on the type of equipment used for

cleanin g the combu stion ga ses. Typica l rotar y dru m

dryers for coal drying are in the follo wing sizes:

(a) Shell diame ter, 1.5 to 3.5 m

(b) She ll length, 12 to 30 m or mo re

The drive mo tor power requir ed depend s on the

dryer diame ter, its lengt h and rotat ing speed, and

holdup weight, and is as follows:

D (m)

L (m)

Motor Power (kW)

1.5

8

8

1.8

12

14

2.2

12–14

17–20

2.8

12–14

28–35

3.2

18

75

3.5

27

120

Typical operating parameters for rotary dryers

used for coa l drying are given in

.

The heat consumption in such dryers amounts to

about 3700 kJ/kg H

2

O. The drying time is about 15 to 40

min at a holdup fraction of 0.15 to 0.25. The gas velocity

at the dryer outlet should not be more than 2 to 3 m/s for

the drying of fine coals derived from washing and not

more than 0.5 to 1 m/s for the postflotation concentrates

to avoid excessive carryover of coal. The dimensions of

the rotary dryer are determined based on the drying rate

per unit volume, which is given in Table 43.1.

Generally, one cannot know the suitable drying

rate per unit volume because it varies with the dryer

diameter, the flow rate, the temperature of the drying

medium, and the rotation speed of the shell. One has

to calculate dryer volume based on the heat transfer

coefficient.

Knowing the drying rate per unit volume

(amount—kilograms—of moisture evaporated in

time unit from 1 m

3

of shell volume), one can calculate

the volume of dryer shell V

b

from the formula

V

b

¼

W

N

V

(43:1)

From the volumetric flow rate of the drying medium

V

g

, assumed fractional holdup b (0.05 to 0.3), and the

velocity of drying medium in the drum u, one can

calculate the diameter of the dryer as

D

¼

1:13

ffiffiffiffiffiffiffiffiffiffiffiffi

1

b

p

ffiffiffiffiffiffi

_

V

V

g

u

s

(43:2)

0

d

1

d

2

d

2

= 0.45D

d

1

= 0.22D

z = 24

a = 0.4D

b = 0.10

c = 0.06D

L

1

= 0.15

D

L

2

= 0.1

D

a

L

1

L

2

c

b

D

(d)

(e)

(f)

(a)

(b)

(c)

L = 0.11D

z = 16

z = Number of plates

FIGURE 43.2 Scheme of the lifting–mixing devices for rotary dryers.

ß

2006 by Taylor & Francis Group, LLC.

The length of the dryer is calcul ated from the form ula

L

¼

V

b

0:785D

2

(43 : 3)

The length –diam eter ratio L /D is us ually in the range

of 5 to 10. The speed of rotat ion of the shell n depend s

on the lengt h L, diame ter D , angle of incli nation of

shell a, and the drying time t. It is determined by the

empirical formula

n

¼

k

1

k

2

L

Dtg a

(43 : 4)

where k

1

¼ coeffici ent charact erizing the motion of

material in the drum. For co current dryers used for

coal drying, k

1

¼ 0.2 to 0.7; k

2

¼ coeffici ent taking

into accou nt the type of distribut ing or mixing device.

For lifting devices, k

2

¼ 0.5; for the cell and section al

devices , k

2

¼ 1.0

In practi ce, the peripher al speed of rotation is

usually 15 to 25 m/min. The dwelli ng tim e of coal in

the dryer t is very impor tant in the drying of coking

coals. Excessi ve dr ying time can worsen the agglom -

erating pro perty of the coal. The drying tim e of co al

can be determined from the form ula

¼

2z

u

b

N

v

X

1

X

2

2

(X

1

X

2

)

(43 : 5)

43.2.2 R

OTARY

-T

UBE

D

RYER

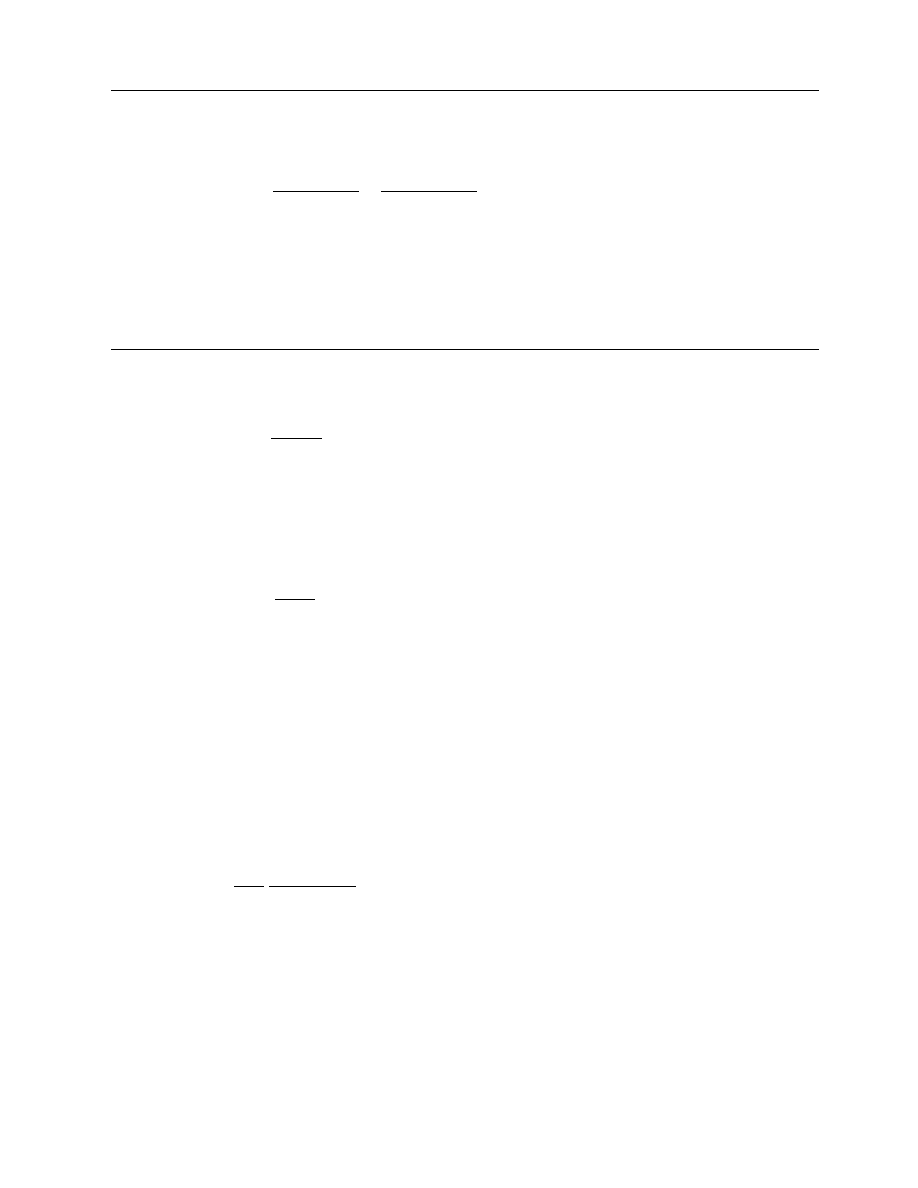

The rotar y-tube dryers are used widely for coal dry ing

in brown co al briquetting plants . They are also used

for drying of hard co als. Thes e dryers are indire ct

dryers he ated by satur ated steam at pressur es of

0.15 to 0.55 MPa . This dryer (

) consis ts

of a slopin g drum (1), in which the pe rforated walls

have seaml ess tubes fasten ed to them (2) at diame ters

of about 102 to 108 mm. The dryer shell roll s

on specia l rings (6) an d rollers (7) and is driven

by power trans mitted (8) by mean s of a gear wheel

(9). The heatin g steam enters the drum throu gh the

pin (3). The mois t coal is fed insid e the heati ng tubes.

As a consequen ce of the slope and rotation, the co al

is displaced gradual ly toward the heati ng tubes

from the inlet to the outlet. In the he ating tubes are

install ed screw guides, which con trol the displ acement

of co al. The varia ble-pitch guides install ed in tube s

prevent the displ acement of co al in tubes very fast .

The dr ied coal is co llected in the low er part of the

chamber (5). The steam c ondensate is drained

through a pin placed in the low er en d of the drum.

In this type of dryer, the convecti ve he at trans fer

coeffici ent from steam to coal is about 25 W/m

2

K.

Some techn ical da ta for the drum- tube dryers are

as foll ows:

.

Diameter D

¼ 2500, 2800, 3130, 3350, 3750, and

4000 mm

.

Drum lengt h L

¼ 7 to 8 m

.

Angle of inclinati on of dr um a

ffi 88

.

Speed of rotation n

¼ 5 to 9 rpm

.

Drying rate per unit expo sed su rface N

F

¼ 5.4 to

8 kg/m

2

h

.

Temperat ure of vap or, 90 8 C

.

Coal tempe rature at outlet, 80 8 C

.

Heat con sumption , 2950 to 310 0 kJ/kg H

2

O

.

Dust co ntent in va por in drying of brown coal,

~25 g/m

3

In brown coal briquet ting plants , these dry ers are

heated by exhau st steam from the briquet ting ma-

chines. The steam carrie s away oil drop lets, which are

carbonized, forming deposits on the tube walls. To

remove impurities from the dryer tubes, these tubes

may be washed by circulation of trichloroethylene at

TABLE 43.1

Operating Parameters for Rotary Dryers Used for Coal Drying

Coal Type

Coal Moisture

(%)

Heating Medium

Temperature (

˚

C)

System of

Mixing Devices

Drying Rate per Unit Volume,

N

v

(kg/m

3

h)

Before

Dryer

After

Dryer

Before

Dryer

After

Dryer

Hard coal

9

0.6

900

60

Figure 43.2, type a

35–40

Fine coal mixed with

postflotation concentrate

17

5

740

110

Figure 43.2, types a, b

93

Postflotation concentrate

22

5

770

105

Figure 43.2, types a, b

116

High-ash mud, grain

size 0–2 mm

30

1

750

120

Figure 43.2,

types b, d, e, f

120

ß

2006 by Taylor & Francis Group, LLC.

70 to 808C for about 3 h. The spent trichloroethylene is

distilled for reuse.

43.2.3 C

HAMBER

D

RYER

E

QUIPPED WITH

S

TIRRERS

Chamber dryers equipped with stirrers are commonly

used for drying of flotation concentrates (Figure

43.4). The dryer operates in a cocurrent mode. Hot

combustion gases supplied to the dryer by a duct (5)

meet at the outlet the cold and moist coal supplied by

another duct (7). The dryer consists of a chamber (1)

fitted with baffles (9) and two shafts (2) rotating in

opposite directions on which paddles are mounted

(3,4). The moist coal supplied by a duct (7) is lifted

and thrown by stirrers (3,4) from the inlet to the

outlet (8). The stirrer paddles (3,4) are also useful

for breaking sintered coal. Some technical data are

as follows:

.

Combustion gas temperature at inlet, 7008C

.

Combustion gas temperature at outlet, 1108C

.

Chamber width, 2000 to 2400 mm

.

Chamber length, 2000 to 3400 mm

.

Drying rate per unit volume, N

v

¼ 600 to 750 kg

H

2

O/m

3

h

.

Coal moisture content at inlet, 18 to 22%

.

Coal moisture content at outlet, 8.5%

.

Heat consumption, ~3150 kJ/kg H

2

O

.

Speed of rotation of shaft, 7 to 10 rpm

For pasty feeds, which tend to cake during drying,

chains are fastened to the paddles to break the cakes

formed during drying.

43.2.4 P

NEUMATIC

D

RYERS

Pneumatic dryers are widely used for drying coal and

flotation concentrates. The basic element of the dryer

is a vertical tube of diameter 650 to 1100 mm and

length 14 to 35 m through which the hot drying

medium (e.g., combustion gases or air) flows from

bottom to the top. The coal being dried is lifted by

the stream of drying gases and transported from

Inlet of coal

Outlet of vapors

6

1

Inlet of steam

3

8

9

7

4

Outlet of coal

5

Outlet of

condensate

2

FIGURE 43.3 Drum-tube dryer.

7

5

1

9

2

3

4

8

6

FIGURE 43.4 Chamber dryer equipped with stirrers.

ß

2006 by Taylor & Francis Group, LLC.

bottom to top. Duri ng pneumat ic transpo rt, the co al

grains are heated a nd dried. Thus , the drying gas

velocity dep ends on the grain size of coal being

dried; in practi ce this amoun ts to 10 to 40 m/s . In a

commer cial dryer, the disi ntegra tor con nected to the

vertical drying tube at the bot tom is installed , which

serves to cru sh and dry mois t lump coal from the

feedin g chute. Dryi ng hot gas enters the disi ntegra tor

and meet s the moist coal. The mois t coal is highly

disturb ed and mixed with hot gas, and drying is

strong ly ac celerated. Genera lly, abo ut 5 0% of the

water to be dried is remove d from the coal in the

disintegra tor. The most intens ive drying oc curs in

the first 2 to 3 m of the dryer. The drying pro cess is

conditi oned by the heati ng medium veloci ty in rela-

tion to the grain size of coal. This velocity increa ses

with grain size, as shown in Figu re 43.5. Thi s is ve ry

impor tant becau se co arser grains reside a longer time

in the he ating medium . The large surface of contact of

the grains with the heatin g medium allows rapid dry-

ing, whi ch for finely ground c oals is of the or der of a

few seco nds. The short drying time relate s only to the

first drying period, i.e., to the evaporat ion of surface

moisture. The heating medium pa rameters ha ve a

decisive effect on this period. The pressure drop char-

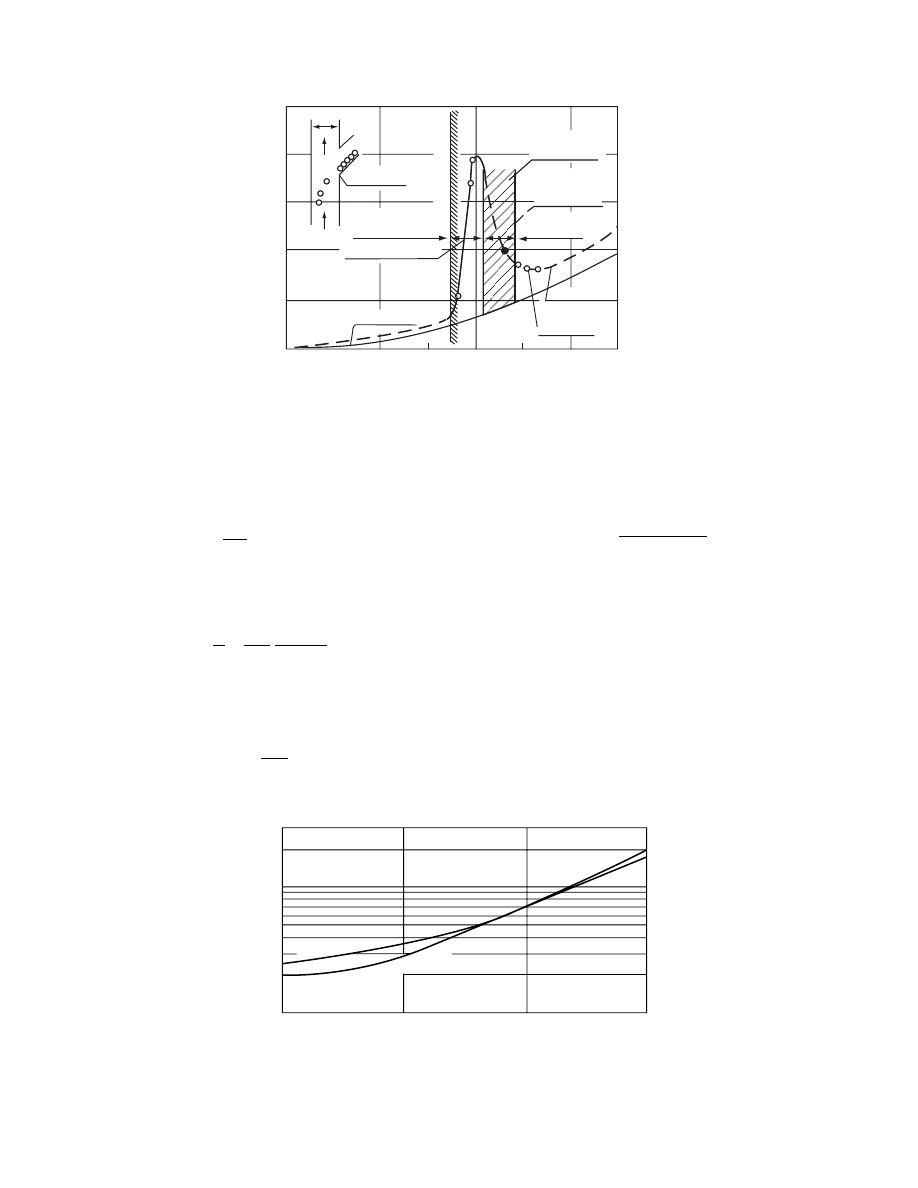

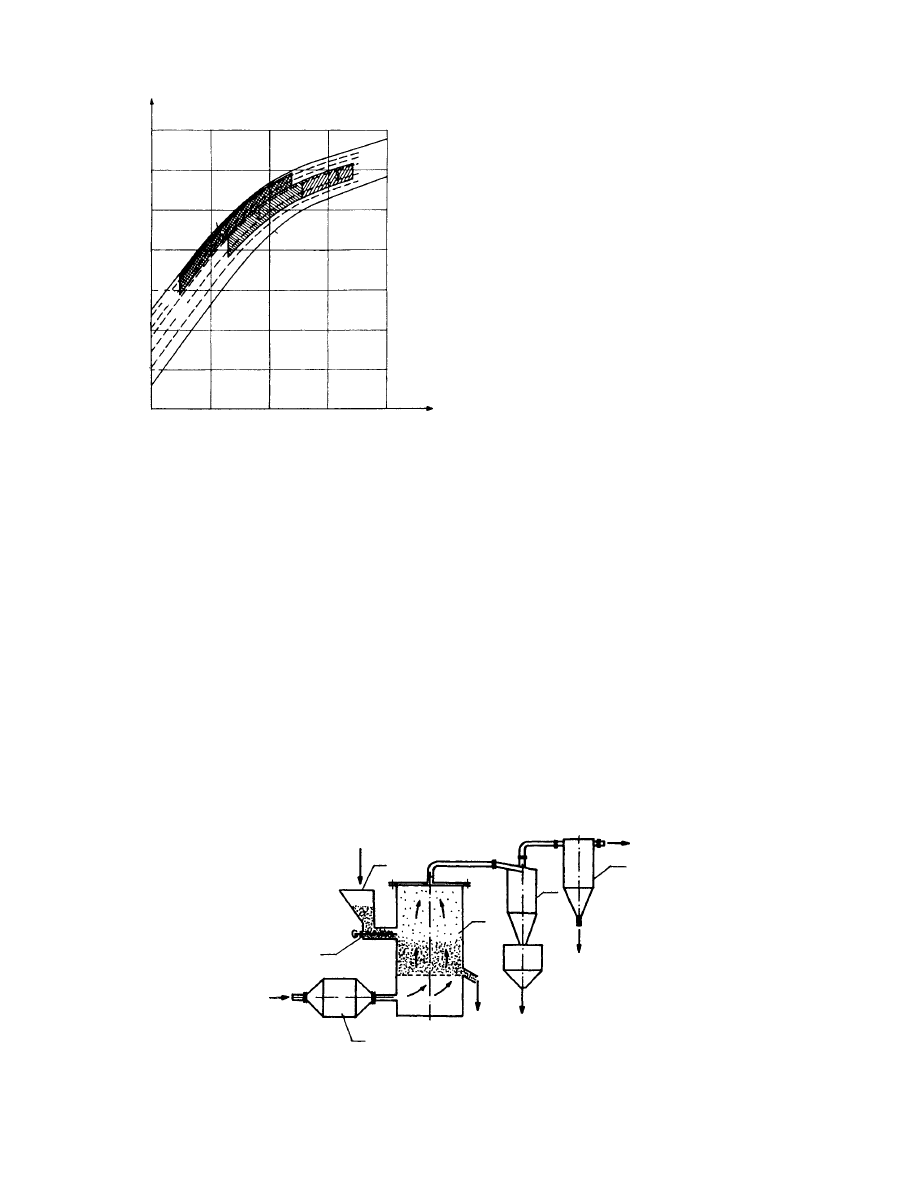

acterist ics of a pneumat ic dryer are illu strated in

, given by Barth. In the vertical tube, the air

flows upwar d. Into the a irstream is supplied a graine d

material shaped as globule s. At low air veloci ties the

globule s fall down ward; at a high veloci ty they are

entrained by the airs tream. The pressur e drop is in-

crease d rap idly at the moment when the globule s are

entrained be cause the mate rial begins to colle ct in the

tube. Bey ond the c ritical zone charact erized by a

rapid dro p of pressur e is the operation zo ne of pne u-

matic dry ers. To selec t the optim um flow velocity, one

must a void operatio n at the cloggin g zone. The clog-

ging z one is idios yncrat ic to each dryer. Here, a slig ht

increa se in solid loading or slight fall in pressur e drop

causes the cloggi ng of the pipe. The cloggi ng zone

separates the critical trans ition zone from the zone

of pneu matic trans port. Altho ugh Figu re 43.6 doe s

not refer to coal trans port, be havior is sim ilar when

transp orting groun d coals. In pne umatic trans port,

heat and mass exchange take place mostly by con vec-

tion. The heat exchange between the drying med ium

and the co al pa rticles suspended in this medium can

be defined by the Fro¨ sslin g form ula

Nu

¼ 2 þ 0:55Pr

1=3

Re

1=2

(43:6)

In the first 2 to 3 m of drying tube, heat transfer to the

coal particles takes place promptly, so the heat trans-

fer coefficient in this zone is defined as

Nu

max

¼ 0:95 10

4

Re

2:15

,

400 < Re < 1300

Nu

max

¼ 0:76Re

0:65

30 < Re < 400

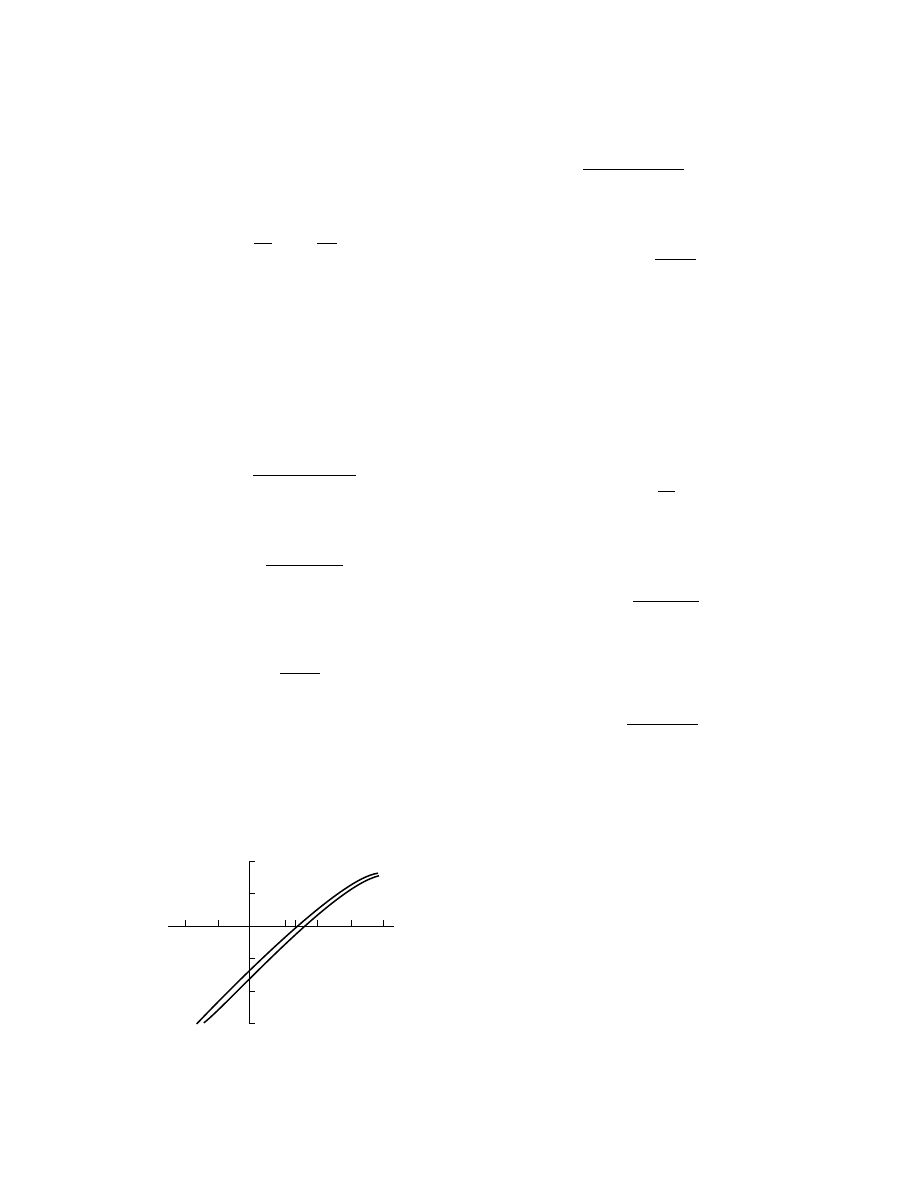

shows the relationshi p betwee n the Nus-

selt number and the Reynolds number for heat trans-

fer between particles transported by the air at 0 to

1008C.

The heat supplied to the coal particle suspended in

the gas stream is

_

Q

Q

¼ h

c

pd

2

p

Q

m

(43:7)

The mean temperature difference Q

m

is calculated as

the logarithmic mean

Q

m

¼

Q

1

Q

2

ln Q

1

=Q

2

where

Q

1

¼ T

1

T

m1

and

Q

2

¼ T

2

T

m2

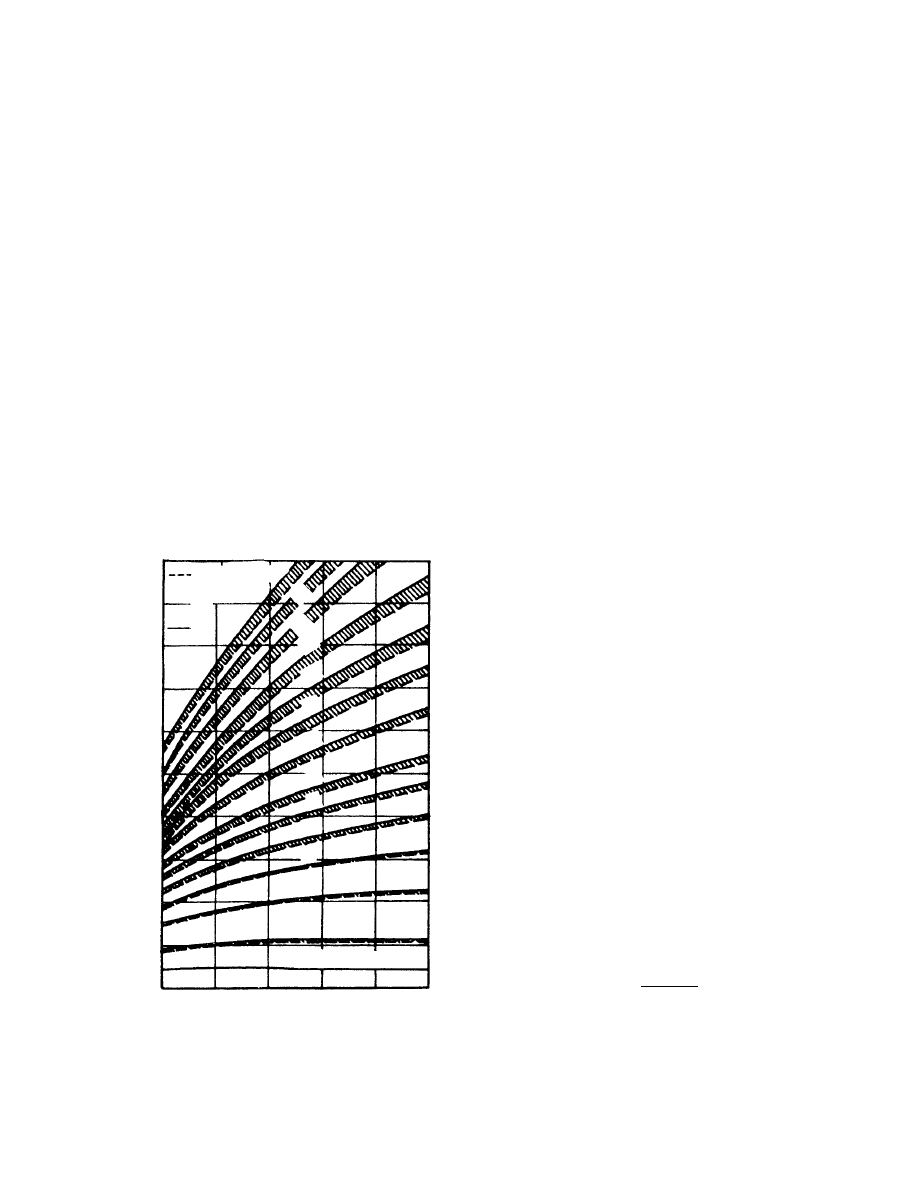

50

45

40

35

30

25

20

15

10

5

0

200

400

600

800

1000

Combustion

gases from

coke oven

gas

Air

30

25

20

15

12

8

6

5

4

3

2

1

d = 0.5 mm

Drift velocity (m/s)

Temperature (

⬚C)

FIGURE 43.5 Drift velocity of coal grains according to

Rammler and Augustin.

ß

2006 by Taylor & Francis Group, LLC.

The quantity of heat necessary to evaporate the sur-

face moisture is

Q

¼

pd

3

p

6

z

s

(X

1

X

2

)DH

(43:8)

The time of the drying process is estimated from the

formula

¼

Q

_

Q

Q

¼

d

p

z

s

6h

c

X

1

X

2

Q

m

DH

(43:9)

At low Reynolds numbers (Re

ffi 0) the Fro¨ssling

formula gives

Nu

¼

h

c

d

p

l

ffi 2

After substitution of this value in Equation 43.9, the

drying time is given by

¼ DH

d

2

p

z

s

(X

1

X

2

)

12Q

m

l

(43:10)

In practice, the moist coal particle diameter is larger

than the dried, and the particle diameter continues to

change with the moisture decrease, so the correction

for the drying time based on the coal particle diameter

must be taken into account. The length of the drying

duct, i.e., the effective length of the drying tube, is

then

L

0

¼ u

(43:11)

The velocity u is the mean velocity with which the coal

grain flows in time t through the lifting tube.

Ø 100

1250

1000

750

500

250

1000

750

500

250

0

0

5

10

15

Velocity

u (m/s)

Pressure drop

Δp

(Pa)

20

25

30

35

Loss of energy (pressure)

T

/m

3

(Pa)

Without material

With material

Pneumatic

transport

Critical

transition

zone

Plugging limit

Upper limit of velocity

Economical

transport

Fluidized layer

Particles are

falling down

m = 0.42 kg/s

FIGURE 43.6 Pressure drop of drying medium in empty tube as well as during transport of material (type of material:

spheres, 7.5 mm diameter).

Johnstone

, Pigf

ord,

Cha

pin

Frössling

1

1

2

3

4

6

8

10

20

30

10

100

1000

Nu

Re

FIGURE 43.7 Heat reception by globules in air at temperatures of 0 to 1008C.

ß

2006 by Taylor & Francis Group, LLC.

u

¼ u

g

u

0

(43 : 12)

The veloci ty of the dr ying medium is taken as

u

g

¼ (1 : 1 1:25)u

0

(43 : 13)

The sedim entation veloci ty can be defined on the

basis of the Archi medes number.

Ar

¼

gd

3

p

u

2

g

z

s

z

g

z

g

(43 : 14)

Know ing the Archimed es numb er, one can calcul ate

the Reyno lds numb er; for Ar < 84,000 ,

Re

¼

Ar

13 : 9

1 =1 :4

(43 : 15)

For Ar > 84,000

Re

¼ 1: 71

ffiffiffiffiffiffi

Ar

p

(43 : 16)

From the Reynol ds number we estimate the theoret -

ical sedim entation veloci ty of the co al parti cle as

u

0

¼

Rev

g

d

p

(43 : 17)

The tube length calcula ted based on formula [11] is

too small since with coarse grains (0.2 to 1.0 mm) this

does not take into account the star ting length ov er

which the grains reach their terminal ve locity. For the

correct ion of this star ting (tran sient) length we sug-

gest the formu la

L

00

¼ k

L

u

g

d

p

(43 : 18)

where k

L

¼ 10

3

s/m . The total length of the lifting tube

will be

L

T

¼ L

0

þ L

00

(43 : 19)

The qua ntity of drying medium requir ed depends on

the heat needed for the drying acco rding to the he at

balance equati on

_

G

GC

p

(T

1

T

2

)

¼ _L

L

0

(C

s

þ Cw

1

)(T

w

T

m1

)

þ _L

L

0

(w

1

w

2

)DH

þ L

0

(C

s

þ Cw

2

)(T

m2

T

w

) (43 : 20)

where _

L

L

0

¼ dry soli d flow rate (kg/ s), C

s

¼ specific

heat of solid (kcal /kg

K), W ¼ dr y basis mois ture co n-

tent, T

w

¼ wet bulb tempe ratur e ( 8 C), an d T

m

¼ solid

tempe rature ( 8 C).

In indu strial practi ce, the lengt h of the lifting tube

is determ ined most frequen tly based on the drying

rate per unit vo lume, which is a s follo ws:

N

v

¼ 400 600 kg H

2

O =m

3

h for ground coal

N

v

¼ 700

900 kg H

2

O =m

3

h for postf lotation

co ncentra te

N

v

varies general ly with hot gas tempe ratur e, solid–

gas rati o, and gas veloci ty. Therefor e, suit able drying

tube volume must be calculated on the ba sis of the

equati on of heat transfer an d he at balance. N

v

gives

the approxim ate va lue of the drying tube volume . The

drying rate per unit volume is defi ned by

N

v

¼

_

W

W

V

p

(43 : 21)

The diame ter of the liftin g tube is calcul ated from the

formu la

D

¼

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

_

V

V

g

0:785u

g

s

(43 : 22)

The volume tric gas rate of the drying medium can be

calculated based on the heat balance Equation 43.20:

_

V

V

g

¼

_

G

G

z

g

(43 : 23)

From Equat ion 43.21, the volume of the lifti ng tube

V

p

can be calculated. Know ing the liftin g tube vol-

ume V

p

and its diame ter, we c an calculate the length

of the lifting tube as

L

e

¼

4V

p

pD

2

(43:24)

In general, the lengths of lifting tubes do not exceed

35 m. The coal feed to the lifting tube is situated 4 to

6 m above the gas feed. The dryer capacity depends

on the diameter of lifting tube.

Diameter (mm)

700

830

900

1100

Capacity (Mg/h)

20–35

30–55

40–65

50–75

The heating medium temperature at the dryer inlet

is 550 to 7008C and 70 to 1708C at the dryer outlet.

The initial moisture of coal is usually 10 to 15%; the

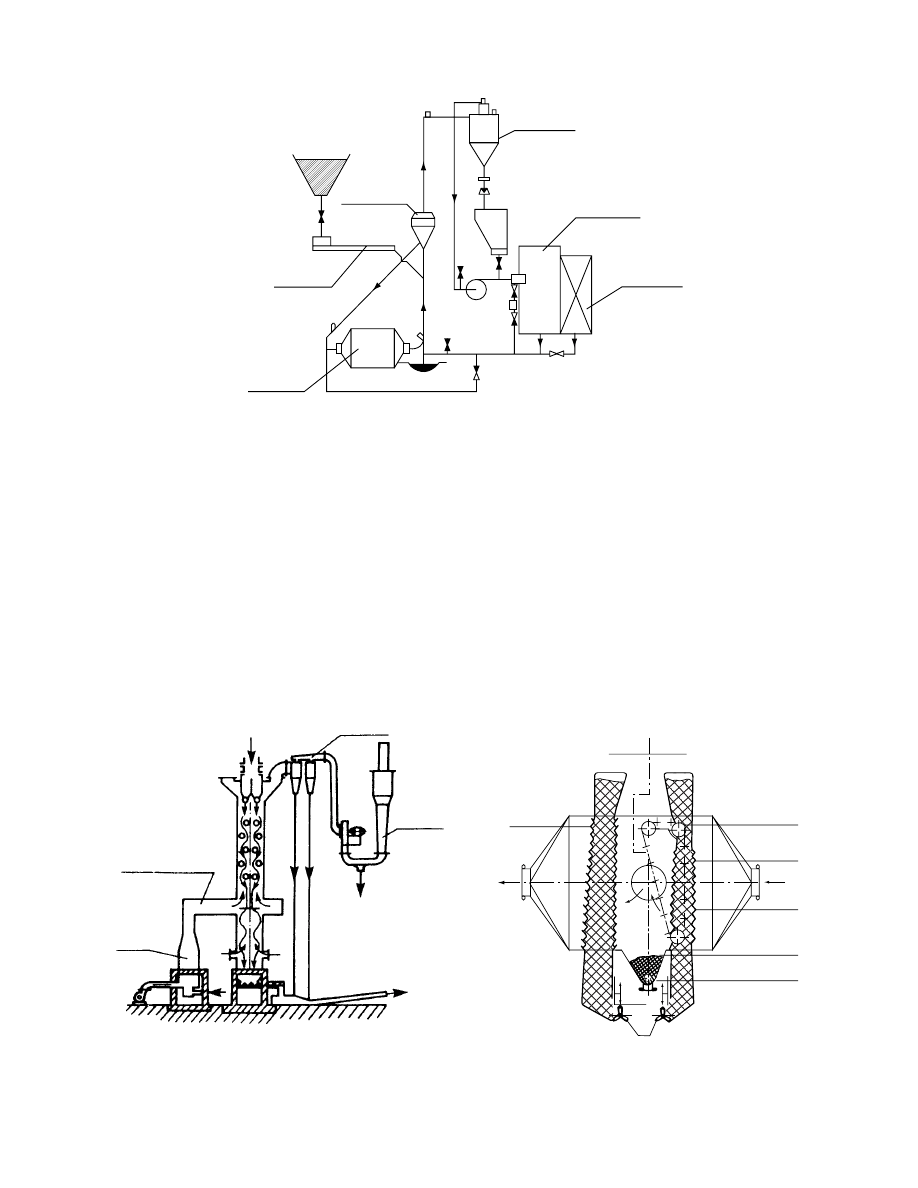

final moisture is about 4 to 6%. A typical pneumatic

dryer setup for coal drying is shown in

.

Wet coal from the bin (11) is proportioned by feeder

ß

2006 by Taylor & Francis Group, LLC.

(12) to the lifting tube (5), where it is carried away by

the combustion gas stream derived from fuel combus-

tion in the furnace (2). Drying occurs in the tube, after

which the coal is separated from combustion gases in

the cyclone (6) and then in a bank of cyclones (7).

Negative pressure in the system is generated by a fan

(8). The dried and separated coal is directed to the

conveyor (10) through the shutter closures (15,16),

which are the lower seals of the cyclones (6 and 7).

The heavier coal particles, which fall down in the

lifting tube (5), are directed to the dried coal conveyor

(10) through the screw (9). The system is equipped

with explosion flaps (17).

The Parry-type dryer for coal drying is shown in

Figure 43.9. Here, wet coal is proportioned into the

drying chamber (2) by means of a feeder. Around

the drying chamber are installed cyclones to separate

the coal from combustion gases. The combustion

gases necessary for drying are generated in the cham-

ber (1) by combustion of a solid or liquid fuel. The air

for combustion is supplied by the fan (6). Another fan

(5) allows recycling of a part of the combustion gases

to the drying process. The capacity for this type of

dryer generally exceeds 50 Mg/h at initial and final

coal moisture levels of 35 and 4%, respectively.

The dimensions of a typical dryer of this type are

as follows:

.

Diameter

¼ 2.7 m

.

Height

¼ 6 m

.

Diameter of furnace chamber

¼ 4.2 m

.

Height of furnace chamber

¼ 10 m

.

Thermal power of chamber

¼ 13.4 MW

The combustion process is controlled automatically;

the temperature of the combustion gases outflowing

to the environment is the signal for control.

43.2.5 F

LUID

-B

ED

D

RYERS

Fluid-bed dryers are widely applicable for coal owing

to the high intensity of this drying process. Intense

drying is achieved as a result of good mixing, use of a

high-temperature heating (and fluidizing) medium,

10

16

18

15

6

17

11

12

13

7

8

4

4

14

3

2

1

5

17

9

FIGURE 43.8 Schematic of pneumatic dryer for coal drying.

Outlet

Fuel

Circulating

gases

Wet

coal

2

3

Air

5

6

1

FIGURE 43.9 Schematic of Parry-type dryer for coal drying.

ß

2006 by Taylor & Francis Group, LLC.

and ease of control . A fluidized stat e is achieve d when

gas with a pro per velocity passes throu gh the co al

layer. The gas flow velocity at which the pa cked bed

is con verted into a fluidized bed is know n as the

minimum fluid ization veloci ty. One feature of the

fluidized bed is its high porosit y, defi ned by

c

¼

V

0

p

V

z

¼ 1

V

m

V

z

(43 : 25)

where V

p

0

¼ volume of solid-free space, V

z

¼ total vol-

ume of bed, and V

m

¼ volume of soli d material in the

bed (

¼ L/ z

s

).

A packed be d of coal has a por osity in the range

of 0.4 to 0.5. The poro sity of a fluidized bed can v ary

over a wi de range, dep ending on the gas flow veloci ty

(c

¼ 0.4 to 1). The mini mum veloci ty of fluidiza tion

for the co al and other fri able materials for which the

porosit y c

0

¼ 0.4 can be calcul ated from the form ula

Re

cr

¼

Ar

1400

þ 5: 22

ffiffiffiffiffiffi

Ar

p (43 : 26)

For c

0

¼ 0.48

Re

cr

¼

Ar

710

þ 4

ffiffiffiffiffiffi

Ar

p (43 : 27)

From the crit ical Reynol ds numb er Re

cr

, one can

calcula te minimum (critical) veloci ty of fluid ization as

u

cr

¼

Re

cr

u

g

d

p

(43 : 28)

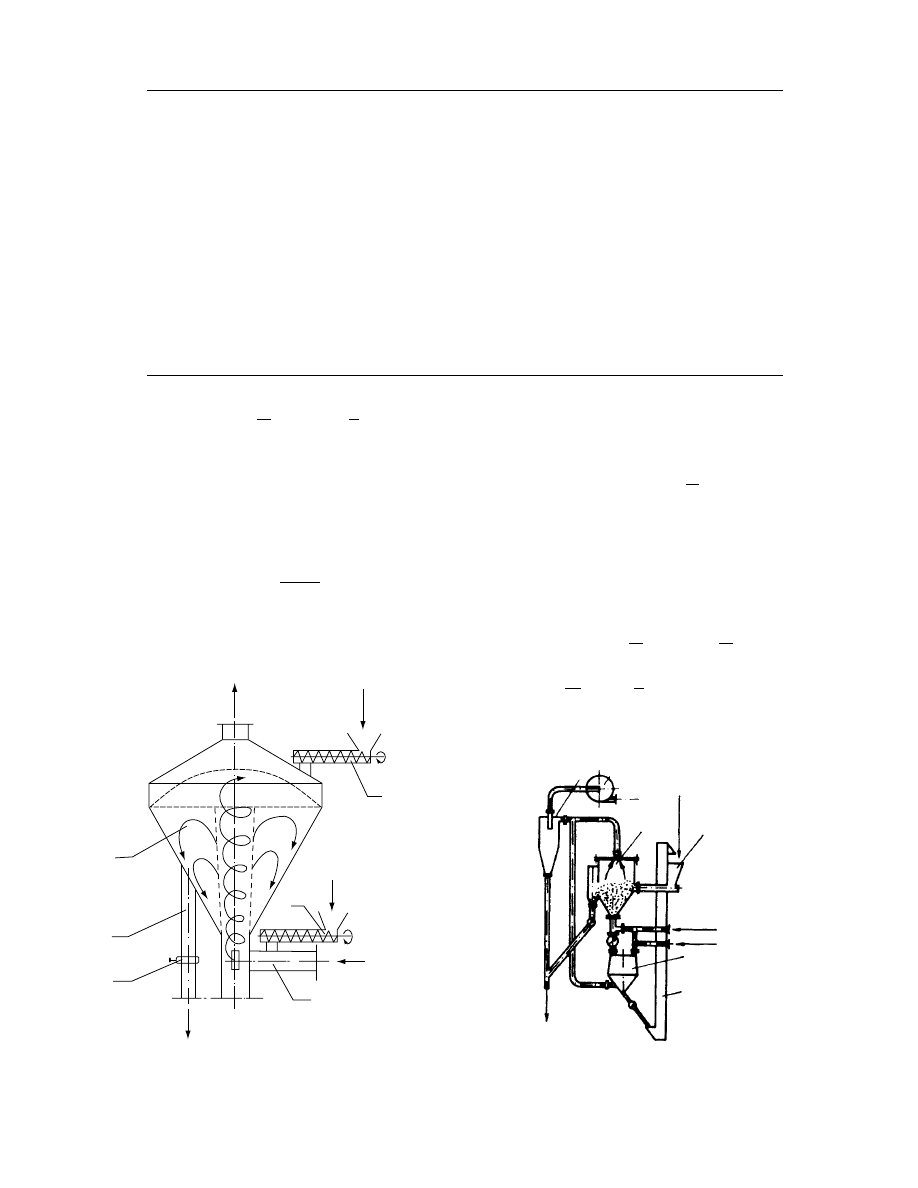

Equation 43.26 and Equat ion 43.27 are sh own grap h-

ically in Figure 43.10. For bed s of coal, the pr essure

drop can be estimat ed from the formu la

Dp

¼ H (1 c)(z

s

z

g

)g (43 : 29)

The por osity of the flui dized bed can be estimat ed

using

c

¼

18Re

þ 0: 36Re

2

Ar

0 :21

(43 : 30)

The height of the fluidized bed is readil y given by

H

¼ H

0

1

c

0

1

c

(43 : 31)

For coal drye rs, a space of a bout 3.5 to 4.5 times the

fluid-bed he ight should be allowed as the disenga ge-

ment he ight h

1

:

h

1

¼ 3: 5H 4: 5H (43 : 32)

The con vective heat trans fer co efficien t betwee n ga s

and solid in the fluidized bed can be estimat ed from

the co rrelatio n

Nu

¼ 10

2

Re

c

Pr

1 =3

(43 : 33)

Drying kinetics in the fluid ized bed requ ires in add -

ition the fulfillment of the relationship

H

¼

_

G

G

z

s

(1

c)S

(43:34)

The mean residence time t of coal in the fluid-bed

dryer is determined empirically and t can be calcu-

lated by

¼

3600H

0

Az

s

F

where F

¼ coal feed rate (kg/h), A ¼ fluid-bed area

(m

2

), and H

0

¼ static coal bed height (m).

In coal drying, the temperature of drying gases at

the dryer inlet is 300 to 7008C and the temperature of

the fluidized bed is 70 to 808C.

shows the relationshi p betwee n ga s

velocity and particle diameter for various porosities

of bed for coal of density z

¼ 1200 kg/m

3

and for gas

temperature T

¼ 1008C. Between curves 1 and 5 there

is a zone of dryers operating as a loose bed. Industrial

fluid-bed dryers operate in the range of c

¼ 0.55 to

0.75. Zone 2 includes coal particles from 30 to 40 mm

up to 6 to 7 mm. For fountain-type dryers, this zone

can widen (3) up to 25 to 30 mm. The aerofountain-type

dryers (4) operate at bed porosity c

¼ 0.75 to 0.9. In

dryers of this type, one can dry coal-containing particles

from several micrometers to tens of millimeters. Owing

to their simple design and high capacity, fluid-bed

10

–6

10

–2

10

2

10

4

Re

cr

Ar

y

0

= 0.48

y

0

= 0.4

10

–4

10

4

10

6

10

8

10

–2

10

2

1

FIGURE 43.10 Relationship between critical Reynolds

number and Archimedes number.

ß

2006 by Taylor & Francis Group, LLC.

dryers are widely applicable in the industry for coal

drying. One type of fluid-bed dryer commonly used

for coal drying is the Fluo-Solids dryer marketed by

Dorr-Oliver (United States). This dryer operates with a

small coal bed (300 to 400 mm) and has a very high

drying rate per unit exposed surface of 2000 kg H

2

O/

m

2

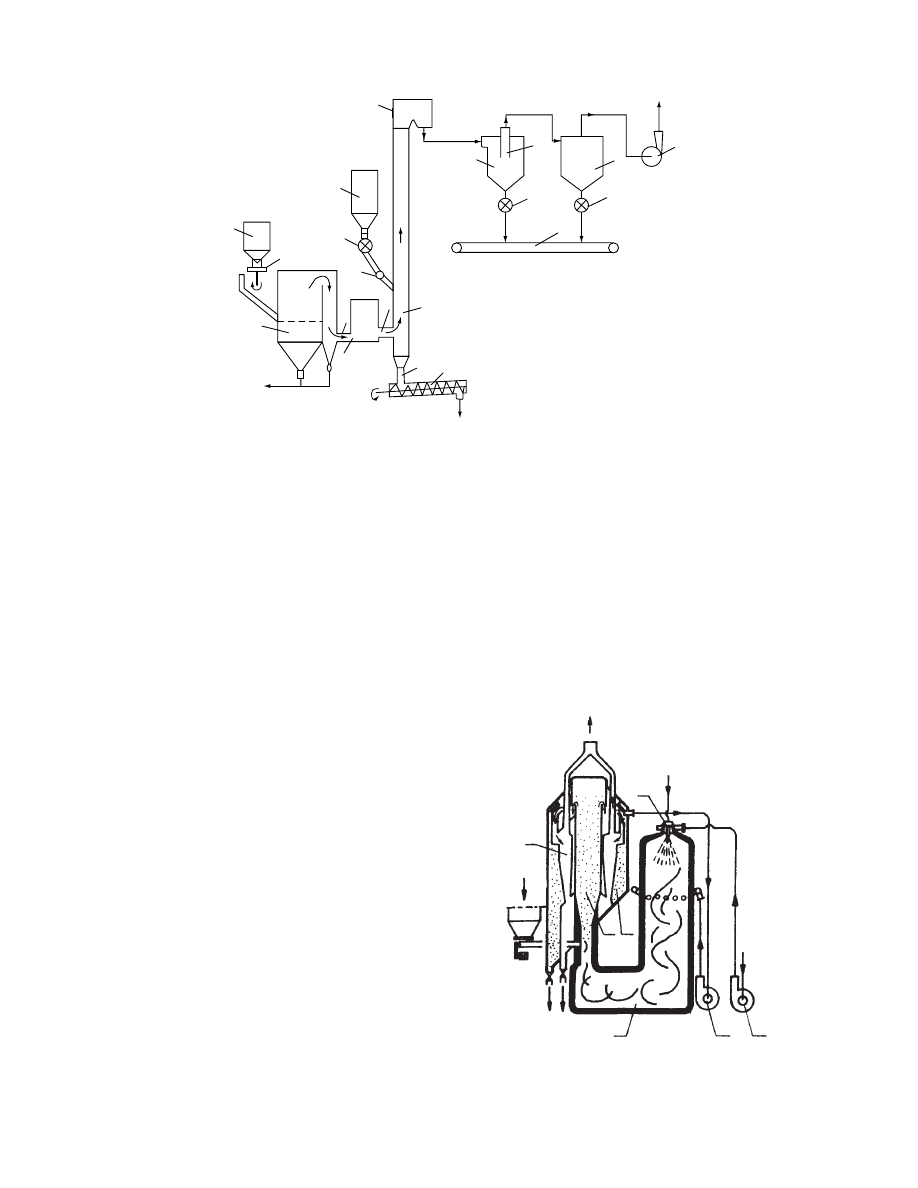

h. Figure 43.12 schematically shows the Fluo-Solids

dryer with the roller chamber designed by Dorr-Oliver

for coal drying. Moist coal from the bin (1) is propor-

tioned by feeder (2) to the drying chamber (3). Com-

bustion gases from the combustion chamber (4) are

mixed with air to obtain the desired temperature (300

to 7008C). The heat consumption is typically in the

range of 3100 to 4000 kJ/kg H

2

O. The hot gases pass

through a screen and the coal layer, causing fluidization

of coal. The exhaust gases leaving the dryer are cleaned

in a cyclone (5) and cloth filter (6). Some technological

data for typical coal fluid-bed dryers for coal operating

in the United States are given in Table 43.2.

43.2.6 F

LUID

-B

ED

D

RYER WITH

F

OUNTAIN

B

ED

(S

POUTED BED

)

In recent years, fluid-bed dryers wi th a foun tain

(spout ed) bed have be come popul ar for drying of

coal. The fountain bed is ach ieved in a co nical–

cylind rical apparat us (

) . The hot gas

stream supplie d to the dryer by tube (3) carries away

the coal g rains supplied by screw (2) an d moves them

upwar d. The lifted co al grains fall aside and move

downward along the annulus.

sho ws a schema tic of a spou ted bed

dryer for coal as designed by Fiodorov and Michai-

lov. Wet coal is supplied to the conical drying cham-

ber. The gas velocity decreases gradually in the

conical chamber owing to which coarser coal grains

fall downward. The finest grains are entrained by the

gas stream and then separated in the cyclone (3). The

intermediate fractions are circulated in the drying

chamber (1), after which they pass through a vertical

slit in the chamber wall for discharge. Control of the

slit opening allows control over the dryer holdup. The

coarse coal particles fall into the bin (5) from which

they are recycled to the dryer by a bucket elevator (6).

For spouted bed dryers, it is very important to deter-

mine the gas velocity at which the spouting process

begins and ends. The critical velocity for spouting

depends on the bed height and the physical properties

of the coal and gas, as well as on the geometric shape

and dimensions of the dryer. The incipient spouting

velocity can be estimated from the correlation

m

(m/s)

10

2

10

1

10

0

10

−1

10

−2

10

−3

10

−4

10

−4

10

−3

10

−2

10

−1

10

−5

Drift

(y = 1)

Constant bed

(y = 0.4)

y

= 0.4

y

= 1

0.8

0.6

5

1

d

p

(m)

FIGURE 43.11 Relationship between gas velocity and par-

ticle diameter.

Wet coal

Inlet

air

2

1

Outlet air

6

5

3

Dry coal

4

Dry coal

FIGURE 43.12 Schematic of Fluo-Solids-type fluidized bed dryer.

ß

2006 by Taylor & Francis Group, LLC.

Re

cr

¼ 0:364 Re

f

D

d

0

1

0:82

tg

f

2

0:1

(43:35)

where Re

cr

¼ critical Reynolds number at which

spouting starts, D

¼ diameter of upper bed section,

d

0

¼ diameter of lower bed section, and f ¼ apex

angle of cone; generally, f

¼ 16 to 708.

Then

u

cr

¼

Re

cr

u

g

d

p

(43:36)

In polydisperse systems, the maximum particle diam-

eter is taken as the particle diameter in Equation

43.36. For optimum geometry one may use

f

¼ 30 50

and

D

d

0

¼ 2 4

For fine grains (Ar < 10

4

), the bed becomes unstable

and may pulsate with a frequency at a low amplitude.

It is found that the dryer height H and separator

diameter D

s

also affect the minimum spouting vel-

ocity. These effects are included in the correlation

Re

cr

¼ 0:176Re

f

D

d

0

1

0:087

H

d

0

0:6

D

s

d

0

0:94

tg

f

2

0:323

(43:37)

TABLE 43.2

Operating Parameters for Some Typical Fluid-Bed Dryers for Coal Used in Various Parts

of the United States

Parameters

Indiana

West Virginia

Kentucky

Utah

Diameter, m

2.1

4.2

4.2

4.2

Screen area, m

2

3.46

13.9

13.9

13.9

Capacity, Mg/h

100

700

230

800

Drying rate per unit exposed

surface, kg/m

2

h

2900

2500

1800

1800

Coal grain sizes, mm

0–6

0–10

0–15

0–38

Moisture at inlet, %

18–22

14.5

—

—

Moisture at outlet, %

2

4.8

—

—

Gas temperature at inlet, 8C

650

410

—

—

Gas temperature at outlet, 8C

80

70

—

—

Gas

Coarse-grained

coal

Fine-grained coal

or coal mud

Hot gas

Dried

coal

5

4

1

2

3

2

Drying of coal

FIGURE 43.13 Schematic of dryer with spouted bed.

3

2

Wet coal

4

1

Combustion gases

Air

5

6

Dry coal

FIGURE 43.14 Schematic of fluidized system with spouted bed.

ß

2006 by Taylor & Francis Group, LLC.

Figure 43.15 presents the relationship between Re

cr

and the Reynolds number for the settling velocity

of grain Re

f

as well as various operating zones of

spouted beds. To estimate the pressure drop across

a spouted bed, one can use the approximate formula

Dp

¼ (0:64 0:75)gz

u

H

0

(43:38)

It is very difficult to calculate the values of convective heat

transfer coefficients for a spouted bed. Uemaki and

Kugo give the following correlation for convective heat

transfer from the gas to the solid particles.

Nu

¼ 5 10

4

Re

1:46

min

u

u

min

1:30

(43:39)

where the Reynolds number is defined by formula

Re

min

¼

u

min

d

p

u

g

where u

¼ flow velocity and u

min

¼ minimum velocity

for spouting.

From Equation 43.39, it appears that the convect-

ive heat transfer coefficients in the spouted bed are in

the range of 3.4 to 17 W/m

2

K; according to other

investigators these coefficients are much higher, say,

up to 51 to 142 W/m

2

K. The drying rates per unit

volume in such dryers are high: N

v

¼ 110 to 290 kg/

m

3

h. For coal drying, the temperature of the drying

medium (e.g., combustion gases or air) is usually not

more than 2008C, unlike the case of conventional

fluid-bed dryers, which operate with much higher

inlet temperatures.

43.2.7 V

IBRATORY

D

RYERS

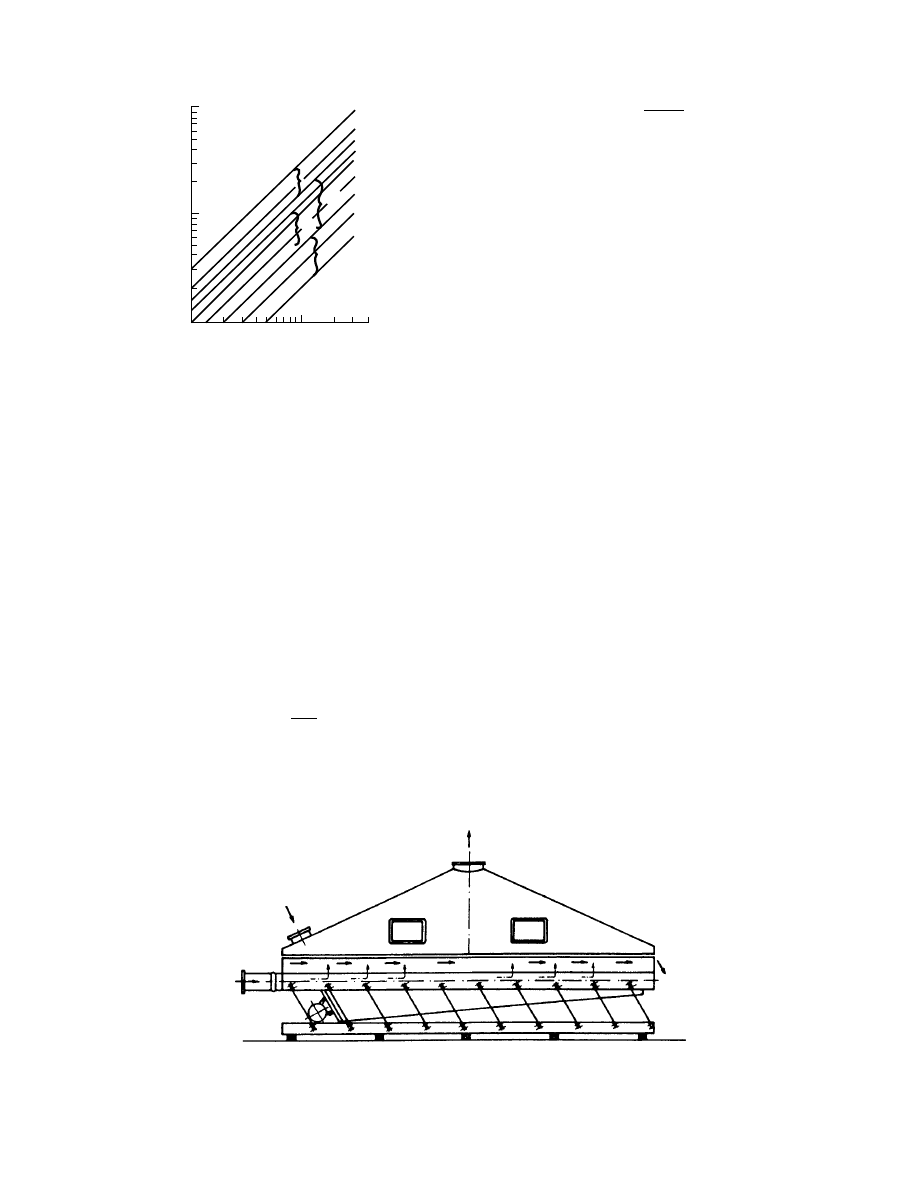

A vibratory dryer designed by Escher-Wyss is

sketched in Figure 43.16. Vibratory dryers are used

for drying hard and brown coals, especially if it is

necessary to combine coal transport or proportioning

operations with the drying operation. Drying is ac-

complished by hot air or combustion gases passing

through the vibrating coal layer. The coal to be dried

is led into the perforated trough oscillated by an

electromagnetic oscillator. The trough is inclined to

the horizontal at an angle of about 1 to 58. Owing to

the slope of the trough the coal is conveyed with a

velocity dependent on the slope of the trough and on

the vibration amplitude and frequency. For an elec-

tromagnetic vibrator at frequency f

¼ 50 and 100 Hz

and amplitude x

¼ 0.05 to 3 mm, the conveying vel-

ocity of coal is 0.01 to 0.3 m/s. This type of unit can

also be used to cool coal. In vibratory dryers, the heat

requirement is much lower as a consequence of better

utilization of the drying medium.

I

II

IV

III

V

VI

10

4

10

3

10

2

10

3

–10

3

4

Re

cr

Re

f

FIGURE 43.15 Relationship between critical Reynolds

number at incipient spouting and Reynolds number calcu-

lated for sedimentation velocity Re

f

.

Outlet air

Moist air

Hot air

Dry coal

FIGURE 43.16 Schematic of Escher-Wyss-type vibratory dryer.

ß

2006 by Taylor & Francis Group, LLC.

The capacity of vibratory dryers depends on the

trough width B, coal layer height h

0

, and coal drift

velocity u. It can be calculated using the formula

_

L

L

¼ Bh

0

uz

u

(43:40)

The coal layer in the trough is typically

h

0

¼ 2030 mm,

for ground coal

h

0

¼ 4060 mm,

for coal in lump form

For vibratory dryers, the length of troughs does not

usually exceed 10 m. In case the drive is located in the

center of the trough, the trough length can be as high

as 30 m. For long troughs, difficulties are encountered

with proper distribution of the heating medium.

Sometimes the electromagnetic oscillator is replaced

by a power drive in the form of rotating disks that

push the trough that is mounted elastically. Some

technoeconomic data for coal drying in vibratory

dryers are given in Table 43.3.

43.2.8 M

ILL

-T

YPE

D

RYERS

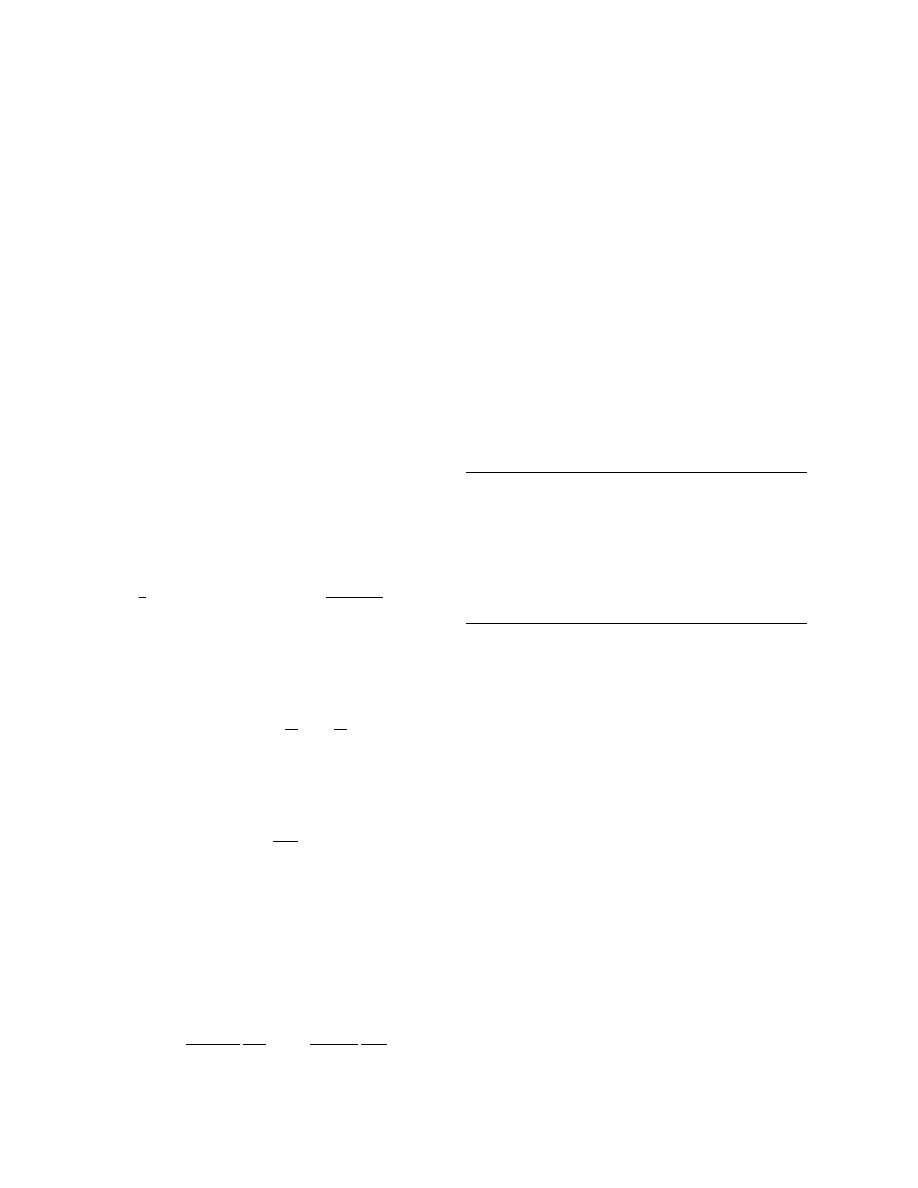

Mill-type dryers are used for coal only when it is

advisable to combine grinding and drying operations.

For satisfactory grinding performance, a low mois-

ture level must be achieved. The mill-type dryers are

used generally in power plants using steam boilers

fired by pulverized coal. Figure 43.17 shows a mill-

type dryer, which is really a ball mill in which the coal

is broken and partly ground by the balls. The dryer

consists of a horizontal drum with cones fitted on

both ends. From inside the drum is lined with the

protective lining of basalt, cast iron, carbon, or man-

ganese cast steel (14% Mn).

The drum is filled with balls (diameter, 30 to 80

mm). The filling ratio of the drum is typically 14 to

30%. The filling ratio of the mill has a decisive effect

on the quality and capacity of coal grinding. The balls

are made of manganese or carbon steel toughened to

obtain high hardness and durability. The ball con-

sumption is 80 to 100 g/Mg for soft coals, and it can

reach up to 800 g/Mg for hard coals. The drums are of

2 to 3 m diameter and 3 to 5 m long. The speed of

rotation of the drum is 16 to 30 rpm. For grinding, the

electricity consumption varies over a wide range, from

7 kWh/Mg for short brown coals up to 30 kWh/Mg for

anthracite. Coal grinding in mill-type dryers requires

additional electrical energy (5 to 10 kWh/Mg), which is

consumed by the fan. Coal is fed into the mill through

one of the pins; the heating medium in the form of hot

air or combustion gases is also supplied through the

same pin. The rotary motion of the drum causes the

movement of balls near the drum wall up to about

three quarters of drum diameter as the falling down

of balls under gravity. The falling balls break and

partly grind the coal. The hot air or combustion

gases supplied to the drum simultaneously heat the

balls and coal as well as dry the coal.

The quantity of heating medium used in ty-

pical commercial units is 1.3 kg/kg for brown coals

and 2.0 kg/kg for anthracite. The heating medium

temperatures depend on the moisture of the coal. Fig-

TABLE 43.3

Technoeconomic Data for Vibratory Dryers for Coal

Parameter

Sizes of Grains

3–10 mm

10–32 mm

Capacity, Mg/h

40

80

Moisture at inlet, %

12

7

Moisture at outlet, %

1.0

1.5

Gas temperature at inlet, 8C

370

275

Gas temperature at outlet, 8C

60

54

Dried coal temperature, 8C

66

40

Pressure drop, Pa

380

320

Combustion

gases

Moist coal

Combustion

gases

Dry coal

FIGURE 43.17 Schematic of mill-type dryer.

ß

2006 by Taylor & Francis Group, LLC.

ure 43.18 sh ows the relationshi p betwee n the co mbus-

tion gas tempe ratur e, moisture content in co mbustion

gases at the dryer inlet, and the coal mois ture content .

The flow velocity of the hot medium in the mill is in the

range of 1 to 3 m/s .

The tempe ratur e of the coal–air mixt ure is 70 to

80 8 C for ha rd coal and 80 to 90 8C for brown coal. The

capacit y of the mill-type drum dry ers is 50 M g/h or

more. For drying ha rd and brown coal, beater mills

may be use d. A beater mill, includi ng the separato r, is

shown in Figure 43.19. Here, drying and grinding

proceed without the use of a fan. The mill consists of

a separat or hous ing and articulat ed rotat ing beater s.

The beaters num ber 2 to 12 per ro w and weigh 4 to

10 kg each. The be aters are made up of manganes e

steel, manganes e cast steel , cast iron, or carbon steel .

The be ater size can be different . The beater s are su b-

jected to abrasive wear and must be replac ed periodi c-

ally. In grindi ng quick cok e, the lifeti me of the beater s

is 200 to 400 h. The rotation al speed of the beater s

is 40 to 60 m/s; the num ber of revolut ions of the sh aft is

720 to 1420 rpm. Wet coal from a bin is charged by

gravity into the mil l through the feeder ; the hot air or

combust ion gases are suppli ed by lateral stub pipes.

The rotat ional moti on of beater s causes bounc ing of

coal particles up to a certa in he ight of the sh aft (up to

about 5 m), whi ch causes intens ive drying of co al as

well as grindi ng of coal g rains owin g to the direct

impac t. Coarser grains are recycle d for grindi ng; fine r

grains a re en trained, form ing a dust–air mixtu re su p-

plied directly to the boiler furnace .

The power consumpt ion for grindi ng is typic ally

15 to 20 kWh/Mg for ha rd co al and 4 to 14 kWh /Mg

for brown coal. The metal consumpt ion is 60 to 1 60 g/

Mg for hard coal, 20 to 80 g/Mg for brown coal, and

2000 g/Mg for qui ck coke. For coals at mois ture level s

of 10 to 14%, air at 300 to 400 8 C may be used as the

heatin g medium . W hen the mois ture con tent is above

15 to 25%, combu stion gases at tempe ratur e of 700 to

1000 8 C should be us ed. Coal at a high mois ture con -

tent (25 to 35%) shou ld be predri ed partially at the

chute to the mill by means of hot combust ion gases.

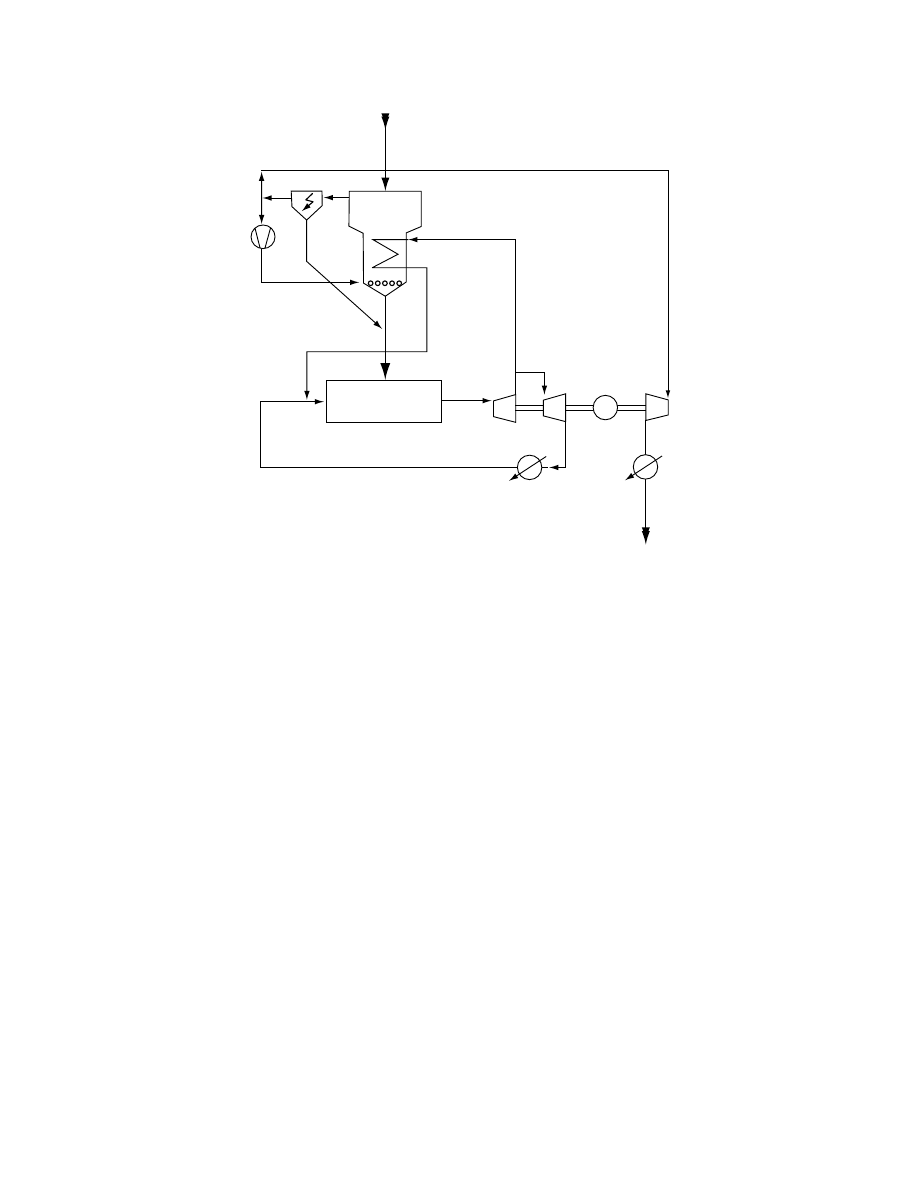

shows pulverized c oal produ ction

with simultaneous dr ying of coal. Wet coal is sup-

plied t o t he ball mill through the scales, feeder, and

drying tube. Hot air together with the coarse particle

recycling stream f rom t he separator i s directed t o the

mill and t he combustion gases are supplied t o the

drying tube.

43.2.9 S

HAFT

D

RYERS

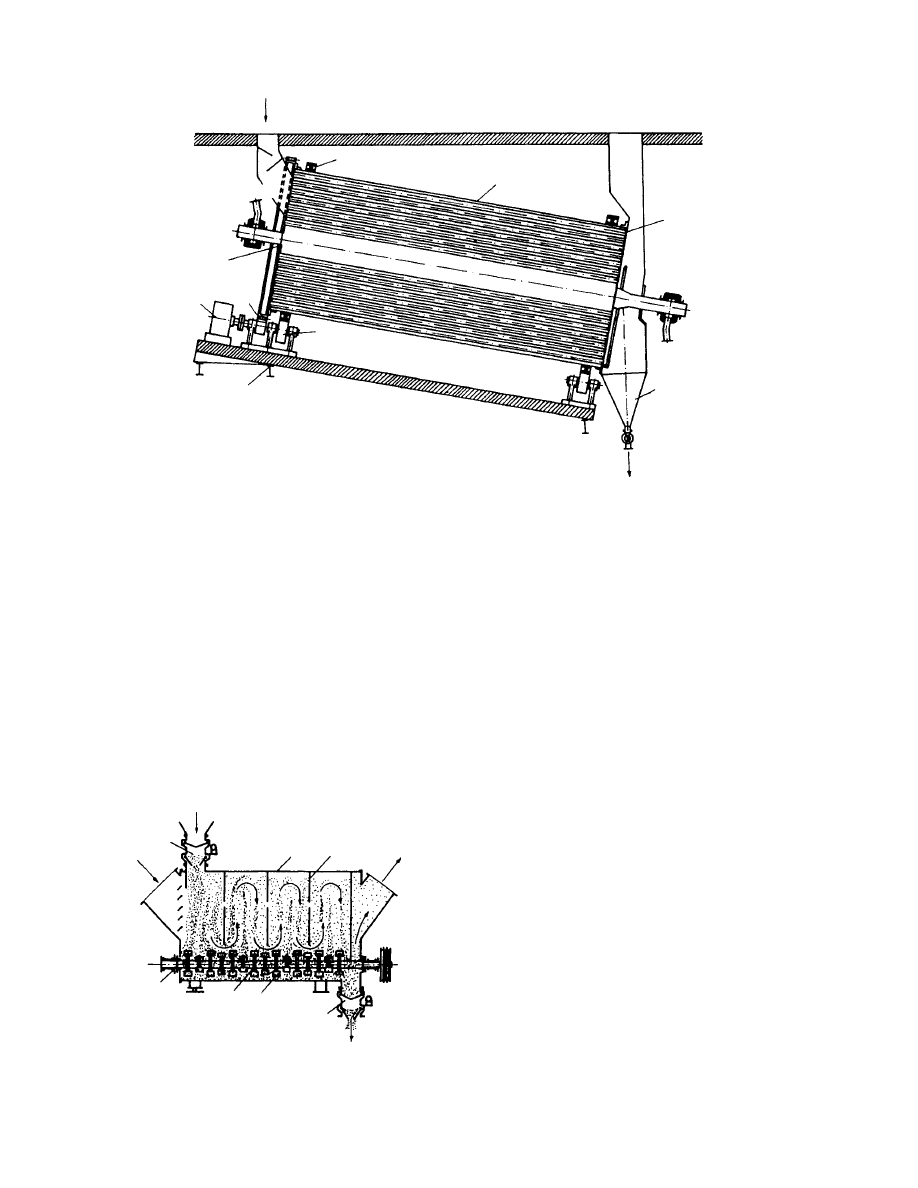

A shaft dryer de signed by Konrer -Ledant for drying

of coal fed to cok e ovens is shown sch ematical ly in

. This dryer consists of two vertical

shafts of rectangular s ection. These r otating shafts,

fitted w ith paddles, a re intended t o fluff the coal

and t o transport i t downward. T he dryer has t wo

zone s, a drying zone and a cooling zone. C ombus-

tion gases g enerated in the c ombustion chamber

flow to the two vertical shafts, where they contact

with the wet coal moving down t he shaft. Cooling i s

achieved by means of ambient air s upplied t o the

lower part of t he shaft. The c ombustion gas is at

6508 C, and a ft er m ixi ng w it h the a ir leaving the

cooling zone its temperature drops to 250 to

3008C. At the dryer outlet the exhaust gas temperature

is 60 to 708C. In this type of dryer, the pressure drop

is about 700 Pa.

The combustion gases leaving the dryer shaft

are cleaned in a battery of cyclones and in a wet

scrubber. The dried coal withdrawn from the lower

part of the shaft by screw conveyor or a Redler-type

conveyor, the trough of which is hermetically sealed,

130

110

90

70

50

30

10

400 440 480 520 560 600

Combustion gases temperature before dryer (

⬚C)

Moisture content in combustion

gases before dryer (g/kg)

640 680 720 760 800

20%

30%

40%

x = 55%

FIGURE 43.18 Combustion gas temperature; relationship

between combustion gas humidity and coal moisture content.

Coal

Air

D

FIGURE 43.19 Mill-shaft dryer (beater mill including

separators).

ß

2006 by Taylor & Francis Group, LLC.

is transported to the coal bins. The entire coal-drying

and transport operation can be automated.

43.2.10 D

RYER WITH

M

OVING

B

ED

A modification of the shaft dryer is the convection

dryer with a moving bed (Figure 43.22), developed

and designed by the author of this chapter and used

for the drying of coal and quick coke. The particular

advantages of this dryer are observed when drying

quick coke, which has a high porosity and strong

abrasive properties. These properties considerably

hinder the use of fluid-bed dryers, spouted bed dryers,

and rotary dryers. The wet coal or quick coke is led to

the dryer by the stub pipe K

1

, and after passage

between the louver walls (1) and after drying, it is

introduced by stub pipe K

2

by means of a feeder (2).

Version 1 represents a dryer with gravity-assisted

movement of the bed, which is used for the drying

of quick coke.

Version 2, used for the drying of ground coal, has

a forced movement of the bed by means of the shelf

conveyor (3). Hot combustion gases or air are sup-

plied to the inlet chamber by stub pipe K

3

and after

passage through the bed leave the dryer by stub pipe

K

4

. The capacity of the dryer is controlled by varying

the speed of the feeders (2), as well as by alteration of

Air heater

Furnace

Cyclone

Separator

Feeder

Ball mill

FIGURE 43.20 Pulverized coal production with simultaneous drying.

Combustion gases

Fuel

Cyclones

Scrubber

Mud

Dry coal

Wet coal

Air

Air

FIGURE 43.21 Schematic of Konrer-Ledant-type shaft

dryer.

Version 1

K

1

K

1

K

3

K

4

K

4

K

5

K

2

K

2

7

2

6

Version 2

5

3

1

4

1

FIGURE 43.22 Convection dryer with moving bed.

ß

2006 by Taylor & Francis Group, LLC.

the sli t size of the stub pipes K

2

. The basic advan tage

of this dryer is its compact co nstruction an d sim ple

design, as well as the possibi lity of full automa tion. It

is pos sible to selec t the flow veloci ty to mini mize the

carryov er of particles from the bed; in many cases this

allows one to do away wi th any de dusting equipment .

Low-temper ature (150 to 200 8 C) was te comb ustion

gases from steam boilers can be us ed as the dry ing

medium . Low-temp erature operatio n great ly redu ces

the danger of ignition. Also, the drying rate pe r unit

volume is very high , up to about 0.2 kg/m

3

s at an

inlet air temperatur e of 200 8 C. For co mparison , for

rotary an d pneumat ic dr yers this amo unts to abo ut

0.014 and 0.14 kg/m

2

s, respect ively. Rotary, pneu -

matic, an d fluid -bed dryers are operate d at much

higher tempe ratures (400 to 800 8 C). The low veloci ty

(about 1 mm/ s) of movem ent of the coal be d consid-

erably de creases the wear of the dryer walls from

abrasio n. The he at consumpt ion is 2800 to 3500 kJ/

kg H

2

O. The drying tim e is the ke y design parame ter

for the calcul ation of the moving bed dr yer. The dry-

ing tim e is eq ual to the resi dence time in the dryer.

Hence the drying time has an effe ct on the velocity of

the bed in the dr yer. The drying time at co nstant

parame ters of the heatin g medium can be calcula ted

from

¼

1

£

[(X

1

X

cr

)

þ (X

cr

X

)] ln

X

cr

X

X

2

X

(43 : 41)

The drying co efficient £ charact erize s the rate of dry-

ing unde r con stant dr ying cond itions an d can be esti-

mated from the co rrelatio n

P

¼ 0: 469Re

0 :896

K

0 :633

H

d

e

1

§

u

§

g

1

(43 : 42)

The eq uivalent parti cle diame ter is calcul ated from

the form ula

d

e

¼

1

P

x

i

d

i

(43 : 43)

where x

i

¼ mass fract ion of diameter d

i

kg/kg,

u

¼ superfi cial gas veloci ty at inlet tempe ratur e, and

Q

¼ T

s

–T

D

¼ tempe ratur e differen ce betw een gas at

inlet T

s

and wet bulb tempe rature T

D

.

The be d pressur e dro p Dp through the layer of

coal can be calculated from the wel l-known Erg un’s

equati on:

Dp=H

¼ 150

(1

c

0

)

2

c

3

0

m

g

u

d

2

e

þ 1: 75

(1

c

0

)

c

3

0

§

g

u

2

d

e

(43 : 44)

43.2.11 S

UPERHEATED

S

TEAM

D

RYING OF

C

OAL

The ad vantage s of us ing su perheat ed steam as the

drying medium are well known an d noted in the

chapter on this subject in this handb ook. Among

those of major inter est in coal drying are no fire or

explosio n hazard, ability to dry at elevated tempe rat-

ures, fast er drying rates leading to smal l equ ipment

size, and others (Beeby and Potter , 1984; Weiss et al.,

1991; W olf et al., 1988).

Steam -fluidi zed be ds with steam have been in suc-

cessful ope ration in South Africa for ne arly a decade

(Faber et al., 1986). Fabe r et al. (1986) have sho wn

that fluid-bed steam dr ying of activated carbon pelle ts

saves en ergy (15% ) as well as capit al costs (14).

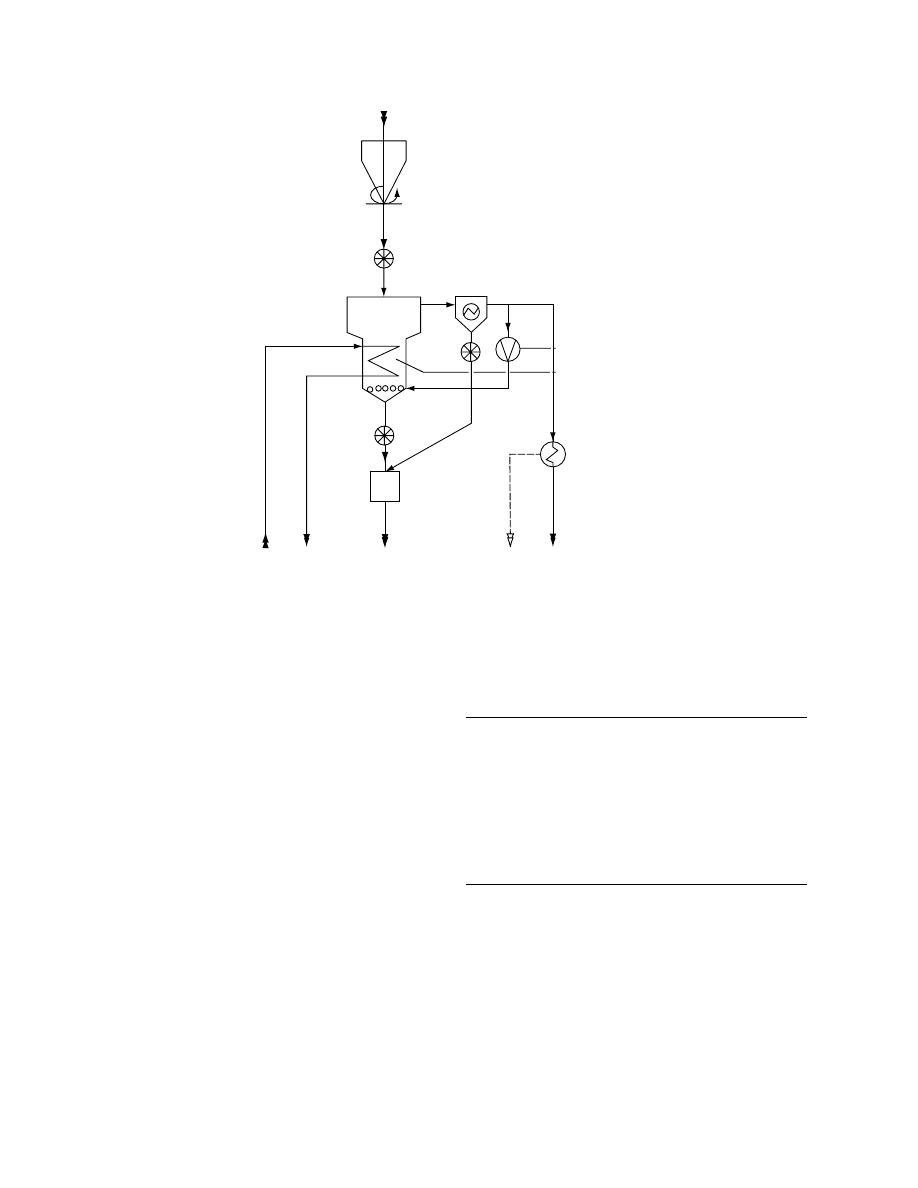

shows conceptually the steam-

fluidized bed drying (Dampf-Wirbelschicht-Trocknung

[DWT]) described by Weiss et al. (1991). Typical oper-

ating conditions for drying of brown coal are given

be lo w.

Fluid-bed pressure drop

and temperature

1–10 kPa, 110–1208 C

Fluidizing steam 15–25 kPa, superheated

Heating steam 400–500 kPa absolute, saturated

Coal grain size (feed) up to 6 mm

Coal grain size (output) up to 4 mm

Dry coal moisture 10–20%, dry basis

Note that RBC stands for raw brown coal. Dry

brown co al (DBC) is withdrawn through the inflow

plate. Exhaust steam is clear ed in an electrost atic

precipitat or and is partially recycled by a co mpres sor

as fluidizi ng steam . Excess steam is conden sed and

the late nt hea t is recover ed at 100 8 C. If this he at is

utilized elsewh ere, the ne t energy consumpt ion for

coal drying is very low. The internal heat exchange r

uses 4 to 5 bar satur ated steam and is taken out a s

clean condensate. The condensation temperature

must be 30 to 508C above the bed temperature for

efficient heat exchange between the bed and the

exchanger tubes. The bed is operated at a slight over-

pressure to eliminate air in leakage.

shows a schema tic of a steam -

fluidized bed dryer with combined generation of

power and heat. In a conventional coal-fired power

plant, up to two thirds of fuel energy is lost since the

latent heat of turbine exhaust steam is dissipated un-

used to the cooling water because of its low tempera-

ture level. In DWT process, the latent heat can be used

to dry the input coal. Figure 43.24 shows a coal-fired

power plant schematic with a circulating fluid-bed

ß

2006 by Taylor & Francis Group, LLC.

boiler, turbogenerator set, and condenser for turbine

exhaust steam. The top half is the DWT scheme. Use

of DWT is claimed to improve the energy efficiency

from 34 to 37%. If the DWT latent heat is also utilized

the efficiency is expected to rise to 39%. The reader is

referred to Faber et al. (1986) for details. Large-scale

pilot plants have successfully demonstrated this tech-

nology. The pilot-plant capacities range from 1 to 24 t/h

evaporation capacity. The latter can generate 20 t/h

of dry coal (12% moisture) from 44 t/h of raw coal

(60% moisture).

43.3 RECENT DEVELOPMENTS AND STATUS

OF COAL TECHNOLOGIES

Coal is a raw material for many chemical syntheses as

well as fuel. Coal is dried to increase its calorific value

and simplify loading, unloading, transport, and to

improve boiler combustion efficiency. It is also dried

for processes like briquetting, coking, gasification,

carbonization, and liquid fuel synthesis Coke oven

efficiency can increase 30 to 50% in preheating and

10 to 15% in drying.

Only high-moisture coals need to be dried prior

to usage. The type of dryer and extent of drying

required depends on many factors. Some of the prin-

cipal ones are the utilization of the mined coal,

whether it needs to be ground for firing into combus-

tion chambers and whether the application is near

‘‘mine-mouth’’ or far away from the mine. If the coal

contains substantial amounts of water (could be 50 to

70% wet basis depending on the coal), it may be

necessary to dehydrate it to reduce the transportation

cost. The calorific value also increases this way while

the combustion efficiency is also enhanced. Recent

work at Monash University in Australia has demon-

strated in laboratory and pilot tests that reduction of

moisture from Australian brown coal or lignite can

reduce greenhouse gas emissions from a power plant

by 30%

Direct dryers (e.g., rotary, pneumatic, fluid-bed,

vibrating fluid-bed, and shaft dryers) can be used with

hot air or combustion gases as drying media at 700 to

9008C before dryer and 60 to 1208C after dryer. It is

important not to have high oxygen content in the

drying gas to avoid explosion and fire hazard. This

is a key issue in coal drying. Low-rank coals can be

highly reactive and hence they are more susceptible to

fire and explosion hazard due to spontaneous com-

bustion. Hence indirect dryers have some advantages

RBC

DWT vapors

DWT

LP steam

LP condensate

Boiler

Turbine condensate

HP steam

12.5

MPa

HP

LP

8 kPa

100 kPa

500 kPa

G

~

Vapor

condensate

FIGURE 43.23 Steam-fluidized bed dryer (DWT, Dampf-Wirbelschicht-Trocknung) with internal heat exchangers.

ß

2006 by Taylor & Francis Group, LLC.

in this regard. Rotary dryers with indirect heating are

used for hard coals. These have higher energy effi-

ciency, about 3100 kJ/kg water evaporated. For air

fluidized bed dryers the corresponding figure is 3100

to 4000 kJ/kg water evaporated. A commercial vibra-

tory dryer for hard and brown coals (manufactured

by Escher-Wyss of Switzerland) uses a vibration fre-

quency of 50 to 100 Hz and amplitude of 0.5 to 3 mm

giving a conveying velocity in the range of 0.01 to

0.3 m/s with an angle of inclination of 58 to the

horizontal. Low gas velocities are needed since vibra-

tion suspends most of the pseudo-fluidized beds. The

efficiency is better than a conventional fluid-bed

employing high gas velocities. Attrition is reduced and

gas cleaning requirements minimized in a vibrated

bed dryer (Mujumdar, 1989; Erdez and Mujumdar,

1991).

In pilot trials Potter (Potter, 1979; Potter and

Keogh, 1979, 1981; Potter and Beeby, 1982, 1986;

Potter et al., 1988) have shown that extremely favor-

able heat transfer rates as well as drying efficiencies

are obtained when drying brown coal in a steam-

fluidized bed with internal heat exchanger tubes im-

mersed within it. Typical processing conditions are

reported as:

High tube temperature

140–1708C

Bed temperature

110–1278C

Minimum fluidizing velocity

5.7 cm/s (approx)

Steam temperature

130–1558C

Steam velocity (m/s)

0.20–0.30

Coal feed rate (kg/h) w.b.

40–70

Product (kg/h) w.b.

16–28

Drying rate (kg/h)

24–32

Using steam exhausted from one dryer stage as

carrier steam for another stage, multiple-effect oper-

ation (similar to that common to evaporators) can be

achieved yielding a steam economy of 1.9 for a triple-

effect dryer.

Potter et al. (1988) used a continuous fluid-bed dryer

for drying Victoria brown coal. The fluidized bed (FB)

dryer was 0.3

0.3 3 m (high) with four bubble caps to

distribute steam. The disengaging region was 2.5 m.

Both horizontal and vertical tube bundles were tried.

RBC (raw

brown coal)-

bunker

RBC discharge

Vapor dust

precipitation

Vapor compression

Vapor

condensor

Vapor

condensate

Energy

(~110

⬚C)

DBC

Condensate

Steam

(Dry brown

coal) cooler

FB (fluidized bed)

with heat exchanger

RBC

FIGURE 43.24 Steam-fluidized bed dryer with combined generation of power and heat.

ß

2006 by Taylor & Francis Group, LLC.

Faber et al. (1986) have compared drying rates in

air and steam-fluidized beds of pulverized coal. They

confirmed existence of the inversion temperature

above which steam drying is faster than air drying.

Above about 1808C the steam drying rate in the

constant-rate period in fluid-bed drying exceeds that

in (dry) air drying. For a 2000 kg/h dryer for alumina

they found the capital cost to be 20% lower for steam

dryer while the total energy cost was 15% lower. No

credit was given to the steam produced in the steam

dryer.

Faber et al. (1986) also report on a successful

industrial installation using steam dryer for activated

carbon pellets (2000 kg/h, dry basis) from an initial

moisture content of 50 to 2% (dry basis). The pellets

are dried to 8% on dry basis before they are fed to an

evacuated chamber in which the final moisture con-

tent of 2% is achieved. The steam enters the dryer at

3008C and leaves at 1508C. The steam discharged is

used to preheat the feed. The authors report smooth

operation of the dryer since 1985. The installed cost

of the steam drying system was 40% lower than that

for a conventional air dryer. The air dryer can operate

at a maximum temperature of 1258C to avoid com-

bustion in the dryer. The energy costs (1986 data)

were estimated to be about $3.60 per ton of dry

product in South Africa.

A Russian book on drying and thermo-aero clas-

sification of coal presents interesting results on steam

drying of 1- to 13-mm coal particles and volatiles

evolution during drying. Mujumdar (1990) notes

that in steam drying the drying time (actually resi-

dence time in dryer) does not affect the volatiles

liberation unlike air drying. Further, he found that,

under conditions of his experiment, the constant-rate

drying period is 6 to 7 times longer in steam drying

and the heat transfer rate is 1.7 to 2 times than that in

air drying. He also reports on favorable industrial

experience in steam-fluidized bed drying in a 35

9

12 m, 46 t/h of brown coal with an evaporative

capacity of 25 t/h. No details are given about the

steam reuse.

From energetic and safety viewpoints, super-

heated steam drying appears to be the most attractive

technology for drying of coal. This could be done

using a flash dryer, a fluid-bed dryer, a vibrating bed

dryer or a rotary dryer, if traditional dryer equipment

is to be used. A part of the energy can be supplied

indirectly using immersed heat exchangers. As

Mujumdar (1990) has noted there may be potential

to use variants of multistage impinging stream dryer

using superheated steam for coal drying applications,

but no work appears to be done yet on this design.

Furthermore, use of a two-dimensional design is

expected to allow modular design and reduced scale-

up problems. If used as a fuel after briquetting, there

may be opportunities to blend pulverized wet coal

with wood residues and various organic sludges either

before or after drying since these biomasses are also

excellent candidates for superheated steam drying.

43.4 DRYING OF LOW-RANK COALS

Low-rank coals (LRCs)—e.g., brown, lignite, and

subbituminous coals—represent nearly one half of

the estimated coal resources in the world and are the

only source of low-cost energy in many developing

nations. LRCs are typically present in thicker seams

with less overburden than bituminous coals, thus

making them recoverable by low-cost strip mining.

From a user angle, LRCs have a lower fuel ratio

(i.e., fixed carbon to volatile matter) and are typically

more reactive than bituminous coals; many also have

extremely low sulfur contents (a few tenths of 1%).

Low mining costs, high reactivity, and extremely low

sulfur content would make these coals premium fuels

if not for their high moisture levels, which range from

around 25% to more than 60%. Among coal import-

ers, high moisture creates a mistaken perception of

inferior quality and hence many positive features of

LRCs are neglected. LRCs can be combusted either

as a blending component with high-rank coal in exist-

ing boilers, or in new boilers designed for LRCs. For

example, more than one third of U.S. electrical power

currently comes from power stations that are fired by

LRCs. Until recently the high moisture levels of

LRCs have also excluded them from the rapidly

growing coal–water fuel (CWF) market. Of all the

coal-based alternative fuels, CWFs appear the most

promising (Willson et al., 1992).

It is now accepted that no single process can be

suitable as a universal drying technology for all

LRCs. The needs of the end user dictate the type of

process. If the end user requires dried lump coal for

stoker applications, a process that uses or generates

fines would not be a reasonable option. An end user

with advanced combustion applications will require

finely ground coal. From a producer’s angle, a pre-

ferred process could make use of both technologies:

one to produce sized dry coal and the other to make

coal–water fuel from the fines for a different market.

However, three stability issues must be solved before

bulk-dried LRCs can be used: (a) moisture reabsorp-

tion; (b) dust generation; and (c) spontaneous com-

bustion. Since the strength of LRCs is significantly

reduced when their gel-like structure is destroyed by

drying, the dried product breaks down rapidly, gen-

erating large amounts of dust, and becoming more

liable to spontaneous combustion.

ß

2006 by Taylor & Francis Group, LLC.

Direct drying of brown coal by recirculating boiler

flue gas or its equivalent, has become standard prac-

tice in Victoria, Australia. It should be noted that

significant drying occurs during normal coal grinding

and other operations associated with preparation of

the feed to a boiler.

Recently, a steam–fluidized bed drying process

being implemented at a plant operated by the State

Electricity Commission of Victoria, Australia (SECV)

uses a heat exchanger supplied by an external high-

pressure steam source to dry finely ground brown

coal. A tube network immersed in the bed supplied

heat. The high heat transfer rates of the bed, together

with condensing steam, yield a compact heat exchan-

ger. Water evaporated from the coal is used to fluidize

the system. Test results show that the water content of

Victoria’s brown coal can be reduced from 60 to 15%

and carbon dioxide (CO

2

) emissions can be decreased

to 17%.

In Australia, indirect drying has been used for

many decades to prepare brown coal for briquetting.

In this process, low-pressure steam is condensed on

the outside of tubes conveying brown coal to provide

process heat; the more water removed in liquid form,

the higher the efficiency. After reducing the moisture

to nominally 15%, dried brown coal is compacted into

strong briquettes using stamp presses.

43.5 HOT OIL DRYING

Hot oil is an alternative drying medium used by a

number of process developers as early as 1926. In the

two-stage Carbontech process, raw coal is first dried

in hot oil. Most of the oil is recovered in the second-

stage flue gas stripper. Some of the oil is absorbed,

which allegedly helps to stabilize the product and

increase its heating value. The process costs for this

system will depend on the amount of oil that can be

economically recovered.

The Exxon donor solvent, direct liquefaction

process also used hot oil drying. In this process,

LRC is dried by a high-pressure hydrogenation

reactor contact with hot recycle hydrogen donor

solvent prior to entering. Unfortunately, no data

were developed for solvent recovery after drying,

because the dried coal and vehicle solvent were

reacted immediately with hydrogen in the liquefaction

reactor.

Other methods have been tested to improve

the stability of the dried LRC, including spraying

with residual tars or oils and briquetting or palle-

tizing dried pulverized coal. All of these additional

processing steps increase the cost of the final pro-

duct and must be evaluated on a site and coal-

specific basis.

43.6 HOT WATER DRYING

Hot water drying (HWD) developed at EERC, is

a drying process that produces a safe, quasiliquid

fuel. This technology features high temperature,

high pressure nonevaporative drying that removes

much of the inherent moisture and allows the produc-

tion of CWFs with solid loading in the range of those

of commercial bituminous CWFs.

In HWD process, ground LRC is treated at coal-

specific temperatures, beginning at as low as 2408C,

and the corresponding saturated steam pressure for

less than 10 min. Moisture is removed from the coal

by expansion and expulsion from the micropores by

CO

2

, which is liberated during decarboxylation. Devo-

latilized tars/oils, being hydrophobic, remain on the

coal surface in the pressurized aqueous environment.

It is hypothesized that this produces a uniform coating

that seals the micropores and limits moisture re-

absorption, which is a major advantage of the process.

Because the coating retains most of the LRC’s volatile

matter, high energy recovery and excellent combustion

performance can be obtained. The developers claim

that alkali cations, a major source of boiler fouling,

associated with the carboxyl groups, are released in the

aqueous phase in their process and are removed during

the final mechanical dewatering step.

The technical feasibility of HWD and low-rank

coal–water fuel (LRCWF) production has been dem-

onstrated in a 7.5-tpd pilot plant at EERC with LRCs

from around the world. As a general rule, the energy

densities of LRCWFs produced after HWD are

around 30% for subbituminous coals, 50% for lignite,