42

Drying of Enzymes

Ana M.R. Pilosof and Virginia E. Sa´nchez

CONTENTS

42.1 Introduc tion ........ ............... .......... .......... ............... .......... ............. ............... .......... .......... ............... ...... 981

42.2 Spray Drying .......... ............... .......... .......... ............... .......... .......... ............... .......... .......... ............... ...... 982

42.2. 1 Dryin g-Chamber Layou ts ..... .......... ............. ............... .......... ............. ............... .......... .......... .. 982

42.2. 2 Solute- Induced Protect ion in Spr ay Dryi ng .......... .......... ............... .......... .......... ............... ...... 985

42.3. 1 Granul ation by Fas t Mixer Sy stems ............. ............... .......... ............. ............... .......... .......... .. 988

42.3. 2 Granul ation by the Prilling Process ............. ............... .......... ............. ............... .......... .......... .. 988

42.3. 3 Granul ation by Extrusi on Pro cess ..... .......... ............... .......... ............. ............... .......... .......... .. 989

42.3. 4 Granul ation by Spr ay Coat ing of Core Par ticles ..... .......... ............... .......... .......... ............... ... 989

42.1 INTRODUCTION

Enzymes are protein ca talysts of high molec ular

weight, which are produ ced not only by plants and

anima ls but also mainly by micr oorganis ms as a resul t

of fermen tation pro cesses. Enzy mes fall into tw o cat-

egorie s: (1) bulk indust rial enzymes , whi ch mainly

include pro teases for deterg ents, amylases for textile

desizing and starch hydrolysis, pectinases for fruit-juice

clarificati on, and proteas es for the leather industry

(

); an d (2) analytical enzymes .

In general, enzymes have a disadvantage in that

they ar e deactivated due t o heat-induced structural

changes or, in the c as e of proteolytic enzymes, due

to decom position by t hemselves. It is therefore de-

sirable to distribute and use e nzyme preparations in

the f orm of s olids , such as powders and granules,

instead of l iquids. A lthough drying itself is a valu-

able tool in the improvement of the e nzyme s torage

st ability, the process step itself often causes a sub-

stantial loss of activity and the final product is still

susceptible to inactivation.

Suc h solid enzyme pr eparations are co nventio n-

ally produce d by means of freez e drying or spray

drying. As freeze-dryi ng process is unsuit able for

large-sca le produ ctions, spray drying is used a s the

most fitted process for the indust rial mass produ ction

of soli d enzyme pr eparations. Especial ly in the case of

solid enzyme preparat ions to be used in deterg ents,

spray- drying pro cess is most frequent ly used.

Anal ytical enzymes are invari ably dr ied in smal l

quantities by freez e drying or by spray drying using

low tempe ratures. The spray drying of pa ncreat in, for

exampl e, must not have inlet drying tempe ratures

above 95 8 C [1].

The design of a proper drying process should guar-

antee a high level of acti ve en zyme. Genera lly, enzyme

activit y after drying is a functi on of the composi tion of

the initial liquid to be dehydrated, the process param-

eters, and the physicochemical characteristics of the

enzyme [2], so that drying of each enzyme product

should be considered on an individual basis.

Relevant properties of dried enzymes are listed in

. By modif ying the spray- drying process , it

is possible to alter and control the properties that are

mentioned earlier for spray-dried enzymes.

A major concern in spray drying of enzymes is the

retention of their activities, whereas this complication

is not seen in the case of purely chemical systems.

Therefore, the enzyme activity retention must be

close to 100% in the spray-drying operation; and

moreover, the shelf life of the dried enzyme products

must be excellent, i.e., enzyme activity must be

retained for long-time storage.

The formation of dust during handling of enzyme

preparations in finely divided solid forms is also a

problem. The dust of enzyme preparations incorpor-

ated in detergents and washing compositions could be

dangerous to the health of the workers in detergent

factories and for the end users.

ß

2006 by Taylor & Francis Group, LLC.

Ther e a re relative ly few studi es on the drying of

enzymes in the c hemical an d biologi cal literatu re.

This could partly be due to the indust rial nature of

the subject with the concomitan t proprie tary know-

ledge an d confiden tiality agreem ents abo ut prod ucts

and specific process parame ters . However, a large

number of patent s exist in this field. Selected patent s

where drying plays the dominan t role in the manufa c-

ture of enzyme produ cts are lis ted in

42.2 SPRAY DRYING

Spray drying is a co nvective drying techni que that

uses hot air to trans fer the heat an d remove the

evaporat ed water. It is a short-ti me pro cess in the

range of few seconds; and if proce ssing co nditions

are optim ized and stabili zers are added, it is suitab le

even for heat-sensi tive enzymes . The pro cess may

be su mmarized in three pha ses: (1) spray form ation,

(2) drying, an d (3) air–powder separat ion.

A wi de range of feed and drying propert ies are

success fully han dled to pro duce the powder with de -

sired qualities . The wi de ap plication of spray drying

has been due to the flex ibility of the system and the

developm ent of different drying- chamber designs that

combine with rotar y or nozzle atomizers to hand le

particular products in co ntinuous operation s.

If the desired powder specifica tion cann ot be

achieve d in the single-s tage process , multistage ope r-

ations are necessa ry. By combini ng atomizat ion, flui d-

ization, and agglom eration technol ogies in advanced

spray-d ryer designs , it is possible to meet the quality

specifica tions of the end pro duct, enzyme, within a

safe, hygieni c, and environm ental ly fri endly process .

W hen the spray- drying operati on is cocurrent , i.e.,

hot air intr oduced into the dryer close to the atomi z-

ing de vice, there is less danger of overh eating as the

evaporat ion rates are high (34 to 160 kg/h/m

2

of

particle area) [3]. Thus, co current drying ch ambers are

preferred to minimiz e heat deactivati on of en zymes

during the pro cess.

In the case of enzymes that are particu larly sensi -

tive to oxidation , it is preferable to use inert gas, such

as nitr ogen, during spraying and drying [4].

42.2.1 D

RYING

-C

HAMBER

L

AYOUTS

Several drying- chamber designs may be used to atta in

the desired powd er specifica tions. Standard co current

TABLE 42.1

Major Indust rial Applicati ons of Industria l Enzyme s

Application Enzyme Source

Detergents Protease Bacillus

Amylase Bacillus

Lipase Humicola,

Pseudomonas

Cellulase Bacillus, Humicola

Starch industry Amylase Bacillus

Glucoamylase Aspergillus

Glucose isomerase Bacillus, Streptomyces

Dairy Protease Rhizomucor

Lipase Aspergillus

Lactase Klyveromyces,

Aspergillus

Sulfhydryloxidase Aspergillus

Wine and Juice Pectinase Calf Stomach

Cellulase Aspergillus

Cellobiase Aspergillus,

Trichoderma

Glucose oxidase Aspergillus

Polyphenol oxidase Aspergillus

Distilling industry Amylase Trametes

Glucoamylase Aspergillus

Brewery b-glucanase Aspergillus

Acetoacetate

decarboxylase

Aspergillus, Bacillus

Bakery Amylase Bacillus

Protease

Aspergillus, Bacillus

Glucose oxidase

Aspergillus

Textiles

Amylase

Aspergillus

Cellulase

Bacillus

Catalase

Trichoderma,

Humicola

Animal feed

Phytase

Aspergillus

Cellulase

Aspergillus

Plant cell

wall–degrading

enzyme

Trichoderma,

Humicola,

Aspergillus

Pulp and paper

Xylanase

Aspergillus

Leather

Protease

Trichoderma, Bacillus

Tea

Tannase

Aspergillus

Source: From Oxenboll, K., Aspergillus enzymes and industrial

uses, in The Genus Aspergillus, Powell, K. ed., Plenum Press, New

York, 1994, 147–153.

TABLE 42.2

Quality Parameters for Dried Enzyme Products

Retention of activity

Dust properties

Solubility and dispersibility

Enzyme stability per se

Enzyme stability in detergent

Flow properties

Enzymes protein purity

Mean particle size and particle size distribution

Homogeneity

Bulk density

Color

Odor

ß

2006 by Taylor & Francis Group, LLC.

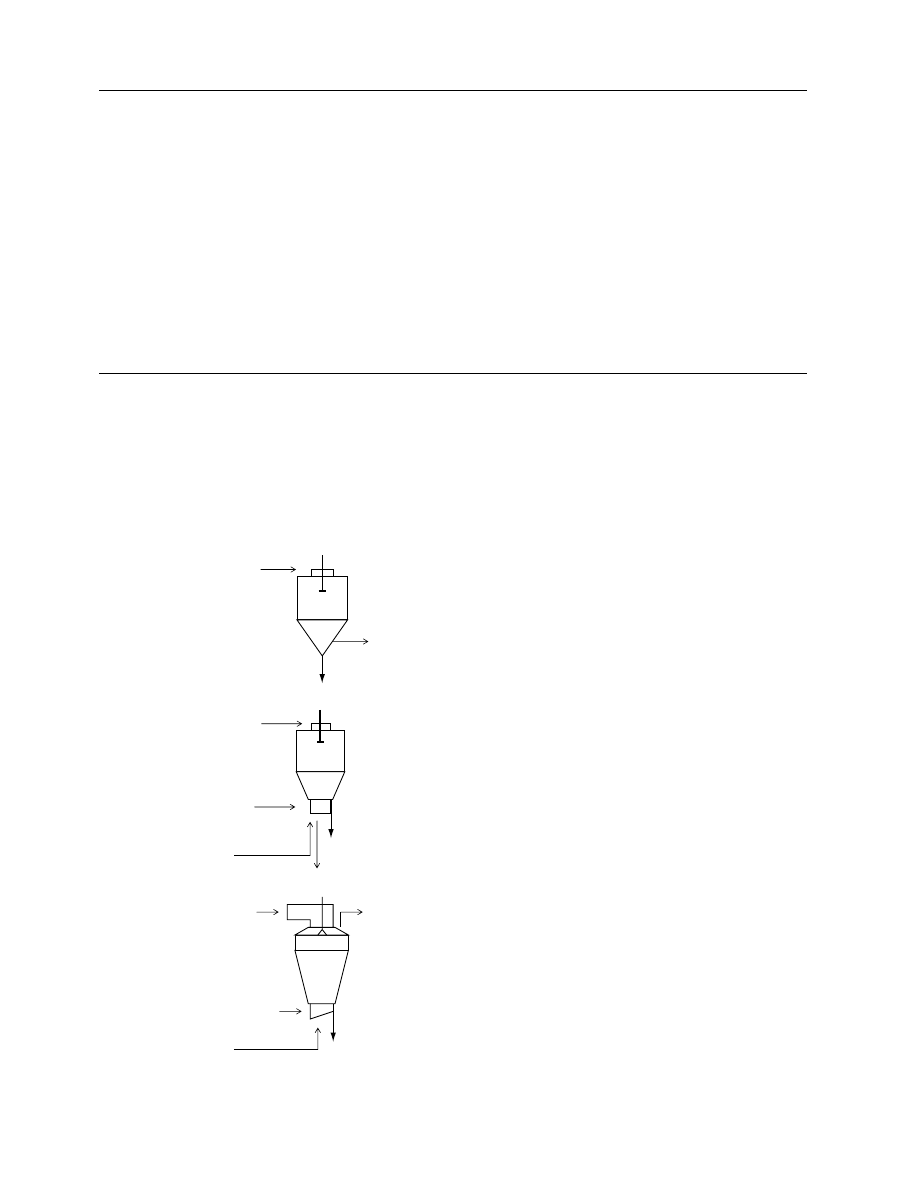

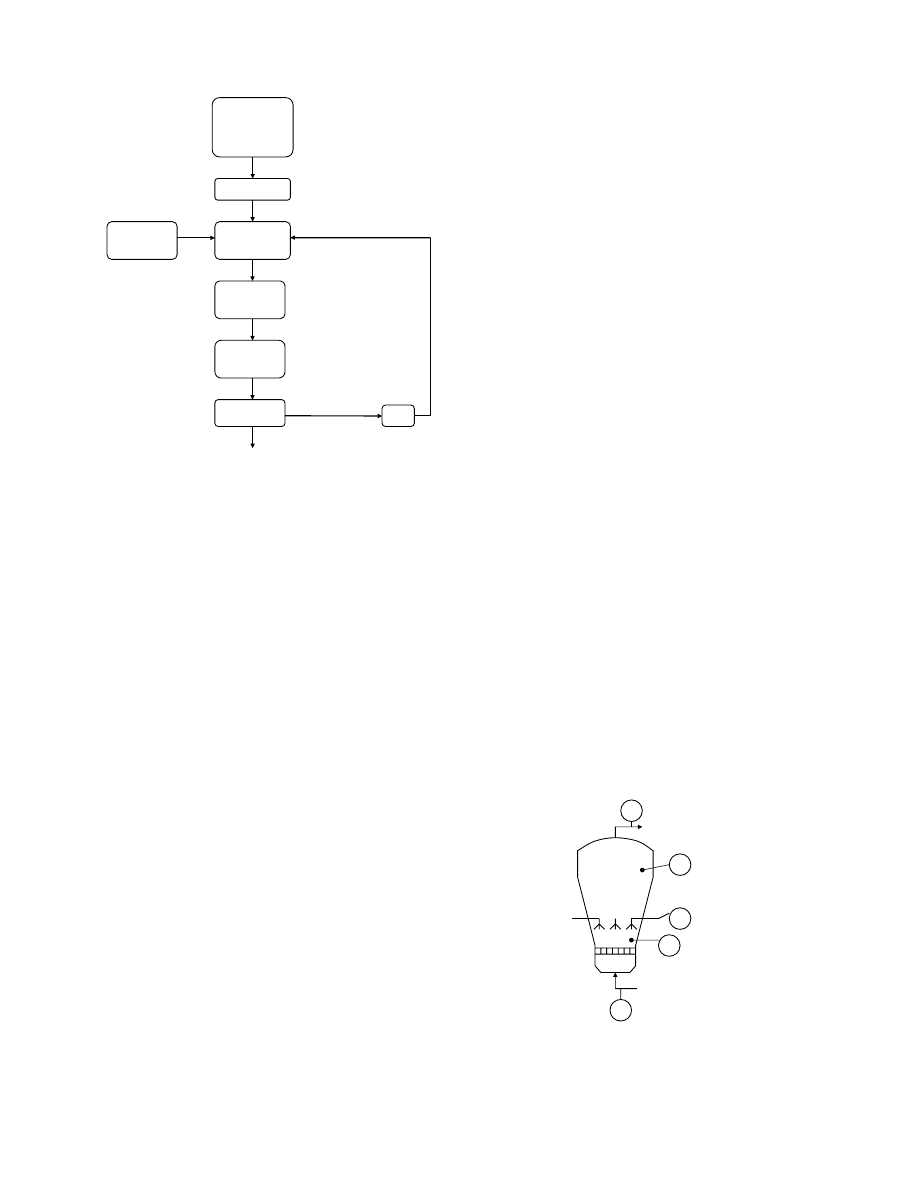

conical chambers (Figur e 42.1a) with eithe r rotary

atomizer or noz zles enable both fine - and coarse-

particled powder s to be pro duced. This layout is

used for therm ostable enzyme pr oducts wher e fair ly

high outlet air tempe ratures may be used. For a sin-

gle-stag e spray drying, enzy me activ ity losses may be

significa nt. Tabl e 42.4 shows the effect of some spray-

drying parame ters on the loss of acti vity of severa l

enzymes . Enzy me activit y decreas es wi th increa sing

outlet air temperatures. Low outlet temperatures were

also found to be important for the preservation of

tyrosinase, glucose oxidase, b-galactosidase, alkaline

phosphatase, and lact ate dehydroge nase (LDH ) [5–7] .

Enzy me activit y also decreas es with increa sing

inlet tempe ratur es. Signific ant enzyme inact ivation

occurs when mois ture decreas es below 15 to 20%.

The loss of enzymat ic acti vity ca n be reduced and

even almost co mpletely av oided when a co ntrolled

combinat ion of spray drying and fluid ized-bed dry ing

is used.

Spr ay drier s with integ rated fluid bed represen t

the latest in the spray- dryer design wher eby the com-

pletion of drying is accompl ished in a fluid bed lo-

cated in the lower con e of the chamber. The ope ration

of the fluid bed enables low er outlet tempe ratures to

accompl ish complet ion of drying, leadi ng to lower

powder tempe ratur es an d higher dryer thermal effi-

ciencies. The integ ration of flui d beds into drying

chambers allow s to pro duce, unde r low pro duct tem-

peratur e co nditions, nondus ty, free-flow ing, coa rse

powder s of indivi dual pa rticles or agglom erates.

Cham ber designs are shown in Figure 42.1b and

Figure 42.1c. Figure 42.1b shows a modificat ion of

the standar d layout wher e the fluid bed locat ed in the

base of the drying chamber is of an an nular de sign

enabli ng the exhaust air to be ducted out through the

center of the chamber base.

dimensions, i.e., a short cylindrical side in relation

to an extended cone section, and has a mixed flow

concept with air entering and leaving the top of the

chamber. This chamber is ideal for heat-sensitive,

sticky products and has enabled many products to

TABLE 42.3

Applications of Enzyme Drying

Issue

Patent No.

Patentee

Date

Process for freeze-drying enzymes

US 4 180 917

Rohm and Haas Co., Philadelphia, PA

January 1, 1980

Spray drying with additives

US 4 233 405

Rohm and Haas Co., Philadelphia, PA

November 11, 1980

Enzyme spraying onto a heated

fluidized bed of inert particles

US 4 617 272

Economics Laboratory Inc., St. Paul, MN

October 14, 1986

Disaccharide-stabilized enzyme preparation

EP 0 501 375 A1

KAO Corporation, Tokyo, Japan

July 2, 1992

Spray auxiliary composed of

hydrophobic silicas

US 5 318 903

BASF, Aktiengesellschaft, Germany

June 7, 1994

Process for storage of materials

US 5 928 469

Inhale Therapeutic Systems, San Carlos, CA

July 27, 1999

Enzyme preparation for leather

RU 2 127 311

Sergeevna et al.

March 10, 1999

Salt-stabilized enzyme preparations

US 5 972 669

Gist-brocades, B.V., The Netherlands

October 26, 1999

Microgranular enzyme composition

US 6 120 811

Genencor International Inc., Palo Alto, CA

September 19, 2000

Drying air

(a)

air

Product

(b)

Annular fluid bed

Product

air

(c)

Drying air

Drying air

Drying air

Drying air

Fluid bed

Product

air

FIGURE 42.1 Drying-chamber designs.

ß

2006 by Taylor & Francis Group, LLC.

TABLE 42.4

Effect of Some Spray-Drying Parameters on the Loss of Enzyme Activity

Enzyme

Spray Dryer

Temperature (

˚

C)

Moisture Spray-Dried

Product (%)

Loss of

Activity (%)

Reference

Inlet

Outlet

Bacillus alkaline protease

Conventional spray-drying tower

131.0

73.0

10.2

2.7

British patent 1 360 969

(Alcalase, Novozymes)

with spinning disk as atomizer

131.0

70.0

7.6

13.6

145.0

40.0

26.8

1.5

146.0

57.0

15.3

7.8

Fungal a-amylase prepared

Conventional spray-drying tower

150 + 5

63.0

5.2

19.0

British patent 1 360 969

by reverse osmosis

with spinning disk as atomizer

150 + 5

66.0

8.3

10.0

150 + 5

78.0

4.4

26.0

150 + 5

80.0

2.1

38.0

Fungal amyloglucosidase

Conventional spray-drying tower

150 + 5

90.0

14.0

34.0

British patent 1 360 969

with spinning disk as atomizer

150 + 5

80.0

17.0

20.0

150 + 5

70.0

20.0

10.0

Aspergillus oryzae protease

Small-scale spray drier

160.0

75.0

14.1

72.7

US patent 4 233 405

120–130

70.0

9.4–10.1

28–49

Neutral fungal protease

prepared by ultrafiltration

Small-scale spray drier

154.5

79.5

6.5

21.0

US patent 4 233 405

Bacillus subtilis neutral bacterial

protease prepared by

ultrafiltration

Small-scale spray drier

154.5

76.6

5.07

22.3

US patent 4 233 405

ß

2006

by

Taylor

&

Francis

Group,

LLC.

be s pr a y dr ie d su c c e s s fu l ly fo r t he fir s t ti m e . A l -

th o ug h it ha s be e n de v e lo pe d fo r f oo d a nd da i ry

pr od uc ts , i t is a ls o us e d fo r dy e st uf f s , a g ro c he m i c al s ,

po lymers, and detergents [8].

Thi s system feat ures a rotar y atomi zer or noz zle

located in an air-d ispersed roof. Pr imary drying takes

place in the conven tional man ner, but the partially

dried product, sti ll having significan t mois ture co n-

tent, passes directly into an e stablished flui dized layer .

As it has been found that gen erally the loss in

enzymat ic activit y increa ses when the water co ntent

in the spray- dried enzyme conce ntrate is lowered

(

), it is desirable that the pr oduct leaving

the spray dr yer has a moisture co ntent of not less than

8 to 10%, prefer ably ab out 20%. This resul ts in ex-

tremely low outlet tempe ratur es from the drying sys-

tem combined with controlled second-s tage drying

that takes place wi thin the stat ic flui d bed at a low er

tempe rature (40 to 50 8 C) to ac hieve the desir ed mois -

ture co ntent. The product from the dryer can be

postcool ed or postdried in a vibrating fluid bed.

A novel featu re of the design is the remova l of the

exhaust air from the roof of the drying chamber [8].

Fine mate rials elutriat ed from the fluidized bed are

carried wi thin the airflow and act to powd er the sur-

face of the drying chamber thereby limit ing deposit

formati on. A pro portion of the elutr iated fines co mes

into con tact with the cloud of atomi zed droplets

resulting in agglom eration prior to their entry into

the fluidized layer. The fine mate rials sep arated from

the exhaust air are recycle d to the chamb er for furth er

agglom eration. The process produ ces a dustl ess free-

flowin g powder with a mean particle size ranging

from app roximatel y 100 to 700 mm depe nding upon

the pr oduct characteris tics.

42.2.2 S

OLUTE

-I

NDUCED

P

ROTECTION

IN

S

PRAY

D

RYING

Several methods have been applied in the fie ld of

stabili zing en zymes agains t losse s dur ing drying and

subsequen t storage and hand ling. The bul k of these

applic ations a re concerned wi th the addition of car-

bohyd rates and, mo re specifica lly, sugars , polyols ,

and salt compon ents to the en zyme co ncentra te [9].

Als o known is the inclus ion of compone nts into

the form ulatio n wi th the aim to produce a glassy

produc t at storage temperatur e, thus impr oving en-

zyme stability. It will general ly be prefer red to emp loy

a carrier substa nce, which must be hy drophil ic (eith er

water- solubl e or water- swellab le), that mu st exist in a

glassy amo rphous state wi th a glass-t ransition tem-

peratur e (T

g

) above 20 8 C (a de sirable range is there-

fore between 60 an d 200 8 C) and should be suffici ently

chemi cally inert [10]. How ever, signi ficant enzyme

inactivat ion oc curs also in form ulation s kept wel l

below their glass -transit ion tempe ratur es [9].

Duri ng the final stage s of air drying, the major

stress that must be ov ercome is the remova l of the

enzyme’ s hy dration shell, which, for at least some

labile enzymes , can result in irreversib le inact ivation

upon rehydrat ion [11]. The mechani sm of this level of

protection is different from that occu rring in solution

[12]. It has been suggest ed that sugars can continue to

protect the dried protei n by hy drogen bonding to the

protein at some critical point during dehyd ration

[13,14], thus servi ng as water substitut es when the

hydratio n shell of the enzyme is remove d.

M oreover, most research ers agree that protection

by compoun ds such as lact ose and trehalose depend s

on the form ation of an amorpho us phase with the

protein [15] . The pro teins are mechan ically imm obil-

ized in the glassy, soli d matrix during de hydratio n.

The restriction of trans lational and relaxati on pro -

cesses is thought to prevent pro tein unfoldi ng, and

spatial separat ion be tween the protein molec ules (i.e.,

dilution of protein molec ules within the glassy matrix)

is prop osed to prevent aggrega tion [12] .

Take n toget her, these studi es support the co nclu-

sion that the impor tance of amorpho us be havior of

the pro tein and the ad ditive is that it allows for ef-

fective hyd rogen bondi ng betw een the add itive and

the protein . A glass y additive that doe s not have

the inter action will not protect the pro tein agains t

dehydrat ion damages [12].

Sug ars are an impor tant grou p of glass-f orming

substa nces, whi ch are also good stabilizers during

drying. Among them malto se- an d trehal ose-type

disacc harides are prefer red. Example s of the mal-

tose-type disacc ha rides include maltose, cello biose,

gentio biose, meli biose, an d lacto se, and exampl es of

the trehal ose-type disacc harides include trehal ose,

isotrehalos e, sucrose , isosuc rose, etc. The amount of

the disacc haride to be included in a solid enzyme

preparat ion may vary de pending on the type of the

enzyme used, but generally it is more prefer ably from

10 to 100% by weight of the enzyme [16].

An addition of 0.5% lact ose in a Bacillu s alkaline

proteas e sp ray-drying process is eno ugh to impr ove

the reco very of active enzyme after drying and ther-

mal treat ment at 90 8 C (

). In the same way,

the exhaust air temperature could be increased by

108C reaching severe drying conditions without sig-

nificant loss of proteas e activit y (

). The solid

enzyme preparation obtained in this process was also

excellent in resistance to mechanical pressure [16].

In addition to plain carbohydrates, other polyhy-

droxy compounds can be used, e.g., carbohydrate de-

rivatives and chemically modified carbohydrates (i.e.,

carbohydrates that have undergone chemical reaction

ß

2006 by Taylor & Francis Group, LLC.

to alte r sub stituent s on the carbon back bone of the

molec ule but withou t alterati on of the back bone).

Protein s are also suitab le. T hus albumin can be used

and also hydrolysis products of ge latin, like Byco

A (Croda Colloids Ltd.) that allowed an excellent en-

zyme storage stab ility afte r hard spray-drying co ndition s

of LD H type XI (ex rabbit muscl e) (Tab le 42.7).

Sug ar copolyme rs may be employ ed as glass -

forming su bstance s. Fico ll (Pharm acia

1

) includes co-

polyme rs with molec ular weigh ts between 5000 and

1,000,000, contain ing sucrose resi dues linked through

ether bridges to bifunct ional groups. Suc h group s

may be alkyl ene of two or more carbon atoms but

not normally more than ten carbon atoms . The bi-

functio nal groups serve to conn ect su gar residues

togeth er. Thes e polyme rs may, for exampl e, be made

by reaction of the sugar with a halohyd rin or a bis-

epoxy compoun d [10] . Ficoll 400 DL (Ph armacia) is a

water- soluble cop olymer of sucrose and ep ichloroh y-

drin that has a T

g

of 97 8C. A mixture of Ficoll 400

DL 4% and LDH type XI (ex rabbit muscle) shows

that enzyme activ ity was effecti vely preser ved

through the spray-d rying proc edure and subsequen t

long-term storage. Good stabilization was also reached

for alcohol oxidase: after 30 d, the spray-dried material

retained 90% of its activit y whi le the freez e-dried

material lost all activit y in 20 d (

) .

Anothe r approach is the add ition to the form ula-

tion of one or severa l compo nents that are able to

bind mo isture. This will reduce the water acti vity of

the final preparat ion or temporaril y prevent the inter -

action of water penetra ting from the surround ings

with the enz yme itself .

The use of organic and inorganic salts as a pro -

cessing aid (e.g., to impro ve flowi ng behavior of the

product) or a s a bulking/ standar dizing agen t is wel l

known. Solid enzyme formulat ions wi th impr oved

drying yiel d a nd stora ge are achieve d by prepari ng a

solution co mprising an enzyme an d a water-so luble

inorgani c salt . The presence of salt prior to drying,

while the enzyme is still in so lution, resul ts not only in

a higher yield dur ing dr ying but a lso in an impr oved

storage stabili ty as well as proce ssing stabi lity of the

obtaine d dry enzy me pr eparation s. Addit ion of mag-

nesium sulf ate to different ind ustrial en zymes allowed

a reco very of more than 100% active enzyme after

drying a nd after long-term storage [17] .

Pr eferably, an inorgani c salt of a dival ent cation ,

like z inc or magnes ium sulfate, can be added to the

enzyme so lution. Als o, a combination of salt s as wel l

as a combinat ion of enzymes can be used. The add -

ition of dival ent cati ons is prefer red be cause they

provide the best storage and process ing stabili ty. Sul-

fate is preferred as anion beca use it provides the best

drying y ield (

Dryi ng of a so lution co ntaining the enzyme and the

salt will result in a soli d composi tion that is homo ge-

neous with respect to the distribution of the enzyme

and the salt. The stabilizing effect of the salt increases

with increasing dosage of the salt to the enzyme solu-

tion, until at a certain point further increases in salt

dosage no longer produce further improvement of the

enzyme stability. For this reason, between 5 and 90%

of salt is added to the enzyme solution based on the

weight of the enzyme in solution.

42.3 POWDERED DETERGENT ENZYMES

Enzymes today are key strategic ingredients for wash-

ing and cleaning formulations. Enzymes not only

remove stains but also improve textile fiber properties.

TABLE 42.5

Effect of Lactose Addition on Production

of Stabilized Enzyme Powders

Lactose

Addition (%)

Residual Activity (%)

after Drying

Residual Activity (%)

after Heating 1 h

at 90

˚

C

0.0

83

84

0.5

90

95

1.0

96

96

2.5

96

96

5.0

95

97

Patent reference: EP 0 501 375 A1.

Enzyme: Bacillus alkaline protease K 16 5%

þ calcium chloride

0.2%

þ sodium sulfate 2.5%.

Drying technology: Atomizer-type spray dryer T

in

: 1508C; T

out

:

608C.

TABLE 42.6

Effect of Lactose Addition on Production of

Stabilized Enzyme Powders by Spray Drying with an

Exhaust Air Temperature Variation from 60 to 70

˚

C

Lactose

Addition (%)

Residual Activity (%) after Drying

60

˚

C

65

˚

C

70

˚

C

0

83

79

70

0.5

96

99

96

1.0

94

95

95

Patent reference: EP 0 501 375 A1.

Enzyme: Bacillus alkaline protease K 16 5%

þ calcium chloride

0.2%

þ sodium sulfate 2.5%.

Drying technology: Atomizer-type Spray Dryer T

in

: 1508C.

ß

2006 by Taylor & Francis Group, LLC.

TABLE 42.7

Solute-Induced Protection of Enzymes during Spray Drying and Storage

Enzyme (w/w %)

Brand Name

Additive

(w/w %)

Drying Technology

Temperature (

˚

C)

Inlet–Outlet

Residual

Activity after

Drying (%)

Storage

Residual

Activity

after

Storage (%)

Time

Temperature

(Weeks)

(

˚

C)

1. Fungal phytase (11)

Gist-brocades

MgSO

4

7 H

2

O (24)

Buchi lab-scale spray drier

130–85

—

8

30

146

2. Bacillus alkaline

protease (12)

Genencor

International Inc.

MgSO

4

0 H

2

O (8.5)

Niro STREA-1 lab-scale

fluid-bed coater

80–50

119

6

35

121

3. Trichoderma

b

-glucanase

þ

endoxylanase (25)

Gist-brocades

MgSO

4

7 H

2

O (24)

Glatt WSG-60 fluid-bed coater

80–50

105

þ 120

12

30

111

þ 120

4. Lactate dehydrogenase

type XI (0.005)

Sigma Chemical Co.

Ficoll 400 DL

a

(4)

Drytec pilot-scale spray drier

210–70

82

20

10–35

100

5. Lactate dehydrogenase

type XI (0.005)

Sigma Chemical Co.

Ficoll 400 DL

a

(10)

Lab-Plant SD-04 spray drier

170–75

91

9

10–35

103

6. Lactate dehydrogenase

type XI (0.005)

Sigma Chemical Co.

Byco A

b

(4)

Drytec pilot-scale spray drier

210–70

88

15

25

113

7. Alcohol oxidase (0.00005)

Provesta Enzymes

Ficoll 400 DL

a

(4)

Drytec pilot-scale spray drier

150–70

52

4

35

90

a

Copolymer of sucrose and epichlorohydrin (Pharmacia Reg. Trade Mark).

b

Cold water–soluble protein obtained from gelatin by enzymatic hydrolysis (Croda Colloids Ltd.).

Patent references 1–3: US 5 972 669.

4–7: US 5 928 469.

ß

2006

by

Taylor

&

Francis

Group,

LLC.

Pr ior to the introd uction of co mpacts, the use of

enzymes in detergen ts was limited prim arily to one

class of en zymes— the proteas es. Pro teases catalyze

the hydrolys is of protei n-based soils like bloo d and

grass. Mo st powder and liquid laund ry de tergen ts on

the market today, both low density and compact s,

employ a proteas e [18]. Recently, protein en gineer ing

has been us ed to constr uct deterge nt pr oteases wi th

impro ved stability and perfor mance charact eristic s.

In add ition to protease s, a limited num ber of

brands employ amyl ases. Dete rgent amylases catalyze

hydrolys is of the a -1,4-gl ycosidic linkag es in star ch.

As such they show be nefits on a number of common

food sols like gravies, sauces, pastas , an d baby foods.

Advan ces in genetic and protei n engineer ing have

led to ne w classes of enzymes with novel ben efits for

use in co mpact pro ducts. In 1988, lipase app eared in

one of the first compact powder s to hit the Japane se

market . Sin ce then lipas e has foun d broad applic ation

in the global de tergen t market . Second -generati on lip-

ases with impr oved cleanin g effici ency were developed

in the compact deterg ent market [19].

Pr oducts contai ning up to four different en zymes

—prote ase, amyl ase, lipase, and cell ulase— are now

on the market . The patent literat ure suggests that

even more novel de tergent enzymes are on the way.

As deterg ent enzymes hav e now become co mmod-

ities and are rather low -priced products , full atten tion

is pa id to the produc tion pr ocess that, despit e all the

techni cal demand s, has to be very econo mical.

The very first enzyme products that were intro -

duced on the market in the 1960s wer e powder s, and

using tod ay’s termino logy they contai ned 100% dust.

Today the powd ers ha ve been replac ed by various

types of granula tes. Ho wever, certa in kind s of a g-

glome rates, e.g. , fluidized- bed agglom erates, are still

available. Thes e agglom erate s have an accep table

particle size dist ribut ion but the physica l stre ngth is

normal ly poor .

To protect both deterg ent plant ope rator s and end

users, the enzyme pa rticles have to be coated in such a

way that no ac tive enzyme dust is presen t or released

during hand ling. Besides avoidance of dust, the coat-

ing has to stabi lize the particles agains t abrasive

forces an d protect the gran ule ag ainst chemi cal agents

such as water, hydroperoxi de, and pe racetic acid (the

bleach that migrates in deterg ent formu lations) . On

the other han d, the coati ng shou ld not be sticky be -

cause this woul d result in oversi zed particles during

the coatin g process and would deteriorat e the free-

flowin g prop erties of the particles in the dos ing sys-

tems of deterg ent manufa cturer s [20]. Finally, the

coatin g ha s to dissol ve readily in the was hing liquor ,

even at low tempe ratur es.

Since the introd uction of enzymes into the deter-

gent and other indust rial segme nts, many develop -

ments have been made regardi ng the granu lation

and coating of enzymes to reduce e nzyme dust. How -

ever, in today ’s state of ever-increa sing environm ental

concern a nd height ened awareness of indust rial hy -

giene, there remains a continuing need for low-dust

enzyme granules. The following are the most important

process es to granula te enzymes [20] .

42.3.1 G

RANULATION BY

F

AST

M

IXER

S

YSTEMS

With fast-rotating mixing systems of ‘‘ploughshare’’

type mixers or Schigi type with horizontal or vertical

shafts, equipped with blenders, the high turbulence in

the rotating mixture of ingredients determines the

particle size.

Usually, a premix of dry powders is loaded into the

equipment and the liquid enzyme concentrate is injected

and mixed. After a certain time, depending on the recipe

and moisture content, granules are formed that are

discharged and dried in a fluid dryer. After sieving the

granules, over- and undersized materials are milled

and recycled to the premix.

42.3.2 G

RANULATION BY THE

P

RILLING

P

ROCESS

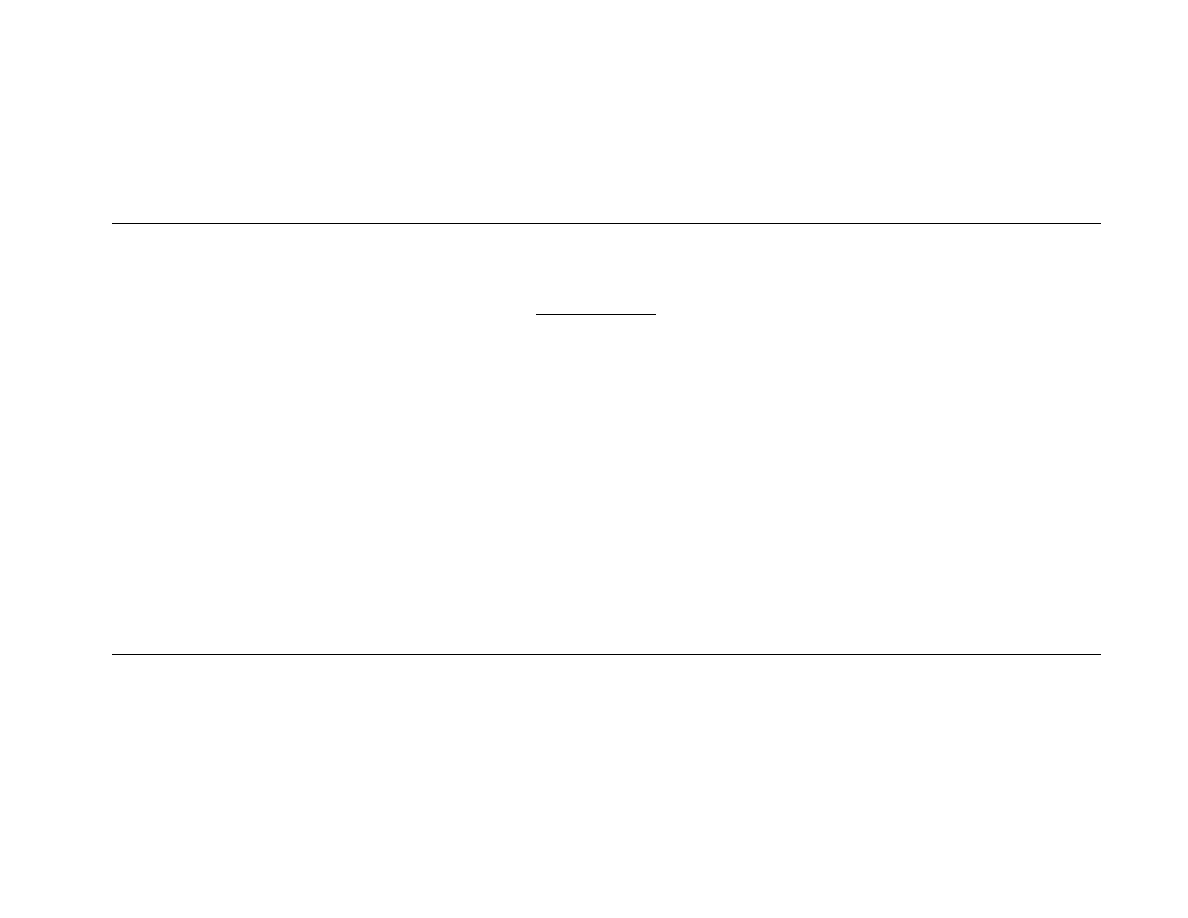

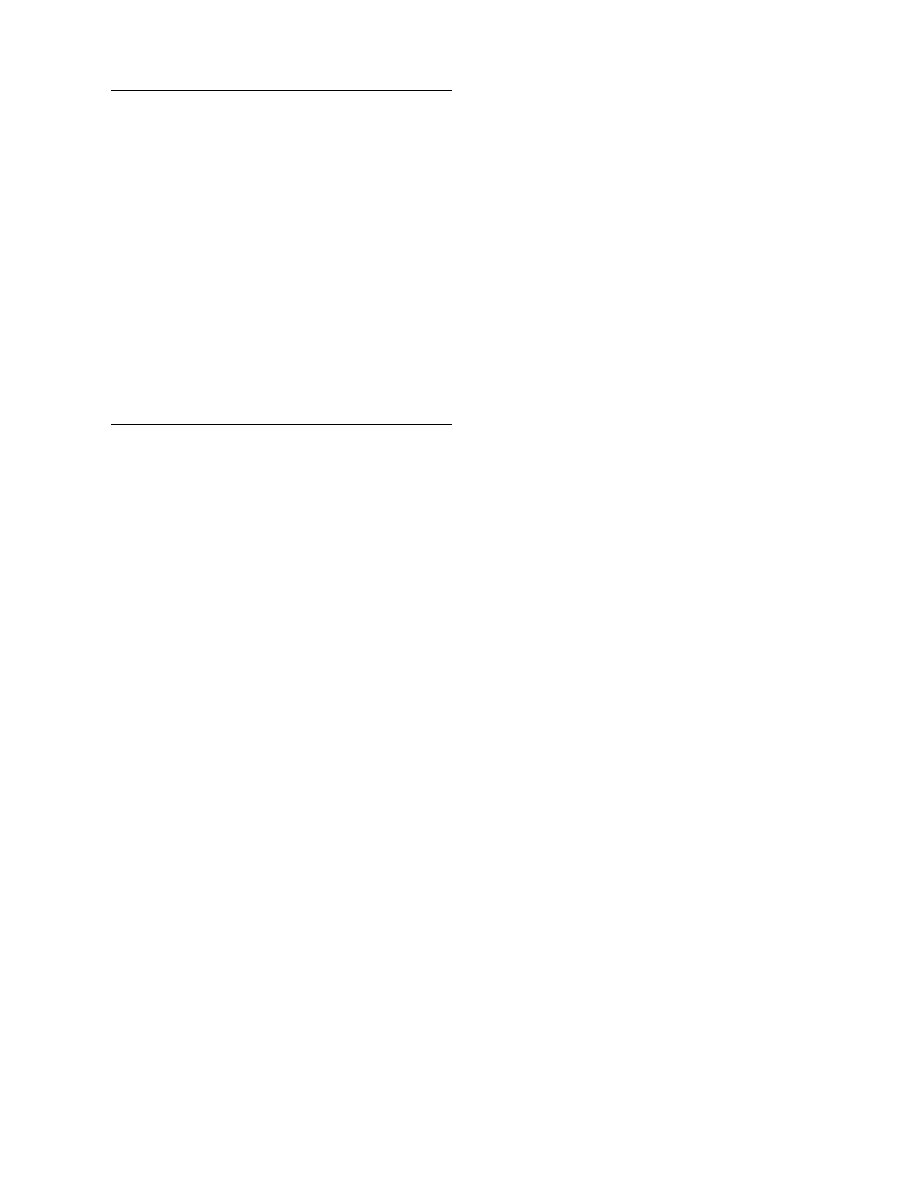

The basic princi ple of this pro cess (

) is that

the total mixture of ingredients is transferred into a

TABLE 42.8

Effect of Salts Addition on Spray Drying and Storage

Losses of Fungal Phytase

Salt Type

Spray Drying

Losses (%)

Storage

Losses (%) after

8 Weeks at 358C

None

6

52

Magnesium sulfate

7

15

Magnesium chloride

26

43

Magnesium nitrate

32

27

Zinc sulfate

5

9

Zinc chloride

48

5

Calcium chloride

40

18

Calcium nitrate

44

13

Sodium sulfate

11

51

Potassium sulfate

17

36

Ammonium sulfate

6

46

Patent reference: US 5 972 669.

Enzyme: Fungal phytase concentrate (Gist-brocades) 17 w/w %

þ

800 mM salt.

Drying technology: Lab-scale Buchi 190 mini spray dryer T

in

:

1408C; T

out

: 808C.

ß

2006 by Taylor & Francis Group, LLC.

molten mass of low viscosity in which insoluble ingre-

dients have to be homogeneously distributed. The melt

is pumped through insulated tubes to the top of a

tower where it is sprayed by nozzles or a rotating disk.

The size of the droplets that fall down the tower is

determined by the diameter of the nozzle, the rotation

frequency of the disk, the surface tension, and the

viscosity of the melt. The heat capacity and the melt-

ing heat of the droplets dictate the distance needed to

solidify the droplets to nearly ideal balls and, there-

fore, also the height of the prill tower. The final steps

are cooling in continuous fluid beds and sieving of the

solidified prills. Over- and undersized materials are

separated and recycled.

With this process, it is of some disadvantage that

all the ingredients, including the enzyme, have to be

anhydrous. Therefore, the enzyme has to be brought

into a dry state, which is often costly because of

energy demand, enzymes losses, and inactivation

because of the (high) drying temperature. The pre-

paration of the melt at elevated temperatures also

inactivates a certain amount of the enzyme, which

additionally increases the cost of the process.

As prilling agents, meltable ingredients, such as

polyethylene glycols, are used as binders. Salts are

used to make the particles brittle and tough, and

they combine the advantage of being cheap.

42.3.3 G

RANULATION BY

E

XTRUSION

P

ROCESS

The extrusion process is very well established in the

plastic and food industry. This technology for the

manufacturing of the enzymes-containing granulate

combines the advantage of a homogeneous particle

size distribution with low-cost ingredients.

After mixing the dry ingredients, the dry premix-

ture and the liquid enzyme concentrate are fed batch-

wise in a mixing system to obtain a moist doughlike

mixture. This mass is fed into a twin-screw screen-

type extruder and presses through thin perforated

metal sheets with holes that are the diameter of the

desired particle size. The extruded noodles fall by

batchwise feeding into a spheronizer. This machine,

equipped with a fast-rotating disk, breaks the noodles

down to cylindrical particles, which are then trans-

ported on the disk to the walls of the apparatus.

After drying the particles in a fluid-bed dryer and

removal of over- and undersized materials by sieving,

the beads are coated in a fluid-bed coater with one or

two coating layers to obtain white or colored beads

and to have a tough protecting layer that completely

avoids the development of enzymatically active dust.

42.3.4 G

RANULATION BY

S

PRAY

C

OATING

OF

C

ORE

P

ARTICLES

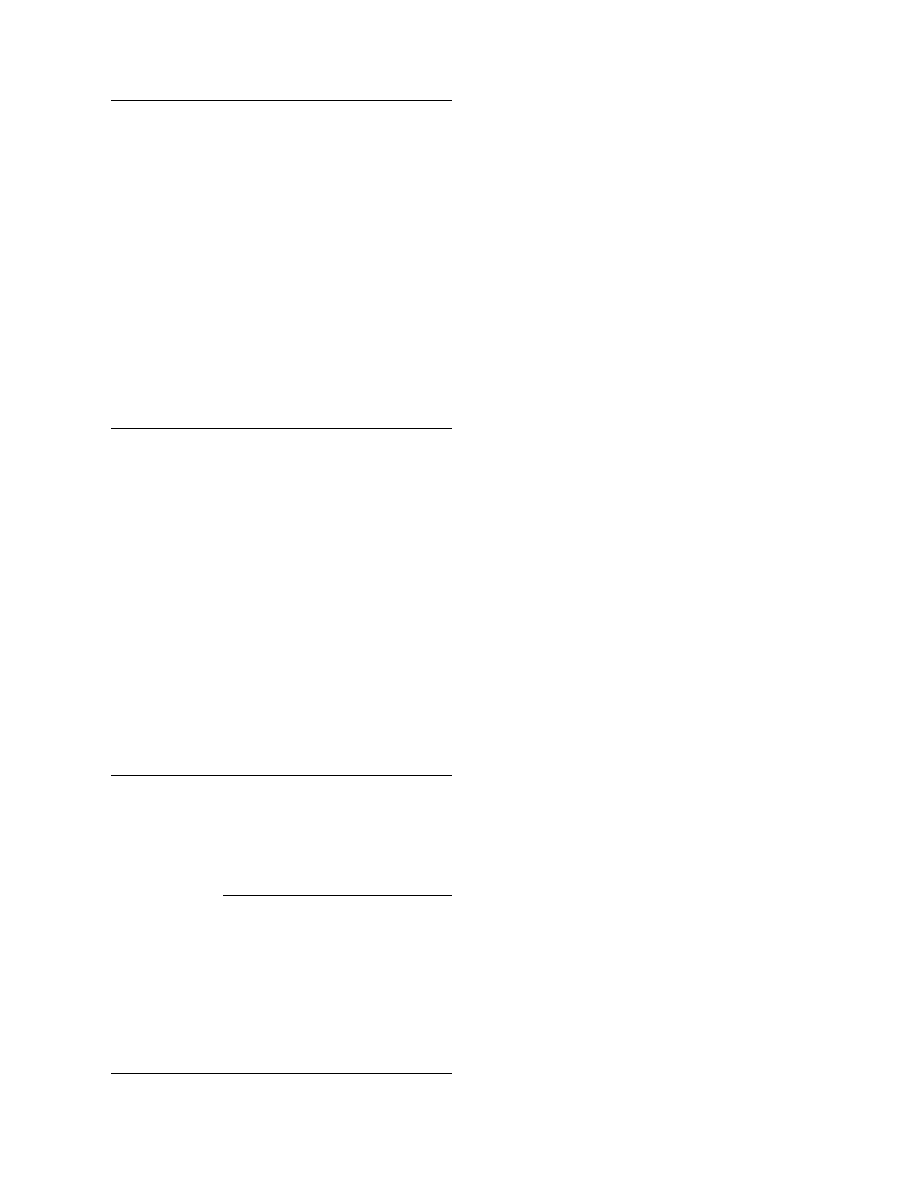

Granulation by spray coating generally refers to pro-

ducing a particle having an average size between 20

and 400 mm by fluidizing a core material in a heated

airstream to pass through an area of atomized liquid

(Figure 42.3). The atomized liquid droplets, which

contain dissolved or suspended solids, form a film

on the surface of the core material. The coated core

material is then transferred from the spray zone into a

drying zone. The solvent in the liquid—generally

water—is dried, leaving the dissolved or suspended

solids as a film on the core material. This process is

continued until the desired amount of film is formed.

Nonstandard size

Melt

preparation

Prilling

tower

Fluid-bed

coater

Sieve

mill

Meltable

component

Spray drying

Liquid

enzyme

concentrate

Enzyme granule

FIGURE 42.2 Prilling process.

Air outlet

4

5

2

3

Air inlet

1

FIGURE 42.3 Principle of the core-coating fluid-bed appar-

atus: (1) air inlet; (2) product bowl; (3) spray nozzles; (4) ex-

pansion chamber; (5) air outlet.

ß

2006 by Taylor & Francis Group, LLC.

Finally, the coated particles, which have an onion-like

structure, may be screened to obtain the desired range

of particles.

Methods for making low-dust granules include:

1. Loading a suitable carrier as a core material

into a fluid-bed granulator

2. Blending an aqueous enzyme source and one or

more suitable binders

3. Spraying the blend of enzyme and binder of

step 2 on the carrier

4. Spraying the product of step 3 with a water-

soluble, food-grade polymer at a rate to form a

coating and to reach the desired particle size

Typical carriers used as core materials and binders

are listed in Table 42.9. As used herein, ‘‘binder’’

indicates one or more materials, which act either

alone or in combination with sugars (such as sorbitol)

to bind the enzymes to the carrier material.

Two objectives are attained during the spraying

process: (1) the enzyme is attached to the carrier

and (2) the particle is built up to a granular form

(within the desired size range). A suitable food-grade

polymer is then sprayed onto the granulated particles

to envelope the enzyme and to hold the agglomerate

or granule together.

This process is economically attractive because the

moisture sprayed onto the carrier is ‘‘flashed off’’ as the

liquid is sprayed on the carrier, and thus a large amount

of aqueous enzyme can be loaded on the carrier.

Atomizing spraying can be done countercurrently

(down spray) to the fluidizing air or cocurrently (up

spray) with the fluidizing air. Down spray usually

results in more agglomeration and is useful when

fine powders are coated to increase the particle size,

resulting in lower dust granules. Cocurrent spraying

(up spray) results in less agglomeration and is used

when the core particle size already approximates the

final product size [20].

Many variables affect the efficiency of the coating

process. The three most important parameters for

manufacturing the microgranules are bed tempera-

ture, fluidization air rate, and spray rate. Careful

adjustment of all the engineering parameters is re-

quired to set the optimal conditions for a dust-free

granulate of desired specifications.

ACKNOWLEDGMENTS

Authors acknowledge the financial support from Uni-

ersidad de Buenos Aires, Consejo Nacional de Investi-

gaciones Cientı´ficas y Te´cnicas, and Agencia Nacional

de Promocio´n Cientı´fica y Tecnolo´gica de la Repu´blica

Argentina.

REFERENCES

1. S. Nath and G.R. Satpathy, A systematic approach for

investigation of spray drying process, Drying Technol.,

16:1173 (1998).

2. E. Dumoulin and J.J. Bimbenet, The properties of

water in foods, ISOPOW 6 (D.S. Reid, ed.), Blackie

Academic and Professional, New York, 1998.

3. Z. Pakowski and A.S. Mujumdar, Drying of pharmaceut-

ical products, Handbook of Industrial Drying (A.S.

Mujumdar, ed.), Marcel Dekker, New York, 1987, p. 605.

4. W. Bewert and G. Schwarz, Production of enzyme

preparations comprising an enzyme and finely divided

hydrophobic silica, US Patent 5 318 903 (1994).

5. Flair-Flow Europe, Are all dried foods the same? Flair-

Flow Reports; F-FE 110/93:1 (1993).

6. S. Yamamoto and Y. Sano, Drying of enzymes: En-

zyme retention during drying of a single droplet, Chem.

Engi. Sci., 47:177 (1992).

7. M. Adler and G. Lee, Stability and surface activity of

lactate

dehydrogenase

in

spray-dried

trehalose,

J. Pharm. Sci., 88:199 (1999).

8. H. Helsing, Latest developments in spray drying of

chemical and pharmaceutical products, Danish Tech-

nical Days, A/S Niro, Warsaw and Krakow, Poland

(1990).

9. A.M.R. Pilosof and M.R. Terebiznik, Spray and freeze-

drying of enzymes, Drying Technology in Agriculture

and Food Science (A.S. Mujumdar, ed.), Science Pub-

lishers, Enfield, NH, 2000, p. 167.

10. F. Franks, R.H. Hatley, and S.F. Mathias, Process for

storage of materials, US Patent 5 928 469 (1999).

11. J.F. Carpenter and J.H. Crowe, An infrared spectro-

scopic study of the interactions of carbohydrates with

dried proteins, Biochemistry, 28:3916 (1989).

TABLE 42.9

Typical Carriers and Binders Used in Granulation

of Enzymes by Spray Coating

Binders

Carriers Used as Core Materials

Alginate

Sodium chloride

Carrageenan

Sodium carbonate

Cellulose fibers

Urea

Gelatins

Calcium alginate

Xanthan gum

Saccharose beads

Locust bean gum

Polyvinyl alcohol beads

Gellan gum

Starch

Soluble or hydrolyzed starch

Soy flour, guts

Polyethylene glycols

Corn flour

Ethoxylated fatty alcohols

Cellulose-type materials

Polyvinyl alcohols

Polyvinyl pyrrolidones

Ethoxylated phenols

ß

2006 by Taylor & Francis Group, LLC.

12. J.H. Crowe, J.F. Carpenter, and L.M. Crowe, The role

of vitrificaton in anhydrobiosis, Annu. Rev. Physiol.,

60:73 (1998).

13. J.F. Carpenter and J.H. Crowe, Modes of stabilization

of a protein by organic solutes during desiccation,

Cryobiology, 25:459 (1988).

14. J.F. Carpenter, J.H. Crowe, and T. Arakawa, Compari-

son of solute-induced protein stabilization on aqueous

solution and in the frozen and dried states, J. Dairy

Sci., 73:3627 (1990).

15. B.C. Hancock and G. Zografi, Characteristics and signifi-

cance of the amorphous state in pharmaceutical systems,

Am. Chem. Soc. and Am. Pharm. Assoc., 86:1 (1997).

16. N. Yamada and Y. Shoga, Solid enzyme preparation

and process for producing the same, EP Patent 0 501

375 A1 (1992).

17. H.-P. Harz and J.B. Roland, Salt-stabilized enzyme

preparations, US Patent 5 972 669 (1999).

18. Chem. Mark Reporter, January 16, p. SR 18 (1995).

19. M.S. Showell, Powdered detergents, Powdered Detergents

(M.S. Showell, ed.) Marcel Dekker, New York, 1997, p. 1.

20. H.A. Herrmann, I. Good, and A. La¨ufer, Manufactur-

ing and downstream processing of detergent enzymes,

Powdered Detergents (M.S. Showell, ed.) Marcel

Dekker, New York, 1997, p. 251.

ß

2006 by Taylor & Francis Group, LLC.

Document Outline

- Table of Contents

- Chapter 042: Drying of Enzymes

Wyszukiwarka

Podobne podstrony:

Modeling with shrinkage during the vacuum drying of carrot (daucus carota) (Arévalo Pinedo, Xidieh M

Influence of drying methods on drying of bell pepper (Tunde Akintunde, Afolabi, Akintunde)

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

Microwave Application in Vacuum Drying of Fruits (Drouzaf, H SchuberP)

Microwave vacuum drying of model fruit gels (Drouzas, Tsami, Saravacos)

041 Drying of Polymers

039 Drying of Biotechnological Products

Modeling and minimizing process time of combined convective and vacuum drying of mushrooms and parsl

022 Drying of Fish and Seafood

026 Drying of Herbal Medicines and Tea

Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opi

Microwave Application in Vacuum Drying of Fruits (Drouzaf, H SchuberP)

040 Drying of Coated Webs

Microwave Drying of Parsley Modelling, Kinetics, and Energy Aspects

James Axler Deathlands 042 Way of the Wolf

Microwave Finish Drying of Diced Apples in a Spouted Bed

043 Drying of Coal

więcej podobnych podstron