Inclusion Bodies: Formation and Utilisation

Beatrix Fahnert

1

· Hauke Lilie

2

· Peter Neubauer

3

1, 3

Biocenter Oulu, Department of Process and Environmental Engineering, Bioprocess

Engineering Laboratory, University of Oulu, P.O. Box 4300, 90014 Oulu, Finland

E-mail:

1

beatrix.fahnert@oulu.fi;

3

peter.neubauer@oulu.fi

2

Institute of Biotechnology, Martin-Luther-University Halle-Wittenberg, 06099 Halle

(Saale), Germany

E-mail: lilie@biochemtech.uni-halle.de

Abstract

The efficient in vivo folding of many heterologous proteins is a major bottleneck of

high level production in bacterial hosts and simple optimisation protocols have not been avail-

able yet. Therefore, inclusion body (IB) based processes play a major role as a potential strategy

for the production of complex recombinant proteins. These processes combine the advantages

of a high accumulation of the target protein in well-characterised bacteria such as Escherichia

coli, efficient strategies for IB isolation, purification and in vitro protein refolding without the

need of complicated coexpression systems. Recent advances in the molecular physiology of IB

formation and resolubilisation allow straight-forward optimisation of fermentation processes

to obtain a high-quality product. In addition, simple strategies have been developed to optimise

the purification and renaturation of disulfide bond containing proteins making a fast transfer

of such processes into the industrial production scale realistic.

Keywords

IBs · Aggregation · Proteolysis · Refolding · Stress response

1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

95

2

Protein Aggregation in Prokaryotes – The Formation of IBs . . .

96

2.1

Structural Characteristics of Proteins Favouring Aggregation . .

96

2.1.1

Disulfide Bonds . . . . . . . . . . . . . . . . . . . . . . . . . . .

97

2.1.2

Membrane Proteins . . . . . . . . . . . . . . . . . . . . . . . . .

98

2.1.3

Glycosylation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

98

2.2

Composition and Structure of IBs and Kinetics of IB Formation

99

2.2.1

Architecture and Structure . . . . . . . . . . . . . . . . . . . . .

99

2.2.2

Composition of IBs . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.2.3

Kinetics of In Vivo Aggregation . . . . . . . . . . . . . . . . . . . 101

2.2.4

Stability of IBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

2.3

The Physiology of IB Formation . . . . . . . . . . . . . . . . . . 103

2.3.1

The Metabolic Load of IB Synthesis . . . . . . . . . . . . . . . . . 103

2.3.2

The Response to Misfolded Protein . . . . . . . . . . . . . . . . . 107

2.3.2.1 Stress Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2.3.2.2 Chaperone Action . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.3.2.3 Periplasmic Response to Misfolded Protein . . . . . . . . . . . . 112

2.3.2.4 Response to Misfolded Proteins in Other Organisms . . . . . . . 112

2.3.3

Host Characteristics for High-Quality IBs . . . . . . . . . . . . . 113

2.4

IB Based Processes Versus Soluble Production . . . . . . . . . . . 114

2.4.1

Cultivation Conditions Promoting Aggregation . . . . . . . . . . 114

© Springer-Verlag Berlin Heidelberg 2004

Adv Biochem Engin/Biotechnol (2004) 89: 93– 142

DOI 10.1007/b93995

2.4.2

IBs as a Result of Failure in Formation of Correct Disulfide

Bonds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

2.4.3

How to Avoid IBs and to Favour Correctly Folded Proteins . . . . 115

2.4.3.1 Rate of Synthesis . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.4.3.2 Fusion Proteins . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

2.4.3.3 Coexpression of Chaperones and Foldases . . . . . . . . . . . . . 117

2.4.3.4 Cultivation Conditions and Addition of Folding Promoting

Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.4.3.5 Cellular Redox Situation . . . . . . . . . . . . . . . . . . . . . . . 121

2.5

IBs in Prokaryotes Other than E. Coli . . . . . . . . . . . . . . . . 121

3

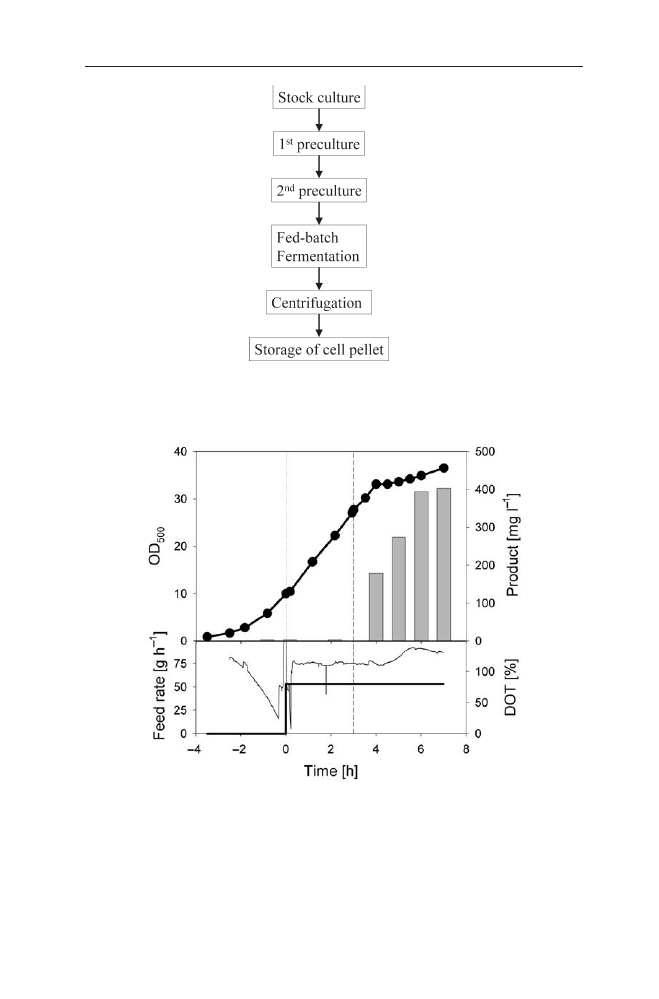

Production of IBs and Down-Stream Functionalisation . . . . . 122

3.1

Fermentation Process for IB Protein Production . . . . . . . . . . 122

3.2

Preparation of IBs . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.2.1

IB Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.2.2

Purification of IBs . . . . . . . . . . . . . . . . . . . . . . . . . . 128

3.2.3

Solubilisation of IBs . . . . . . . . . . . . . . . . . . . . . . . . . 128

3.3

Refolding of Proteins from IBs . . . . . . . . . . . . . . . . . . . 129

3.3.1

Disulfide Bond Formation During Protein Renaturation . . . . . 131

3.3.2

Improving Renaturation . . . . . . . . . . . . . . . . . . . . . . . 132

3.4

Industrial Processes Based on Refolding of IB Proteins . . . . . . 134

3.4.1

Human Tissue-Type Plasminogen Activator (t-PA) . . . . . . . . 134

3.4.2

Antibody Fragments and Immunotoxins . . . . . . . . . . . . . . 135

3.5

The Future of IB Based Processes for Recombinant Proteins . . . 135

4

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

List of Abbreviations

ATP

Adensine 5¢-triphosphate

DNA

Desoxyribonucleic acid

DOT

Dissolved oxygen tension [%]

DTE

Dithioeritrol

DTT

Dithiotreitol

E. coli

Escherichia coli

EDTA

Ethylene diamine tetra-acetic acid

F

Feed rate of concentrated carbon source solution [l h

–1

]

Fab

Antigen-binding fragment

Fv

Antibody fragment (variable regions)

FTIR

Fourier transform infrared spectroscopy

GdmCl

Guanidinium chloride

GSH/GSSG

Reduced/oxidised form of glutathione

Hsp

Heat shock protein

IBs

Inclusion bodies

IMAC

Immobilized metal affinity chromatography

94

B. Fahnert et al.

IPTG

Isopropyl-b-thiogalactopyranoside

LDAO

N,N-dimethyldodecylamine-N-oxide

m, m

max

(Maximum) specific growth rate [h

–1

]

mRNA

Messenger RNA

OD

500

Absorption (optical density) at 500 nm, measure for cell density

PDI

Protein disulfide isomerase

PEG

Polyethylene glycol

PTH

Parathyroid hormone

P

tac

, P

T7

, P

s32

Promoters designations

RNA

Ribonucleic acid

RNAP

RNA polymerase

RP-HPLC

Reversed phase high pressure liquid chromatography

S

0

Initial substrate concentration during the fermentation [g l

–1

]

SDS

Sodium dodecyl sulfate

S

i

Substrate concentration in the feed solution [g l

–1

]

t

D

Doubling time for cell growth [h

–1

]

t-PA

Tissue-type plasminogen activator

tRNA

Transfer RNA

V

Fstart

Fermenter volume [l] at feed start

VP1

Virus protein 1

X, X

Fstart

Cell dry weight [g l

–1

] (at feed start)

Y

X/S

Yield coefficient for cell growth on the carbon source [g g

–1

]

1

Introduction

The effective synthesis of proteins by recombinant hosts has become a widely ap-

plied strategy in research and industry. Although a number of different host sys-

tems are available today E. coli and other prokaryotes are still the first choice if

posttranslational modifications are not needed for protein function. Although

most of the proteins can be expressed at high concentration levels within a short

time in E. coli, in many cases the expressed product accumulates in a non-native

form intracellularly in dense particles called IBs.

We now know about many methods which can be tested to reduce aggregation

and to optimise the in vivo production of the soluble, active form of the protein,

e.g. cultivation at low temperature and limited induction, fusion of the protein to

solubilising partners, coexpression of chaperones and foldases, expression of the

protein in different cell compartments and expression in mutant strains [1–5].

However, the optimal process for a specific product is still unpredictable due to

the many factors influencing the synthesis and folding of proteins in the cellular

environment. The respective optimisation generally takes a lot of time and the fi-

nal yield of the active protein still is often unsatisfactory in comparison to the to-

tal product yield. Therefore, the purification and the refolding of IB proteins is

an attractive alternative, because the aggregates can be easily separated and

mostly contain the product in a high concentration. The in vitro refolding process

is the critical step, but the optimisation can be performed in a strategic way with

Inclusion Bodies: Formation and Utilisation

95

a step by step evaluation of the optimum conditions and additives contrarily to

the in vivo strategy. The major progress in the refolding of IBs was connected to

the development of industrial processes, including the first large-scale industrial

production process of a heterologous product in E. coli (human insulin).

This review aims to elucidate the internal and external factors leading to ag-

gregation. Thereby the paper not only concentrates on the strategies applied to

the production of IBs, but also summarises methods that can be used to avoid ag-

gregation to obtain a soluble (if desired) and active product. The biology of the

host cell is discussed in relation to the production of recombinant proteins and

strategies for the refolding of proteins from IBs are summarised allowing protein

production in a technical and industrial scale.

2

Protein Aggregation in Prokaryotes – The Formation of IBs

By the expression of proteins with cytoplasmic expression vectors product yields

of more than 50% of the total cellular protein can be obtained (see, e.g. [6]). In

case of a eukaryotic target protein the product is often enriched in IBs. These ag-

gregates usually contain the product in a non-native conformation, however in

a high concentration. The formation of IBs mainly depends on the kinetic com-

petition between protein-specific folding and aggregation rates connected to the

synthesis rate [4].Aggregation is a predominant feature in very strong expression

systems, but also increases with high inductor concentration, with the use of

complex growth media and at higher cultivation temperature [1, 7].According to

Rudolph [4] it can be concluded that the IB formation depends on the specific

folding behaviour rather than on the general characteristics of a protein such as

size, fusion partners, subunit structure and relative hydrophobicity. However,

folding-rate-limiting structural characteristics as disulfide bonds and certain

point mutations can significantly promote the formation of aggregates [8, 9].

2.1

Structural Characteristics of Proteins Favouring Aggregation

The primary structure of each protein provides any information necessary for

the functional conformation and activity (Anfinsen’s dogma) [10]. The number

of possible conformations is very high (10

30

for a protein of 100 amino acids with

each having two possible configurations, [11]). However, due to the finite time of

the folding procedure the protein cannot establish all of them (Levinthal’s para-

dox) [12]. Thus there are pathways guiding the folding to the native state being

thermodynamically stable and on a lower energetic level. The number of possi-

ble conformations of the polypeptide is decreased during the folding reaction by

non-covalent interactions (van der Waals contacts, salt bonds, polar interactions,

electrostatic interactions, hydrogen bonds). On the other hand different se-

quences can end in similar conformations (e.g. immunoglobulin G). This implies

an enzymatic folding assistance since thermodynamic processes are not suffi-

cient in every case [11, 13, 14]. Intermediates of the folding pathways can accu-

mulate due to aggregation caused by exposed hydrophobic regions [15]. That is

96

B. Fahnert et al.

why even small changes in the primary structure of a protein may affect its sol-

ubility [11, 16].

2.1.1

Disulfide Bonds

The formation of the correct disulfide bonds is usually the rate-limiting reaction

for the formation of the native structure of disulfide bond containing proteins

under otherwise optimum conditions. Due to the reducing redox conditions in

the cytosol of E. coli disulfide bond containing proteins are often accumulated as

IBs if they are produced in this compartment. Recent studies indicate that mu-

tations leading to a more oxidising intracellular milieu, such as the inactivation

of the genes for thioredoxin reductase (trxB) and glutathione reductase (gor),

promote the formation of correctly folded product and may decrease aggregation

of proteins containing disulfide bonds [17–19]. Although the gor and trxB gene

products are central in the known major reductive pathways in the E. coli cell the

mutations are not lethal and suppressor mutants with an oxidised cytosol can be

easily selected. They even grow well on complex and mineral salt media. The re-

sults from Bessette et al. [17] are very promising even in relation to proteins with

a high content of disulfide bonds, shown for a truncated form of t-PA with nine

disulfide bonds, if foldases such as DsbC or other proteins with a thioredoxin fold

are coexpressed. As a second interesting example recently also the production of

a correctly folded Fab antibody fragment in the cytosol of trxB mutants has been

published [20]. Despite the enthusiasm for the new systems the obtained prod-

uct yields are still low in comparison to processes based on in vitro refolding.

Other disulfide-bond-rich proteins containing more complex structures (e.g.

disulfide knots) have not been successfully produced in vivo in their correct fold

in high amounts yet. In vivo production of BMP2 has been thoroughly investi-

gated under different conditions and with various fusions. Although a soluble

product was obtained in vivo as a fusion to maltose binding protein (MBP) by

Fahnert [21] a high yield of active protein was gained only by in vitro renatura-

tion. In case of another disulfide knot-containing protein, human nerve growth

factor (hNGF), the natural prosequence was shown to support the folding of the

protein and an efficient in vitro refolding process from E. coli IBs was established

[22, 23].

Proteins consisting of different subunits, such as antibody Fab fragments –

containing both, intermolecular and intramolecular disulfide bonds – have been

traditionally produced as IBs. Both separate expression of the heavy and light

chains and coexpression systems have been used and in vitro refolding protocols

have been developed [24, 25]. During the last few years many Fab and single-

chain Fv antibody fragments have already been produced successfully in the E.

coli periplasm or displayed on the bacterial surface in correctly folded form

[26–32]. However, the optimisation studies are still time-consuming and the

yields are low in many cases. It is still not possible to predict the strategy for the

correct in vivo folding of a new Fab fragment even if similar molecules only dif-

fering in the sequence of the variable region have been expressed successfully be-

fore.

Inclusion Bodies: Formation and Utilisation

97

Small proteins with disulfide bonds such as human proinsulin still are mainly

produced as IBs as the preprotein, a fusion protein [33] or by separate expression

of the different chains. Although the formation of disulfide bonds is limited in

bacteria the limitation to produce proinsulin as a correctly folded product is not

due to disulfide bond formation, but to the lack of the formation of the correct

disulfide bonds and the stability of the product [34].

2.1.2

Membrane Proteins

Overexpression of membrane proteins has been a complicated challenge. Such

proteins have been considered as very toxic and difficult to express. Membrane

proteins are mostly enriched in small amounts, but nevertheless they are aggre-

gating certainly due to their surface-exposed hydrophobic regions.

Production of heterologous membrane proteins seems to be more problem-

atic for more and more E. coli membrane proteins such as OmpF, OmpC, PhoE

and LamB which have been successfully produced on very high levels (about 80%

of the total cellular membrane protein) [35]. Membrane proteins not only ag-

gregate but are also considered to be toxic to the E. coli cell.A breakthrough came

in 1996 when Miroux and Walker [36] succeeded in isolating specific E. coli mu-

tants allowing the production of membrane proteins. If membrane proteins are

overproduced in these mutants, new intracellular membranes proliferate con-

taining the recombinant product in the correct conformation [37]. The authors

reported the soluble production of the b subunit of F

1

F

0

ATP synthase, contain-

ing one transmembrane span, in the E. coli BL21(DE3) mutants C41 and C43.

Shanklin [38] also expressed an E. coli membrane protein, the acyl-acyl-carrier

protein synthase (80.6 kDa) efficiently in the C41 mutant. In this case a smaller

amount of this protein (1/3) was also correctly integrated in membranes of the

BL21(DE3) [39] strain. Promising results have also been reported by others for

the expression of active membrane bound cytochromes in these mutants [40, 41].

Saribas et al. [40] succeeded in producing as much as 200 mg l

–1

of cytochrome

P450 2B4 in shake flask cultures.

Alternatively, IB production with following renaturation of urea-dissolved IBs

in phosphate buffer containing n-dodecyl-N,N-dimethyl-1-ammonio-3-propane-

sulphonate (SB12) also seems to be promising. Jansen et al. [42] produced Neis-

seria meningitidis PorA using the E. coli BL21/pET system in high amounts as

very pure IBs at 37 °C and established an efficient in vitro refolding protocol of

this outer membrane protein.

2.1.3

Glycosylation

Many therapeutically interesting proteins from eukaryotes are glycosylated. How-

ever, glycosylation is often not a prerequisite for function but influences activity

and degradation characteristics, such as thermostability [43]. Therefore many

proteins can be produced in bacterial hosts lacking the eukaryotic glycosylation

system for therapeutic applications, but extensive tests are necessary to verify the

98

B. Fahnert et al.

function. Recombinant proteins produced in E. coli may even have beneficial

properties compared to the glycosylated forms. For example, a non-glycosylated

recombinant variant of human tissue plasminogen activator obtained by re-

folding from E. coli IBs showed a longer half-life and lower clearance rate in rats

[44, 45].

On the other hand, glycosylation may affect folding behaviour and solubility.

Therefore, glycosylated proteins may be prone to aggregation if produced in

E. coli.

2.2

Composition and Structure of IBs and Kinetics of IB Formation

Although the refolding of recombinant proteins from IBs has been applied as a

technology for many years, surprisingly only few recent studies have been di-

rected to the composition and structure of IBs, slowly improving our under-

standing. An excellent specific review on this subject was recently published by

Carrio and Villaverde [46].

2.2.1

Architecture and Structure

IBs are refractile intracellular protein aggregates. They can be seen as dense parti-

cles in electron microscopy, but are often even visible in light microscopy. Moreover

the production of IBs also affects the optical density measurement becoming ob-

vious after plotting the optical density against the dry cell weight (see Fig. 1).

Inclusion Bodies: Formation and Utilisation

99

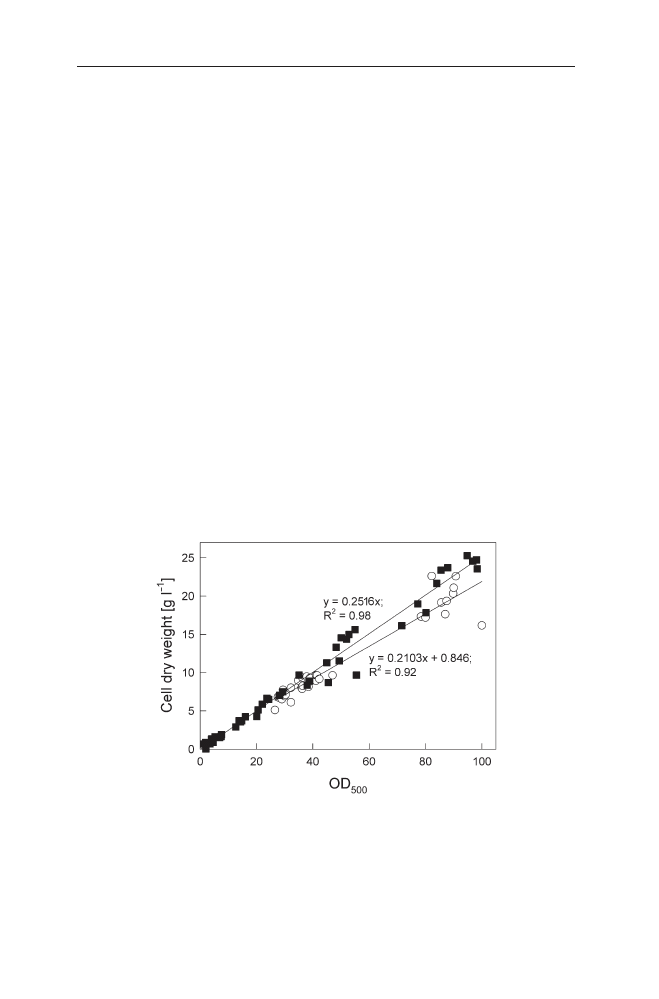

Fig. 1

Relation between the optical density of a culture (OD

500

) and the cell dry weight is in-

fluenced by the formation of IBs. Non-induced culture of E. coli RB791 pKK177glucC pUBS520

(filled squares) and culture induced with 1 mmol l

–1

IPTG (open circles). pKK177glucC contains

the gene for the S. cerevisiae a-glucosidase controlled by P

tac

. Data from fed-batch fermenta-

tions have been described in detail earlier [47, 48]. Induction was performed at approximately

OD

500

of 26. The data are from eight fermentations

Recently, interesting studies have been published by Villaverde and colleagues

concerning the fine-architecture of IBs. The authors show by proteolytic studies

that IBs of their model protein, a b-galactosidase fusion to the foot and mouth

disease virus VP1 capsid, are not homogenous structures, but consist of internal

sub-structures with a different accessibility to proteolysis [49]. The proteolytic

studies were supportingly illustrated by scanning electron micrographs showing

the sub-body structure emerging after protease treatment. The study also indi-

cates that the stability of IBs, measured as the digestion rate by trypsin, depends

on the fusion construct. The N-terminal fusion of VP1 to b-galactosidase

(LacVP1) was significantly more stable than the C-terminal fusion construct

(VP1Lac).

In most cases cytoplasmic IBs consist predominantly of the incorrectly folded

recombinant product. Stabilisation possibly occurs mainly via hydrophobic in-

teractions [4]. Some evidence exists that the product protein in IBs can be par-

tially structured [50–52]. Interestingly, decreases in a-helix- and increases in b-

sheet-contents have been detected in IBs in comparison to the native product

[51]. In b-lactamase IBs the b-sheet-content increases with increasing tempera-

ture independent of the location of the product in cytoplasmic or periplasmic ag-

gregates.

IBs can also be formed from native protein [53], but this seems to be the ex-

ception. By attenuated total reflection FTIR Oberg et al. found the secondary

structure in interleukin-1b IBs to be very similar to the native protein indicating

that these IBs contain a folding intermediate with a native-like secondary struc-

ture [52].

2.2.2

Composition of IBs

IBs consist predominantly of the recombinant product [46, 54, 55]. However,

IB preparations often contain a significant part of other cellular proteins

(membrane proteins, RNA polymerase, ribosomal subunit proteins), ribosomal

RNA and DNA [56–58]. These compounds are mainly integrated due to co-

precipitation of cell debris components during the process of IB preparation

[54, 57]. The co-purification of membrane components with the recombinant

product can be limited by the addition of sarkosyl to the lysis mixture [59].

However, cellular proteins may also be directly incorporated in IBs as shown

by Rinas and Bailey [55] for pre-b-lactamase and by Valax and Georgiou

[60] for IBs formed under different conditions. In the latter study contaminat-

ing polypeptides ranged from less than 5% to over 50% of the total protein

content. Here 0.5–13% of the IBs was phospholipids and nucleic acids repre-

sented only a minor impurity in both cytoplasmic and periplasmic IBs. Cyto-

plasmic IBs of mature b-lactamase had the lowest amount of impurities irre-

spective of the growth conditions, but large amounts of outer membrane

proteins and phospholipids were observed in periplasmic IBs from cells grown

at basic pH.

The protein charge can have a major influence on the composition of IBs as

concluded by Chaturvedi et al. [58]. The authors found high amounts of DNA in

100

B. Fahnert et al.

IBs of d-endotoxin, a crystalline protein from Bacillus thuringiensis with positive

electrostatic potential on most of its solvent accessible surface, after overexpres-

sion in E. coli.

In many cases the presence of the contaminating proteins in IBs is related to

incomplete purification after cell lysis. However, even after stringent washing of

IBs with detergents some E. coli proteins have still been found in a significant

concentration. To a major part these proteins belong to the groups of membrane

proteins such as OmpF, OmpC, OmpA [54] and OmpT [61]. These membrane

components could be a result of the cell lysis and washing procedure leading to

further aggregation of the IBs from different cells. However, additionally also

other proteins can be detected in IBs such as the molecular chaperones GroEL,

DnaK, the neomycin gene product and the small heat shock proteins IbpA and

IbpB [46, 61]. Both IbpA and IbpB seem to be generally connected to intracellu-

lar aggregates [62, 63]. Possibly they are among the first cellular detectors of mis-

folded proteins and act as aggregation controllers [64]. All the proteins men-

tioned above were also found in the soluble cytoplasmic fraction with exception

of IbpB. This protein was only detected in the insoluble fraction. It seems sur-

prising that translation-related proteins are not common in IBs, which should be

expected if aggregation is appearing in an uncontrolled way due to the close con-

nection between translation and folding/aggregation processes. There are only

few studies and at least Rinas and Bailey [54] found the ribosomal L7/L12 pro-

teins in b-lactamase IBs.

Although the recombinant product is mostly accumulated as the major com-

ponent in IBs it often does not appear as a unique spot in two dimensional SDS

gels, but as a smear or as multiple spots in the direction of the isoelectric fo-

cussing (e.g. [54, 57, 61]). This changed electrophoretic mobility of the full-length

protein points to chemical product modifications known from the downstream

processing, but may also originate from folding intermediates or from precipi-

tation during isoelectric focussing. Studies addressing this quality aspect during

the in vivo production of IBs have not been published to our knowledge. Fur-

thermore, IBs often contain truncated forms of the product either having the cor-

rect N- or the correct C-terminus. These fragments principally occur due to

pretermination of translation, internal translation start sites or proteolytic degra-

dation. Finally, other analyses also showed abnormally elongated polypeptides of

the product [65–67].

2.2.3

Kinetics of In Vivo Aggregation

In vivo protein aggregation mostly occurs by folding intermediates with surface-

exposed hydrophobic patches normally buried in the interior of a protein mol-

ecule. Such surface exposed patches are prone to aggregation themselves and this

may end up in a chain reaction if folding intermediates further accumulate or

proteins loose their correct three-dimensional structure, e.g. during heat stress.

To answer the question why preferably eukaryotic proteins aggregate in bac-

terial expression systems it is interesting to evaluate differences in the process of

protein synthesis in prokaryotes and eukaryotes.

Inclusion Bodies: Formation and Utilisation

101

Prokaryotic organisms are characterised by a fast translation process of up to

20 amino acids per second [68]. Therefore protein folding occurs in most cases

posttranslationally, although the translation rate can also be slowed down if the

mRNA contains a high number of rare codons.

In contrast the maturation of nascent proteins in eukaryotic cells often begins

cotranslationally in domains as a vectorial process and continues posttransla-

tionally after the release of the protein from the ribosome [69–71]. The rate of

translation in eukaryotes is slower than in E. coli but varies depending on the cell

type and protein. Proper glycosylation is connected to very slow translation rates,

for example [72]. Furthermore, it has been suggested that the slower rate of trans-

lation in eukaryotic cells has an important role in the proper folding by permit-

ting the sequential folding of individual domains during the translation process

[73]. This is especially relevant for proteins secreted into the endoplasmic retic-

ulum, because in its lumen many chaperones and foldases directly bind to the

protein during the translocation process and assist the folding [74].

Aside from the translation rate, aggregation of proteins is dependent on the

protein amount of unfolded peptides in a solution but is also influenced by the

total concentration of proteins [75]. Therefore in vitro refolding of proteins can

be performed by stepwise addition of denatured protein to the refolding solution

to keep the actual concentration of the unfolded protein low and by this the un-

wanted side reactions [76]. Similarly it is known that in vivo a high synthesis rate

of the target protein positively affects aggregation and that one way to decrease

the aggregation probability is to slow down the synthesis rate, e.g. by lowering the

cultivation temperature or the inducer concentration [77].

The kinetics of IB formation have been currently studied in detail for a b-

galactosidase fusion protein by Carrio et al. [78]. In this study the amount of

aggregated target protein was increasing with an approximately constant rate

over 5 h.

IBs are mainly accumulating at the proximal ends of a bacterium. Possibly

many primary micro aggregates fuse to a larger amorphous body if the concen-

tration of the unfolded protein is increasing. This suggestion is strongly sup-

ported by the electron microscopic visualisation of purified and protease treated

IBs by Carrio et al. [49]. Another interesting question is how many IBs accumu-

late per cell. Carrio et al. found mainly two distal IBs per cell shortly after in-

duction, but later the fraction of cells with two IBs decreased to only 20% [78].

The number of IBs and their size is changing with the genetic background of the

cell.A detailed study on VP1Lac by Carrio and Villaverde indicated a low amount

of IB protein, but a high number of aggregates (140) in a groE mutant [79]. This

recent study also strongly supports the hypothesis that the formation of IBs is not

a stochastic process, but that cellular components are involved in the construc-

tion of IBs. IBs were about two times larger and contained more recombinant

protein in a dnaK mutant in comparison to the WT. In contrast, IB formation was

strongly suppressed in a groEL mutant. Aside from being interesting for the de-

sign of new recombinant production strains, these results indicate GroE and

DnaK as the main antagonistic controllers of IB formation. DnaK prevents IB for-

mation by reducing aggregation. GroEL transits the protein between soluble and

insoluble fractions and positively participates in IB formation.

102

B. Fahnert et al.

2.2.4

Stability of IBs

As discussed above, IBs appear as a result of an imbalance between protein syn-

thesis, folding and aggregation reactions. Their formation is mainly supported by

tight hydrophobic interactions. In general IBs are highly stable and resistant to

proteases in vivo. Although IBs mostly contain incorrectly folded proteins, in

some cases enzymatic activities can be associated to enzyme-based IBs [53] and

native-like secondary structures have been detected in other IB proteins [52].

Such aggregation intermediates are prone to proteolysis and, correspondingly,

IBs disappear either due to proteolysis of the resolubilised polypeptide or due to

further protein functionalisation. The equilibrium between formation of aggre-

gates and their resolubilisation has currently obtained more interest, because

bacterial IBs could be seen as models for dynamic and structural analysis of pro-

tein aggregation as it also occurs in several degenerative diseases [79].

In vivo resolubilisation of IBs has been mainly observed in case of homolo-

gous host proteins and fusions to b-galactosidase, but IBs from heterologous pro-

teins often seem to be more resistant to degradation.An extensive study was pub-

lished by Carrio and Villaverde [80] investigating the in situ resolubilisation of

the P22 tailspike protein from IBs. This is interesting since the P22 tailspike pro-

tein is an example for a protein with a very slow and complex folding pathway.

The protein finally forms trimers to be integrated into functional bacteriophages.

Aside from refolding, IB proteins can also be degraded. It has been suggested that

this process is ATP-dependent, which is in agreement with recent molecular data,

showing that aggregated proteins can be solubilised in vivo by ClpB in connec-

tion with the Hsp70 chaperone system [81].

However, the exact network of the resolubilisation of IBs is still not fully un-

derstood.Also data from a larger group of proteins are necessary to evaluate with

respect to whether the in vivo solubilisation affects the quality of IBs in processes

aiming for the production of the target protein in an aggregated form.

2.3

The Physiology of IB Formation

2.3.1

The Metabolic Load of IB Synthesis

Metabolic consequences of the production of recombinant proteins are exclu-

sively reviewed in Chap. 2 by Hoffmann and Rinas. The following paragraph dis-

cusses the molecular physiological aspects in connection to conditions typical for

the production of IBs characterised by a very high synthesis rate from a differ-

ent point of view.

The accumulation of a specific protein population in a cell is connected with

a complex multifactorial synthetic pathway. Parameters include the general rates

of transcription, translation and protein folding, the specific rates of these

processes as well as the rate of formation of a single mRNA molecule, of a single

polypeptide or of a correctly folded protein molecule. Although the single

Inclusion Bodies: Formation and Utilisation

103

processes and their reactions have been thoroughly investigated in vitro and are

well understood, the complex cellular network is actually still too complex to be

thoroughly considered concerning the optimisation of a recombinant process.

Therefore all optimisation studies still have to be performed on a trial and error

basis.

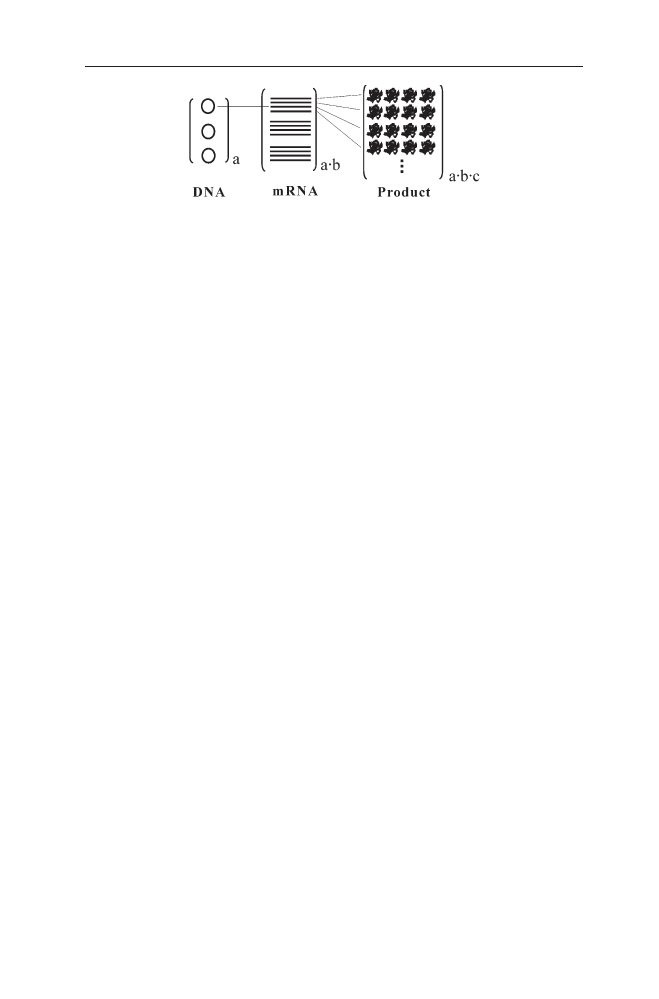

The copy number of the target protein gene has a major impact on the rate of

product accumulation, because it is the basis of the signal amplification cascade

(see Fig. 2). The gene copy number is determined by the origin of replication of

the plasmid and is mostly in the range of 20–50 copies per cell in the case of

medium-copy plasmids or up to more than 100 copies for high-copy number

plasmids.

The copy number basically affects the sum of the cellular components engaged

in the synthesis process and therefore has a significant impact on the competing

reactions in the cell. At the start of a screening process for product optimisation

a low copy number of a stably maintained vector is strongly recommended, since

signal amplification is more easily and more accurately controlled at the level of

transcription and translation than at the level of copy number control. Further-

more, the gene copy number not only depends on the plasmid origin, but also

changes during a process depending on the strain, the growth medium, the

growth rate and the cultivation temperature. A proper control of the exact copy

number is rarely possible for vectors with a higher copy number.

Most optimisation strategies aim to control properly the transcription rate.

This includes the choice of an inducible promoter and the variation of the in-

ducer concentration based on a given expression system. It may be important to

consider that the inducer concentration influences the number of mRNA mole-

cules produced per time, but does not affect the synthesis rate of a single mRNA.

It is assumed that the E. coli RNA polymerase has a constant transcription rate

of about 40 to 50 nucleotides per second lowered by pausing sites leading to tran-

sient stoppage of the transcription especially under detrimental environmental

conditions and resulting in up to a 50% reduction of the total transcription rate

[82]. In case of E. coli RNA polymerase the transcription rate is in the order of the

translation rate of ribosomes varying dependent on the codon bias between ap-

proximately 15 nucleotides per second for rare codons and 62 nucleotides per

second for abundant codons [68]. These rates for transcription and translation

suggest that ribosomes stack closely to each other behind the E. coli RNA poly-

merase if the recombinant genetic construct contains a strong ribosome binding

104

B. Fahnert et al.

Fig. 2

Scheme of the signal amplification cascade from a recombinant gene to the final

product (a, b and c are factors indicating the degree of amplification in each step)

site (Fig. 3). In this case the synthesis time of a single protein molecule is limited

either by the transcription rate of the RNA polymerase or by the codon usage if

rare codons with low translation rates are contained at higher levels in the se-

quence of a recombinant gene.

T7 RNA polymerase in connection with a T7 promoter is generally applied as

an alternative strong expression system [83]. This polymerase synthesises the

mRNA with a four- to fivefold higher transcription rate (about 230 nucleotides

per second) than E. coli RNA polymerase [84–86]. As the initiation rate of both

RNA polymerases is similar (E. coli RNA polymerase: 1–3 per second; T7 RNA

polymerase: 1 per second) the higher accumulation of proteins in the T7 systems

is most probably due to the high elongation rate of the enzyme. Therefore in T7

RNA polymerase systems the synthesis rate of the single protein molecule is not

limited by the formation rate of the mRNA, but it is only limited by the codon us-

age of the gene. That is why many proteins show a higher accumulation rate than

in case of E. coli RNA polymerase based expression systems. However, the high

synthesis rate of mRNA may be also a disadvantage. The mRNA not covered by

ribosomes can be easily attacked by RNases or form stable secondary structures

(see Fig. 3B).

The higher rate of synthesis of proteins by the T7 RNA polymerase is

possibly also the reason why formation of IBs seems to be more significant with

this expression system than with E. coli RNA polymerase based expression

systems.

The described physiological data indicate that a high expression rate of the re-

combinant protein should be optimal for an IB production process. Therefore a

strong ribosome binding site is beneficial. In contrast a weaker ribosome bind-

ing site could improve the yield of correctly folded product by causing a higher

distance between the ribosomes which eventually should decrease the aggrega-

tion between different product molecules but may also decrease the mRNA sta-

bility.

The codon bias of a gene is a major factor for the synthesis rate of a target pro-

tein. The codon bias varies between different organisms and is well reflected by

the respective tRNA population [87]. If an mRNA from a heterologous target gene

is overexpressed in E. coli, differences in codon bias of the gene to the codon bias

of E. coli can impede translation. In practice the presence of a small number of

rare codons does not affect the target protein synthesis very much. However, the

accumulation of a recombinant gene product can be very low if the gene contains

clusters and/or numerous rare E. coli codons. The most severe effects have been

Inclusion Bodies: Formation and Utilisation

105

Fig. 3A, B

Schematic drawing of the hypothetical distribution of ribosomes on their cognate

mRNAs in relation to the RNA polymerase in recombinant systems with a strong ribosome

binding site and with: A E. coli RNA polymerase; B T7 RNA polymerase

observed in case of multiple consecutive rare codons situated near the N-termi-

nus of a coding gene sequence.

Analysis of the codon bias in all 4290 E. coli genes reveals a number of un-

derrepresented codons. In particular arginine codons AGG, AGA and CGA,

isoleucine codon AUA and leucine codon CUA represent less than 0.1% of the

codon bias of all genes and less than 8% of the population of the codons for the

specific amino acid [88]. On the assumption that the codon bias was evolution-

ary optimised to support fast growth of an organism, further rare codons can be

defined rarely contained in genes which are highly and continuously expressed

during fast growth [89]. If such abundantly expressed genes are analysed the

codons GGA for glycine, CGG for arginine and CCC for proline must also be con-

sidered as rare since they only represent less than 2% of the respective popula-

tions for a specific amino acid [90]. Problems with the codon bias of a recombi-

nant target gene can be solved either by redesigning the codons through

site-directed mutagenesis or by a higher expression of the rare tRNAs. The first

method can be very laborious and is only used in cases where multiple consec-

utive codons occur in a gene, but coexpression of tRNAs has become a valuable

tool and a number of vectors as well as E. coli strains for overexpression of dif-

ferent tRNAs are commercially available.

The problem of the codon bias seems to be very relevant for the production

of target proteins in IBs if a high synthesis rate of the protein is desired since the

codon bias directly influences the translation rate as described above. An exper-

imental indication that a higher translation rate stimulates aggregation was ob-

tained from overproduction of a recombinant yeast a-glucosidase rich in AGA

and AGG codons. Co-overexpression of the cognate argU tRNA increases the to-

tal a-glucosidase amount per cell from 4% of the total cell protein to about 16%.

The positive effect of argU on the translation speed is in accordance with the in-

vestigations of the translation rates for single codons by Soerensen and Peder-

sen [68] and with the analysis of the tRNA levels in E. coli by Kurland and

coworkers [87]. The higher speed of translation not only leads to a higher amount

of product, but also increases the relative amount of aggregated product. In con-

trast the expression of soluble a-glucosidase is decreased if argU was co-over-

expressed (Table 1).

The optimisation of the codon bias of a target gene is very important for the

production of high quality IBs because a non-optimised codon bias also increases

the rate of translation errors appearing due to codon hopping, pretermination

of translation, frame-shift mutations etc. However, the codon bias also directly

influences the maintenance of the cellular translation system. The preferential

withdrawal of rare tRNAs directly inhibits protein synthesis and cell viability [93].

A high synthesis rate of a protein with slow folding characteristics may exceed

the available resources of foldases, chaperones and proteases. In this context IBs

may represent reservoirs of protease-resistant protein steadily accumulating un-

til chaperones and proteases become available either for successful protein fold-

ing or for proteolysis. This model, recently suggested by Carrio and Villaverde

[46], is supported by data on higher IB accumulation in a dnaK mutant (see also

Fig. 5). In contrast, a groEL mutant had a lower content of IBs and a higher

amount of folded protein which might be explained by the early function of the

106

B. Fahnert et al.

Hsp70 chaperone system in the protein folding pathway and the GroEL system

as a “second stage” folding supporter (see “Molecular Components of Physio-

logical Stess Responses in E. coli” by L.M. Wick and T. Egli, this volume).

2.3.2

The Response to Misfolded Protein

2.3.2.1

Stress Responses

During their evolution all organisms have evolved mechanisms to respond to un-

favourable environmental conditions. In bacteria the corresponding adaptational

network ensuring a better survival of the cells is mainly controlled at the level of

transcription. An environmental stimulus such as heat induces a number of reg-

ulatory cascades. The different modules are grouped in dependence on their spe-

cific response regulators into regulons. The complexity of the bacterial response

network results from the possibility that one stimulus is inducing different reg-

ulons and that different genes can be multiple controlled.

Strong induction of recombinant protein expression is an artificial stress redi-

recting the metabolism of a bacterium to the production of a specific target pro-

tein.Although the metabolic network of a cell has some flexibility to increase cer-

tain pathways, the load of a high induction of a gene with a strong promoter and

a strong ribosome binding site is considerable with respect to necessary energy

resources [94] and imposes a stress situation. Compared to stress situations oc-

curring in natural evolution, recombinant protein synthesis is possibly most sim-

ilar to the induction of lysogenic bacteriophages or to bacteriophage infection in

general. In these situations the bacteriophage occupies the bacterial protein syn-

thesis system for its own purposes to produce daughter phages. In a similar way

Inclusion Bodies: Formation and Utilisation

107

Table 1

Influence of the co-overexpression of the rare argU tRNA on the concentration and

activity of a-glucosidase expressed in E. coli RB791

a-Glucosidase

a

–argU overexpression

+argU overexpression

–IPTG

+IPTG

–IPTG

+IPTG

Activity (U ml

–1

)

b

0.42

3.18

0.08

1.07

(U mg

–1

)

c

0.03

0.41

0.007

0.12

Total (mg ml

–1

)

b

0

111.44

0

446.13

(mg mg

–1

)

c

0

14.36

0

49.64

(% of TCP)

d

0

4

0

16

a

Data calculated at 3–4 h after induction.

b

mg a-glucosidase per ml cultivation broth.

c

Units or mg a-glucosidase per mg cell dry weight.

d

% of total cell protein.

Data according to Lin [91]. Experimental conditions: E. coli RB791 pUBS520 glucC containing

the glucC gene under P

tac

control. Coexpression of argU by pUBS520 [92]. Experiments were

performed under fed-batch conditions at 35 °C on glucose based mineral salt medium with

induction with 1 mmol l

–1

IPTG in the fed-batch phase as described earlier [47].

the induction of a recombinant gene channels the bacterial resources for the pro-

duction of the target protein. Although the strong synthesis of a recombinant

protein can principally induce a number of different stress signals connected to

cellular regulons such as the stringent response, the general stress response and

the SOS response it depends on the strength of the competition whether the cor-

responding gene expression pattern can be found, because all responses are con-

nected to the synthesis of new proteins. If the competition is strong, the protein

synthesis apparatus including transcription and translation, can be fully occu-

pied by the synthesis of the product and no cellular responses are observed, but

the cell will loose its ability to divide and slowly die [48]. However, if the synthe-

sis of the product allows the synthesis of cellular proteins in parallel, typical stress

responses can be observed, such as the SOS response [95]. Only a heat shock like

response is always found if misfolded forms of the target protein accumulate in-

dependent of the expression system used (e.g. [96–99]). The high speed and com-

petitiveness of the heat shock response by s

32

can be explained from the regula-

tory mechanism of this response.

As discussed above, IBs result from aggregation of non-native polypetides. In

connection to bacterial stress responses the accumulation of proteins recognised

as non-functional or unfolded molecules is very critical and induces mechanisms

to counteract this process. Analogously, in nature unfolded proteins appear dur-

ing heat stress causing the unfolding and following aggregation of proteins. It has

been elucidated that the bacterial heat shock response is regulated by a sensitive

measure of the appearance of unfolded molecules. This regulation centrally in-

volves the heat-shock sigma factor s

32

and its binding to the DnaK and DnaJ

chaperones. Both chaperones contribute to downregulation of s

32

activity and

stability (see Fig. 4 and see “Molecular Components of Physiological Stess

Responses in E. coli” by L.M. Wick and T. Egli, this volume).

After a heat shock, while proteins are inactivated and aggregated proteins ap-

pear, s

32

is released from the chaperones leading to higher stability and activity

of s

32

. Consequently, s

32

edging out the house-keeping sigma factor s

70

of RNA

polymerase and the RNAPs

32

holoenzyme initiates transcription from promot-

ers belonging to the heat-shock regulon. Additionally the heat shock contributes

to transient inactivation of s

70

[100], which however is not relevant in recombi-

nant protein production without temperature shift.

Among others, the s

32

connected response leads to increased transcription of

dnaK, of other chaperone genes and of heat shock related protease genes such as

lon and clpP [101, 102]. Therefore the concentration of both the Hsp70 chaper-

one proteins (DnaK, DnaJ and GrpE) and the Hsp60 chaperonins (GroEL and

GroES) increases rapidly and transiently. This transient increase of the chaper-

ones furthermore leads to binding and degradation of s

32

causing the transient

character of the heat shock response [103, 104].

Unlike a heat shock primarily causing the unfolding of existing proteins, in-

duction of a recombinant protein causes the synthesis of misfolded proteins. Sim-

ilar to a heat shock this also induces a heat shock-like response and corre-

spondingly enhanced proteolytic activities [105–108] and increasing levels of

Hsp60 and Hsp70 chaperones [21, 97, 109–112]. Strong overexpression in con-

nection to protein aggregation also induces ibpA and ibpB gene expression and

108

B. Fahnert et al.

incorporation of these proteins in IBs [62, 110]. Although even the presence of

plasmids is known to increase the levels of heat shock proteins in comparison to

the plasmid-free host strain [113] a true induction of the heat shock like response

is found if a temperature sensitive promoter, such as the l P

L

and P

R

promoters

with the thermosensitive cI

857

repressor, is used for induction of the target pro-

tein [110]. However, a heat shock like response is also induced without a change

of the temperature by the accumulation of abnormally folded protein [108] and

by the accumulation of export-defective secretory protein precursors [114].

The regulation of the heat shock like response to misfolded recombinant pro-

teins is similar to a heat shock. The accumulation of newly synthesised misfolded

proteins also attracts the chaperones and leads to an activation and stabilisation

of s

32

[103, 115, 116]. However, this response is longer lasting [99, 117] as the syn-

thesis of the recombinant protein is continuing. Furthermore, as s

32

must com-

pete for the very effective synthesis of the recombinant protein, the accumulation

of new chaperones is lower than after a heat shock, inactivation of s

32

is retarded.

The detailed kinetics of this however remains to be evaluated.

Aside from a potential positive effect of the heat shock-like response on the

folding of a recombinant protein by increasing the level of chaperones, the in-

duction of the heat shock response also can negatively affect the production of

recombinant proteins because it is connected to induction of cytoplasmic (Lon,

Clp) and periplasmic (DegP, OmpT) proteases [118]. Therefore, methods to re-

duce the heat shock-like response and thus the proteolytic activities during over-

expression of target proteins can submit positive effects. Such positive effects

were obtained by lowering the cultivation temperature [108, 119], by using htpR

or lon mutants [119] and by antisense down-regulation of s

32

[120].

Inclusion Bodies: Formation and Utilisation

109

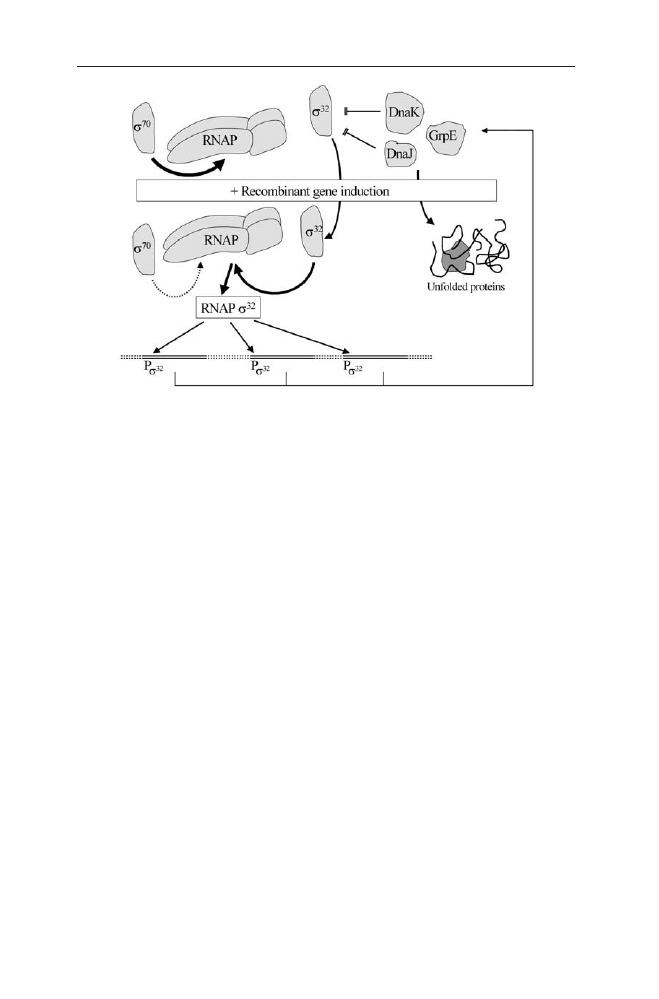

Fig. 4

Regulation of the s

32

connected unfolded protein response after induction of recombi-

nant genes

2.3.2.2

Chaperone Action

Although the correct folding of the three-dimensional structure of a protein is an

intrinsic characteristic, chaperones and foldases decrease the folding time and

protect the protein from aggregation. It has been calculated that in E. coli only

10–20% of the host’s proteins are folded with the help of the Hsp60 and Hsp70

chaperone systems during exponential growth and this increases to about 30%

under heat shock conditions [121–123]. In contrast, many of the interesting het-

erologous target proteins fold slowly and would therefore benefit from the avail-

ability of chaperones. Accordingly there are many examples where coexpression

of chaperones significantly increased the yield of correctly folded product.

The chaperones prevent aggregation of heat-inactivated proteins and other

misfolded proteins in an ATP-dependent manner. Supported by GrpE and ClpB,

Hsp40 (DnaJ) and Hsp70 (DnaK) prevent the aggregation of nascent protein mol-

ecules (in case of at least 20% of all cellular proteins sized 14–90 kDa) until their

synthesis is finished. DnaK binds to a short linear consensus motif of 4–5 hy-

drophobic amino acids (mainly leucine) flanked by basic ones [124–127]. Hsp60

substrates consist preferentially of partially structured, hydrophobic protein mol-

ecules [128]. In case of a misfolding (indicated by exposed hydrophobic areas) of

the now non-linear, compact protein it can enter the hydrophobic cavity of the

GroEL chaperonin. A special sequence is not needed [129], but the non-native

state is sufficiently attractive. This is the fate of about 30% of all cellular proteins

sized 10–55 kDa. An additional binding of trigger factor to GroEL even enhances

the interaction with the substrate. By assembling GroES (Hsp10) and consuming

ATP the conformation of GroEL changes. This causes the bound substrate pro-

tein to be released from the cavity surface of GroEL. So it is enabled to fold again

according to the principle of the Anfinsen cage (spontaneous self-assembly of

polypeptides [10]) in the hydrophilic milieu of the chaperon’s interior. The pro-

tein is released after the dissociation from the chaperone. If the correct confor-

mation were not achieved the protein could enter GroEL again [130, 131].

During the folding process proteins can be transferred from one chaperone

system to the other. Thereby the chaperones do not refold the protein actively to

the correct structure, but they lower the aggregation potential by repeated bind-

ing and releasing of the substrate and allow the protein successively to reach a

kinetically favourable state and finally the active conformation.

Irreversibly damaged proteins may be further presented to the Clp chaper-

ones. These proteins are structurally similar to GroEL in having an interior cham-

ber formed by one or two stacked rings of six or seven monomers. ClpB of E. coli

can apparently act exclusively as a molecular chaperone, whereas other Clp fam-

ily members such as ClpA and ClpX function both as chaperones and as com-

ponents of ATP-dependent proteases. Damaged proteins may be either directed

to further degradation by proteases such as ClpPX [132] or alternatively they can

be resolubilised by the ClpB chaperone in concert with the Hsp70 chaperone sys-

tem [81, 133, 134].

The mechanism behind this is that hydrophobic regions of polypeptides are

exposed either as the newly made proteins emerge from the ribosome or because

110

B. Fahnert et al.

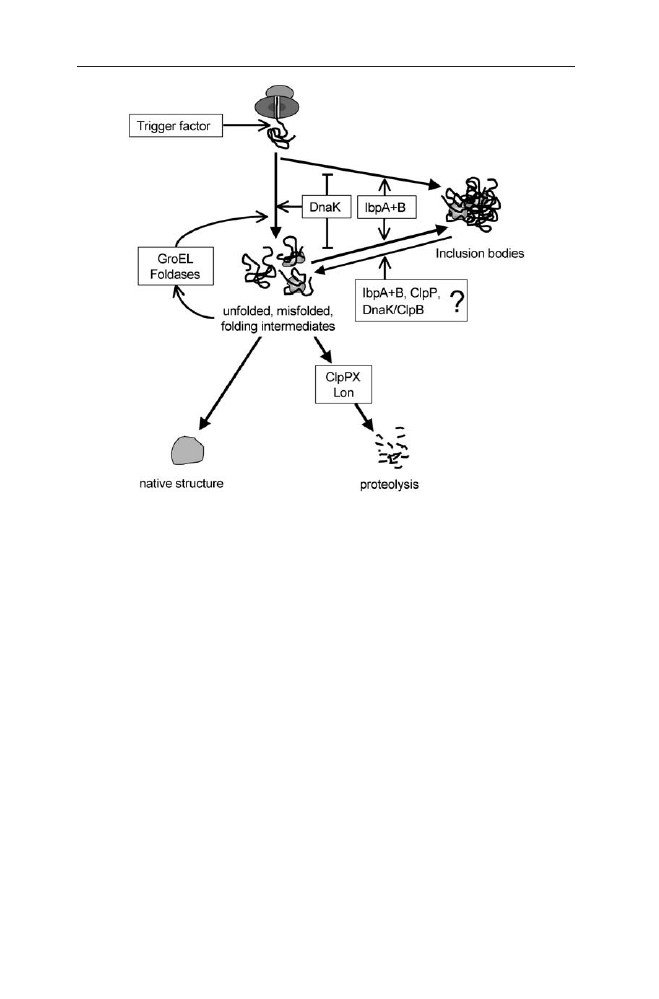

of subsequent misfolding or failure to assemble properly (see Fig. 5). These ex-

posed regions are subject to binding by any of the chaperones or by the ATP-de-

pendent proteases. Chaperone binding and release of folding intermediates may

allow proteins to reach their native conformation or may return them to the pool

of non-native proteins that can rebind chaperones or proteases. Protease bind-

ing followed by ATP-dependent unfolding and subsequent degradation removes

the protein from the pool of non-native proteins. At a high rate of synthesis of

polypeptides needing the chaperone and foldase systems, unfolded, misfolded

and partially folded proteins will eventually aggregate to IBs.

Although the chaperones act most generally to prevent aggregation, they are

also able to dissolve aggregates [133, 135, 136]. The resolubilisation of protein ag-

gregates seems also to be connected to the action of two low molecular weight

proteins, IbpA and IbpB [62]. The synthesis of these proteins is also induced by

heat shock through s

32

[137]. The function of these small proteins is still unclear

[138]; however there is indication that IbpB is a molecular chaperone that assists

the refolding of denatured proteins in the presence of other chaperones [64]. In

case of malate dehydrogenase and lactate dehydrogenase it has been shown that

IbpB-stabilised proteins alone do not refold spontaneously, but they are prefer-

entially delivered to the Hsp70 chaperone system where they refold in a strict

Inclusion Bodies: Formation and Utilisation

111

Fig. 5

Model of competitive pathways for aggregation, refolding and protein degradation for

the process of recombinant protein production (Æ positive effect,

negative effect)

ATPase-dependent manner. GroEL/GroES chaperones do not interact directly with

IbpB-released MDH, but mediate further processing of Hsp70 released folding in-

termediates. In this connection IbpB seems to bind and stabilise aggregation-

prone folding intermediates during stress and thus prevents the further irre-

versible aggregation of these proteins. On the other hand, as an integral part of

a cooperative multi-chaperone network IbpB may be involved in the active re-

folding of stress-denatured proteins by delivering them to the Hsp70 and Hsp60

chaperone systems [64].

2.3.2.3

Periplasmic Response to Misfolded Protein

In addition to the induction of the s

32

response by proteins overexpressed within

the bacterial cytoplasm, a s

24

(s

E

) dependent heat shock response is induced by

misfolded proteins in the periplasm. The response to protein misfolding in the

cell envelope is a finely tuned system regulated by a cascade of phosphorylation

and dephosphorylation reactions [139]. Interestingly, overexpression of periplas-

mic proteins not only induces the s

E

regulon, but also leads to a significant in-

crease of the expression of the cytoplasmic s

32

dependent chaperones GroEL,

GroES, DnaJ and DnaK as revealed by transcriptome analysis [21]. Similar to the

cytoplasm there exist chaperones and proteases in the periplasm contributing to

degradation or refolding of damaged proteins. One example is the protease DegP

consisting of a double ring to be entered by a protein before it is proteolytically

cleaved. Therefore the protein has to be partially unfolded or disaggregated, re-

spectively. Interestingly, DegP changes its tertiary structure and activity in a tem-

perature-dependent manner. It is only a protease at high temperatures but may

act as a chaperone in the lower temperature range [140, 141].

2.3.2.4

Response to Misfolded Proteins in Other Organisms

The response to unfolded proteins is not restricted to E. coli but common for

other microorganisms, too. In Bacillus subtilis overexpression of insoluble pro-

teins induces the so-called class I and class III heat shock genes (according to the

classification of Hecker et al. [142] and Derré et al. [143]) as detected by Mogk et

al. [144] and Jürgen et al. [145]. Mogk et al. [144] found non-native proteins to in-

duce the CIRCE regulon controlled by the HrcA repressor. The authors supposed

that high levels of non-native proteins to titrate the GroE chaperonins, which pre-

vents reactivation of the HrcA repressor and thus causes induction of class I heat

shock genes. Jürgen et al. [145] have confirmed these results for another recom-

binant protein and showed additionally induction of clpP, clpC and clpE, be-

longing to the class III heat shock proteins. Interestingly, the authors proved that

the Clp proteins ClpC, ClpP and ClpX are associated with the IBs, suggesting that

these proteins also in Bacillus subtilis contribute to resolubilisation of recombi-

nant aggregates. In contrast to E. coli, the authors found no significant induction

of the mRNAs of the proteases LonA and LonB, which they discuss in relation to

the major importance of the ClpP protease with its subunits ClpC or ClpX in

112

B. Fahnert et al.

Bacillus subtilis. Additional differences between the response of Bacillus subtilis

and E. coli have been detected by Jürgen et al. [145] in connection to the signif-

icant increase of the mRNA levels of genes encoding purine and pyrimidine syn-

thesis enzymes (purB, purC, purM, pyrA, pyrD) and ribosomal proteins (rpsA,

rpsB, rplJ) in Bacillus subtilis.

2.3.3

Host Characteristics for High-Quality IBs

In vivo protein aggregation is mainly connected to the competition of protein

synthesis, folding and misfolding of a certain recombinant protein. Parameters

in this process are the intrinsic characteristics of the protein, but this process in-

volves additionally external factors of the host system such as availability of

chaperones and foldases. Furthermore, aggregates principally can be resolu-

bilised by the bacterial chaperone and protease systems.

In conclusion the accumulation of IBs seems to be best at a high synthesis rate

of aggregation prone proteins in connection to a low content of chaperones (es-

pecially DnaK) and proteases. Therefore high induction at the transcription level

and strong ribosome binding sites are generally used, e.g. strong promoters such

as P

lacUV5

in connection to the P

10

promoter of the T7 phage or P

tac

. These pro-

moters are induced with a high concentration of IPTG (0.4 to 2 mmol l

–1

final

concentration).Also heat inducible systems, e.g. the phage l promoters P

L

and P

R

can be applied.

If the target protein is proteolytically sensitive or the IBs are very unstable,

chaperones and heat shock related proteases could be suppressed by the use of

rpoH mutants, protease mutants or by antisense titration of rpoH [120]. In this

context E. coli BL21 is considered to be a useful host strain for IB formation be-

cause of the lon mutation [146].

The small heat shock proteins IbpA and IbpB may be involved in the con-

struction and resolubilisation of IBs. Our own data on two different recombinant

proteins suggest that IBs produced in ibp mutants may be of higher purity (un-

published). However, in a recent study from Carrio and Vilaverde [46] an ibp mu-

tant also showed much lower production. More studies are needed to evaluate the

effects of such mutations with respect to different target proteins.

Changes in the concentration of the main chaperon systems may affect the

quality and concentration of IBs.A dnaK mutant contained a significantly higher

amount of aggregated VP1Lac in comparison with a WT and all product was ag-

gregated [79]. Additionally the IBs had a higher stability if protein synthesis was

inhibited suggesting that a dnaK mutant could be a good host strain for IB-based

recombinant processes.

As IB formation is normally connected with a short induction time (2–5 h)

and high product synthesis, the codon bias is a major factor determining the

quality of the aggregates. Overexpression of rare tRNAs can increase the total

yield but also the relative amount of product contained in IBs by increasing the

translation rate (see Table 1).

Inclusion Bodies: Formation and Utilisation

113

2.4

IB Based Processes Versus Soluble Production

2.4.1

Cultivation Conditions Promoting Aggregation

Aggregation is caused by protein-protein-interactions. Therefore the high con-

centration of unfolded proteins within the cell during recombinant protein pro-

duction is especially aggregation promoting. The so-called crowding effect [147]

is characterised by competing interchain and intrachain interactions leading to

wrong intermolecular contacts. Secreted proteins are less likely to aggregate be-

cause of the increased volume of the periplasm and the thereof resulting dilution

effect [16].

All the processes from transcription to folding affected by recombinant ex-

pression have to be considered on both sides (target protein and host) and in

their interaction in order to find the optimal cultivation conditions (temperature,

medium, cell density, host strain). The most common and still useful approach

is empirical testing since every target protein is different [16, 148, 149].

The following conditions have been shown to promote aggregation: high tem-

perature, high cell density, high concentrations of the inducer and a short induc-

tion time [77, 150, 151]. By varying the expression level and the input of thermal

energy, conditions leading to an optimised yield of IBs can be found. Complex me-

dia are favouring the formation of IBs as well [152]. The high temperatures help

to cross the thermodynamic threshold necessary for intermolecular reactions and

thus aggregation. All the expression conditions mainly influence the aggregation

kinetics by varying the protein concentration and synthesis rate.

2.4.2

IBs as a Result of Failure in Formation of Correct Disulfide Bonds

In prokaryotes, proteins mainly fold post-translationally due to the rapid trans-

lation (see above). However, a cotranslational folding of certain proteins might

also occur. In contrast, eukaryotic proteins are considered to fold cotranslation-

ally in domains. This is thought to be one reason for the often incorrect folding

of eukaryotic proteins in prokaryotic hosts [71, 73]. The tendency of IB forma-

tion is, among other parameters, dependent on the number of cysteines. Ac-

cording to this the cystine-rich mammalian proteins are reported to be especially

difficult to express in E. coli solubly [153].

Moreover, the natural folding environment is different in many other aspects.

In eukaryotes the disulfide bonds are formed within the endoplasmic reticulum.

It contains about 100 g l

–1

of protein. Permeases import ATP from the cytoplasm.

It is needed by some chaperones. As the endoplasmic reticulum is oxidising (ra-

tio of reduced to oxidised glutathione: 1–3:1 [154]) it provides the basis for disul-

fide bond formation. Different foldases are present. The PDIs (protein disulfide

isomerases, e.g. PDI, Ero1p) perform the disulfide shuffling and the PPIs (pep-

tidyl-prolyl-cis/trans-isomerases, e.g. cyclophilin B) the propeptidyl-bond iso-

merisation [155]. PDI has got two active site motifs (Cys-X-X-Cys, thioredoxin

114

B. Fahnert et al.

superfamily). One of them is oxidising and the other isomerising. The reoxida-

tion of PDI is probably performed by Ero1 [156]. There are also the heat shock

proteins 70 (e.g. BiP), 40 (e.g. Sec63p), 90 (Grp94) and lectins (calnexin, calreti-

culin, both of them being glycoprotein chaperones) [14]. Glycosylation improves

solubility and is often a prerequisite of correct folding. In the endoplasmic retic-

ulum ATP is consumed for forming disulfide bonds. In contrast the presence of

ATP is unlikely in the prokaryotic periplasm [157].

The catalysis of the formation of disulfide bonds is more complicated in the

periplasm than in the endoplasmic reticulum, because its oxidising milieu (redox

potential) is affected by the environment of the cell. Small molecules are con-

stantly diffusing through the cell envelope [158]. The foldases of the periplasm

are independent of ATP. Redox proteins catalyse the slow formation of disulfide

bonds. These disulfide bond forming proteins (Dsbs) also belong to the thiore-

doxin superfamily. DsbA oxidises the thiolgroups of proteins within the

periplasm and is reoxidised by DsbB. Spontaneous formation of disulfide bonds

and even the effective catalysis performed by DsbA is at random. DsbC, E and G

repair the non-native bonds and are reduced again by DsbD. It is not known so

far when the disulfide bonds are formed (co- or post-translationally) and

whether the involved cysteines are chosen specifically [17, 158–162].

Due to the known differences between disulfide bond formation in the natural

eukaryotic environment of the most target proteins and the recombinant

prokaryotic host there is no question about the likelihood of misfolding. More-

over the cytoplasm as the most important compartment for the production of IBs

is reducing. Thus the IBs formed there might be mainly due to the absence of the

correct disulfide bonds. Nevertheless IBs found in the periplasm are caused by

the factors (incorrect disulfide bond formation vs folding characteristics) dis-

cussed above.

2.4.3

How to Avoid IBs and to Favour Correctly Folded Proteins

The first problem to occur during heterologous protein expression in E. coli is the

high local concentration of molecules. Moreover the recombinant host is lacking

the specific foldases needed by the product, any compartments and post-trans-

lational modifications [163].

The results of the product expression depend on different factors such as

strain, expression plasmid, induction conditions, temperature and compartment.

The corresponding impact cannot be predicted [164]. So every problem of the

production (e.g. expression, solubility, functionality) has to be solved for every

target protein separately. Solubility, functionality and minimal proteolysis can be

achieved by combining different upstream strategies.

2.4.3.1

Rate of Synthesis

The expression rate and the correct folding of the product are among other pa-

rameters determined by the level of gene induction, by the gene codon bias and

Inclusion Bodies: Formation and Utilisation

115

by the mRNA stability [165]. In actual optimisation procedures for soluble,

correctly folded proteins, the rate of synthesis is mostly controlled at the in-

duction level. The best results are usually obtained by lowering the cultivation

temperature down to 18–25 °C and applying low inducer concentration

[77, 152]. Therefore processes for soluble proteins are mostly characterised by

a low specific synthesis rate and long cultivation time after induction (6–24 h)

[166, 167].

The rate of synthesis of a single polypeptide depends on the elongation rate

in the translation process dependent on the codon bias [68]. It is well known that

an accumulation of unfavourable codons within a gene (see above) causes read-

ing errors (e.g. frameshifts, hops), mRNA instability and degradation [168, 169],

misincorporation of other amino acids at rare codons [170] and even death of the

cells [93]. Therefore, extra copies of rare tRNAs, e.g. argU, ileY and leuW, are in-

troduced into the host cells resulting in up to a 100-fold increase of the product

yield [171]. Alternatively the sequence of the recombinant gene can be adapted.

The codon usage of the first 20 amino acids is crucial for the expression level of

the product [172–174]. However, it is not considered in most cases that an im-

provement of the codon bias to abundant codons increases the probability of ag-

gregation by a high specific synthesis rate. Moreover, although the rate of trans-

lation might have a profound effect on the in vivo folding reaction and the

accessibility of chaperones, it has not been possible yet to tune the translation

process.

2.4.3.2

Fusion Proteins

Aggregation problems and other limitations, such as inefficient translation ini-

tiation and an incomplete removal of the start methionine, can often be solved

by fusion of the target protein to other proteins. Both eukaryotic (glutathione-S-

transferase from Schistosoma japonicum) and prokaryotic (protein A from

Staphylococcus aureus; maltose binding protein, thioredoxin and DsbA from

Escherichia coli) proteins are used as partners [34, 175]. Additionally the folding

and solubility promoting effect of the prosequences of eukaryotic proteins dur-

ing their recombinant production have been shown [21, 176, 177]. Those prose-

quences (steric chaperones) are essentially supporting the correct folding due to

lowering the activation energy and covering hydrophobic regions causing a sta-

bilisation of folding intermediates within the folding pathway. Moreover,

dimerisation is supported [178].

Fusion proteins are applied both in basic research and biotechnology not only

because of their folding promoting effect, but also with respect to using them as

a purification and immobilisation tool [179].

The order of the fusion partners is often determining the solubility of the

product. An N-terminal fusion of maltose binding protein leads to a soluble ex-

pression in most cases, whereas IBs accumulate in case of C-terminal fusions.

Thus the preliminarily translated maltose binding protein prevents aggregation

of the partner protein during its translation. The yield of the renaturation of

those IBs is higher than that of the unfused target protein [180–182].

116

B. Fahnert et al.

A comparison of six different insoluble target proteins each fused to maltose

binding protein, glutathione-S-transferase or thioredoxin showed maltose bind-

ing protein to be the most effective one in promoting solubility independent of

the expression temperature. Thioredoxin was more effective than glutathione-S-

transferase [183]. So the success is not necessarily correlated with the relative size

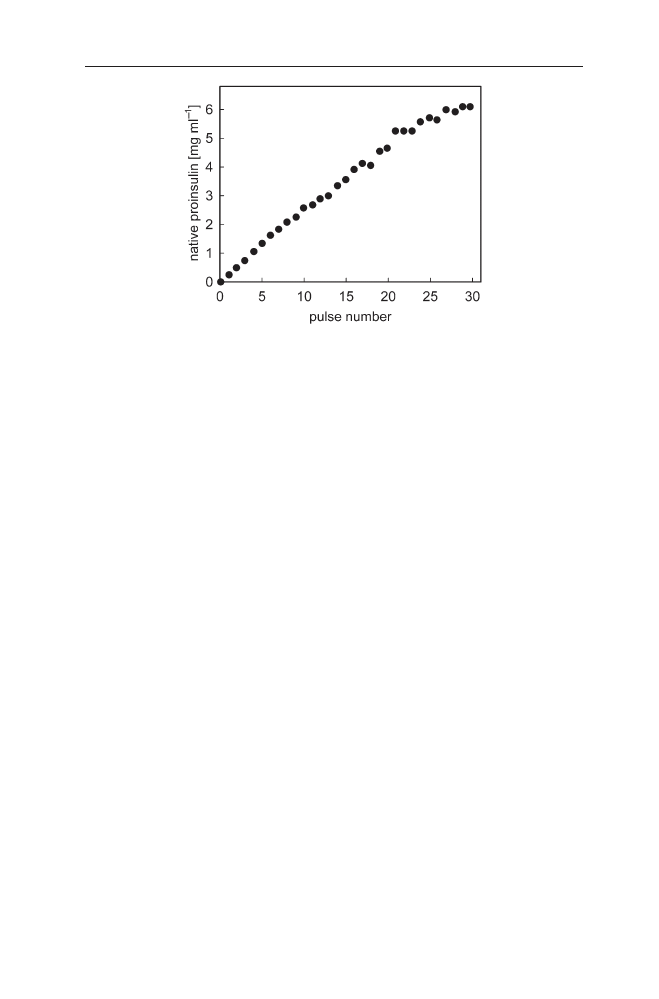

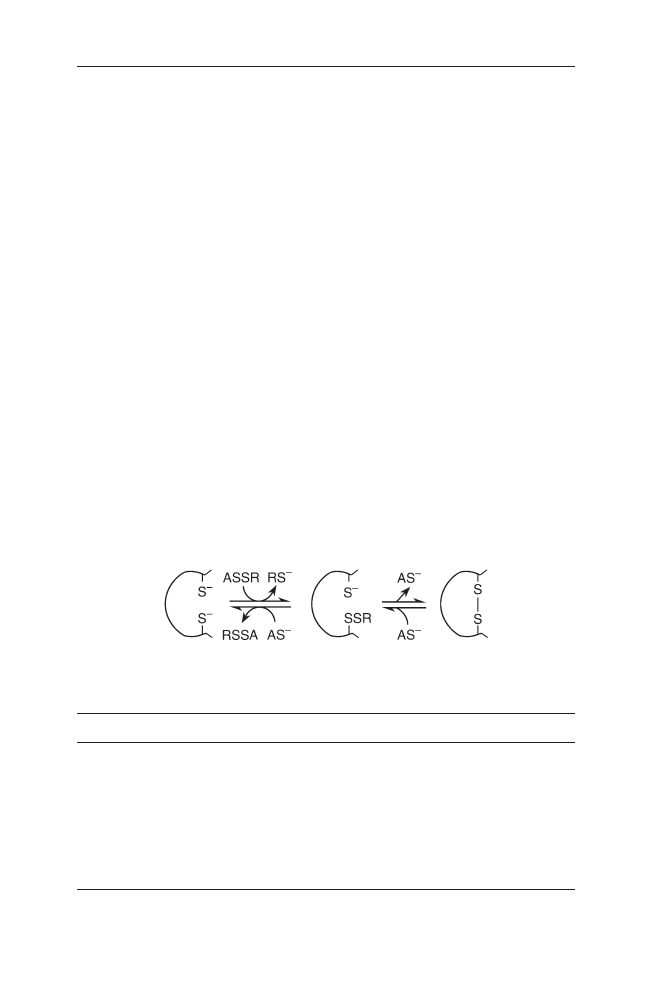

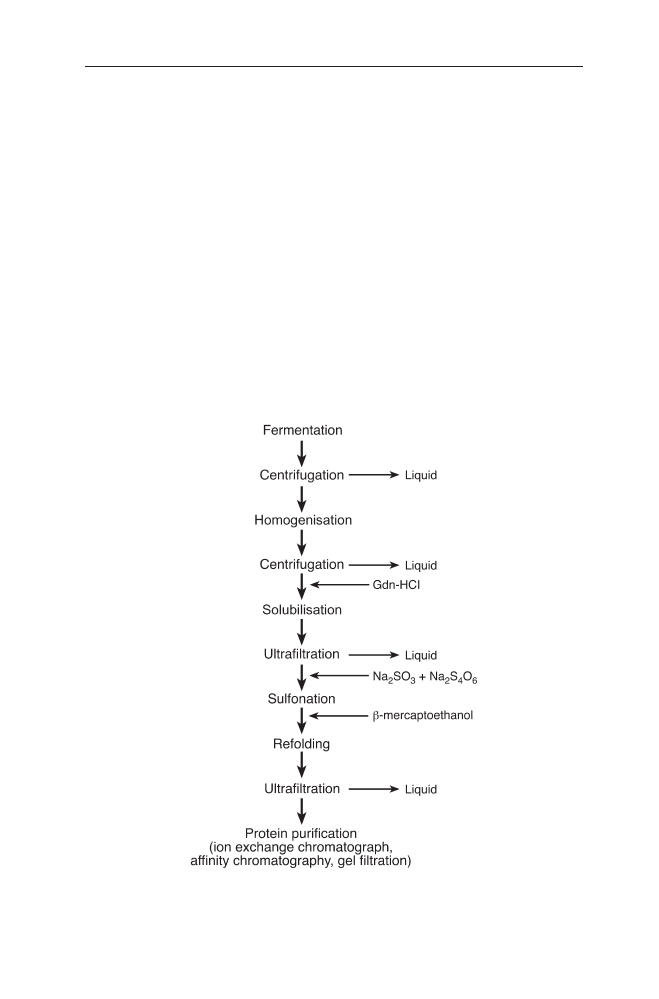

of the fusion partners.