CORRECTION OF APERTURE ABERRTIONS

OF HYBRID LENS

Marek ZAJĄC and Jerzy NOWAK

Instytute of Physics, Technical University of Wrocław

Wybrzeże Wyspiańskiego 27, PL 50-370 Wrocław, Polska

E-mail: zajac@if.pwr.wroc.pl

ABSTRACT

The possibilities of aberration correction in the case of a single lens are limited. It is well known that,

if classic glasses are used, it is impossible to compensate spherical aberration. It can be, however,

minimised by proper choice of the ratio between the first and second surface radii of curvature (referred

here as

ζ). It is possible also, in cost of uncorrected spherical aberration, to compensate III order coma.

Additional possibilities of aberration correction occur, however, if a thin diffractive structure is deposited

on one of the lens surface. Such lens is usually referred as a hybrid (diffractive-refractive) lens. The

diffractive structure typically corresponds to the holographic lens generated by the interference of two

spherical waves. The ratio of these waves radii of curvature is treated as a parameter (called here

β)

describing fully aberration properties of this structure. A focusing power of the diffractive part typically

is only a small fraction (

η ) of total focusing power of a hybrid lens, so the diffractive part acts mainly as

aberration corrector. Aberration properties of hybrid lens are determined by two parameters:

ζ and β so it

is possible to achieve simultaneous correction of aperture aberrations: spherical aberration and coma.

In the paper formulas describing the III-order aberration coefficients were used for calculating the

values of parameters

ζ and β assuring such correction for several values of parameter η and different

locations of object plane. The calculations were performed with help of the MATHCAD programme.

Basing on the results a number of hybrid lenses (collimating and imaging) were designed. Their imaging

quality was then evaluated by numerical calculation of aberration spots. Estimated values of such image

characteristics as the aberration spot moment of inertia or third order moment of the spots distribution

enable to compare the imaging quality. The essential improvement of imaging quality for the investigated

lenses (F-number equal to 1:10, maximum field angle 0.06) is achieved.

1. INTRODUCTION

In some applications it might be useful to use as simple optical imaging element as possible.

Unfortunately the imaging quality of single spherical lens is fairly unsatisfactory. It is well known, that (if

classic glasses are used) it is impossible to correct spherical aberration, which can be only minimized.

Additional possibility of aberration correction occurs, however, if the diffractive structure is deposited on

one of the lens surfaces. Such lens is usually referred as a hybrid (diffractive-refractive) lens. The

diffractive structure typically is manufactured synthetically but its geometry corresponds to the

holographic lens generated by the interference of two spherical waves. Thus additional parameters

enabling to correct aberrations appear when using a hybrid lens.

As it was pointed out above, the hybrid lens is understood as a conventional glass lens with a

diffractive structure deposited on one of its surfaces. The diffractive power of the hybrid lens is splitted

between the diffractive and refractive parts. The diffractive part plays the role of an aberration corrector,

so its refractive power can be only a small fraction of the total focusing power. Therefore the average

2

spatial frequency of diffractive structure can be relatively low which enables its manufacturing in a

typical interferometric laboratory or synthetically by printing with typical computer equipment (e.g. laser

printer).

The imaging properties of hybrid lenses were investigated extensively and described in the literature

[1-5]. For example, an analysis of sphero-chromatic aberration has been performed in [6, 7], from which

it follows that due to relatively large secondary spectrum such lens may be applied mainly in

quasi-monochromatic light. The possibilities of aplanatic correction of hybrid lens was discussed by the

authors of the present publication in the paper [8]. There they showed that for plano-convex hybrid lens

with diffractive structure deposited on the first (plane) surface, the correction of coma is possible only if

the real object is located at the distance

'

04

.

2

f

z

≤

; hence a lens focusing parallel light beam cannot be

aplanatic. In the paper [9] they investigated the aberrations of plano-convex hybrid lens with a diffractive

structure deposited on the second surface. In such case it is possible to obtain aplanatic correction even

for the object in infinity. In the present paper a hybrid lens of general shape is investigated.

2. ANALYTICAL RELATIONS

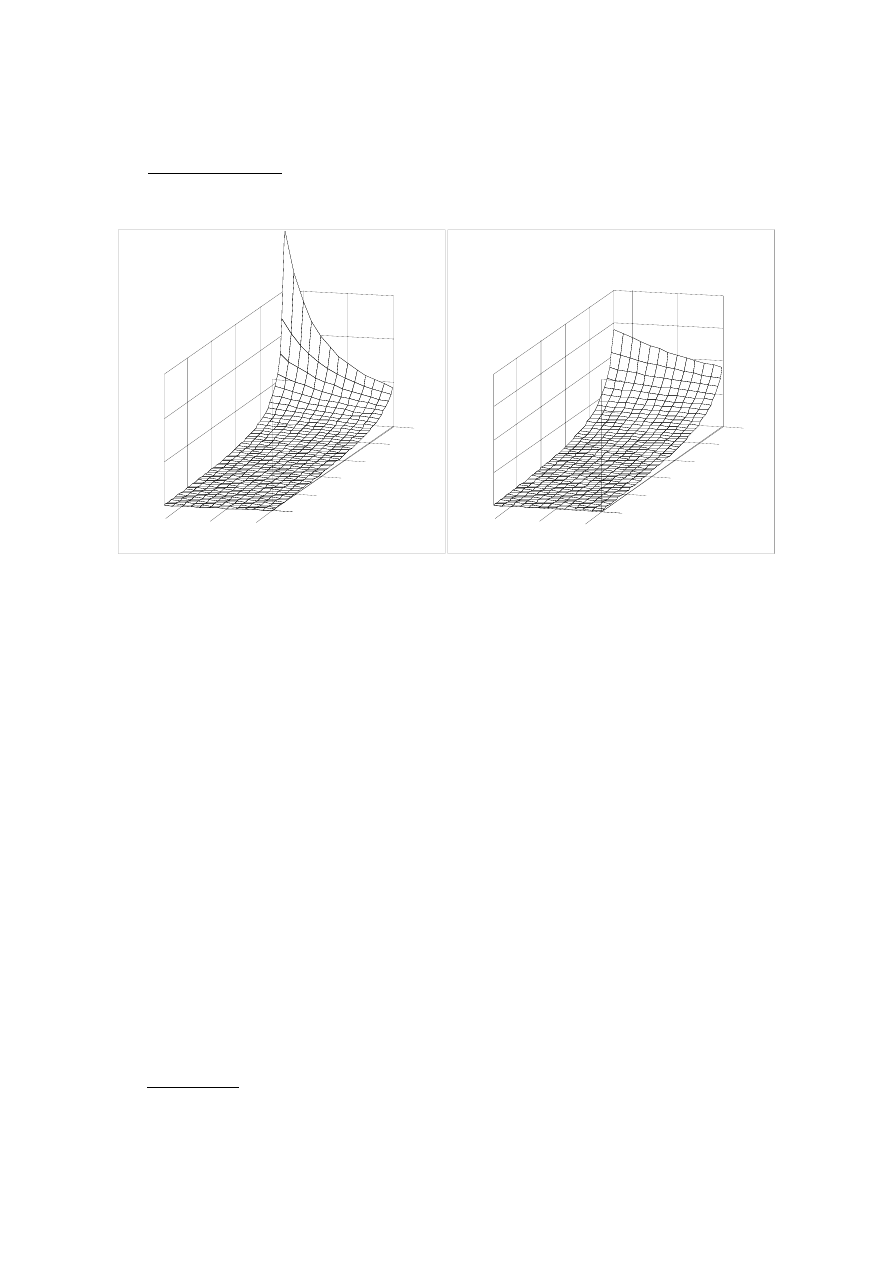

Fig. 1 Geometry parameters of hybrid lens

The hybrid lens under investigation is presented in the Fig. 1. The notation used there, as well as in the

following text is:

1

1

1

ρ

ρ

=

V

- curvature of the first refractive surface,

2

2

1

ρ

ρ

=

V

- curvature of the second refractive surface,

n

- refractive index of a lens material,

α

α

z

V

1

=

- wavefront curvature of the first wave creating the diffractive structure

β

β

z

V

1

=

- wavefront curvature of the second wave creating the diffractive structure

z

V

1

=

- reciprocity of the distance from the object point to the lens,

'

1

'

z

V

=

- reciprocity of the distance from the lens to the image point,

µ

±

- ratio of the imaging wavelength and the "recording wavelength" (+ sign corresponds to

the primary image, - sign to the secondary one).

ρ1

ρ2

Ζα1

Ζβ1

Ζα2

Ζβ2

n

3

Distances

α

z

and

β

z

are not necessarily connected to physically existing point light sources (as in a

lens manufactured holographically), but rather are treated as parameters.

In order to describe aberrations of the hybrid lens, the most convenient method seems to be proposed

by VERBOVEN and MASAJADA [10, 11]. After [12] we can express the coeficients of the III-order

aberrations, in the general case of a hybrid lens with diffractive microstructure deposited on both

surfaces. The coefficients of third order spherical aberration and coma (only meridional cross-section and

infinitely thin lens is considered) have the form.

(

)

[

]

(

)

+

−

−

+

+

+

−

−

−

=

1

1

1

1

1

1

1

2

1

n

V

V

n

n

V

V

S

R

D

D

R

R

ϕ

ϕ

ϕ

ϕ

ϕ

(

)

(

)

+

−

−

+

+

−

2

2

1 n

V

V

ρ

ϕ

ϕ

ϕ

[

]

(

)

+

−

−

+

+

+

+

n

n

V

V

n

R

D

R

D

R

1

1

2

1

1

1

1

2

ϕ

ϕ

ϕ

ϕ

ϕ

(

)

(

) (

)

(

) (

)

+

−

−

−

±

−

−

−

−

±

−

+

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

β

ϕ

β

µ

β

ϕ

β

β

ϕ

β

µ

ϕ

β

ϕ

R

D

R

D

D

(

)

(

) (

)

(

) (

)

−

−

−

±

−

−

−

−

±

−

+

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1

1

1

1

1

β

ϕ

β

µ

β

ϕ

β

β

ϕ

β

µ

ϕ

β

ϕ

R

D

R

D

D

(1)

(

) (

) (

)

−

+

+

+

−

+

−

+

+

+

−

−

=

1

1

1

1

2

1

1

1

2

n

V

V

n

n

V

n

V

V

yV

C

R

R

R

R

D

R

y

ϕ

ϕ

ϕ

ϕ

ϕ

ϕ

ϕ

ϕ

(2)

where

1

1

1

α

β

β

V

V

=

,

(3)

2

2

2

α

β

β

V

V

=

,

(4)

and

(

)

1

1

1

ρ

ϕ

V

n

R

−

=

(5)

(

)

2

2

1

ρ

ϕ

V

n

R

−

=

(6)

(

)

1

1

1

β

α

µ

ϕ

V

V

D

−

±

=

(7)

(

)

2

2

2

β

α

µ

ϕ

V

V

D

−

±

=

(8)

are focusing powers of first and second refractive surfaces and first and second diffractive structure,

respectively. Coefficient

µ typically equals 1, and is omitted in the following.

Obviously the total focusing power of a hybrid lens is

2

1

2

1

D

D

R

R

ϕ

ϕ

ϕ

ϕ

ϕ

+

+

+

=

(9)

For the sake of simplicity new parameter describing the hybrid lens are introduced:

2

1

2

1

R

R

D

D

R

D

ϕ

ϕ

ϕ

ϕ

ϕ

ϕ

η

+

+

=

=

(10)

4

This parameter determines a fraction of the overall refractive power due to the diffractive corrector.

Additionally it is set

1

2

R

R

ϕ

ϕ

ζ

=

(11)

and:

ϕ

V

v

=

(12)

Using this notation formula (2) expressing coma changes to:

(

)(

)(

)

+

+

+

−

−

=

η

ζ

ϕ

η

ζ

ϕ

1

1

1

1

1

)

,

,

,

,

(

2

1

n

v

n

v

C

(13)

(

)(

) (

)

(

)

(

)(

)(

)

(

)

(

)(

)(

)

+

+

−

−

+

+

−

+

+

−

+

+

+

+

+

+

η

ζ

ζ

η

ζ

ζ

η

η

η

ζ

1

1

1

1

1

1

1

1

1

1

1

1

1

n

v

v

n

n

v

if the diffractive strusture is deposited on the first surface, and

(

)(

)(

)

+

+

+

−

−

=

η

ζ

ϕ

η

ζ

ϕ

1

1

1

1

1

)

,

,

,

,

(

2

2

n

v

n

v

C

(14)

(

)(

)

(

)

(

)(

)(

)

(

)

(

)(

)(

)

+

+

−

−

+

+

−

+

+

−

+

+

+

+

η

ζ

ζ

η

ζ

ζ

η

ζ

1

1

1

1

1

1

1

1

1

1

1

1

n

v

v

n

n

v

if it is located on the second surface of the hybrid lens.

It is easy to note, that coma does not depend on the properties of the diffractive part (eqs. 13 and 14 do

not include parameter

β1 nor β2), but it depends only on the fraction of the total focusing power η of this

part.

For given refractive index n and total focusing power

ϕ it is possible to calculate the shape of

refractive part of the hybrid lens assuring coma correction in dependency on the object location v and the

parameter

η. It is determined by the value of parameter ζ from which the radii of its both surfaces of the

refractive part of a hybrid lens can be calculated

(

)(

)(

)

ϕ

η

ζ

ρ

n

−

+

+

=

1

1

1

1

(15)

and

5

(

)(

)(

)

ϕζ

η

ζ

ρ

n

−

+

+

=

1

1

1

2

(16)

0

5

10

0

10

20

30

40

50

0

10

20

30

ζζ 1

0

5

10

0

10

20

30

40

50

0

5

10

15

20

ζζ 2

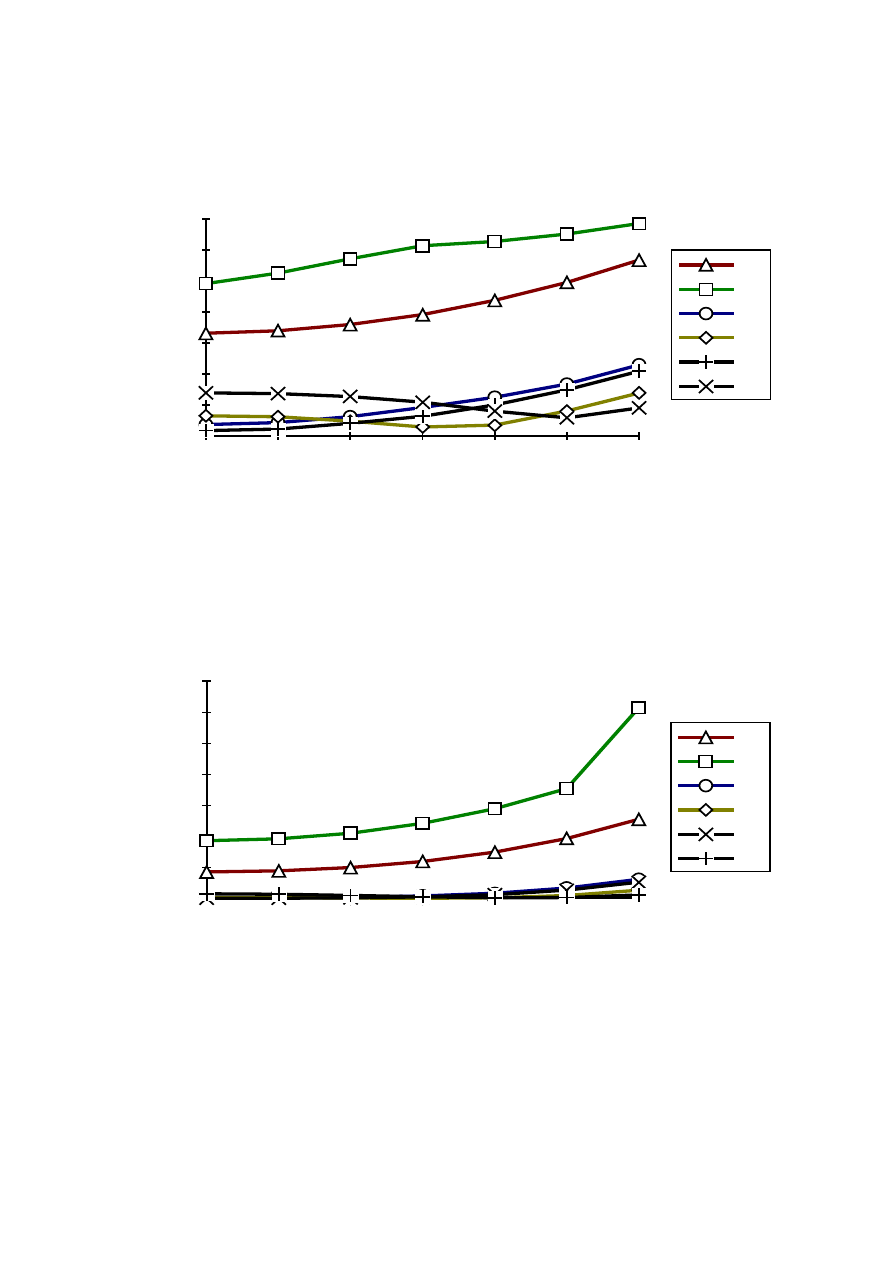

Fig.2 Condition for correction of coma. Parameter

ζ vs object location v and parameter η

Necessary calculations were performed with help of the Mathcad program and are presented on the

graphs shown in the Figure 2. The considered object location varies from minus infinity (focusing lens) to

the front focal length (collimating lens). The corresponding values of the parameter v vary thus from

0 to -1. Parameter

η determining the diffractive corrector focusing power is assumed to vary from zero

(pure refractive lens) to 12% which is treated as a limit.

The formula describing the spherical aberration (1) is more complicated, but the Mathcad program

enables to handle it. After symbolic solution of the equations

0

)

,

,

,

,

(

1

=

η

ζ

ϕ

n

v

C

and

0

)

,

,

,

,

(

2

=

η

ζ

ϕ

n

v

C

with respect to the value of

ζ (assuming v and η as parameters) and substituting the result into (1) the

relation between the spherical aberration and the value of parameter

β characterizing the geometry of

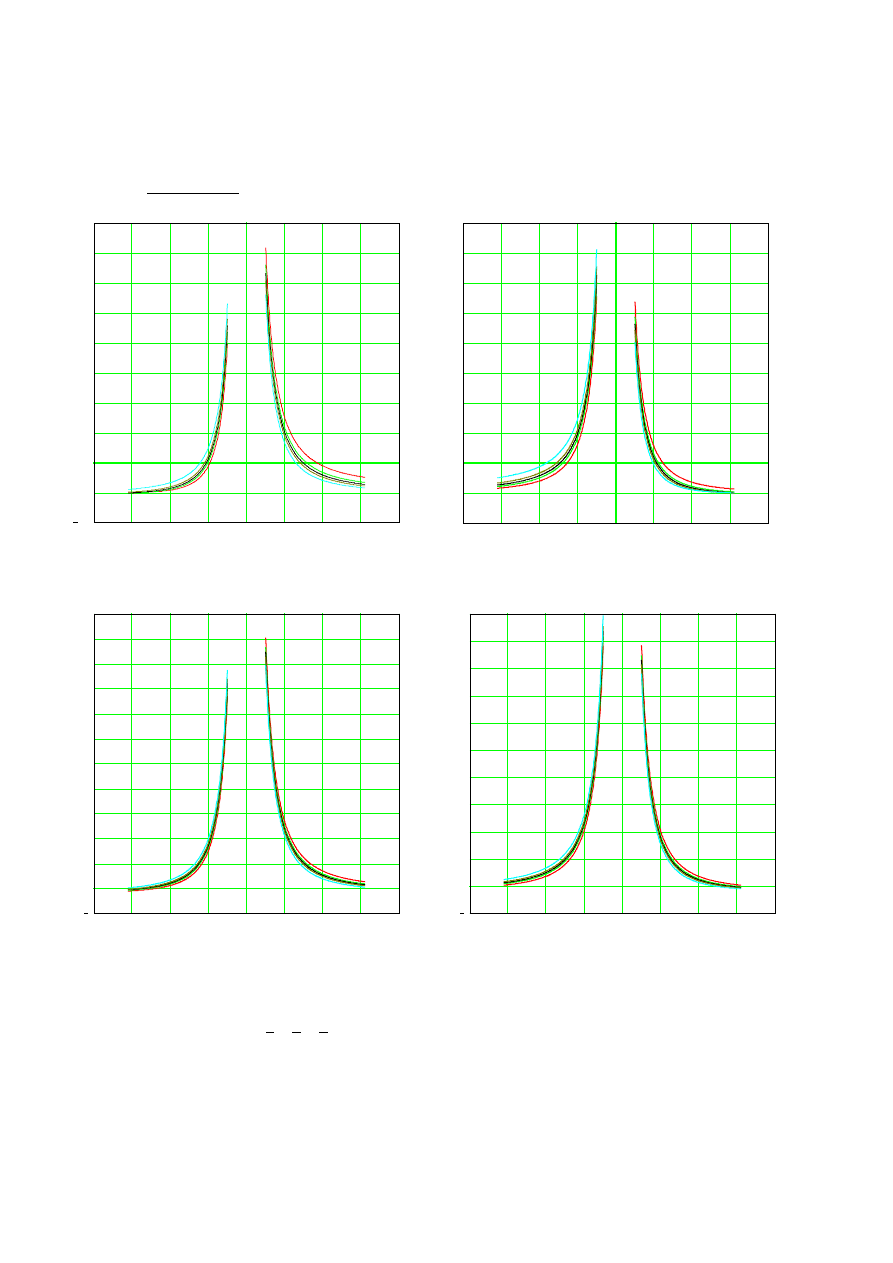

diffractive structure may be determined. Fig. 3a-d present the exemplary curves illustrating the spherical

aberration vs parameter

β for different object point locations and ratio η if the diffractive corrector is

located on the first or second surface of the hybrid lens. It can be seen that for each investigated case two

solutions exist.

Taking the value of

β for which spherical aberration equals to zero leads to aplanatic hybrid lens. The

value of parameter

β determines the geometry of diffractive structure deposited on the refractive part as it

is

(

)(

)

ϕη

η

β

α

+

−

=

1

1

z

(17)

6

and

(

)(

)

ϕηβ

η

β

β

+

−

=

1

1

z

(18)

0.96 0.97 0.98 0.99 1

1.02 1.03 1.04

4

0

4

8

12

16

β

1.01

S

a)

1.04

4

8

12

16

1

1.01

-4

0

1.02

1.03

0.99

0.98

0.97

0.96

β

S

b)

0.96 0.97 0.98 0.99

1

1.01 1.02 1.03 1.04

10

0

20

40

60

80

100

β

-

S

c)

0.96 0.97 0.98 0.99

1

1.01 1.02 1.03 1.04

10

0

20

40

60

80

100

S

β

-

d)

Fig. 3

Spherical aberration vs parameter

β, for different locations of object plane

(

1

,

,

,

,

3

2

2

1

3

1

−

−

−

−

−∞

=

v

),

a) diffractive corrector on the first surface,

05

.

0

=

η

b) diffractive corrector on the second surface,

05

.

0

=

η

7

c) diffractive corrector on the first surface,

10

.

0

=

η

d) diffractive corrector on the second surface,

10

.

0

=

η

As it could be expected there is no solution for

β if the fraction η tends to zero, but the solutions for

05

.

0

=

η

and

10

.

0

=

η

are presented in the Fig. 4

v

β

0,94

0,96

0,98

1

1,02

1,04

1,06

1,08

-1

-0,9

-0,8

-0,7

-0,6

-0,5

-0,4

-0,3

-0,2

-0,1

0

eta=0.05 I surface

eta=0.10 I surface

eta=0.05 II surface

eta=0.10 II surface

Fig. 4 Condition for simultaneous correction of coma and spherical aberration. Parameter

β vs object

location v for diffractive corrector on the first or second surface and two values of parameter

η

(

05

.

0

=

η

and

10

.

0

=

η

)

3. NUMERICAL ILLUSTRATION

To illustrate the obtained results several examples of aplanatic lenses were choosen and their imaging

quality was analysed. Focal length of all lenses was assumed to be

mm

f

100

'

=

and relative F-number to

1:10. The value of the lens material refractive index was taken as

5

.

1

=

n

. Two arbitrarily choosen values

of parameters determining the ratio of diffractive corrector focusing power to the total hybrid lens

focusing power were chosen:

05

.

0

=

η

, and

10

.

0

=

η

. Three imaging geometries were investigated:

object point was located in minus infinity (collimating lens), as well as in dostance

f

z

3

−

=

(magnification = -1/2) and

f

z

2

−

=

(magnification = -1). For comparison two pure refractive lenses of

the same imaging characteristics were investigated. One of them has compensated coma, the other -

minimized spherical aberration.

8

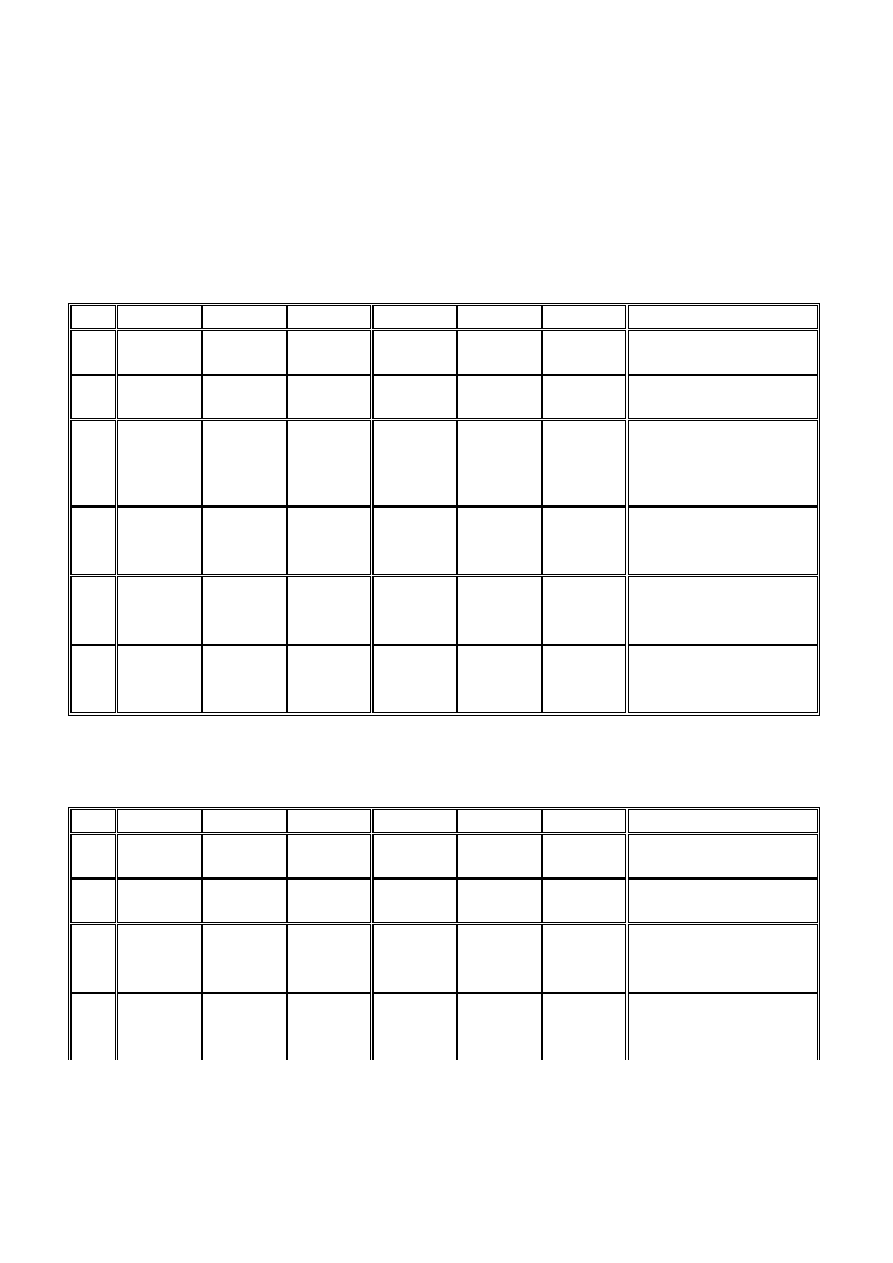

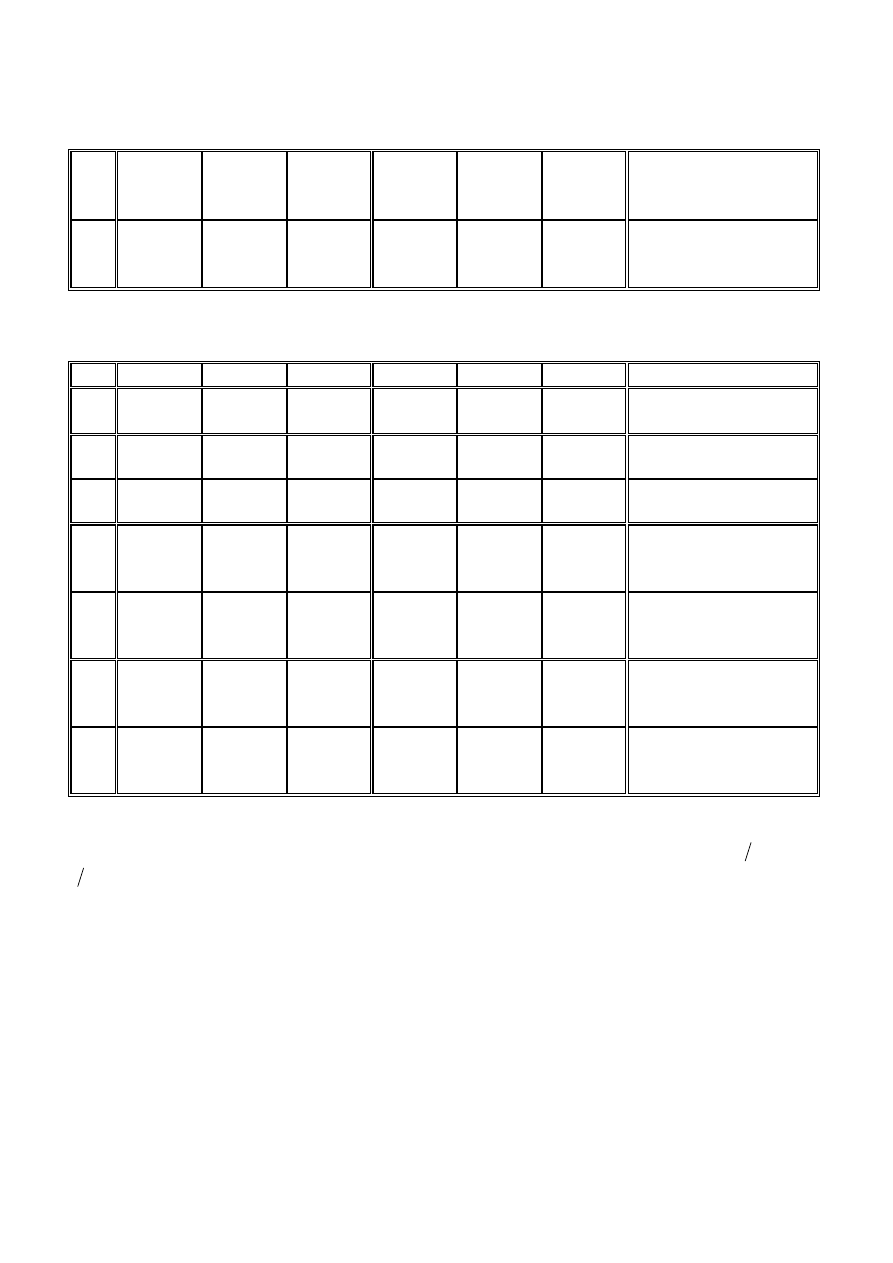

Geometry parameters of all chosen lenses are given in the Tables 1-3

Table 1

Geometry parameters characterizing the analysed lenses

(collimating lens - object in infinity)

No

ζ

R1 [mm] R2 [mm]

β

zβ [mm] zα [mm]

remarks

R10

55.555

-500.00

-

-

-

refractive lens,

coma corrected

R20

58.824

-333.33

-

-

-

refractive lens, spherical

aberration minimized

P10 0.094871

57.481

-605.88 1.018485

or

0.09489

-38.819

or

20.233

-38.114

or

20.430

hybrid lens,

05

.

0

=

η

diffractive corrector on

the first surface

P20 0.072079

56.284

-780.88 1.012345

or

0.987245

-25.925

or

26.785

-25.608

or

27.132

hybrid lens,

05

.

0

=

η

diffractive corrector on

the second surface

S10 0.07833

59.308

-757.16 1.062085

or

0.976095

-68.293

or

26.295

-64.301

or

26.939

hybrid lens,

10

.

0

=

η

diffractive corrector on

the first surface

S20 0.03617

56.989

-1576.0 1.033925

or

0.966155

-37.317

or

37.230

-36.093

0r

38.534

hybrid lens,

10

.

0

=

η

diffractive corrector on

the second surface

Table 2

Geometry parameters characterizing the analysed lenses

(imaging lens, object distance

f

z

3

−

=

)

No

ζ

R1 [mm] R2 [mm]

β

zβ [mm] zα [mm]

remarks

R11

78.947

-136.36

-

-

-

refractive lens,

coma corrected

R21

59.322

-318.18

-

-

-

refractive lens, spherical

aberration minimized

P11 0.584006

83.160

-142.40 1.015795

or

0.989795

-33.170

or

21.431

-32.654

or

21.651

hybrid lens,

05

.

0

=

η

diffractive corrector on

the first surface

P21 0.53674

80.679

-150.31 1.011145

or

0.986125

-23.404

or

26.785

-23.147

or

27.132

hybrid lens,

05

.

0

=

η

diffractive corrector on

the second surface

9

S11 0.58765

87.319

-148.60 1.048145

or

0.974075

-52.960

or

28.517

-50.527

or

29.276

hybrid lens,

10

.

0

=

η

diffractive corrector on

the first surface

S21 0.49788

82.383

-165.468 1.029605

or

0.961495

-32.566

or

42.356

-31.629

or

44.052

hybrid lens,

10

.

0

=

η

diffractive corrector on

the second surface

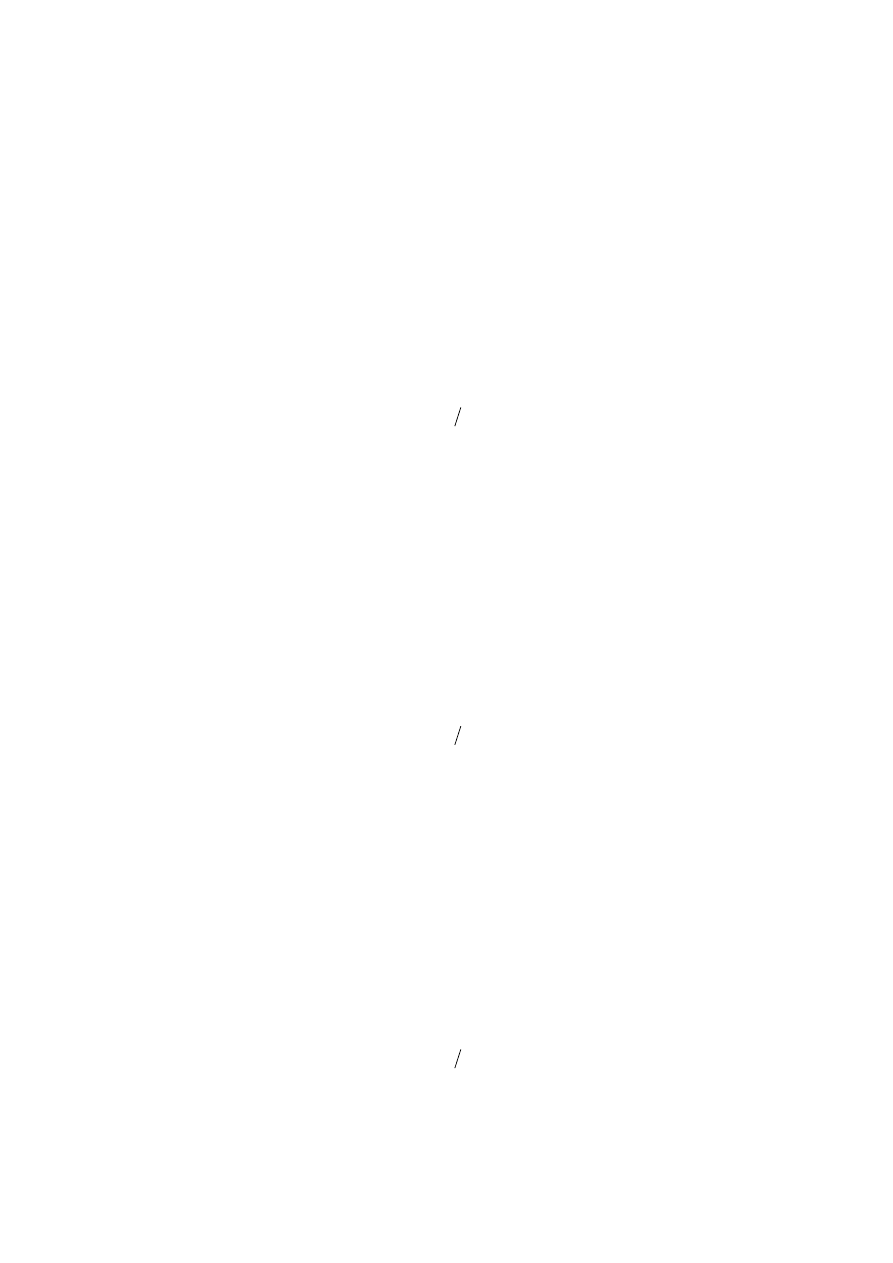

Table 3

Geometry parameters characterizing the analysed lenses

(imaging lens, object distance

z

f

= −2

)

No

ζ

R1 [mm] R2 [mm]

β

zβ [mm] zα [mm]

remarks

No

ζ

R1

[mm]

R2

[mm]

β

zβ

[mm]

zα

[mm]

remarks

R12

100.00

-100.00

-

-

-

refractive lens,

coma corrected

R22

59.322

-318.18

-

-

-

refractive lens, spherical

aberration minimized

P12 1.039604

107.08

-103.00 1.014845

or

0.989415

-31.174

or

22.228

-30.718

or

22.466

hybrid lens,

η = 0 05

.

diffractive corrector on

the first surface

P22 0.96190

375.00

-107.08 1.010695

or

0.985375

-22.459

or

30.712

-22.222

or

31.168

hybrid lens,

η = 0 05

.

diffractive corrector on

the second surface

S12 1.07843

114.31

-106.00 1.043655

or

0.972775

-48.020

or

29.95

-46.012

or

30.786

hybrid lens,

η = 0 10

.

diffractive corrector on

the first surface

S22 0.92727

106.00

-114.312 1.027985

or

0.958165

-30.783

or

46.018

-29.945

or

48.028

hybrid lens,

η = 0 10

.

diffractive corrector on

the second surface

The imaging quality was evaluated by typical ray-tracing computer simulation. In the Figs. 5 - 10 spot

diagrams for the lenses R12, R22, P12, S12 are presented for the field angles equal to

0

=

z

y

, and

04

.

0

=

z

y

. The circle containing 80% total number of ray traces (considered as 80% total light spot

energy) is marked on the graphs.

10

Fig 5 Aberration spots for the lens No.R11 (refractive, coma corrwected)

field angles

04

.

0

,

0

=

z

y

Fig 6 Aberration spots for the lens No.R21 (refractive, minimum spherical aberration)

field angles

04

.

0

,

0

=

z

y

Fig 7 Aberration spots for the lens No.S11 (hybrid, diffractive corrector on first surface,

η=0.05)

field angles

04

.

0

,

0

=

z

y

11

Fig 8 Aberration spots for the lens No.S12 (hybrid, diffractive corrector on second surface,

η=0.05)

field angles y z

= 0 0 04

, .

Fig 9 Aberration spots for the lens No.P11 (hybrid, diffractive corrector on first surface,

η=0.10)

field angles y z

= 0 0 04

, .

Fig 10 Aberration spots for the lens No.P12 (hybrid, diffractive corrector on second surface,

η=0.10)

field angles

04

.

0

,

0

=

z

y

Several parameters characterising aberration spots were calculated from the spot diagrams:

12

8

.

0

d

- diameter of a light spot containing 80% of total energy,

2

M

- second order moment of the light intensity distribution in the aberration spot being the measure of

its spread:

(

)

∑

=

−

=

N

i

i

y

y

y

N

M

1

2

2

1

(19)

3

M - third order moment of the light intensity distribution in the aberration spot being the measure of its

non symmetry according to the spot centre of gravity y :

(

)

∑

=

−

=

N

i

i

y

y

y

N

M

1

3

3

1

(20)

RMS

- mean square deviation of the rays distribution the spot diagram being the measure of the rays

distribution (similar as

M

2

):

(

) (

)

[

]

∑

=

−

+

−

=

N

i

i

i

y

y

y

y

N

RMS

1

2

2

1

(21)

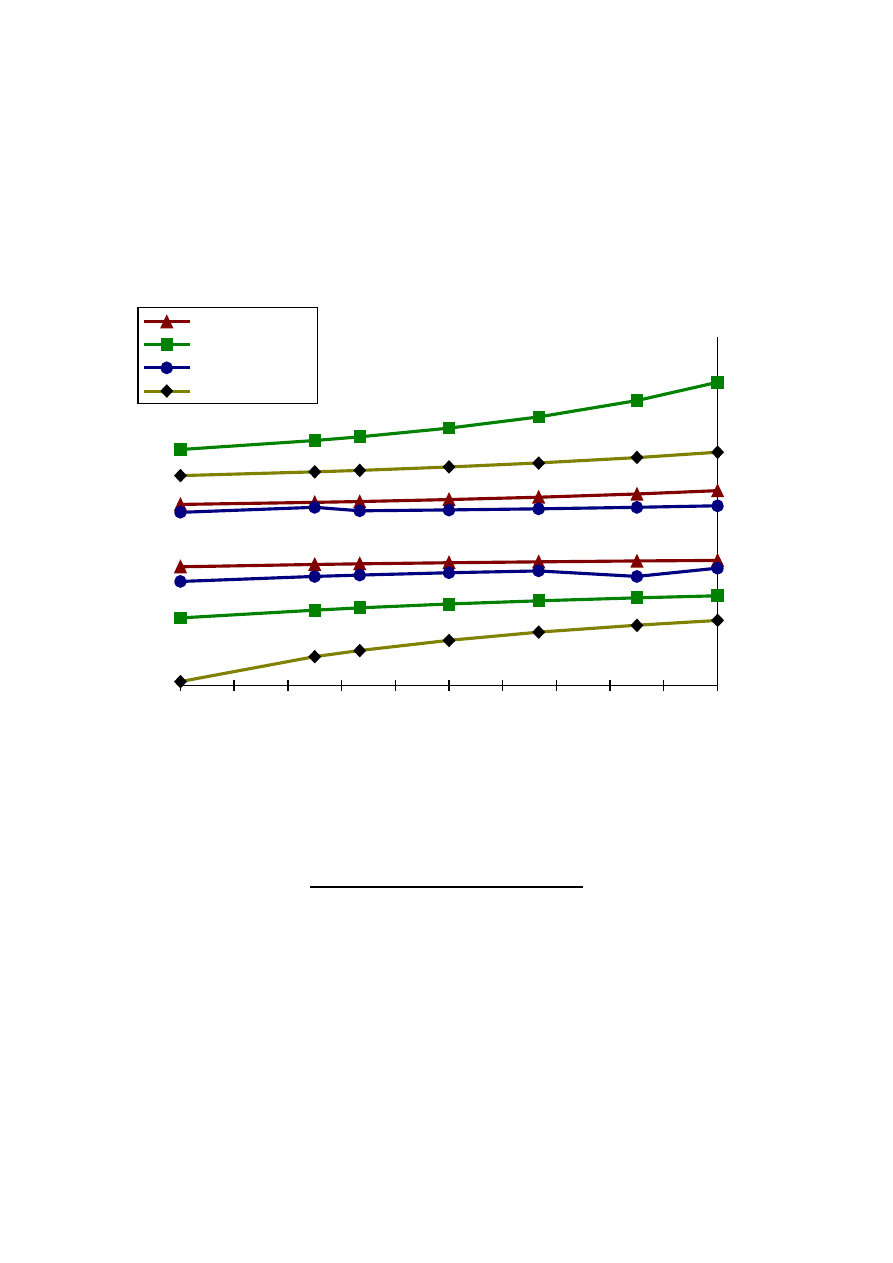

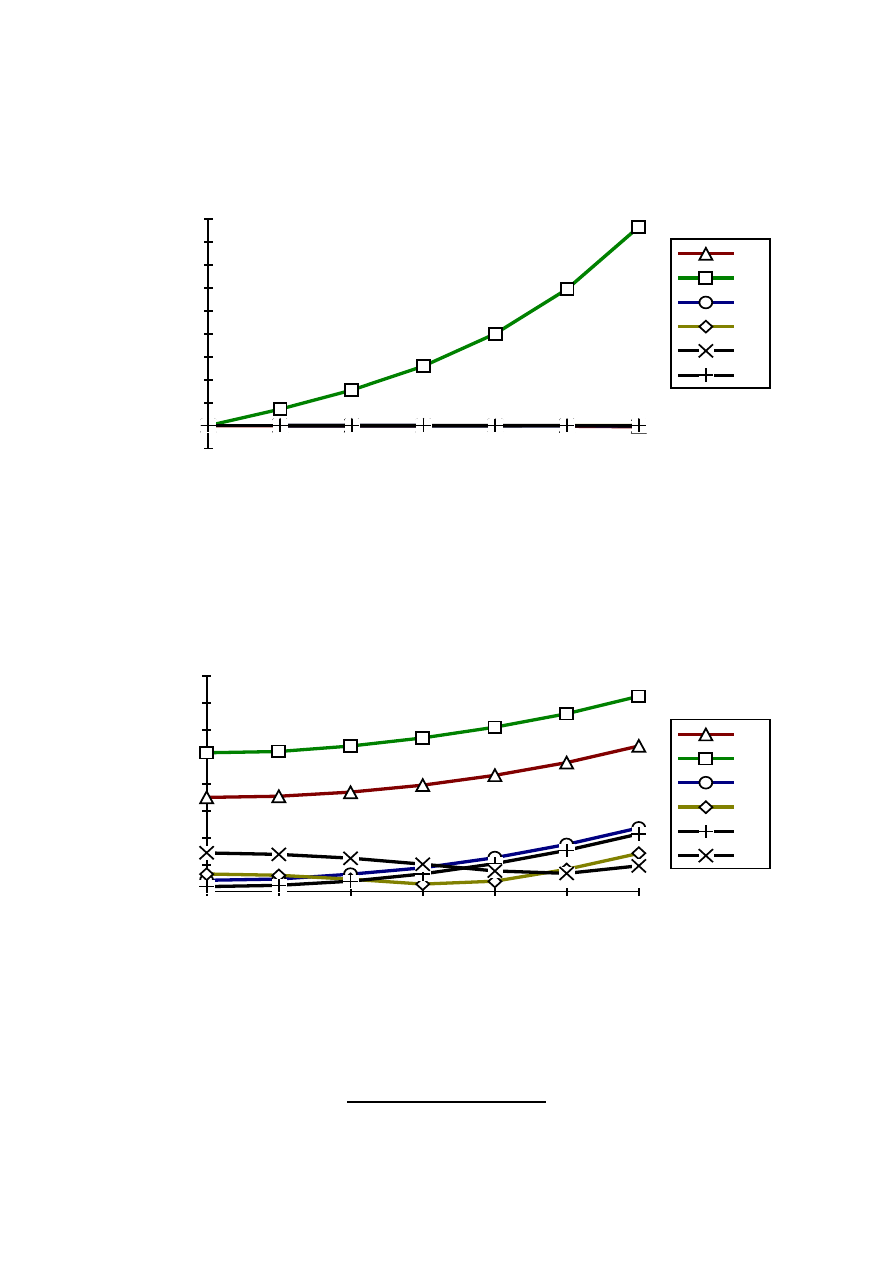

Values of these parameters versus field angle for all investigated lenses are presented in the Fig. 11, 12,

13 and 12. From these pictures it is evident, that imaging quality of all hybrid lenses is practically the

same.

The analysis of the obtained results confirms that it is possible to obtain the aplanatic correction for

simple hybrid lens. The assumption, that one of the surface is flat is not necessary. Diffractive corrector

can be located on either first or second surfsce as well. There is no limitation for the object location. The

imaging quality is considerably better, than for corresponding classic lens. Field curvature and

astigmatism remains uncorrected, as it was expected. The image is acceptable for the field angle not less

than

05

.

0

=

z

y

, what is satisfactory for one-piece optical element.

13

d08

0,00E+00

5,00E-02

1,00E-01

1,50E-01

2,00E-01

2,50E-01

3,00E-01

3,50E-01

0

0,01

0,02

0,03

0,04

0,05

0,06

R12

R22

P12

P22

S12

S22

Fig. 11 Diameter of a light spot containing 80% of total energy (

8

.

0

d ) vs field angle for imaging lens

of magnification -1 (v = -0.5, object distance z = -2f).

R12, R22 - pure refractive lenses,

P12, P22 - hybrid lenses with corrector of

η = 0.05,

S12, S22 - hybrid lenses with corrector of

η = 0.10.

M2

0,00E+00

1,00E-02

2,00E-02

3,00E-02

4,00E-02

5,00E-02

6,00E-02

7,00E-02

0

0,01

0,02

0,03

0,04

0,05

0,06

R12

R22

P12

P22

S12

S22

Fig. 13 Second order moment of the light intensity distribution in the aberration spot (

2

M

) vs field

angle for imaging lens of magnification -1 (v = -0.5, object distance z = -2f).

R12, R22 - pure refractive lenses,

P12, P22 - hybrid lenses with corrector of

η = 0.05,

S12, S22 - hybrid lenses with corrector of

η = 0.10.

14

M3

-1,00E-03

0,00E+00

1,00E-03

2,00E-03

3,00E-03

4,00E-03

5,00E-03

6,00E-03

7,00E-03

8,00E-03

9,00E-03

0

0,01

0,02

0,03

0,04

0,05

0,06

R21

R22

P12

P22

S12

S22

Fig. 14 Third order moment of the light intensity distribution in the aberration spot (M

3

) vs field

angle for imaging lens of magnification -1 (v = -0.5, object distance z = -2f).

R12, R22 - pure refractive lenses,

P12, P22 - hybrid lenses with corrector of

η = 0.05,

S12, S22 - hybrid lenses with corrector of

η = 0.10.

RMS

0,00E+00

2,00E-03

4,00E-03

6,00E-03

8,00E-03

1,00E-02

1,20E-02

1,40E-02

1,60E-02

0

0,01

0,02

0,03

0,04

0,05

0,06

R12

R22

P21

P22

S12

S22

Fig. 12 Mean square deviation of the rays distribution the spot diagram (

RMS

) vs field angle for

imaging lens of magnification -1 (v = -0.5, object distance z = -2f).

R12, R22 - pure refractive lenses,

P12, P22 - hybrid lenses with corrector of

η = 0.05,

S12, S22 - hybrid lenses with corrector of

η = 0.10.

ACKNOWLEDGMENTS

15

This publication was supported by Committee for Scientific Research (KBN) under the contract

No. 34165-7

REFERENCES

1 S. Bobrov, G. Greisukh, Yu. Turkavich, "Optika diffraktsionnykh elementov i sistem" [ in Russian],

Mashinostroenie, Leningrad 1986;

2 E. Jagoszewski, " Holograficzne elementy optyczne" [ in Polish], Oficyna Wydawnicza

Politechniki Wrocławskiej, Wrocław 1995;

3 N, C. Gallagher, SPIE Proc., 1396, 722-733 (1992);

4 A. P. Wood, Appl. Optics, 31, 2377-2384 (1992);

5 M. Larson, C. C. Beckman, A. Nystrom, S. Hard, J. Sjostrand, Appl. Optics, 31, 2377 -2384 (1992);

6 N. Emerton, Proc. III Int. Conf. on Holographic Systems, Components and Applications,

Edinburgh, 1991,

7 B. Dubik, S. Koth, J. Nowak. M. Zając, Optics and Laser Technology, 27, 315 (1995),

8 S. Koth, J. Nowak M. Zając, Pure and Applied Optics, 4, 543-552, (1995);

9 S. Koth, J. Nowak, M. Zając, Opt. Applicata, 25, 245 (1995),

10 P. E. Verboven, P. E. Lagasse, Appl. Opt. 25, 1791-1795 (1991);

11 J. Masajada, J. Nowak, Appl. Opt. 30, 1791-1795 (1991);

12 B. Dubik, S. Koth, M, Zając, SPIE Proc 2169, 130-137 (1993).

Wyszukiwarka

Podobne podstrony:

Correction Of Chromatic Abberration In Hybrid Objectives

DESIGN OF HYBRID PHOTOVOLTAIC POWER GENERATOR, WITH OPTIMIZATION OF ENERGY MANAGEMENT

1The effects of hybridization on the abundance of parental taxa depends on their relative frequency

E E (Doc) Smith Lensman 06 Children of the Lens

Effectiveness of hybrid drying (S J Kowalski, K Rajewska)

Dynamic Simulation Of Hybrid Wind Diesel Power Generation System With Superconducting Magnetic Energ

Possibilities of Aberration Correction in a Single

Existence of the detonation cellular structure in two phase hybrid mixtures

Hybrid Inorganic Organic Materials by Sol Gel Processing of Organofunctional Metal Alkoxides (2)

Correction Procedure of Nautical Charts

Nonlinear Control of a Conrinuously Variable Transmission (CVT) for Hybrid Vehicle Powertrains

Flames of War Ostfront Corrections

10 Past Simple or Present Perfect Provide the correct form of the verb

17 Present Perfect or Past Simple Provide the correct form of the verb

Are the google translations of the sentences in the left column correct

The Role of Vitamin A in Prevention and Corrective Treatments

Correction Procedure of Nautical Charts

ABC Investigation of liver correct

MacAvoy, RA Lens 3 The Belly of the Wolf

więcej podobnych podstron