177

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

Mechanical Properties of the Composite Material Based on Modified Scrap Tires and Polymer Binder

*

Corresponding author: Tel. +37129570655; fax: +37167615765.

E-mail address: renate.plesuma@gmail.com

©

Smithers Rapra Technology, 2013

Mechanical Properties of the

Composite Material Based on

Modified Scrap Tires and Polymer

Binder

R. Plesuma*, A. Megne, I. Mateusa-Krukle and L. Malers

Institute of Polymer Materials, Riga Technical University, Latvia

Received: 10 February 2012, Accepted: 25 October 2012

SUMMARY

The present work focuses on the investigation of the mechanical properties of

the composite material composed of preliminary modified rubber crumb and

a polymer binder. The modification of rubber crumb was realized by means of

treatment with water or sulphuric acid, in order to change the degree of polymer

crosslinking or to intensify adhesion interaction between rubber particles and

polymer binder. The Shore C hardness, compressive stress at 10% deformation

and compression modulus of elasticity, ultimate tensile strength and elongation

at break of composite material, in correlation with its composition and adhesion

between rubber and polymer binder were investigated.

Obtained results show possibility of attaining significant changes in the mechanical

properties of composite material by selected rubber crumb treatment methods,

in correlation with the composite material composition. This gives additional

opportunity for meaningful improvement of composite material production

technology.

INTRODUCTION

Recycling of used automobile tyres must be considered as an important

activity from the point of view of not burdening the environment from the

non-degradable waste. Various ways of utilization and recycling methods

178

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

R. Plesuma, A. Megne, I. Mateusa-Krukle and L. Malers

exist [1];one of the most common approaches for recycling tyres is mixing of

rubber crumb with a polymer binder to produce composite materials [2, 3].

In our previous investigations, optimization of the composition and technology

of composite material production from mechanically ground scrap tyres and

a polyurethane type binder, were realized [4, 5, 6]. It was elucidated that the

properties of the studied composite material are highly dependent, not only

on the material composition and the type of polyurethane binder used, but

also on several technological parameters and production conditions such as

molding pressure and formation temperature [6].

The present work must be considered as a continuation of previous

investigations on composite material and focuses on clarifying the influence

of preliminary rubber crumb modification on selected mechanical properties

of the composite material, in what must be considered as insufficiently

investigated question. Two different methods of modification were selected

based on experience and published composite material research [7, 9, 11-

13]. Hence ,the methods of rubber crumb modification detailed in this study

could be useful in improving the mechanical properties of composite material

and production technology.

EXPERIMENTAL

Description and Preparation of Materials and Samples

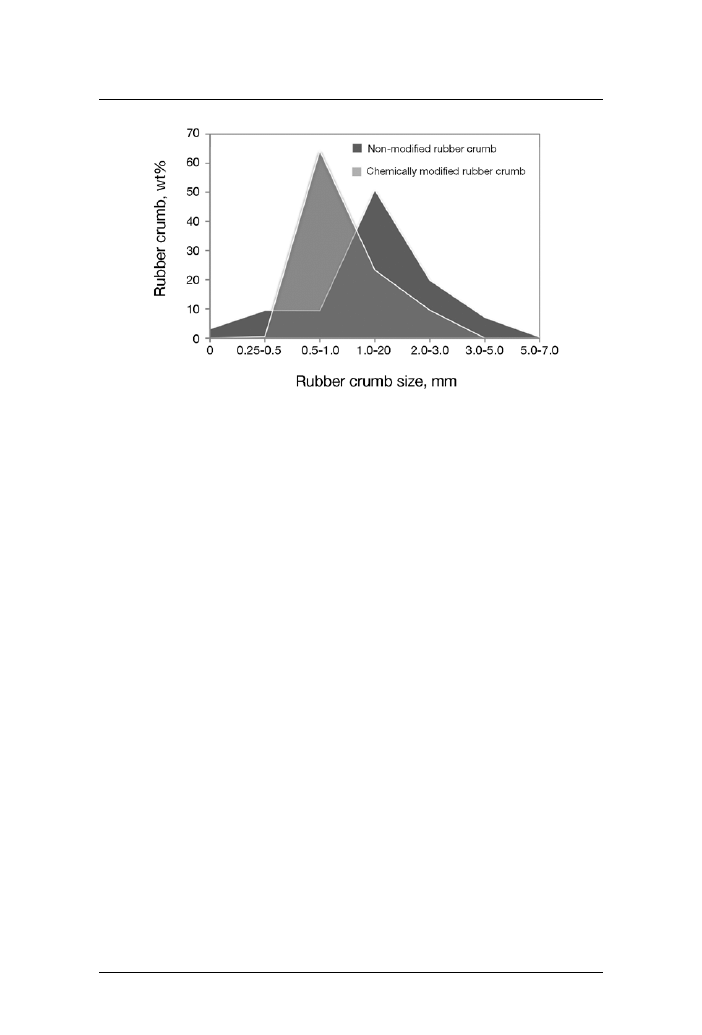

Mechanically ground at ambient temperature, modified and non-modified

rubber crumb obtained from used tyres, with a particle size ranging from

0.2-7.0 mm (

Figure 1), and polyurethane type binder with a different reactivity

(isocyanate group content - 2.42%, 5.4% and 7.4%) were used in order to

produce composite material samples. Different compositions of rubber crumb

and polymer binder (from 8-23 wt%) were used in the composite material.

Uniform samples of composite material were prepared under constant and

defined conditions: formation temperature (18-22°C), pressure (0.004 MPa),

molding time (24 h) and relative air humidity (23-30%).

It is well known [7] that environmental moisture content directly affects the

hardening degree of polyurethane polymers, containing isocyanate groups,

due to the degree of change of polymer crosslinking.

Direct preliminary

rubber crumb modification using water was implemented in order to clarify

the possibility of intensifying the degree of crosslinking of the polymer binder

used directly in the composite material. The conditions employed for the

179

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

Mechanical Properties of the Composite Material Based on Modified Scrap Tires and Polymer Binder

rubber treatment with water in the present work were selected taking into

account our previous investigations [8]. The modification of rubber crumb

was realized by the direct treatment of previously dried rubber crumb with a

defined amount of water.

Chemical modification of rubber crumb with 96% sulphuric acid at different

reaction times was used in order to explore the possibility of intensifying the

adhesion between the polymer binder and rubber particles, thereby affecting

the mechanical properties of the investigated composite material [9, 11, 12].

The particle size distribution of scrap tyres before and after surface modification

with sulphuric acid is shown in

Figure 1.

Testing

In order to examine constituent materials used in the production of the

composite material and determine the essential characteristics which could

affect the final properties of the material, the following test methods were used:

• Determinationofmoisturecontentinrubbercrumbwasascertainedby

simple calculations with preliminary dried (different drying times were

selected) and modified rubber particles.

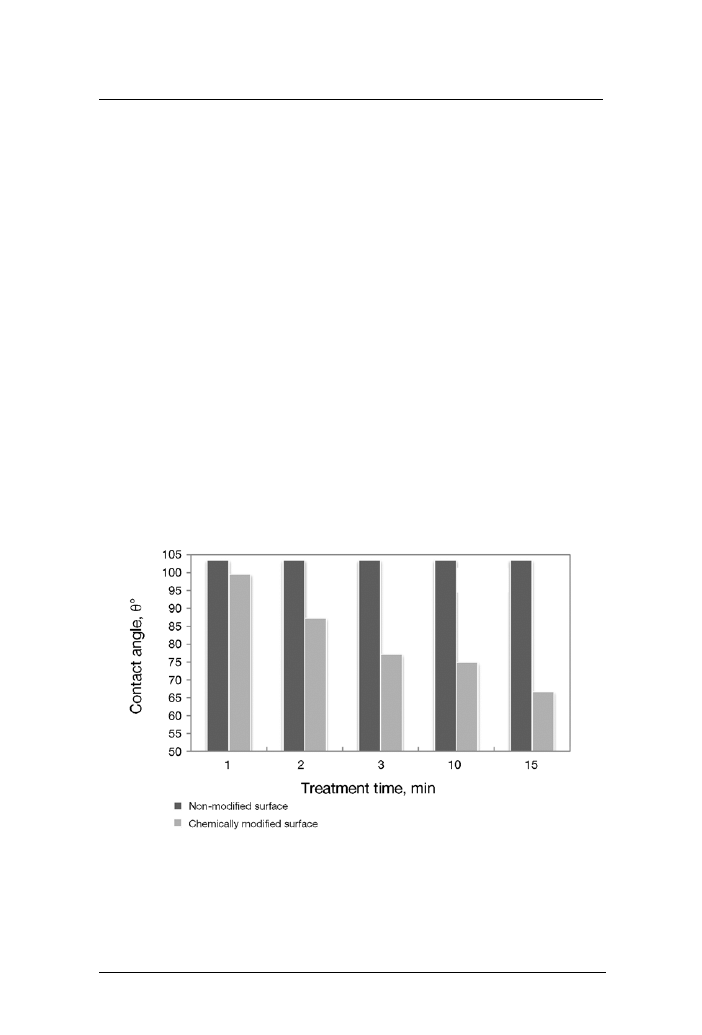

• In order to determine some wetting properties, the contact wetting

angle q° of a water droplet on a rubber surface of the non-modified and

Figure 1.

Particle size distribution of scrap tyres before and after surface modification

with sulphuric acid

180

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

R. Plesuma, A. Megne, I. Mateusa-Krukle and L. Malers

modified solid rubber samples were examined. The possible change of

hydrophilic properties, depending on the rubber surface energy, was

estimated (

Figure 2).

• Special samples were prepared in order to examine the strength of

adhesive bonding between the polymer binder and modified rubber

surface. For this purpose Peel test (90°, speed 50 mm/min) was used

according to LVS EN 28510-1.

• The apparent density AD (kg/m

3

) of the composite material was

determined according to LVS EN 1602.

• ShoreChardnesswasinvestigatedbyusingaShoretester(TypeC;ISO

7619, ISO 868).

• Mechanical properties of the composite material (compressive stress

at 10% deformation and compressive modulus E) were determined by

using the testing apparatus, Zwick/Roell7020, according to EN 826. In

the tensile mode of loading, the ultimate tensile strength and elongation

at break, for specially prepared samples with defined dimensions, were

determined according to LVS EN ISO 527-3.

Figure 2. Contact angle q° of solid rubber samples before and after modification with

sulphuric acid

181

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

Mechanical Properties of the Composite Material Based on Modified Scrap Tires and Polymer Binder

RESULTS AND DISCUSSION

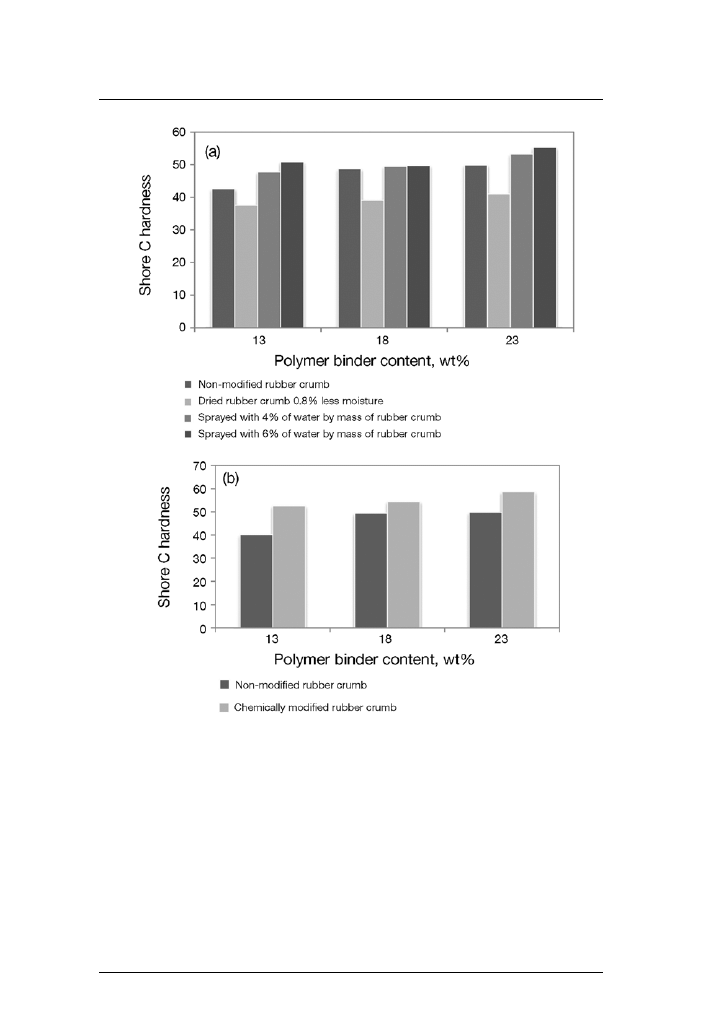

In previous investigations it was clarified that the composite material

composition and its hardness is highly interdependent [5]. Close correlation

between mechanical properties and Shore C hardness was demonstrated,

hence proving that Shore hardness can be used as a tool to determine other

mechanical properties (for example, compressive stress at 10% deformation)

without direct material testing

[5, 6].

It was also elucidated that elevated air humidity, during formation of the

composite material, reduces the composite material hardening time of due

to intensification of polymer crosslinking reactions: thus making it possible to

achieve significantly higher values of Shore C hardness after 24 h hardening,

compared with the testing results of composite material samples hardened

at ambient air humidity [10]. Therefore, the effect of moisture content on

the properties of the composite material must be considered as potentially

significant, and for that reason additional investigations were carried out using

a rubber crumb special treatment with water spraying before production of

the composite material samples.

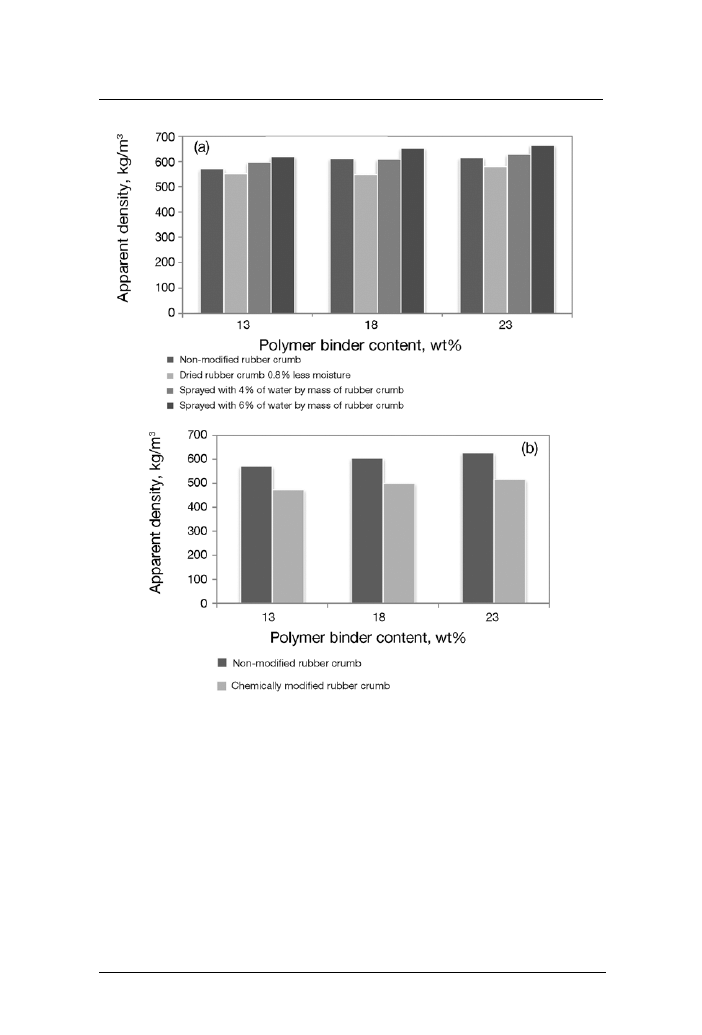

The results show that values of apparent density increase upon increasing

the sprayed water and binder content (

Figure 3a). The correlation between

characteristics and properties of the composite material with the binder

content, used in the production of the samples, has also been investigated

and demonstrated in several previous investigations [4-6].

Similar tendencies were observed in the determination of Shore C hardness for

composite material samples containing modified rubber particles (

Figure 4a).

This can possibly be explained by the specific nature of polymer binder in

improving the hardening process, as the rubber particle-polymer binder

interface is highly dependent on the environmental moisture [8].

Chemical modification of rubber crumb was carried out by treatment with

sulphuric acid under defined conditions prior to the production of the

composite material samples. The results show a significant decrease of

apparent density compared with the composite material samples prepared

under the same conditions using non-modified rubber crumb (

Figure 3b).

This can possibly be explained by the changes in the particle size distribution

of rubber crumb after chemical modification (

Figure 1). At the same time,

experiment showed that Shore C hardness increased by up to 15% when

modified rubber crumb was used; probably a result of the destruction of double

bonds on the rubber surface and consequent loss of elasticity (

Figure 4b).

In addition, a more similar shape of rubber particles was observed after

chemical modification.

182

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

R. Plesuma, A. Megne, I. Mateusa-Krukle and L. Malers

The chemical modification of the rubber surface with sulphuric acid was

carried out mainly in order to investigate subsequent changes of adhesive

interaction (bonding) between the rubber and polymer binder. Surface oxidant

treatment, in order to improve interfacial compatibility in composite materials,

has also been demonstrated in systems containing polyolefins [12, 13].

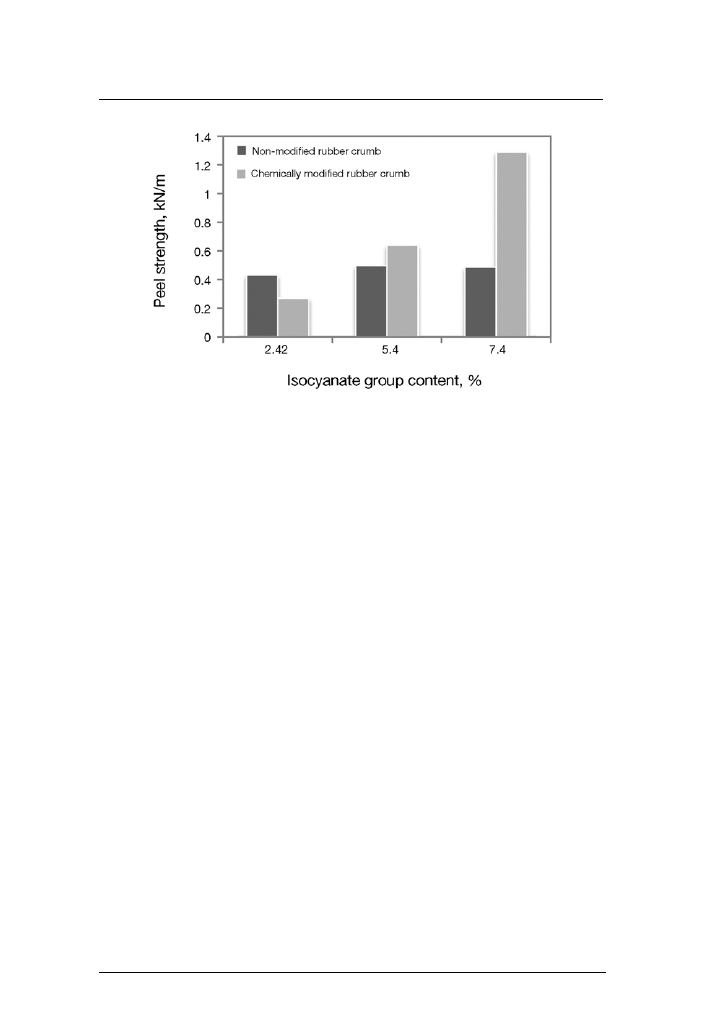

Peel test results show that the chemical modification of the rubber surface

promotes adhesive bonding for selected samples (

Figure 5). The results of

the Peel test correlate with rubber surface wettability measurements shown

Figure 3. Variation in composite material apparent density AD (kg/m

3

) with

composition of material and modification of rubber crumb: a) treated with water, b)

treated with sulphuric acid

183

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

Mechanical Properties of the Composite Material Based on Modified Scrap Tires and Polymer Binder

in

Figure 2. A visual evaluation of the failure character of adhesive joints

after the Peel test demonstrated mainly adhesive type of destruction. It was

shown that with the increase of concentration of reactive isocyanate groups

in the polymer binder, Peel strength increased due to a more active interaction

between components of the adhesive joint (

Figure 5).This fact establishes

the importance of the individual properties of constituent materials used in

the production of composite material.

Figure 4. Variation in composite material Shore C hardness with composition of

material and modification of rubber crumb: a) treated with water, b) treated with

sulphuric acid

184

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

R. Plesuma, A. Megne, I. Mateusa-Krukle and L. Malers

Figure 5. Variation in Peel strength with polymer binder activity before and after

chemical modification of rubber surface

In order to investigate subsequent changes of mechanical properties - ultimate

tensile strength (σ

t

) and elongation at break (ε

t

) in the tensile mode of loading

of the composite material (polymer binder with 2.42% isocyanate group

content) were determined. The samples of composite material were prepared

using modified and non-modified rubber crumb. Results are given in

Table 1.

The results presented in

Table 1 show that the rubber crumb treatment with

water demonstrated mainly higher ultimate elongation values and lower

values of tensile strength for the tested material samples. This can be possibly

explained due to some of the water not being involved in the crosslinking

reactions of the polyurethane binder and therefore acting as a plasticizer of

the composite material.

Chemical modification of the rubber crumb resulted in the ultimate tensile strength

exhibiting lower values compared with the non-modified samples. However, the

elongation at break in the tensile mode of deformation demonstrated an inverse

situation. The explanation for this must take into account the fact that rather

different rubber particle shape and size distributions (

Figure 1) were observed

for modified and non-modified rubber crumb, and therefore the compactness

and also properties of the composite material samples differ [11].

Similar samples of composite material, produced with the methods mentioned

above, were also tested in a compressive mode of loading; compressive

modulus of elasticity and compressive stress at 10% deformation were also

determined (

Table 1).

185

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

Mechanical Properties of the Composite Material Based on Modified Scrap Tires and Polymer Binder

In the case of using water spraying as a modification method, test results

show that the mechanical properties of the composite material are highly

dependent on moisture content; explained by the improvement of the particular

polymer binder hardening. The significance of water treatment prior to the

production of composite material samples was established and therefore the

role of moisture presence is emphasized once again.

Similar tendencies were observed when chemical modification of the rubber

crumb was used (

Table 1). In this case, mechanical properties such as

modulus of elasticity and compressive stress at 10% of deformation were

enhanced due to the improvement of adhesion between the rubber and

polymer binder. This is highly connected with the improvement of wetting

capability (hydrophilicity) of the rubber crumb due to the processes arising

from the influence of sulphuric acid on the chemical structure of the rubber

surface [9]. This was also demonstrated by the experiment investigating the

Table 1. Ultimate tensile strength (σ

t

),elongation at break (ε

t

),

compressive stress at 10% deformation (σ

10%

) and compressive

modulus of elasticity (E) of the composite material

Nr.

Description of rubber crumb Polymer

binder

content

(wt.%)

σ

t

(MPa)

ε

t

(%)

σ

10%

(MPa)

E

(MPa)

1.

Non-modified

13

0,068

66

0.21

0,25

18

0,152

57

0,28

0,36

23

0,175

51

0,39

0,42

2.

Modified with water

2.1. Preliminary dried ( 0.5 h; 80°C)

13

0,086

58

0,42

1,09

18

0,088

-

-

1,10

23

0.090

63

0,51

1,40

2.2. Treated with water -1 ( 4 wt% )

13

0,070

73

0,59

1,38

18

0.118

-

0,60

1,60

23

0.116

75

0,69

1,63

2.3. Treated with water -2 (6 wt% )

13

0,074

67

0,61

1,30

18

0.088

71

-

1,36

23

0,142

75

0,79

1,70

3.

Modified with sulphuric acid

13

0,064

67

0,80

1,50

18

0,104

-

1,00

6,80

23

0,106

62

1,38

7,00

186

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

R. Plesuma, A. Megne, I. Mateusa-Krukle and L. Malers

adhesion between the preliminary treated rubber substrate and the polymer

binder (

Figure 5).

CONCLUSIONS

The results show that the selected properties of the composite material are

highly dependent on both the rubber crumb treatment with water spraying

and surface modification with sulphuric acid.

The remarkable influence of rubber crumb treatment with sulphuric acid on

selected properties (Shore C hardness, compressive stress and modulus of

elasticity, peel strength) of the composite materials was observed; attributed

to the increase of rubber surface hydrophilicity and thereby improved adhesion

with the polymer binder.

It is postulated that the rubber treatment with water leads to the increase

of Shore C hardness and ultimate tensile strength of composite material,

due to the intensification of crosslinking and thus hardening process of the

polyurethane binder.

Therefore, the methods of the modification of rubber crumb, detailed in this

study, could lead to a meaningful improvement of mechanical properties and

production technology of composite material.

REFERENCES

1.

Mark J.E., Erman B., and Erich R., The Science and Technology of Rubber,3

d.

Ed., Elsvier Inc., USA, (2006) 763.

2.

Lund H.F., McGraw – Hill recycling handbook, R.R.Donelly & Sons Company,

USA, (1993) 18.2-18.35.

3.

Adhikari B. and Maiti S., Progress in Polymer Science,

25, (2000) 909-948.

4.

Malers L., Plesuma R., and Locmele. L., Mech. Comp. Mat.,

45, (2009) 1-6.

5.

Malers L., Plesuma R., and Locmele L., Scientific Journal of Riga Technical

University: Material Science and Applied Chemistry

,

21, (2010) 35-38.

6. Malers L., Plesuma R., Locmele. L., Megne A., and Mateusa-Krukle I.,

Polymer composites: Book of abstracts,

Zapodočeska Univerzita v Pilzen,

the Czech Republic, ( 2011) 135-136.

7.

Wicks Z.W., Jones F.N., and Pappas S.P., Organic Coatings: Science and

Technology, Volume I

, John Wiley & Sons Inc., USA, (1992) 189-191.

187

Progress in Rubber, Plastics and Recycling Technology, Vol. 29, No. 3, 2013

Mechanical Properties of the Composite Material Based on Modified Scrap Tires and Polymer Binder

8.

Malers L., Plesuma R., and Locmele L., Scientific Journal of Riga Technical

University: Material Science and Applied Chemistry

,

23, (2011) 103-106.

9. Cepeda-Jimenez C., Pastor-Blas M.M., Ferrandiz-Gomez T.P., Martin-

Martinez J.M., J. Adhes.,

73, (2000) 135-160.

10. Megne A., Mateusa-Krukle I., Plesuma R., and Malers L., Baltic Polymer

Symposium: Book of abstracts

, Tallin University of technology, Estonia,

(2011) 29.

11. Goncharuk G.P., Knunyants M.I., Kruchkov A.N., Obolonkova E.S., and

Vysokomolekularnye Soedineniya,

40, (1998) 877.

12. Colom X., Carrillo.F., and Canavate J., Composites,

38, (2007) 44-50.

13. Pat.US 6833396B2 (21.12.2004).

Copyright of Progress in Rubber, Plastics & Recycling Technology is the property of Rapra Technology and its

content may not be copied or emailed to multiple sites or posted to a listserv without the copyright holder's

express written permission. However, users may print, download, or email articles for individual use.

Wyszukiwarka

Podobne podstrony:

wpływ dodatku nanowypełniacza na wlaściwości mechaniczne i tribiologiczne kompozytów do zastosowań s

Badania właściwości mechanicznych materiałów izolacyjnych, Pim c6, Politechnika Wrocławska

Właściwoście mechaniczne materiałów

Nawierzchnie chodnikowe dwufazowe na bazie modyfikowanych bitumów alternatywa dla pow

Wlasciwosci mechaniczne materiałow

Właściwości mechaniczne materiałów i metody ich badania (Łukasz Makarowski)

WD7 Kompozyty na bazie ceramiki

Uczymy poprawnej wymowy wzorujac sie na bazie literatury dzieciecej -Materialy na WDN, pomoce logop

Pytania na egzamin z mechaniki, Materiały na studia, Polibuda, AiR Semestr I, Mec, bonus

ćw9 - Badanie właściwości i mikrostruktury żeliw, Wstępy na materiałoznawstwo

Materiały stosowane na śrubę-pkm, mechanika, BIEM- POMOCE, pkm

Kompozyty ceramiczne, POLITECHNIKA ŚLĄSKA Wydział Mechaniczny-Technologiczny - MiBM POLSL, Inżyniers

Badanie wpływu właściwości materiałów magnetycznych na reluktancję obwodu magnetycznego

właściwości mechaniczne(1), I rok, materiały budowlane, Sprawka

wpływ zaw. węgla na właściw. stali, Materialoznawstwo

Zakres materiału z Mechaniki, Materiały na studia, Polibuda, AiR Semestr I, Mec, bonus

więcej podobnych podstron