Research review paper

Biotransformation of terpenes

Carla C.C.R. de Carvalho *, M. Manuela R. da Fonseca

Centro de Engenharia Biolo´gica e Quı´mica, Instituto Superior Te´cnico, Av. Rovisco Pais, 1049-001 Lisboa, Portugal

Received 17 July 2005; accepted 13 August 2005

Available online 5 October 2005

Abstract

The main application of terpenes as fragrances and flavors depends on the absolute configuration of the compounds because

enantiomers present different organoleptic properties. Biotransformations allow the production of regio- and stereoselective

compounds under mild conditions. These products may be labeled as bnaturalQ. Commercially useful chemical building-blocks

and pharmaceutical stereo isomers can also be produced by bioconversion of terpenes. Enzymes and extracts from bacteria,

cyanobacteria, yeasts, microalgae, fungi, plants, and animal cells have been used for the production and/or bioconversion of

terpenes. In addition, whole cell catalysis has also been used. A variety of media and reactors have been assessed for these

biotransformations and have produced encouraging results, as discussed in this review.

D 2005 Elsevier Inc. All rights reserved.

Keywords: Monoterpenes; Terpenoids; Biotransformations; Enantiomeric resolution

Contents

1.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

134

2.

Biocatalysts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

135

3.

Reaction media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

137

4.

Reactor type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

138

5.

Bio-kinetic resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

139

6.

Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

140

Acknowledgements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

140

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

140

1. Introduction

Terpenes occur widely in nature. Terpenes such as lim-

onene and a-pinene are inexpensively available in large

quantities. Monoterpenes in plants are known to have

mainly ecological roles in acting as deterrents against

feeding by herbivores, as antifungal defenses and attrac-

tants for pollinators (

). In mammals

terpenes are involved in stabilizing cell membranes,

metabolic pathways and as regulators of enzymatic re-

actions. For example, cholesterol and related steroids

are triterpenes that are derived from 6 isoprene units.

Herbs and higher plants containing terpenoids and

their oxygenated derivatives have been used as fra-

0734-9750/$ - see front matter

D 2005 Elsevier Inc. All rights reserved.

doi:10.1016/j.biotechadv.2005.08.004

* Corresponding author. Tel.: +351 21 8417681; fax: +351 21

8419062.

E-mail address: ccarvalho@ist.utl.pt (C.C.C.R. de Carvalho).

Biotechnology Advances 24 (2006) 134 – 142

www.elsevier.com/locate/biotechadv

grances and flavors for centuries. More than 22,000

individual terpenoids are known at present, making

terpenoids the largest group of natural products. Ter-

penes have drawn increasing commercial attention be-

cause of increasing understanding of their roles in

prevention and therapy of several diseases, including

cancer; their activity as natural insecticides and antimi-

crobial agents; properties that can be useful in storing

agricultural produce (e.g., sprouting inhibitor in pota-

toes); and as building blocks for the synthesis of many

highly value compounds.

The biotransformation of terpenes is of interest

because it allows the production of enentiomerically

pure flavors and fragrances under mild reaction condi-

tions. Products produced by biotransformation process-

es may be considered as bnaturalQ. Industrial use of

monoterpenes as substitutes of ozone-depleting chlor-

ofluorocarbons is also flourishing (

Terpenes may be used as substitutes for chlorinated

solvents in applications such as cleaning of electronic

components and cables, degreasing of metal and clean-

ing of aircraft parts (

). This review

discusses recent developments in biotransformation

catalysts, reaction media, reactor types and biokinetic

resolution of terpenes.

2. Biocatalysts

Studies describing the biotransformation of terpenes

using enzymes, cell extracts and whole cells of bacteria,

cyanobacteria, yeasts, microalgae, fungi and plants

have been published. Both soluble and immobilized

enzymes have been used in biotransformations of ter-

penes. Isolation and purification of the relevant

enzymes can be expensive and difficult. Whole cell

biocatalysts may be cheaper and simpler to obtain

than isolated enzymes, but can add contaminants to

the reaction mixture. In whole cells, membranes and

walls protect the enzymes from shear forces and other

factors while cofactors can be regenerated within the

cell under certain conditions. Cascade of reactions, such

as those needed for steroid production, can be carried

out by a single whole cell biocatalyst. Nevertheless,

control and reproducibility of the bioconversions with

whole cells are more difficult to accomplish than in

enzymatic processes and side reactions may occur.

Cells can be used as freely suspended or immobilized.

The cells used as biocatalysts may be in various phys-

iological states: viable and growing; viable, but non

growing; and non viable. In the latter case, in situ

regeneration of cofactors will not occur. A good com-

parison of the various forms of biocatalyst was pre-

sented by

Straathof and Adlercreutz (2000)

.

Werf et al. (1997)

discussed opportunities in microbial

biotransformation of monoterpenes and the difficulties

associated with the conduct of these biotransformations

on industrial scale.

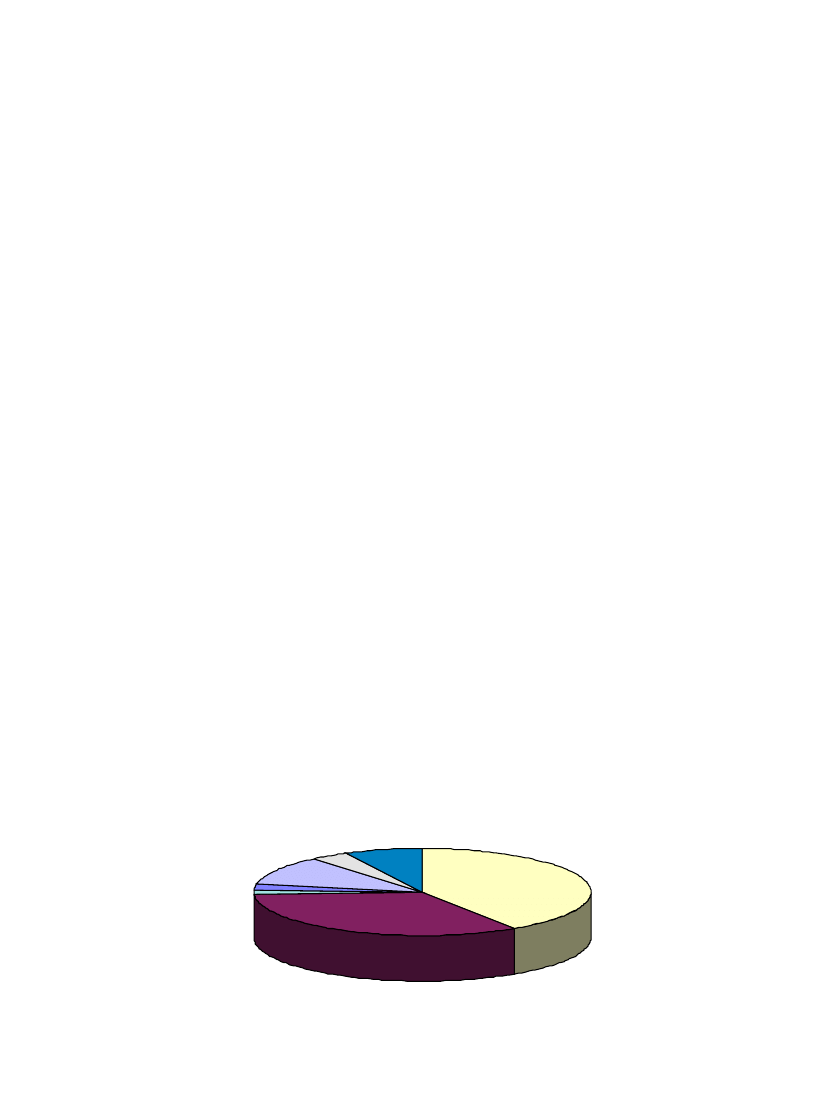

In nearly two-thirds of the manuscripts published on

production and/or biotransformation of terpenes in the

last decade, the biocatalysts used were either bacteria or

fungi (

). Only 7% of the studies used isolated

enzymes. Simple furan compounds from molecules

containing an a-isopropylidene ketone unit were enzy-

matically synthesized by

(2002)

. The role of cytochrome P450 in this transfor-

mation was described. Synthesis of terpenes esters

using a Candida rugosa lipase encapsulated in a dioctyl

sulfosuccinate-reversed-micellar solution showed a rel-

atively high activity for the transesterification reaction

of geraniol with tributyrin (

), but this

was not regarded as a feasible commercial process for

producing terpene esters.

The first sesquiterpene cyclase obtained and purified

from a whole plant/pathogen system catalyzed the con-

version of (E,E)-farnesyl diphosphate to (+)-y-cadinene

(

showed that,

Bacteria

41%

Fungi

33%

Plants

11%

Microalgae

4%

Enzymes

7%

Yeasts

2%

Cyanobacteria

2%

Fig. 1. Percentage of papers published on various biocatalyst types in the last ten years.

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

135

although ( )-(4S)-limonene synthase and ( )-(4S)-lim-

onene/( )-(1S,5S)-a-pinene synthase from grand fir

(Abies grandis) has around 91% amino acid sequence

homology, they produced significantly different mix-

tures of monoterpenes olefins starting from the same

substrate. The results indicated that fewer than 10% of

the amino acid residues of the two enzymes determined

the reaction velocity and the product distribution

achieved.

Among enzymes, epoxide hydrolases are probably

one of the most versatile biocatalysts. These enzymes

belong to the a/h-hydrolase-fold family. They are able

to carry out the asymmetric hydrolysis of racemic

epoxides, producing the corresponding vicinal diols

and the biokinetically resolved non-hydrolyzed epox-

ides. The processes they catalyze can be enantiocon-

vergent, with the production of a single enantiomeric

diol from a racemic oxirane. Use of microbial epoxide

hydrolases for preparative biotransformations has been

reviewed by

.

Werf et al. (1998)

characterized a novel hydrolase

(i.e., limonene-1,2-epoxide hydrolase) from Rhodococ-

cus erythropolis DCL14 that did not belong to the a/h-

hydrolase superfamily, but to a separate class of epox-

ide hydrolases. This enzyme catalyzed the hydrolysis of

limonene-1,2-epoxide to limonene-1,2-diol and its ac-

tivity in cell extracts was 795 nmol/min mg protein

when the cells were grown in (+)-limonene (

Werf et al., 1998

). An organic:aqueous phase reaction

system that used whole cells of R. erythropolis strain

DCL14 was reported by

. A

production level of 72.4 g diol/g protein was obtained

in a magnetically stirred fed-batch reactor. This corre-

sponded to yields of 98.5% and 94.1% of trans-limo-

nene-1,2-epoxide and limonene-1,2-diol, respectively

(

). In situ separation of the

product was achieved in an external loop by recircula-

tion of the aqueous phase through a column filled with

an adsorbent. Production could be further improved by

using mechanical stirring. In this case, 197.2 g of diol

per g of protein were produced and the trans-epoxide

and diol yields were 98.2% and 67.9%, respectively.

The reactor operated for 22 days.

R. erythropolis strain DCL14 is known to have

several carveol dehydrogenase activities that allow the

cells to carry out the cofactor dependent stereoselective

oxidation of carveol (

). The

catalytic efficiency is much higher for the (6S)-stereo-

isomers of carveol than for the (6R)-stereoisomers.

der Werf et al. (1999)

achieved a specific activity of 115

nmol/min mg

prot

for the DCPIP-dependent enzyme in

cell extracts of R. erythropolis DCL14 grown on lim-

onene. In 1 : 5 dodecane:aqueous phase systems that

used whole cells of R. erythropolis DCL14, a maximum

production rate of 124.1 nmol/min mg

prot

was attained

de Carvalho and da Fonseca, 2002a

). In a mechanical-

ly stirred reactor, a maximum production rate of 188

nmol/min mg

prot

was maintained for nearly 23 h (

Carvalho and da Fonseca, 2002b

). Several additions of

substrate were possible during reactor operation, result-

ing in a productivity of 0.12 mg/hd mL. When the cells

were allowed to adapt/grow in the presence of both

carveol and carvone in dodecane, they were able to

overcome carvone toxicity. In a column reactor, after

an adaptation period of 268 h, the freely suspended

cells produced carvone at 0.19 mg/hd mL, yielding

0.96 g

carvone

/g

carveol

).

The cell population was able to endure a final concen-

tration of 1.03 M of carvone. Whole cells thus allowed

in situ cofactor regeneration under conditions in which

cell viability remained high. In the air-driven column

reactor, maximum production rates could be main-

tained by whole cells for remarkably longer periods

than those that would be possible with cell extracts.

The problems encountered during lipase-or esterase-

catalyzed esterification and transesterification (e.g., in-

hibitory effects of acyl donors, alcohols and esters;

inactivation of enzymes by added organic solvents)

were overcome by

by coupling

acetyl coenzyme A formation and microbial esterifica-

tion. Pichia quercuum IFO 0949 and Pichia heedii IFO

10019 showed a strong double coupling activity of

acetyl-CoA formation and microbial esterification

with alcohol acetyltransferase in an interface bioreactor

and a triple coupling activity of acetyl-CoA formation,

microbial reduction of citronellal to citronellol and

microbial esterification of the latter with acetyl-CoA.

Fungal cells have also been used in biotransforma-

tion of terpenes and terpenoids (

). Aspergillus

niger was used in hydroxylation reactions with terpenes

(

) and

showed the resemblance between bioconversion of ter-

penoid pharmaceuticals by A. niger and mammalian

systems. A. niger was further used by

Reese (2002)

to bioconvert terpenes from Stemodia

maritima. Fungal spores of Penicillium digitatum

were able to biotransform geraniol, nerol, citrol (mix-

ture of the alcohols nerol and geraniol) and citral (mix-

ture of the aldehydes neral and geranial) to 6-methyl-5-

hepten-2-one (

Demyttenaere and De Kimpe, 2001

).

Aleu and Collado (2001)

reviewed biotransformations

carried out by Botrytis sp. Some of these transforma-

tions of terpenoids to volatile substances in grapes are

important in producing a distinctive aroma in wine.

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

136

Prior to the development of high-pressure homoge-

nization and other methods of large scale cell disruption

(

Hetherington et al., 1971; Chisti and Moo-Young,

), only extracellular enzymes or those extractable

by chemical cell lysis were available to industry. Note-

worthy growth of biotransformation as an alternative to

chemical synthesis was made possible by the ability to

produce large quantities of intracellular enzymes by cell

disruption and development of immobilization techni-

ques that allowed the recovery and reuse of enzymes

(

). Furthermore, enzyme immobilization

allowed modification of enzyme properties and en-

hancement of stability of enzymes. Similarly, immobi-

lization of cells provided a method of regulating

metabolism and hence product formation (

1994

). Freely suspended cells tend to readily metabo-

lize exogenous terpenes (

). Acceptable product

yields are generally only attained if the desired product

can be extracted to a non-polar organic phase or

adsorbed on a resin (

Do¨rnenburg and Knorr, 1995

).

3. Reaction media

Biotransformations have been traditionally carried

out in aqueous systems. This is because aqueous

media are generally compatible with enzymes and

growing whole cells. Unfortunately, terpenes are poorly

soluble in water. Water solubilities at 25 8C of some of

the common terpenes are the following (in mmol/L):

(R)-(+)-limonene, 0.15; ( )-a-pinene, 0.037; ( )-a-pi-

nene oxide, 2.55; ( )-carveol, 19; and (+)-carvone, 8.8

(

). Use of an organic phase in the

aqueous reaction system improves enzymatic and mi-

crobial biotransformations of terpenes compared with

the use of pure aqueous media.

By allowing continuous removal of the product

from the aqueous phase, the presence of a water im-

miscible organic phase decreases product inhibition of

the biocatalyst. Furthermore, removal of product shifts

the thermodynamic equilibrium of kinetically unfavor-

able reactions so that more product can be produced

(

). In addition, the re-

covery of both product and biocatalyst becomes easier

compared to when only the aqueous phase is used.

Enzyme catalysis in non-aqueous media have been

reviewed recently (

Halling, 2000; Klibanov, 2001;

Lee and Dordick, 2002

). Similarly, whole cell biocata-

lysis in organic media has been reviewed (

1998

). While multiphasic production systems have

advantages, organic-solvents can inactivate enzymes

and cause loss of cell viability by interfering with the

cell membrane.

In a biotransformation system, the organic phase

may be the only liquid phase present with minute

quantities of water dissolved within it (

al., 1998; de Carvalho et al., 2004; Angelova et al., in

press

), or a distinct aqueous phase and an organic-

phase may coexist (

van Keulen et al., 1998; de Car-

valho et al., 2000b; Tecela˜o et al., 2001; de Carvalho

and da Fonseca, 2002a

). In the latter case, the organic

phase may be the substrate itself or an organic solvent

that acts as a reservoir for the substrate/product. Most

terpenes have antimicrobial properties and dilution with

the organic solvent likely helps in reducing their tox-

icity towards the microorganisms being used for the

biotransformation. The overall log P of the organic

phase also appears to have an impact on the biotrans-

formation capability and viability of the microbial cells

used in the biotransformation (

Fonseca, 2002a

).

In studies comparing responses of the bacteria R.

erythropolis, Xanthobacter Py2, Arthrobacter simplex

and Mycobacterium sp. to toxic solvents and substrates,

the major factor that influenced the behavior of the cells

in organic-aqueous multiphase systems was found to be

the toxicity of the solvent (

2004a,b

). More than 33% of the variability of the data

could be explained by solvent toxicity; the remaining

variability was ascribed to factors related with substrate

concentration, cells’ ability to adapt and the composi-

tion of the cell membrane. The latter may be signifi-

cantly influenced by the carbon source used for

growing the cells. Growth history of cells influences

their ability to carry out biotransformations in the rest-

ing state. In one study (

), all

alkanes, long-chain alkanols and terpenes tested as

carbon sources caused a dose-dependent increase in

the degree of saturation of the fatty acids of the cell

membrane. Growing the cells with short-chain alcohols

caused a dose-dependent decrease in the degree of

saturation of the fatty acids of the membrane. The

resulting differences in membrane composition led to

cells with different membrane hydrophobicities and

therefore differences in the cells’ ability to uptake

hydrophobic/hydrophilic compounds.

Cell growth has traditionally been considered det-

rimental in biotransformations with bresting cellsQ if

the cells use the substrate, product or both as carbon

source. However, cell growth during the incubation

phase and/or during the biotransformation of carveol

into carvone in a n-dodecane:mineral medium system

resulted in the emergence of better adapted cells and

consequent high production of carvone (

et al., in press

). The adapted cells retained viability in

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

137

the presence of 1.03 M carvone. In contrast, cells that

were not adapted died at a carvone concentration of

50 mM.

Other non conventional media that may be used in

biotransformation studies include ionic liquids and su-

percritical fluids. Ionic liquids are low melting point

salts. They are non-aqueous polar solvents and can

dissolve many compounds. Several enzymes have

been successfully used in ionic liquids (for a review

see e.g.,

). These liquid should prove

useful in production/transformation of terpenes.

Pfruen-

der et al. (2004)

showed that ionic liquids can act as a

substrate reservoir and sink in a biotransformation per-

formed with viable whole cells.

(S)-( )-terpene esters were stereoselectively synthe-

sized by Candida cylindracea lipase in supercritical

carbon dioxide in the near-critical region (

1997

). The supercritical carbon dioxide triggered the

activation of the enzyme by causing movement of the

surface groups and creating active sites. However, most

studies with supercritical media have focused on their

use in extraction of terpenes from essential oils and not

their use as reaction media.

4. Reactor type

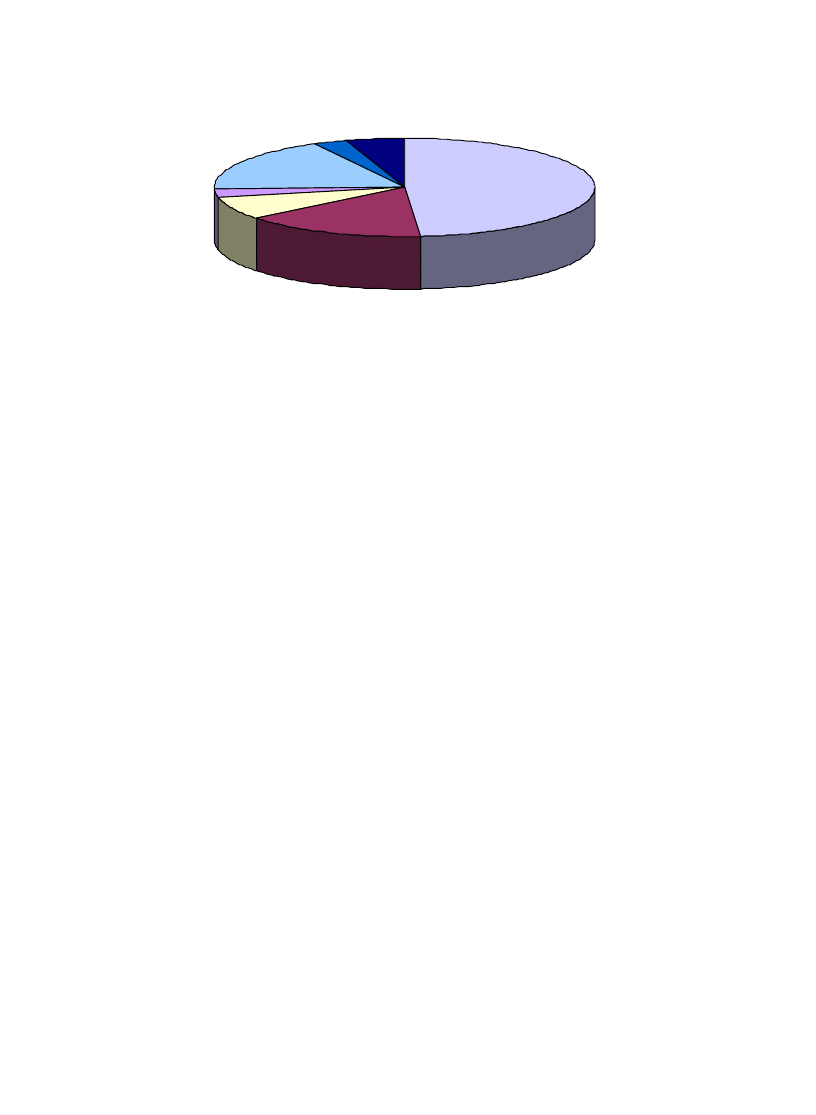

Approximately 48% of the papers describing bio-

transformation of terpenes concern reactions carried out

in shake flasks (

). Shake flasks are simple and

efficient for screening microorganisms, substrates and

reaction conditions rapidly and inexpensively. Cultures

of bacteria (e.g.,

Carter et al., 2003; Carballeira et al.,

2004

), fungi (e.g.,

Demyttenaere and De Kimpe, 2001;

Chen and Reese, 2002

), plant cells (e.g.,

Henriksson et al., 2004

) and microalgae (e.g.,

et al., 2002; Hook et al., 2003

) have been investigated

for terpene biotransformations in shake flasks.

Vials, reaction wells and other microscale devices

have been used to obtain reliable biotransformation data

at extremely low costs. For example,

carried out sesquiterpene cyclase activity assays using

ca. 1 Ag of total protein and 5 AL of substrate stock

solution in a total reaction volume of 245 AL. The

bioconversion pathway for limonene in Xanthobacter

sp. C20 was established by

reaction mixtures having a total volume of 1.5 mL in 15

mL vials fitted with Teflon Mininert valves to prevent

Table 1

Examples of terpene biotransformations using whole cells

Publication

Microorganism

Result

Aspergillus niger

3h-Hydroxy derivatives of confertifolin

Gongronella butleri, Schizosaccharomyces

octosporus and Diplogelasinospora grovesii

Stereoselective reduction of ketones

Escherichia coli

( )-Carvone, ( )-limonene

Rhodococcus erythropolis

Trans-limonene-1,2-epoxide and limonene-1,2-diol

de Carvalho and da Fonseca, 2002a,b

Rhodococcus erythropolis

( )-Carvone from ( )-carveol

de Carvalho and da Fonseca, 2003

Rhodococcus opacus

Trans-carveol and carvone from limonene

Aspergillus niger

Several metabolites from stemodin, stemodinone and

stemarin

Botryococcus braunii

Novel terpene epoxides

Rhodococcus erythropolis

Trans-carveol from limonene

13 Airborne fungi

Volatile organic compounds

Pseudomonas rhodesiae

Isonovalal from a-pinene oxide

Mucor plumbeus

Several products from ribenone

Fulzele et al., 1995

Artemisia annua

Several terpenoids

Alcaligenes defragans

Isoterpinolene from isolimonene

Microalgae

Aliphatic and aromatic ketones

Penicillium caseifulvum

Limonene, h-caryophyllene and other terpenoids

Lindmark-Henriksson et al., 2004

Picea abies cell cultures

Trans-pinocarveol and other minor products from

h

-pinene

Glomerella cingulata

Transformation of (+)-cis-nerolidol and nerylacetone

Pichia quercuum and P. heedii

Citronellol

Onken and Berger, 1999

Pleurotus sapidus

Carveol and carvone from limonene

Bovista sp.

Bovistol and new sesquiterpenes

Xanthobacter sp. C20

Limonene-8,9-epoxide from limonene

Pseudomonas putida

a-Pinene oxide from a-pinene

Verstegen-Haaksma et al., 1995

Several bacterial and fungal strains

Biologically active compounds from (S)-(+)-carvone

Pseudomonas sp. PIN

Conversion of a-and h-pinene and related compounds

Peganum harmala

Several terpenes and non-terpenes

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

138

evaporation of limonene.

studied the metabolism of terpenes by denitrifying

Alcaligenes defragrans strains in systems with 30 AL

monoterpene, 150 AL nitrate and 15 mL of aqueous

medium.

used 15 mL test tubes to

study terpene ester production in a solvent phase con-

taining a reverse micelle-encapsulated lipase.

Petri dishes with agar media are good reactors for

terpene producing/transforming fungi (

1997; Larsen, 1998; Fischer et al., 1999

). Although such

solid-state fermentations are not easily scaled up, they

are used in several commercial large volume processes

(

). Solid-state fermentation has certain im-

portant advantages compared to submerged culture

(

The application of terpene biotransformations in

bioreactors at the liter-scale suggests that these process-

es are technically feasible at larger scales.

Metzger (1997)

used an airlift reactor to produce ter-

pene epoxides with two strains of the green microalga

Botryococcus braunii. Further work on the occurrence

and biotransformation of various terpenes in B. braunii

was reviewed by

. For biotrans-

formations involving fungi, processing conditions ap-

parently need to be selected to avoid swelling of cell

membrane that is in contact with the solvent and ter-

penes (

We have tested magnetically and mechanically

stirred tank reactors for the transformation of terpenes

with freely suspended whole cells (

2000b; de Carvalho and da Fonseca, 2002b

); mem-

brane reactors (

de Carvalho and da Fonseca, 2002b

);

and air-driven column reactors (

Fonseca, 2002b; de Carvalho et al., in press

). The

stirred reactors with suspended cells were particularly

efficient for the diastereomeric resolved conversion of

limonene-1,2-epoxide in limonene-1,2-diol, because

the epoxide partitioned preferentially to the organic

phase while the diol remained in the aqueous phase. In

situ removal of the product could be achieved by

recirculating the aqueous phase through a column

filled with an adsorbent. The membrane reactor was

able to maintain the aqueous and organic phases sep-

arate, thus improving downstream processing, but the

production rate became mass transfer controlled due to

biofilm adhesion to the membrane. The air-driven

column reactor performed best in terms of productiv-

ity. Cell viability and activity could be maintained for

several weeks after the cells were adapted to the

substrate, product and solvent. Also, the relatively

gentle mixing in the air-driven reactor contributed to

its long term stability.

5. Bio-kinetic resolutions

Compared to conventional chemical catalysts, bio-

catalyts function under mild conditions to perform reac-

tions that are regio-, stereo- and enantiospecific. Chiral

building blocks, pharmaceutical and agrochemical com-

pounds and food additives are commercially considered

as pure enantiomers only when one enantiomer is pres-

ent in excess of ca. 98%. Although the majority of flavor

and pharmaceutical compounds are racemic, usually

only one of the enantiomers has the desired activity.

The other enantiomer may be inactive or it may have an

unwanted activity. The US Food and Drug Administra-

tion has declared that if a drug is chiral, the biological

effects of both enantiomers must be studied because the

non-therapeutic enantiomer may have unwanted side

effects (

). As with pharmaceu-

tical products, chirality is important in fragrances and

flavors because perception of odor and flavor depends

on the absolute conformation of the isomers. Different

isomers of the same compound can have quite different

Shake flasks

48%

Membrane reactor

3%

Agar plates

8%

Small scale

15%

Column reactor

5%

Stirred tank reactor

18%

Airlift reactor

3%

Fig. 2. Percentage of papers published on various reactor types in the last ten years.

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

139

odors (

). This subject has been reviewed in depth

and

.

Compared to biotransformations with isolated en-

zymes, microorganisms generally produce compounds

with lower enantioselectivity because a microbial cell

may have multiple enzymes that are capable of trans-

forming a substrate (

). Enantioselectiv-

ity of microorganisms can be altered by adding organic

solvents and inhibitors of undesired enzyme activities.

An optically active epoxide was prepared using

whole cells of Bacillus megaterium (

2005

). Resolution of racemic glycidyl phenyl ether

was carried out in an iso-octane:aqueous phase system

in a mechanically stirred reactor to obtain a 44.5% yield

of the (S)-isomer with a 100% enantiomeric purity. R.

erythropolis DCL14 cells were able to diastereomeri-

cally resolve a mixture of (+)-limonene-1,2-epoxide

because only the cis-limonene-1,2-epoxide was con-

verted to limonene-1,2-diol and the trans-epoxide

remained unchanged (

2002

). Reactions were carried out in two-phase sys-

tems. When the degree of conversion of limonene-1,2-

epoxide reached 43%, the diastereomeric excess of the

trans-limonene-1,2-epoxide was greater than 99%. The

same cells also stereoselectively carried out the oxida-

tion of ( )-trans-carveol to ( )-carvone (

and da Fonseca, 2002a; de Carvalho et al., 2002

). The

unreacted ( )-cis-isomer was recovered at the end of

the reaction. A diastereomeric excess higher than 98%

was attained when the conversion of ( )-carveol was

59% in n-dodecane:aqueous phase systems. As in these

examples, some substrate mixtures are non-racemic,

i.e., they initially contain unequal amounts of the two

enantiomers. A model relating the initial enantiomeric

ratio to the extent of substrate conversion and enantio-

meric excess was reported by

6. Concluding remarks

The low water solubility, high volatility and cyto-

toxicity of both terpenes and terpenoids make their

production at industrial scale a difficult task. Although

processes have been published for producing a single

target compound, microbial metabolism usually results

in the production of multiple products which compli-

cates downstream processing. In recent years, the yields

obtained in biotransformations and improved technolo-

gy of production suggest that economically viable pro-

duction of many terpene compounds will become

possible in the future.

Acknowledgements

This work was supported by a post-doctoral grant

(SFRH/BPD/14426/2003) awarded to Carla da C. C. R.

de Carvalho by Fundac¸a˜o para a Cieˆncia e a Tecnolo-

gia, Portugal.

References

Aleu J, Collado IG. Biotransformations by Botrytis species. J Mol

Catal, B Enzyme 2001;13:77 – 93.

Angelova B, Fernandes P, Cruz A, Pinheiro HM, Mutafov S, Cabral

JMS. Hydroxylation of androstenedione by resting Rhodococcus

sp. cells in organic media. Enzyme Microb Techno in press.

Aranda G, Moreno L, Corte´s M, Prange´ T, Maurs M, Azerard R. A

new example of 1a-hydroxylation of drimanic terpenes through

combined

microbial

and

chemical

processes.

Tetrahedron

2001;57:6051 – 6.

Banerjee A, Sharma R, Chisti Y, Banerjee UC. Botryococcus braunii:

a renewable source of hydrocarbons and other chemicals. Crit Rev

Biotechnol 2002;22:245279.

Brenna E, Fuganti C, Serra S. Enantioselective perception of chiral

odorants. Tetrahedron: Asymmetry 2003;14:1 – 42.

Brown LM, Springer J, Bower M. Chemical substitution for 1,1,1-

trichloroethane and methanol in an industrial cleaning operation.

J Hazard Mater 1992;29:179 – 88.

Carballeira JD, Valmaseda M, Alvarez E, Gago JVS. Gongronella

butleri, Schizosaccharomyces octosporus and Diplogelasinospora

grovesii: novel microorganisms useful for the stereoselective

reduction of ketones. Enzyme Microb Technol 2004;34:611 – 23.

Carter OA, Peters RJ, Croteau R. Monoterpene biosynthesis path-

way construction in Escherichia coli. Phytochemistry 2003;64:

425 – 33.

Chen ARM, Reese PB. Biotransformation of terpenes from Stemodia

maritima by Aspergillus niger ATCC 9142. Phytochemistry

2002;59:57 – 62.

Chisti Y. Solid substrate fermentations, enzyme production, food

enrichment. In: Flickinger MC, Drew SW, editors. Encyclopedia

of bioprocess technology: fermentation, biocatalysis, and biose-

paration, vol. 5. New York7 Wiley; 1999. p. 2446 – 62.

Chisti Y, Moo-Young M. Disruption of microbial cells for intracellular

products. Enzyme Microb Technol 1986;8:194 – 204.

Clark DS. Can immobilisation be exploited to modify enzyme

activity? Trends Biotechnol 1994;12:439 – 43.

Davis EM, Tsuji J, Davis GD, Pierce ML, Essenberg M. Purification

of (+)-y-cadinene synthase, a sesquiterpene cyclase from bacteria-

inoculated cotton foliar tissue. Phytochemistry 1996;41:1047 – 55.

de Carvalho CCCR, da Fonseca MMR. Maintenance of cell

viability in the biotransformation of ( )-carveol with whole

Table 2

Odor properties of enantiomers of some terpene compounds

Monoterpene

Enantiomer

Fragrance

Carvone

(R)-( )

Spearmint

(S)-(+)

Caraway

Limonene

(R)-(+)

Orange

(S)-( )

Turpentine

a-Pinene

(1R,5R)-(+)

Slightly minty

(1S,5S)-( )

Pine tree

Menthol

(1R,3R,4S)-( )

Minty

(1S,3S,4R)-(+)

Phenolic

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

140

cells of Rhodococcus erythropolis. J Mol Catal, B Enzyme

2002a;19–20C:389 – 98.

de Carvalho CCCR, da Fonseca MMR. Influence of reactor config-

uration on the production of carvone from carveol by whole cells

of Rhodococcus erythropolis DCL14. J Mol Catal, B Enzyme

2002b;19–20C:377 – 87.

de Carvalho CCCR, da Fonseca MMR. Towards the bio-production

of trans-carveol and carvone from limonene: induction after

cell growth on limonene and toluene. Tetrahedron: Asymmetry

2003;14:3925 – 31.

de Carvalho CCCR, da Fonseca MMR. Principal component analysis

applied to bacterial cell behaviour in the presence of organic

solvents. Biocatal Biotransform 2004a;22:203 – 14.

de Carvalho CCCR, da Fonseca MMR. Solvent toxicity in organic-

aqueous systems analysed by multivariate analysis. Bioprocess

Biosyst Eng 2004b;26:361 – 75.

de Carvalho CCCR, van Keulen F, da Fonseca MMR. Biotransfor-

mation of limonene-1,2-epoxide to limonene-1,2-diol by Rhodo-

coccus erythropolis cells An Introductory approach to selective

hydrolysis and product separation. Food Technol Biotechnol J

2000a;38:181 – 5.

de Carvalho CCCR, van Keulen F, da Fonseca MMR. Production and

recovery of limonene-1,2-diol and simultaneous resolution of a

diastereomeric mixture of limonene-1,2-epoxide with whole cells

of Rhodococcus erythropolis DCL14. Biocatal Biotransform

2000b;18:223 – 35.

de Carvalho CCCR, van Keulen F, da Fonseca MMR. Modelling the

biokinetic resolution of diastereomers present in unequal initial

amounts. Tetrahedron: Asymmetry 2002;13:1637 – 43.

de Carvalho CCCR, Cruz A, Angelova B, Fernandes P, Pons MN,

Pinheiro HM, et al. Behaviour of Mycobacterium sp NRRL B-

3805 whole cells in aqueous, organic-aqueous and organic media

studied by fluorescence microscopy. Appl Microbiol Biotechnol

2004;64:695 – 701.

de Carvalho CCCR, Parren˜o-Marchante B, Neumann G, da Fonseca

MMR, Heipieper HJ. Adaptation of Rhodococcus erythropolis

DCL14 to growth on n-alkanes, alcohols and terpenes. Appl

Microbiol Biotechnol 2005;67:383 – 8.

de Carvalho CCCR, Poretti A, da Fonseca MMR. Cell adaptation to

substrate, solvent and product: a successful strategy to overcome

product inhibition in a bioconversion system. Appl Microbiol

Biotechnol. In press.

Delahais V, Metzger P. Four polymethylsqualene epoxides and one

acyclic tetraterpene epoxide from Botryococcus braunii. Phyto-

chemistry 1997;44:671 – 8.

Demyttenaere J, De Kimpe N. Biotransformation of terpenes by fungi

Study of the pathways involved. J Mol Catal, B Enzyme

2001;11:265 – 70.

de Oliveira BH, dos Santos MC, Leal PC. Biotransformation of the

diterpenoid isosteviol by Aspergillus niger, Penicillium chryso-

genum and Rhizopus arrhizus. Phytochemistry 1999;51:737 – 41.

Do¨rnenburg H, Knorr D. Strategies secondary for the improvement of

metabolite production in plant cell cultures. Enzyme Microb

Technol 1995;17:674 – 84.

Duetz WA, Fjallman AHM, Ren SY, Jourdat C, Witholt B. Biotrans-

formation of D-limonene to (+)-trans-carveol by toluene-grown

Rhodococcus opacus PWD4 cells. Appl Environ Microbiol

2001;67:2829 – 32.

Fernandes P, Cabral JMS, Pinheiro HM. Influence of some opera-

tional parameters on the bioconversion of sitosterol with immo-

bilized whole cells in organic medium. J Mol Catal, B Enzyme

1998;5:307 – 10.

Fichan I, Larroche C, Gros JB. Water solubility, vapor pressure, and

activity coefficients of terpenes and terpenoids. J Chem Eng Data

1999;44:56 – 62.

Fischer G, Schwalbe R, Mo¨ller M, Ostrowski R, Dott W. Species-

specific production of microbial volatile organic compounds

(MVOC) by airborne fungi from a compost facility. Chemosphere

1999;39:795 – 810.

Fontanille P, Le Fle`che A, Larroche C. Pseudomonas rhodesiae PF1:

a new and efficient biocatalyst for production of isonovalal from

a-pinene oxide. Biocatal Biotransform 2002;20:413 – 21.

Fraga BM, Herna´ndez MG, Gonza´lez P, Lo´pez M, Sua´rez S. Bio-

transformation of the diterpene ribenone by Mucor plumbeus.

Tetrahedron 2001;57:761 – 70.

Fritter G, Bajgrowicz JA, Kraft P. Fragrance chemistry. Tetrahedron

1998;54:7633 – 703.

Fulzele DP, Heble MR, Rao PS. Production of terpenoid from Arte-

misia annua L. plantlet cultures in bioreactor. J Biotechnol

1995;40:139 – 43.

Gaikwad NW, Madyastha KM. Biosynthesis of b-substituted furan

skeleton in the lower furanoterpenoids: a model study. Biochem

Biophys Res Commun 2002;290:589 – 94.

Gong PF, Xu JH. Bio-resolution of a chiral epoxide using whole cells

of Bacillus megaterium ECU1001 in a biphasic system. Enzyme

Microb Technol 2005;36:252 – 7.

Halling PJ. Thermodynamic predictions for biocatalysis in nonconven-

tional media: theory, tests and recommendations for experimental

design and analysis. Enzyme Microb Technol 1994;16:178 – 206.

Halling PJ. Biocatalysis in low-water media: understanding effects of

reaction conditions. Curr Opin Chem Biol 2000;4:74 – 80.

Hashimoto T, Noma Y, Asakawa Y. Biotransformation of terpenoids

from the crude drugs and animal origin by microorganisms.

Heterocycles 2001;54:529 – 59.

Hetherington PJ, Follows M, Dunnill P, Lilly MD. Release of protein

from baker’s yeast (Saccharomyces cerevisiae) by disruption in an

industrial homogeniser. Trans Inst Chem Eng 1971;49:142 – 8.

Heyen U, Harder J. Cometabolic isoterpinolene formation from iso-

limonene by denitrifying Alcaligenes defragrans. FEMS Micro-

biol Lett 1998;169:67 – 71.

Ho¨lker U, Ho¨fer M, Lenz J. Biotechnological advantages of labora-

tory-scale solid-state fermentation with fungi. Appl Microbiol

Biotechnol 2004;64:175 – 86.

Hook IL, Ryan S, Sheridan H. Biotransformation of aliphatic and

aromatic ketones, including several monoterpenoid ketones and

their derivatives by five species of marine microalgae. Phyto-

chemistry 2003;63:31 – 6.

Ikushima Y. Supercritical fluids: an interesting medium for chemical

and biochemical processes. Adv Colloid Interface Sci 1997;

71 72:259 – 80.

Jirage KB, Martin CR. New developments in membrane-based

separations. Trends Biotechnol 1999;17:197 – 200.

Katoh S, Hyatt D, Croteau R. Altering product outcome in Abies

grandis ( )-limonene synthase and ( )-limonene/( )-a-pinene

synthase by domain swapping and directed mutagenesis. Arch

Biochem Biophys 2004;425:65 – 76.

Kirchner EM. Environment, health concerns force shift in use of

organic solvents. Chem Eng News 1994;72:13 – 20.

Klibanov AM. Enzymes that work in organic solvents. Chemtech

1986;16:354 – 9.

Klibanov AM. Improving enzymes by using them in organic solvents.

Nature 2001;409:241 – 6.

Kragl U, Eckstein M, Kaftzik N. Enzyme catalysis in ionic liquids.

Curr Opin Biotechnol 2002;13:565 – 71.

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

141

Langenheim JH. Higher plant terpenoids: a phytocentric overview of

their ecological roles. J Chem Ecol 1994;20:1223 – 80.

Larsen TO. Volatile flavour production by Penicillium caseifulvum.

Int Dairy J 1998;8:883 – 7.

Lee MY, Dordick JS. Enzyme activation for nonaqueous media. Curr

Opin Biotechnol 2002;13:376 – 84.

Lee KKB, Poppenborg LH, Stuckey DC. Terpene ester production in

a solvent phase using a reverse micelle-encapsulated lipase. En-

zyme Microb Technol 1998;23:253 – 60.

Leo´n R, Fernandes P, Pinheiro HM, Cabral JMS. Whole-cell bio-

catalysis in organic media. Enzyme Microb Technol 1998;23:

483 – 500.

Lilly MD. Advances in biotransformation processes. Chem Eng Sci

1994;49:151 – 9.

Lindmark-Henriksson M, Isaksson D, Vanek T, Valterova´ I, Ho¨gberg

HE, Sjo¨din K. Transformation of terpenes using a Picea abies

suspension culture. J Biotechnol 2004;107:173 – 84.

Miyazawa M, Nankai H, Kameoka H. Biotransformations of acyclic

terpenoids, (+)-cis-nerolidol and nerylacetone, by plant pathogenic

fungus, Glomerella cingulata. Phytochemistry 1995;40:1133 – 7.

Nakamura K. Highly stereoselective reduction of ketones by Geotri-

chum candidum. J Mol Catal, B Enzyme 1998;5:129 – 32.

Oda S, Ohta H. Double coupling of acetyl coenzyme A production

and microbial esterification with alcohol acetyltransferase in an

interface bioreactor. J Ferment Bioeng 1997;83:423 – 8.

Onken J, Berger RG. Effects of R-(+)-limonene on submerged cul-

tures of the terpene transforming basidiomycete Pleurotus sapi-

dus. J Biotechnol 1999;69:163 – 8.

Pfruender H, Amidjojo M, Kragl U, Weuster-Botz D. Efficient whole-

cell biotransformation in a biphasic ionic liquid/water system.

Angew Chem Int Ed 2004;43:4529 – 31.

Rasser F, Ankea T, Sternerb O. Terpenoids from Bovista sp 96042.

Tetrahedron 2002;58:7785 – 9.

Scha¨fer S, Schrader J, Sell D. Oxygen uptake rate measurements to

monitor the activity of terpene transforming fungi. Process Bio-

chem 2004;39:2221 – 8.

Steinreiber A, Faber K. Microbial epoxide hydrolases for preparative

biotransformations. Curr Opin Biotechnol 2001;12:552 – 8.

Straathof AJJ, Adlercreutz P. Applied biocatalysis. Reading7 Harwood

Academic Publishers; 2000.

Tecela˜o CSR, van Keulen F, da Fonseca MMR. Development of a

reaction system for the selective conversion of ( )-trans-carveol

to ( )-carvone with whole cells of Rhodococcus erythropolis

DCL14. J Mol Catal, B Enzyme 2001;11:719 – 24.

van der Werf MJ, de Bont JAM, Leak DJ. Opportunities in microbial

biotransformation of monoterpenes. Adv Biochem Eng Biotech-

nol 1997;55:147 – 77.

van der Werf MJ, Overkamp KM, de Bont JAM. Limonene-1,2-

epoxide hydrolase from Rhodococcus erythropolis DCL14

belongs to a novel class of epoxide hydrolases. J Bacteriol

1998;180:5052 – 7.

van der Werf MJ, van der Ven C, Barbirato F, Eppink MHM, de Bont

JAM, van Berkel JH. J Biol Chem 1999;274:26296 – 304.

van der Werf MJ, Keijzer PM, van der Schaft PH. Xanthobacter

sp. C20 contains a novel bioconversion pathway for limonene.

J Biotechnol 2000;84:33 – 143.

van Keulen F, Correia CN, da Fonseca MMR. Solvent selection for

the biotransformation of terpenes by Pseudomonas putida. J Mol

Catal, B Enzyme 1998;5:295 – 9.

Verstegen-Haaksma AA, Swarts HJ, Jansen BJM, de Groot A, Bot-

tema-MacGillavry N, Witholt B. Application of S-(+)-carvone in

the synthesis of biologically active natural products using chem-

ical transformations and bioconversions. Ind Crops Prod 1995;

4:15 – 21.

Yoo SK, Day DF. Bacterial metabolism of a-and h-pinene and related

monoterpenes by Pseudomonas sp. strain PIN. Process Biochem

2002;37:739 – 45.

Zhu W, Asghari G, Lockwood GB. Factors affecting volatile terpene

and non-terpene biotransformation products in plant cell cultures.

Fitoterapia 2000;71:501 – 6.

C.C.C.R. de Carvalho, M.M.R. da Fonseca / Biotechnology Advances 24 (2006) 134–142

142

Document Outline

Wyszukiwarka

Podobne podstrony:

Biotransformation of Tryptamine in Fruiting Mycelia of Psilocybe cubensis Planta Med (1989) 55 (3) 2

Biotransformation of Tryptamine in Fruiting Mycelia of Psilocybe cubensis Planta Med (1989) 55 (3) 2

Biotransformation of menthol and geraniol by hairy root cultures of Anethum graveolens

biotransformation of tryptamine derivatives in mycelial cultures of Psilocybe J Basic Microbiol 29 (

biotransformation of some monoterpenoid ketones by chlorella vulgaris

Factors affecting volatile terpene and non terpene biotransformation products in plant cell cultures

~$Production Of Speech Part 2

World of knowledge

The American Society for the Prevention of Cruelty

The law of the European Union

05 DFC 4 1 Sequence and Interation of Key QMS Processes Rev 3 1 03

terms of trade

Izoprenoidy, terpeny

Historia gry Heroes of Might and Magic

24 G23 H19 QUALITY ASSURANCE OF BLOOD COMPONENTS popr

7 Ceny międzynarodowe trems of trade Międzynarodowe rynki walutowe

więcej podobnych podstron