Nishotech Systems Pvt Ltd

W-199-E, MIDC Khairne,Thane Belapur Road,Navi mumbai - 400705,

: +91- 022 -

41515151, Fax: +91-022 - 41515150 Website: www.nishotech.com

Email:- Shraddha@nishotech.com

AN ISO 9001, 14001 & OHSAS 18001 CERTIFIED COMPANY

Cleaning In Place Technology

The sanitary aspects of producing food and beverage products are of extreme importance.

Plants must meet high hygienic standards to avoid product's degradation and

contamination during operation, and plant cleaning must be carried out quickly and

thoroughly. The cleaning requirements are best met with Cleaning-in-Place (CIP) systems.

CIP systems offer fast, efficient and reliable cleaning of all types of process plant. It's a

method which cleans complete items of plant equipment or pipelines circuits without

dismantling the equipment.

We are always striving to find the optimum balance between chemicals, mechanics,

temperature and time – with additional focus on environmental protection and downtimes.

Using a modern CIP system ensures the optimum quality assurance and increases product

quality.

Advantages of CIP

:

Technical Data and considerations

1. Reducing cleaning cycle times

2. Improved Cleaning

3. Uniformity in cleaning

4. Optimization of the use of detergent

and water

1. Flow velocity: Max up to up to 3 m/s

2. Flow rate: Normally up to 140 m³/h and 10 bar

3. Number of tanks: Depending on the required detergent an disinfectant

volumes - this number rarely exceeds 8 tanks per system

4. Volume of depending on the effective volume needed for cleaning the

pipes, tanks, etc...

5. Number of CIP circuits: depending on plant areas to be cleaned and

the availability of utility.

6. common cleaning media: caustic, acid, disinfectant, return water, fresh

water

7. Standard of cleaning required?

8. The available cleaning time?

9. The type of cleaning medium?

10.Whether recycled detergent can be used?

11.Common cleaning media: caustic, acid, disinfectant , return water,

fresh water.

Nishotech Systems Pvt Ltd

W-199-E, MIDC Khairne,Thane Belapur Road,Navi mumbai - 400705,

: +91- 022 -

41515151, Fax: +91-022 - 41515150 Website: www.nishotech.com

Email:- Shraddha@nishotech.com

AN ISO 9001, 14001 & OHSAS 18001 CERTIFIED COMPANY

CIP systems are divided in different operations :

1- Flushing in order to eliminate residues

2- Alkaline cleaning operation : alkaline detergents dissolve fat and proteins, and

cleaning where harder deposits have occurred

3- Intermediate water rinse

4- Acidic cleaning operation: for neutralising the caustic remaining on the surfaces

of the plant. The acidic detergents remove mineral deposits in the equipment

(especially warm areas like in the pasteurizer)

5- Final water rinse : Cold/hot water purges out the residual acid solution

CIP is a closed system where recirculating cleaning solution is applied (often with

nozzles) that cleans, rinses and sanitises equipment. The CIP system is usually

automatically controlled and the cleaning sequences are given the optimum timing

for efficient cleaning of all parts of the plants.

Nishotech Systems Pvt Ltd

W-199-E, MIDC Khairne,Thane Belapur Road,Navi mumbai - 400705,

: +91- 022 -

41515151, Fax: +91-022 - 41515150 Website: www.nishotech.com

Email:- Shraddha@nishotech.com

AN ISO 9001, 14001 & OHSAS 18001 CERTIFIED COMPANY

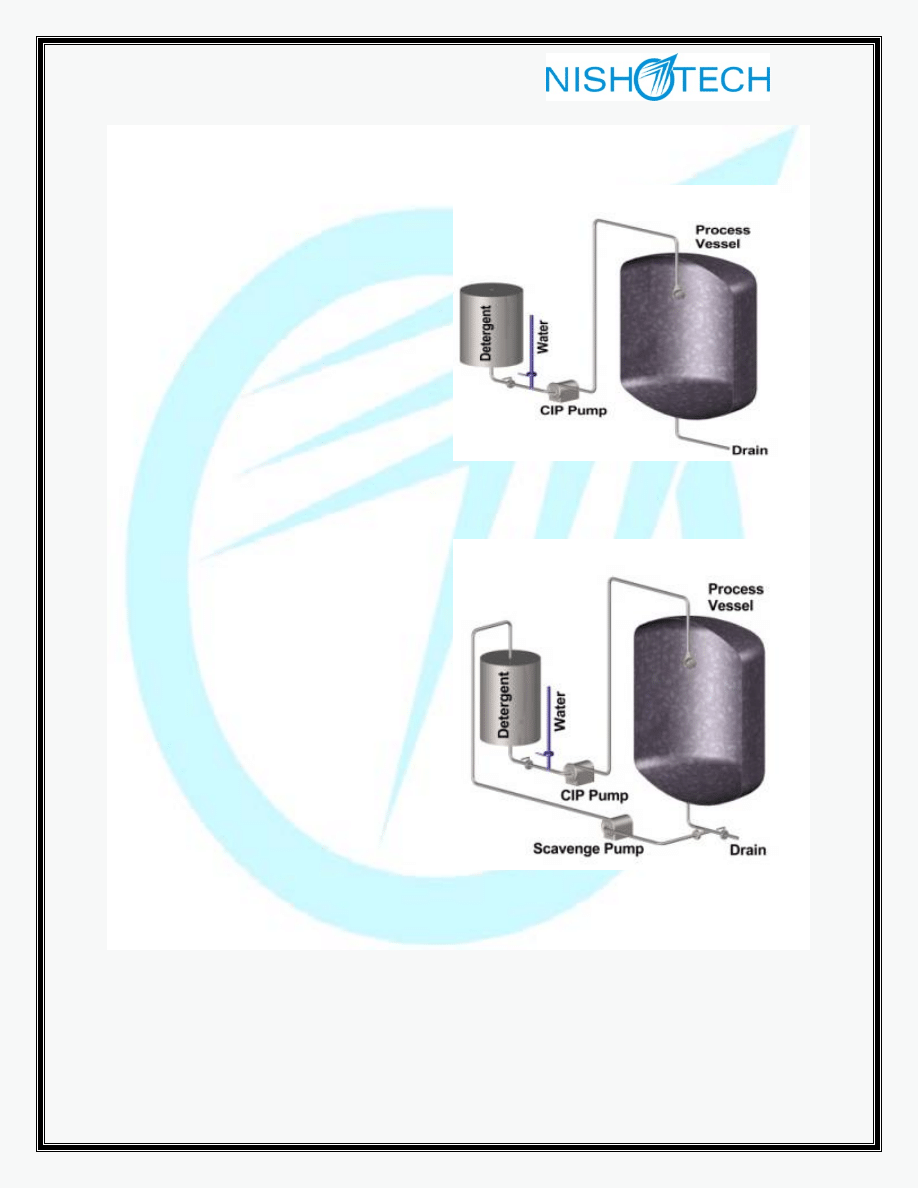

Different types of Cleaning-in-Place systems:

Single pass system :

New cleaning solution is introduced to the

plant to be cleaned and then disposed to

drain. In most cases, a single pass system

would start with a pre-rinse to remove as

much soil as possible. The detergent clean

and a final rinse would follow this.

Recirculation system :

The cleaning solution is made up in an

external tank and then introduced to the

plant to be cleaned. It is recirculated and

topped up as required until the cleaning

cycle is complete. When the detergent

clean is complete it is then normal to carry

out a final rinse.

Recirculation systems uses less water and

cleaning detergents but require greater

capital outlay and in some circumstances

may be unsuitable due to cross

contamination from one process to

another.

Nishotech Systems Pvt Ltd

W-199-E, MIDC Khairne,Thane Belapur Road,Navi mumbai - 400705,

: +91- 022 -

41515151, Fax: +91-022 - 41515150 Website: www.nishotech.com

Email:- Shraddha@nishotech.com

AN ISO 9001, 14001 & OHSAS 18001 CERTIFIED COMPANY

As with every system, CIP systems show some

advantages and disadvantages :

Advantages :

Reduced labour (minimise cleaning

time)

Improved hygiene (automated

systems clean and sanitise more

effectively and consistently than

manual cleaning)

Conservation of cleaning solution

Improved equipment and storage

utilisation

Improved safety

Maintain high plant production

availability

Optimisation of the use of detergent

and water

Difficult to access areas can be

cleaned

Disadvantages :

Installation: the optimisation of

cleaning programmes should be

carried out by qualified people

Maintenance: pressure or flow

rate of cleaning chemicals

through the system should be

measured and reviewed routinely

to ensure that these elements are

applied consistently and

continuously

Nishotech Systems Pvt Ltd

W-199-E, MIDC Khairne,Thane Belapur Road,Navi mumbai - 400705,

: +91- 022 -

41515151, Fax: +91-022 - 41515150 Website: www.nishotech.com

Email:- Shraddha@nishotech.com

AN ISO 9001, 14001 & OHSAS 18001 CERTIFIED COMPANY

Applications :

CIP has been used in dairies and breweries for many years but has been adapted in

other plants because of equipments and installation costs and the difficulty of

cleaning certain processing equipment. So CIP could be used for :

- liquid filling, especially in the dairy

industry

- dairy products

- cream & shampoo manufacturing

- short shelf-life, chilled food

- food processing such as jams,

ketchup, etc.

- finished salads

- ice-cream production post-

pasteurisation

- cook-in sauce lines

- cook-chill production

- sandwich manufacture

- pastry production

- dust control units and silos

(infestation risks)

Nishotech Systems Pvt Ltd

W-199-E, MIDC Khairne,Thane Belapur Road,Navi mumbai - 400705,

: +91- 022 -

41515151, Fax: +91-022 - 41515150 Website: www.nishotech.com

Email:- Shraddha@nishotech.com

AN ISO 9001, 14001 & OHSAS 18001 CERTIFIED COMPANY

Our Installations

Wyszukiwarka

Podobne podstrony:

Cleaning In Place Technology(1)

Cleaning In Place Technology(1)

Cleaning In Place Systems

Cleaning in Place

Clean In Place Review

Development of organic agriculture in Poland, Technologie

making tea in place experiences of women engaged in a japanese tea ceremony

2BUDYNKI I BUDOWLE IN YNIER, Technologiczne

Clean In Place Review

Laurence M Janifer Agent in Place

[7] Core Strength Variation of In Place Concrete tcm77 1305833

Jerry Olton Abandon in Place

UNIQUE ETHICAL PROBLEMS IN INFORMATION TECHNOLOGY

13c Przykładowy WPS m in instrukcja technologiczna spawania

Human resources in science and technology

więcej podobnych podstron