Biomaterials 21 (2000) 765}773

Coatings on zirconia for medical applications

M. Ferraris

!, E. Verne

H

!,*, P. Appendino!, C. Moisescu!, A. Krajewski",

A. Ravaglioli

", A. Piancastelli"

!Department of Materials Science and Chemical Engineering, Polytechnic of Torino, C. so Duca degli Abruzzi 24, 10129 Torino, Italy

"IRTEC/CNR, Via Granarolo, 64-48018 Faenza, Italy

Received 14 July 1998; accepted 22 September 1999

Abstract

In order to combine the mechanical properties of a high-strength inert ceramic (yttria-stabilised zirconia, ZrO2}3%Y2O3, de"ned

as zirconia in the text) with the speci"c properties of bioactive materials, some zirconia samples were coated by two bioactive

phosphosilicate glasses and glass-ceramics: RKKP and AP40. Coatings of about 200}300

lm thickness were prepared by a simple and

low-cost "ring method. They were characterised by optical and scanning electron microscopy (SEM) and compositional analysis

(EDS). The adhesion of the coatings on zirconia was tested by shear tests. Vickers indentations at the coating/zirconia interface were

performed in order to observe the crack propagation path. The reactivity of glasses and glass-ceramics coatings towards a simulated

body #uid (SBF), having the same ion concentration as that of human plasma, was evaluated and compared to that of the bulk glass

and glass-ceramics, by examining the morphology of the reaction layer formed on the surface of the coated zirconia after one month of

soaking in the SBF at 373C.

( 2000 Elsevier Science Ltd. All rights reserved.

Keywords: Bioactive coatings; Glasses; Glass-ceramics

1. Introduction

In the recent years, prostheses for the human body

parts substitution are more and more often made of

ceramics. Zirconia, is one of the newest and most promis-

ing ceramics [1], which exhibits much more toughness

than alumina. A certain interest has spread in the bio-

medical "eld on the utilisation of zirconia for applica-

tions in bone surgery or for devices that need good and

reliable mechanical performances. It is considered an

&inert ceramic' and not a bioactive one because, when

implanted, it only shows a morphological "xation with

the surrounding tissues, without any chemical or biologi-

cal bonding. At the same time, a big number of bioactive

glasses and glass-ceramics have found increasing use in

biomedical applications due to their bioactivity, i.e. the

ability of inducing a speci"c biological activity, in this

case to form a strong bond with hard and soft tissues [2].

The uses of these bioactive materials are especially

concentrated in the "eld of odontoiatry, maxillofacial

plastics and for small bones replacement, generally

* Corresponding author. Fax: #39-011-5644699.

speaking, when the replaced part is not meant to be load

bearing [3].

The use of bioactive glasses and glass-ceramics as

coatings on zirconia is proposed in order to combine the

mechanical properties of this high-strength material with

the peculiar properties of the bioactive coatings.

Twenty six years ago, the "rst bioactive glass composi-

tion from the SiO2}CaO}Na2O}P2O5 system were syn-

thesised and tested in vitro and in vivo [2,3]. Since then,

di!erent kinds of glasses and glass-ceramics showing

bioactive behaviour have been developed. It is well

known that the essential condition for glasses and glass-

ceramics to form an interfacial bond with living bone is

the formation of a hydroxy-carbonate apatite layer on

their surface [3] and that the layer can be reproduced

even in an acellular simulated body #uid which has an

ion concentration almost equal to that of the human

blood plasma [4]. Nowadays, many bioactive glasses

and glass-ceramics are commercialised and implanted in

humans: Bioglass

t [3], Ceravitalt [5], Bioveritt [6],

Cerabone

t [7] and Ilmaplantt [8]. Ilmaplantt was ini-

tially named AP40 (code name, also used in this work)

and Mediceram

t (trade name) [9].

The bioactive glasses chosen for this work as coating

for zirconia were RKKP and AP40: the composition of

0142-9612/00/$ - see front matter

( 2000 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 9 9 ) 0 0 2 0 9 - 4

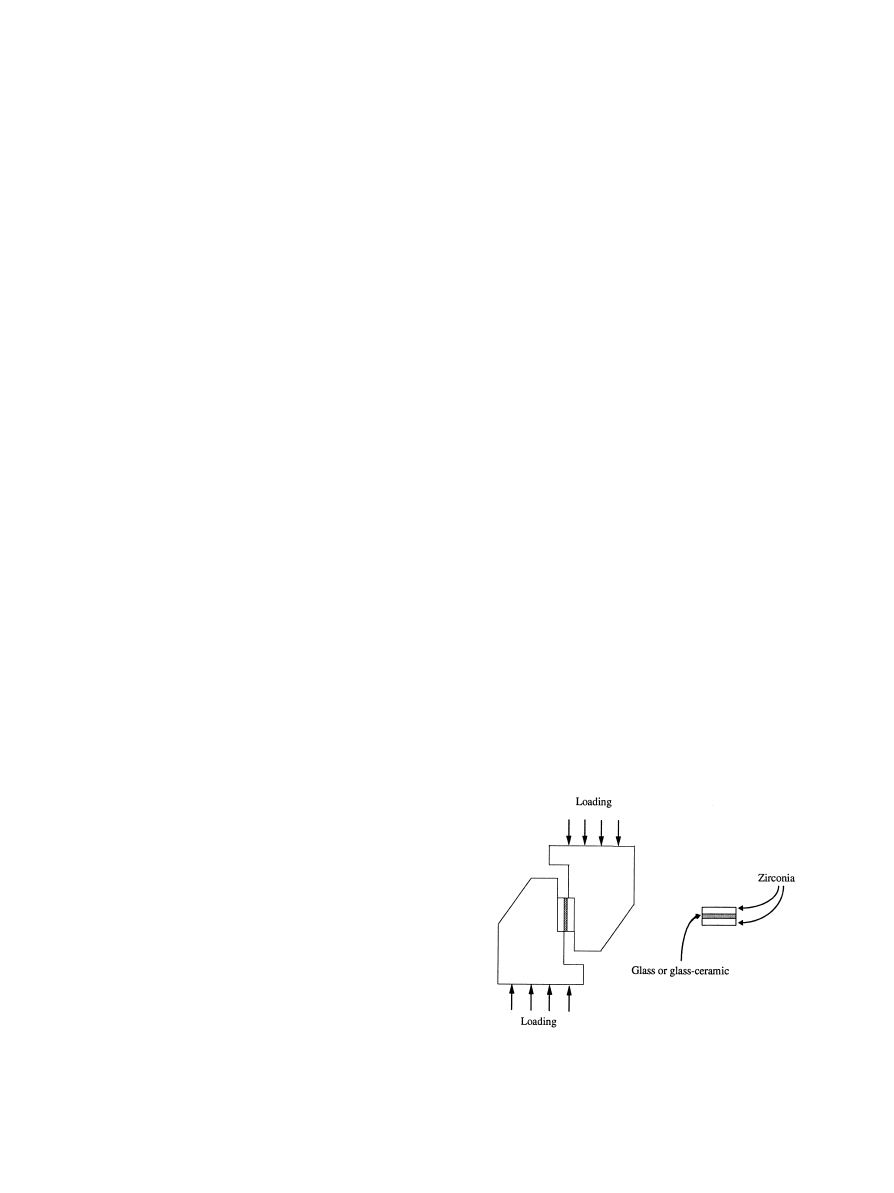

Fig. 1. Shear bond testing of glass- and glass-ceramic joined zirconia

substrates.

RKKP is similar to the AP40 one, with the addition of

Ta and La oxides. It was demonstrated, by means of

Z-potential measurements combined with in vitro test

(albumin absorption) [10] that these ions induce a modi-

"cation of the surface properties of the glass, when put

into biological medium, and an increase in their bioactiv-

ity is seen.

In this work RKKP and AP40 coatings on zirconia

were prepared and characterised; for comparative pur-

poses, both amorphous and glass-ceramic coatings were

produced. There are several coating processes: dipping,

sputtering, plasma spraying, pasting, "ring [11}13]; the

method followed in this work simply consists in "ring

glass powders directly on the ceramic substrate at a suit-

able temperature [14,15]. The process must be carefully

controlled in terms of temperature and time, in order to

avoid detrimental reactions between substrate and coat-

ing, leading to a compositional variation of the glass

matrix and consequently to a decrease in its bioactivity.

The aim of this work was to improve the adhesion of the

coatings to the ceramic substrates [15], to compare the

behaviour of RKKP in respect of AP40, and to observe

the surface reactivity in the case of glass- and glass-

ceramic coatings, respectively.

2. Materials and methods

The two glasses have the following compositions (%

weight):

f RKKP: 43.82 SiO2; 24.23 b-Ca3(PO4)2; 18.40 CaO;

4.55 Na2O; 0.19 K2O; 2.79 MgO; 4.94 CaF2; 0.99

Ta2O5; 0.09 La2O3;

f AP40: 44.30 SiO2; 24.50 b-Ca3(PO4)2; 18.60 CaO;

4.60 Na2O; 0.19 K2O; 2.82 MgO; 4.99 CaF2.

The glasses were prepared by melting the starting

products in a platinum crucible at 14503C for 2 h (Linn

Elektronik HT1800, FKV, BG). The melted glasses were

quenched into cold water or poured on a stainless-steel

plate to obtain bars (4}5 mm thick, 40}50 mm length)

and annealed. The glasses were powdered in a ball-mill

and sieved up to 70}100 mesh. A study of the glasses

characteristic temperatures was performed by di!erential

thermal analysis (DTA 404S Netzsch, Exton, PA) and

heating microscopy (Model A II, Leitz, Gmbh) on the

powders. The thermal expansion coe$cient of AP40,

RKKP and ZrO2 was measured (on bars) by using

a Netzsch dilatometer (Model 402 E, Exton, PA). Zirco-

nia substrates (d"6.00$0.05 g/cm

3, corresponding to

a relative density of 98.5%$0.05 in respect of the theor-

etical one), obtained by 3% Y2O3 stabilised zirconium

oxide powders, was used. Before applying the glass

powders, the substrate was ultrasonically cleaned for

about 5}10 min in acetone. Surface porosity was not

detectable and the average grain size was about 1

lm

diameter. An optimised thermal treatment process was

carefully developed to coat zirconia substrates with

amorphous or glass-ceramic RKKP and AP40: the prep-

aration of the coatings consisted in covering the zirconia

substrate by dry glass powders, and then heating them at

temperatures slightly above the melting temperature, ob-

taining 100}300

lm thick layers. In order to have an

amorphous layer, after the heating treatment, the coating

was simply annealed; otherwise, in order to obtain

a glass-ceramic coating, the samples were thermally

treated with a nucleation and growth process, on the

basis of the characteristic temperatures previously deter-

mined on the pure glasses. Shear strength measurements

were performed on several sandwiches prepared by join-

ing the zirconia substrates (100

]50]3 mm3 size) by

a glass or a glass-ceramic layer, using the same time and

temperature schedule used for preparing the coatings.

Each coating was characterised by optical and scann-

ing electron microscopy (SEM*Philips 525 M) and

compositional analysis (EDS) (Model EDAX 9100, Phi-

lips). Shear tests on zirconia/glass/zirconia and on zirco-

nia/glass-ceramic/zirconia sandwiches were performed,

using a SINTEC D/10 materials testing machine, on

several samples (at least 10), as reported in literature

[16}20] and as described in Fig. 1. The interface adher-

ence between the coatings and zirconia was also quali-

tatively evaluated, as described by several authors in

literature [21}24], by analysing the crack propagation

path induced by Vickers indentation (load"500 g) at

the interface coating/substrate; at least 5 indentations

were performed along this interface, on each sample, in

order to verify the reproducibility of the method.

Bulk glasses, subjected to the same nucleation and

growth thermal treatment as that for the coatings, were

characterised by X-ray di!raction (Model PW 1710, Phi-

lips Electronic Instruments, Mahwah, NJ) in order to

study their microstructure. In vitro experiments on the

766

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

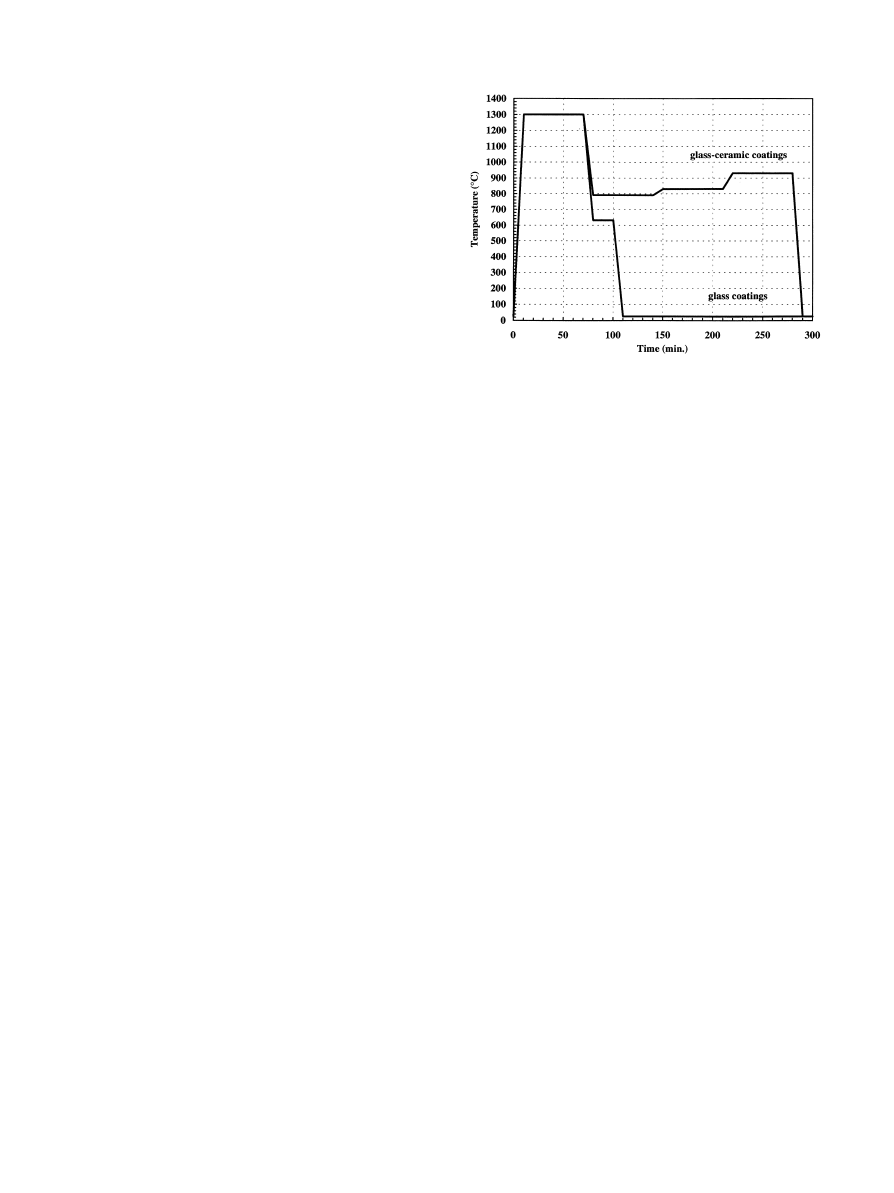

Fig. 2. Thermal treatments for the preparation of glass and glass-

ceramic coatings.

glass- and glass-ceramic-coated samples, having the same

surface roughness (polished with a 6

lm paper), were

carried out by soaking them in a simulated body #uid

(SBF) at 373C; the solution had the same ions concentra-

tion as that of the human plasma [4]. Each sample was

soaked in 15 ml SBF in a polyethylene bottle. After one

month, the samples were removed from the bottles,

washed with distilled water, and dried at room temper-

ature. The coatings were characterised by optical and

scanning microscopy and compositional analysis after

soaking, in order to determine the modi"cation of their

surface. These results were compared with those obtained

on bulk glasses and glass-ceramic, soaked in SBF for

comparative purposes.

3. Results and discussion

3.1. Thermal properties

The characteristics temperatures (glass transition,

dilatometric softening, crystallisation and melting tem-

peratures) for the two glasses were almost the same: the

di!erences between the two samples were within the

experimental reproducibility of the techniques. The glass

transition, softening, crystallisation and melting temper-

ature ranges for the two glasses are 640}650, 690}700,

720}895 and 1275}12953C, respectively; three crystallisa-

tion peaks were revealed by DSC between 720 and 8953C

for both the glasses. The thermal expansion coe$cients

of the two glasses and of zirconia, measured between 100

and 6003C, ranged between 12.0 and 12.5

]10~6 (

3C

~1).

3.2. Coatings preparation and characterisation

The thermal treatments used for the preparation of

RKKP and AP40 glass- and glass-ceramic coatings were

optimised further as compared with those described in

literature [15], and are summarised in Fig. 2: the as-

coated samples were annealed 20 min at 6303C to have

amorphous coatings, while, in order to obtain the glass-

ceramic coatings described in this work, the specimens

were subjected to a three-step crystallisation treatment,

in the range 790}9303C, where the nucleation and growth

of the main crystalline phases take place. It is known

from the literature [9] that AP40 crystallises leading to

the precipitation of hydroxyapatite and/or #uorapatite

(both are possible on the basis of the chemical composi-

tion of this glass) and wollastonite.

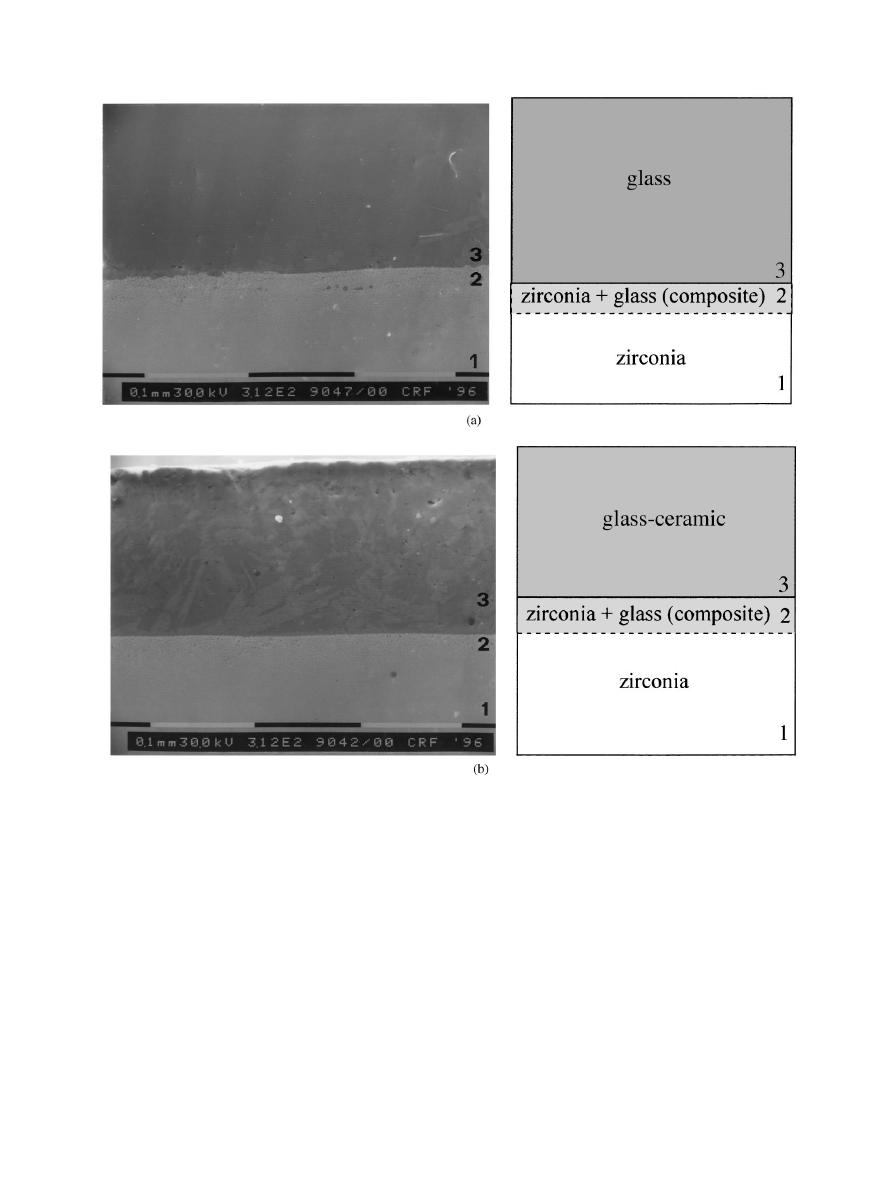

Fig. 3a, b shows the polished cross sections of glass-

and glass-ceramic AP40 coatings on zirconia, respective-

ly: the di!erent zones are also schematised; there are

three di!erent layers in Fig. 3a: (1) the zirconia substrate,

(2) a &composite' layer made of glassy phase and zirconia

particles, (3) the glassy AP40 layer. During the thermal

treatment above its melting point, the glass di!uses

within the zirconia substrate and the zirconia granules

are surrounded by a vitreous matrix, leading to the

formation of a &composite' layer, with an average thick-

ness of 25

lm. The composite layer assures a continuity

of thermal and mechanical properties from the zirconia

substrate to the glass coating and, as discussed below, it

is a tough layer. In Fig. 3b, the cross section of the AP40

glass-ceramic coating on zirconia also shows three layers:

(1) the zirconia substrate, (2) the &composite' layer, (3) the

AP40 glass-ceramic coating. The "rst two regions are the

same as observed in Fig. 3a. In the third zone (approxim-

ately 200

lm thick) (the glass-ceramic layer) several crys-

tals (apatites and wollastonite) can be seen. The

nucleation and growth thermal treatment performed in-

stead of an annealing one provided a glass-ceramic coat-

ing with some crystalline phases already detected on the

bulk glass-ceramic, crystallised by the same thermal

treatment and reported in Ref. [8]. Since the AP40 glass

coating does crystallise at the temperatures chosen on the

basis of the DTA performed on the starting pure glass, it

is quite evident that the interaction with the zirconia did

not substantially modify its chemical composition. The

RKKP glass- and glass-ceramic coatings gave the same

morphological and structural results.

The thermal expansion coe$cients of the two glasses

were found to be very close to that of zirconia: this

prevented the formation of cracks in the glass or at the

interface glass/substrate during cooling to room temper-

ature, due to residual thermal stresses.

It was necessary, for the purpose of this work, to

control any signi"cative reaction between the substrate

and the glass, in order to prevent the modi"cation of the

glass composition and then to a!ect its bioactivity. At the

same time it was important to produce a continuous

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

767

Fig. 3. Cross sections of the AP40 glass: (a) and glass-ceramic; (b) coatings on zirconia.

interface between the coating and the substrate. The time

and temperature schedules (Fig. 2) were optimised in

order to have a good contact between the substrate and

the coatings and, at the same time, to prevent detrimental

chemical reactions at the interface: the lowest temper-

ature and the shortest time to obtain adherent coatings

and unmodi"ed glass compositions were chosen.

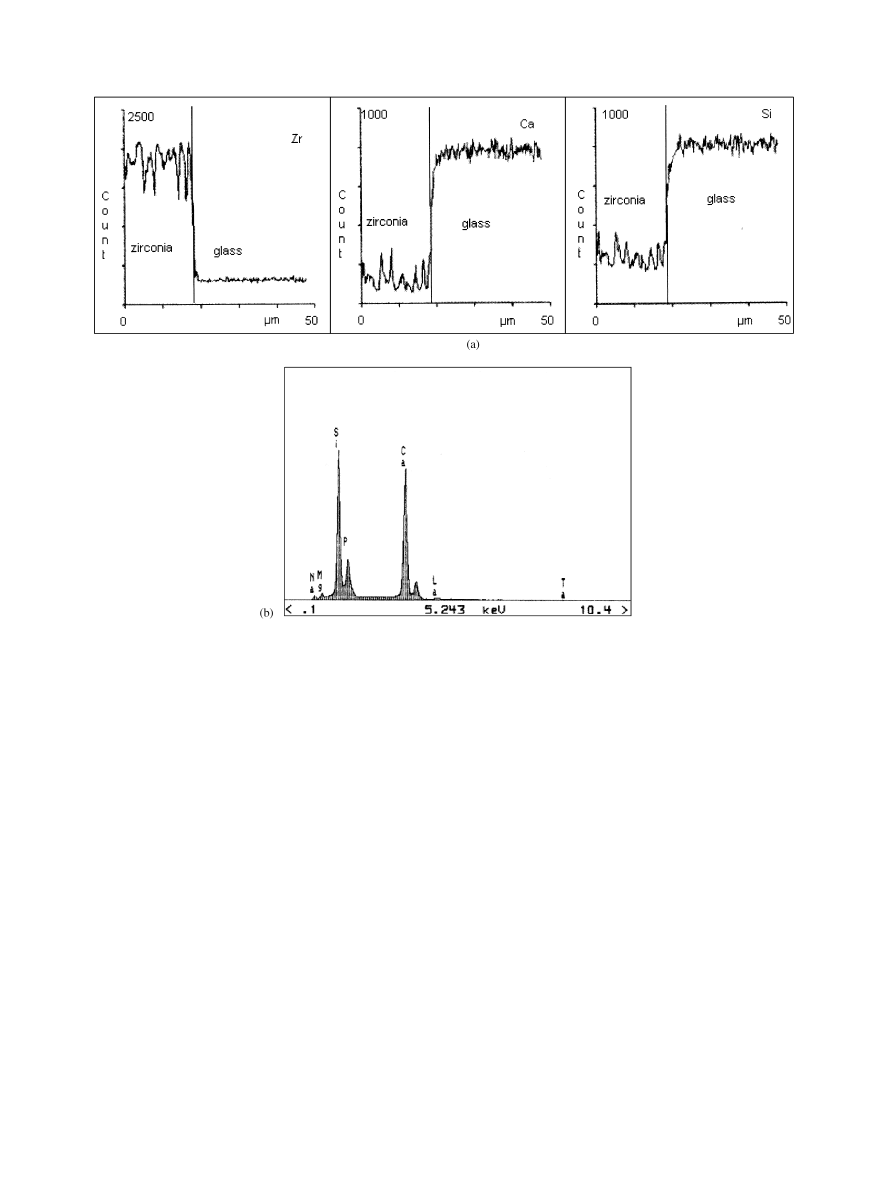

By comparing the EDS analyses made on bulk glasses

and on top of the coatings on zirconia, it was evident that

the glass coatings still have the same starting composi-

tion. The amount of zirconium, detected by this tech-

nique by several analyses performed on the coatings

cross section, revealed that no zirconium di!usion occur-

red from the substrate towards the surface. The concen-

tration of zirconia was also not detectable within the

glass-ceramic, as well as in the case of the glass. The same

results were obtained for glass- and glass-ceramic RKKP

and AP40 coatings. The cross-sectional EDS results for

a RKKP glass-coated sample are presented in Fig. 4a.

The lack of Zr di!usion through the glass coating, and

the evidence of the composite layer (zirconia granules

surrounded by in"ltrated glass) are clearly notable.

Fig. 4b presents the EDS analysis results performed on

top of a RKKP coating surface: no Zr was detectable.

3.3. Mechanical tests

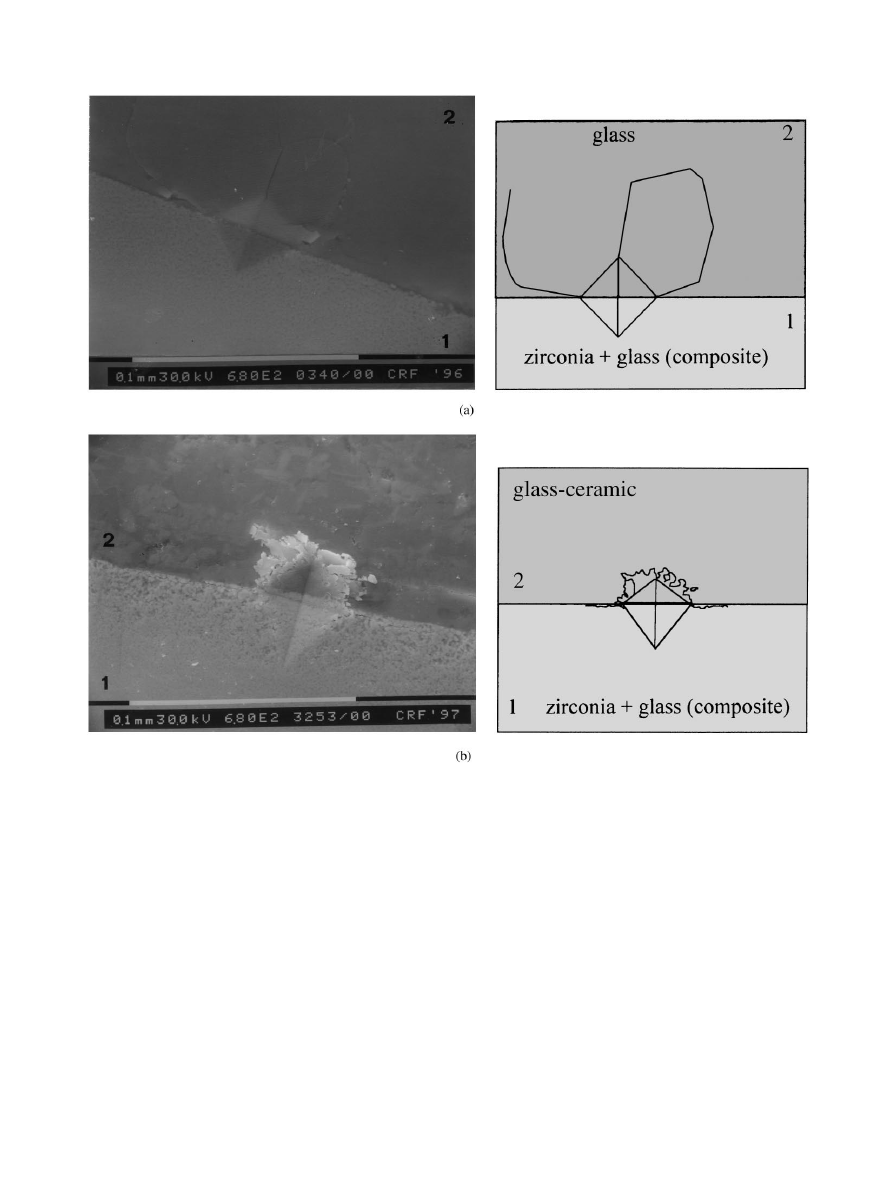

Several Vickers indentations (at loads ranging from

500 to 1000 g) were made at the supposed-to-be

the weakest interface, i.e. between the composite layer

768

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

Fig. 4. (a) EDS average pro"les of the reported elements on a cross section of a RKKP-coated zirconia substrate; (b) EDS analysis performed on top of

a RKKP coating surface.

(zirconia#glass) and the glass coating (Fig. 5a) or the

glass-ceramic coating (Fig. 5b). The fracture pattern of

the cracks induced by Vickers indentation on a homo-

geneous brittle solid, like glasses or glass-ceramics, has

been widely studied [21}24]. This comparative method is

based on measurements of the resistance towards propa-

gation of a crack along an interface: cracks were intro-

duced by Vickers indentations and observed by scanning

electron microscopy. The resistance to cracks propaga-

tion provided a qualitative measurement of the strength

of a brittle material. The induced radial cracks propagate

in a direction parallel to the indentation diagonals and

normal to the specimen surface. When the indentations

are performed at the substrate-coating interface, with one

of the diagonals near or just on the &border line' between

the two materials, the crack propagation gives qualitat-

ive information about the fracture energy of the two

joined materials and about the fracture energy of their

interface. The crack path will propagate into the weakest

materials or it will follow the most weakly bonded inter-

face. If the bonding at the interface is stronger than the

coating, the crack would propagate through the coating.

As shown in Fig. 5a (RKKP glass coating on zirconia),

two cracks initially propagate parallel to the interface,

but they suddenly deviate towards the most brittle mater-

ial (the glass coating), because of the higher toughness of

the interface compared to the glass coating. No cracks

were observed in the composite layer. Fig. 5b (RKKP

glass-ceramic on zirconia) similarly shows the propaga-

tion of some small cracks in the glass ceramic coating,

readily stopped, in this case, by the crystalline phases.

Some cracks propagated into the composite layer with-

out any detachment of the coating from the substrate.

The same behaviour was observed in the case of the

AP40 glass and glass-ceramic coatings. To summarise,

the four coatings were found to be adhering well to the

substrate and the glass-ceramic ones showed a tougher

behaviour than the corresponding glassy ones.

It is well known that the indentation method at the

interface of di!erent materials is a qualitative method

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

769

Fig. 5. Induced crack propagation at the interface between zirconia and (a) the RKKP glass; (b) the RKKP glass-ceramic coatings.

and it gives comparative results for similar materials

[21}24], i.e. brittle coatings on brittle substrates, ductile

coatings on ductile substrates, etc. In the above discussed

cases, we had suitable conditions to compare the mor-

phological results, i.e. the same ceramic substrate coated

by glasses or glass-ceramics of similar composition.

The shear tests performed on zirconia &sandwiches'

joined by a glass or glass-ceramic layer (AP40 and

RKKP) gave very encouraging results. This test is widely

used in the "eld of ceramic joining [16}20] and, if per-

formed in a controlled and reproducible manner, gives

interesting comparative results. At least ten sandwich

structures for each kind of coating (glass-, glass-ceramic,

AP40, RKKP) were tested. The shear strength for the

glass-coatings was 80$3 MPa and that of the glass-

ceramic ones was 84$3 MPa. These results, demon-

strated a very good adherence and a high strength of the

coatings to the substrate, not only in the case of AP40

(glass- and glass-ceramic) but also in the case of RKKP.

The glass-ceramic coatings always gave better results in

comparision with the glassy ones. These results are in

good agreement with those obtained by the indentation

test.

3.4. *In vitro+ tests

The surface reactivity of the RKKP and AP40 glass-

and glass-ceramic-coated samples was investigated by

770

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

Fig. 6. Cross section of the RKKP glass coating after one month in SBF.

observing the morphology of the self-grown layers for-

med after soaking them in SBF; for comparative pur-

poses, the same observations were performed on bulk

glasses, whose bioactivity is well known and already

demonstrated elsewhere [8}12], and on bulk glass-cer-

amics. The bulk glass-ceramic samples were nucleated

and crystallised by following the same thermal treatment

as that used for the glass-ceramic coatings (Fig. 2): the

crystalline phases detected on bulk samples by XRD

showed the formation of apatite and wollastonite, in both

AP40 and RKKP bulk glass-ceramics, according to liter-

ature.

One condition for a glass to be considered bioactive is

the formation of a hydroxy-carbonate apatite layer [3,4]

on its surface after soaking in a simulated body #uid.

Bioactive glasses based on Si and Ca can develop this

layer by a complex mechanism which shows alcaline ions

leaching and surface dissolution, leading to the formation

of a silica-gel layer, which provides good sites for the

nucleation and growth of apatite. This mechanism could

be drastically a!ected by the presence of small amounts

of some multivalent cations [14,25].

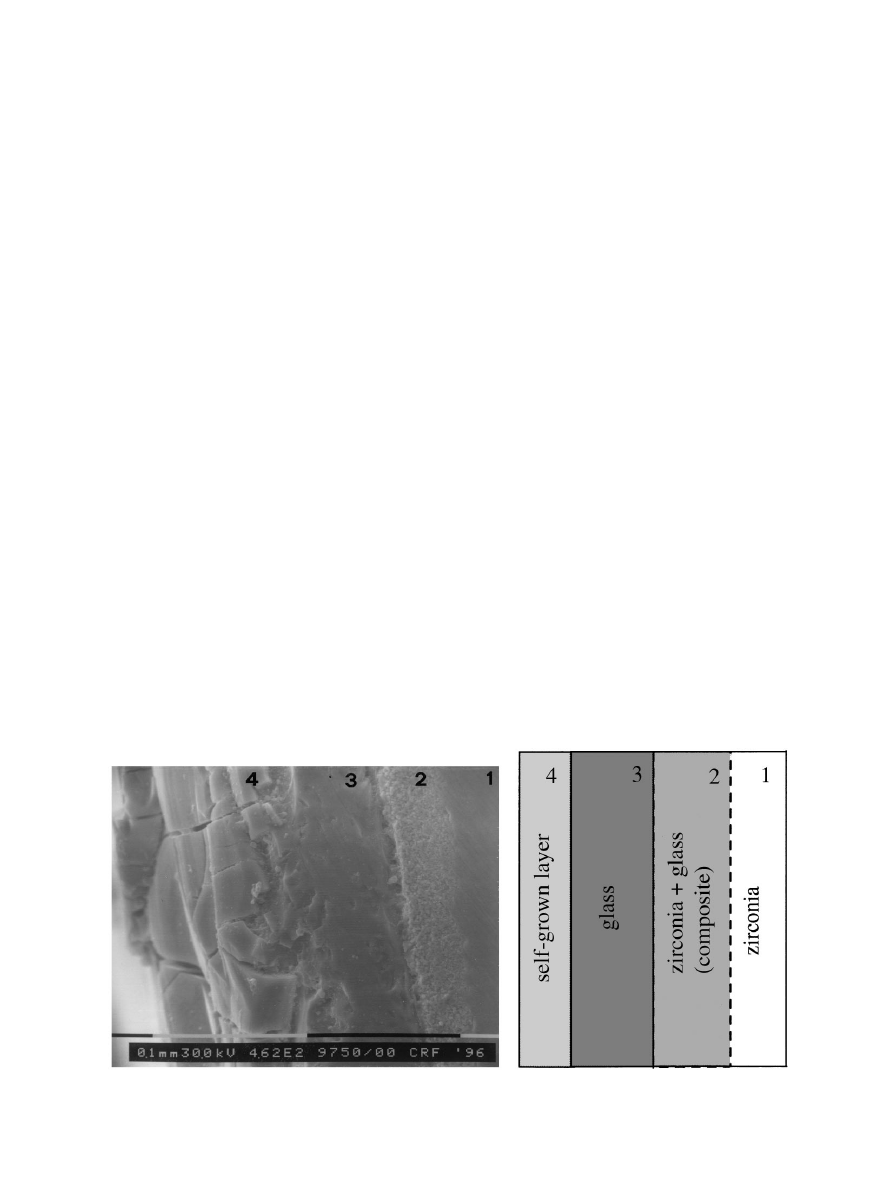

Fig. 6 shows the cross section of an amorphous RKKP

coating on zirconia after soaking in SBF: the four zones

that can be emphasised are also presented: (1) zirconia, (2)

zirconia plus glass (composite), (3) RKKP glass and (4)

self-grown layer rich in Ca and P ions, as detected by

EDS. The self-grown layer is about a hundred microns

thick. The EDS analysis performed on each self-grown

layer showed the presence of Si, P and Ca ions, with

a Ca/P weight ratio of 2.3 (wt%), close to the theoretical

value for apatites (2.15). This feature corresponds to the

apatite formation, according to its growth mechanism on

a bioactive bulk glass [3,4]. The reactivity of the AP40

coatings with zirconia is similar to that observed for the

RKKP coatings. Both kinds of glass coating showed the

same reactivity documented on bulk AP40 and RKKP.

This result is a further evidence that the coating prepara-

tion did not induce any compositional modi"cation of

the base glasses, and that their bioactivity was retained

even in the coating form. No signi"cant di!erences in

terms of surface reactivity were found for AP40 and

RKKP bulks or coatings, despite the di!erence in their

surface properties reported in literature, due to the oppo-

site Z-potential for the two glasses [10]. This feature

seems to be important in biological media, because of its

in#uence on the protein absorption on the glass, and

therefore on its surface properties, as, for example, cell

migration and bone growth. In our case the growth of the

calcium and phosphorus rich layer occurs in an inorganic

simulated body #uid, and therefore it does not seem to be

in#uenced by the di!erence in Z-potentials.

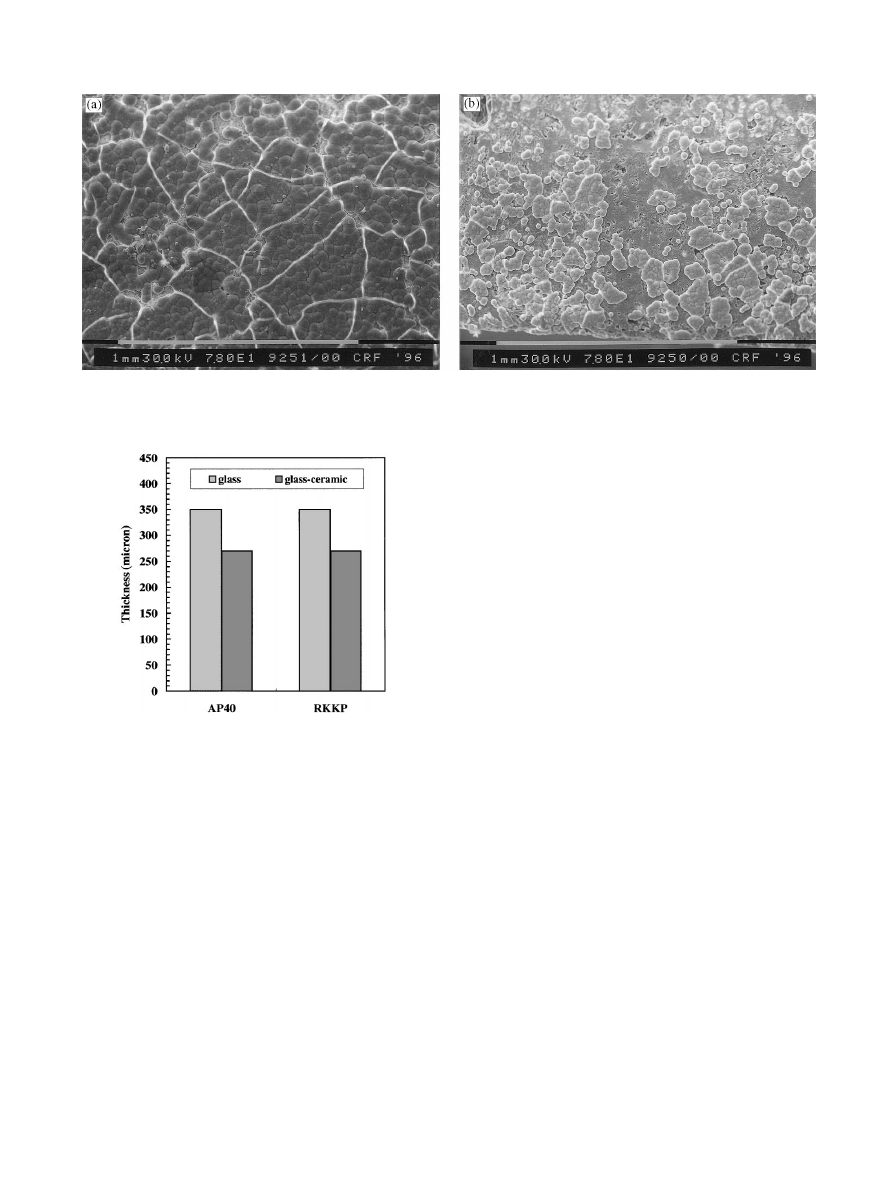

RKKP and AP40 glass coatings showed di!erent in

vitro behaviour with respect to the glass-ceramic ones, as

summarised in Fig. 7a and b, where the plan views of the

glass and glass-ceramic coatings on zirconia, respectively,

after one month soaking in SBF, are shown: the surface

in Fig. 7a (glass coating on zirconia) is completely

covered by the self-grown layer with its typical globular

morphology, while only a partial coverage is observable

in Fig. 7b (glass-ceramic coating on zirconia), under the

same conditions. The thickness of the self-grown Ca and

P rich layer on bulk AP40 and RKKP glass- and glass-

ceramic, soaked for comparative purposes, is reported in

Fig. 8. The glass coatings were found to be more reactive

than the derived glass-ceramic ones, the bulk glasses as

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

771

Fig. 7. Plan view of the self-grown layer on AP40 glass (a) and glass-ceramic; (b) coatings, after one month in SBF.

Fig. 8. Comparison between the thickness of the self-grown layer on

the bulk samples after one month in SBF.

well as the glass-ceramics. It could be reasonable to state

that in the case of a bioactive glass-ceramic (bulk or

coating), this layer grows mostly on the residual amorph-

ous phase [26].

To summarise, the AP40 and RKKP glass and glass-

ceramic coatings on zirconia developed a silicon, calcium

and phosphorous ions rich layer on their surfaces after

one month soaking in SBF; the same layer after the

same period of time was observed on the surface of the

two bulk bioactive glasses and glass-ceramics. This

allows one to state that the glass and glass-ceramic coat-

ings retained the peculiar reactivity towards a simulated

body #uid, as is characteristic of the bulk bioactive glass-

es and glass-ceramics. The glass-ceramics always showed

the growth of a layer thinner than those of the parent

glasses.

4. Conclusions

Coatings of RKKP bioactive glass- and glass-ceramics

on an inert substrate (ZrO2), were successfully prepared

by a simple and low-cost "ring method. Similar coatings

were prepared by AP40 glass and glass-ceramic in order to

compare the mechanical behaviour and the surface reac-

tivity of these two bioactive materials. Each coating

showed a very little reactivity towards zirconia (limited to

the contact area), since it did not change its composition

during the thermal treatments necessary for its preparation.

All the coatings showed good adherence to the sub-

strate and formed a tough composite layer containing

zirconia particles surrounded by a glassy phase between

the coating and the substrate. The glass-ceramic coatings

were found to have a tougher behaviour than the glassy

ones. The very high shear strength results showed that

the coatings are tightly bonded to the substrates.

The reactivity of both RKKP and AP40 coatings was

investigated by soaking them in a SBF solution and by

analysing the self-grown layer on their surface after

a month of soaking. This layer has the same morphology

and composition as that grown on the bulk glasses and

glass-ceramic, whose bioactivity is well known. The glass

coatings were found to be more reactive than the glass-

ceramic ones because of the larger thickness of the for-

med layer in the same period of time. This behaviour was

found also on the bulk materials. No signi"cant di!er-

ence between the AP40 and RKKP behaviour in the SBF

solution was observed.

Acknowledgements

The authors are indebted to the Fiat Research Centre

(To, Italy) for SEM-EDS analyses.

772

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

References

[1] Hulbert SF. The use of alumina and zirconia in surgical implants.

In: Hench LL, Wilson J, editors. An introduction to bioceramics:

advance series in ceramics, vol. 1. Singapore: World Scienti"c,

1993. p. 25.

[2] Cao W, Hench LL. Bioactive materials. Ceram Int 1996;22:

493}507.

[3] Wilson J, Yli-Urpo A, Risto-Pekka H. Bioactive glasses: clinical

applications. In: Hench LL, Wilson J, editors. An introduction to

bioceramics: advances series in ceramics, vol. 1. Singapore: World

Scienti"c, 1993. p. 63.

[4] Kokubo T, Kushitoni H, Ohtsuki C, Sakka S, Yamamuro T.

Chemical reaction of bioactive glass and glass-ceramics with

a simulated body #uid. J Mater Sci Mater Med 1992;3:79}83.

[5] Kas HH. DE 2349859. 1973.

[6] HoKland W, Vogel W. Machineable and phosphate glass-ceramic.

In: Hench LL, Wilson J, editors. An introduction to bioceramics:

advances series in ceramics, vol. 1. Singapore: World Scienti"c,

1993. p. 125.

[7] Kokubo T. A/W glass-ceramic: processing and properties. In:

Hench LL, Wilson J, editors. An introduction to bioceramics:

advances series in ceramics, vol. 1. Singapore: World Scienti"c,

1993. p. 75.

[8] Wihsmann F, Berger G, Bochynek G, et al. Bioaktive implantate

auf der Basis von Vitrokerammaterialien. Wiss Ztschr FSU Jena

1983;2/3:553}69.

[9] Berger G, Gildenhaar R. Long-term stable bioactive glass ceramic

as implant material*ten years of clynical experience. Berlin,

Federal Republic of Germany: Fourth World Biomaterials Con-

gress, 24}28 April, 1992, p. 33.

[10] Krajewski A, Malavolti R, Piancastelli A. Albumin adhesion on

some biological and non-biological glasses and connection with

their Z-potentials. Biomaterials 1996;17:53}60.

[11] Laudadio P, Cunsolo E, Presutti L, Krajewski A, Ravaglioli A,

Hench LL. The importance of the adhesion through biological

glass to the acoustic membrane of the tor protheses. Bioceramics

1995;8:265}71.

[12] VerneH E, Ferraris M, Ventrella A, Paracchini L, Krajewski A,

Ravaglioli A. Sintering and plasma spray deposition of bioactive

glass-matrix composites for medical applications. J Eur Ceram

Soc 1998;18(4):363}72.

[13] Jana C, Wange P, Grimm G, GoKtz W. Bioactive coatings of

glass-ceramics on metals. Glastech Ber Glass Sci Technol 1995;

68(4):117}22.

[14] Ferraris M, VerneH E, Moisescu C, Ravaglioli A, Krajewski A.

Bioactive coatings on Al2O3 and ZrO2. In: Ravaglioli A,

Krajewski A, editors. Bioceramic coatings for guided bone

growth. Faenza, Italy: Gruppo Editoriale Faenza Editrice S.p.A,

1996. p. 31.

[15] Krajewski A, Ravaglioli A, Mazzocchi M, Fini M. Coating of

ZrO2 supports with a biological glass. J Mater Sci Mater Med

1998;9:309}16.

[16] Ferraris M, Salvo M, Isola C, Appendino Montorsi M,

Kohyama A. Glass-ceramic joining and coating of SiC/SiC

for

fusion

applications.

J

Nucl

Mater

1998;258}263:

1546}50.

[17] Isola C, Salvo M, Ferraris M, Appendino Montorsi M. Joining

of surface modi"ed carbon/carbon composites using a barium}

aluminum}boro-silicate glass. J Eur Ceram Soc 1998;18:

1017}24.

[18] Lin J, Kato H. Interfacial structure and strength of silicon}silicon

di!usion bond. Mater Sci Tech 1995;11:1035}40.

[19] VerneH E, Ferraris M, Moisescu C, Ravaglioli A, Krajewski A.

Mechanical characterisation of bioactive coatings on zirconia. In:

Sedel L, Rey C, editors. Bioceramics, vol. 10. Paris, France:

Pergamon Press, 1997. p. 199.

[20] Bushby RS, Scott VD. Liquid phase bonding of aluminium and

aluminium/nicalon composite using copper interlayers. Mater Sci

Tech 1993;9:417}23.

[21] Lin CK, Lin CC, Berndt CC. Simulation of hardness on

plasma

sprayed

coatings.

J

Am

Ceram

Soc

1995;78(5):

1406}10.

[22] Sbaizero O, Lucchini E. In#uence of residual stresses on the

mechanical properties of a layered ceramic composite. J Eur

Ceram Soc 1996;16:813}8.

[23] Loehman RE, Tomsia AP. Indentation method for measuring

interface adherence and stresses in the interfacial zone, In: Ce-

ramic joining: a short course. 98th Annual Meeting and Exposi-

tion of The American Ceramic Society, IN, USA, 13}14 April

1996 [Chapter 9].

[24] Pazo A, Saiz E, Tomsia AP. Silicate glass coatings on Ti-based

implants. Acta Mater 1998;46(7):2551}8.

[25] Ohura K, Nakamura T, Yamamuro T, et al. Bioactivity of

CaO}SiO2 glasses added with various ions. J Mater Sci Mater

Med 1992;3:95}100.

[26] Li P, Yang Q, Zhang F, Kokubo T. The e!ect of residual

glassy phase in a bioactive glass-ceramic on the formation of its

surface apatite layer in vitro. J Mater Sci Mater Med 1992;3:

452}6.

M. Ferraris et al. / Biomaterials 21 (2000) 765}773

773

Wyszukiwarka

Podobne podstrony:

Effective antibacterial adhesive coating on cotton fabric using ZnO

Deposition of highly adhesive ZrO2 coating on Ti and CoCrMo

Biomimetic and electrolytic calcium phosphate coatings on ti

Hydroxyapatite coating on titanium substrate with titania bu

Biomimetic apatite coatings on micro

72 1031 1039 Influence of Thin Coatings Deposited by PECVD on Wear and Corrosion Resistance

More on hypothesis testing

ZPSBN T 24 ON poprawiony

KIM ON JEST2

Parzuchowski, Purek ON THE DYNAMIC

Foucault On Kant

G B Folland Lectures on Partial Differential Equations

free sap tutorial on goods reciept

5th Fábos Conference on Landscape and Greenway Planning 2016

ON CIĘ ZNA (fragm), WYCHOWANIE W CZAS WOJNY RELIGIJNEJ I KULTUROWEJ - MATERIAŁY, TEKSTY

Enochian Sermon on the Sacraments

Post feeding larval behaviour in the blowfle Calliphora vicinaEffects on post mortem interval estima

więcej podobnych podstron