Biomaterials 23 (2002) 1723–1730

Structure and properties of Ti–7.5Mo–xFe alloys

D.J. Lin, J.H. Chern Lin*, C.P. Ju

Department of Materials Science and Engineering, National Cheng-Kung University, Tainan, Taiwan, ROC

Received 13 March 2001; accepted 22 June 2001

Abstract

The present work is a study of a series of Ti–7.5Mo–xFe alloys, with the focus on the effect of iron addition on the structure and

mechanical properties of the alloys. Experimental results indicate that a

00

phase-dominated binary Ti–7.5Mo alloy exhibited a fine,

acicular martensitic structure. When 1 wt% or more iron was added, the entire alloy became equi-axed b phase structure with a grain

size decreasing with increasing iron content. Athermal o phase was formed in the alloys containing iron of roughly between 0.5 and

3 wt%. The largest quantity of o phase and highest microhardness were found in Ti–7.5Mo–1Fe alloy. The binary Ti–7.5Mo alloy

had a lower microhardness, bending strength and modulus than all iron-containing alloys. The largest bending strength was found

in Ti–7.5Mo–2Fe alloy. The present alloys with iron contents of about 2–5 wt% seem to have a great potential for use as an implant

material. r 2002 Elsevier Science Ltd. All rights reserved.

Keywords:

Titanium–molybdenum–iron alloy; Structure; Mechanical properties

1. Introduction

Titanium and titanium alloys have been used in many

medical applications due to their excellent mechanical

performance and corrosion resistance. The relatively

low strength commercially pure titanium (c.p.Ti) is

currently used in dentistry [1–3], and the higher strength

Ti–6Al–4V alloy is used in a variety of stress-bearing

orthopedic applications [2,4,5]. There has been a

speculation that the release of Al and V ions from the

alloy might cause some long-term health problems [6–8].

More recently, a great deal of effort has been devoted

to the study of b and near-b phase alloys, such as Ti–

15Mo [9], Ti–13Nb–13Zr [10], Ti–11.5Mo–6Zr–2Fe [11],

Ti–Zr–Nb–Ta–Pd and Ti–Sn–Nb–Ta–Pd [12]. Advan-

tages of b/near-b titanium alloys over a; near-a or a þ b

alloys include their lower modulus and better form-

ability [13]. Weiss et al. [14] and Ankem et al. [15] have

shown that the b phase titanium alloys generally can be

processed to higher strength levels and exhibit better

notch properties and toughness than a þ b alloys. The

relatively low modulus of b titanium alloys may also

reduce the ‘‘stress-shielding’’ effect [16–21].

A binary Ti–7.5 wt% Mo alloy with an a

00

phase has

been developed recently in the present authors’ labora-

tory [22]. In the as-cast state, this Ti–7.5Mo alloy had a

bending strength similar to that of Ti–15Mo and Ti–

13Nb–13Zr with a bending modulus even lower than

both alloys. The present work is based on Ti–7.5Mo

system with a focus on the effect of iron addition on the

alloy structure and mechanical properties. The b-

eutectoid iron was selected due to its strengthening

potential [13] and possibly better biocompatibility

compared to other b-stabilizers such as Co, Cr, Ni, etc.

2. Experimental procedure

A series of Ti–7.5 wt% Mo–xFe alloys, with Fe

contents up to 7 wt%, as prepared from raw titanium

(99.5% in purity), molybdenum (99.9% in purity) and

iron (99.5% in purity) using a commercial arc-melting,

vacuum-pressure type casting system (Castmatic, Iwa-

tani Corp., Japan). The melting chamber was first

evacuated and purged with argon. An argon pressure of

1.5 kgf/cm

2

was maintained during melting. Appropriate

amounts of metals were melted in an U-shaped copper

hearth with a tungsten electrode. The ingots were re-

melted three times in order to improve chemical

*Corresponding author. Tel./fax: +886-6-2748086.

E-mail address:

chernlin@mail.ncku.edu.tw (J.H. Chern Lin).

0142-9612/02/$ -see front matter r 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 2 3 3 - 2

homogeneity. Prior to casting, the ingots were remelted

again in an open-based copper hearth under an argon

pressure of 1.5 kgf/cm

2

. The difference in pressure

between the two chambers allowed the molten alloys

to instantly drop into a graphite mold at room

temperature.

The cast alloys were sectioned using a Buehler Isomet

low speed diamond saw to obtain specimens for various

purposes. Surfaces of the alloys for a microstructural

study were mechanically polished via a standard

metallographic procedure to a final level of 0.3 mm

alumina powder, then etched in a Kroll’s reagent

comprising water, nitric acid, and hydrofluoric acid

(80 : 15 : 5 in volume). Microstructure of the etched

alloys was examined using an optical microscope (Leitz

Labrorlux 12 Pols, Leica Co., Germany). Transmission

electron microscopy (TEM) was performed using a

JEOL JEM-3010 system (Japan) operated at 200 kV.

Thin foils for TEM were prepared using a twin jet

polisher (Tenupol III, Sturers, Denmark) in an electro-

lyte comprising 30 ml per chloric acid (30%), 175 ml n-

butyl alcohol and 300 ml methanol at 401C with a

voltage of 12–15 V.

X-ray diffraction (XRD) for phase analysis was

conducted using a Rigaku diffractometer (Rigaku D-

max IIIV, Rigaku Co., Tokyo, Japan) operated at 30 kV

and 20 mA. An Ni-filtered CuK

a

radiation was used for

the study. A silicon standard was used for the

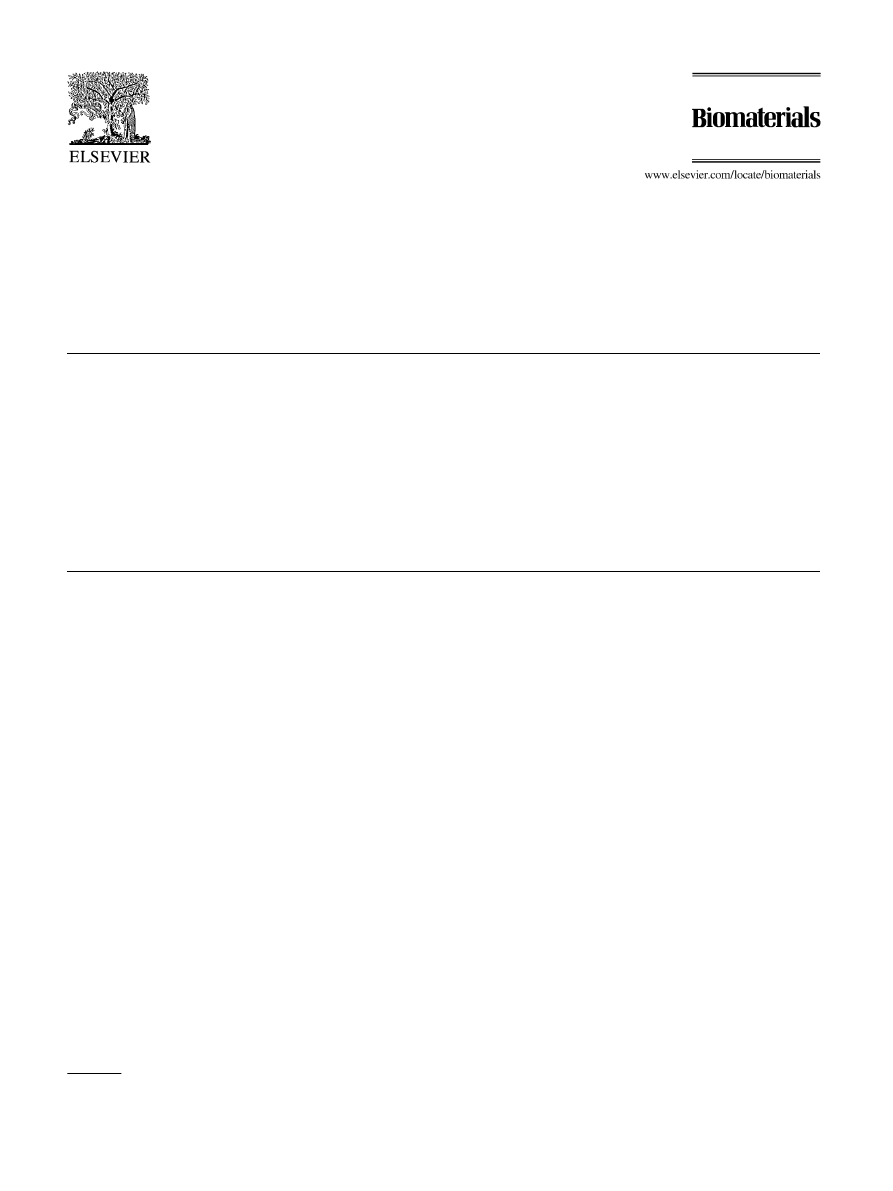

Fig. 1. XRDpatterns of Ti–7.5Mo and Ti–7.5Mo–xFe alloys.

Fig. 2. Lower scanning speed XRDpatterns of Ti–7.5Mo and Ti–

7.5Mo–xFe alloys.

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1724

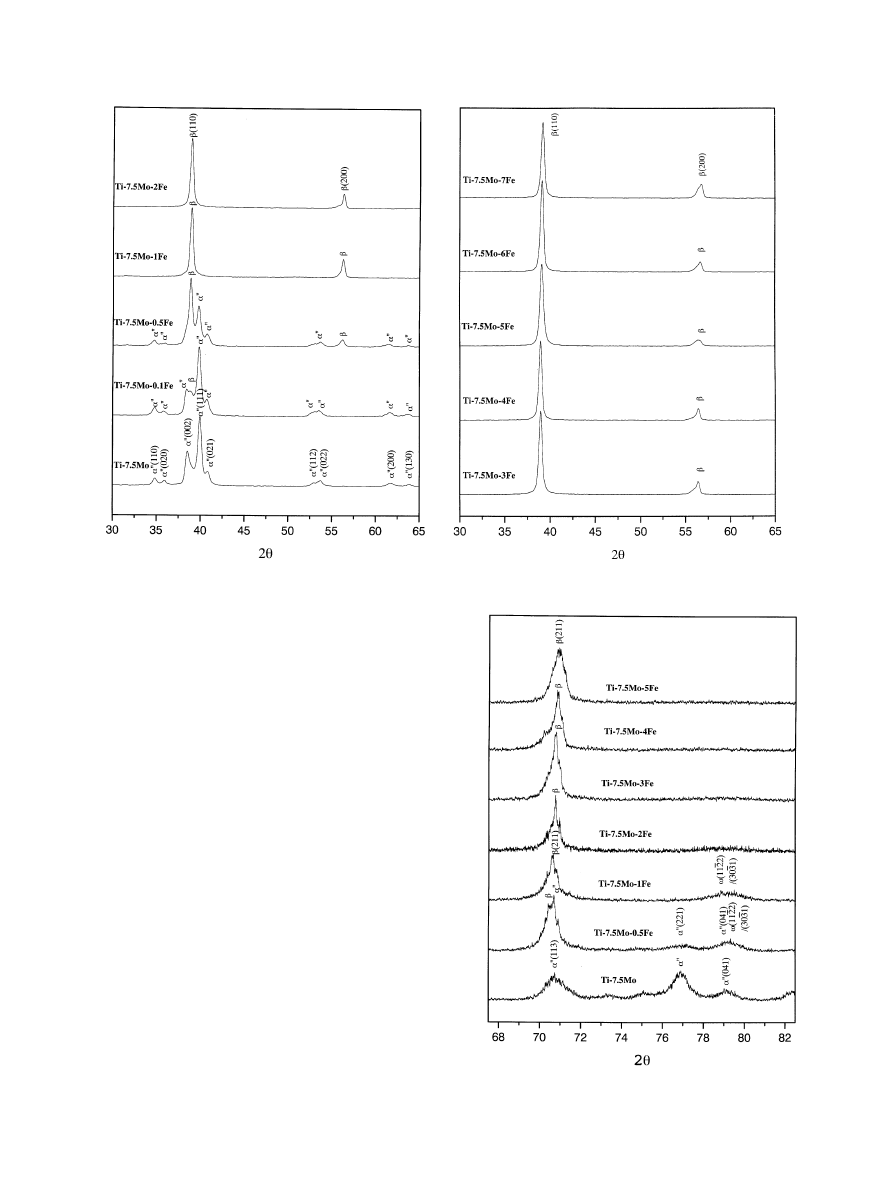

Fig. 3. Light micrographs of Ti–7.5Mo and Ti–7.5Mo–xFe alloys.

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1725

calibration of diffraction angles. Scanning speeds of 11/

min and 0.51/min were both used. The various phases

were identified by matching each characteristic peak in

the diffraction patterns with JCPDS files.

The microhardness of polished alloys was measured

using a Matsuzawa MXT70 microhardness tester at

200 g for 15 s. Average microhardness values were

obtained from at least 15 tests under each condition.

Three-point bending tests were performed using a desk-

top mechanical tester (Shimadzu AGS-500D, Tokyo,

Japan) operated at a crosshead speed of 0.5 mm/s.

Reduced size (36 5 1 mm) specimens were cut from

the castings and polished using sand paper to the #1000

level. The bending strengths were determined using

the equation, s ¼ 3PL=2bh

2

[23], where s is the

bending strength (MPa), P is the load (kg), L is the

span length (mm), b is the specimen width (mm), and

h

is the specimen thickness (mm). The modulus of

elasticity in bending was calculated from the load

increment and the corresponding deflection increment

between the two points on a straight line as far apart as

possible using the equation, E ¼ L

3

DP=4bh

3

Dd; where E

is the modulus of elasticity in bending (Pa), DP is the

load increment as measured from preload (N), and Dd is

the deflection increment at midspan as measured from

preload. The average bending strengths and moduli of

elasticity were taken from at least six tests under each

condition.

3. Results and discussion

3.1. X-ray diffraction

The XRDpatterns of Ti–7.5Mo as well as the series of

Ti–7.5Mo–x alloys are shown in Fig. 1. The binary Ti–

7.5Mo alloy was comprised primarily of metastable a

00

phase, consistent with an earlier report of Ho et al. [22].

This fast cooling-induced athermal orthorhombic struc-

ture was derived from a distorted hexagonal cell in

which the c-axis of the orthorhombic cell corresponds to

the c-axis of the hexagonal cell with a and b

corresponding to the orthogonal axis of the hexagonal

cell [24,25]. Athermal orthorhombic martensite, that can

precipitate on quenching without the assistance of

external stress, has also been reported in other Ti alloy

systems [26].

The effect of iron addition on phase/crystal structure

of the alloy was dramatic. As shown in Fig. 1, with as

little as 0.1 wt% of iron, a significant amount of b phase

was retained. At 1 wt%, the entire alloy became b phase

with a bcc crystal structure. As expected, TiFe

compound was not observed due to the low iron

contents in the alloys [27]. Iron has long been recognized

as a strong b-stabilizing element. In a recent study of a

series of cast binary Ti–Fe alloys, Lin et al. [27] found

that, when iron content was higher than about 5 wt%, b

phase was largely retained.

When the alloy contained iron of roughly between 0.5

and 2 wt%, a metastable o phase was present, as shown

in the lower scanning speed (0.51/min) XRDpatterns

(Fig. 2). The highest o phase intensity appeared in the

Ti–7.5Mo–1Fe alloy.

3.2. Microstructure

A typically etched microstructure under optical

microscope of Ti–7.5Mo and the series of Ti–7.5Mo–

x

Fe alloys are shown in Fig. 3. As shown in Fig. 3(a),

Ti–7.5Mo alloy exhibited a fine, acicular martensitic

structure (identified as a

00

phase by XRD), similar to

that observed by Ho et al. [22]. At 0.1 wt%, the b phase

was co-existent with a

00

phase (Fig. 3(b)). At 0.5 wt% Fe,

the amount of b phase increased and the two-phase

morphology became more obvious (Fig. 3(c)). At 1 wt%

or more iron, the entire alloy turned into an equi-axed b

phase structure (Figs. 3(d)–(j)). In other words, in Ti–

7.5Mo–xFe alloy system, b phase can be entirely

retained upon fast cooling when the iron content is

higher than roughly 1 wt%.

As indicated in Table 1, the b phase grain size

decreased with increasing iron content, possibly due to

an iron-grain boundary interaction that slowed down

the growth of the grain boundaries. The etched granular

structure of high iron alloys became more fuzzy as a

direct result of chemical microsegregation that occurred

during the formation of dendrites [28]. One-way

ANOVA statistical analysis indicates that significant

differences (p

o0:001) in grain size exist among 1, 3, 5

and 7 wt% Fe alloys. In their b phase Ti–14 V alloy,

Ankem and Greene [15] reported that reducing the grain

size reduced the twinning activity, which in turn led to a

reduction in creep strain.

The o phase particles were quite easily resolved by

TEM. Fig. 4 represents a typical microstructure and

selected-area diffraction (SAD) patterns of two selected

alloys, Ti–7.5Mo–1Fe and Ti–7.5Mo–3Fe. According to

Sikka et al. [29] and Collings [30], this o phase may be

defined by a hexgonal lattice with three atoms per unit

cell having coordinates (0 0 0), (1/3 2/3 2/3-z) and (2/3

Table 1

b phase grain sizes of Ti–7.5Mo–xFe alloys

a

Alloys

b grain size (mm)

Ti–7.5Mo–1Fe

46.3

75.8

Ti–7.5Mo–2Fe

40.0

75.6

Ti–7.5Mo–3Fe

23.5

72.5

Ti–7.5Mo–4Fe

22.6

72.4

Ti–7.5Mo–5Fe

19.0

72.9

Ti–7.5Mo–6Fe

13.1

72.1

Ti–7.5Mo–7Fe

13.6

71.0

a

Entries are mean

7standard deviation (NX30).

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1726

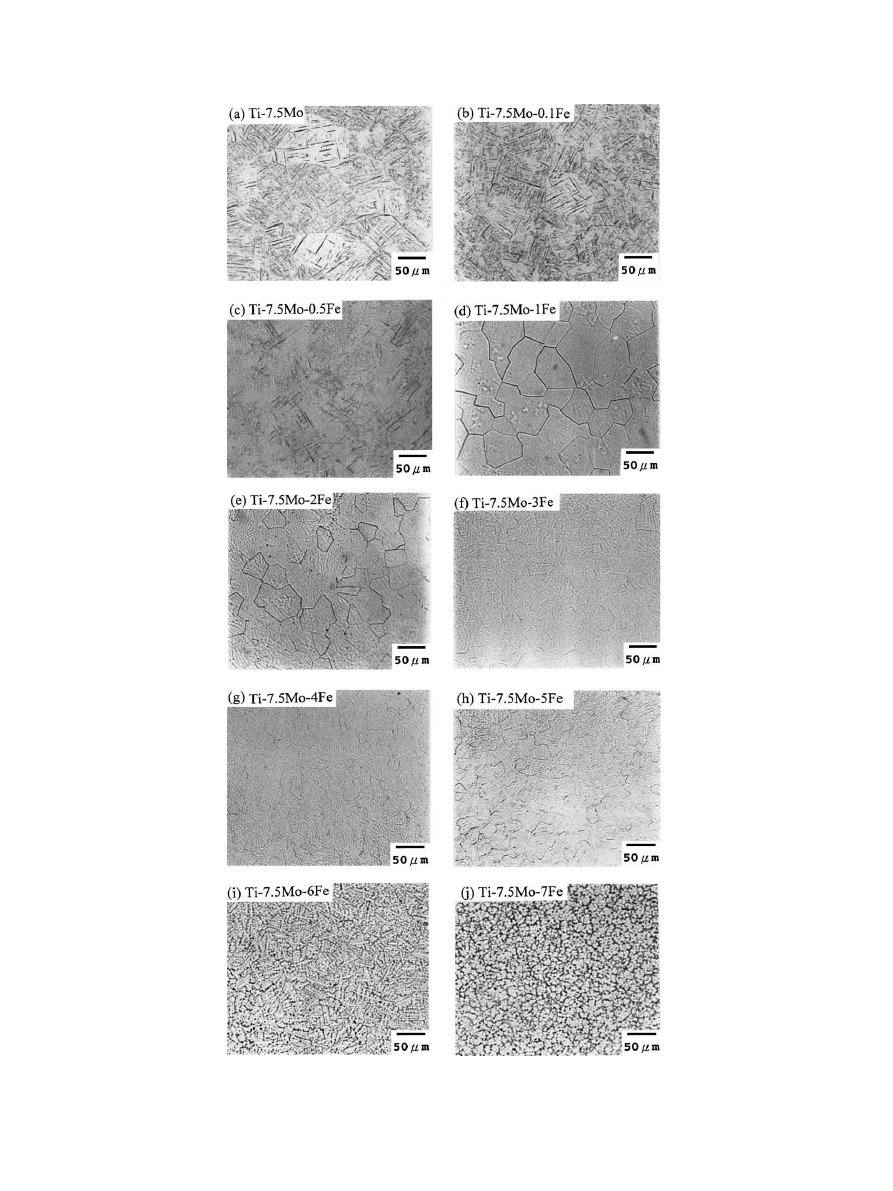

Fig. 4. TEM micrographs and SADpatterns. (a), (b) are, respectively, the dark field image and SADpattern of Ti–7.5Mo–1Fe alloy. (c), (d) are the

dark field image and SADpattern of Ti–7.5Mo–3Fe alloy.

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1727

1/3 1/3-z), wherein z describes the amount of {1 1 1}

b

plane shift along the plane normal and it ranges from 0

to

7(a

b

O3)/12/c

o

=

71/6 for the total collapse of two

neighboring planes. According to Bur

$sı´k’s definition

[32], the present z value was found to be 0.1664 for Ti–

7.5Mo–1Fe alloy and 0.1657 for Ti–7.5Mo–3Fe alloy, in

agreement with the result of Lin et al. [31] that, as solute

content decreased, z increased towards that for an ideal

o phase (1/6).

The overall diffraction patterns of the alloys are

consistent with the report of Sass [33] and indexed in

Fig. 4(e). The extra reflections as marked ‘+’ in Fig. 4(e)

are a result of double diffraction [33]. It was found

that the existence of o phase was always accompanied

with the broadening of diffraction spots as well as

diffuse streaks (diffuse scattering) [34–36] as a result of

an incomplete (1 1 1) plane collapse from b phase. The

fact that more diffuse scattering was found in Ti–

7.5Mo–3Fe than in Ti–7.5Mo–1Fe also indicated

that the hcp o structure was less ideal in the higher

iron alloy [29,37].

3.3. Microhardness

As indicated in Table 2, the a

00

phase-dominated Ti–

7.5Mo alloy had the lowest microhardness (300 HV),

while the alloys having iron contents in the neighbor-

hood of 1 wt% exhibited the highest microhardness level

(435 HV). As described earlier, the alloy comprising

1 wt% iron (Ti–7.5Mo–1Fe) had the largest content of o

phase. This clearly indicates that the o phase is a far

harder phase than a

00

or b phase. When the content of o

phase decreased, the hardness decreased. The slight

increase in hardness for Ti–7.5Mo–7Fe alloy might be

attributed to an increased solution hardening effect. In

lower iron alloys, this solution hardening effect was

probably overshadowed by the strong hardening effect

of o phase.

3.4. Bending strength and modulus

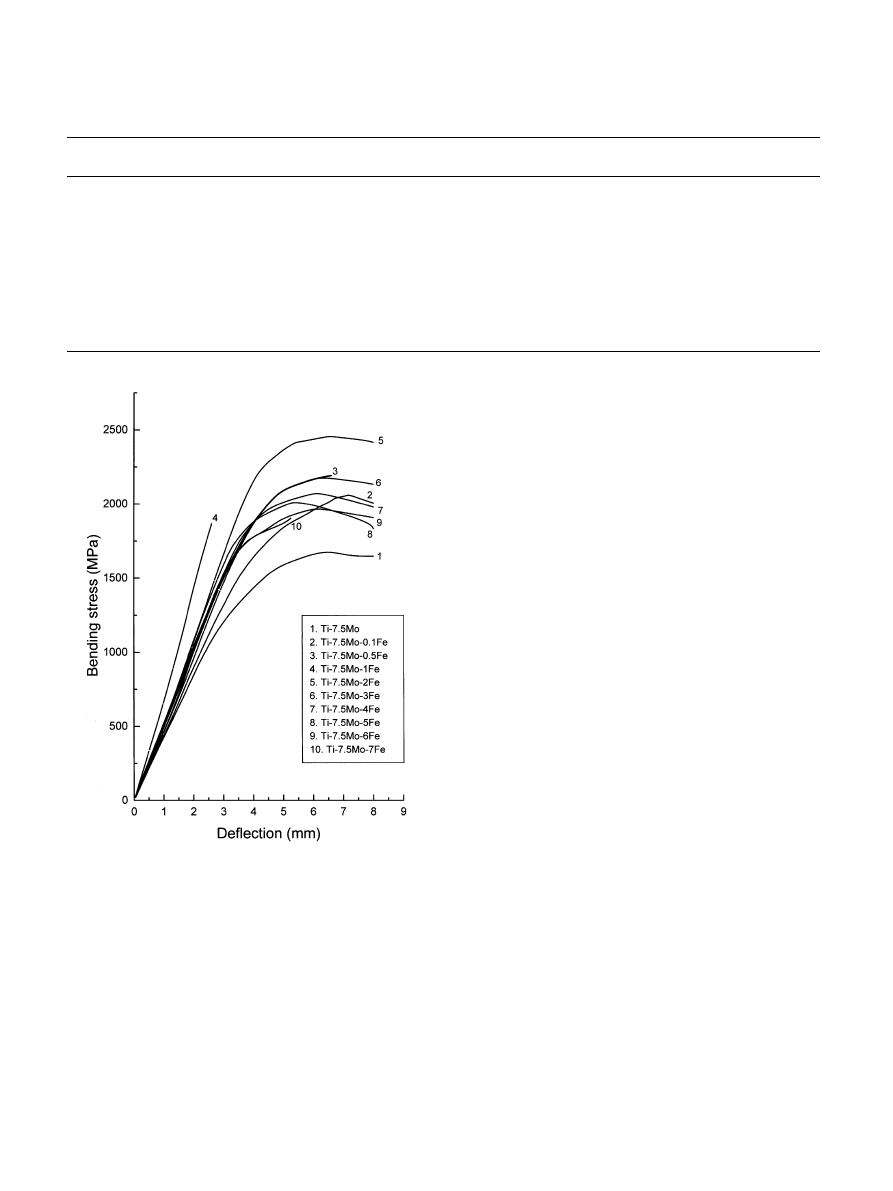

Typical bending stress–deflection profiles of the series

of alloys are shown in Fig. 5. The average bending

strengths and moduli of the alloys are compared in

Table 2, respectively. It is interesting to note that,

despite the strong hardening effect of o phase, the

bending strength of the alloy comprising the largest

amount of o phase (Ti–7.5Mo–1Fe) was lower than

those containing less o: This is due to the premature,

brittle fracture that occurred for Ti–7.5Mo–1Fe, but not

for alloys with other compositions (Fig. 5). This

Table 2

Mechanical properties of c.p.Ti, Ti–7.5Mo and Ti–7.5Mo–xFe alloys

Alloys

Hardness (HV)

Bending strength

(MPa)

Bending modulus

(GPa)

Strength/modulus ratio 1000

c.p.Ti

190.0

900

97

9.3

Ti–7.5Mo

300.8

1749

65

26.9

Ti–7.5Mo–0.1Fe

360.1

1990

72

27.6

Ti–7.5Mo–0.5Fe

428.6

2134

97

22

Ti–7.5Mo–1Fe

435.2

1902

111

17.1

Ti–7.5Mo–2Fe

403.1

2453

92

26.7

Ti–7.5Mo–3Fe

382.4

2201

85

25.9

Ti–7.5Mo–4Fe

364.5

2038

85

24.0

Ti–7.5Mo–5Fe

346.8

1994

89

22.4

Ti–7.5Mo–6Fe

348.5

1967

100

19.7

Ti–7.5Mo–7Fe

367.5

1851

98

18.9

Fig. 5. Bending stress–deflection profiles of Ti–7.5Mo and Ti–7.5Mo–

x

Fe alloys.

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1728

o-induced embrittlement of b phase was considered by

Williams et al. [36] as a result of a process of nucleation,

growth and coalescence of microvoids.

The embrittling/weakening effect was very sensitive to

the composition, or to be exact, to the iron content of

the alloy. As shown in Table 2, when the iron content

was only a little higher (Ti–7.5Mo–1.5Fe) or lower (Ti–

7.5Mo–0.5Fe) than 1 wt%, the weakening effect of o

phase largely diminished. Instead, its strengthening

effect prevailed. In this series of alloys the highest

bending strength was found in the alloy with 2 wt% iron

(2453 MPa). Like hardness, the alloy strength decreased

when the content of o phase decreased.

The a

00

phase-dominated binary Ti–7.5Mo alloy had a

bending strength (1749 MPa) and modulus (65 GPa)

lower than all those containing iron. The low modulus

nature of a

00

phase has been discussed in the literature

[22]. The lowest moduli of b-dominated alloys were

found in the alloys comprising roughly 3–4 wt% Fe

(85 GPa). The effect of o phase on modulus was not

influenced by its weakening effect. As shown in Table 2,

the alloy comprising the largest amount of o phase (Ti–

7.5Mo–1Fe)

had

the

highest

bending

modulus

(111 GPa),

despite

its

relatively

low

strength

(1902 MPa). Although the bending strength seems to

slightly decrease with iron content for high (roughly

higher than 5 wt%) iron alloys, their moduli increased

significantly. For example, when iron content increased

to 6 wt%, the modulus of the alloy increased to

100 GPa. These results indicate that, at high iron

contents, modulus is more sensitive to iron content than

strength.

From an engineering point of view, not only an iron

content of 1 wt% should be avoided, but also a uniform

distribution in iron is also important for such an alloy

system. When any process-induced segregation oc-

curred, o-induced embrittlement may occur in any local

regions which happen to have an iron concentration

near 1 wt%. To be practically used as an implant

material, a combination of high strength and low

modulus is often desired. As indicated in Table 2, the

alloys with iron contents from about 2 to 5 wt% seem to

have the greatest potential.

4. Conclusions

1. The a

00

phase-dominated Ti–7.5Mo alloy exhibited a

fine, acicular martensitic structure. When 0.1 wt%

iron was added, a significant amount of b phase was

retained. When 1 wt% or more iron was added, the

entire alloy became equi-axed b phase structure with

a grain size decreasing with increasing iron content.

2. When the alloy contained iron roughly between 0.5

and 2 wt%, an athermal o phase was formed. The

largest quantity of o phase was found in Ti–7.5Mo–

1Fe alloy. Compared to Ti–7.5Mo–1Fe, the Ti–

7.5Mo–3Fe alloy had a smaller amount of o phase

with a smaller particle size and less ideal crystal

structure.

3. Binary Ti–7.5Mo alloy had a lower microhardness,

bending strength and modulus than all iron-contain-

ing alloys. The alloys with iron contents closer to

1 wt% exhibited the highest microhardness level.

Despite the strong hardening effect of o phase, the

bending strength of Ti–7.5Mo–1Fe alloy was rela-

tively low due to its premature, brittle fracture. The

highest bending strength was found in Ti–7.5Mo–2Fe

alloy.

4. The present alloys with iron contents from about 2 to

5 wt% seem to have a great potential for use as an

implant material.

References

[1] Ida K, Tani Y, Tsutsumi S, Togaya T, Nambu T, Suese K,

Kawazoe T, Nakamura M. Clinical application of pure titanium

crown. Dent Mater J 1985;4:191–5.

[2] van Noort R. Titanium: the implant material of today. J Mater

Sci 1987;22:3801–11.

[3] Lautenschlager EP, Monaghan P. Titanium and titanium alloys

as dental materials. Int Dent J 1993;43:245–53.

[4] Huckstep RL. Early mobilization and rehabilitation in orthopae-

dic conditions. Aust NZ J Surg 1977;47(3):344–53.

[5] Imam MA, Fraker AC. Titanium alloys as implant materials. In:

Brown SA, Lemons JE, editors. Medical applications of titanium

and its alloys: the material and biological issues ASTM STP, vol.

1272. West Conshohocken: ASTM, 1996. p. 3–16.

[6] Rao S, Ushida T, Tateishi T, Okazaki Y, Asao S. Effect of Ti, Al,

and V ions on the relative growth rate of fibroblasts (L929) and

osteoblasts (MC3T3-E1) cells. Biomed Mater Eng 1996;6:79–86.

[7] Walker PR, LeBlanc J, Sikorska M. Effects of aluminum and

other cations on the structure of brain and liver chromatin.

Biochemistry 1989;28:3911–5.

[8] Yumoto S, Ohashi H, Nagai H, Kakimi S, Ogawa Y, Iwata Y,

Ishii K. Aluminum neurotoxicity in the rat brain. Int J PIXE

1992;2(4):493–504.

[9] Zardiakas LD, Michell DW, Disegi JA. Characterization of Ti–

15Mo beta titanium alloy for orthopaedic implant applications.

In: Brown SA, Lemons JE, editors. Medical applications of

titanium and its alloys: the material and biological issues, ASTM

STP, vol. 1272. West Conshohocken: ASTM, 1996. p. 60–75.

[10] Mishra AK, Davidson JA, Poggie RA, Kovacs P, FitzGerald TJ.

Mechanical and tribological properties and biocompatibility of

diffusion hardened Ti–13Nb–13Zr

Fa new titanium alloy for

surgical implants. In: Brown SA, Lemons JE, editors. Medical

applications of titanium and its alloys: the material and biological

issues, ASTM STP, vol. 1272. West Conshohocken: ASTM, 1996.

p. 96–113.

[11] Wang KK, Gustavson LJ, Dumbleton JH. Microstructure and

properties of a new beta titanium alloy, Ti–12Mo–6Zr-2Fe,

developed for surgical implants. In: Brown SA, Lemons JE,

editors. Medical applications of titanium and its alloys: the

material and biological issues, ASTM STP, vol. 1272. West

Conshohocken: ASTM, 1996. p. 76–87.

[12] Ito A, Okazaki Y, Tateishi T, Ito Y. In vitro bio-compatibility,

mechanical properties, and corrosion resistance of Ti–Zr–Nb–Ta–

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1729

Pd

and

Ti–Sn–Nb–Ta–Pd

alloys.

J

Biomed

Mater

Res

1995;29:893–900.

[13] Donachie MJ, editor. Titanium: a technical guide, vol. 31. ASM

International: Metal Park, OH, 1989. p. 218.

[14] Weiss I, Semiatin SL. Thermomechanical processing of beta

titanium alloys

Fan overview. Mater Sci Eng A 1998;243:46–65.

[15] Ankem S, Greene SA. Recent developments in microstructure/

property relationships of beta titanium alloys. Mater Sci Eng A

1999;263:127–31.

[16] Sumner DR, Galante JO. Determinants of stress shielding: design

versus materials versus interface. Clin Orthop Relat Res

1992;274:202–12.

[17] Cheal E, Spector M, Hayes W. Role of loads and prosthesis

material properties on the mechanics of the proximal femur after

total hip arthroplasty. J Orthop Res 1992;10:405–22.

[18] Prendergast P, Taylor D. Stress analysis of the proximo-medical

femur after total hip replacement. J Biomed Eng 1990;12:379–82.

[19] Wang K. The use of titanium for medical applications in the

USA. Mater Sci Eng A 1996;213:134–7.

[20] Niinomi M. Mechanical properties of biomedical titanium alloys.

Mater Sci Eng A 1998;243:231–6.

[21] Long M, Rack HJ. Titanium alloys in total joint replacement

Fa

materials science perspective. Biomaterials 1998;19:1621–39.

[22] Ho WF, Ju CP, Chern lin JH. Structure and properties of cast

binary Ti–Mo alloys. Biomaterials 1999;20:2115–22.

[23] Guha A. Metals handbook, 9th ed.,vol. 8, 1985. p. 133–6.

[24] Bagariaskii IA, Nosova GI, Tagunova TV. Factors in the

formation of metastable phase in titanium-based alloys [Engl.

trans.]. Sov Phys Dokl 1959;3:1014–8.

[25] Brown ARG, Clark D, Eastabrook J, Jepson KS. The titanium–

niobium system. Nature 1964;201:914–5.

[26] Baker C. Shape memory effect in a Ti–35Nb alloy. Metal Sci J

1971;5:92–100.

[27] Lin DJ, Ju CP, Chern lin JH. Structure and properties of cast Ti–

Fe alloys. AFS Trans 1999;216:859–64.

[28] Kurz W, Fisher DJ. Fundamentals of solidification, Switzerland,

vol. 13. Trans Tech Publications, 1992.

[29] Sikka SK, Vohra YK, Chidambaram R. Omega phase in material.

Progr Mater Sci 1982;27:245–310.

[30] Collings EW. Physical metallurgy of titanium alloys: revised from

‘‘The physical metallurgy of titanium alloys. (ASM International,

1984)’’ and ‘‘Introduction to titanium alloys design’’ in alloys

(ASM International, 1988). Columbus, OH: Battelle Memorial

Institute, USA. p. 43.

[31] Lin W, Spalt H, Batterman BW. Study of the omega phase in Zr–

Nb alloys by mossbauer and X-ray diffuse scattering. Phys Rev B

1976;13:5158–69.

[32] Bur

$sı´k J, Weatherly GC. Transformation of the b-(Ti,V) phase in

Ti–V–C alloys. Scripta Mater 1999;40:1381–6.

[33] Sass SL. The o phase in a Zr–25 at % Ti alloy. Acta Metall

1969;17:813–20.

[34] Dawson CW, Sass SL. The as-quenched form of the omega phase

in Zr–Nb alloys. Metall Trans 1970;1:2225–33.

[35] Sass SL, Borie B. Symmetry of the structure of the omega phase in

Zr and Ti alloys. J Appl Crytall 1972;5:236–8.

[36] Williams JC, de Fontaine D, Paton NE. The o phase as an

unusual shear transformation. Metall Trans 1973;4:2701–8.

[37] Collings EW, Ho JC, Jaffee RI. Superconducting transition

temperature, lattice instability and electron-to-atom ratio in

transition-metal binary solid solutions. Phys Rev B 1972;

5:4435–49.

D.J. Lin et al. / Biomaterials 23 (2002) 1723–1730

1730

Wyszukiwarka

Podobne podstrony:

Crystal structure and properties of the copper(II) complex of sodium monensin A

Walker The Production, Microstructure, and Properties of Wrought Iron (2002)

Structure and reactivity of alkenes and alkynes

Fibrillar Structure and Mechanical Properties of Collagen

71 1021 1029 Effect of Electron Beam Treatment on the Structure and the Properties of Hard

Guide to the properties and uses of detergents in biology and biochemistry

Modeling of Polymer Processing and Properties

Syntheses, structural and antimicrobial studies of a new N allylamide

Characteristic and adsorption properties of iron coated sand

52 737 754 Relationship Between Microstructure and Mechanical Properts of a 5%Cr Hot Works

32 425 436 Ifluence of Vacuum HT on Microstructure and Mechanical Properties of HSS

Mechanical Properties of Native and Cross linked Type I Collagen Fibrils Yang

Effect of heat treatment on microstructure and mechanical properties of cold rolled C Mn Si TRIP

Guide to the properties and uses of detergents in biology and biochemistry

Modeling of Polymer Processing and Properties

Microstructure and mechanical properties of plasma sprayed H

The Structure and the Unity of Beowulf Arthur G Brodeur

więcej podobnych podstron