417 (11)

390

Dress Accessońes

positions which show some overlap between alloys. However, any overlap is not particularly significant in the description of the overall pattern of alloy types.

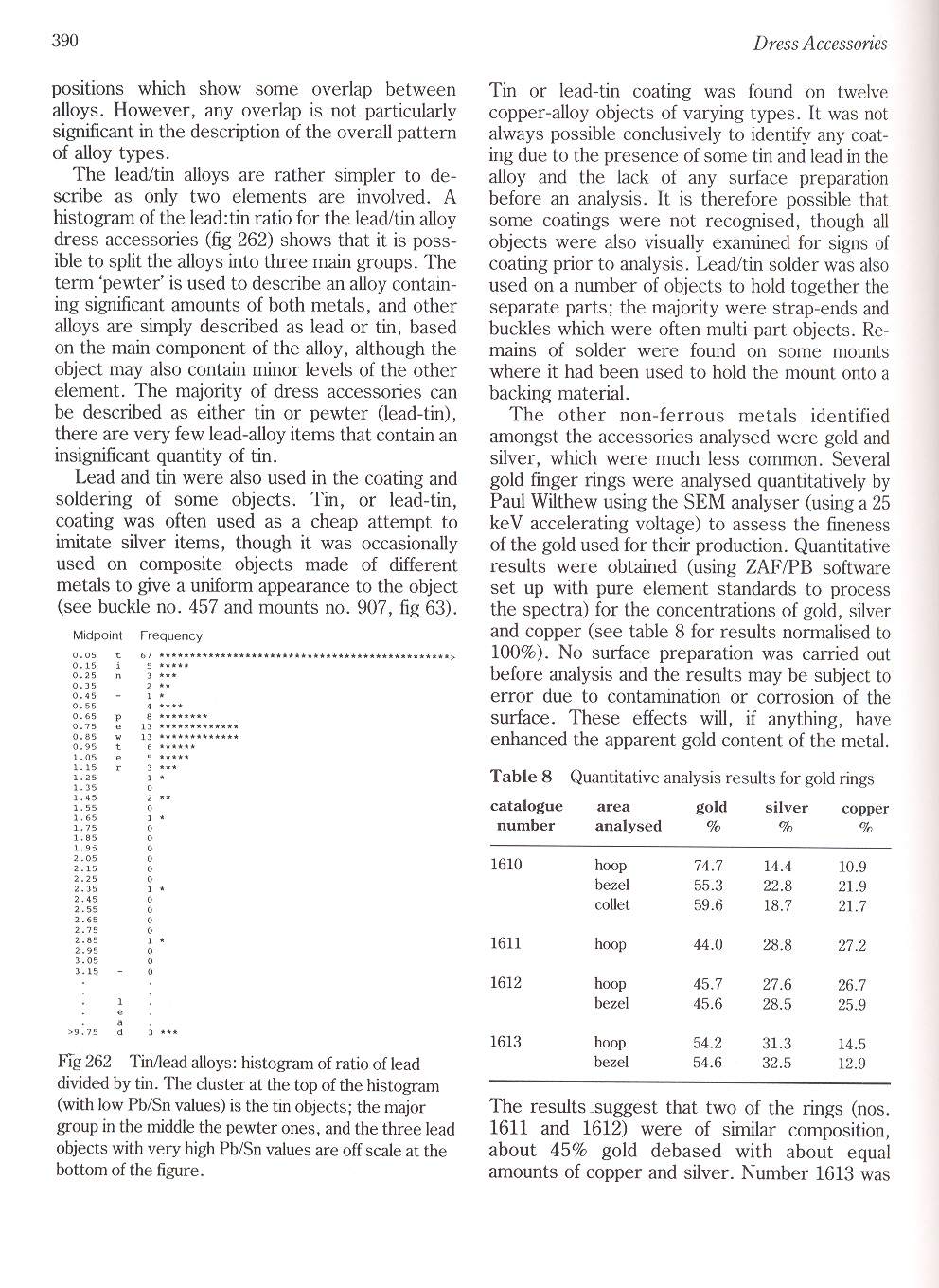

The lead/tin alloys are rather simpler to de-scribe as only two elements are involved. A histogram of the lead:tin ratio for the lead/tin alloy dress accessories (fig 262) shows that it is poss-ible to split the alloys into three main groups. 'l'he term ‘pewter’ is used to describe an alloy contain-ing significant amounts of both mctals, and other alloys are simply described as lead or tin, based on the main component of the alloy, although the object may also contain minor levels of the other element. The majority of dress accessories can be described as either tin or pewter (lead-tin), there are very few lead-alloy items that contain an insignificant ąuantity of tin.

Lead and tin were also used in the coating and soldering of some objects. Tin, or lead-tin, coating was often used as a cheap attempt to imitate silver items, though it was occasionally used on composite objects madę of different metals to give a uniform appearance to the object (see buckie no. 457 and mounts no. 907, fig 63).

Midpoint Freguency

0,05 t 67 ***********************************************>

0.55 4 ****

0.65 p 8 ********

0.75 e 13 *************

0.85 w 13 *************

0.95 t 6 ******

>9.75 d 3 ***

FTg 262 Tin/lead alloys: histogram of ratio of lead divided by tin. The duster at the top of the histogram (with Iow Pb/Sn values) is the tin objects; the major group in the middle the pewter ones, and the three lead objects with very high Pb/Sn values are off scalę at the bottom of the figurę.

Tin or lead-tin coating was found on twelve copper-alloy objects of varying types. It was not always possible conclusively to identify any coating due to the presence of some tin and lead in the alloy and the lack of any surface preparation before an analysis. It is therefore possible that some coatings were not recognised, though all objects were also visually examined for signs of coating prior to analysis. Lead/tin solder was also used on a number of objects to hołd together the separate parts; the majority were strap-ends and buckles which were often multi-part objects. Re-mains of solder were found on some mounts where it had been used to hołd the mount onto a backing materiał.

The other non-ferrous metals identified amongst the accessories analysed were gold and silver, which were much less common. Several gold finger rings were analysed quantitatively by Paul Wilthew using the SEM analyser (using a 25 keV accelerating voltage) to assess the fineness of the gold used for their production. Quantitative results were obtained (using ZAF/PB software set up with pure element standards to process the spectra) for the concentrations of gold, silver and copper (see table 8 for results normalised to 100%). No surface preparation was carried out before analysis and the results may be subject to error due to contamination or corrosion of the surface. These effects will, if anything, have enhanced the apparent gold content of the metal.

Table 8 Quantitative analysis results for gold rings

|

catalogue number |

area analysed |

gold % |

silver % |

copper % |

|

1610 |

hoop |

74.7 |

14.4 |

10.9 |

|

bezel |

55.3 |

22.8 |

21.9 | |

|

collet |

59.6 |

18.7 |

21.7 | |

|

1611 |

hoop |

44.0 |

28.8 |

27.2 |

|

1612 |

hoop |

45.7 |

27.6 |

26.7 |

|

bezel |

45.6 |

28.5 |

25.9 | |

|

1613 |

hoop |

54.2 |

31.3 |

14.5 |

|

bezel |

54.6 |

32.5 |

12.9 |

The results .suggest that two of the rings (nos. 1611 and 1612) were of similar composition, about 45% gold debased with about equal amounts of copper and silver. Number 1613 was

Wyszukiwarka

Podobne podstrony:

427 (11) 400 Dress AccessoriesAcknowledgements In a work of tliis size and comp!exity the principal

413 (9) 386 Dress Accessories lining, which was presumably glued into place, so that the lining proj

310 (36) 282 182 Lace chapes: terminology Dress Accessories O edge to edge seam overlapping seam end

416 (14) 389Metallurgical Analysis of the Dress Accessories Lead Lead Fig 258 Ali copper alloys. Eac

259 (35) 230 Dress Accessońes large enough, and some seem to be specifically shaped to cater for a s

296 (37) 268 Dress Accessońes Brooches with circular frames Leaf 1374 BC72 2037 (83) 11 fig 174 Poss

322 (32) 294 Dress Accessories Unthrown silk was bound round the wire in at least 11 examples (nos.

422 (13) Metallurgical Analysis of the Dress Accessories site form which include a forked spacer san

359 (16) 332 Dress Accessońes which to produce a finger ring, it is not a solitary example. Another

377 (19) 350 Dress Accessońes 1700 BC72 2822 (150) 11 fig 231 Pouch madę from a rectangular strip of

397 (13) 370 Dress Accessońes piąte were held securely in position (fig 247). A further feature of t

Shuttle Tatting Without A Teacher (11) The smali motif on which we will be working is for practice p

274 (42) Dress Accessońes 246 1078 805 1095 (A) mounts with fields of dots (1:1) (

276 (40) 248 Dress Accessońes because no indication has been recognized on them of the wearer’s adhe

278 (40) 250 Dress Accessories 1314 1311 SWA81 2186 (2055) 9 fig 160 Corroded

284 (41) 256 Dress Accessońes Hooked annular brooch Copper alloy 1338 SWA81 acc. no. 1493 (context

286 (34) 258 Dress Accessońes 166 Pentagonal, hexagonal and six-lobed brooches -odginał shapes resto

292 (37) 264 Dress Accessories 1365 171 Yiolet brooches (drawings 1:1, photograph 2:1) (?)flower bud

więcej podobnych podstron