Biosystems Engineering (2006) 93 (4), 403–413

doi:10.1016/j.biosystemseng.2006.01.017

PH—Postharvest Technology

Microwave Drying of Parsley: Modelling, Kinetics, and Energy Aspects

Y. Soysal

1

; S. O¨ztekin

2

; O¨. Eren

1

1

Department of Agricultural Machinery, Faculty of Agriculture, Mustafa Kemal University, Tayfur Sokmen Campus, 31040 Antakya, Hatay,

Turkey; e-mail: ysoysal@mku.edu.tr

2

Department of Agricultural Machinery, Faculty of Agriculture, C¸ukurova University, 01330 Balcalı, Adana, Turkey

(Received 23 March 2005; accepted in revised form 27 January 2006; published online 20 March 2006)

Parsley (Petroslinum crispum Mill.) leaves were dried in a 900 W 2450 MHz domestic microwave oven to assess

the effects of material load on drying time, drying rate, drying efficiency, and specific energy consumption.

Microwave drying experiments with different material loads ranging from 6430 to 12857 g were performed at

microwave power cycle of 9 s on/9 s off at 900 W microwave output power. Drying took place mainly in

constant rate and falling rate periods. A relatively long constant rate period was observed after a short heating

period. Among the 11 mathematical models tested to fit the drying rates of parsley leaves, the Midilli et al.

model with drying rate as a log–log and linear function of time gave the best fit for all the data points. The

value of the drying coefficient k decreased with the increase in the dried material load. The multiple regression

on the coefficients of the Midilli et al. model for the effects of material load being dried gave the successful

results and showed to satisfactorily represent microwave drying kinetics of parsley leaves for the material

loads between 6430 g and 12857 g. Increasing the material load resulted in a considerable increase in drying

efficiency and a significant decrease in specific energy consumption. About 95% increase in drying efficiency

and about 18% (092 MJ kg

1

[H

2

O]) decrease in specific energy consumption could be obtainable by

increasing the material load from 6430 to 12857 g.

r

2006 Silsoe Research Institute. All rights reserved

Published by Elsevier Ltd

1. Introduction

The fresh or dried leaves, roots, and seeds of parsley

are widely used in the food, cosmetic, and pharmaceu-

tical industries to produce spice, essential oils, and

drugs. The dried leaves known as parsley flakes are

particularly used in the instant food sector as an

ingredient to flavour soups and sausages.

Natural drying (drying in the shade) and hot air

drying are still the best known and widely used methods

of drying. Natural drying has many disadvantages due

to the inability to handle the large quantities and to

achieve consistent quality standards (

). The major drawbacks of conventional hot air

drying are the low energy efficiency and lengthy drying

time during the last stage of drying. For example,

carried out the drying experiments for sweet

basil, pesto basil, marjoram, lemongrass, and parsley in

a hot air dryer with a capacity of 500 g fresh leaf

materials. It was reported that the hot air drying process

to attain the moisture content of 10% wet basis (wb)

took 18, 15, 6, and 5 h for 30, 40, 50, and 65 1C drying

air temperatures, respectively. It was also stated that the

drying temperature of 40 1C was ideal for drying parsley

regarding that colour is of primary importance in dried

herbs. Furthermore, in drying of leafy herbs, high initial

moisture contents up to 85% wb and low drying air

temperatures cause relatively high specific energy con-

sumption values up to 10 MJ kg

1

[H

2

O] (

).

carried out bulk drying

experiments for peppermint, sage and hops in a green-

house type solar dryer with a capacity of 3 tonnes fresh

material. They reported that the specific energy con-

sumption for peppermint, sage and hops were 864, 936,

and 558 MJ kg

1

[H

2

O], respectively.

, performed batch drying experiments in

a tray type dryer with 145 kg of Mentha piperita and

120 kg of Hypericum perforatum. The specific energy

ARTICLE IN PRESS

1537-5110/$32.00

403

r

2006 Silsoe Research Institute. All rights reserved

Published by Elsevier Ltd

consumption

of

the

dryer

for

M.

piperita

and

H. perforatum were reported as 4480 and 7694 MJ

kg

1

[H

2

O], respectively.

In general, energy efficiency in drying is closely related

to drying times. Compared to hot air drying, microwave

or hybrid/combined microwave drying techniques can

greatly reduce the drying time of biological materials

without quality degradation (

;

). Parsley like many

other agricultural crops is very attractive for microwave

drying as it contains high level of moisture.

studied the microwave drying of parsley leaves

with different microwave output power levels ranging

from 360 to 900 W. It was shown that by performing

microwave drying at 900 W output power instead of 30,

40, 50, and 65 1C hot air drying up to the moisture

content of 010 db, the drying time can be shortened

by 111, 92, 37, and 31 fold, respectively. The author

further stated that no significant difference was found

between the colour of fresh and microwave dried leaf

materials, except some decrease in brightness. Hence,

application of microwave energy to dry agricultural

materials may be a good approach to overcome certain

drawbacks of conventional drying techniques (

There has been extensive research on microwave

drying examining a broad spectrum of fruits and

vegetables (

;

;

;

). However, most of the literature presents

the quality of dried product, drying kinetics, dielectric

properties, application of the microwaves, and the

microwave heating mechanism. In addition, a number

of successful drying models have been developed to

explain the convective drying kinetics of various

agricultural products for use in design, construction,

and control of drying systems. However, less effort has

been made on the modelling of microwave drying

process including the process parameters embedded into

the drying model to explain the influence of process

variables on microwave drying kinetics. Only the New-

ton and the Page equations were used in some studies to

describe the microwave drying kinetics of the several

materials including: banana (

), pear

), carrot (

), kiwi (

), garlic (

Sharma &

), grape

), parsley (

), model

fruit gel (

), and olive pomace (

Moreover, a number of successful microwave drying

attempts have been done at a research level (

). Nevertheless, microwave drying of fruits

and vegetables is still in its initial phase of acceptance in

industry due to the high initial costs and a lack of

documented energy analysis (

). Several

strategies have been suggested and applied by some

researchers to enhance the energy utilisation in micro-

wave drying (

;

;

). These

are: (a) combination of microwave and conventional

drying systems; (b) vacuum microwave drying to lower

the drying temperature; and (c) as opposed to contin-

uous exposure, pulsed or intermittent application of

microwave energy to avoid the overheating and improve

the energy efficiency.

In the research of

, the specific

energy consumption value was about 8115–9035 MJ

kg

1

[H

2

O] for convective drying of grapes. It is stated

that under similar convective conditions by the im-

plementation of microwave, the energy consumption

reduced to values ranging from 711 to 2432 MJ kg

1

[H

2

O] depending on the process conditions.

reported that despite the

increase in total drying time of corn, intermittent

microwave drying yielded the product of higher quality

and reduced the energy consumption by reducing the

total microwave exposure time as compared to contin-

uous microwave drying.

Yongsawatdigul and Gunasekaran (1996)

studied

microwave vacuum drying of cranberries and showed

the pulsed application of microwave is more energy

efficient than the continuous application. The most

favourable value of specific energy consumption was

obtained at microwave power cycle of 30 s on/150 s off

at 250 W microwave output power. The mean value of

the specific energy consumption under this condition

was 266 MJ kg

1

[H

2

O] that indicates an improvement

of about 40–60% over conventional hot air drying and

about 46% over continuous microwave vacuum drying

(490 MJ kg

1

[H

2

O]).

used combined microwave–hot

air drying for finish drying of osmotically dehydrated

cranberries and compared the effects of power densities

(075, 10, 125 W/g and power cycles of 30 s on/30 s off

and 30 s on/60 s off at 750 W microwave output power)

on the specific energy consumption and the quality of

product. Both microwave cycling period and applied

power density in intermittent microwave drying influ-

enced the energy consumption. It was concluded that

the combination of 075 W/g with cycling period of 30 s

on/60 s off was appropriate to dry cranberries in terms

of energy efficiency (90 MJ kg

1

[H

2

O]) and quality of

dried product.

ARTICLE IN PRESS

Y. SOYSAL ET AL.

404

Apparently, microwave drying offers high potential

for savings in energy and time due to the volumetric

heating throughout the volume of the material ‘targeting’

mostly water, (

). However,

there are two issues that need to be thoroughly clarified:

(a) research on the efficiency of microwave drying

concerning both energy and time of process is very

limited; and

(b) modelling of the microwave drying process including

the process variables embedded into the drying

model has not completely been studied.

Therefore, the aims of the present work were to:

(a) determine the effects of material load on the

efficiency of microwave drying including drying

time, drying rate, drying efficiency, and specific

energy consumption;

(b) compare the fitting ability of several drying equa-

tions to express the drying kinetics of parsley leaves

with the most suitable drying model; and

(c) describe the whole process in a general drying model

by embedding the effects of material load on the

coefficients of the best fitting model for the purpose

of simulation and scaling up of the process.

2. Materials and methods

2.1. Material

Fresh green parsley (Petroselinum crispum Mill.) leaves

used for the drying experiments were obtained from a

grower in the Hatay region of Turkey. The samples were

stored at 4

705 1C before they were used in experiments.

Prior to each of drying experiments, the samples were

taken out of storage and leaves from stems were

separated. Three 30 g leaf samples were dried in an oven

at 105 1C for 24 h to determine initial moisture content.

The initial moisture content of the parsley leaves were

ranged from 494 to 511 kg [H

2

O] kg

1

[dry matter, DM].

2.2. Drying equipment and experimental procedure

A programmable domestic microwave oven (Galanz

WP900AL23-Z1, China) with maximum output of 900

W at 2450 MHz was used for the drying experiments.

The dimensions of the microwave cavity were 215 mm

by 350 mm by 330 mm.The oven has a fan for air flow in

drying chamber and cooling of magnetron. The

moisture from drying chamber was removed with this

fan by passing it through the openings on the right side

of the oven wall to the outer atmosphere. The oven was

fitted with a glass turntable (314 mm diameter) and had

a digital control facility to adjust the microwave output

power by the 10% decrements and the time of

processing. The microwave oven power was set to cyclic

heating with 50% rating. This provided an intermittent

heating for a period of 9 s, followed by a pause for 9 s.

Six different amount of material loads (12857, 11240,

9990, 9010, 7513, and 6430 g) were investigated in

drying experiments at microwave power cycle of 9 s on/

9 s off at 900 W. The fresh leaf materials were uniformly

spread on the turntable inside the microwave cavity, for

an even absorption of microwave energy. Three

replicates were carried out for each experiment accord-

ing to preset time schedule based on the preliminary

tests. Depending on the drying conditions, moisture loss

was recorded at 1 or 3 min intervals during drying at the

end of power-on time by removing the turntable from

the microwave, and placing this, along with the leaf

sample on the digital balance (

The microwave power was applied until the mass of

the sample reduced to a level corresponding to a

moisture content of about 010 kg [H

2

O] kg

1

[DM].

2.3. Mathematical modelling of microwave drying curves

To determine the most suitable drying equation, the

microwave drying curves were fitted to experimental

data using 11 different moisture ratio M

R

equations

(

). The equilibrium moisture content M

e

was

assumed to be zero for microwave drying, so that the

moisture ratio M

R

was simplified to M=M

0

instead of

the

M M

e

ð

Þ

= M

0

M

e

ð

Þ

), where M

0

is the initial moisture content in kg

[H

2

O] kg

1

[DM] and M is the moisture content at any

time in kg [H

2

O] kg

1

[DM] and M

e

is the equilibrium

moisture content in kg [H

2

O] kg

1

[DM].

The root mean square error E

RMS

and the modelling

efficiency Z

m

were used as the primary criterion to select

the best equation expressing the microwave drying curves

of parsley (

). The E

RMS

gives the deviation between the predicted

and experimental values. The lower the values of the

E

RMS

, the better the goodness of fit. The value for Z

m

, on

the other hand, determines the fitting ability of the

equation and it is required to reach 1 for the best results.

These statistical criterions can be calculated as follows:

E

RMS

¼

1

N

X

N

i¼1

M

R;cal;i

M

R;exp;i

2

"

#

1=2

(1)

Z

m

¼

P

N

i¼1

M

R;exp;i

M

R;exp;av

2

P

N

i¼1

M

R;cal;i

M

R;exp;i

2

P

N

i¼1

M

R;exp;i

M

R;exp;av

2

(2)

ARTICLE IN PRESS

MICROWAVE DRYING OF PARSLEY

405

where: E

RMS

is the root mean square error; M

R;exp;i

is the

ith experimental moisture ratio; M

R;cal;i

is the ith

predicted moisture ratio; N is the number of observa-

tions; and M

R;exp;av

is the mean value of the experi-

mental moisture ratio.

In this study, the effect of material load on the

coefficients of the drying expression was also investi-

gated by multiple regression analysis. The coefficients of

the best fitting model involving the material load were

determined by investigating multiple combinations of

the different type of equations as simple linear,

logarithmic, exponential, power, arrhenius and rational.

2.4. Determination of the energy efficiency of microwave

drying

Effect of material load on the energy efficiency of

microwave drying at microwave power cycle of 9 s on/9 s

off at 900 W was evaluated by two different efficiency

indices as microwave drying efficiency in % and specific

energy consumption in MJ kg

1

[H

2

O]. The microwave

drying efficiency [Eqn (3)] was calculated as the ratio of

heat energy utilised for evaporating water from the

sample to the heat supplied by the microwave oven

(

Yongsawatdigul & Gunasekaran, 1996

Mousa &

). The cumulative drying efficiency values

were calculated as the averaged energy consumption for

water evaporation divided by the supplied microwave

energy in the, total power-on time t

on

in s:

Z

d

¼

m

w

l

w

PDt

on

100

(3)

where: Z

d

is the microwave drying efficiency in %; m

w

is

the mass of evaporated water in kg; l

w

is the latent heat

of vaporisation of water in J kg

1

; P is the average

microwave power in W; and Dt

on

is the time interval in s.

The latent heat of vaporisation of water at the

evaporating temperature (100 1C) was taken as 2257

kJ kg

1

The specific energy consumption [Eqn (4)] was

calculated as the energy needed to evaporate a unit

mass of water (

Yongsawatdigul & Gunasekaran, 1996

Q

s

¼

t

on

P 10

6

m

w

(4)

where: Q

s

is the specific energy consumption to

evaporate a unit mass of water from the product in

MJ kg

1

[H

2

O].

3. Results and discussion

3.1. Effect of material load on drying kinetics

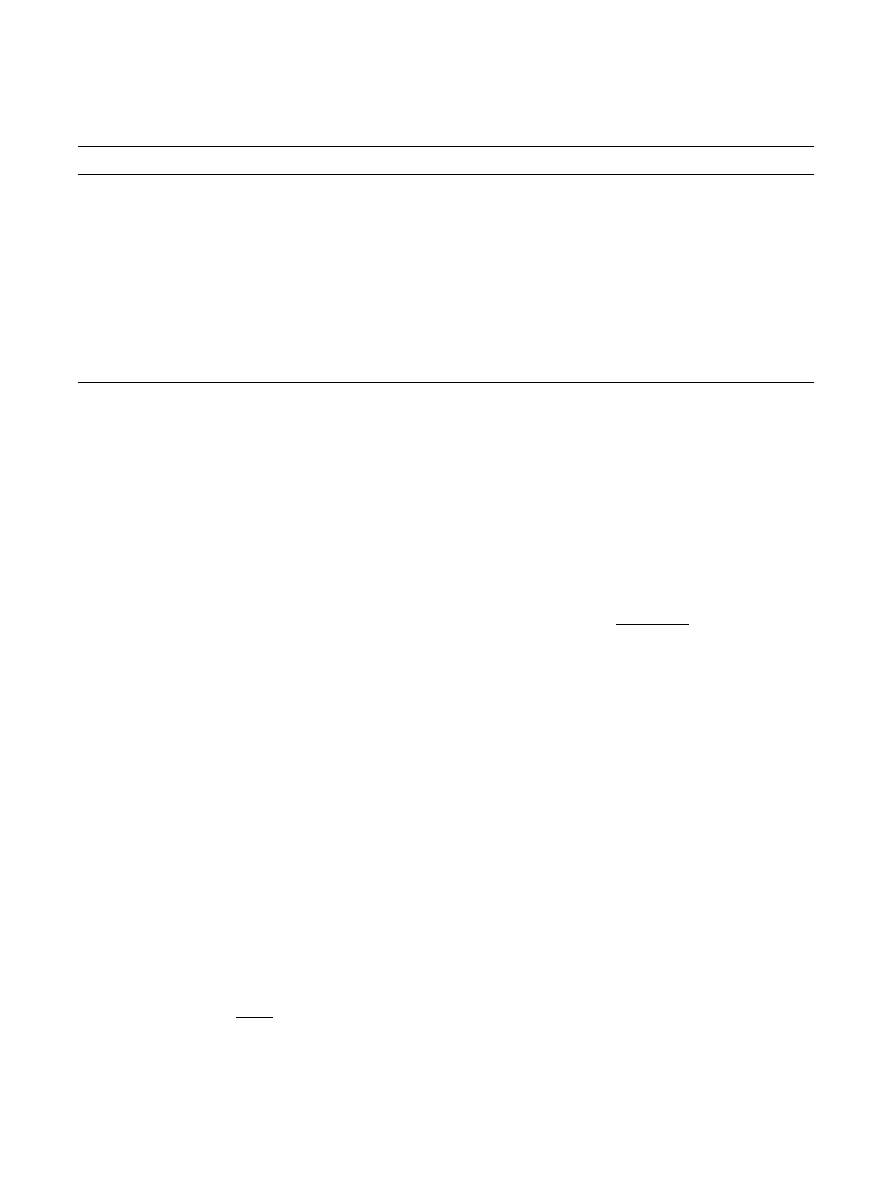

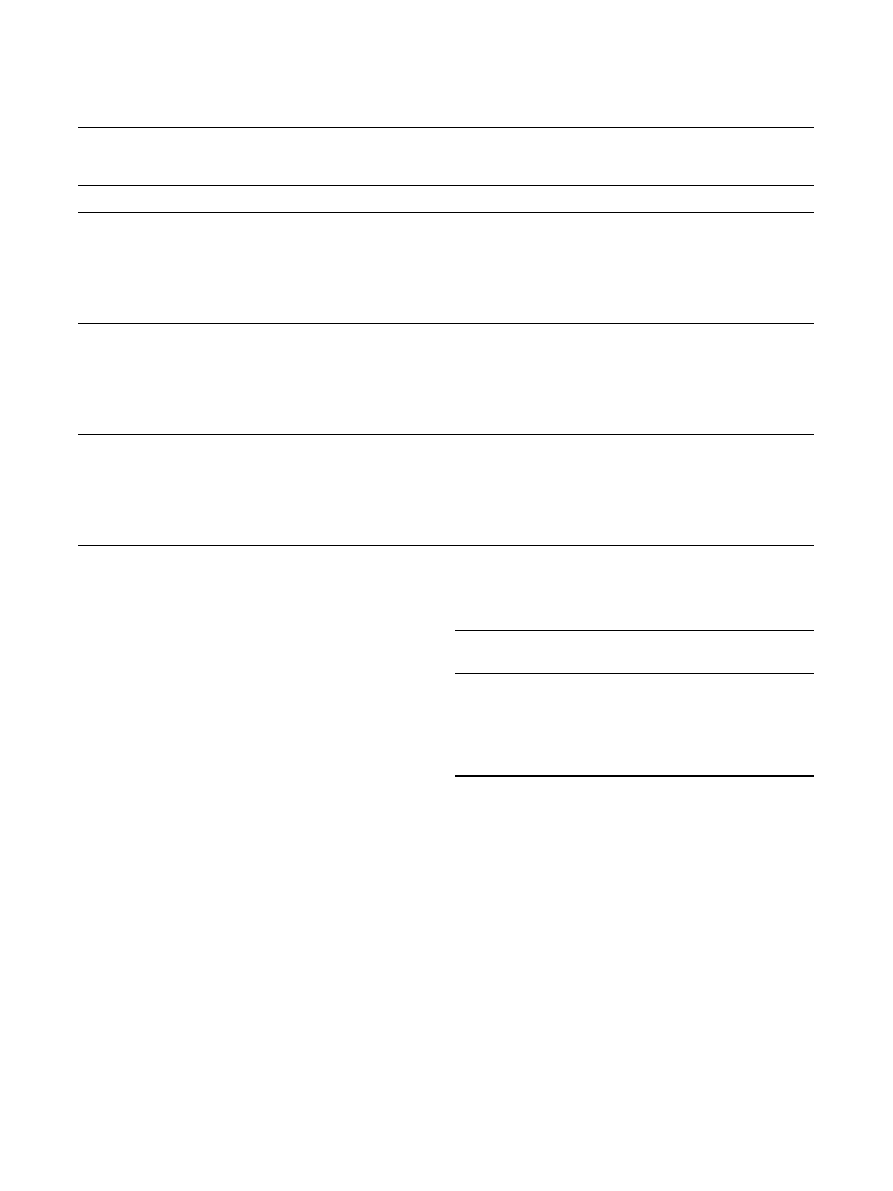

The moisture content versus time curves for micro-

wave drying of parsley leaves as influenced by the

material load dried at microwave power cycle of 9 s on/

9 s off at 900 W are shown in

. The microwave

drying process which reduced the material moisture

contents from 494 to 511 kg [H

2

O] kg

1

[DM] to

moisture content of 010 kg [H

2

O] kg

1

[DM] took

900–1467 min, depending on the drying conditions

(

). The higher the material load, the longer was the

drying time of parsley leaves. As the variation in initial

moisture contents of the material used in drying

experiments were relatively very small, the difference

in drying time requirements was considered to be mainly

due to the difference in material load. Further, the

applied microwave power density for unit mass of dried

ARTICLE IN PRESS

Table 1

Mathematical models given by various authors for drying curves

Model no

Model equation

Name

References

1

M

R

¼

expðktÞ

Newton

2

M

R

¼

expðkt

n

Þ

Page

3

M

R

¼

a expðktÞ

Henderson and Pabis

4

M

R

¼

a expðktÞ þ b

Logarithmic

5

M

R

¼

a expðkt

n

Þ þ

bt

Midilli et al.

6

M

R

¼

1 þ at þ bt

2

Wang and Singh

7

M

R

¼

b=ð1 þ a expðktÞÞ

Logistic

8

M

R

¼

a expðktÞ þ b expðk

1

tÞ

Two–term

9

M

R

¼

a expðktÞ þ ð1 aÞ expðbtÞ

Verma et al.

10

M

R

¼

a expðktÞ þ ð1 aÞ expðkatÞ

Two-term

exponential

11

M

R

¼

a expðktÞ þ ð1 aÞ expðkbtÞ

Diffusion

approximation

M

R

, moisture ratio (dimensionless); k and k

1

drying coefficients in min

1

; n, exponent (dimensionless); t, time in min; a and b, coefficients

(dimensionless), specific to individual equations.

Y. SOYSAL ET AL.

406

material decreased with increased material load. Higher

drying rates were obtained at lower material loads due

to the increase in applied microwave power density for

unit mass of dried product. When drying the leaf

materials, a period of constant drying rate which

depends on the applied microwave power density,

material load and duration was observed (

). The

length of this period decreased with increased power

density. And at a maximum power density or lowest

material load, the constant rate period was practically

absent as inferred from

. These results were in

good agreement with some studies (

;

;

;

). The rapidly decreasing falling rate period

followed the constant rate period and started below

the 05 kg [H

2

O] kg

1

[DM].

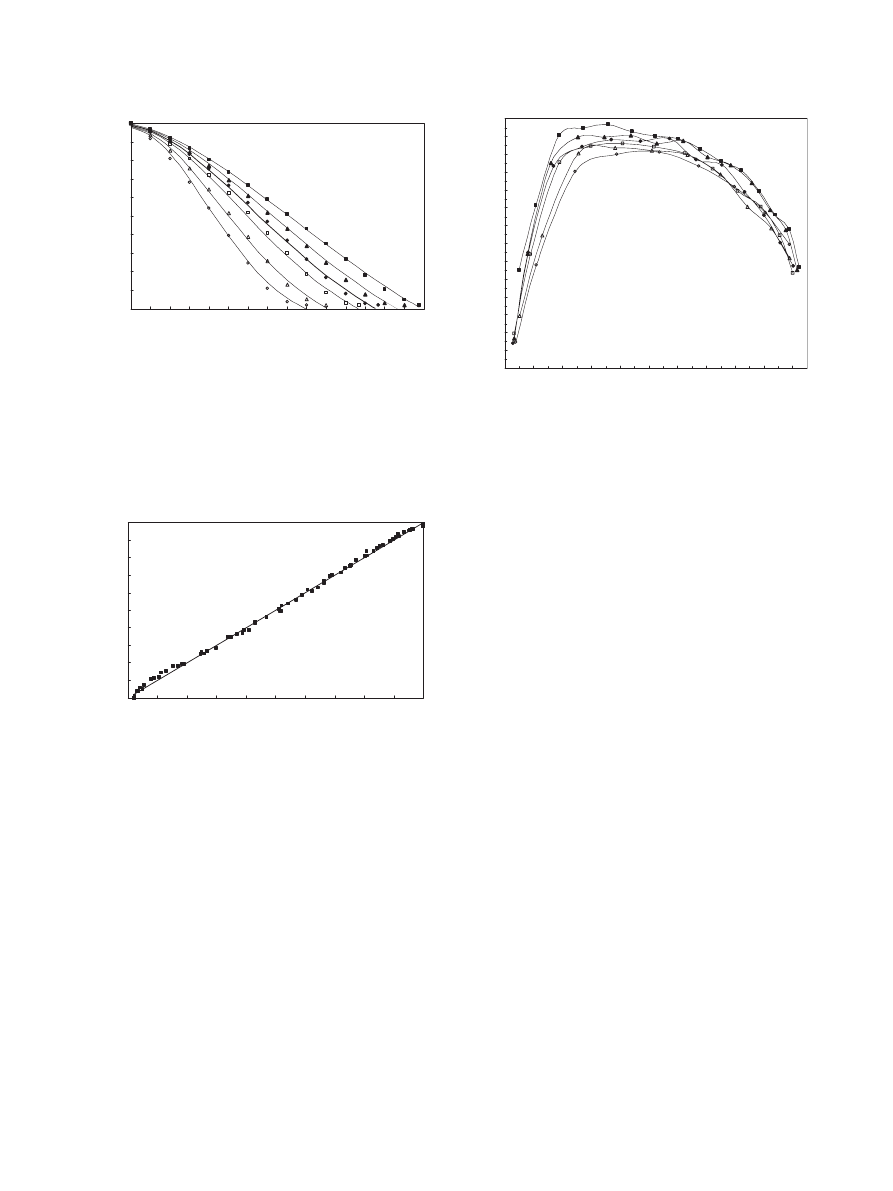

3.2. Modelling of drying curves

The results of the statistical computations for the

microwave drying data are shown in

. The fitting

ability of 11 drying models expressing the changes in the

moisture ratios with drying time are presented in

as the values of the coefficients and statistical para-

meters found for the respective models. Among the all

drying models used in this study, the

model, with drying rate as a log–log and linear function

of time, gave the best fit for all the experimental data

point with values for the Z

m

of greater than 09974 and

the E

RMS

of lower than 00179. Thus, this model

represented the experimental values satisfactorily.

The drying coefficient k decreased with the increase in

dried material load. These results were in good

agreement with the drying rate data, which follow the

similar trends.

Further regressions were undertaken to account for

the effect of material load on the Midilli et al. model

coefficients. The effect of the material load on the

coefficients of a and b, exponent n and drying coefficient

k were also included in the model by multiple regression

analysis [Eqn (5)]. The consistency of model (5) and

relationship between the coefficients and dried material

load is evident with the values for E

RMS

of 00019 and

Z

m

of 09982 for the combined data.

M

R

¼

M

M

0

¼ ð

08717m

00274

Þ

expðð728601m

18344

Þ

t

ð

31159m

0113

Þ

Þ þ ð

00001m

10367

Þ

t

ð

5Þ

where: m is the material load in g; t is the drying time

in min.

On the other hand, the most suitable result of model

(5) depending on the material load are given in

The E

RMS

values were changed between 00002 and

00013 and the Z

m

between 09966 and 09995 depending

on the material load. It can be seen that model (5) was in

good agreement with the experimental results. However,

it should be noted that these data are specific to

microwave dryer used in this study. This expression is

only valid for the material load between 6430 and

12857 g and can successfully be used to estimate the

moisture content of parsley leaves at any time during the

microwave drying at microwave power cycle of 9 s on/9 s

off at 900 W microwave output power.

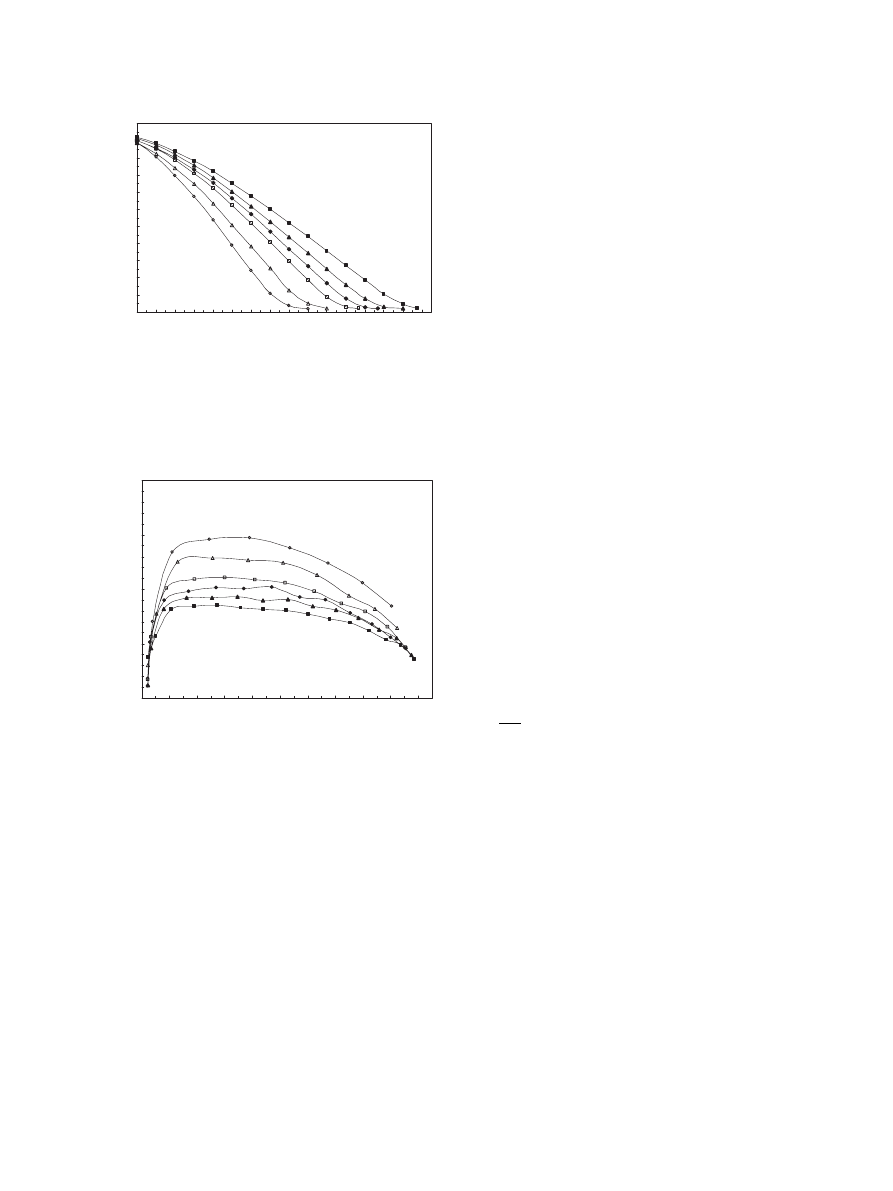

Changes of the experimental and predicted moisture

ratio values with drying time for different material load

ARTICLE IN PRESS

0.00

0.25

0.50

0.75

1.00

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Moisture content kg [H

2

O] kg

−1

[DM]

Drying rate, kg [H

2

O] kg

−

1

[DM] min

−

1

Fig. 2. Relationship between the drying rate and moisture

content (kg [H

2

O] kg

1

[DM]) at different material load dried

at microwave power cycle of 9 s on/9 s off at 900 W microwave

output power; ’, 12857 g; m, 11240 g; E, 9990 g; &, 9010

g;

W

, 7513 g; J, 6430 g

0.0

0

1 2 3 4 5 6

7 8 9 10 11 12 13 14 15

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

Drying time, min

Moisture content, kg [H

2

O] kg

−

1

[DM]

Fig. 1. Relationship between the moisture content (kg [H

2

O]

kg

1

[DM]) and drying time at different material load dried at

microwave power cycle of 9 s on/9 s off at 900 W microwave

output power; ’, 12857 g; m, 11240 g; E, 9990 g; &, 9010

g;

W

, 7513 g; J, 6430 g

MICROWAVE DRYING OF PARSLEY

407

ARTICLE IN PRESS

Table 2

Statistical parameters and the values of the coefficients specific to each model for various material loads dried at microwave power

cycle of 9 s on/9 s off at 900 W output power

Model

no

Material load, g

Drying

coefficient

(k),min

1

Drying

coefficient

(k

1

)

Exponent

(n)

Coefficient

(a)

Coefficient

(b)

Root mean

square

error

Modelling

efficiency

1

12857

01027

01169

08727

11240

01177

01182

08773

9990

01281

01221

08720

9010

01398

01219

08736

7513

01674

01169

08832

6430

02045

01113

08982

2

12857

00102

20529

00325

09902

11240

00130

20530

00299

09922

9990

00137

21078

00305

09921

9010

00165

21030

00304

09921

7513

00265

20487

00289

09929

6430

00433

19647

00279

09936

3

12857

01199

11458

01008

09054

11240

01370

11488

01019

09088

9990

01486

11482

01062

09032

9010

01616

11415

01064

09038

7513

01910

11313

01033

09089

6430

02296

11210

00993

09190

4

12857

00009

757615

746987

00262

09936

11240

00024

326707

316159

00304

09919

9990

00020

434841

424252

00311

09917

9010

00022

425134

414561

00310

09918

7513

00053

209279

198807

00334

09905

6430

00324

42884

32463

00386

09878

5

12857

00094

18167

09931

00191

00071

09995

11240

00131

18883

09854

00111

00134

09984

9990

00136

19336

09845

00127

00123

09987

9010

00166

19165

09862

00138

00127

09986

7513

00251

19165

09820

00125

00145

09982

6430

00408

18799

09794

00091

00179

09974

6

12857

00493

00014

00209

09959

11240

00616

00010

00337

09901

9990

00642

00015

00323

09911

9010

00704

00016

00327

09909

7513

00901

00015

00363

09887

6430

01218

00006

00422

09854

7

12857

03695

00556

10276

00261

09937

11240

04124

00573

10319

00241

09949

9990

04620

00502

10223

00242

09950

9010

04999

00514

10250

00247

09948

7513

05812

00573

10313

00220

09959

6430

06570

00694

10447

00212

09963

8

12857

02445

02802

99388

89837

00543

09726

11240

00173

00282

22771

12335

00301

09921

9990

00094

00270

28875

18475

00292

09927

9010

00109

00284

28994

18591

00285

09926

7513

00205

00282

27708

17316

00332

09906

Y. SOYSAL ET AL.

408

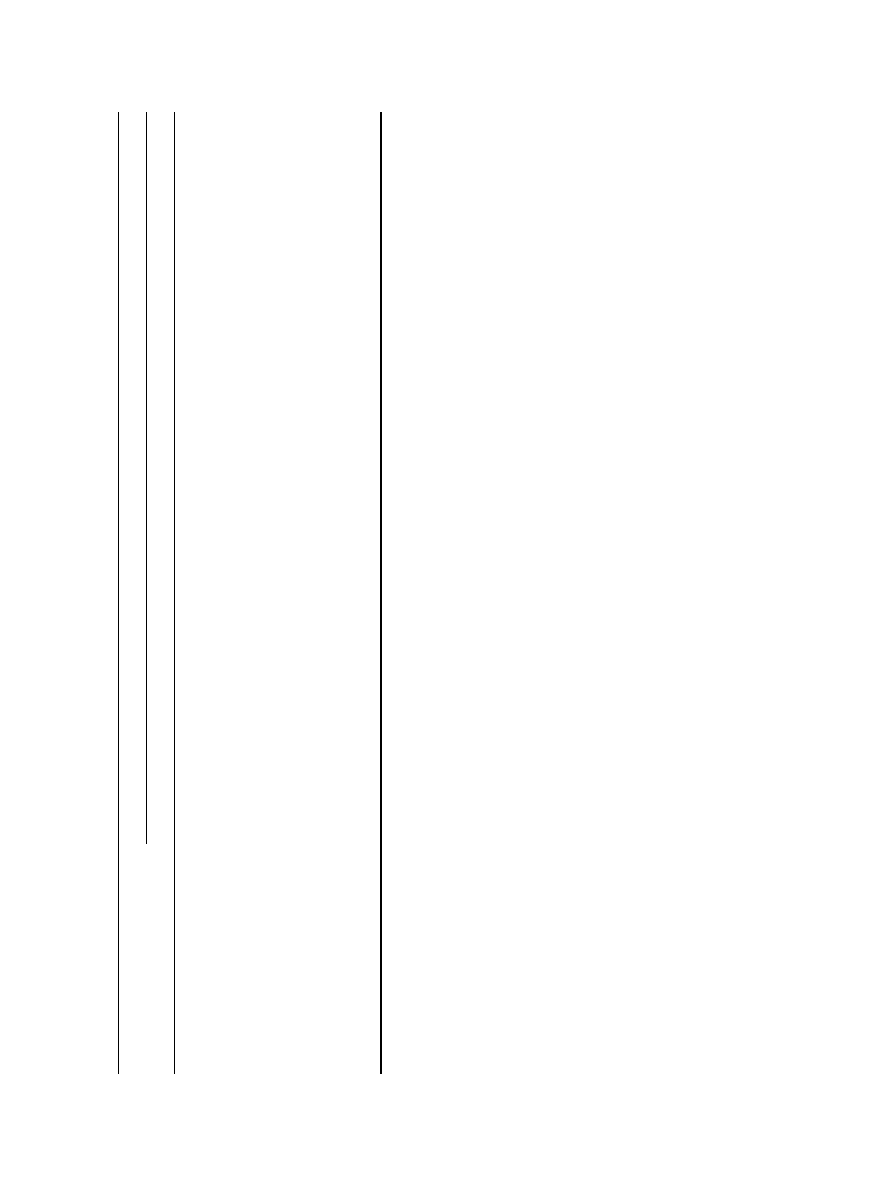

dried at microwave power cycle of 9 s on/9 s off at 900 W

microwave output power were given in

. The

established model was validated by comparing the

predicted moisture ratios to the experimental values

from all drying experiments. The predicted data banded

over the straight line of the 1:1 ratio, with a value for the

determination coefficient R

2

of 09982 (

). The

linear regression of these results gave the expression as

M

R;cal

¼

09975M

R;exp

þ

00017

(6)

3.3. Effect of material load on the energy efficiency of

microwave drying

Effect of material load on the energy efficiency of

microwave drying was evaluated by two different

efficiency indices as microwave drying efficiency in %

and specific energy consumption in MJ kg

1

[H

2

O]. The

changes of the microwave drying efficiency with

moisture content for various material loads were

illustrated in

.

Although the microwave drying efficiency for the leaf

material differed between material loads, the microwave

drying efficiency was about 30% at the beginning of

drying process, and then showed a rapidly increasing

tendency to a moisture content of about 375 kg [H

2

O]

kg

1

[DM]. Apparently, during the initial few minutes,

the microwave energy applied was used in raising the

material temperature and very little moisture was

evaporated (

). Thus, initial heating phase

during the first few minutes lead to lower drying

efficiency values compared to cumulative drying effi-

ciency values for the respective drying conditions given

in

. After a slow increasing tendency to about the

moisture content of 175 kg [H

2

O] kg

1

[DM], the

microwave drying efficiency reached to its maximum

value and was varied between 60% and 68% depending

on the material load ranging from 6430 to 12857 g,

respectively. Then, it was almost remained constant up

to the moisture contents of about 125 kg [H

2

O] kg

1

[DM] to 075 kg [H

2

O] kg

1

[DM]. Below these moisture

ARTICLE IN PRESS

Table 2 (

continued )

Model

no

Material load, g

Drying

coefficient

(k),min

1

Drying

coefficient

(k

1

)

Exponent

(n)

Coefficient

(a)

Coefficient

(b)

Root mean

square

error

Modelling

efficiency

6430

00419

00101

28926

18498

00387

09877

9

12857

–00054

31094

00323

00222

09954

11240

00025

29668

00282

00343

09897

9990

00042

24144

00394

00333

09905

9010

00052

24254

00418

00337

09903

7513

00089

27960

00370

00368

09884

6430

00291

28016

00225

00424

09852

10

12857

259691

00039

01178

08707

11240

290603

00040

01191

08754

9990

496827

00026

01227

08709

9010

625201

00022

01224

08727

7513

666134

00025

01174

08822

6430

848084

00024

01117

08973

11

12857

00018

21657

223710

00225

09953

11240

00092

22070

38835

00345

09895

9990

00077

21669

55549

00334

09904

9010

00108

20651

44428

00340

09902

7513

00140

23948

30185

00369

09883

6430

00254

32422

06966

00423

09852

Table 3

Effect of material load on Midilli

et al. model and its results

Material load (m),

g

Root mean square

error

Modelling efficiency

(Z

m

)

12857

000024

099945

11240

000104

099763

9990

000062

099857

9010

000080

099811

7513

000075

099806

6430

000130

099661

MICROWAVE DRYING OF PARSLEY

409

contents, microwave drying efficiency decreased rapidly

and reached to a value as low as 8%. This could be

attributed to the decrease in moisture content of the

material at the later stages of the drying. The dielectric

properties of the product being dried are proportionally

related to moisture content (

). Thus,

intensity of heat generation or the ability of the product

to absorb microwave energy decreases due to the

reduction of moisture during the microwave drying

process (

;

).

Despite the significant reduction in microwave drying

efficiency at the latter stages of the drying process,

cumulative drying efficiencies were still high. Cumula-

tive drying efficiencies were calculated as 5368, 4992,

4783, 4683, 4648, and 4422% for the material loads

12857, 11240, 9990, 9010, 7513, and 6430 g, respec-

tively (

). However, it should be noted that

maximum loading rate of the microwave dryer used in

this study is limited to about 130 g when drying the leaf

parsley. Therefore, these data are specific to microwave

dryer used in this study. A considerable increase in

drying efficiency with increasing material load signifies

that the microwave was efficiently absorbed by water, so

as water is depleted microwave absorption is reduced

leading to lower efficiency values (

;

Mousa &

;

). As the size

of load relative to cavity determines the amount of

power reflection back to the magnetron, the larger the

load size, the lower the power reduction by reflection

and cavity loss and, hence, the higher the efficiency of

power absorption (

). Conse-

quently, it can be said that energy required to remove

unit mass water from the product at higher material

loads is less than at lower load size.

Specific energy consumption values for the respective

drying conditions are given in

. Although the

parsley and the peppermint are different in nature, the

specific energy consumption values were relatively low

as compared to those obtained for peppermint 1000,

864, and 484 MJ kg

1

[H

2

O], reported by

and

, respectively. The higher the material

ARTICLE IN PRESS

Experimental moisture ratio

Predicted moisture ratio

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Fig. 4. Experimental (’) and predicted (—) moisture ratio at

different microwave drying conditions

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Moisture content, kg [H

2

O] kg

−1

[DM]

Microwave drying efficiency, %

Fig. 5. Microwave drying efficiency versus moisture content (kg

[H

2

O] kg

1

[DM]) at different material load dried at

microwave power cycle of 9 s on/9 s off at 900 W microwave

output power; ’, 12857 g; m, 11240 g; K, 9990 g; &, 9010

g;

W

, 7513 g; J, 6430 g

0.0

0 1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Drying time, min

Moisture ratio

Fig. 3. Moisture ratio versus time at different material load

dried at microwave power cycle of 9 s on/9 s off at 900 W

microwave output power, comparing experimental curve with the

predicted one (—) through Midilli et al. model [Model 5] for

parsley (Petroselinum crispum Mill.) leaves; ’, 12857 g; m,

11240 g; K, 9990 g; &, 9010 g;

W

, 7513 g; J, 6430 g

Y. SOYSAL ET AL.

410

loads the lower the specific energy consumption

(

). As the intensity of heat generation is

proportional to the content of moisture in a dielectri-

cally dried material (

), the

bigger amount of water trapped inside the material

provided the higher drying efficiency and lower specific

energy consumption values.

Although the discussion about the quality of dried

product is beyond the scope of this paper, no significant

difference was observed between the colour of fresh and

microwave-dried leaf materials, except for some de-

crease in brightness of leaf material.

4. Conclusion

Based on the results of this study, the following

conclusions were drawn.

(a) Drying took place mainly in the falling rate period

followed by a constant rate period after a short

heating period.

(b) The higher the material load, the longer the drying

time of parsley leaves. Higher drying rates were

obtained at lower material loads.

(c) The Midilli et al. model, with dying rate as a log–log

and linear function of time, gave the best fit for all

the experimental data points with values for the

modelling efficiency of greater than 09974 and the

root mean square error of lower than 00179.

(d) The value of the drying coefficient k decreased with

the increased material load indicating slower drying

of the product.

(e) The multiple regression on the coefficients of the

Midilli et al. model for the effects of material load

being dried gave the high modelling efficiency value

of 09982 and low root mean square error of 00019,

and showed to satisfactorily represent the micro-

wave drying kinetics of parsley leaves dried at

microwave power cycle of 9 s on/9 s off at 900 W

microwave output power.

(f) The initial heating phase during the first few minutes

of drying process lead to lower drying efficiency

values as low as 30% compared to the values for

cumulative drying efficiency which ranged from

4422% to 5368% for the material loads between

6430 and 12857 g, respectively.

(g) At the later stages of the drying process, drying

efficiency values decreased considerably to a value as

low as 8%.

(h) When the material load being dried was higher,

more of the microwave energy was used for

evaporating moisture while the lower material load

tended to decrease the drying efficiency and increase

the specific energy consumption.

ARTICLE IN PRESS

Table

4

Efficiency

of

microwave

drying

depending

on

material

load

dried

at

microwave

power

cycle

of

9

s

on/9

s

off

at

900

W

microwave

output

power

Parameter

Material

load,

g

128

57

(7

0

06)

112

40

(7

0

00)

99

90

(7

0

00)

90

10

(7

0

00)

75

13

(7

0

06)

64

30

(7

0

00)

Initial

moisture

content

5

11

(7

0

00)

5

08

(7

0

03)

5

01

(7

0

15)

5

00

(7

0

05)

4

94

(7

0

03)

4

94

(7

0

03)

M

0

,k

g[

H

2

O]

kg

1

[DM]

Final

moisture

content

0

10

(7

0

00)

0

10

(7

0

01)

0

10

(7

0

00)

0

10

(7

0

01)

0

10

(7

0

00)

0

10

(7

0

00)

M

f

,k

g[

H

2

O]

kg

1

[DM]

Evaporated

water

D

M

,

g

105

30

(7

0

00)

91

97

(7

0

21)

81

52

(7

0

45)

73

52

(7

0

18)

61

16

(7

0

01)

52

37

(7

0

06)

Drying

time

t,

min

14

75

14

00

12

67

11

67

10

00

9

00

Total

power

on

time

t

on

,

s

489

0

462

0

418

0

385

0

330

0

297

0

Drying

rate,

0

34

(7

0

09)

0

36

(7

0

12)

0

38

(7

0

14)

0

41

(7

0

14)

0

48

(7

0

17)

0

54

(7

0

22)

kg

[H

2

O]

kg

1

[DM]

min

1

Cumulative

microwave

drying

53

68

(7

0

06)

a

49

92

(7

0

12)

b

47

83

(7

0

37)

c

46

83

(7

0

10)

d

46

48

(7

0

01)

e

44

22

(7

0

05)

f

efficiency

Z

d

,%

Specific

energy

consumption

4

18

(7

0

00)

a

4

52

(7

0

01)

b

4

62

(7

0

02)

c

4

71

(7

0

01)

d

4

86

(7

0

00)

e

5

10

(7

0

01)

f

Q

s

,M

J

k

g

1

[H

2

O]

Valu

es

in

par

enthe

sis

indica

te

the

st

andard

de

viatio

n.

Du

ncan

groupin

gs;

The

same

lett

ers

w

ithin

the

same

row

are

not

significan

tly

differ

ent

at

a

prob

abil

ity,

P

o

0

05.

MICROWAVE DRYING OF PARSLEY

411

(i) About 95% increase in drying efficiency and about

18% (092 MJ kg

1

[H

2

O]) decrease in specific

energy consumption could be obtainable by working

at 12857 g material load instead of 6430 g.

(j) In order to maximise the benefits of micro-

wave drying, further studies are required at lower

power outputs with different microwave power

cycles.

Acknowledgements

This study was supported by the Research Founda-

tion of Mustafa Kemal University (Project no: 04 B

1001).

References

Araszkiewicz M; Koziol A; Oskwarek A; Lupinski M (2004).

Microwave drying of porous materials. Drying Technology,

22(10), 2331–2341

Beaudry C; Raghavan G S V; Rennie T J (2003). Microwave

finish drying of osmotically dehydrated cranberries. Drying

Technology, 21(9), 1797–1810

Bouraout M; Richard P; Durance T (1994). Microwave and

convective drying of potato slices. Journal of Food Process

Engineering, 17, 353–363

Bushbeck E; Keiner E; Klinner J (1967). Trocknungsphysika-

lische und wa¨rmetechnische Untersuchung zur Trocknung

von Pfefferminze. [Physical and thermal properties effecting

drying characteristics of peppermint.] Archiv fu¨r Land-

technik, 2, 163–200

Chandra P K; Singh R P (1995). Applied Numerical Methods

for Food and Agricultural Engineers. CRC Press, Boca

Raton, FL pp. 163–167.

Changrue V; Sunjka P.S.; Gariepy Y; Raghavan G.S.V; Wang

N (2004). Real-time control of microwave drying process.

Drying 2004—Proceedings of the 14th International Drying

Symposium (IDS 2004). Sa˜o Paulo, Brazil, 22–25 August

2004, Vol. B, pp 941–948

Drouzas E; Tsami E; Saravacos G D (1999). Microwave/

vacuum drying of model fruit gels. Journal of Food

Engineering, 28, 203–209

Ertekin C; Yaldiz O (2004). Drying of eggplant and selection of

a suitable thin layer drying model. Journal of Food

Engineering, 63, 349–359

Fumagalli F; Silveira A.M (2004). Quality evaluation of

microwave dried Packman’s Triumph pear. Drying 2004—

Proceedings of the 14th International Drying Symposium

(IDS 2004). Sa˜o Paulo, Brazil, 22–25 August 2004, Vol. C,

pp 2069–2076

Funebo T; Ohlsson T (1998). Microwave-assisted air dehydra-

tion of apple and mushroom. Journal of Food Engineering,

38(3), 353–367

Go¨gu¨s F; Maskan M (2001). Drying of olive pomace by a

combined microwave-fan assisted convection oven. Nah-

rung/Food, 45(2), 129–132

Gunasekaran S (1990). Grain drying using continuous and

pulsed

microwave

energy.

Drying

Technoloy,

8(5),

1039–1047

Gunasekaran S (1999). Pulsed microwave-vacuum drying of

food materials. Drying Technology, 17(3), 395–412

Hayes G D (1987). Food Engineering Data Handbook.

Longman Scientific and Technical, England

Henderson S M (1974). Progress in developing the thin-layer

drying equation. Transactions of the ASAE, 17, 1167–1168/

1172

Henderson S M; Pabis S (1961). Grain drying theory I:

temperature effect on drying coefficient. Journal of Agri-

cultural Research Engineering, 6, 169–174

Kaensup W; Chutima S; Wongwises S (2002). Experimental

study on drying chilli in a combined microwave-vacuum-

rotary drum dryer. Drying Technology, 20(10), 2067–2079

Khraisheh M A M; Cooper T J R; Magee T R A (1997).

Microwave and air drying I. Fundamental considerations

and assumptions for the simplified thermal calculations of

volumetric power absorption. Journal of Food Engineering,

33, 207–219

Maskan M (2000). Microwave/air and microwave finish drying

of banana. Journal of Food Engineering, 44, 71–78

Maskan M (2001). Drying, shrinkage and rehydration

characteristics of kiwifruits during hot air and microwave

drying. Journal of Food Engineering, 48, 177–182

Midilli A; Kucuk H; Yapar Z (2002). A new model for single-

layer drying. Drying Technology, 20(7), 1503–1513

Moreno J; Chiralt A; Escriche I; Serra J A (2000). Effect of

blanching/osmotic dehydration combined methods on qual-

ity and stability of minimally processed strawberries. Food

Research International, 33, 609–616

Mousa N; Farid M (2002). Microwave vacuum drying of

banana slices. Drying Technology, 20(10), 2055–2066

Mowlah G; Takano K; Kamoi I; Obara T (1983). Water

transport mechanism and some aspects of quality changes

during air dehydration of bananas. Lebensmittel Wissen-

shaft und Technologie, 16, 103–107

Mudgett R E (1982). Electric properties of foods in microwave

processing. Food Technology, 36(2), 109–115

Mu¨ller J; Reisinger G; Mu¨hlbauer W (1989). Trocknung von

Heil- und Gewu¨rzpflanzen mit Solarenergie im Folienge-

wa¨chshause. [Drying of medicinal and aromatic plants in a

greenhouse solar dryer.] Landtechnik, 2, 58–65

Nijhuis H H; Torringa H M; Muresan S; Yuksel D; Leguijt C;

Kloek W (1998). Approach to improving the quality of dried

fruit and vegetables. Trends in Food Science and Technol-

ogy, 9, 13–20

Nindo C I; Sun T; Wang S W; Tang J; Powers J R (2003).

Evaluation of drying technologies for retention of physical

quality and antioxidants in asparagus (Asparagus officinalis

L. ). Lebensmittel Wissenschaft und Technologie, 36,

507–516

O’Callaghan J R; Menzies D J; Bailey P H (1971). Digital

simulation of agricultural dryer performance. Journal of

Agricultural Engineering Research, 16, 223–244

Page, G (1949). Factors influencing the maximum rates of air

drying shelled corn in thin layers. MSc Thesis, Purdue

University, Indiana, USA

Parker, J.C (1999). Developing a Herb and Spice Industry in

Callide Valley, Qeensland. A report for the Rural Industries

Research and Development Corporation (RIRDC). RIRDC

Publication No: 99/45, RIRDC Project No: DAQ-194A.

Available online at

Prabhanjan D G; Ramaswamy H S; Raghavan G S V (1995).

Microwave assisted convective air drying of thin layer

carrots. Journal of Food Engineering, 25, 283–293

ARTICLE IN PRESS

Y. SOYSAL ET AL.

412

Raghavan G.S.V; Rennie T.J; Sunjka P.S; Orsat V; Pha-

phuangwittayakul W; Terdtoon P (2004). Energy aspects of

novel techniques fore drying biological materials. Drying

2004—Proceedings of the 14th International Drying Sym-

posium (IDS 2004). Sa˜o Paulo, Brazil, 22–25 August 2004,

Vol. B, pp. 1021–1028

Sharaf-Elden Y I; Blaisdell J L; Hamdy M Y (1980). A model

for ear corn drying. Transactions of the ASAE, 5,

1261–1265

Sharma G P; Prasad S (2001). Drying of garlic (Allium

sativum) cloves by microwave–hot air combination. Journal

of Food Engineering, 50, 99–105

Shivhare U S; Raghavan G S V; Bosisio R G; Mujumdar A S

(1992). Microwave drying of corn III. Constant power,

intermittent operation. Transactions of the ASAE, 35(3),

951–957

Shivhare U S; Raghavan G S V; Bosisio R G; Mujumdar A S;

Van de Voort F R (1990). Drying corn in microwave

environment with varying initial moisture contents. Inter-

national Winter Meeting, Heating of Foods Technical

Session, Chicago IL, 18–21 Decembre 1990. ASAE Paper

No. 90-6605, St Joseph MI.

Soysal Y (2004). Microwave drying characteristics of parsley.

Biosystems Engineering, 89(2), 167–173

Soysal Y; O¨ztekin S (2001). Technical and economic perfor-

mance of a tray dryer for medicinal and aromatic plants.

Journal of Agricultural Engineering Research, 79(1), 73–79

Tog˘rul I T; Pehlivan D (2002). Mathematical modelling of

solar drying of apricots in thin layers. Journal of Food

Engineering, 55, 209–216

Torringa E; Esveld E; Scheewe I; van den Berg R; Bartels P

(2001). Osmotic dehydration as a pre-treatment before

combined microwave–hot-air drying of mushrooms. Journal

of Food Engineering, 49, 185–191

Tulasidas T N; Raghavan G S V; Mujumdar A S (1995).

Microwave drying of grapes in a single mode cavity at

2450 MHz—II. Quality and energy aspects. Drying Tech-

nology, 13(8–9), 1973–1992

Tulasidas T N; Raghavan G S V; Norris E R (1993). Microwave

and convective drying of grapes. Transactions of the ASAE,

36, 1861–1865

Tulasidas T N; Ratti C; Raghavan G S V (1997). Modelling of

microwave drying of grapes. Canadian Agricultural En-

gineering, 39(1), 57–67

Venkatesh M S; Raghavan G S V (2004). An overwiev of

microwave processing and dielectric properties of agri-food

materials. Biosystems Engineering, 88(1), 1–18

Verma L R; Bucklin R A; Endan J B; Wratten F T (1985).

Effects of drying air parameters on rice drying models.

Transactions of the ASAE, 28, 296–301

Wang C.Y; Singh R.P (1978). A single layer drying equation

for rough rice. ASAE Paper No: 78-3001, ASAE, St. Joseph,

MI

Yagcioglu A; Degirmencioglu A; Cagatay F (1999). Drying

characteristics of laurel leaves under different drying

conditions. Proceedings of the 7th International Congress

on Agricultural Mechanization and Energy in Agriculture,

pp 565-569. Adana, Turkey, 26–27 May

Yaldız O; Ertekin C (2001). Thin layer solar drying of some

different vegetables. Drying Technology, 19(3), 583–596

Yongsawatdigul

J;

Gunasekaran

S

(1996).

Microwave–

vacuum drying of cranberries:—Part I: energy use and

efficiency. Journal of Food Processing and Preservation, 20,

121–143

ARTICLE IN PRESS

MICROWAVE DRYING OF PARSLEY

413

Document Outline

- Microwave Drying of Parsley: Modelling, Kinetics, and Energy Aspects

Wyszukiwarka

Podobne podstrony:

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

027 Drying of Potato, Sweet Potato and Other Roots

Drying kinetics and drying shrinkage of garlic subjected to vacuum microwave dehydration (Figiel)

Drying kinetics and drying shrinkage of garlic subjected to vacuum microwave dehydration (Figiel)

Drying kinetics and quality of vacuum microwave dehydrated garlic cloves and slices

Drying kinetics and rehydration characteristics of microwave vacuum and convective hot air dried mus

Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum microwav

Thin layer modelling of the convective, microwave, microwave convective and microwave vacuum drying

Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying

Microwave–vacuum drying kinetics of carrot slices (Zheng Wei Cui, Shi Ying Xu, Da Wen Sun)

Modelling of dehydration rehydration of orange slices in combined microwaveair drying

Modeling and minimizing process time of combined convective and vacuum drying of mushrooms and parsl

Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opi

Effect of vacuum microwave drying on selected mechanical and rheological properties of carrot

Microwave drying characteristics of potato and the effect of different microwave powers on the dried

A comparative study on heat pump, microwave and freeze drying of fresh fruits

więcej podobnych podstron