GREG BANISH

2

E NG I N E MANAG E M E NT: ADVANCE D TU N I NG

Copyright © 2007 Greg Banish

All rights reserved. All text and photographs in this publication are the property of the author, unless otherwise noted or cred-

ited. It is unlawful to reproduce – or copy in any way – resell, or redistribute this information without the express written per-

mission of the publisher.

All text, photographs, drawings, and other artwork (hereafter referred to as information) contained in this publication is

sold without any warranty as to its usability or performance. In all cases, original manufacturer’s recommendations, pro-

cedures, and instructions supersede and take precedence over descriptions herein. Specific component design and

mechanical procedures – and the qualifications of individual readers – are beyond the control of the publisher, therefore

the publisher disclaims all liability, either expressed or implied, for use of the information in this publication. All risk for

its use is entirely assumed by the purchaser/user. In no event will CarTech

®

, Inc., or the author, be liable for any indirect,

special, or consequential damages, including but not limited to personal injury or any other damages, arising out of the

use or misuse of any information in this publication.

This book is an independent publication, and the author(s) and/or publisher thereof are not in any way associated with, and are

not authorized to act on behalf of, any of the manufacturers included in this book. All registered trademarks are the property

of their owners. The publisher reserves the right to revise this publication or change its content from time to time without oblig-

ation to notify any persons of such revisions or changes.

Edited By: Josh Brown

ISBN-13 978-1-932494-42-6

ISBN-10 1-932494-42-1

Printed in China

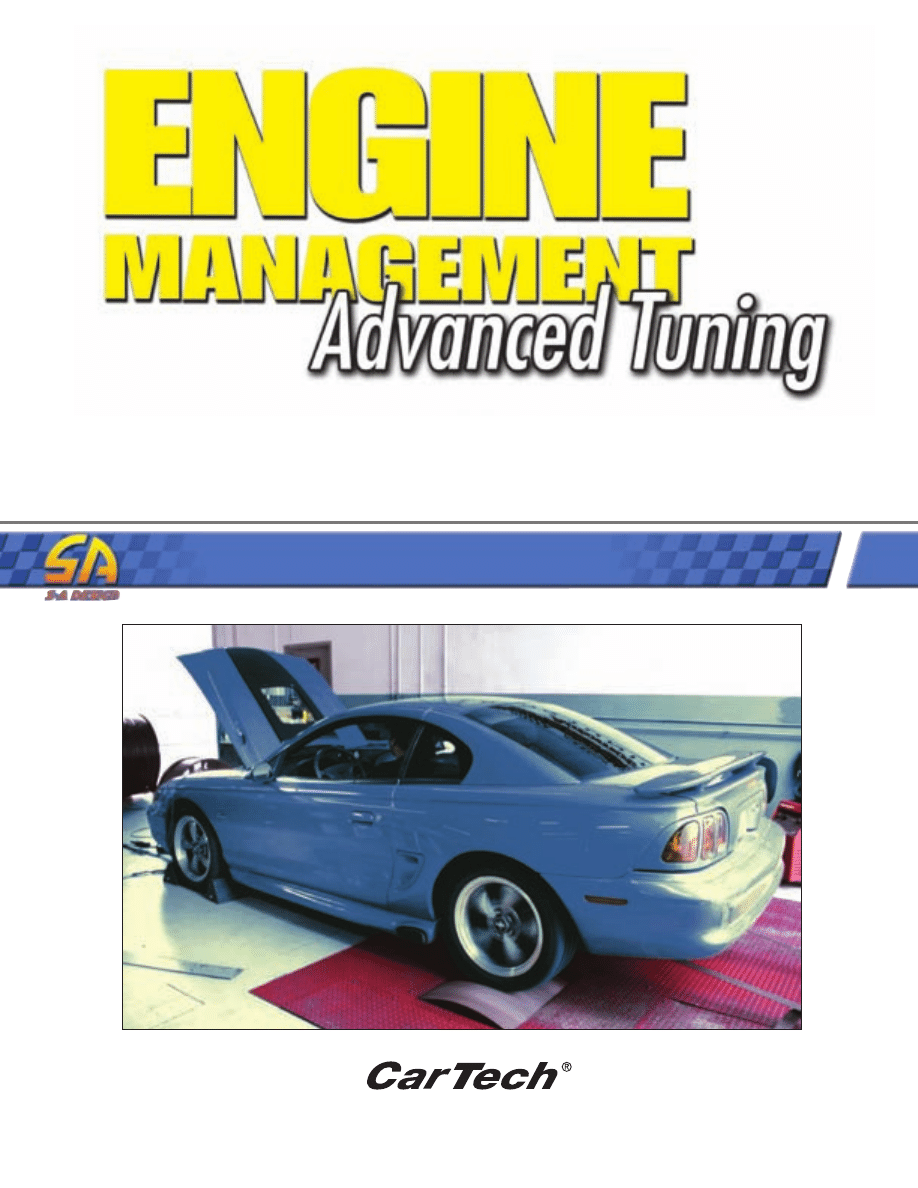

Title Page:

The inertial chassis dyno is perhaps the most common dyno used

today. Low cost and easy operation make them an attractive tool to

the aftermarket. (Nate Tovey)

Back Cover:

Top: Dyno time costs money, and a logical approach to calibration

can often save hours of time and aggravation. When done correctly,

the results of a good tune are both good drivability and excellent

power. (Nate Tovey)

Middle: Modern PCMs pack as much processing power as the

desktop computers of several years ago. In the time it took you to

read this caption, this processor can perform over 16 million calcu-

lations. (Nate Tovey)

Bottom: A cold air kit installed in front of the factory MAF alters the

way air flows into the sensor. The new MAF output versus actual

airflow must be entered into the EEC for proper fuel, load, and

spark calculations. (Nate Tovey)

39966 Grand Avenue

North Branch, MN 55056

Telephone (651) 277-1200 • (800) 551-4754 • Fax: (651) 277-1203

www.cartechbooks.com

OVERSEAS DISTRIBUTION BY:

Brooklands Books Ltd.

P.O. Box 146, Cobham, Surrey, KT11 1LG, England

Telephone 01932 865051 • Fax 01932 868803

www.brooklands-books.com

Brooklands Books Aus.

3/37-39 Green Street, Banksmeadow, NSW 2019, Australia

Telephone 2 9695 7055 • Fax 2 9695 7355

E NG I N E MANAG E M E NT: ADVANCE D TU N I NG

3

TA B L E O F C O N T E N TS

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . .4

About the Author . . . . . . . . . . . . . . . . . . . . . . . .4

Chapter 1:

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Chapter 2:

The Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4 Cycles of an Engine . . . . . . . . . . . . . . . . . . . .11

Air and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chapter 3:

The Goold Ol’ Days . . . . . . . . . . . . . . . . . . . . .19

Carburetion . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Cam Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Chapter 4:

Taking Measure . . . . . . . . . . . . . . . . . . . . . . . . .23

Throttle Position . . . . . . . . . . . . . . . . . . . . . . . .23

Coolant Temperature . . . . . . . . . . . . . . . . . . . .24

Air-Inlet Temperature . . . . . . . . . . . . . . . . . . . .25

Manifold-Surface Temperature . . . . . . . . . . . . .25

Mass Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . .25

Manifold Pressure . . . . . . . . . . . . . . . . . . . . . . .29

Barometric Pressure . . . . . . . . . . . . . . . . . . . . . .30

Crank/Cam Position . . . . . . . . . . . . . . . . . . . . .30

Rail Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

System Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .31

Oxygen Sensors . . . . . . . . . . . . . . . . . . . . . . . . .31

Knock Sensors . . . . . . . . . . . . . . . . . . . . . . . . . .34

Chapter 5:

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Fuel Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Throttle/ETC/Fly by Wire . . . . . . . . . . . . . . . .41

Idle Air Control . . . . . . . . . . . . . . . . . . . . . . . . .44

Runner Controls . . . . . . . . . . . . . . . . . . . . . . . .45

Cam Controls . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Boost Control . . . . . . . . . . . . . . . . . . . . . . . . . .46

Chapter 6:

“The Recipe” . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Modeling Airflow . . . . . . . . . . . . . . . . . . . . . . .48

Mass Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . .49

Speed Density . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Fuel Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Picking a Ratio . . . . . . . . . . . . . . . . . . . . . . . . . .52

Transients and Modifiers . . . . . . . . . . . . . . . . . .53

Correction Factors . . . . . . . . . . . . . . . . . . . . . . .55

Chapter 7:

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56.

Burn Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

“Blancing the Players” . . . . . . . . . . . . . . . . . . .60

Chapter 8:

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . .62

Know Your Load . . . . . . . . . . . . . . . . . . . . . . . .64

Chapter 9:

Getting into the Zip Code . . . . . . . . . . . . . . .68.

Mass Air Flow Modeling . . . . . . . . . . . . . . . . .70

MAF Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Speed Density Airflow Modeling . . . . . . . . . .72

Spark Advance . . . . . . . . . . . . . . . . . . . . . . . . . .73

Chapter 10:

Settling Down . . . . . . . . . . . . . . . . . . . . . . . . . .77

Dashpot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Chapter 11:

More Power . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Chapter 12:

Polising a Sculpture . . . . . . . . . . . . . . . . . . . . .85

Integrating Fuel Maps . . . . . . . . . . . . . . . . . . . .85

Integrating Spark maps . . . . . . . . . . . . . . . . . . .85

Tip-In Ignition . . . . . . . . . . . . . . . . . . . . . . . . . .86

Deceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Closing the Loop (or not?) . . . . . . . . . . . . . . . .87

Choosing Cam/Runner Timing . . . . . . . . . . . .88

Choosing a Shift Point . . . . . . . . . . . . . . . . . . .89

Almost Done . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Chapter 13:

Forced Induction . . . . . . . . . . . . . . . . . . . . . . .90

Centrifugal Superchargers . . . . . . . . . . . . . . . . .91

Positive Displacement Superchargers . . . . . . .93

Turbochargers . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Nitrous Oxide . . . . . . . . . . . . . . . . . . . . . . . . . .98

Chapter 14:

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Appendix A:

Ford Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Appendix B:

GM Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . .111.

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Appendix C:

Standalone EFI Systems . . . . . . . . . . . . . . . .118.

Accel DFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

F.A.S.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

AEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

MegaSquirt . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Electromotive TEC

3

r . . . . . . . . . . . . . . . . . . .122

Appendix D:

INCA OEM Calibration Tool . . . . . . . . . . .123.

Appendix E:

External Controllers . . . . . . . . . . . . . . . . . . .124.

Electronic Ignition Boxes . . . . . . . . . . . . . . . .124

VAFC/MAF Adjusters . . . . . . . . . . . . . . . . . .125

Piggyback Controllers . . . . . . . . . . . . . . . . . . .125

Auxiliary Injector Control . . . . . . . . . . . . . . .126

Hobbs Switches . . . . . . . . . . . . . . . . . . . . . . . .126

Mechanical Adjustable Fuel

Pressure Regulators . . . . . . . . . . . . . . . . .126

The FMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Manual Boost Controllers

and Wastegates . . . . . . . . . . . . . . . . . . . . .127

Exhaust Cutouts . . . . . . . . . . . . . . . . . . . . . . .128

4

E NG I N E MANAG E M E NT: ADVANCE D TU N I NG

A

CKNOWLEDGMENTS

Greg Banish is a mechanical

engineer and motorsports enthusiast

who works as an OEM calibrator by

day and professional engine tuner

in his spare time. Greg earned a

bachelor’s degree in Mechanical

Engineering at GMI Engineering &

Management Institute (Kettering

University) with a specialty in auto-

motive applications, engine design

and power systems. He wrote his the-

sis on vehicle instrumentation and

wheel torque measurement.

Putting this education to practical

use, he founded his own performance

shop outside of Detroit and has

served local enthusiasts, shops, auto-

motive companies and OEMs. A

background in engineering drove

him to approach engine tuning logi-

cally by applying an OEM-style

approach. As one of the earliest pro-

ponents for using a load bearing

chassis dyno for general enthusiast

tuning work, he worked to realign

the public view of how performance

tuning should be done. With over a

thousand unique aftermarket cali-

brations performed on the dyno and

“track,” he has had the opportunity

to work with a wide variety of

engines and control systems.

Currently working as a calibra-

tion engineer, Greg works closely

with engineers from U.S. and Euro-

pean OEMs including environmental

testing in some of the most extreme

conditions. His assignments have

covered engine control technologies

ranging from torque-based controls

to thermal modeling to gasoline

direct injection. He is also a member

of the Society of Automotive Engi-

neers and SEMA.

To this day, he continues to

serve the performance industry pro-

viding EFI calibration and consulting

services to shops as well as teaching

seminars on engine calibration that

are available to both professional

tuners and individual enthusiasts

alike. He enjoys road racing his Ford

Mustang and instructing at open

track events.

A

BOUT THE

A

UTHOR

This book would not have been

possible without a lot of help

through the years. Many of the rela-

tionships I’ve made both personally

and professionally have been fuel to

keep me going over the years and

opened the doors that made this all

possible.

I would like to thank the people

at SCT, Mustang Dynamometer,

Dynojet Research, HPTuners, Engine

Controls and Monitoring, Mr. Gas-

ket, F.A.S.T., Vortech Engineering,

MRT Racing, SiemensVDO, Magnu-

son Products, Diablosport, MSD,

Autronic, Trick Flow Specialties,

Ford, and Mopar for their recent help

and opportunities to challenge

myself over the years.

Nate Tovey, my photographer

for this book, put in plenty of long

hours alongside me when it counted.

Thanks buddy, we made it happen.

Andrea, my wife, put in just as

many long hours as I ever did. You

stood by me while I chased my

dream and earned my experience the

hard way: one long night at the shop

after another. Not only have you

gracefully put up with my obses-

sions, but you did it with a smile.

You’ve always been there for me and

helped me keep my focus. What

more could a guy ask for?

Dave and Jay, if only you could

join me now for the good times.

Godspeed and God bless.

–Greg Banish

Author Greg Banish with

his dog, Turbo.

E NG I N E MANAG E M E NT: ADVANCE D TU N I NG

5

I

NTRODUCTION

C H A P T E R 1

Before this book even begins, I

wish to make it perfectly clear that

this is not an engine design or com-

bustion theory text. The goal here is

for the educated enthusiast, skilled

technician, and automotive engi-

neer alike to all be able to come

away with something. To this end,

we explore the basics of engine oper-

ation to reinforce what is really going

on under the hood. From there, we

move on to the “ins and outs” of

modern electronic fuel injection sys-

tems and ultimately some specifics of

calibration methods and horsepower

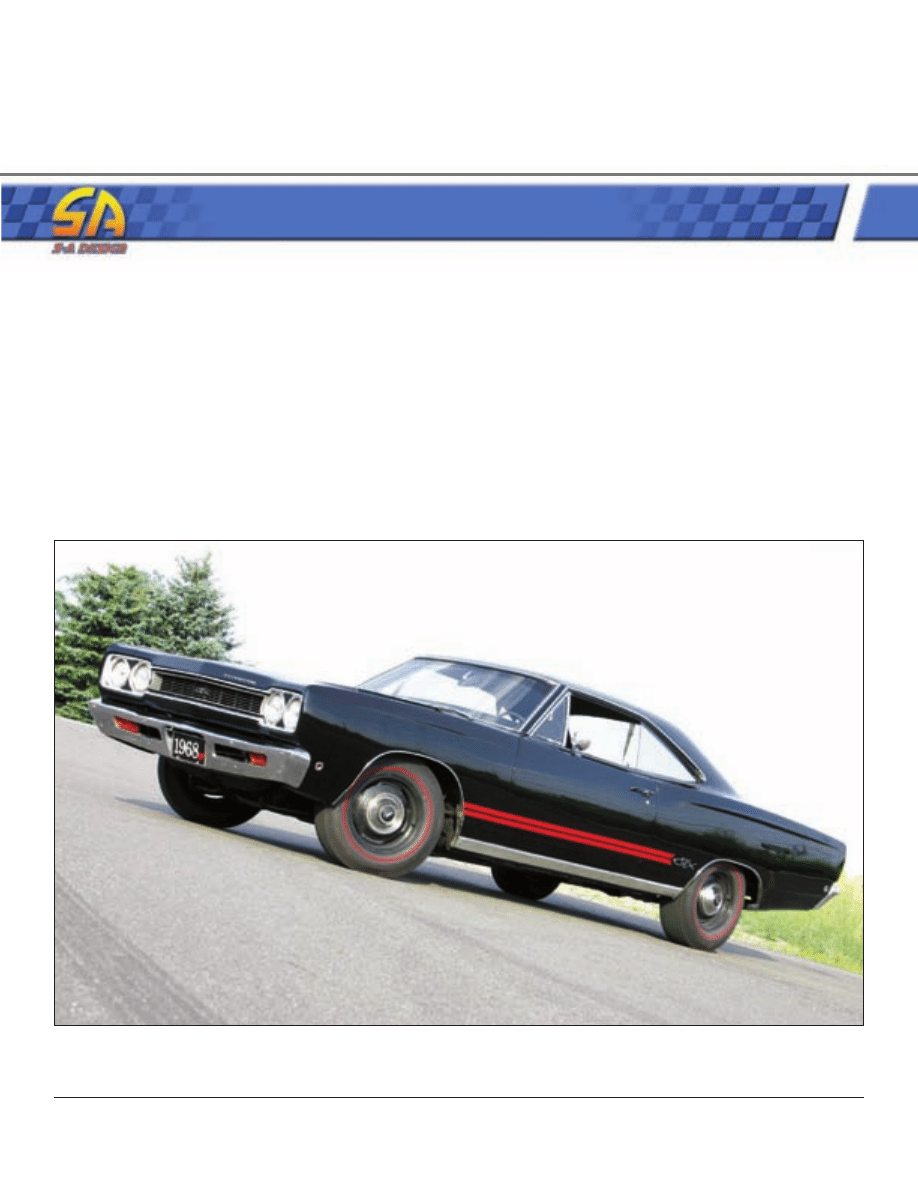

The 1968 Plymouth GTX 440 made 375 gross hp and was considered state of the art for its time. In reality, this engine

has a specific output of 0.85 hp per cubic inch and would fail modern emissions tests miserably. (Nate Tovey)

6

E NG I N E MANAG E M E NT: ADVANCE D TU N I NG

production. The focus of this book is

gasoline engines; however, many of

the concepts can carry over to other

applications. While much of the

material may seem like a review to

many, it is important to keep in

mind the fundamentals of engine

operation while attempting to

change calibrations. A solid under-

standing of what is happening

inside the manifold and combustion

chamber gives the calibrator an edge

in tuning.

Let’s face it, today’s perfor-

mance enthusiast doesn’t want to

compromise. We want tons of

power, reliability, drivability, and

worry-free operation. Gone are the

days of living with the compromises

between the horsepower seekers and

the emissions regulators. We now

live in a time where one can walk

into a new car dealership and simply

buy an honest 400-horsepower car

that idles quietly, drives smooth as

silk, and is backed by a full factory

warranty. Considering that in the

heyday of the muscle car wars 300

gross horsepower was astounding

and it still came with a rough idle

and terrible gas mileage, today’s per-

formance car market is as good as it

has ever been.

So how did we get here? First

and foremost, the automakers have

learned a thing or two about engine

design in the last three decades. Seri-

ous advances in the areas of cylin-

der head, intake, and camshaft

design have allowed engines to

make far more power out of much

smaller packages and displacements.

What the OEM engineers call spe-

cific output, or power per cubic

inch, has gone way up directly as a

result of the increase in flow poten-

tial of modern component designs.

Compare today’s injection molded

CHAPTE R 1

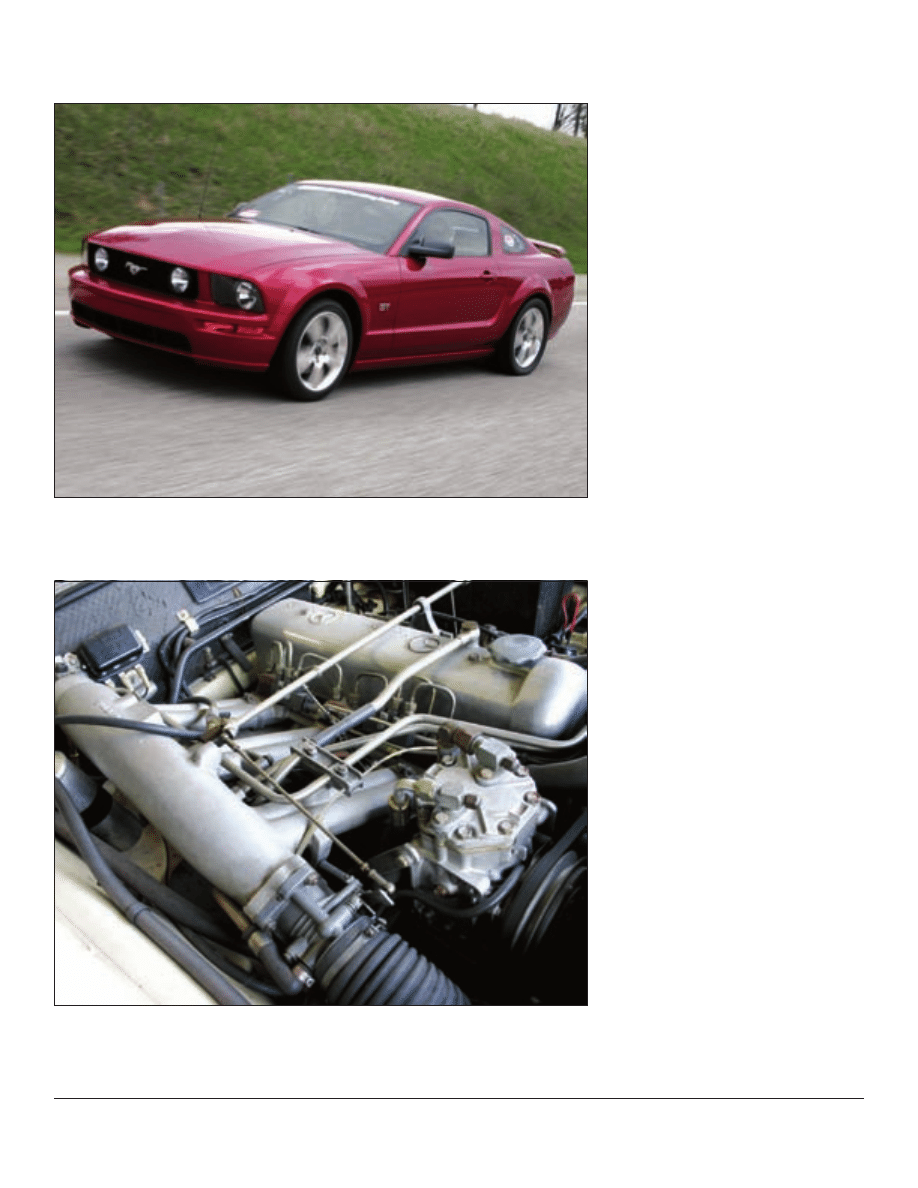

The 2006 Ford Mustang makes 300 hp out of a 281 cubic engine for a specific

output of 1.07 hp/ci, with complete compliance to today’s stringent emissions

standards. (Nate Tovey)

The engine in this Mercedes 220SE is equipped with mechanical fuel injection

and makes about 120 hp from 2.2 liters. It has limited capability to adjust for

changing weather conditions. (Nate Tovey)

Wyszukiwarka

Podobne podstrony:

8046

8046

8046

8046

8046

8046

8046

8046

8046

więcej podobnych podstron