Accelerated drying of welsh onion by far infrared radiation

under vacuum conditions

S. Mongpraneet, T. Abe

*

, T. Tsurusaki

Laboratory of Agricultural Process Engineering, Department of Biomechanical Systems, The United Graduate School of Agricultural Sciences,

Ehime University, Tarumi 3-5-7, Matsuyama 790-8566, Japan

Received 12 January 2001; accepted 28 January 2002

Abstract

Far infrared radiation has excellent radiation characteristics and high energy conversion rates can be achieved using ceramic

coated radiators. Using such a radiator, the dehydrating synergy, generated by far infrared radiation heating under vacuum con-

dition, the drying of welsh onion was studied. The radiation intensity levels influenced dramatically the drying rate and the product

qualities: the a

for rehydrated onions, and the L

and DE

ab

for dehydrated onions. A rising-rate period, a constant-rate period, and

a falling-rate period were ascribed to the drying behaviour. The radiation also had significant effects on chlorophyll content. The

long time in drying and the high temperature may have contributed to a decrease in rehydration properties.

Ó 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Welsh onion; Far infrared drying; Vacuum drying

1. Introduction

Welsh onion (Allium fistulosum LINN.) is a perish-

able vegetable that easily deteriorates at room temper-

ature and even if stored in a cold room. This is an

important vegetable, and local varieties exist in each

part of Japan. The aggregate planted area of welsh on-

ions in Japan from 1980 to 1997 averaged 24,317 hect-

ares or 546,283 tones production and was 3.76% of the

total planted area of vegetables or 5.0% of total vege-

table production (Kishida, 1998). This vegetable sees

widespread use in both the fresh and the dried forms.

The leaf part is rich in chlorophyll and dried welsh on-

ions in cut form are used widely in ready-to-eat Japanese

foods such as noodles, curry sauce, canned foods, etc.

The technique of dehydration is probably the oldest

method of food preservation practiced by mankind. The

use of artificial drying to preserve agricultural products

has expanded widely, creating a need for more rapid

drying techniques and methods that reduce the large

amount of energy required in drying processes. New

and/or innovative techniques that increase drying rates

and enhance product quality have achieved considerable

attention.

The hot air drying method has been widely adopted

in manufacturing of conventional dried food. Freeze–

drying was developed later, when a higher quality prod-

uct was required. Nevertheless, there are still many

losses of thermal energy in hot air drying. However,

there is smaller energy loss in methods such as infrared

drying, since, unlike hot air drying, the electromagnetic

wave energy is absorbed directly by the dried food.

Infrared radiation has significant advantages over

conventional drying. Among these advantages are higher

drying rates giving significant energy savings, and uni-

form temperature distribution giving a better quality

product. Therefore, it can be used as an energy saving

drying method. At present, it has been developed in

various driers using infrared radiators. Using the char-

acteristics of these radiators, technology development

on the utilization of far infrared radiation is an energetic

advance that can give an increase in drying efficiency,

space saving, clean working environment, etc. (Ratti &

Mujumdar, 1995; Yamazaki, Hashimoto, Honda, &

Shimizu, 1992).

Earlier attempts to apply infrared to drying of agri-

cultural materials have been reported in the literature

Ginzburg (1969) and Yagi and Kunii (1951). Combined

Journal of Food Engineering 55 (2002) 147–156

www.elsevier.com/locate/jfoodeng

*

Corresponding author. Tel./fax: +81-89-9469827.

E-mail address:

(T. Abe).

0260-8774/02/$ - see front matter

Ó 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 26 0 - 8 7 7 4 ( 0 2) 0 0 0 5 8 - 4

infrared radiation and convection or vacuum drying has

also been reported as promising (Abe & Afzal, 1997;

Dontigny, Angers, & Supino, 1992; Hasatani, Harai,

Itaya, & Onoda, 1983; Hasatani, Itaya, & Miura, 1986).

In intermittent infrared and continuous convection

heating of a thick porous material the drying time was

two to two and a half times less compared to convection

alone while keeping good surface quality and high energy

efficiency (Dostie, Seguin, Maure, Ton-That, & Chat-

ingy, 1989). Far infrared drying of potato achieved high

drying rates with infrared heaters of high emissive power

(Masamura et al., 1988). The drying rate was also re-

ported to be increased when the electric power supplied

to the far infrared heater was increased and consequently

the temperature of the sample was also observed to be

high. Far infrared and near infrared drying using three

types of granular bed and their quantitative comparison

to hot air drying from the viewpoint of the heat transfer

has been reported by Hashimoto, Hirota, Honda, Shi-

mizu, and Watanabe (1991).

Infrared has its place in drying technology, but it is

not a panacea for all drying processes. It appeals be-

cause it penetrates and produces heating inside the ma-

terial being dried, but its penetrating powers are limited.

However, research which quantitatively analyzed heat-

ing and drying by infrared radiation are limited in

number in the literature.

This paper describes laboratory-scale experimental

results on the drying of the leaf parts of welsh onion by

far infrared radiation under vacuum condition. Because

infiltration distance of the far infrared radiation to

agricultural products in a drying chamber is short,

welsh onion was selected as a sample of this study.

Using conventional natural seasoning and hot-air dry-

ing method discoloration and loss of hue can occur with

only partial recovery when reconstituted in boiling

water. Significant cost increases occur if vacuum or

freeze–drying methods are use as alternatives. A similar

study has not been carried out on the vacuum operation

(Itoh & Chung, 1995).

The objective of this study is to examine the drying

behavior of the combination of far infrared drying with

the vacuum operating condition on the leaf parts of

welsh onion by comparing the physical and thermal

parameters and the drying qualities. The outcome would

provide an innovative approach to further research and

development.

2. Experimental apparatus and procedures

2.1. Experimental apparatus

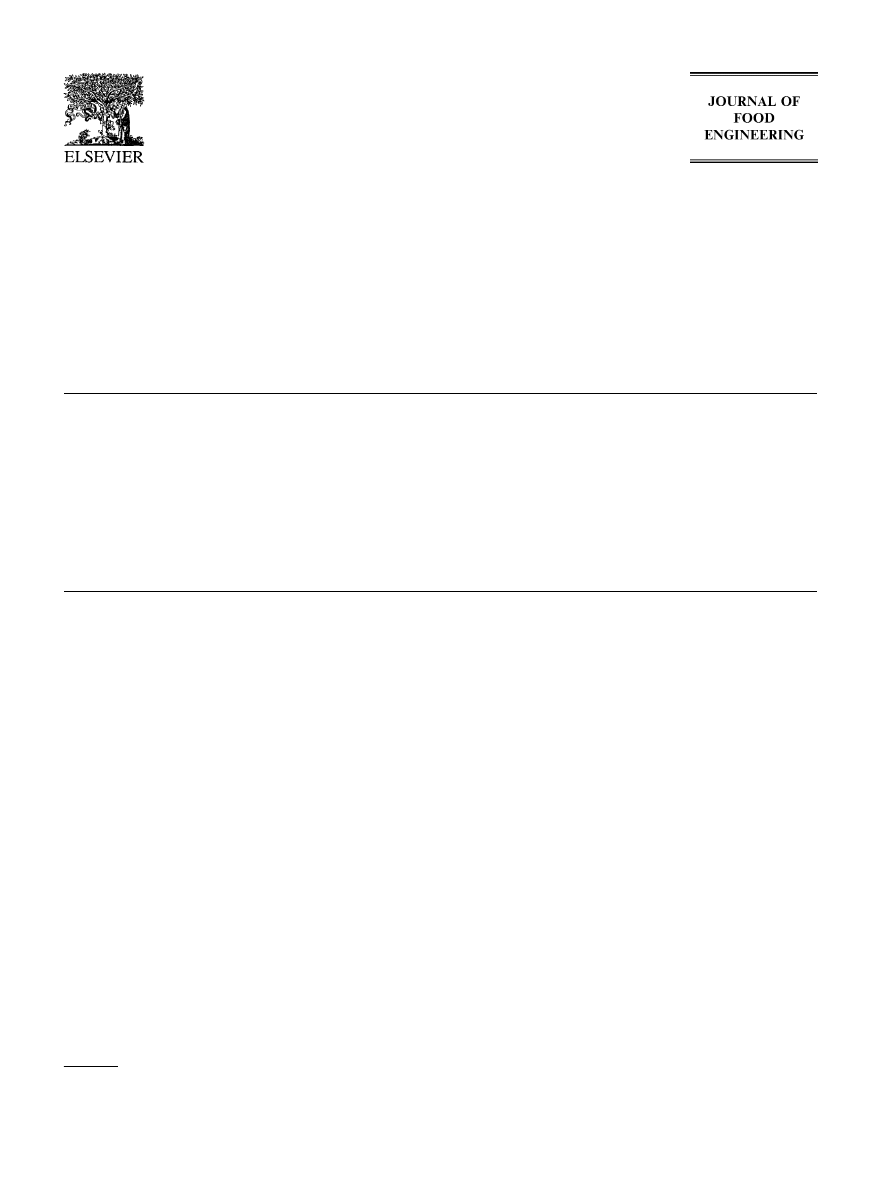

Fig. 1 depicts the experimental apparatus used for the

far infrared vacuum drying of the samples. The drying

procedure involved: a wire netting tray which contained

the material to be dried, fitted in the interior of a acrylic

resin vessel (infrared drying chamber), capable of op-

erating at the desired vacuum level by means of a cold

aspirator; a vacuum meter for ease of seeing the vacuum

pressure charge; and a pressure controller for fine ad-

justment of the pressure level. The materials are dried

by placing them in the vacuum drying chamber, and

then simultaneously reducing the pressure by means of

the aspirator while starting the heater. Vaporization is

promoted even at low temperature by the application of

a vacuum. Simply by putting the sample in the vacuum

atmosphere, a part of water immediately evaporates, and

the water in the remainder may add increased stiffness,

since heat of vaporization is taken from the surrounding

material. However, vacuum alone is not enough when it

is intended to completely dry the food. The heat neces-

sary for continuation of the boiling condition must be

provided externally and this is a role of the infrared

heater.

2.1.1. Far infrared heater

A stainless steel heating coil comprises the heating

element and is effectively made into a fluororesin plate

heater by covering the surface in fluororesin which it has

an excellent radiation efficiency for far infrared radia-

tion with a thickness as little as 1 mm, it is outstanding

in water resistance, and corrosion resistance, in addition

to having a very rapid response rate. The coated fluorine

Nomenclature

c

speed of the light

E

total emissive power

p

Planck constant

T

temperature

d

distance

Subscripts

b

black body

e

emitter

h

heater

k

monochromatic

s

sample

Greek

e

emissivity

j

Boltzmann constant

k

wavelength

r

Stefan–Boltzmann constant

148

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

resin plastic board infrared heater was 23

18 cm in

area and operated at 100 V, with a maximum power of

150 W.

Every body emits radiation due to its temperature

level. It is called thermal radiation because it generates

heat in the wavelength range of 0.1–100 lm within the

spectrum. The total amount of radiation released by a

body per unit area and time is identified as its total

emissive power, E, and depends on the temperature and

the surface characteristics of the body. This energy is

emitted from a surface in all directions and at all

wavelengths. A black body is also defined as one that

emits the maximum radiation per unit area and its

emissive power, E

b

, depends only on its temperature.

The emissivity of a body, e, is then defined as the ratio of

its total emissive power to that of a black body at the

same temperature, e

¼ E=E

b

(Nicholas, 1943; Ratti &

Mujumdar, 1995).

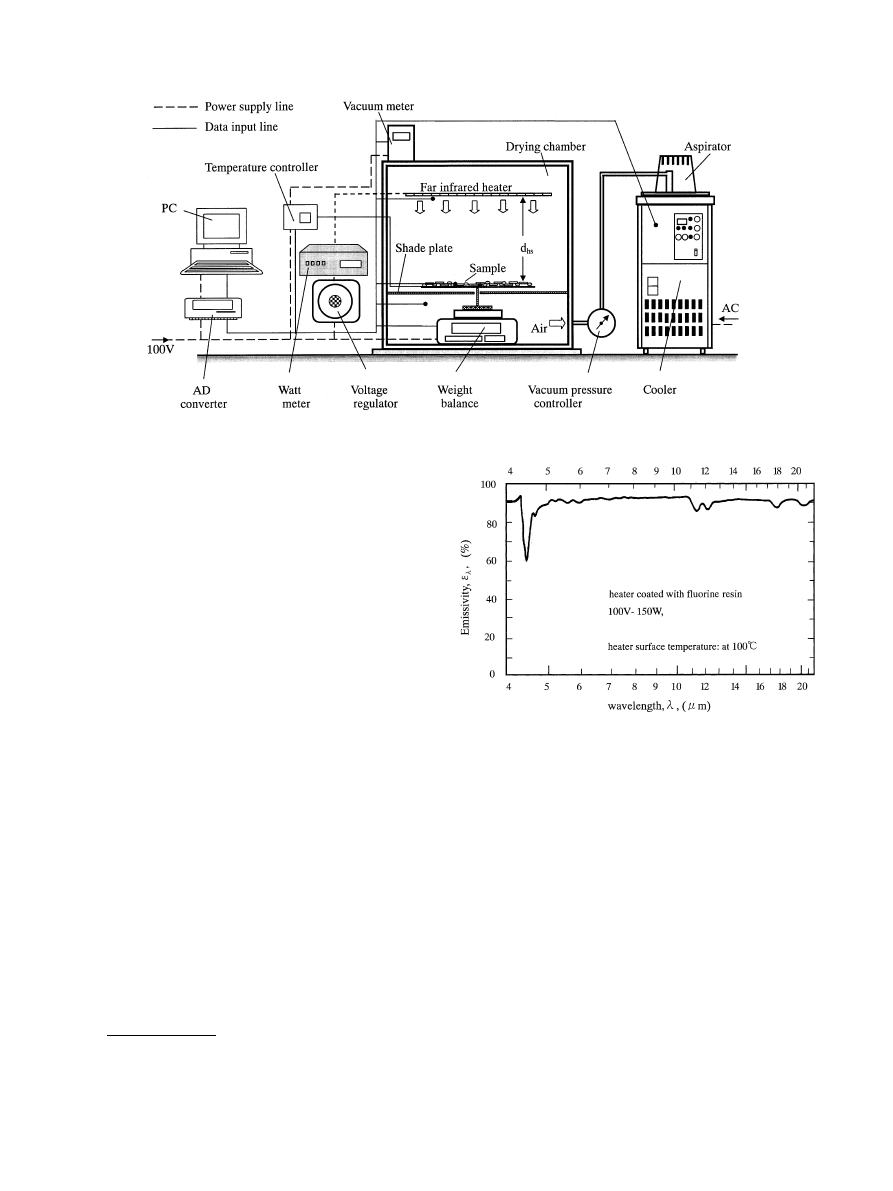

The distribution of the spectral emissivity of the

heater used in this experiment is uniform for each

wavelength, and, when averaged over the surface, the

radiation characteristics are over about 0.7 (Fig. 2). An

infrared radiation body of this type may be deemed

similar to a black body or a high-efficiency radiator. The

features of such a far infrared radiator are that the

heater can radiate the far infrared radiation maximally

even at low temperature, because spectral emissivity is

high in the full wavelength range.

For a black body, this power is expressed by

(Planck’s law of radiation):

E

b;k

¼

2pc

2

p

k

5

exp cp=jkT

ð

Þ 1

ð1Þ

So the monochromatic emissivity of a body is defined as

e

k

¼ E

k

=E

b;k

. Kirchhoff’s law states that under thermo-

dynamic equilibrium (which requires all surfaces to be at

the same temperature), the monochromatic absorptivity

and emissivity of a body are equal. Eq. (1) has a maxi-

mum that is related to the temperature by the following

expression (Wein’s displacement law):

k

max

T

¼ 2897:6 lm K

ð2Þ

Eq. (1) may be integrated over all wavelengths to obtain

the total emissive power for a black body (Stefan–

Boltzmann law):

E

b

¼

Z

1

0

E

b;k

dk

¼ rT

4

ð3Þ

where r is the Stefan–Boltzmann constant.

As pointed out above, the total emissive power

includes the energy from all the wavelengths in the

spectrum of the radiation. On the other hand, the

Fig. 2. Emissivity characteristics of FIR heater.

Fig. 1. Schematic view of experimental far infrared dryer with vacuum extractor.

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

149

monochromatic emissive power E

k

is the radiant energy

contained between wavelengths k and k

þ dk.

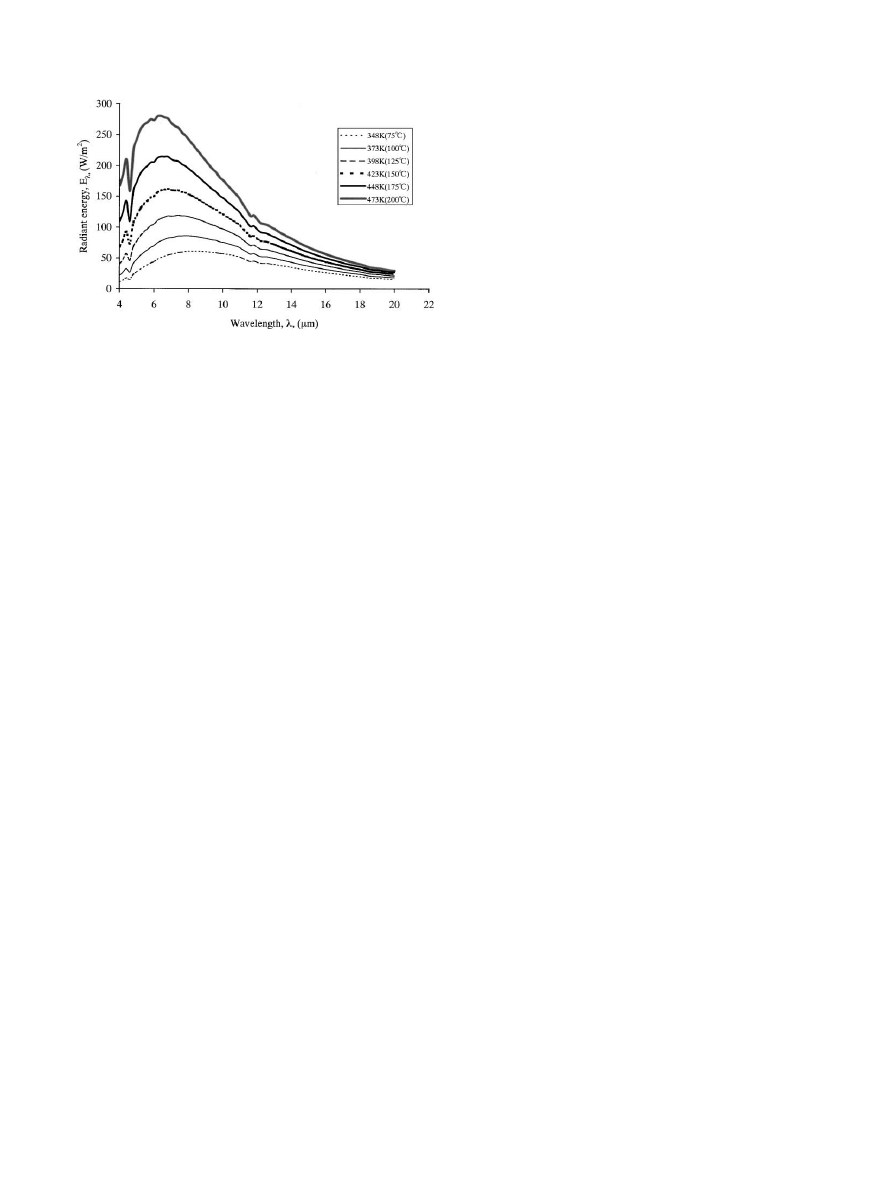

Fig. 3 describes the quantity of radiant energy emit-

ted at each individual wavelength from a heater source

at selected temperatures. As can be seen, varying the

source’s temperature cause changes in the amount of

energy radiated by the heater. Increasing the tempera-

ture of the heater brought about a shift in the peaks to

shorter wavelengths. This heater can be deemed to have

radiation characteristics suitable for this experiment,

because the experiment is carried out under vacuum and

the temperature cannot be high in such an enclosed

chamber. Although the spectral emissivity in the small

wavelength region may be small for one type of far in-

frared radiation heater, in the long wavelength region it

can be high and can be regarded as a large heater. A low

spectral emissivity in the short wavelength area can

be advantageous to the heating efficiency, because the

conversion of radiation energy distribution to the small

wavelength area suppresses the radiation of near infra-

red radiation and visible rays which have little or no

heating effects. At high temperatures with heaters of this

type, there is a significant amount of both the near in-

frared radiation and visible rays. Nevertheless, while

there is no clear guideline for the selected application of

the heater of either types, about 300

°C is regarded as

the heater surface temperature forming the boundary

between the two areas, and when below this tempera-

ture, the similarity to a black body may be regarded as

an advantage.

2.1.2. Sample

Welsh onions of uniform initial moisture content were

bought directly from the countryside. Only the leaf part

was used for this experiment. The samples were cut into

5 and 10 mm lengths and immediately wrapped in a

plastic film, and stored at 5

°C in a refrigerator. Before

each run, the total amount of samples required was

taken from the refrigerator and left to equilibrate to the

room temperature. For each run, the sample was placed

on a tray (20

25 3 cm) made from the wire gauze

and connected to an electronic balance (Shimadzu Co.,

model BL-1200H, Tokyo, 0.01-g accuracy). The tray

was spaced to permit air circulation between the mate-

rials. The initial mass of sample was set to be about 50 g

by spreading one or two layers on the tray. The initial

moisture content of the leaf part of the welsh onion for

each experiment was determined by drying at least three

replications in a forced convection oven at 65

°C for 5 h

(Resource Investigative Committee, Science & Tech-

nology Agency edition, 1982). The values varied be-

tween 91.3% and 93.5% wet basis. The drying was ended

when the moisture content of the sample reached 5% wet

basis. The drying rate was calculated as the amount of

moisture evaporating in 1 min per original kg of the

sample.

2.1.3. Drying chamber

The drying chamber used for this experiment was

a vacuum desiccator (Iuchi Co., model VW) that was

made from a transparent acrylic resin with 40

30 40

cm internal dimensions, and 133 Pa vacuum tolerance.

All inner walls of the drying chamber were covered with

aluminum foil from which the infrared rays were re-

flected (Ginzburg, 1969). An electronic balance, not di-

rectly exposed to the infrared rays was placed under the

sample in the drying chamber.

For vacuum drying, the pressure in the drying cham-

ber was lowered to approximate 1/76 of atmospheric

pressure so that the water boiled and evaporated at a

temperature as low as 10

°. As is normal in vacuum

drying, the temperature of dried material was rapidly

lowered as evaporation commenced. The drying then

stops, as long as there is no supply of heat of vapor-

ization, when it approaches the boiling temperature

appropriate to the degree of vacuum.

2.1.4. Aspirator

Since the drying was to be accomplished in the vac-

uum state, an aspirator was used. An aspirator is a

pump forcing liquid through a pipe that has a con-

striction in its diameter and using the ensuing pressure

drop to pull a vacuum in the chamber (through a tubing

connected to the point of constriction). It is necessary to

lower the water temperature in order to increase the

level of vacuum, because there is the relationship be-

tween a water vapor pressure and the water temperature

(e.g. water vapor pressure is 0.93 kPa at 5

°C). It is also

possible to bring the water temperature to

10 °C, by

mixing ethylene glycol into the water. For this experi-

ment, the mass flow rate of cold water through the as-

pirator (Iwaki Glass Co., Ltd., model CLU33-ASP) was

19 l/min, and the ultimate vacuum was 0.28, 0.61, 1.22,

and 2.32 kPa when using water at

10, 0, 10, and 20 °C,

respectively.

Fig. 3. Monochromatic emissive power of heater at various absolute

temperature.

150

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

In the vacuum state, the heat supplied is of course

radiant heat, because there is no air for convection.

Efficient drying can be expected, since 3 lm far infrared

radiation is radiated from the far infrared radiation

plate heater used in this experiment, and since it radiates

uniformly from the full face of the heater. Also, there is

some water in the pores of the food since diffusion of

water molecule from the interior of the food is rapid.

2.1.5. Data acquisition system

All experimental measuring equipments were con-

nected to a personal computer to continuously record

the weight loss and the other data as a function of

drying time without removing samples from the drying

chamber. A computer program written in BASIC was

used for this purpose. Type K thermocouples (chromel

vs. alumel) with a thickness of 0.3 mm were fixed at two

locations to record the infrared heater surface temper-

ature and one for the drying chamber temperature.

Three samples of the food material temperature were

recorded by 0.1 mm diameter of type-T thermocouples

(copper vs. constantan).

2.1.6. Heat power regulator

The radiation intensity was varied by regulating the

voltage and hence output of the heater. As a result, the

power of heater was regulated at 40, 50, 60, 70, 80, 90,

and 100

2W. Each level was tested for at least five

drying runs.

2.2. Experimental procedure

The sample set was placed at the middle of the drying

chamber directly facing the far infrared heater. The

vacuum operation was achieved through the sidewall of

the chamber. Seven levels of distance between the sam-

ple and the far infrared radiation heater were used and

tested for the selected radiation intensity levels. These

were 7.5, 10, 12, 15.2, 17, 20, and 22.5 cm.

2.3. Measurement and evaluation of drying quality

2.3.1. Chlorophyll content

Chlorophyll was extracted from the sample in abso-

lute (100%) acetone, and the absorbance at 644 and 662

l

m of the filtered acetone extract was obtained using a

spectrophotometer (Shimadzu Co., model UV-120-01,

Tokyo, 325–1000 nm sensitivity). The chlorophyll con-

tent was calculated using the equations quoted in the

literature Cupina (1969) and Holm (1954).

2.3.2. Color

The color and hue of both the dried onion in each

drying run and fresh onion sample were measured using

a colorimeter (Minolta Camera Co., Ltd., model CR-

100). In tristimulus color measurements, L

, a

, and b

coordinates show the degree of brightness, the degree of

redness (

þa) or greenness (a), and the degree of yel-

lowness (

þb) or blueness (b), respectively. Hue angle

can be computed from the a

and b

parameters (Chen,

Koh, & Park, 1999). In the Lab color solid, as the dis-

tance (

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

a

2

þ b

2

p

) from the origin increases, the color

becomes more vivid. For each sample, this was mea-

sured directly on the product seven times in different

locations to determine the average values. Color differ-

ence values, L

, a

, and b

, were thus quantified (Nsonzi

& Ramaswamy, 1998; Venkatachalapathy, 1997):

DL

¼ L

L

0

;

Da

¼ a

a

0

;

Db

¼ b

b

0

ð4Þ

where L

, a

, and b

are the measured values of ground

dried onion and after soaking in distilled water for 2h,

L

0

, a

0

, and b

0

are the values of the initial onion. The

total color difference (DE

ab

) was defined using the Mi-

nolta equation as follows:

DE

ab

¼

DL

ð

Þ

2

h

þ Da

ð

Þ

2

þ Db

ð

Þ

2

i

0:5

ð5Þ

2.3.3. Rehydration ratio

The measurement of the water rehydration rate was

based on the following procedure. 200 g of distilled

water was brought to a temperature of 90

°C in a con-

stant temperature water bath. Then a precisely weighed

1 g sample of the dried material was placed in a wire

gauze basket and soaked for 20 min. Afterwards, the

samples were centrifuged to remove free water and

the weight of each was taken (Itoh & Chung, 1995). The

ratio of the mass after the water rehydration to the pre-

drying mass of the sample was calculated as a recovery

ratio (Fasina, Tyler, & Pickard, 1997; Nsonzi & Ra-

maswamy, 1998; Venkatachalapathy, 1997).

3. Results and discussion

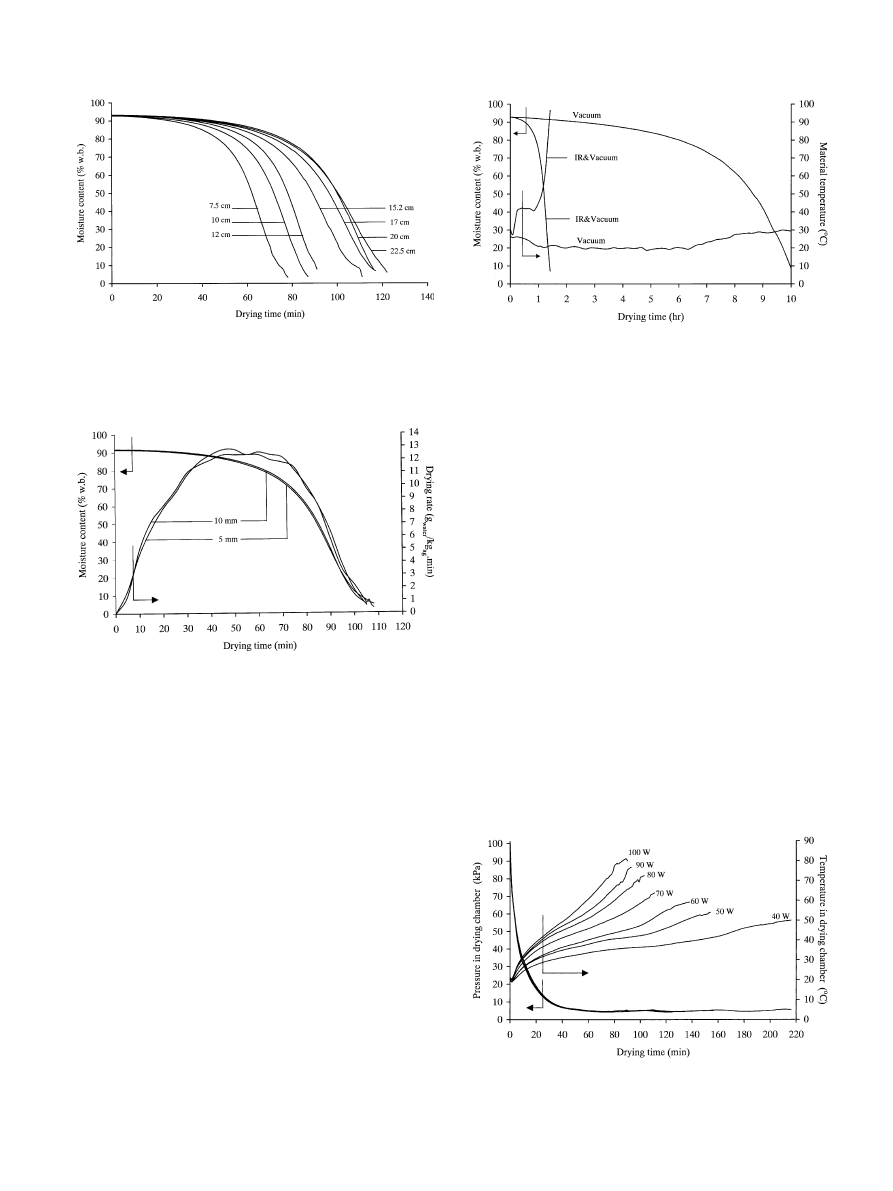

3.1. Effect on the preliminary study

It has been mentioned previously that a range of

distances between the samples and the heater were used.

The electric power was 80 W and the samples were of 5

mm length. Fig. 4 shows that all spacings gave a gradual

moisture content decrease at the beginning of drying

and a dramatic decrease after approximately 50 min.

Decreasing the spacing gave a more rapid moisture

content decrease. This is because the radiation pene-

trated into the product directly. However, the dehy-

drated products at the lower spacings were scorched due

to intense radiation. On the other hand, at the 17 cm

spacing and greater, the effect seems to be marginal

because of the dissipation of thermal radiation. As a

result, the 10 cm spacing was used entirely for this study.

This conclusion is consistent with Dontigny et al. (1992),

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

151

in their article that studied the use of medium wave-

length where the electric emitters were placed 10 cm

above the top of products.

The effects of the length of welsh onion under a

combined far infrared radiation and vacuum is provided

in Fig. 5. Two lengths of cut welsh onions, 5 and 10 mm,

the electric power of 80 W, and a 10 cm distance of the

heater from the sample surface were used for this study.

The results were somewhat unexpected with the 5 mm

length seeming to have a drying rate close to that of the

10 mm samples. There is quite unlike the results of Itoh

and Chung (1995) who found that drying rate (using

long wave infrared radiation) increased as the length of

the welsh onion decreased. According to the experience

of Japanese instant food factories and observed during

the experiments, the vapor pressure of 10 mm length had

reached equilibrium before reaching the required state

of 5% wet basis. Consequently, the 5 mm length was

subsequently used in the experiment.

Fig. 6 plots the relationship between drying time

against moisture content and material temperature

under a combined far infrared radiation and vacuum

compared to a vacuum operation alone. The same con-

ditions as used when investigating the effects of length

were considered. As can be seen, the only moisture

transfer in the vacuum operation was that vaporized

from the products over long times, but the penetration

of internal heating into the products caused a rapid

increase in water vapor pressure inside the materials

(Fasina et al., 1997). Thus, far infrared radiation can be

combined effectively with vacuum operation to ensure

rapid removal of evaporated moisture.

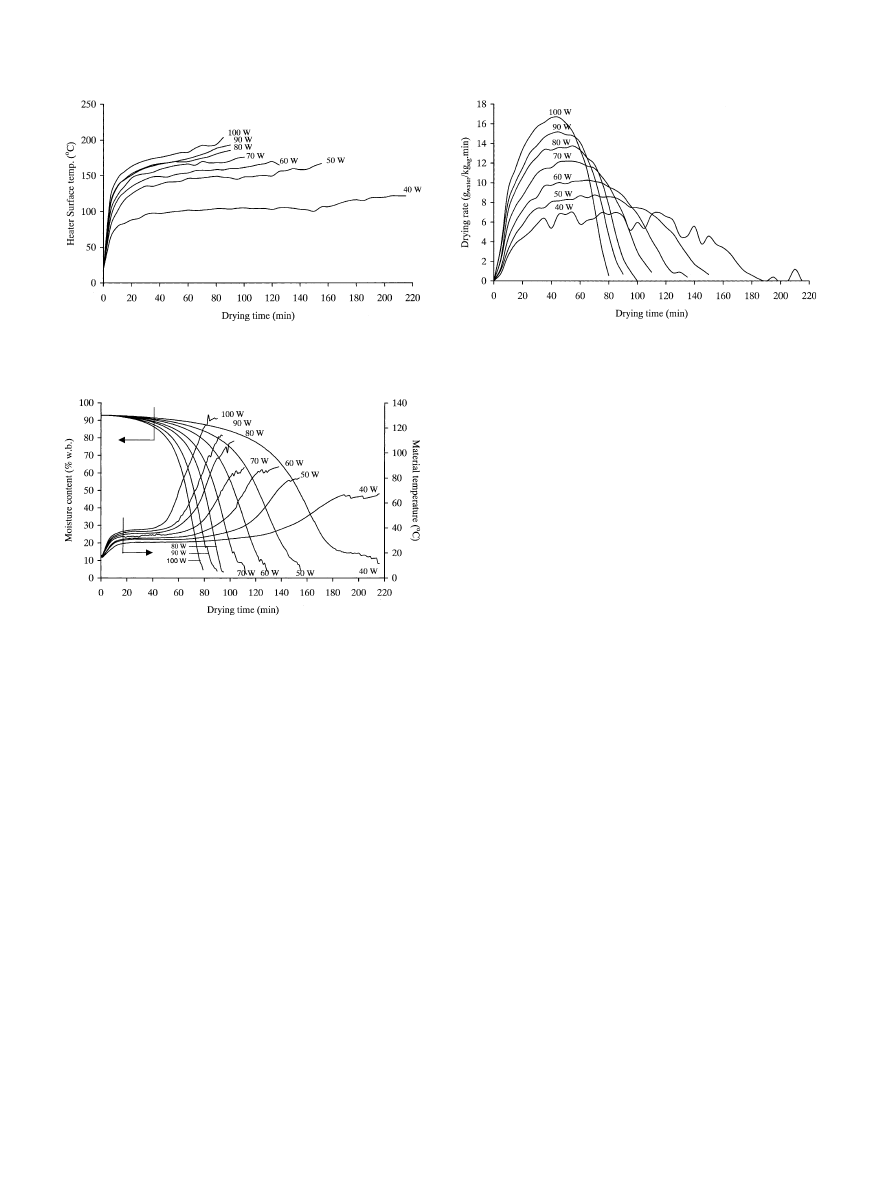

3.2. Effect on physical and thermal parameters

The pressure and temperature in the drying chamber

are plotted against drying time in Fig. 7. The results

indicate that electrical power in intense radiation had a

significant effect on drying chamber temperature, but

did not affect the pressure depression. Increasing radi-

ation intensities increase heater surface temperature

(Fig. 8) and material temperature (Fig. 9). However,

moisture content decreases. The line of moisture content

Fig. 4. Effect of the height, d

hs

, between sample and heater on moisture

content.

Fig. 5. Effect of the length of welsh onions on moisture content and

drying rate.

Fig. 6. Effect of the combination of a far infrared radiation drying and

vacuum operation against a vacuum operation alone on moisture

content and material temperature.

Fig. 7. Pressure and temperature in drying chamber at different levels

of radiation intensities.

152

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

goes down marginally from the initial state and drops

substantially from 50 min of drying time to the end of

drying at a 5% wet basis of moisture content. The higher

the radiation intensity, the quicker a removal of evap-

orated moisture. The material temperature illustrates

that the higher the radiation intensities by increasing an

electrical power, the quicker the rise in material tem-

perature. As revealed by this graph, the temperature

inside the products climbs dramatically within 10 min

after running the heater and vacuum operation, after

this, it remains stable at 30–40

°C, and rise severely after

50 min running the system. The rise in temperature de-

creases gradually with falling infrared radiation. It is

generally known that the rate of moisture loss of a

product is proportional to the difference between the

moisture content and its equilibrium moisture content.

It is certain that the drying rates shown in Fig. 10 in-

creases with increasing radiation intensity, which was

one of the causes of the rapidly evaporated moisture.

However, from experience in an occasional drying run,

the lowest intensity (40 W power level solely) cannot

reach the needed moisture content (5% wet basis). This

can be explained because of the vapor pressure of the

water inside the product is equal to the water vapor

pressure of the surroundings. On the other hand, it can

be stated that the equilibrium moisture content has been

reached.

Fig. 10 gives the results of the drying rates over dif-

ferent levels of radiation intensities. The characteristic

drying rate under a combined far infrared radiation and

vacuum operation gives a parabolic shape for all radi-

ation intensity levels. Each level (especially at 90 W and

under) seems to behave with three drying behaviors: a

rising-rate period, a constant-rate period, and a falling-

rate period. The rising-rate period occurred during

the drying process because the samples were put into the

drying chamber at atmospheric pressure before the

chamber was evacuated. The initial rate of drying in this

period increases rapidly from the beginning to about 40

min into the drying run. The constant-rate period re-

mains wide in range especially at the less intense radia-

tion levels (40 W), and peaks at 17 g water per kg initial

material in a minute for 100 W. This can be because the

internal resistance to moisture transport is possibility

much less than the external resistance to water vapor

removal from the product surface. This period appears

too narrow in cases of high intensity, e.g. 100 W. On the

other hand, it is quite large for the low intensities such as

40, 50, and 60 W. The falling-rate period displays be-

havior as for conduction and convection drying and is

caused by the internal resistance to moisture transport

becoming grater that the external resistance. The vapor

pressure at the product surface decreases resulting in a

lowering of the drying rate.

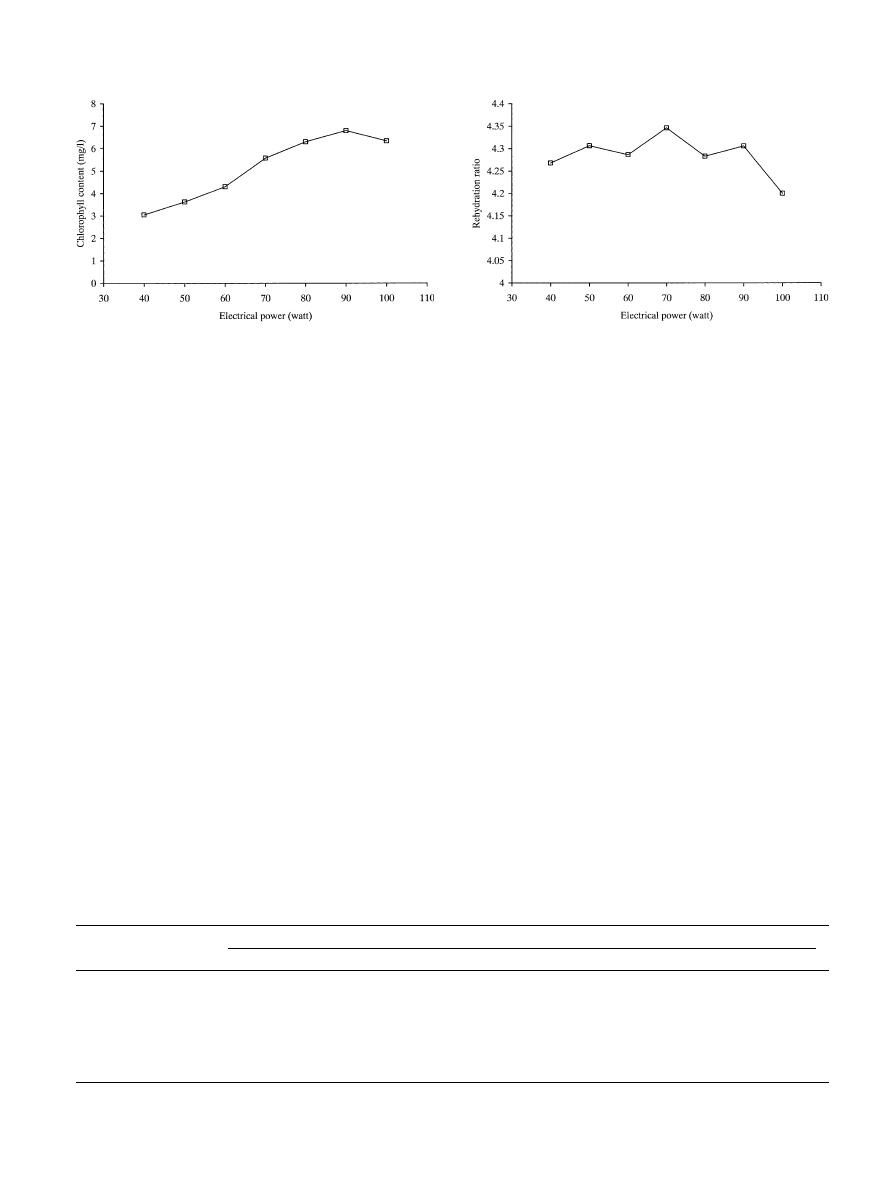

3.3. Effect on drying qualities

The chlorophyll in higher plants is composed of two

constitutions: chlorophyll a and b, which are distin-

gu\ished by their physical and chemical properties

(Cupina, 1969). In addition, it is also widely acknowl-

edged that high temperature drying denatures the nu-

tritive value of dehydrated food products. As can be

Fig. 8. Heater surface temperature at different levels of radiation in-

tensities.

Fig. 9. Moisture content and material temperature at different levels of

radiation intensities.

Fig. 10. Drying rate at different levels of radiation intensities.

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

153

seen in Fig. 11, total chlorophyll content climbs rapidly

with an increase radiation intensity and peaks at 90 W,

after which it falls slightly at 100 W. The results also had

significant effects on pigment and the least significant

difference (LSD) is tabulated in Table 1. The results at

the 70 W power level or over were largely non-signifi-

cant. The outcomes can be explained in two ways: (1)

the time required to dry welsh onions at 40–80 W is too

long, causing a reduction in total chlorophyll value

of the dehydrated onions, (2) the high temperature

contributed to a decrease in pigments. This is similar to

results of Holm (1954) who affirmed that excessively

strong light changes the pigment in a short time. Cupina

(1969) also explained that dehydration of the plant

material in the air at room or higher temperatures leads

to a certain loss of pigments. Nicholas (1943) pointed

out that the shorter the time of the preservation in fruits

and vegetables processes, the smaller the loss of original

quality.

Fig. 12gives the rehydration ratio at different radia-

tion intensities. As revealed in the graph, the rehydra-

tion ratio seems to have a nebulous term, because the

effect of radiation intensity on this property fluctuates

widely. However, the long period of drying and the high

temperature may contribute to a decrease in rehydra-

tion, because the product surface was destroyed as were

the pores that allowed water reenter into the kernel. The

results suggest that onions dehydrated at 70 W power

seem imbued with fresh-like properties. Fasina et al.

(1997) described cracking of seeds that allowed for

easier diffusion of moisture into the kernel and the mi-

gration of soluble out of the seeds into the soaking

water. Similar results from Yang and Atallah (1985)

explained that a porous and non-shrunken structure

facilitates a good rehydration. Kim and Toledo (1987)

also maintained that the lower rehydration ratios

were attributed to the added solids, which reduced the

amount of water that could be absorbed during rehy-

dration.

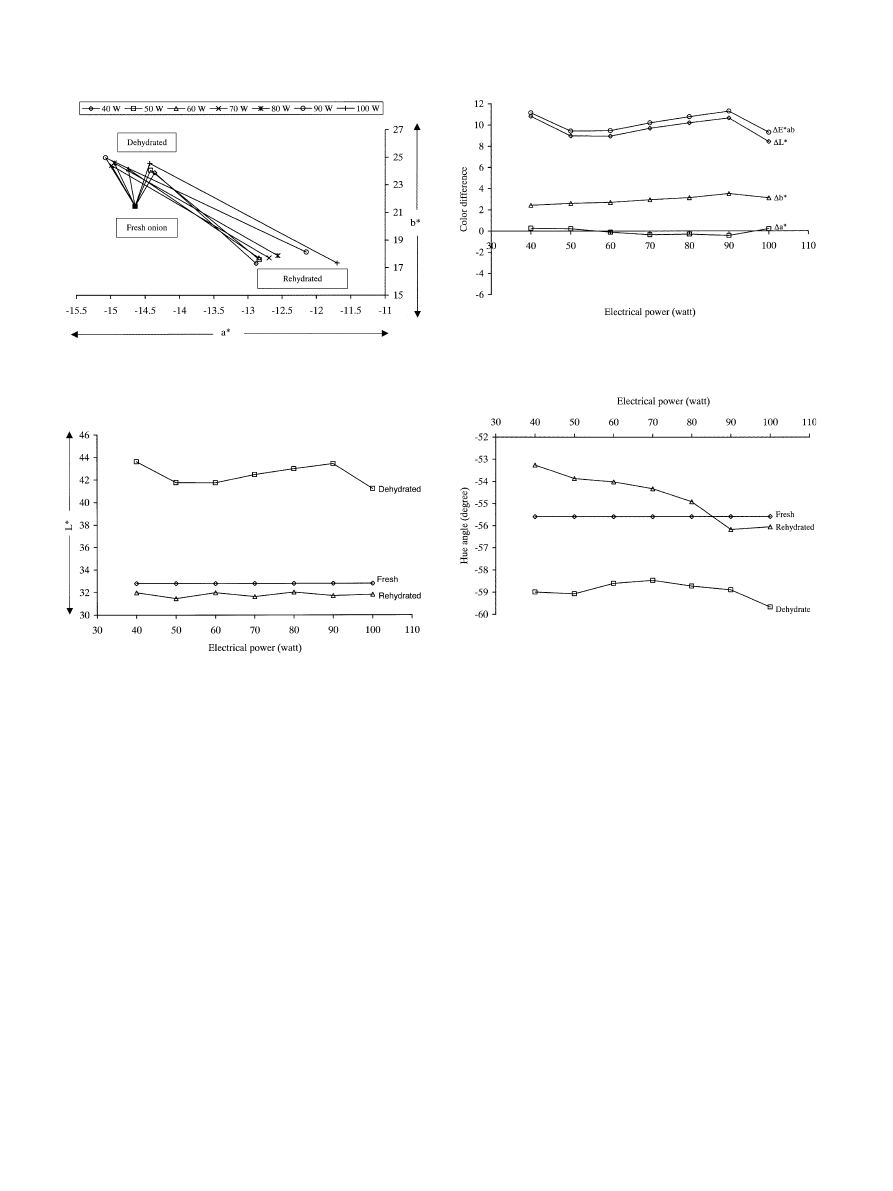

Color is a psychological property of food products

that affects to the enjoyment of eating. Temperature and

relative humidity during drying is one of the causes of

color degradation in dehydrated products (Lozano &

Ibarz, 1997). The results of the color solid (dimensions

a

and b

) of welsh onions are provided in Fig. 13. A

combined far infrared radiation and vacuum process has

a complicated effect on the a

and b

of dehydrated

onions with no clear pattern in the results. Rehydration

of the onions by soaking in distilled water demonstrated

that a change in the a

parameter was more obvious

than that in the b

. The results show the higher intensity

radiation, 90 and 100 W, yielded a rehydrated product

Fig. 11. Chlorophyll content of dehydrated welsh onions at different

levels of radiation intensities.

Table 1

Least significant difference for chlorophyll content of dehydrated onions at different radiation intensities

Power (W)

Chlorophyll content (mg/l)

1

23

4

Average

a

40

2.930

2.137

3.513

3.625

3.051a

50

2.926

3.316

4.804

3.470

3.629a

60

3.295

5.577

5.688

2.688

4.312ab

70

4.839

6.874

5.757

4.857

5.582bc

80

5.423

7.886

6.020

5.914

6.311c

90

6.425

8.501

6.591

5.702

6.805c

100

6.0424.913

7.311

7.110

6.344c

a

The average values with the same letter are non-significant at 95% confidence interval (LAD

0:05

¼ 1:493 mg/l).

Fig. 12. Rehydration ratio of dehydrated welsh onions at different

levels of radiation intensities.

154

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

closer to redness, and the lower intensity experiments at

40, 50, and 60 W, put it nearer to greenness. That is to

say, the radiation intensity influences more the a

pa-

rameter.

Fig. 14 shows the effect on the L

parameter. As can

be seen, the dehydrated product was moved by the ra-

diation intensity closer to whiteness. This effects in-

creased slightly from the 50 W power level and declined

slightly at 100 W. The rehydrated product showed a

fluctuating effect with intensity level and was closer to

the blackness of the initial product. Krokida, Tsami,

and Maroulis (1998) implied that the brightness of de-

hydrated of apple, banana, carrot, and potato during

conventional and vacuum drying was not affected by

temperature and relative humidity during drying, but

the redness and the yellowness were strongly affected.

Fig. 15 also provides further details of color difference

based upon the initial onion against dehydrated onions,

and shows the results having the same tendency for a

and b

. Furthermore, as revealed in this graph, the total

color difference, DE

ab

, goes up slightly with the power

level similar to results of Venkatachalapathy (1997) who

stated that the greatest differences were found at the

highest power level in microwave drying. Nsonzi and

Ramaswamy (1998) also concluded that the DE

ab

was

related to temperature in a forced air cabinet dryer and a

freeze dryer.

The hue angle of products is shown in Fig. 16. The

rehydrated product at 40 W is furthest from the fresh

product and reduces dramatically to the fresh product

and remains stable at 90 through 100 W. That is to say,

the 85 W power level gives a rehydrated product that is

the same as the initial product. As for the dehydrated

product, the outcomes show that the nearest hue angle

to the fresh is given by the 70 W treatment.

4. Conclusions

The radiation intensity levels influenced dramatically

the temperature in the drying chamber, that on the heater

surface and moisture content, while drying rate had a

parabolic shape for all power levels. There is a strong

possibility that the area under each curve can be divided

Fig. 15. The color differences from initial onions of the a

, b

, L

, and

DE

ab

parameters at different levels of radiation intensities.

Fig. 13. The a

and b

parameters of fresh, dehydrated and rehydrated

welsh onions at different levels of radiation intensities.

Fig. 14. The L

and b

parameters of fresh, dehydrated and rehydrated

welsh onions at different levels of radiation intensities.

Fig. 16. The hue angle of fresh, dehydrated and rehydrated welsh

onions at different levels of radiation intensities.

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

155

into three periods: (1) a rising-rate period, (2) a constant-

rate period, and (3) a falling-rate period. The intensity of

radiation had significant effects on chlorophyll content,

the means of this pigment being non-significant at a 70 W

power level and over. The long period of drying and the

high temperature may have contributed to a decrease in

rehydration. At the 70 W power level, however, fresh-like

properties were obtained. The radiation intensity influ-

enced the a

for rehydrated onions, and the L

and DE

ab

for dehydrated onions.

Acknowledgements

This research was partially supported by a fund from

the Japanese Government and the Ministry of Educa-

tion, Science and Culture (Monbusho) who granted a

Ph.D. scholarship to Sunate Mongpraneet.

References

Abe, T., & Afzal, T. M. (1997). Thin-layer infrared radiation drying of

rough rice. Journal of Agricultural Engineering Research, 67, 289–

297.

Chen, Q., Koh, H. K., & Park, J. B. (1999). Color evaluation of red

pepper powder. Transactions of the ASAE, 42(3), 749–752.

Cupina, T. (1969). Methods of determining chlorophyll a and b in

plant material. Contemporary agriculture, 17(10), 89–100.

Dontigny, P., Angers, P., & Supino, M. (1992). Graphite slurry

dehydration by infrared radiation under vacuum conditions. In A.

S. Mujumdar, & M. A. Roques (Eds.), Drying ’92. New York:

Hemisphere.

Dostie, M., Seguin, J. N., Maure, D., Ton-That, Q. A., & Chatingy, R.

(1989). Preliminary measurements on the drying of thick porous

materials by combinations of intermittent infrared and continuous

convection heating. In A. S. Mujumdar, & M. A. Roques (Eds.),

Drying ’89. New York: Hemisphere.

Fasina, O., Tyler, B., & Pickard, M. (1997). Infrared heating of legume

seeds effect on physical and mechanical properties. Paper No.

976013An ASAE Meeting Presentation. Minnesota: Mirmeapolis.

Ginzburg, A. S. (1969). Application of infrared radiation in food

processing. Chemical and Process Engineering Series. London:

Leonard Hill.

Hasatani, M., Harai, N., Itaya, Y., & Onoda, N. (1983). Drying of

optically semitransparent materials by combines radiative convec-

tive heating. Drying Technology, 1(2), 193–214.

Hasatani, M., Itaya, Y., & Miura, K. (1986). Hybrid drying of coals by

combined radiative and convective heating. In A. S. Mujumdar

(Ed.), Drying ’86 (pp. 227–231).

Hashimoto, A., Hirota, K., Honda, T., Shimizu, S., & Watanabe, A.

(1991). Factors influencing constant drying rate of wet granular

bed irradiated by infrared radiation. Journal of Chemical Engi-

neering of Japan, 24(6), 748–755.

Holm, G. (1954). Chlorophyll mutation in barley. Acta Agriculturae

Scandinavica, 4, 457–471.

Itoh, K., & Chung, S. H. (1995). Drying of agricultural products using

long wave infrared radiation (part 2)––Drying of welsh onion.

Journal of the Agricultural Society of Agricultural Structures, 26,

89–96.

Kim, M. H., & Toledo, R. T. (1987). Effect of osmotic dehydration and

high temperature fluidized bed drying on properties of dehydrated

rabbiteye blueberries. Journal of Food Science, 52(4), 980–

989.

Kishida, Y. (1998). 1999 Edition farm machinery yearbook. Tokyo:

Shin-norinsha Co., Ltd.

Krokida, M. K., Tsami, E., & Maroulis, Z. B. (1998). Kinetics on color

changes during drying of some fruits and vegetables. Drying

Technology, 16(3–5), 667–685.

Lozano, J. E., & Ibarz, A. (1997). Color changes in concentrated fruit

pulp drying heating at high temperatures. Journal of Food

Engineering, 31, 365–373.

Masamura, A., Sado, H., Honda, T., Shimizu, M., Nabethani, H.,

Hakajima, M., & Watanabe, A. (1988). Drying of potato by far

infrared radiation. Nippon Shokuhin Kogyo Gakkaishi, 35(5), 309–

314.

Nicholas, J. E. (1943). Some preliminary investigations on dehydration

of fruits and vegetables with infrared energy. Dehydration of Fruits

and Vegetables, 236, 285–291.

Nsonzi, F., & Ramaswamy, H. S. (1998). Quality evaluation of osmo-

convective dried blueberries. Drying Technology, 16(3–5), 705–723.

Ratti, C., & Mujumdar, A. S. (1995). Infrared drying. In S. M. Arun

(Ed.), Handbook of industrial drying (2nd ed., pp. 567–588). New

York: Marcel Dekker, Inc.

Resource Investigative Committee, Science and Technology Agency

edition, (1982). Japanese Standard Ingredient table of food (4th ed.,

pp. 22–23). Ministry of Finance: Printing Bureau.

Venkatachalapathy, K. (1997). Osmotic and microwave drying of

strawberries. Journal of Food Processing and Preservation, 20, 145–

156.

Yagi, S., & Kunii, D. (1951). Infrared drying characteristics of

granular or powdery materials. Kagaku Kikai, 15(3), 108–123.

Yamazaki, Y., Hashimoto, T., Honda, T., & Shimizu, M. (1992).

Optical characteristics gelatinous materials in infrared radiation

drying. In A. S. Mujumdar, & M. A. Roques (Eds.), Drying ’92.

New York: Hemisphere.

Yang, C. S. T., & Atallah, W. A. (1985). Effect of four drying methods

on the quality of intermediate moisture lowbush blueberries.

Journal of Food Science, 50, 1233–1237.

156

S. Mongpraneet et al. / Journal of Food Engineering 55 (2002) 147–156

Document Outline

- Accelerated drying of welsh onion by far infrared radiation under vacuum conditions

Wyszukiwarka

Podobne podstrony:

Accelerated Drying of Single Hardwood Boards by Combined Vacuum Microwave Application

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

Practical Analysis Techniques of Polymer Fillers by Fourier Transform Infrared Spectroscopy (FTIR)

Far Infrared Energy Distributions of Active Galaxies in the Local Universe and Beyond From ISO to H

Preparation of garlic powder with high allicin content by using combined microwave–vacuum and vacuum

Preparation of dry honey by microwave–vacuum drying

Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum microwav

Far Infrared Spectroscopy of Star Forming Galaxies Expectations for the Herschel Space Observatory

Drying of garlic (Allium sativum) cloves by microwave hot air combination

Assessment of cytotoxicity exerted by leaf extracts

Modeling with shrinkage during the vacuum drying of carrot (daucus carota) (Arévalo Pinedo, Xidieh M

Induction of two cytochrome P450 genes, Cyp6a2 and Cyp6a8 of Drosophila melanogaster by caffeine

USŁUGI, World exports of commercial services by region and selected economy, 1994-04

Myth & Religion of The North by Turville Petre

Influence of drying methods on drying of bell pepper (Tunde Akintunde, Afolabi, Akintunde)

Microwave Application in Vacuum Drying of Fruits (Drouzaf, H SchuberP)

Microwave vacuum drying of model fruit gels (Drouzas, Tsami, Saravacos)

więcej podobnych podstron