Page 1

Global Development and Launch System

(GDLS)

26June 2007

Page 2

Global Development and Launch System - GDLS

Global Development and Launch System or,

“GDLS”,

includes

Product and Process Development

and

Product and Process Launch

KEY

Must Involve Cross Functional Team

Page 3

Global Development and Launch System - GDLS

Mission for the new “IAC Way”

GDLS and ProLink is a world class program management system which guides our program teams

through the product development cycle and forms the basis for a successful launch considering

quality, cost, design, and delivery.

GDLS and ProLink key objectives:

Method – GDLS

Utilize best practices from “former C&A way” and “former Lear way”

Incorporate appropriate phases with senior management review and approval at the end of each

phase

Based on the elements of APQP

Will tie into a change management system – Under development

A common system with enough flexibility to allow our global program teams to adapt to specific

product or customer program requirements

Means – ProLink (https://learconnect.lear.com/prolink)

Easily accessible by all members of the program team

Facilitates reporting – Senior management, within the program team, to the customer, etc

Other

Defines roles and responsibilities of all functions

Is marketable to our customers and suppliers

Makes life simpler for the program management team, not harder

Page 4

Global Development and Launch System - GDLS

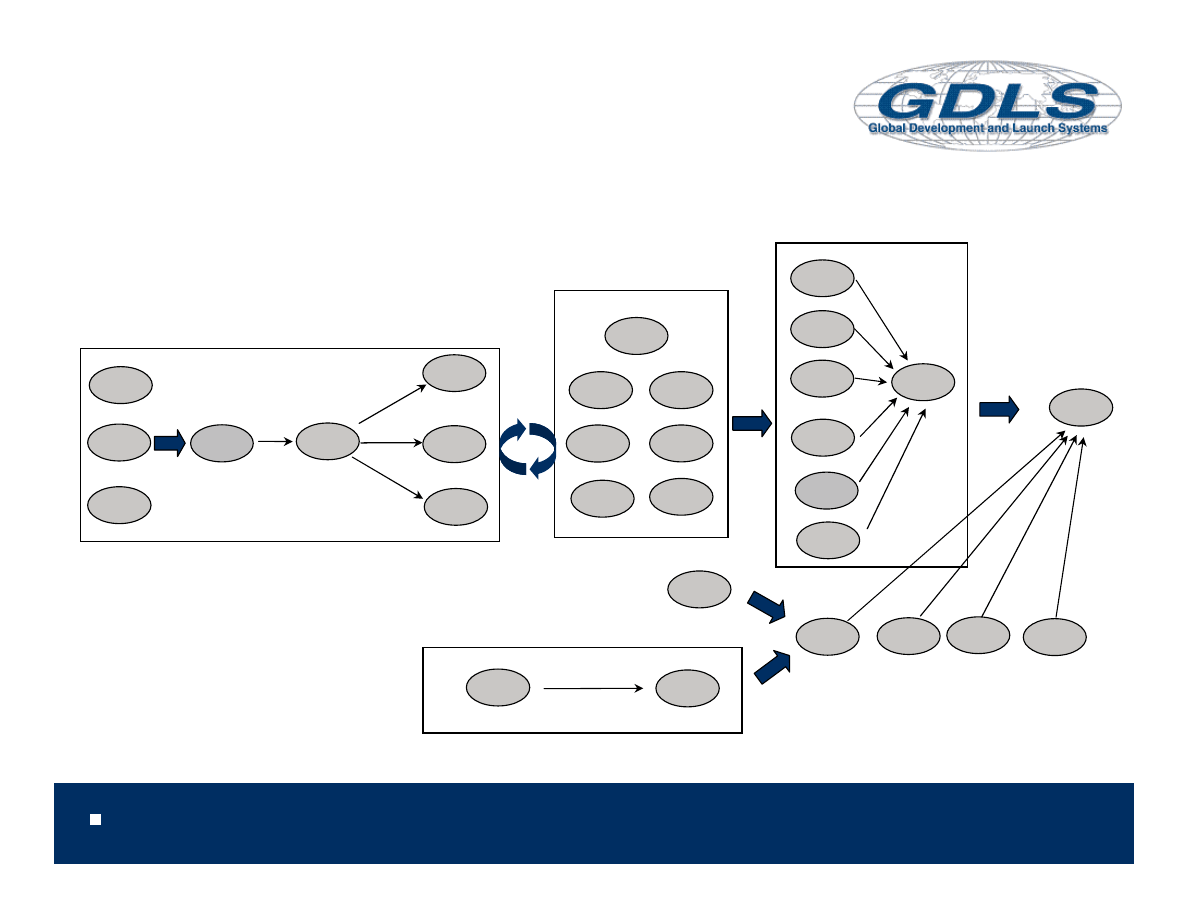

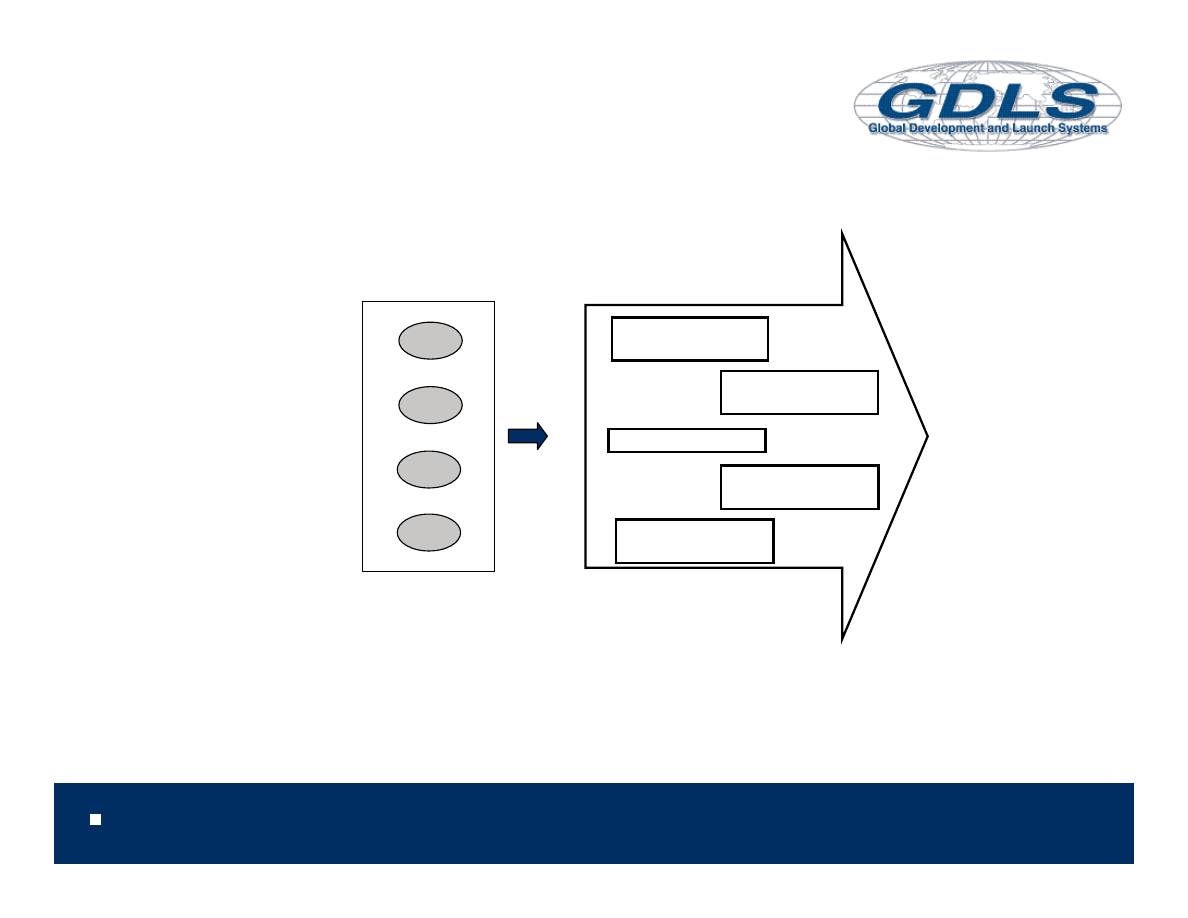

Phase / Gate System

GDLS is a phase / gate system:

•

Starts with activities to acquire the business

Also includes a earlier phase for new product and/or process

development

•

Phases are defined and titled to match typical planning and methodology

used by our customers including all APQP elements

•

Focus on deliverables

•

Structure of phases and deliverables provide flexibility for application with

all products and with all customers

•

Organizes deliverables into functional responsibility – “Work Groups”

•

Deliverables to be completed by the end of the phase

•

GDLS methodology continues into the post-launch or continuous

improvement phase

Page 5

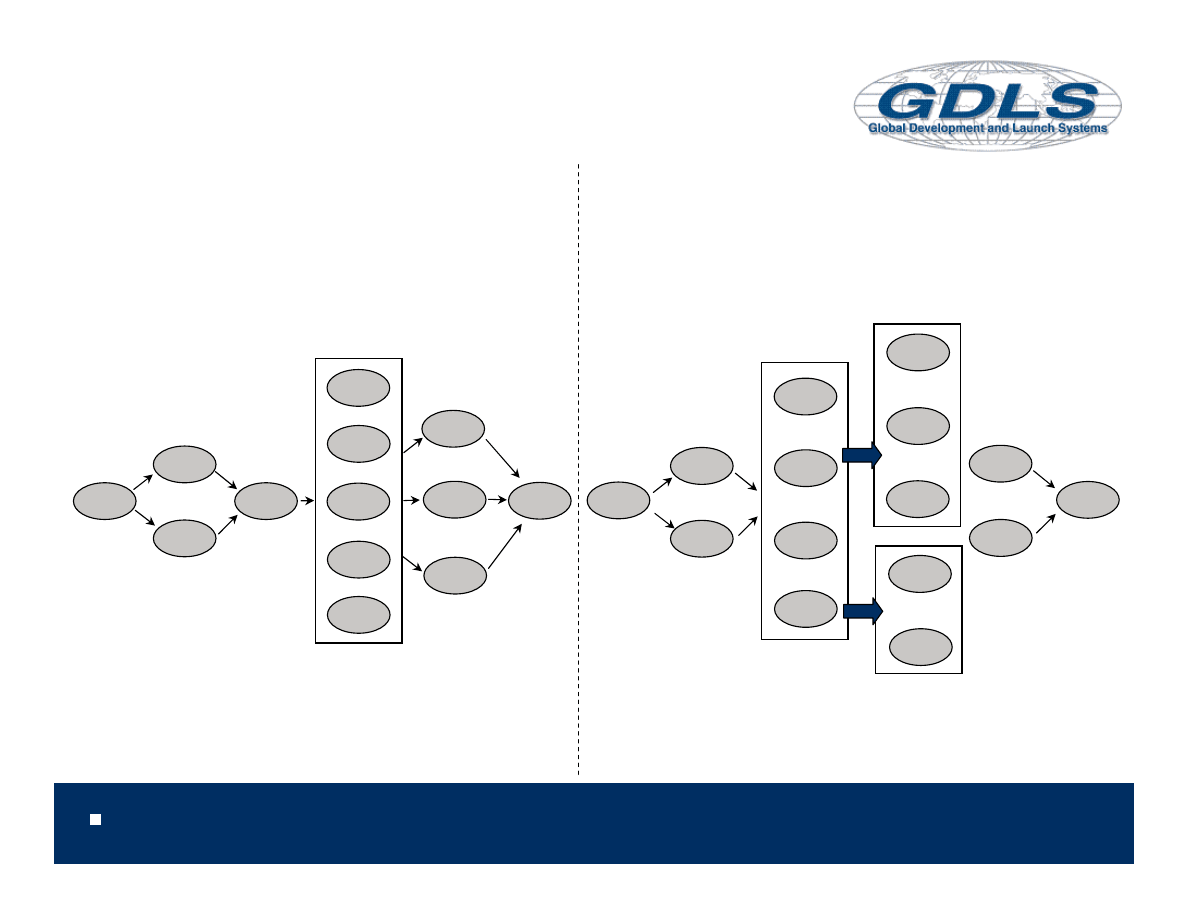

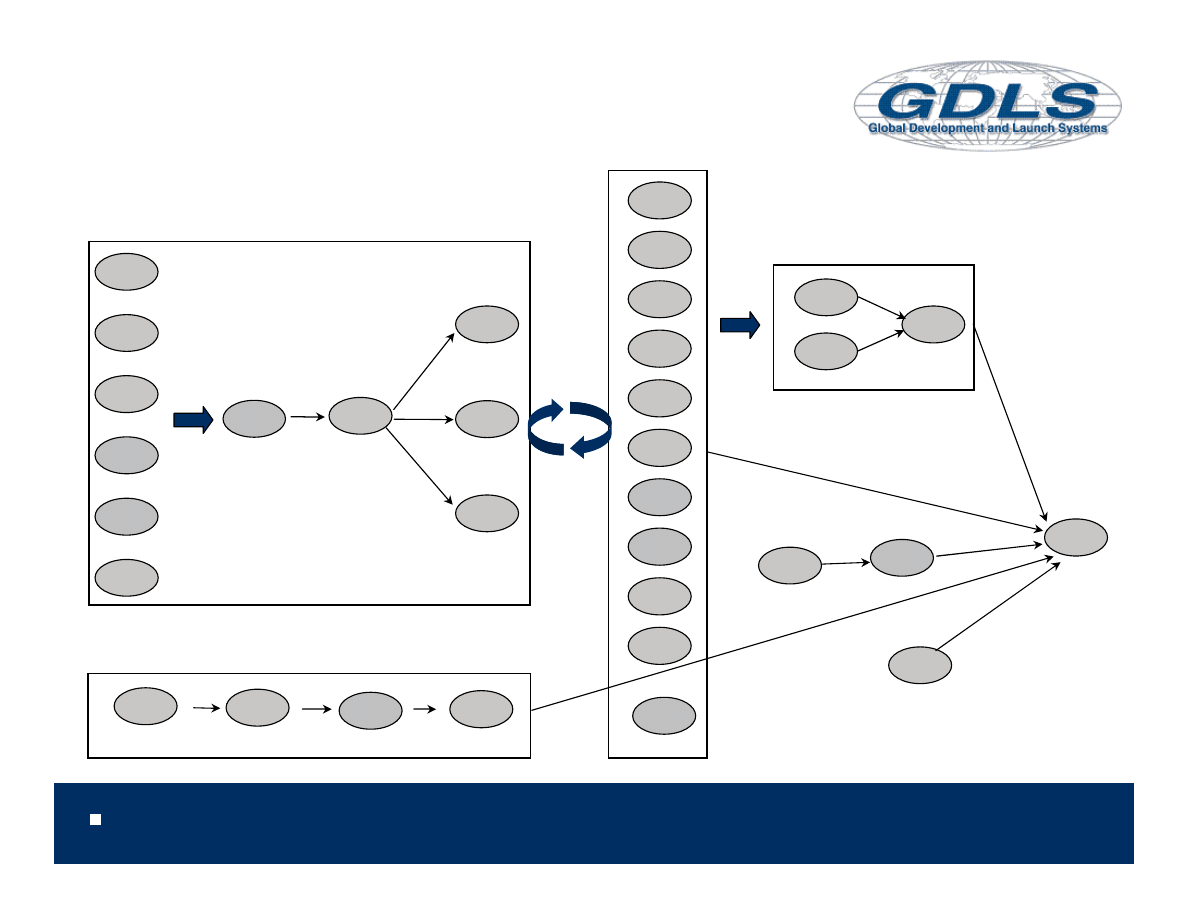

Global Development and Launch System - GDLS

The “Work Groups” are designed to assist in defining functional

responsibility, relation between deliverables, and lead to a “Series

of Reviews”:

•

Design Reviews

•

Supply Base Reviews

•

Plant Reviews – Manufacturing Readiness Reviews

•

Management Gateway Reviews

Purpose of Reviews:

•

Obtain “Fresh Eyes” Inputs

•

Information sharing

•

Decision making

•

Identify risk – Risk mitigation

•

Check status against requirements and monitor performance

to targets

“Work Groups” and “Series of Reviews”

Page 6

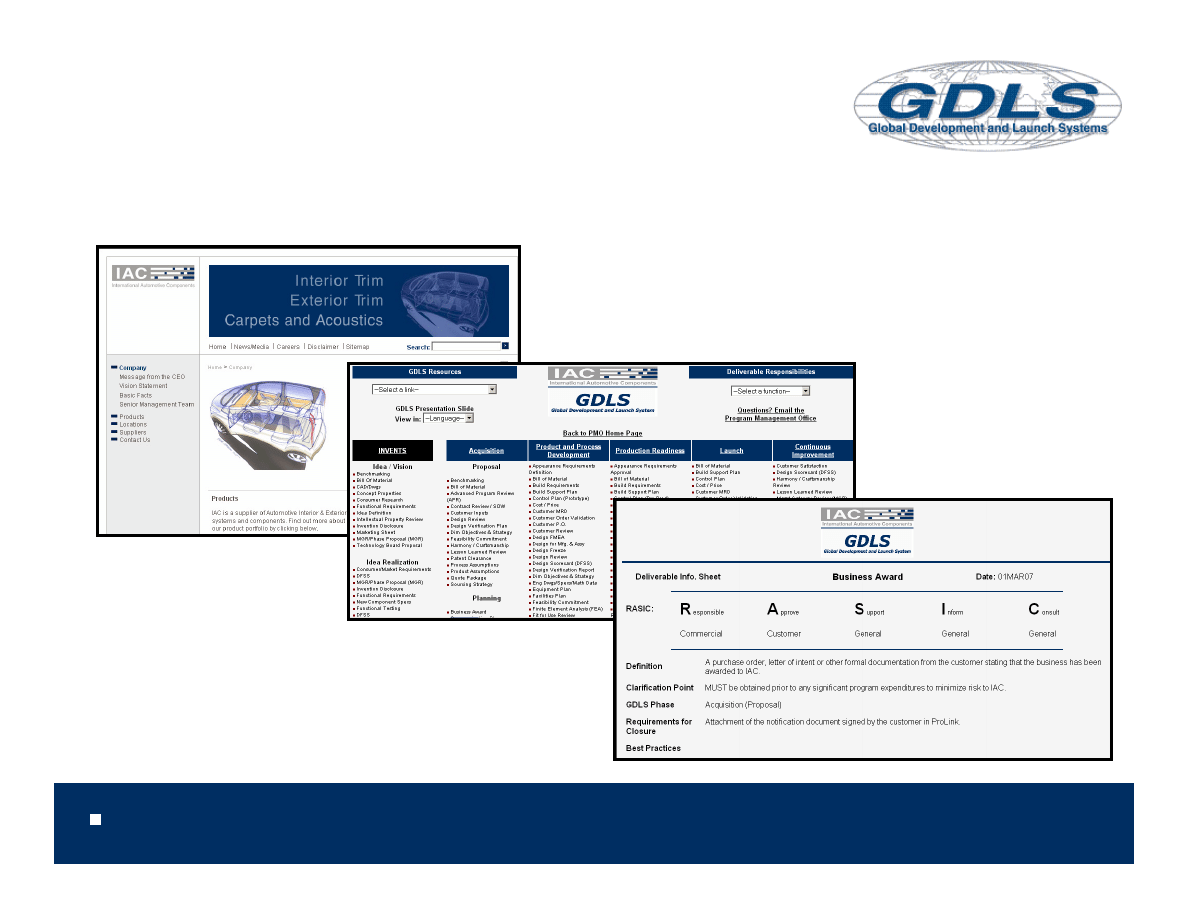

Global Development and Launch System - GDLS

Web-Based Manual and Connectivity

•

IAC Intranet

•

Easy “click” on deliverables

•

Access to deliverable information sheets which include:

Page 7

Global Development and Launch System - GDLS

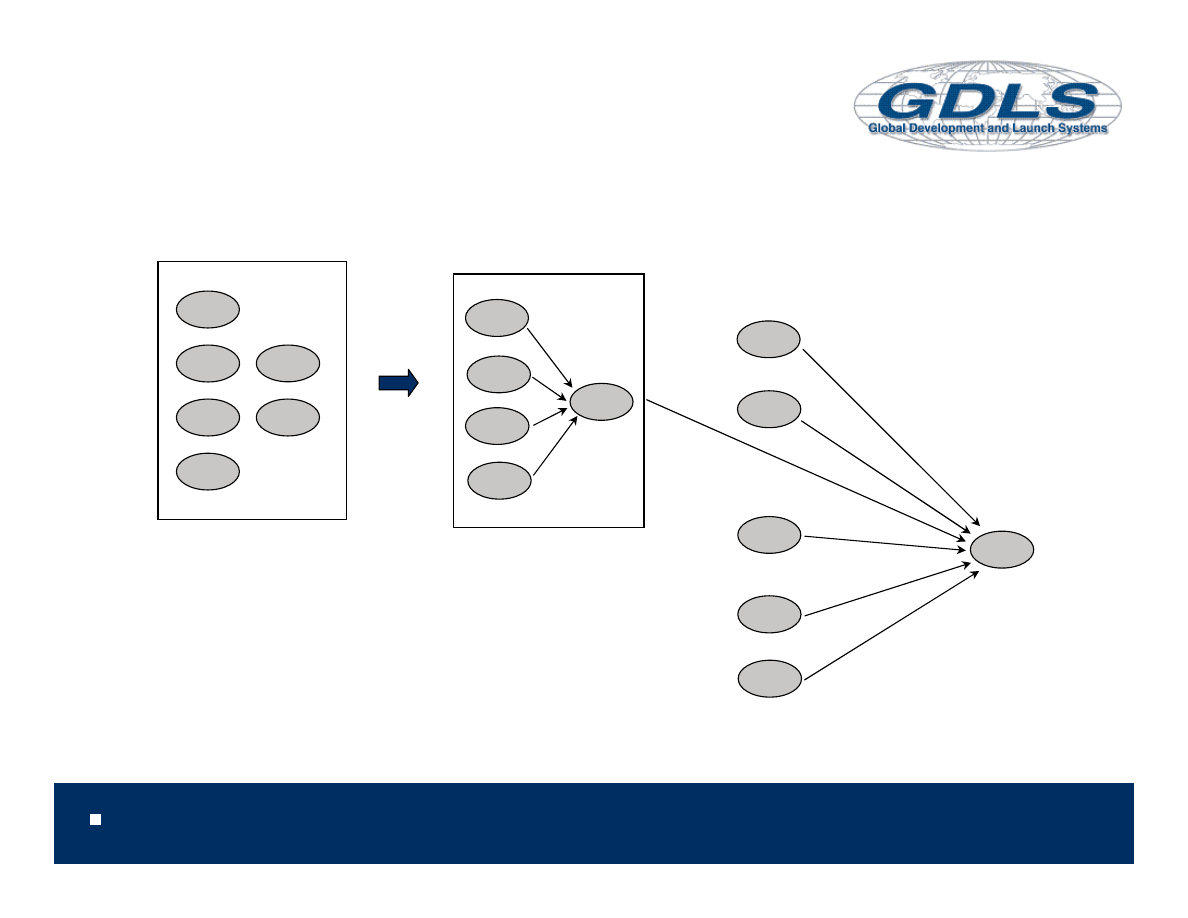

ProLink is…

The web based project management

software

tool to

manage execution of the GDLS process and all related

issues and information.

Manages:

- Timing Plan

- Open Issues

- Supplier Status

- Customer Contacts

- Documents

- APR’s/QMS

- Risks

- And More……

- O/I Roadmap

All program information managed in one location.

Provides everyone in the organization with real time

access to key information they need to do their jobs

better.

Improved efficiency, accuracy, and accountability drives

lower costs and better launches.

GDLS is . . .

The “One IAC”

methodology

for product

development, quality planning, and

product launch

Applies to all Products and Customers

Web manual provides guidance on what should be

done, who should do it, when it should be done, and

at times how it must be done.

Process is flexible and easy to understand

Encompasses APQP

Process begins with activities to win new business

and ends approximately 90 days after start of

production.

Requires a cross-functional program team to

execute the process.

GDLS and ProLink

Page 8

Global Development and Launch System - GDLS

Global Development & Launch System

Proposal and

Award

Continuous

Improvement

Launch

Production

Readiness

Product and

Process

Development

C

u

s

to

m

e

r

M

il

e

s

to

n

e

IA

C

G

D

L

S

M

il

e

s

to

n

e

Idea \

Vision

SOP

PPAP

IA

C

G

D

L

S

K

e

y

D

e

li

v

e

ra

b

le

s

MGR 2

MGR 1

Program

Kick-off

Bus. Case

Review

DR

APQP

Base

FC

SR

PR

Launch

Tools and Equipment

PPAP

SOP

Design

Release

Design

Release

Cost

Reduction

VAVE

Quality

Improvement

MGR 4

Full Ramp-

up

Prototype

Build

Pre-

Production

Build

APQP

Base

SR

PR

MGR 5

MGR 3

Invents

DR

APQP

Base

FC

SR

PR

Program

Award

Supplier

Sourcing

Decision

MGR 0

Concept

Properties

Functional

Testing

Benchmarking

CAD \

Drwgs

Design Reviews Feasibility Commitment Supplier Reviews Plant Reviews Management Gateway Reviews

COMMUNICATION COMMITMENT INTEGRITY DISCIPLINE

Production

Effectiveness

Teardown

Reduce

Variation

MGR -1

Page 9

Global Development and Launch System - GDLS

This phase begins with establishing and understanding the scope of the technology or concept being considered

for development. This phase is designed to assure that the idea is clearly defined, examined and visualized.

Advanced concept activities are performed to ensure IAC objectives will be met and that the target market has

been identified. The Invents Phase also determines how this part will be manufactured, tested, and validated.

This phase concludes with the completion of all Invents Phase Deliverables and report out through the final

MGR/Phase Proposal.

Key elements include:

• Concept Visualization

• Invention Disclosure and Intellectual Property Reviews

• Market Assessment and Financial Analysis

• Consumer Market Testing

• Identification and development for Engineering Analysis and Testing

• Working Prototypes or Models

• Target Program Reviews

Invents Phase

Page 10

Global Development and Launch System - GDLS

GDLS - Invents Phase

Relationship Diagram

Functional

Requirements

Prototype

Tooling

Intellectual

Property

Review

MGR/Phase

Proposal

Consumer

Research

Tooling

Cost/Timing

Functional

Testing

Target

Pricing

Benchmarking

Invention

Disclosure

Concept

Properties

BOM

CAD/

Drawings

Marketing

Sheet

Functional

Requirements

DFSS

BOM

CAD/

Drawings

Sales

Presentation

Finite

Element

Analysis

Target

Program

Review

Business

Case Review

Idea

Definition

New

Component

Specs

Technology

Board Proposal

and Approval

Intellectual

Property

Review

MGR/Phase

Proposal

Idea / Vision

Idea Realization

Business

Case Review

Page 11

Global Development and Launch System - GDLS

This phase begins with the identification of activities required to pursue a new business award. The Proposal and

Award Phase is designed to assure that the customer needs and expectations are clearly understood and that

advanced planning activities are performed to ensure both customer and IAC objectives will be met. This phase

concludes with the completion of all Proposal and Award Phase deliverables and report out through the first

Management Gateway Review.

Key elements include:

• Activities to prepare Quote Package

• Award of business

• Program transition from Business Award to Program Development

• Identification of program sponsor, program manager and support team

• Identification and approval of internal Financial, and Quality Objectives

• Development and approval of program plan with identification and concurrence of respective resources

• Identification of all IAC Platform content and development of the integration plan

Proposal and Award Phase

Page 12

Global Development and Launch System - GDLS

Proposal

Planning

Program

Assumptions

Customer

Input

Bill of

Material

Tooling and

Gage Plan

Quote

Package

Business

Award

Negotiation

Benchmarking

Cross

Functional

Team

Program

Timing

Plan

Mfg.

Location

Assignment

Program

Kick Off

Program

Targets

Management

Gateway

Review

Lessons Learned/

Best Practice

Review

Business

Case Review

Concept/Proposal Development

ER&D

Plan

Business Award

GDLS – Proposal and Award Phase

Relationship Diagram

Manufacturing

Plan

Page 13

Global Development and Launch System - GDLS

In the Product and Process Development Phase the first design to support a deliverable to the customer is

developed and released. Typically, there are several prototype product builds within this phase and the product

design matures with each prototype build ultimately resulting in release of a production intent design. Planning

for the production manufacturing process evolves in a similar manner including identification of tooling and

equipment requirements. Since most customers conduct several prototype builds, the deliverables identified in

this phase may be accomplished several times as required to meet the programs needs. The program team will

determine the appropriate requirements and document this in the project plan. This phase concludes with the

completion of all Product and Process Development Phase deliverables, formal report out in the Management

Gateway Review on progress, risk and performance to objectives, and delivery of all product to support customer

prototype build requirements.

Key elements include:

• DFM/DFA reviews to optimize manufacturability and assembly

• Identification of suppliers and involvement of supply base on design

• Coordinated management of IAC platform content to optimize design for integration

• Approval of program funding and order long-lead gages, tooling and equipment

• Design validation testing

Product and Process Development Phase

Page 14

Global Development and Launch System - GDLS

GDLS - Product and Process Development Phase

Relationship Diagram

Bill of

Material

Design

Release

Process

FMEA

Process Flow

Packaging

Specifications

Business

Case

Review

Control Plan

Equipment

Plan

Tooling and

Gage

Plan

CAR/PAR

Supplier Day

Logistic

Requirements

Process

Capability

Plant

Review

Management

Gateway

Review

Floor Plan

Layout

Facility Plan

Build

Plan

Supply Base

Review

DV Test Plan

And Report

Customer P.O.

Design

Freeze

Analyze

Design

Requirements

Finite

Element

Analysis

Design/

Team Feasibility

Review

Design

FMEA

Dimensional

Objectives and

Strategy

Supplier

Sourcing

DFM/DFA

Service

Requirements

and Review

Make/Buy

Analysis

Operator

Instructions

Design and Engineering

APQP

Supplier Readiness

Plant Readiness

Product

Review

Page 15

Global Development and Launch System - GDLS

In the Production Readiness Phase development of the product design and manufacturing process is completed

and validated. A formal validation that product can consistently be produced at production rates while meeting all

applicable specifications occurs through the Production Part Approval Process (PPAP) or other customer specific

processes. Typically, a representative production trial run is conducted utilizing production intent tooling, equipment

and processes. This does not imply that the full compliment of production tooling is certified and in place for

production. Formal plans for activities to support launch are prepared and reviewed by the team. This phase

concludes with the completion of all Production Readiness Phase deliverables, formal report out in the Management

Gateway Review on progress, risk and performance to objectives, and delivery of warranted product to support

customer build requirements

Key elements include:

• Completion of PV testing and incorporation of any design changes

• Preparation and review of Personnel, Tooling, Equipment, Facilities and Ramp Up plans.

• Delivery of part to customer that are warranted to meet all customer requirements (PSW or Customer

Specific)

• Production Trial Run, validation of production packaging

• Supplier production tooling buy-off and receipt of Supplier warranted material

Production Readiness Phase

Page 16

Global Development and Launch System - GDLS

Bill of

Material

Design

Release

Process

FMEA

Process Flow

Business

Case

Review

Control Plan

Floor Plan

Layout

Packaging

Evaluation

Supply Base

Review

Operator

Instructions

Design

Freeze

Design

FMEA

Dimensional

Objective and

Strategy

Service

Requirements

and Review

Appearance

Approval

Gage

Qualification

PPAP

Plant

Review

Management

Gateway

Review

Equipment

Qualification

Tooling

Qualification

Build Plan

Run at Rate

Process

Capability

PV Test Plan

& Report

Supplier PPAP

IMDS

GDLS - Production Readiness Phase

Relationship Diagram

APQP

Plant Readiness

Supplier Readiness

Design and Engineering

Product

Review

Customer

PO

Design/

Team Feasibility

Review

Page 17

Global Development and Launch System - GDLS

The launch phase is designed to ensure readiness for full production. The full compliment of tooling and

equipment is in place and validated. The product design should be stable throughout this phase with the

exception of any modifications required to address PV test issues or customer mandated changes. IAC

manufacturing plants begin production to ramp up toward full production rates and the phase culminates in

the achievement of full ramp up at the customer assembly plants.

Key elements include:

• Hire and train new employees

• Validation of full compliment of production tooling and equipment

• Strategy and processes put in place to support service part requirements

• Review of customer assembly processes and related issues

• Start of production in IAC and customer plants

• Achievement of full ramp up at the IAC and Customer plant(s)

Launch Phase

Page 18

Global Development and Launch System - GDLS

Process

FMEA

Process Flow

Control Plan

Floor Plan

Layout

Supply Base

Review

Operator

Instructions

Gage

Verification

Plant

Review

Management

Gateway

Review

Equipment

Verification

Tooling

Verification

Process

Capability

Business

Case

Review

Packaging

Verification

Service

Requirements

and Review

GDLS - Launch Phase

Relationship Diagram

APQP

Plant Readiness

Customer

Satisfaction

Lessons Learned/

Best Practice

Review

Page 19

Global Development and Launch System - GDLS

The Continuous Improvement phase is designed to review production effectiveness and ensure all customer

expectations are being met. Actual program performance is evaluated against planned objectives and action

plans generated to address issues.

Key elements include

• Validation of manufacturing process to planned standards

• Continuous improvement in product and process designs

• Value Analysis & Value Engineering (VA/VE)

Continuous Improvement Phase

Page 20

Global Development and Launch System - GDLS

Teardown

Supplier

Performance

Reduce

Variation

Production

Effectiveness

GDLS – Continuous Improvement Phase

Relationship Diagram

Cost

Reduction

Quality

Improvement

VA/VE

Process

Improvement

Engineering

Changes

Page 21

Global Development and Launch System - GDLS

When to Implement GDLS

•

Active Programs that have a status equivalent to being in the GDLS

Phase “Production Readiness” or FURTHER will continue to use the

Development system it was started in (ProLink with existing

deliverables, APQP, CALM).

•

Active Programs that have a status equivalent to being PRIOR to

the GDLS Phase “Production Readiness” need to begin using IAC’s

GDLS process and tool immediately.

•

The conversion to ProLink is completed.

•

NOTE: Any work you had in ProFile has been transferred 100%

to ProLink.

Page 22

Global Development and Launch System - GDLS

GDLS Regional Contacts

IAC Europe

Eric Bos

Office: Born, Netherlands

E-mail:

eric.bos@iacgroup.com

Phone/Mobile: +

31 (0) 651584415

IAC North America

Philip Martin

Office: Rochester Hills, MI USA

E-mail:

pmartin03@iacna.com

Phone: (248) 371-8609

Mobile: (248) 877-0055

Wyszukiwarka

Podobne podstrony:

june 2007 uppersecondary teachers

june 2007 uppersecondary students

PI Manual Production June 2007 lr

31 may 1 june 2007 interim meeting

PDOP 2007

Prezentacja KST 2007 new

Podstawy MN 2007

Prezentacja JMichalska PSP w obliczu zagrozen cywilizacyjn 10 2007

Chłoniaki nieziarnicze wykład 2007

Zaburzenia widzenia obuocznego A Buzzeli 2007

Wyklad I SFP 2007

4 wykład0 24 10 2007

więcej podobnych podstron