The use of electron beam lithographic graft-polymerization on thermoresponsive

polymers for regulating the directionality of cell attachment and detachment

Naokazu Idota

,

, Takahiko Tsukahara

, Kae Sato

,

, Teruo Okano

, Takehiko Kitamori

a

Department of Applied Chemistry, School of Engineering, The University of Tokyo, 7-3-1 Hongo, Bunkyo, Tokyo 113-8656, Japan

b

Core Research for Evolutional Science and Technology (CREST), Japan Science and Technology Agency, 4-8-1 Honcho, Kawaguchi, Saitama 332-0012, Japan

c

Center for NanoBio Integration, The University of Tokyo, 7-3-1 Hongo, Bunkyo, Tokyo 113-8656, Japan

d

Institute of Advanced Biomedical Engineering and Science, Tokyo Women’s Medical University, 8-1 Kawadacho, Shinjuku, Tokyo 162-8666, Japan

a r t i c l e

i n f o

Article history:

Received 13 November 2008

Accepted 26 December 2008

Available online 21 January 2009

Keywords:

Electron beam

Polymerization

Thermally responsive material

Cell patterning

Cell morphology

a b s t r a c t

A simple process for nano-patterned cell culture substrates by direct graft-polymerization has been

developed using an electron beam (EB) lithography system requiring no photo-masks or EB-sensitive

resists. The compound N-isopropylacrylamide (IPAAm) was locally polymerized and grafted directly by

EB lithographic exposure onto hydrophilic polyacrylamide (PAAm)-grafted glass surfaces. The size of the

surface grafted polymers was controlled by varying the area of EB dose, and a minimal stripe pattern

with a 200 nm line-width could be fabricated onto the surface. On the stripe-patterned surfaces, above

the lower critical solution temperature (LCST), the cells initially adhered and spread with an orientation

along the pattern direction. The magnitude of the spreading angle and elongation of adhered cells

depended on the pattern intervals of the grafted PIPAAm. When culture temperature was lower than the

LCST, cultured cells detached from the surfaces with strong shrinkage along the pattern direction, and

sometimes folded and became parallel with the stripe pattern. This patterned cell recovery technique

may be useful for the construction of muscle cell sheets with efficient shrinkage/relaxation in a specific

direction and spheroidal 3D cell structures, with application to tissue engineering and microfluidic

cellular devices.

Ó 2009 Elsevier Ltd. All rights reserved.

1. Introduction

Microfabrication based on surface chemistry offers the possi-

bility of improving the chemical and structural properties of

material interfaces

. These patterning technologies have been

used routinely for cellular assays that spatially and temporally

control cell adhesion

, due to the ability to promote dense and

well-defined cell alignments. Chemical and topographic features on

patterned surfaces can provide external cues for various aspects of

cellular development, such as adhesive morphology

, prolif-

eration

, differentiation

, and gene expression

. Cells in

vivo are immobilized within tissue via extracellular matrix (ECM)

proteins, and receive biophysical cues from micrometer- and

nanometer-scale ECM structural components. Advances in cell

patterning methods hold promise for mimicking the in vivo cellular

microenvironment, and may be applied to biological assays dealing

with cell functions and to the field of regenerative medicine

Functional cell recovery systems for in vitro tissue reconstruc-

tions have been developed using thermoresponsive polymers

. Thermoresponsive poly(N-isopropylacrylamide) (PIPAAm)

responds to external temperature changes by discontinuous

changes in water solubility

. Surfaces grafted with this

compound, which exhibit significant hydrophilic/hydrophobic

property changes with temperature changes, are used in biomed-

ical applications

. Various proteins and cells can be bound

onto PIPAAm-grafted surfaces above the lower critical solution

temperature (LCST), which spontaneously release when the incu-

bation temperature is lowered below the LCST, via dynamic

hydration of graft PIPAAm layers. In these cell recovery systems, all

of the cells can be harvested as a single continuous cell sheet with

intact cell–cell junctions and ECM upon a decrease in culture

temperature after the cells reach confluency on PIPAAm-grafted

surfaces

. The harvested cell sheets maintain their function and

membrane proteins, so that they can be transferred for stratifica-

tion with other cell sheets in vitro

and for direct transplant in

vivo

. Recently, two-dimensional functional cell sheets, such as

patterned co-cultures of heterotypic cells

and vascularized

tissues consisting of endothelial cells

, have been success-

fully recovered from PIPAAm-grafted surfaces improved by

*

Corresponding author. Department of Applied Chemistry, School of Engi-

neering, The University of Tokyo, 7-3-1 Hongo, Bunkyo, Tokyo 113-8656, Japan. Tel.:

þ81 3 5841 7231; fax: þ81 3 5841 6039.

E-mail address:

(T. Kitamori).

Contents lists available at

Biomaterials

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / b i o m a t e r i a l s

0142-9612/$ – see front matter Ó 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biomaterials.2008.12.058

Biomaterials 30 (2009) 2095–2101

micro-patterning methods. These sheets were on a micrometer

scale for construction of a macro-ordered tissue structure. For the

next generation, nanometer-scale patterning is needed to obtain

cell sheets to allow more precise control of cellular alignment and

functionality of surface chemical and topographic features. This

patterning approach shows promise for the construction of func-

tional tissue mimicking cell sheet materials for clinical applications.

Here, we present a simple graft-polymerization method using

an electron beam (EB) lithography system to fabricate micrometer-

and nanometer-patterned PIPAAm layers. Conventional prepara-

tion of nano-patterned grafted polymer layers requires multiple

processes, such as polymerization after nanofabrication

and pre-polymerization for EB-lithographed patterned cross-link-

ing

. However, for surface modification of patterned poly-

mers,

it

is

desirable

to

perform

polymerization,

surface

modification, and pattern formation in a single process. The

simplest fabrication of nano-patterned polymer-grafted surfaces

simultaneously controls both patterning and graft-polymerization

from the monomer solution without any photo-sensitive resists. A

previous study has reported the covalent grafting and polymeri-

zation of an IPAAm monomer onto silanized glass surfaces during

EB irradiation

. To take this study a step further, here the

simultaneous local polymerization and direct surface grafting of

IPAAm monomers are examined by irradiation with a focused EB

lithography system. This EB lithographic polymerization of IPAAm

on glass substrates permits easy fabrication of patterning surfaces,

as well as the ability to harvest cell sheets with cellular morpho-

logies and functions controlled by micrometer- and nanometer-

scale surface features. A discussion then is presented on whether

designed surface patterning can regulate cellular adhesive orien-

tation and detachment behavior from these PIPAAm-grafted

surfaces.

2. Experimental

2.1. Materials

IPAAm was obtained form Wako Pure Chemicals, Industries, Co. Ltd. (Osaka,

Japan), purified by recrystallization from n-hexane, and thoroughly dried under

vacuum at 25

C. The following reagents were used as received: 2-propanol from

Kanto Chemical Co., Inc. (Tokyo, Japan), Acrylamide (AAm) and Ammonium peroxo-

disulfate (APS) from Wako Pure Chemicals, and 3-methacryloxypropyltrimethoxy-

silane (MPTMS) from ShinEtsu Chemical Industry (Tokyo, Japan). Espacer 300,

a conductive water-soluble polymer, was obtained from Showa Denko (Tokyo,

Japan). Trypsin–EDTA solution and penicillin/streptomycin solution were obtained

from Gibco BRL (Grand Island, NY). Dulbecco’s modified Eagle’s medium (DMEM)

was purchased from Sigma Chemical Co. (St Louis, MO).

2.2. Silane immobilization onto glass surfaces

Glass substrates were treated by O

2

plasma ashing (irradiation intensity: 500 W,

oxygen pressure: 0.1 Pa) for 300 s using a plasma-etching system (NE-550; ULVAC,

Chigasaki, Japan) to activate silanol groups on the surface. These plasma-treated

glass substrates were placed in a Teflon vessel together with a glass bottle containing

1 mL MPTMS. The vessel was sealed with a cap followed by heating in an oven.

Silanization of the substrate surfaces by vaporized MPTMS was conducted for 2 h at

70

C. After the coupling reaction, the MPTMS-immobilized glass was immediately

dried at 70

C for 1 h.

2.3. Surface modification with PAAm by free radical polymerization

Hydrophilic PAAm species were covalently grafted onto MPTMS-modified glass

surfaces for preparation of protein-repelling adsorption surfaces. AAm (5 wt%) and

APS (50 mg), acting as a polymerization initiator, were dissolved in 50 mL of distilled

water, and this solution was degassed gently by bubbling with argon gas for 1 h in an

ice bath. After degassing, 0.1 mL of TEMED was added into the AAm monomer

solution. Then, the reaction solution was immediately poured into a plastic tube,

into which an MPTMS-immobilized glass was inserted, and the polymerization

reaction conducted for 2 h at 4

C. The PAAm-grafted glass substrates then were

rinsed repeatedly with distilled water, and dried at 25

C under vacuum.

2.4. EB lithographic graft-polymerization of IPAAm onto glass surfaces

A patterned thermoresponsive PIPAAm was prepared by exposure to a focused

EB using an EB lithography system (ELS-7500; Elionix, Hachioji, Japan) on PAAm-

grafted glass substrates. IPAAm (55 wt%) was dissolved in 2-propanol, followed by

filtration through a 0.25

m

m pore filter. The PAAm-grafted glass substrates were

sequentially covered with the IPAAm monomer solution and Espacer 300 using

a spin coater. This coated substrate then was placed in the vacuum chamber of an EB

lithography system, and a computer-controlled EB scanner was used to draw

a nanometer- or micrometer-sized pattern. Only the IPAAm monomers in EB-

exposed areas were directly polymerized and covalently grafted onto the PAAm-

grafted surfaces. After the exposure, unreacted IPAAm monomer and the conductive

polymer layer were removed with pure water, and the substrates were dried at 25

C

under reduced pressure. For surface characterization, MPTMS-immobilized surfaces

with patterned PIPAAm also were prepared using the same protocol.

2.5. Surface characterization

The sessile drop method was used for measuring temperature-dependent

contact angles with a contact angle meter (DropMaster500; Kyowa Interface

Science, Saitama, Japan). A drop of de-ionized water from a syringe was placed on

the surface of the plate in air. Sample temperature was regulated with a Thermo

Plate

Ò

(TOKAI HIT Co. Ltd., Shizuoka, Japan). To estimate the grafted polymer

morphologies, the patterned PNIPAAm-grafted surfaces were observed using atomic

force microscopy (AFM: SPA-400; SII NanoTechnology, Tokyo, Japan) in non-contact

mode in air. The pattern size and thickness of PNIPAAm layers were determined

from the three-dimensional surface profiles.

2.6. Cell culture

Bovine carotid aortic endothelial cells (BAECs) and NIH-3T3 mouse fibroblast

cells were purchased from the Japan Health Science Foundation (Osaka, Japan). The

cells were cultured on commercial tissue culture polystyrene (TCPS) dishes with

DMEM supplemented with 10% fetal bovine serum, 100 units mL

1

penicillin, and

100

m

g mL

1

streptomycin at 37

C in a humidified atmosphere with 5% CO

2

. The cells

were harvested from the TCPS dishes with 0.25% trypsin–EDTA in phosphate-buffered

saline. For the cell adhesion and spreading assay, cells were seeded to the patterned

PIPAAm-grafted glass substrates at a density of 1.0 10

4

cells cm

2

followed by

culturing at 37

C. Cellular morphology was monitored at intervals and photographed

using a phase-contrast microscope (Eclipse TS100; Nikon, Tokyo, Japan).

3. Results and discussion

3.1. Surface characterization of patterned surfaces by EB

lithographic graft-polymerization

One of the key features of patterned cell cultures is the ability to

spatially control cell–substrate interactions. Fundamentally, cellular

responses, such as adhesion, proliferation, and differentiation, are

triggered by an interaction between the cell transmembrane and

the extracellular proteins, which are adsorbed onto the surface of

the substrates. Thus, surface modifications are needed that can

facilitate site-selection of protein adsorption. To achieve these

surface properties, protein-repulsive surfaces were prepared by

redox polymerization to modify MPTMS-immobilized substrates

with a layer of PAAm

. The wettability of these surfaces then was

investigated by measurement of static contact angles. The contact

angles were 74.7 0.7

for MPTMS-immobilized surfaces and

18.1 1.0

for PAAm-grafted surfaces. We hypothesized that the

methacryloyl groups in the surface-introduced MPTMS would react

with the growing PAAm chains during polymerization, resulting in

a hydrophilic surface. Fibroblast cells were cultured on the surfaces

to confirm that cellular adhesion was consistent with the surface

properties. While the fibroblast cells adhered, spread, proliferated,

and reached confluency on the MPTMS-immobilized surfaces,

exactly as observed on the commercial TCPS dishes, cell adhesion

onto the PAAm-grafted surfaces was completely inhibited (data not

shown). This was probably because hydration of the grafted PAAm

prevents adsorption of the serum protein in the culture medium,

inhibiting cellular adhesion.

As patterned cell-adhesive surface domains, thermoresponsive

PIPAAm was locally bound onto the cell-repulsive PAAm-grafted

N. Idota et al. / Biomaterials 30 (2009) 2095–2101

2096

surfaces in this study. The PIPAAm-grafted surfaces exhibited

temperature-induced hydrophilic/hydrophobic properties, conse-

quently providing surface adsorption of proteins at temperatures

higher than the PIPAAm transition temperature

. An attempt

was

made

to

fabricate

micrometer-

and

nanometer-scale

patterning of grafted PIPAAm by EB lithographic graft-polymeri-

zation and to confirm the surface modification of patterned PNI-

PAAm by wettability and pattern profiles of the surfaces. When

PAAm-grafted glass is used as the basal substrate for patterned

PNIPAAm grafting, the strong hydrophilicity and roughness of pre-

grafted PAAm interfere with evaluation of wettability and geometry

changes by the patterning of PIPAAm. Hence, the hydrophobic and

smooth MPTMS-immobilized glass is used as basal substrates for

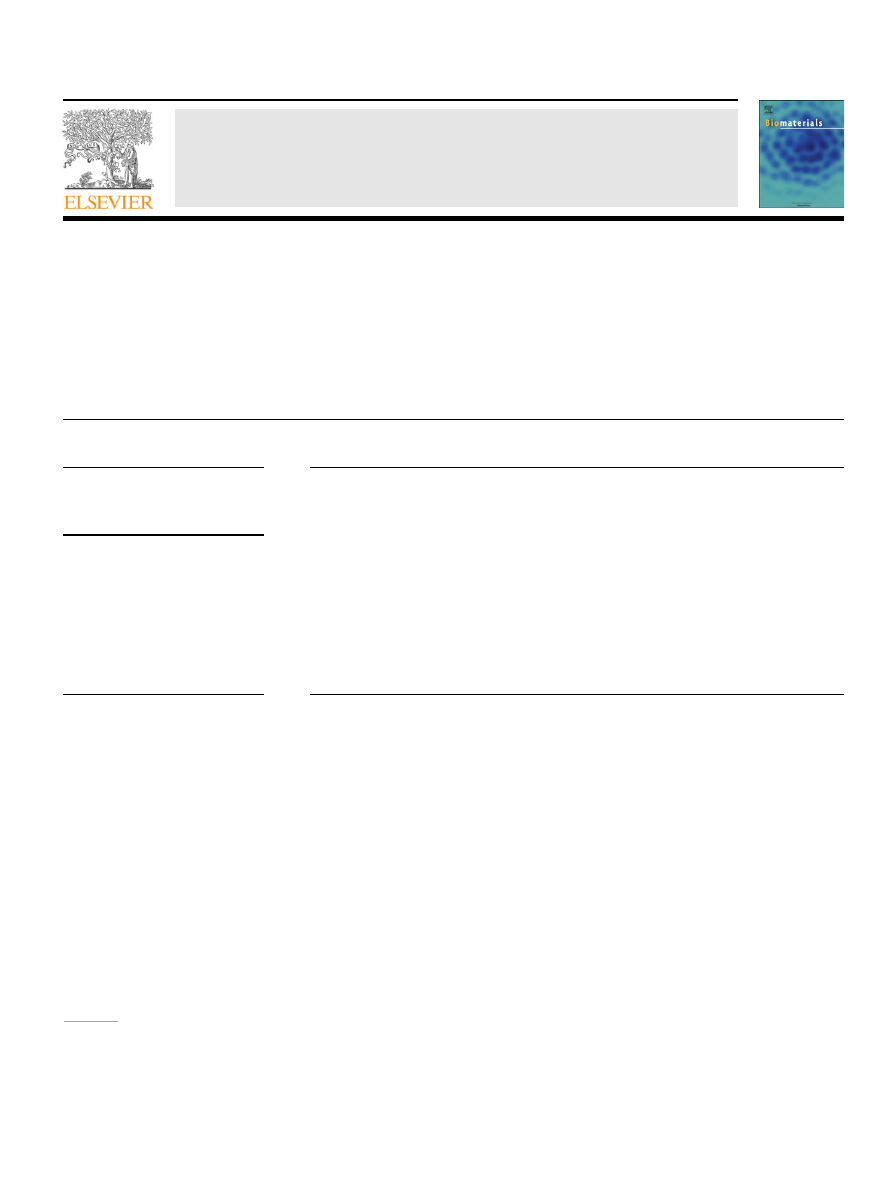

the simple evaluation of a patterning process. Changes in the

contact angle of water on the patterned PIPAAm-grafted glass

substrates, caused by variations in electron beam exposure, were

measured and results are shown in

. Results showed that the

contact angle on the surfaces decreased with increasing electron

dose at either 25

C or 37

C. The contact angles showed hydro-

phobicity below a dose of 440

m

C cm

2

, while above that dose the

aqueous wettability of the surfaces increased significantly. The

gelation dose of poly(vinylmethyl ether) was estimated based on

a comparison between EB lithography and bulky EB irradiation

(1.0

m

C cm

2

z 1.3 kGy)

. This unit conversion, used to estimate

the dose inducing the aqueous wettability transition, was ca.

580 kGy (acceleration voltage: 50 kV). Previous reports stated that

EB irradiation of 250–300 kGy (acceleration voltage: 150 kV)

enabled successful modification of PIPAAm on TCPS surfaces for

cellular adhesion/detachment control

. Considering

the difference in acceleration voltage, the exposure conditions used

in this study are similar to those used in the successful bulk EB-

induced polymerization of IPAAm. Therefore, it is likely that IPAAm

was successfully polymerized and grafted onto the surfaces by EB

lithographic graft-polymerization.

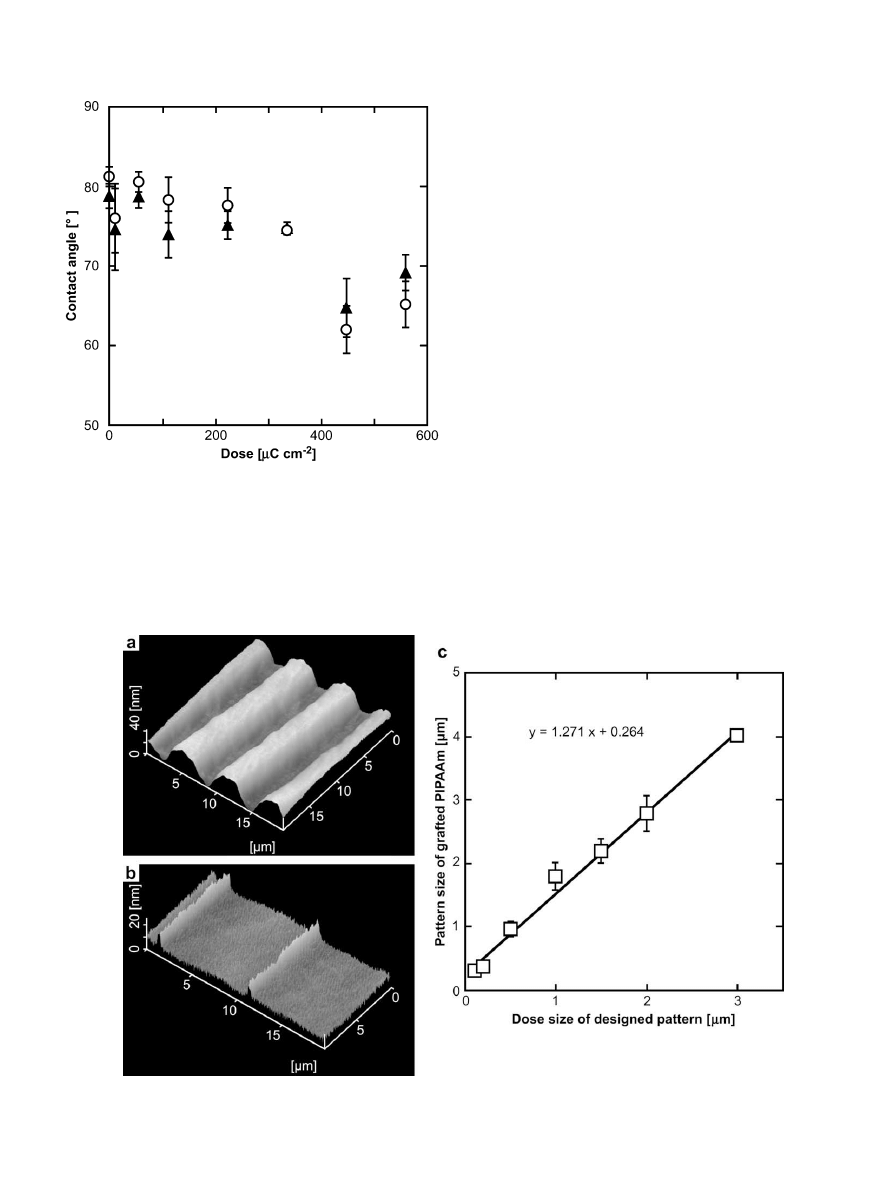

The patterning areas of PIPAAm-grafted onto MPTMS-immobi-

lized surfaces were controlled by changing the EB-exposed areas.

(a) and (b) shows AFM images of the PIPAAm-grafted stripe

Fig. 1. Dose-dependent static contact angles on patterned PIPAAm-grafted surfaces at

below and above LCST. Symbols: open circle, 25

C; closed triangle, 37

C.

Fig. 2. AFM images of PIPAAm-grafted surfaces with (a) 3

m

m (interval: 6

m

m) and (b) 200 nm (interval: 10

m

m) stripe pattern. (c) Effect of dose size of designed pattern on

fabricated pattern size of grafted PIPAAm.

N. Idota et al. / Biomaterials 30 (2009) 2095–2101

2097

patterns with a 3

m

m and 200 nm width on the surface, respec-

tively. The patterned structures of grafted PIPAAm can be observed

by AFM, and the nanometer-scale patterning is easily fabricated

using the present technique. The designed dose vs. patterned sizes

of grafted PIPAAm stripe patterns had a linear relation, as shown in

(c), and the fabricated sizes expanded approximately 13%

compared with designated sizes. These results indicated that the

patterning area of grafted PIPAAm depended on the EB-exposed

areas, and only monomers exposed to EB were polymerized and

covalently grafted onto the surfaces. Although previous fabrication

methods of nanometer-scale patterns of polymers required

multiple difficult processes

, the method presented here of

the nanometer-scale patterned PIPAAm can be created directly on

a surface by growth of polymer chains based on a single step of EB

irradiation. The active radicals of a growing chain end propagate

toward a non-irradiated area to react with monomers, so that the

PIPAAm-grafted nanopatterns are slightly larger than the EB-

exposed areas would suggest. Even with this technique, pattern

fidelity and resolution are on the order of 200 nm, a scale much

smaller than cultured cells allowing control of chemical and topo-

logical features.

3.2. Cellular orientation and elongation dependent on pattern size

In the patterning technique based on EB lithographic graft-

polymerization, the fabrication of patterned polymer layers can be

controlled on a nanometer-scale area without any EB-sensitive

resist. The utility of this technique for biomedical applications was

demonstrated by regulating the adhesion and detachment of cell

sheets in response to patterning features induced by temperature

changes. Topographic and chemical nanometer-scale patterned

surfaces have been fabricated previously to control the adhesion

and spreading behavior of NIH-3T3 cells

. Such patterning

enables NIH-3T3 cells to attach and elongate along the stripe, with

their morphologies dependent upon stripe width and spacing size.

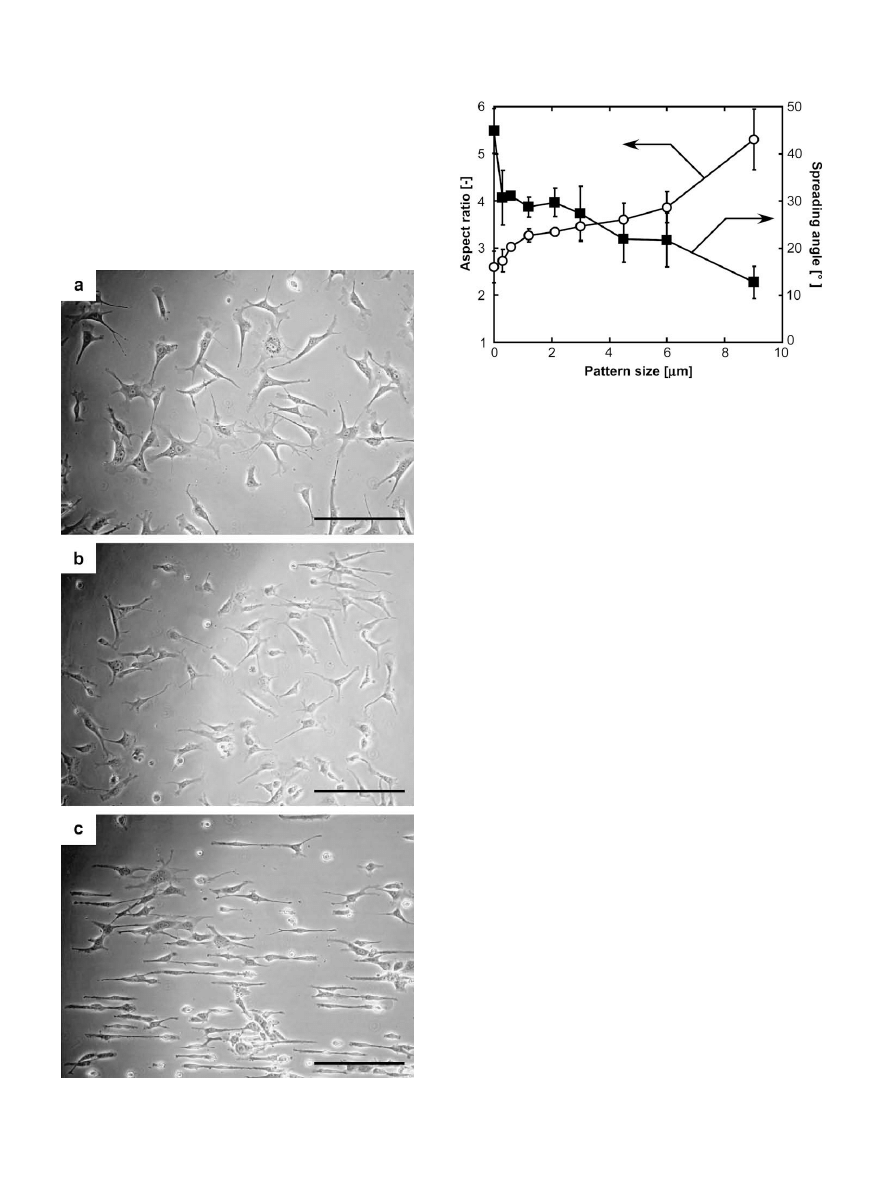

For this study, striped nanometer-scale patterns of PIPAAm on

hydrophilic PAAm-grafted glass substrates were fabricated by the

EB lithographic graft-polymerization method. The BAECs were

cultured on the surface at 37

C, and their adhesive morphology

was observed one day after seeding. Most of the BAECs on the non-

patterned surfaces adhered randomly and spread uniformly by

occupying large adhesion areas [

(a)]. The nanometer-scale

stripe patterns showed that the adhered cells possessed a relatively

slender shape in random directions [

(b)]. In contrast, a large

number of adhered BAECs visibly elongated and oriented them-

selves along the stripe lines of the micrometer-patterned surfaces

[

(c)]. The PAAm-grafted surfaces prevented protein adsorption

and cellular adhesion, allowing cells to adhere on the PIPAAm-

grafted surfaces in a manner similar to that seen in ungrafted

culture dishes at 37

C

. Hence, the cultured cells can be

expected to selectively change their shapes and adhesive directions

Fig. 3. Photographs of BAECs’ adhesion onto (a) 0

m

m, (b) 0.6

m

m and (c) 9

m

m stripe-

patterned PIPAAm-grafted surfaces. Scale bar: 200

m

m.

Fig. 4. Effect of stripe pattern size of grafted PIPAAm on aspect ratio and spreading

angle of adhered BAECs. Symbols: open circle, aspect ratio; closed square, spreading

angle.

N. Idota et al. / Biomaterials 30 (2009) 2095–2101

2098

depending on the spacing of PIPAAm-grafted surfaces above their

LCST, to areas that exhibit greater cell adhesion properties, and thus

maintain more stable adhesive morphology than in the PAAm-

grafted domains.

To evaluate the dependence of cellular morphology on pattern

area, the magnitude of orientation and elongation of adhered cells

was determined using two measurements: the average value of the

angle of cellular spreading with respect to the stripe pattern

direction, and the aspect ratio (ratio of the long to the short axis of

the adhered cells)

. The results are summarized in

. The

BAECs adhered and spread in many directions on non-patterned

PIPAAm-grafted surfaces, a process resulting in a spreading angle of

ca. 45

. In contrast, enlarging the pattern area decreased the

spreading angles, which indicates that the cells aligned parallel to

the pattern direction. The aspect ratios of the BAECs cultured on the

patterned PIPAAm-grafted surfaces increased with enlargements in

pattern size. The PAAm and PIPAAm stripe patterns occur at equal

intervals, so that the BAECs spread to overlap the PAAm-grafted

regions, since the nanometer-scale patterning is much smaller than

the cell size. As pattern size increased, the BAECs adhered selec-

tively onto a line-shape patterned surface grafted with PIPAAm,

resulting in their orientation and elongation along the pattern.

However, the cultured cells could not reach confluency on the large

spacing of patterned surfaces, due to the difficulty of contact with

other cells by crossing over the stripe patterns. Thus, few

micrometer-scale stripe patterns should be required to construct

a cell sheet with intact cell–cell junctions with controllable adhe-

sive morphologies.

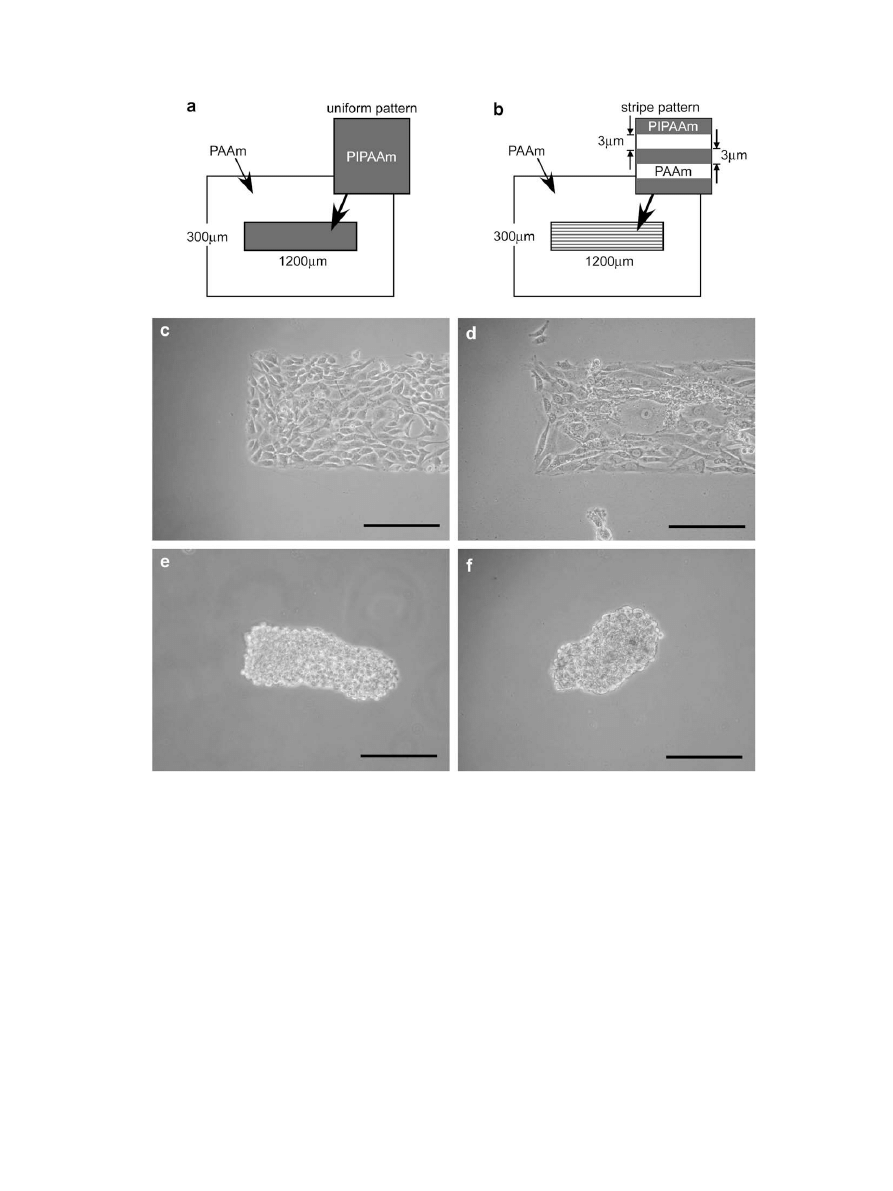

3.3. Direction control of adhesion/detachment of cell sheets on

patterned surfaces

A decrease in culture temperature below the LCST can release

cultured cells from PIPAAm-grafted surfaces as a monolayer

Fig. 5. Photographs of detached fibroblast cell sheets from patterned PIPAAm-grafted surfaces by reducing temperature from (c, d) 37

C to (e, f) 25

C. Pattern design: (a, c, e)

uniform pattern, (b, d, f) stripe pattern. Scale bar: 200

m

m.

N. Idota et al. / Biomaterials 30 (2009) 2095–2101

2099

without the need for enzymatic digestion. Thus, detachment of

fibroblast cells from patterned thermoresponsive surfaces was

examined upon reducing the temperature from 37 to 25

C. These

surfaces consisted of a 3

m

m pitch stripe-patterning of grafted

PIPAAm and PAAm [

(b)]. For comparison, patterned PIPAAm-

grafted surfaces without stripes were prepared on PAAm-grafted

substrates [

(a)] by commercial photolithographic techniques

similar to those previously reported

. The fibroblast cells were

placed on both pattern-grafted surfaces at 37

C; the cells adhered,

spread, proliferated, and reached confluency only within the

PIPAAm-grafted domains [

(c) and (d)]. The cells growing on

the striped surfaces loosely maintained their orientation along the

pattern direction. When the culture temperature decreased to

25

C after the cells reached confluency, the patterned cells

detached from both PIPAAm-grafted surfaces as a continuous cell

sheet with intact cell–cell junctions [

(e) and (f)]. The cell

sheets obtained could be re-cultured on other TCPS surfaces, indi-

cating that the patterned surfaces can be harvested as intact cell

sheets non-invasively. To evaluate cellular detachment behavior,

the shrinkage ratios of the patterned cell sheets were measured,

which indicates the ratios of the length of the detached cell sheet to

the cell adhesion area along its long and short axes. The shrinkage

ratios of the patterned cell sheets from the uniform PIPAAm-

patterned surfaces were 60.7 3.6% and 54.2 6.1% for the long

and short axes, respectively (n ¼ 10), a result indicating isotropic

shrinkage. In contrast, shrinkage ratios from the striped PIPAAm-

patterned surfaces were 73.6 2.3% and 47.8 3.7% for the long

and short axes, respectively (n ¼ 7). The cell sheets were strongly

contracted in the stripe pattern direction. After treatment at

temperatures below the LCST, the remaining intact cell–cell junc-

tions and peripheral actin filament bands in the cells induced

contractile forces that caused shrinkage of entire cell sheets

On stripe-patterned PIPAAm surfaces, such contractile forces

worked mainly along the stripe pattern direction, because the cells

oriented and elongated at a culture temperature of 37

C. Thus,

strong contractile forces in a specific direction can be controlled by

appropriate patterning design of stripe width and spacing, and is

useful for actuation controls using muscle cell sheets (i.e., tissue

engineering of cardiac muscle

and microfluidic pumping using

cardiomyocyte sheets

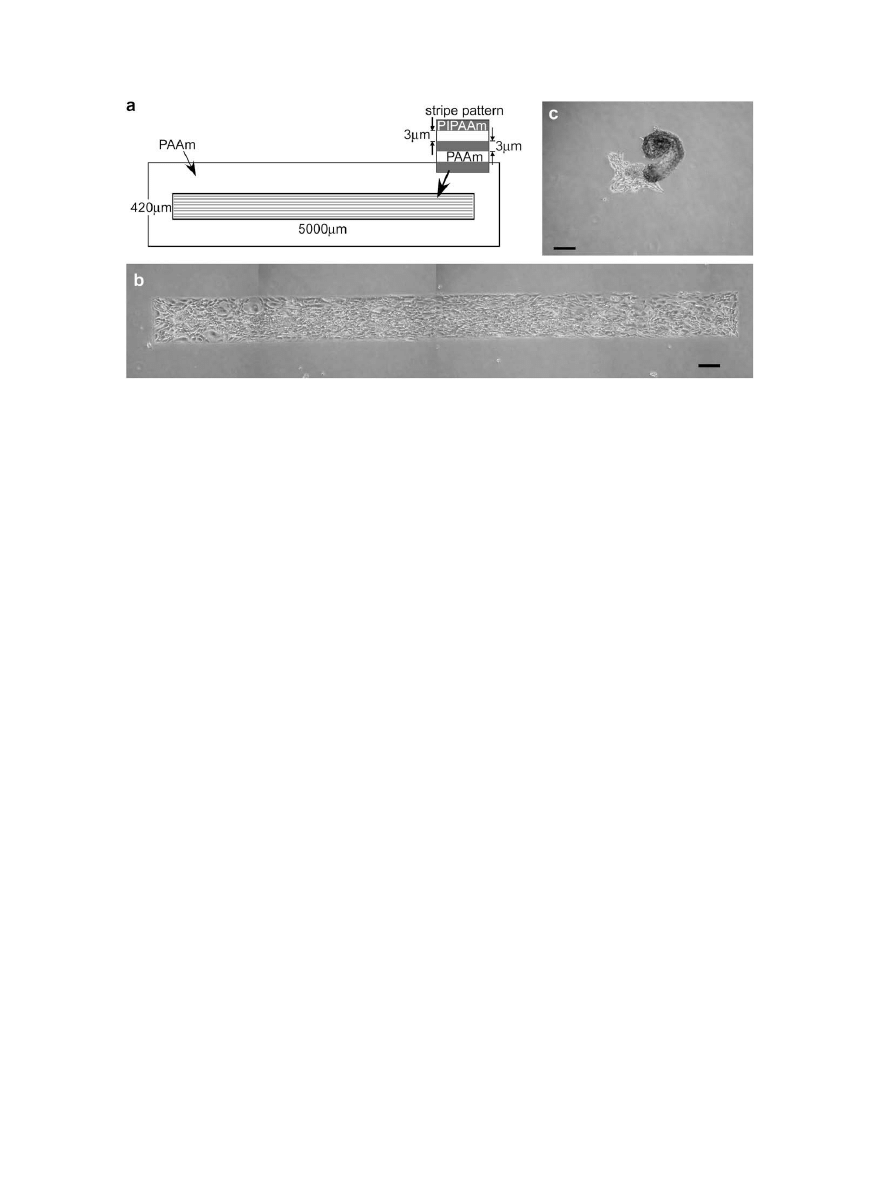

). In addition, 3

m

m pitch stripe-

patterning surfaces with a large aspect ratio of cell culture area

were prepared [

(a)], and fibroblast cells cultured on those

surfaces for 5 days at 37

C [

(b)]. In some cases, after the cell

sheets gradually detached from the edges of the pattern domain at

culture temperatures below 25

C, they then folded and rolled in

parallel with the stripe-patterning [

(c)]. When a cell sheet

detached from its edges, the folding of the cells in their elongated

direction was more stable stereoscopically at the confluent state.

The cell sheets with a large aspect ratio consequently formed rolled

structures through continuous folding behavior. Regulation of the

folding behavior of cell sheets is possible using local temperature,

which controls the starting point of cell detachment from the

stripe-patterned PIPAAm surfaces. Evidently, the shrinking and

folding direction of detached cell sheets can be controlled on the

striped PIPAAm-grafted surfaces simply by reducing the tempera-

ture, resulting in the formation of spheroidal cell structures.

4. Conclusions

Temperature-responsive PIPAAm was applied directly onto glass

surfaces on nanometer-scale stripe patterns using EB lithographic

graft-polymerization. This modification method is simple and can

be applied to a wide variety of polymers without photo-sensitive

resist. The patterned area of the grafted PIPAAm can be controlled

on a nanometer-scale by changes in the irradiated area. At

temperatures above the LCST, cells adhered on these surfaces were

oriented and elongated along the stripes of grafted PIPAAm. Below

the LCST, they detached with shrinkage and folding along the

pattern direction. This patterning and cell recovery system could be

useful for applications such as engineering of functional cell sheets,

cell-based bioreactors, and the construction of spheroidal 3D cell

structures.

References

[1] Zhao B, Brittain WJ. Polymer brushes: surface-immobilized macromolecules.

Prog Polym Sci 2000;25:677–710.

[2] Whitesides GM, Ostuni E, Takayama S, Jiang X, Ingber DE. Soft lithography in

biology and biochemistry. Annu Rev Biomed Eng 2001;3:335–73.

[3] Ginger DS, Zhang H, Mirkin CA. The evolution of dip-pen nanolithography.

Angew Chem Int Ed 2004;43:30–45.

[4] Suh KY, Seong J, Khademhosseini A, Laibinis PE, Langer R. A simple soft

lithography route to fabrication of poly(ethylene glycol) microstructures for

protein and cell patterning. Biomaterials 2004;25:557–63.

[5] Falconnet D, Csucs G, Grandin HM, Textor M. Surface engineering approaches

to micropattern surface for cell-based assays. Biomaterials 2006;27:3044–63.

Fig. 6. Photographs of folding and rolling detachment of fibroblast cell sheets from patterned PIPAAm-grafted surfaces by reducing temperature. (a) Pattern design. Culture

temperature: (b) 37

C, (c) 25

C. Scale bar: 200

m

m.

N. Idota et al. / Biomaterials 30 (2009) 2095–2101

2100

[6] Teixeira AI, Abrams GA, Bertics PJ, Murphy CJ, Nealey PF. Epithelial contact

guidance on well-defined micro- and nanostructured substrates. J Cell Sci

2003;116:1881–92.

[7] Goto M, Tsukahara T, Sato K, Kitamori T. Micro- and nanometer-scale

patterned surface in a microchannel for cell culture in microfluidic devices.

Anal Bioanal Chem 2008;390:817–23.

[8] Gerecht S, Bettinger CJ, Zhang Z, Borenstein JT, Vuniak-Novakvoic G, Langer R.

The effect of actin disruption agents on contact guidance of human embryonic

stem cells. Biomaterials 2007;28:4068–77.

[9] Goto M, Tsukahara T, Sato K, Konno T, Ishihara K, Sato K, et al. Nanometer-scale

patterned surfaces for control of cell adhesion. Anal Sci 2007;23:245–7.

[10] Zinger O, Zhao G, Schwartz Z, Simpson J, Wieland M, Landolt D, et al. Differ-

ential regulation of osteoblasts by substrate microstructural features. Bioma-

terials 2005;26:1837–47.

[11] Dalby MJ, Riehle MO, Yarwood SJ, Wilkinson CDW, Curtis ASG. Nucleus

alignment and cell signaling in fibroblasts: response to a micro-grooved

topography. Exp Cell Res 2003;284:274–82.

[12] Andersson H, van den Berg A. Microfabrication and microfluidics for tissue

engineering: state of the art and future opportunities. Lab Chip 2004;4:98–103.

[13] Khadembosseini A, Langer R, Borenstein J, Vacanti JP. Microscale technologies

for tissue engineering and biology. Proc Natl Acad Sci U S A 2006;103:2480–7.

[14] Yamada N, Okano T, Sakai H, Karikusa F, Sawasaki Y, Sakurai Y. Thermo-

responsive polymer surface: control of attachment and detachment of

cultured cells. Makromol Chem Rapid Commun 1990;11:571–6.

[15] Okano T, Yamada N, Sakai H, Sakurai Y. A novel recovery system for cultured

cells using plasma-treated polystyrene dishes grafted with poly(N-iso-

propylacrylamide). J Biomed Mater Res 1993;27:1243–51.

[16] Heskins M, Guillet

JE, James E.

Solution properties of

poly(N-iso-

propylacrylamide). J Macromol Sci Chem 1968;A2:1441–5.

[17] Kikuchi A, Okano T. Intelligent thermoresponsive polymeric stationary phases

for aqueous chromatography of biological compounds. Prog Polym Sci

2002;27:1165–98.

[18] Ebara M, Hoffman JM, Hoffman AS, Stayton PS. Switchable surface traps for

injectable bead-based chromatography in PDMS microfluidic channels. Lab

Chip 2006;6:843–8.

[19] Kushida A, Yamato M, Konno C, Kikuchi A, Sakurai Y, Okano T. Decrease in

culture temperature releases monolayer endothelial cell sheets together with

deposited fibronectin matrix from temperature-responsive culture surfaces.

J Biomed Mater Res 1999;45:355–62.

[20] Shimizu T, Yamato M, Isoi Y, Akutsu T, Setomaru T, Abe K, et al. Fabrication of

pulsatile cardiac tissue grafts using a novel 3-dimensional cell sheet manip-

ulation technique and temperature-responsive cell culture surfaces. Circ Res

2002;90:e40–8.

[21] Yang J, Yamato M, Shimizu T, Sekine H, Ohashi K, Kanzaki M, et al. Recon-

struction of functional tissues with cell sheet engineering. Biomaterials

2007;28:5033–43.

[22] Tsuda Y, Kikuchi A, Yamato M, Nakao A, Sakurai Y, Umezu M, et al. The use of

patterned dual thermoresponsive surfaces for the collective recovery as

co-cultured cell sheets. Biomaterials 2005;26:1885–93.

[23] Tsuda Y, Yamato M, Kikuchi A, Watanabe M, Chen G, Okano T. Thermores-

ponsive microtextured culture surfaces facilitate fabrication of capillary

networks. Adv Mater 2007;19:3633–6.

[24] Tsuda Y, Shimizu T, Yamato M, Kikuchi A, Sasagawa T, Sekiya S, et al. Cellular

control of tissue architectures using a three-dimensional tissue fabrication

technique. Biomaterials 2007;28:4939–46.

[25] Kaholek M, Lee WK, Ahn SJ, Ma H, Caster KC, LaMattina B, et al. Stimuli-

responsive poly(N-isopropylacrylamide) brushes and nanopatterns prepared

by surface-initiated polymerization. Chem Mater 2004;16:3688–96.

[26] He Q, Ku¨ller A, Grunze M, Li J. Fabrication of thermoresponsive polymer

nanopatterns through chemical lithography and atom transfer radical poly-

merization. Langmuir 2007;23:3981–7.

[27] Ballav N, Schilp S, Zharnilkov M. Electron-beam chemical lithography with

aliphatic self-assembled monolayers. Angew Chem Int Ed 2008;47:1421–4.

[28] Schmidt T, Mo¨nch JI, Arndt KF. Temperature-sensitive hydrogel pattern by

electron-beam lithography. Macromol Mater Eng 2006;291:755–61.

[29] Tirumala VR, Divan R, Ocola LE, Mancini DC. Direct-write e-beam patterning of

stimuli-responsive hydrogel nanostructure. J Vac Sci Technol B 2005;23:

3124–8.

[30] Idota N, Kikuchi A, Kobayashi J, Sakai K, Okano T. Microfluidic valves

comprising nanolayered thermoresponsive polymer-grafted capillaries. Adv

Mater 2005;17:2723–7.

[31] Xiao D, Zhang H, Wirth M. Chemical modification of the surface of poly-

(dimethylsiloxane) by atom-transfer radical polymerization of acrylamide.

Langmuir 2002;18:9971–6.

[32] Kawaguchi H, Fujimoto K, Mizuhara Y. Hydrogel microspheres III. Tempera-

ture-dependent

adsorption of proteins on poly-N-isopropylacrylamide

hydrogel microspheres. Colloid Polym Sci 1992;270:53–7.

[33] Au HTH, Cheng I, Chowdhury MF, Radisic M. Interactive effects of surface

topography and pulsatile electrical filed stimulation on orientation and

elongation of fibroblasts and cardiomyocytes. Biomaterials 2007;28:4277–

302.

[34] Itoga K, Kobayashi J, Yamato M, Kikuchi A, Okano T. Maskless liquid-crystal-

display projection photolithography for improved design flexibility of cellular

micropatterns. Biomaterials 2006;27:3005–9.

[35] Tanaka Y, Sato K, Shimizu T, Yamato M, Okano T, Kitamori T. A micro-spherical

heart pump powered by cultured cardiomyocytes. Lab Chip 2007;7:207–12.

N. Idota et al. / Biomaterials 30 (2009) 2095–2101

2101

Document Outline

- The use of electron beam lithographic graft-polymerization on thermoresponsive polymers for regulating the directionality of cell attachment and detachment

Wyszukiwarka

Podobne podstrony:

Tomaszewski P (2008) Child visual discourse The use of language, gestures, and vocalizations

Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit

VERDERAME Means of substitution The use of figurnes, animals, and human beings as substitutes in as

71 1021 1029 Effect of Electron Beam Treatment on the Structure and the Properties of Hard

Dispute settlement understanding on the use of BOTO

Illiad, The Analysis of Homer's use of Similes

Resuscitation- The use of intraosseous devices during cardiopulmonary resuscitation, MEDYCYNA, RATOW

or The Use of Ultrasound to?celerate Fracture Healing

The use of Merit Pay Scales as Incentives in Health?re

Kinesio® Taping in Stroke Improving Functional Use of the Upper Extremity in Hemiplegia

A Common Use of the 'den', ❑Języki, ►Język turecki, turkish grammar

The use of 了 to imply completed?tionx

Capo Ferro Great Representation Of The Art & Of The Use Of Fencing

A Common Use of the 'den' (2)

Oren The use of board games in child psychotherapy

or The Use of Extracorporeal Shock Wave Therapy to Improve Fracture Healing

William Varner The Christian Use Of Jewish Numerology

więcej podobnych podstron