The role of drying, grinding, torrefaction and flash

pyrolysis in the production of liquids and chemicals

from biomass via gasification

Ilkka Hannula &

Kari Vanhatalo

Introduction

• Thermochemical processes are sensitive

to feedstock quality

• Biomass feedstocks are very

heterogeneous

Æ Need for pretreatment technologies

Introduction

• Economies of scale exist

• Biomass is rarely available abundantly

Æ Logistics are crucial

Æ Role of energy densification?

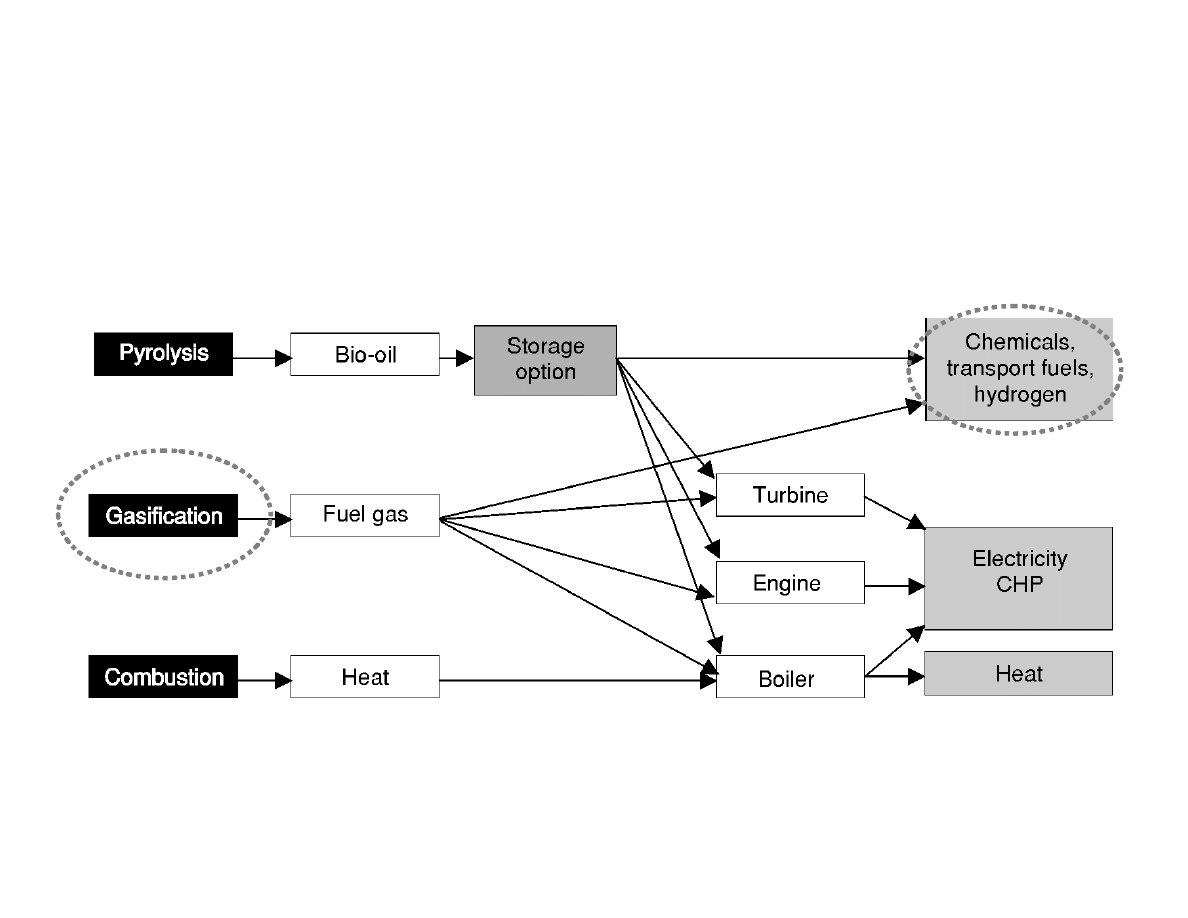

Thermochemical routes

Figure 1. A schematic diagram of different thermal process routes for biomass conversion

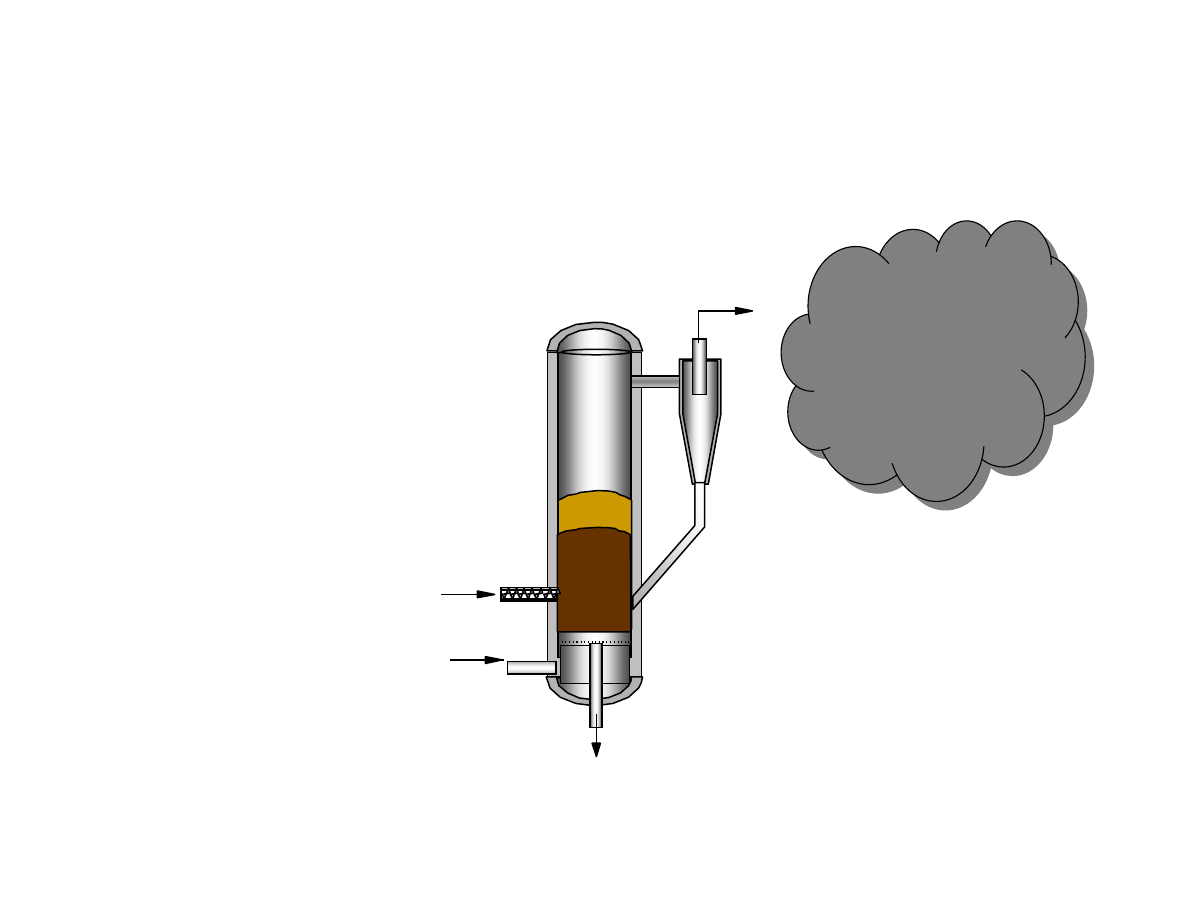

Gasification in large scale

FEEDSTOCK

AIR

ASH

GAS

Feedstock size <10 mm

Tars

Tars

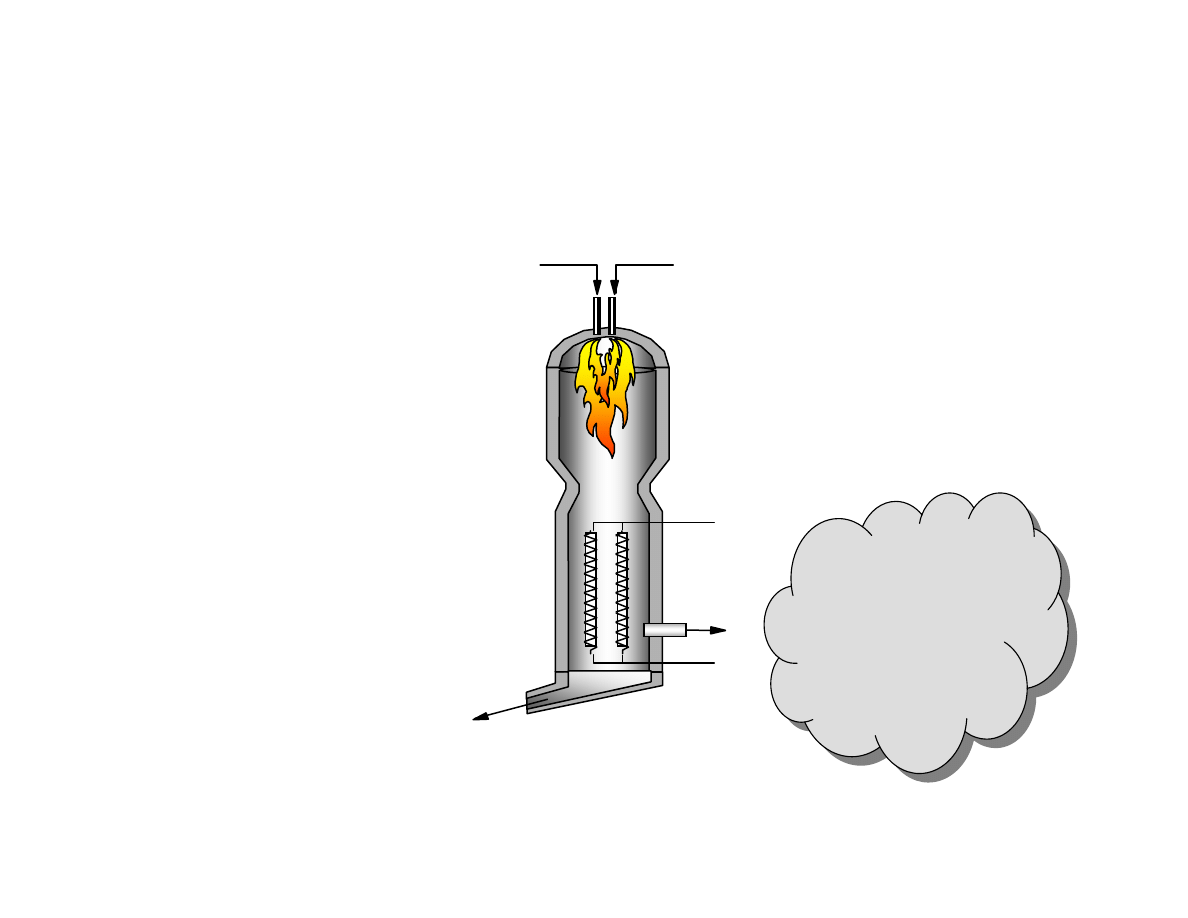

Gasification in large scale

GAS

SLAG

FEEDSTOCK

OXYGEN & STEAM

Feedstock size <0.1 mm

No tars

No tars

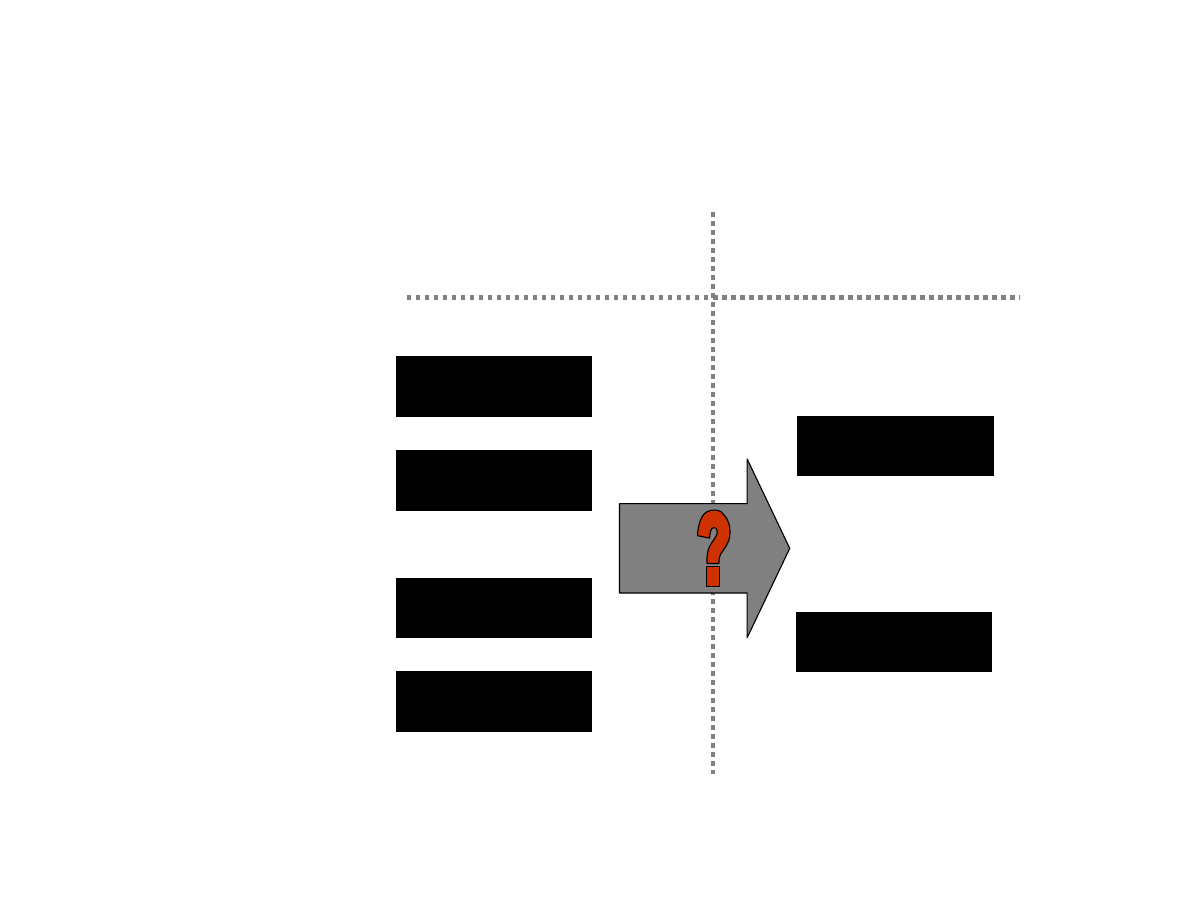

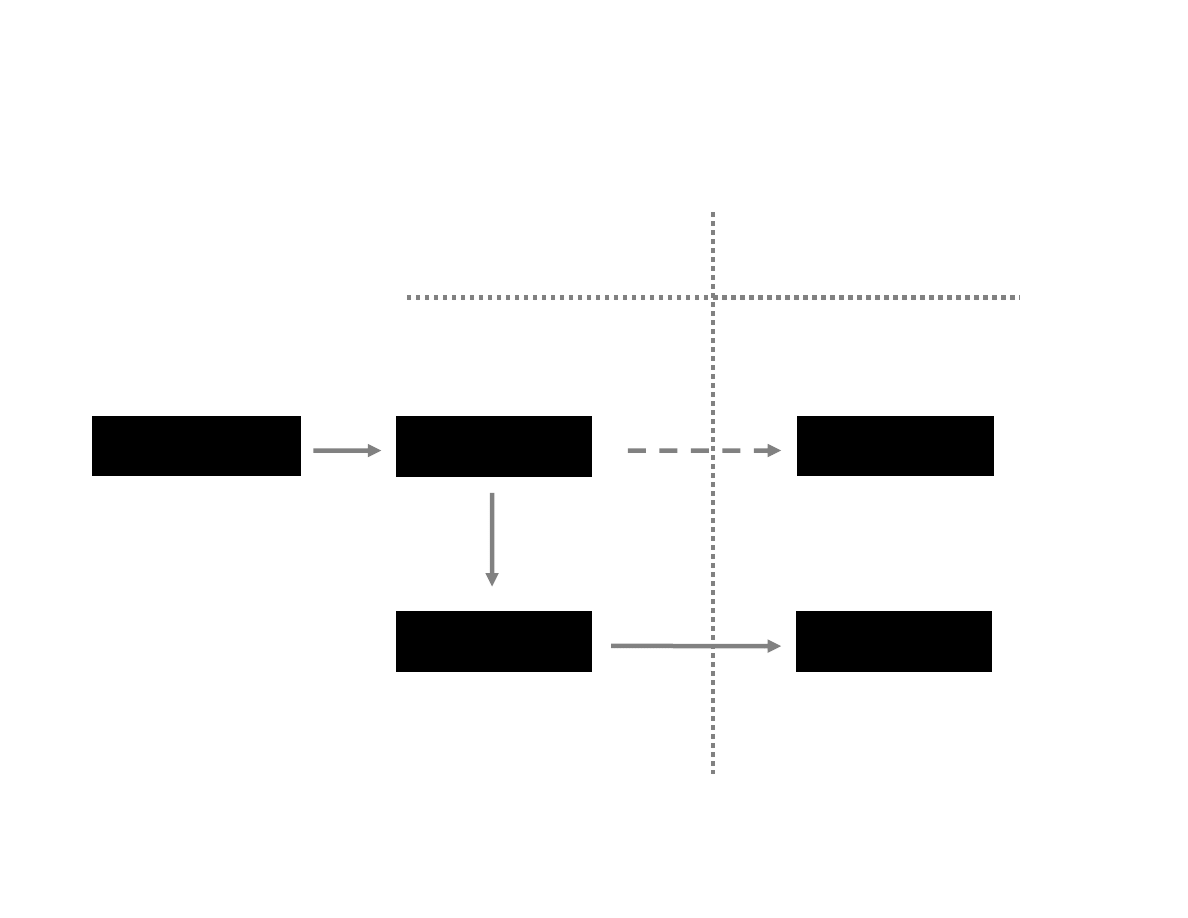

Pretreatment for gasification

Fluidised-bed

Entrained flow

Gasification

Pre-treatment

Drying

Grinding

Pyrolysis

Torrefaction

Commercial

{

Require R&D

{

Drying

• Biomass moisture content could be 40 – 60%

• For synthesis gas production purposes,

feedstock moisture content must usually be

dried down to 15-30 %.

• Choosing of right drying technology is a

question of operational and economic factors

of the specific application

Drying

• Important issues in drying are energy

efficiency, emissions, heat integration and

dryer capacity

• Heat integration: air, flue gas, or steam as

drying medium

• Because of organic raw material, dust

emissions can cause fire or explosion risk

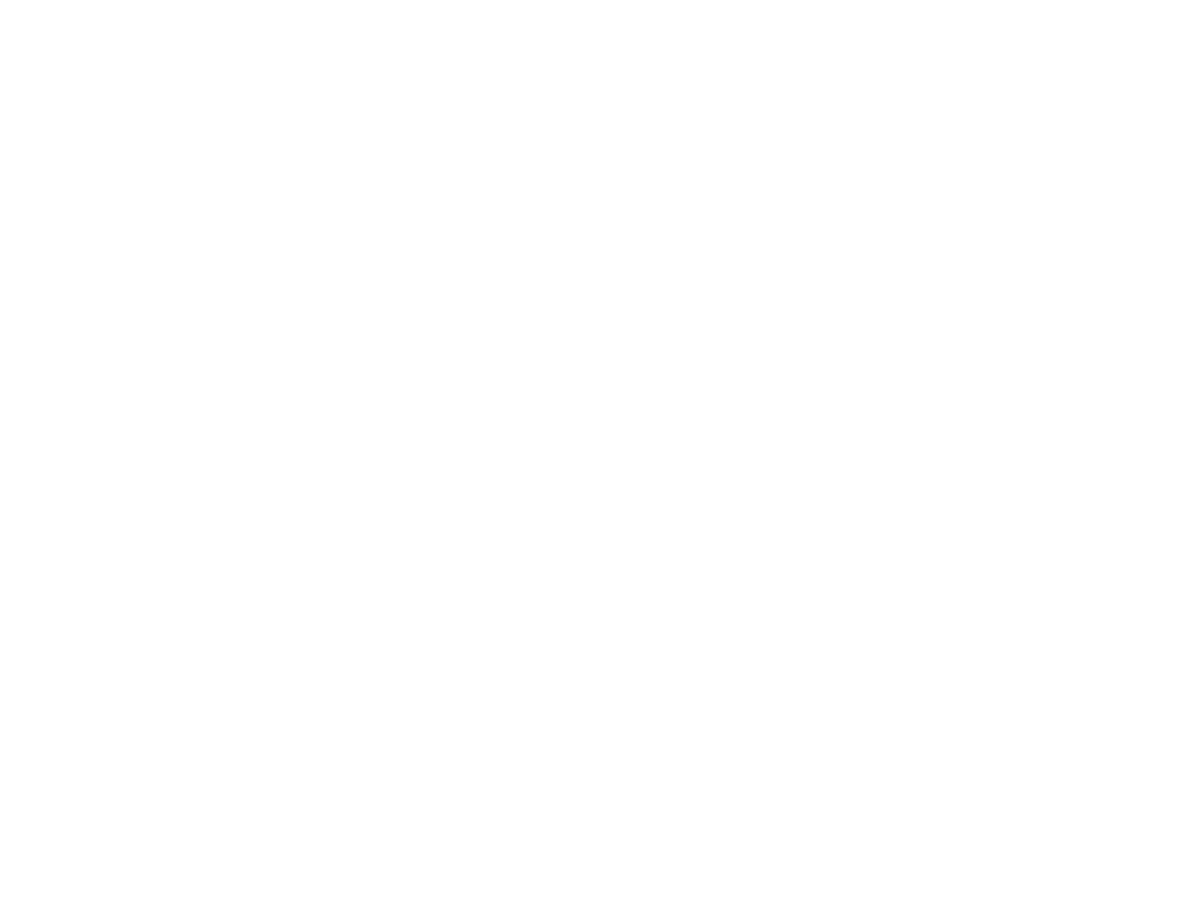

Biomass dryer types

• Commonly used dryer types

for biomass

• Flash dryer

• Belt dryer

• Drum dryer

Grinding

• Biomass is a very heterogeneous raw material

and requires size reduction

• Feedstock particle size to gasification processes

have to be <10 mm

Crushing,

shredding,

cutting

10- 100 mm

Grinding

Synthesis gas

production

”Pre-pre”-treatment methods

< 10 mm

Drying

Grinding

• Feedstock hardness, moisture content and

shape have an effect to processing efficiency

and equipment choosing

• Energy consumption of grinding is between 30-

300 kwh/t

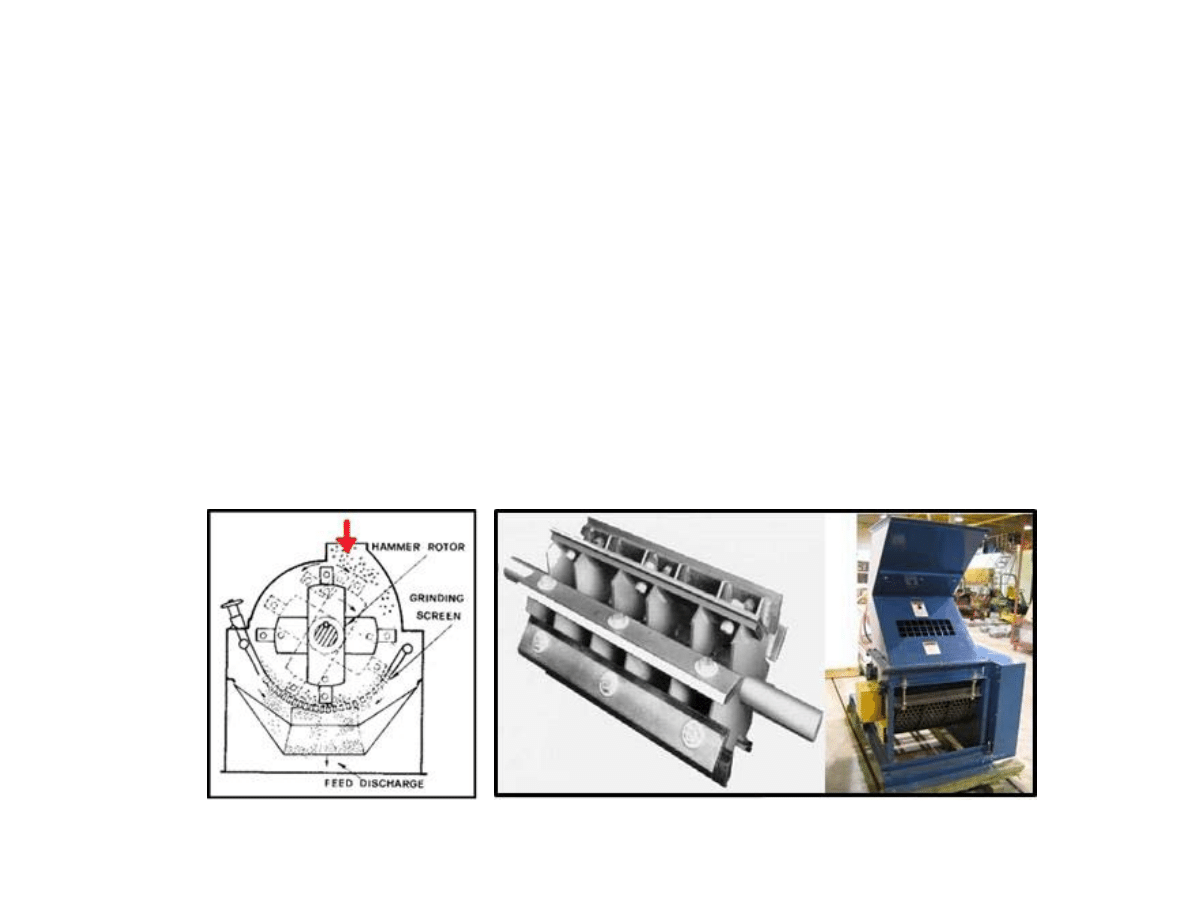

Grinding

• Commonly used equipment for biomass

to achieve required particle size (< 10 mm)

– Hammer mill (Wide feedstock scale)

– Knife mill (Suitable for annual plants)

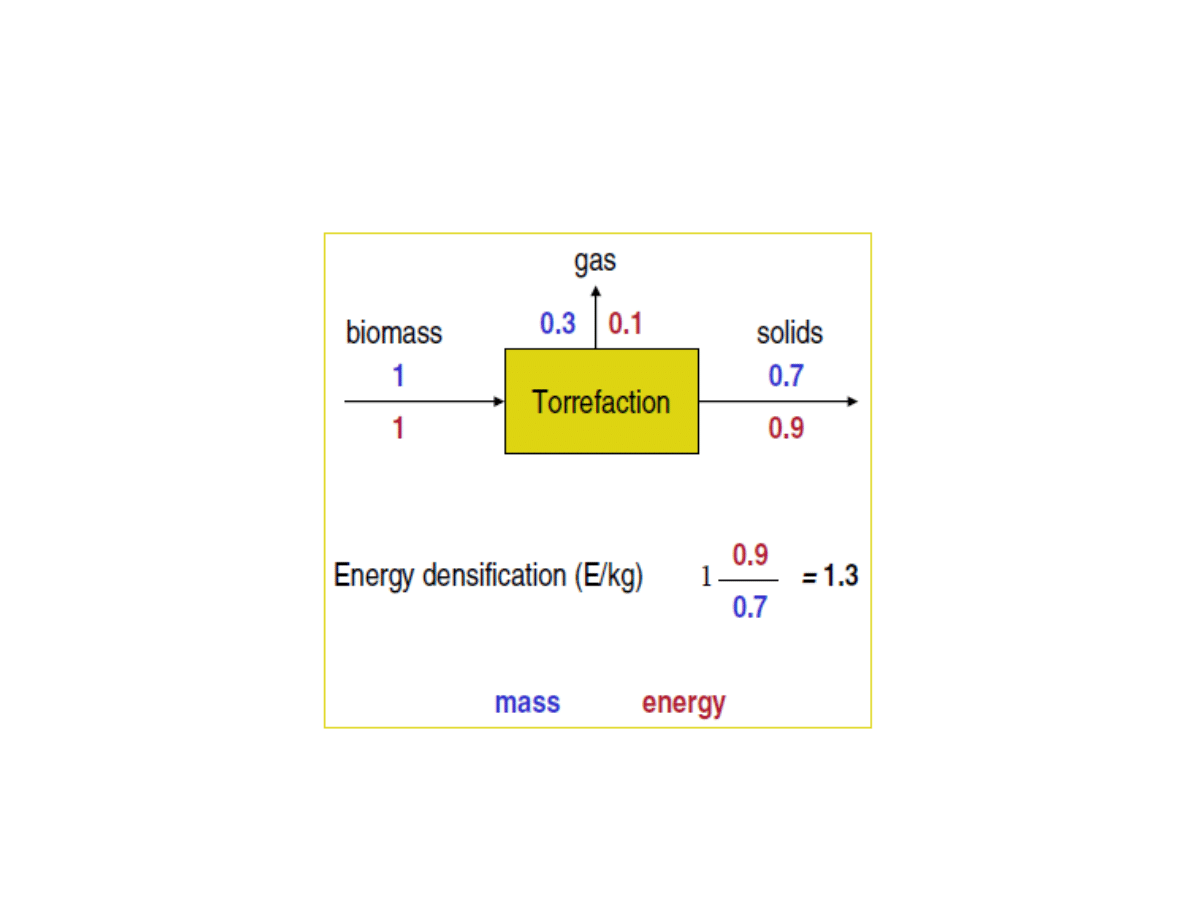

Torrefaction

• Thermal treatment

• T range of 200 to 300 °C

• Atmospheric pressure, absence of O2

Torrefaction

• Low particle heating rates (< 50 °C/min)

• Residence time from 10 to 30 minutes

Æ Particle size < 4 cm

• Loss of mass and chemical energy

Torrefied wood

• Slightly higher heating value (21–22 MJ/kg,

LHV)

• Improved storing properties (is hydrophobic,

limited biological degradation)

• Brittle in character leading to lower energy

consumption in grinding

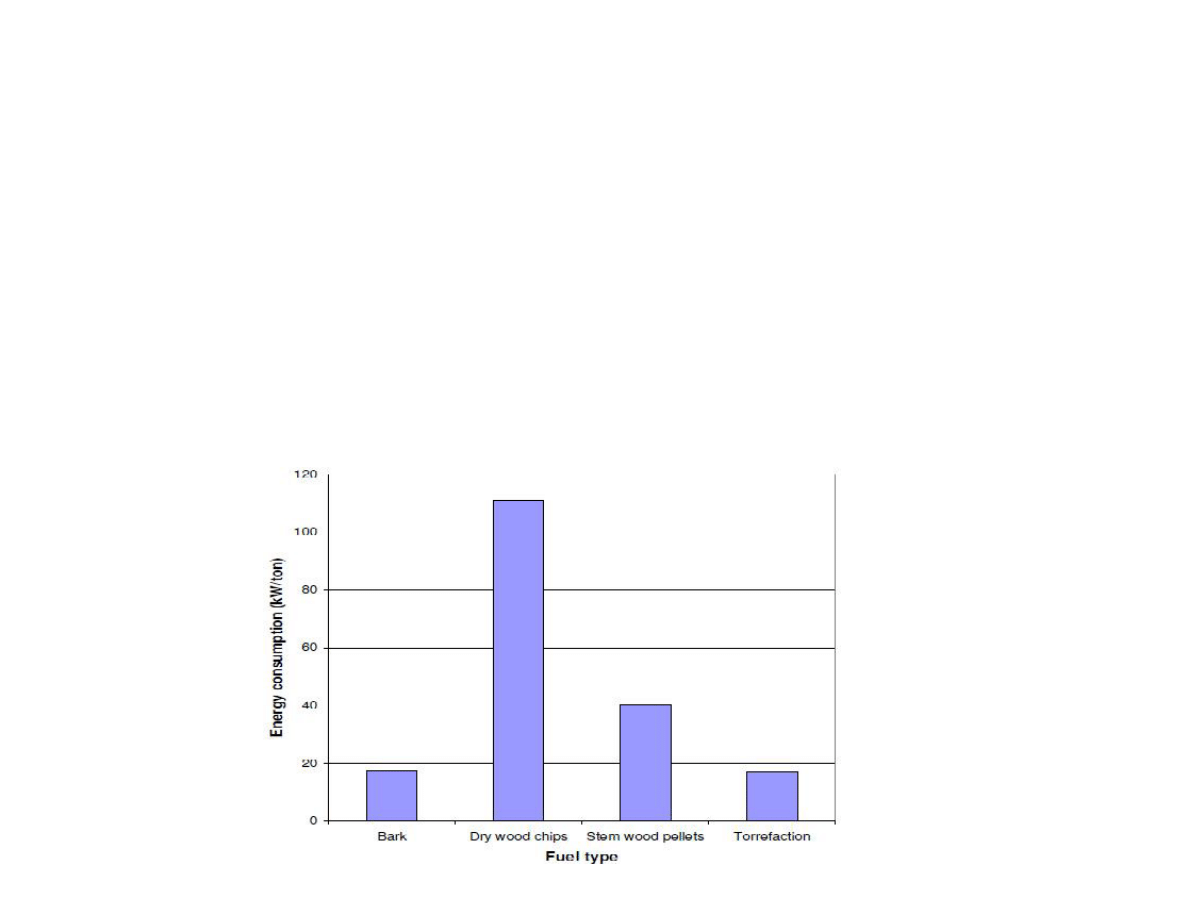

Effect of torrefaction to grinding

• Torrefaction change energy consumption of

grinding.

• 80 % less energy is required comparing dry

wood chips and torrefied chips.

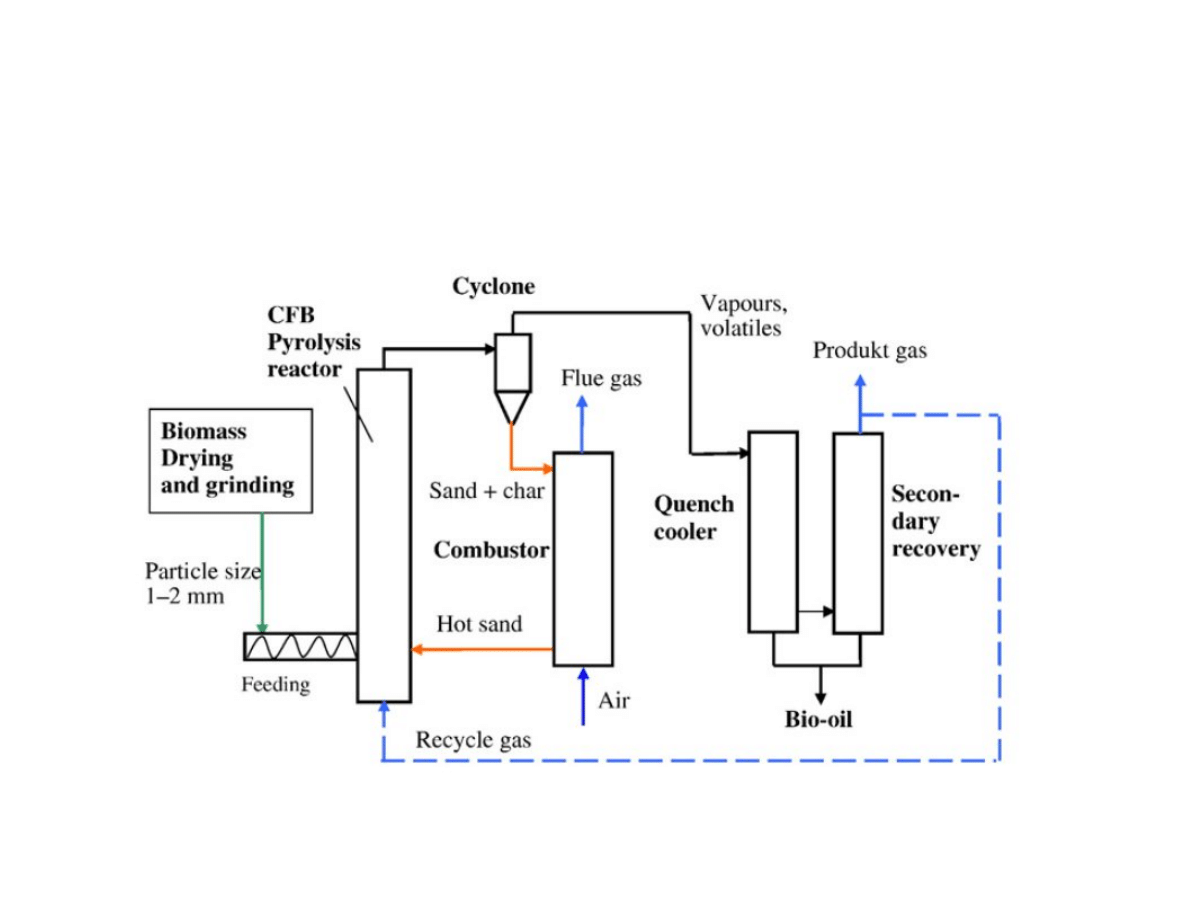

Flash pyrolysis

• Thermal decomposition phenomenon

• Absence of oxygen

• First step in combustion and gasification

Flash pyrolysis

• Process conditions that maximise liquid

production

– moderate temperature

– rapid heat up rate

Æ small particle size

– short vapour residence time

• In addition

– dry feestock to prevent high water content in

the product

Flash pyrolysis

Flash pyrolysis

• Very high heating and heat transfer rates

• Carefully controlled pyrolysis reaction

temperature of around 500 ºC and vapour

phase temperature of 400-450 ºC,

• Short vapour residence times of typically less

than 2 seconds, and rapid cooling of the

pyrolysis vapours to give the bio-oil product

Pretreatment for gasification

Fluidised-bed

Entrained flow

Gasification

Pre-treatment

Drying

Grinding

Pulverising

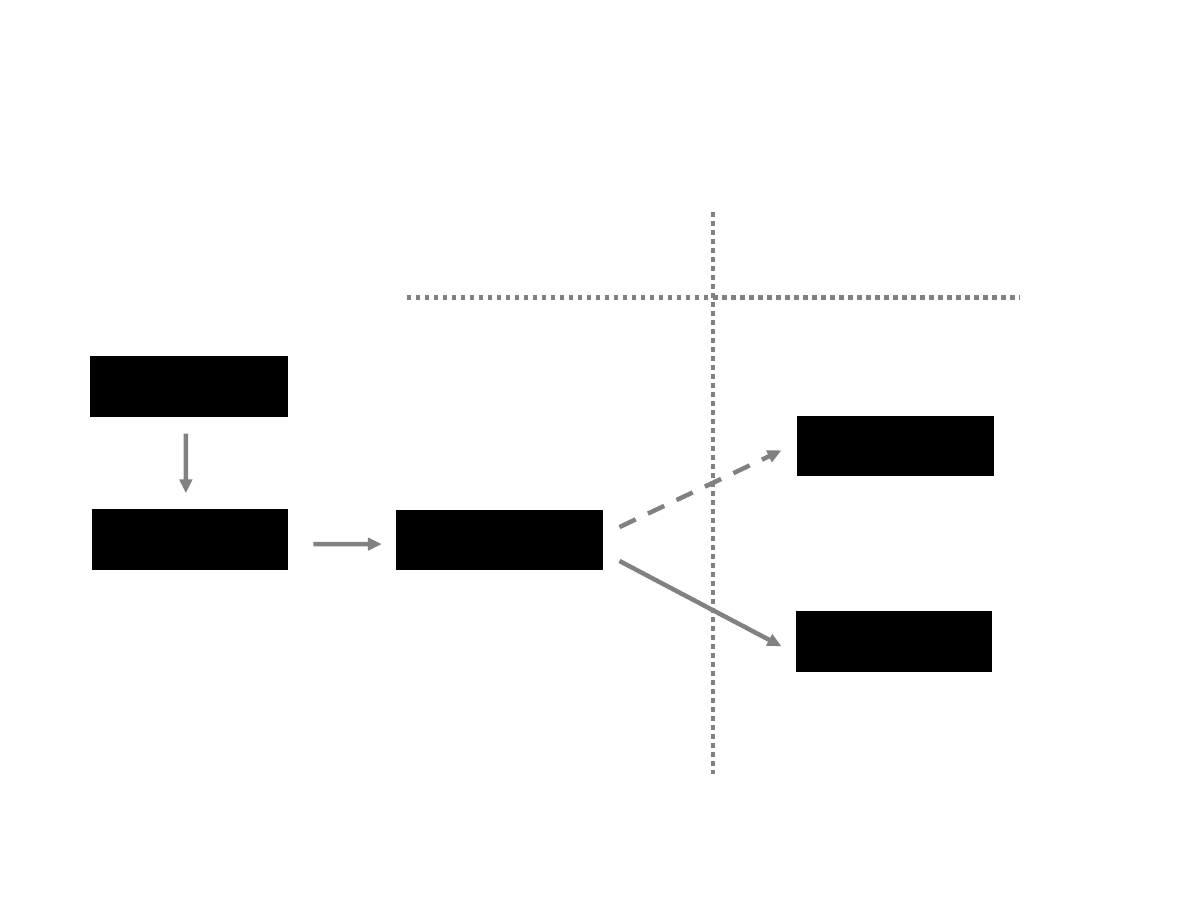

Pretreatment for gasification

Fluidised-bed

Entrained flow

Gasification

Pre-treatment

Torrefaction

Grinding

Pulverising

Pretreatment for gasification

Fluidised-bed

Entrained flow

Gasification

Pre-treatment

Pyrolysis

Grinding

Grinding

Drying

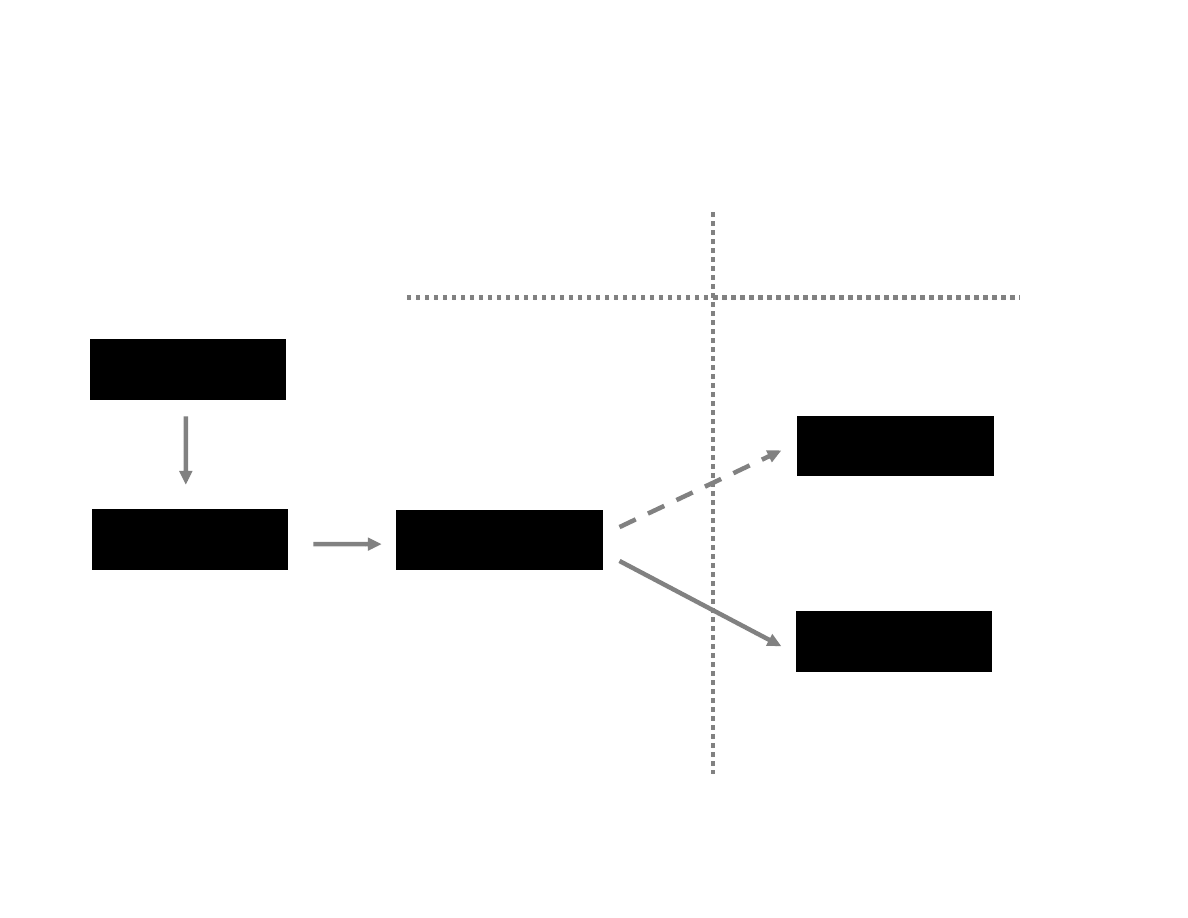

Pretreatment for gasification

Fluidised-bed

Entrained flow

Gasification

Pre-treatment

Pyrolysis

Grinding

Torrefaction

Discussion

• Two commercial pre-treatment methods exist for

larger capacities than 50 t/h, namely drying and

grinding.

• Two solutions exist for large scale gasification,

namely fluidised-bed and entrained flow reactors

– Both require drying to around 15 - 30 wt-%.

– Fluidised-bed reactors require feedstock sizing to

around 10 - 50 mm

– Entrained-flow reactors require additional

pulverisation to achieve <0.2 mm.

Discussion

ÆPre-treatment requirements more challenging for

entrained-flow than for fluidised-bed.

ÆDifferences (economic) could be leveled by

constructing larger plants.

ÆUsing torrefaction or pyrolysis as an energy

densification method.

Discussion

Two interesting options exist for lowering the energy

consumption of biomass pulverisation, namely

torrefaction and pyrolysis.

ÆFast pyrolysis of biomass makes pulverization step

unnecessary by turning the solid feedstock into liquid

form.

ÆTorrefaction requires additional pulverization step, but

significantly lowers the energy consumption of this step.

Discussion

• The final choice of pre-treatment/gasification

configuration should be a result of overall evaluation

• Operational and economic factors specific to the

application.

• Economies of scale usually dictate that the larger the

operational scale, the more expensive treatment

systems are available to choose from.

• Successful integration of the system is always of

importance

Wyszukiwarka

Podobne podstrony:

OTŻ 31-40, ogólna technologia żywności SGGW

karta operacyjna 40 gotowa, Politechnika Lubelska, Studia, Studia, wszystkie, Uczelnia, Technologia

40.wiercenie otworów, Politechnika Lubelska, Studia, Studia, technologia maszyn, mój projekt - techn

cwiczenie 40 otrzymywanie sody metoda solvaya, Technologia chemiczna, Technologia nieorganiczna

Operacja 40.1, POLITECHNIKA ŚLĄSKA Wydział Mechaniczny-Technologiczny - MiBM POLSL, Semestr 6, Semes

Operacja 40.2, Technologia maszyn

Coating Methods, Powder Technology

Str.9 - Operacja 40, Politechnika Lubelska, Studia, Studia, organizacja produkcji, laborki-moje, tec

MSR 40 KOREFERAT NIERUCHOMOSCI INWEST

PORÓWNYWANIE TECHNOLOGII

19 Mikroinżynieria przestrzenna procesy technologiczne,

Technologia informacji i komunikacji w nowoczesnej szkole

Technologia spawania stali wysokostopowych 97 2003

SII 17 Technologie mobilne

W WO 2013 technologia

TECHNOLOGIA PŁYNNYCH POSTACI LEKU Zawiesiny

technologia prefabrykowana

więcej podobnych podstron