53

Cost-Estimation Methods for Drying

Zbigniew T. Sztabert and Tadeusz Kudra

CONTENTS

53.1 INTRODUCTION

Reliable estimates of the fixed capital investment (FCI)

of a drying system as well as the system’s fixed and

operating costs are essential in the preliminary equip-

ment selection or when comparing different competing

systems. In general, estimation of the costs involved in a

drying process follows the well-known methods used

widely in the process industries [1–9]. This chapter pro-

vides the empirical information on shortcut methods

that may be used to quicken the predictions of FCI and

operating costs on the basis of the previously prepared

process balances and one-parameter equipment sizing.

The method described here is useful for preparing the

rough cost estimates applicable to many conventional

drying systems. However, extending this information to

unique or newest methods of drying must be regarded

with caution. When capital cost estimates of a definitive

investment are required to obtain budget authorization,

competitive quotes from vendors have to be requested,

as these quotes are the most reliable estimates.

A dryer itself is only one component of the overall

drying system. The system may comprise preprocessing

equipment (extruders, grinders, mixers, and blenders),

feeders, product-discharge devices, and postprocessing

equipment such as gas cleaners (cyclones, filters, and

scrubbers) and solvent-recovery systems (condensers

and separators). In some cases, heat-recovery systems

(exhaust-gas recycle, run-around coil, heat pump, or

heat wheel) may also be used. Thus, drying systems

for the same end product can be different. Therefore,

the total fixed costs as well as the operating costs should

be calculated for the complete drying system.

Cost components of drying are usually divided

into the following two groups:

1. Fixed costs (fixed charges), which are incurred for

a long period of time, tend to be unaffected by

fluctuations in the level of production activity.

They include: depreciation of equipment and

buildings, interest charges for the investment cap-

ital, plant protection, insurance, fixed part of

taxes and rents, fixed part of maintenance costs,

and executive salaries (administration, overhead).

2. Variable costs (operating costs) tend to vary

with the production level. They include: cost

of raw materials, cost of product degradation,

costs of energy and utilities, direct labor (oper-

ating, works transport, supervision, and la-

boratory control), interest on working capital,

royalties, variable part of maintenance costs,

and miscellaneous direct costs.

The estimation process of drying costs is schemat-

. The foll owing is a

detailed presentation of the method for preliminary

estimates preparation, together with a worked ex-

ample of cost estimates.

53.2 FREE-ON-BOARD COST AND

INSTALLED COST OF THE EQUIPMENT

Equipment-price data concern the free-on-board

(FOB) cost and the installed cost of the equipment.

The installed cost of a drying system covers the cost

ß

2006 by Taylor & Francis Group, LLC.

of the pur chased equipment , co st of equipment instal-

lation, and costs of piping, wiring, and instrumentation.

These costs can be estimat ed on the basis of ven dors’

data or, with less a ccuracy, on the basis of known

costs for the equipment or syst em bui lt previous ly,

assum ing a great de gree of simila rity.

Data for equ ipment costs obt ained from techni cal

literatu re are usuall y ba sed on the techni cal an d e co-

nomic cond itions of the pa st. Among the various

methods accounti ng for price chan ges due to inflation

and inevi table fluctuat ions in econ omic condition s,

the method of the Chem ical Engineer ing Pl ant Cost

Index (based on the 1957/ 1959 cost level and ab bre-

viated as CE Index) and the method of the Marshal l

and Swi ft All-I ndustry Equip ment Cost Index (for -

merly known as the M arshall an d Stevens Ind ex) a re

the mo st commonl y used. This last inflation index

(formula ted in the US market in the year 1926 wi th

the set value of 1 00, and ab breviated as M&S Ind ex)

is recomm ended for updating the costs of high-l evel

process eq uipments [4,10]. The upda ted M &S Index

as well as the CE Index are listed regularly in Chem -

ical Eng ineering , a periodi cal publish ed by McGra w-

Hill, New York [11] , and are valid for cost upda ting

in US$ and for the US market. A part of such listing

for the equipment -cost indice s over the pe riod 1989–

2004 is given in Tabl e 53.1. The followi ng formu la

using M&S Index is wid ely acc epted for equipment -

cost upda ting:

Updated cost

¼ Original cost

M&S Index at updated time

M&S Index at the time of original cost

(53 : 1)

The M&S Index an d the CE Index c an also be used

for world-pr ice c omparison , if the changes in costs

accordi ng to the local eco nomics , type of indust ry,

and kind of equipment (besi des time) a re accounted

for [12] .

For scale -up or scale -down of the drying syst em,

the cost of the equipment of the same type but of

different capacity can be predict ed approxim ately

from the followin g emp irical correl ation:

Predicted cost

¼ Original cost

[desired capacity=original capacity]

n

(53:2)

where desir ed capacity is the capacit y of the eq uip-

ment for whi ch the cost is to be estimat ed and origi nal

capacity is the capa city of the same- type equ ipment

for whi ch the cost is known (original cost). Val ues of

the exp onent n for the typic al equipment used in

drying systems are lis ted in

given he re or in the refer ence literat ure (e.g ., [4,13]) ,

n

¼ 0.6 can be taken for rou gh estimat ion. The expo -

nent n may vary with the design detai ls. For exampl e,

in the case of cloth dust collectors, n ranges from 0.70

to 0.86. The cost estimated according to Equation

53.2 must be corrected not only for the inflation

index according to Equation 53.1 but also for the

Preliminary

estimation of fixed

and variable costs

of drying

Prediction of plant cost:

1. FOB cost of equipment

2. Installed cost of system

3. Total direct cost of system

4. Fixed capital investment

Calculations:

1. Mass and heat

balances

2. One-parameter

equipment sizing

Drying system

version

FIGURE 53.1 The steps of preliminary estimation of drying cost.

TABLE 53.1

Marshall and Swift All-Industry Equipment Cost

Index and Chemical Engineering Plant Cost Index

(1989–2004)

Year

M&S

Index

CE Index

Year

M&S

Index

CE

Index

1989

895.1

355.4

1997

1056.8

386.5

1990

915.1

357.6

1998

1061.9

389.5

1991

930.6

361.3

1999

1068.3

390.6

1992

943.1

358.2

2000

1089.0

394.1

1993

964.2

359.2

2001

1093.9

394.3

1994

993.4

361.1

2002

1104.2

395.6

1995

1027.5

381.1

2003

1123.6

402.0

1996

1039.2

381.7

2004

1178.5

444.2

Source: Marshall and Swift Equipment Cost Index. Chem. Eng.,

last pages of every issue (excerpted by special permission from

Chemical

Engineering

(2005).

Copyright

2005,

by

Access

Intelligence, New York, NY 10038).

ß

2006 by Taylor & Francis Group, LLC.

local eco nomic situati on when install ation will be

erected in a cou ntry other than the United State s

[14]. Plavsic [12] has given a num ber of useful refer -

ences [15–20 ] and pr ovided a simp lified ‘‘direct fact or-

ing’’ method for convert ing the US data to numb ers

that are applic able elsewhere . Howe ver, furt her dis-

cussio n of this aspect is beyond the scope of this

chapter .

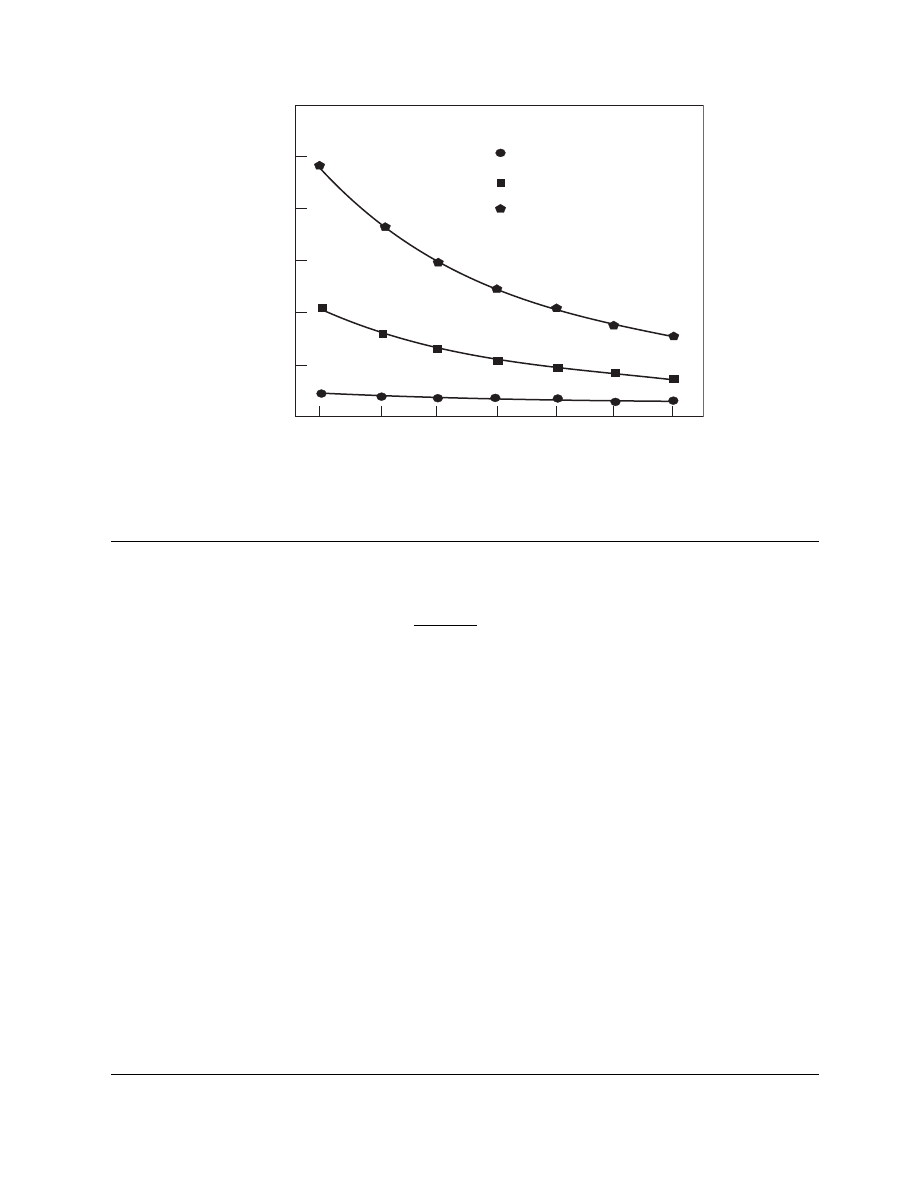

Ver y app roximate co st of carbon steel dryers can

be calculated as [4]

C

¼ (M& S Index) 30 þ 36 : 74

W

(17 : 77

þ T )

(53 : 3)

where C is the installe d cost (US$ in the year of the

M&S Index) cov ering the dr yer and auxil iaries, includ-

ing foundati ons and erection, but no secondary dus t

collectors or buildin g; W is the evapo ration capacit y,

kg mois ture/h; and T is the inlet-ai r temperatur e ( 8 C).

This relation, howeve r, does not reflect the material

propert ies, so the calculated prices are unde restima ted.

The graphs accordi ng to Equation 53.3 are presen ted

in

for the M&S Index equal to 1100.

Asi de from the general form ula, numerous da ta

on dryer cost depen dence on ev aporation capacity

exist in literat ure for the given dryers and defi nite

operatin g parame ters [13, 21,22]. For exampl e, co st

of a spray dryer with a pr essure nozzle atomi zer,

residen ce time of 16 s, inlet- and outlet-ai r tempe ra-

ture of 538 an d 121 8 C, respectivel y, can be calcula ted

as [21] :

Price

¼ 13793 :8

E

0 :435

(first-qu arter-199 5 US $)

(53 : 4)

where E is the evaporat ive load (181 < E < 38,780

kg/h) and the price includes the 304-stai nless steel

dryer body , the access platform , support steel , bur ner,

air-heate r shell, feedi ng system, and instrument ation.

Insula tion, refractor y mate rial, fan, a nd soli ds-rec ov-

ery syst em a re not included.

The ab ove method of prices present ation is

restricte d to a na rrow range of technol ogy. Taking

into accoun t that dryer cost de pends mainl y on its

size and the material of constr uction, drying indice s

such a s dryer through put, evaporat ion rate, or unit

heat co nsumpt ion shou ld not be used as parame ters

for cost estimat ion, mainl y be cause the same indice s

may be obtaine d for dryers of different size by

manipul ating the ope rating condition s. This situ ation

changes when a contrac t relating to techn ology and

equipment is consider ed—then a depen dence of dry er

cost on evaporat ion capacit y can be a valuabl e criter-

ion for dryer selection.

The best charact eristic parame ters for preli minary

cost esti mation of most dryers a re:

.

The volume of the drying chamber (e.g., for

spray or rotar y dryers )

.

The surface area of the suppo rting grid, shelve s,

belt con veyors etc.

.

The heat- transfer area in case of co ntact dryers

Usually, the estimat ed fabricati on cost of a dryer can

be calculated from the follo wing correlati on:

P

¼ (M& S Index) A Q

c

(US$ in the year of M &S Index)

(53 : 5)

where Q is the capacit y of a dryer defi ned eithe r by its

effecti ve volume (V ) or by its characteris tic surface

area (S ), de pending on the dryer type. Valu es of the

coeffici ent A and expo nent c for some common

dryers , determ ined from the available cost data, a re

listed in

The fabricatio n co st of a drying unit besides its

size dep ends also on the mate rial of co nstruc tion; it is

the lowest for carbo n steel. If the process requir es a

TABLE 53.2

Typical Expo nents Re lating Equ ipment Cost

to Capa city

Equipment Capacity Range Unit Exponent

Centrifugal fan 0.4–40 m

3

/s 0.44

Cyclone 0.01–4 m

3

/s 0.61

Multiple cyclone 4–94 m

3

/s 0.66

Dust collector (cloth) 1–470 m

3

/s 0.78

Electrostatic precipitator 23–470 m

3

/s 0.74

Gravity spray scrubber

0.7–189

m

3

/s

0.66

Venturi scrubber

3.3–38

m

3

/s

0.46

Impingement scrubber

1–23

m

3

/s

0.78

Centrifugal scrubber

3.3–47

m

3

/s

0.73

Ribbon blender

a

0.2–7

m

3

0.54

Cage-type disintegrator

0.3–6

kg/s

0.68

Roll crusher

3–66

kg/s

0.97

Screen (vibrating)

0.2–6

m

2

0.66

Bucket elevator

a

3–50

m

0.52

Belt conveyor

a

5–19

m

2

0.50

Screw conveyor

b

0.4–0.8

m

2

0.53

Pan dryer

1–19

m

2

0.50

Vacuum-shelf dryer

1.4–92

m

2

0.54

Tunnel dryer

2–10

m

2

0.50

Roto-Louvre rotary dryer

4–93

m

2

0.62

a

Carbon steel.

b

Stainless steel, conveyor length

diameter.

Source: Sztabert, Z.T., in A.S. Mujumdar, Ed., Drying of Solids,

Sarita Prakashan, New Delhi, 1990, pp. 136–153.

ß

2006 by Taylor & Francis Group, LLC.

Cost, (US$)

20,000

70,000

120,000

170,000

220,000

270,000

320,000

70 100 130 160 200 250 300

T, (⬚C)

W = 20 kg/h

W = 100 kg/h

W = 500 kg/h

FIGURE 53.2 The dependence of dryer cost on evaporation capacity in kg moisture/h and inlet-air temperature in 8C,

according to

¼ 1100).

TABLE 53.3

Param eters A and c in

Dryer Type

Capacity Range

Parameter

Construction

Equipment Included

A

c

Cabinet (atmospheric)

16 < V < 160

7

0.50

Aluminum

Heater, instrumentation

Cabinet (low vacuum)

5 < V < 30

18

0.62

Aluminum

Heater, instrumentation, vacuum pump

Vacuum with unheated agitator

0.02 < V < 9

66

0.30

Carbon steel

Vacuum with unheated agitator

0.02 < V < 9

103

0.42

304-stainless steel

Vacuum double-cone tumbler

0.1 < V < 14

80

0.70

304-stainless steel

Indirect rotary (steam tube)

3 < V < 300

55

0.58

Carbon steel

a

Instrumentation

Drum (single or double)

1 < S

b

<

40

21

0.50

Cast iron

Drive, fan

Belt conveyor (through-flow)

18 < S

c

<

50

21

0.59

304-stainless steel

Drive, fan, steam heater

Direct rotary, flue-gas heated

20 < S < 300

17

0.68

Carbon steel

d

Drive, burner, heat exchanger, fan, dust

collector, instrumentation

Direct rotary, hot-air heated

20 < S < 300

14

0.66

Carbon steel

d

Drive, burner, heat exchanger, fan, dust

collector, instrumentation

Fluid bed (batch)

0.003 < V

e

<

0.66

141

0.47

304-stainless steel

Heater, fan, filter, instrumentation

Spray

1 < V < 300

47

0.52

304-stainless steel

Heater, atomizer, fan, filter,

instrumentation

Vibrated bed

1 < S

f

<

12

9

0.70

Carbon steel

g

a

For 304-stainless steel, cost is multiplied by 1.7.

b

Drum peripheral surface area.

c

Deck surface area.

d

For 304-stainless steel, cost is multiplied by 1.5.

e

Bed volume.

f

Surface area of vibrated grid.

g

For 304-stainless steel, cost is multiplied by 1.64.

Note: Dryer capacity is defined by dryer volume V in m

3

or surface area S in m

2

.

ß

2006 by Taylor & Francis Group, LLC.

more chemical- resistant material, a claddin g may be

applie d in so me cases. In certain drying operatio ns,

optimu m de sign of the equipment as well as pro duct-

quality requ irements calls for the use of not only more

durable but also more expensi ve material s. In general ,

drying equipment built of 304-stai nless steel typic ally

costs from 1.5 to 1.7 tim es more than that made of

carbon steel and 2 to 3 times more if built of titanium .

The co st depen ds also on the au xiliary e quipment ,

and this is a reason for some uncerta inty in co st

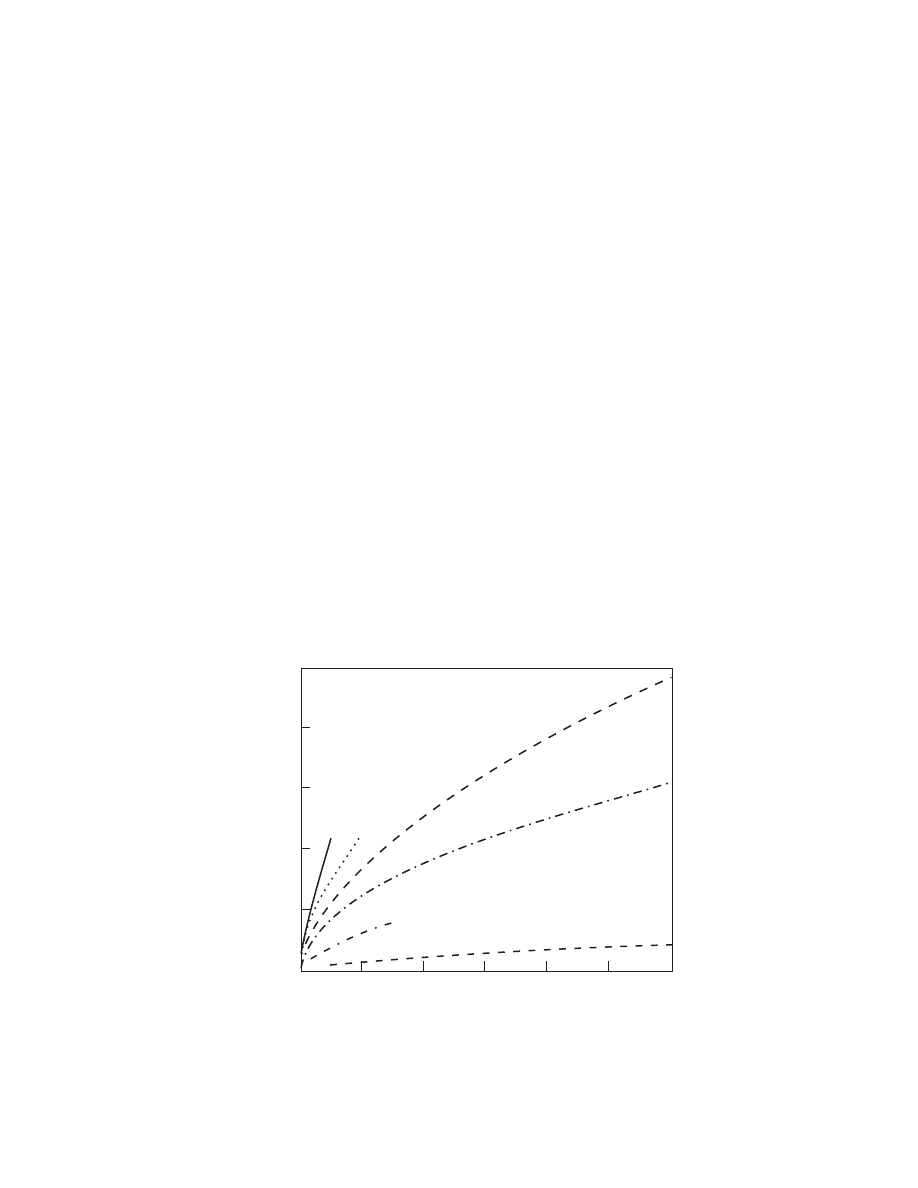

predict ion from literat ure sources withou t vend ors’

data. Figu re 53.3 present s, as an exampl e, the pur -

chase co st for severa l dryers in relat ion to their ca p-

acity that is updated to the yea r 2000 wi th the M&S

Index equal to 1089.

Once the FOB costs of all equipment compri sing

the drying syst em are establ ished, the install ed cost

and other costs of the plan t, as well as fixed costs , can

be estimat ed us ing the factor method of cost estima-

tion. Usually, the follo wing co mponents of inst alled

cost are consider ed:

1. FOB cost (vendo rs’ prices or estimat ed prices)

2. Assembly, piping, wiring, instrumentation using

vendors’ data, or the following factors:

.

Fully eq uipped compact syst em—25 to 3 0%

of FOB cost

.

Fully equipped syst em, deliv ered in many

parts —40 to 45% of FOB cost

.

Equip ment delivered without piping and in-

strumen tation—71 to 99% of FOB cost

3. Freight (funct ion of trans port method, weight,

and dist ance, or 7% of [componen t 1

þ com-

ponent 2])

The total direct co st of the plant ex pressed in

terms of the ‘‘batter y limit s’’ is much higher than the

install ed cost of the equ ipment becau se of addition al

costs such as

.

Buildi ngs, laborat ories , wareh ouses

1. If a dryer syst em is inst alled insid e a build-

ing, the cost of the bui lding is fact ored in as

20 to 35% of the inst alled cost.

2. If a dryer system is outsi de of the buildin g,

the cost of the building is factored in as 1 5%

of the inst alled cost.

.

Utility-supply facilities, site development,

other direct expenses (20 to 40% of the in-

stalled cost).

To roughly estimate the total direct cost of the dry-

ing installation, it is recommended to multiply the

equipment FOB cost by a factor of 2.25 if the equip-

ment is made of carbon steel or by 2.75 if stainless-steel

equipment is used [22]. These figures include the cost of

piping, instrumentation, electrical connections, insula-

tion, building space, and engineering when applied to

0

20

40

60

80

100

120

0

200,000

400,000

600,000

800,000

1,000,000

V, (m

3

)

6

5

4

3

2

1

Cost, (US$)

FIGURE 53.3 FOB costs (US$, in the year 2000) vs. dryer volume in m

3

of selected dryers according to

: 1,

atmospheric cabinet dryer (aluminum); 2, vacuum cabinet dryer (aluminum); 3, spray dryer fully equipped (304-stainless

steel); 4, steam tube rotary dryer (carbon steel) with instrumentation; 5, vacuum dryer with unheated agitator (304-stainless

steel); 6, double-cone tumbler dryer (304-stainless steel).

ß

2006 by Taylor & Francis Group, LLC.

spray, flash, rotary, or fluid-bed continuous dryers. In

specific cases, however, different factors may have to be

used. For instance, the costs of instrumentation and

piping may be included in the purchase price of a fully

equipped dryer [23].

Besides the total direct cost, the FCI of a drying plant

contains

.

Contractor’s fee (10 to 27% of direct plant cost)

.

Insurance, customs, taxes, land, and other

owner’s costs (as per local regulations or 7% of

direct plant cost)

.

Contingencies (10 to 30% of direct plant cost)

.

Procurement, supervisory, administration, and

other owner expenses related to the plant (5 to

15% of direct plant cost)

Overall, the FCI of a drying plant that is sensitive

to the dryer type and the product processed may be

much higher, even by 3 times of the equipment cost.

A number of dryers that form multistage, combined,

or hybrid drying systems are often assembled from the

components purchased from different suppliers.

Therefore, the cost of the entire installation is not

directly related to the dryer capacity but depends

greatly on the cost of the ancillary equipment. When

other operations such as conveying, grinding, or

screening must be performed simultaneously with dry-

ing, the investment and operating costs can be reduced

significantly by allowing for a partial write-off of the

dryer cost for these secondary functions [13].

53.3 FIXED COST

Fixed costs (fixed charges) of a drying process are

incurred for a long period of time and tend to be

unaffected by fluctuations in the production level.

The factor method of fixed-cost estimating is based

on some simplifications such as:

.

Fixed cost of drying is a function of installed

cost of a drying system and FCI.

.

Variable part of maintenance cost is given to-

gether with fixed part as a percentage of FCI.

The factors depend on the current economic conditions

that should be analyzed up front, especially interest

charges for the investment. Also the inflation index for

local currency should be taken into account. In devel-

oped countries, the estimation of an annual fixed cost for

drying can be made on the basis of the following factors:

.

Depreciation of equipment—7 to 9% of in-

stalled cost

.

Depreciation of buildings, utility facilities, site

improvement—5% of these costs

.

Interest charges on the investment—3 to 5% of

FCI

.

Fixed taxes and rent—2% of FCI

.

Plant protection, insurance—1% of FCI

.

Maintenance cost (fixed and variable):

1. Complex system, explosive or toxic raw ma-

terials, significant number of rotating or vi-

brating parts—10% of FCI

2. Simple system—5% of FCI

.

Executive salaries and other fixed costs

6%

of FCI

53.4 VARIABLE COST

The variable cost of drying is the last item in the cost-

estimation process and it is predicted on the basis of

heat and mass balances, shortcut factors, or, if avail-

able, vendors’ data, unit cost of raw materials, labor,

and utilities.

The cost of raw material depends on the applied

technology and required characteristics of the end

product. In any case, this cost should take into ac-

count the transportation costs to the considered site.

When one compares several drying methods for the

same product, it may be convenient to judge only

costs of the lost and degraded material.

The cost of labor depends significantly on the

mode of a drying process: batch or continuous. The

labor cost of batch processes depends on the quantity

of handled material, the type of the equipment, the

method of material transportation, the method of

feeding, and the schedule of plant operation. Rough

estimation can be made considering the following

rule: 2 man-hour/(m

3

of dried material)

þ 1/3 man/

dryer/shift. The unit cost of labor should reflect the

local economic conditions and the cost should include

the insurance, taxes, and social charges. The labor

cost of continuous drying with an automatic process

control is almost independent of the production rate

because supervision of control panels and supervision

of the feeding and discharge systems do not depend

on the throughput of the drying system. Overall, with

the increasing automation, the direct labor cost de-

creases, but they are somewhat offset by the increase

in labor cost to maintain the control devices and

higher initial capital costs. Rough estimation can be

made considering the following rule: 1/2 man/dryer/

shift

þ operating labor of the other equipment in add-

ition to the dryer.

The utilities costs are usually estimated on the

basis of mass and heat balances, on the equipment

characteristics, and on the utilities’ prices. The prices

ß

2006 by Taylor & Francis Group, LLC.

of util ities have to be co rrected for local co ndition s

and historical trends . The main constr aint at this

point is the cost of energy becau se of unstabl e prices

of fuels, which may signi ficantl y vary bot h in the long

and sho rt term s. The hist orical trends are sho wn in

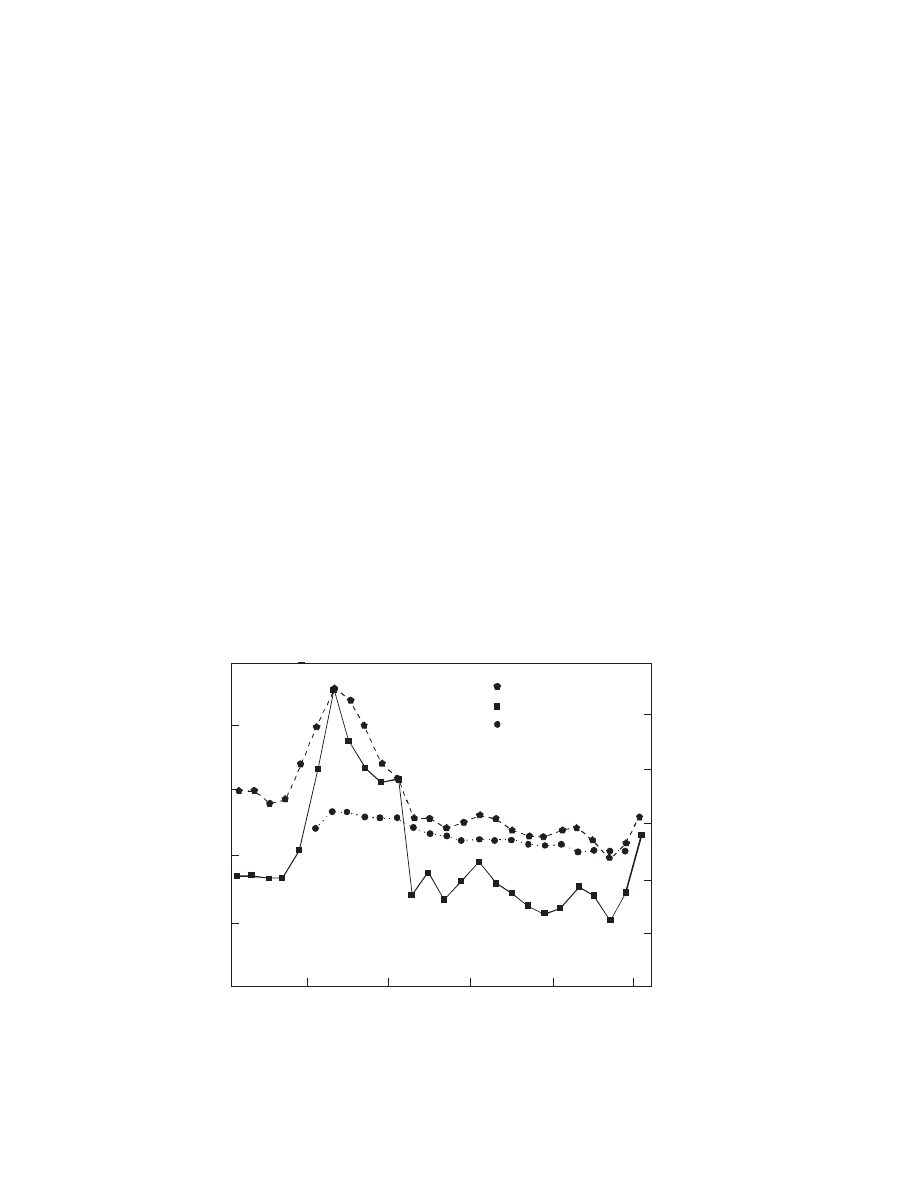

Figure 53.4, wher e one ca n see the well- known effe cts

of the Irani an Revol ution and the Iran–I raq W ar

during 1979–198 0 on the crude oil and seconda ry

fuel prices . Besides fuel-pri ce fluctuat ion caused by

historical ev ents, there is also a seasonal fluc tuation

influenced by sup ply and de mand. For examp le, price

of heati ng oil given by NYMEX increa sed from 32

/c/L in Sep tembe r 200 4 to 40 /c/L in Octo ber and

Novem ber 2004, and then decreas ed to 34 /c/L in

January 2005 [24].

Fuel -prices da ta an d estimat ion for the years 2001–

2006 in the US market are present ed in

Trends of elect ricity prices indicate slow er increase

than the increa se of natural gas and oil prices [26] .

In lon g term s, the most stable prices are ch aracteris -

tically for elect ricity and coal though the cost of c oal

delivery and managi ng may be signifi cant. Average

costs of co al recei pts at elect ric-uti lity plants in

the United States by some states in dollar s (Sprin g,

2000) per sho rt ton are present ed in

More infor mation on fuel prices can be found on the

http: //www.w trg.com/ prices.htm

The problem of energy price vo latility can be re-

solved by dividin g the utility price into separate term s,

each of them be ing a produ ct of a certa in coefficie nt

and the price parame ter [27]. The first term reflect s

the co nventio nal inflati on rate whi le the second one

repres ents the con tribution from the fuel price:

P

utility

¼ A (CE Inde x) þ B P

fuel

(53 : 6)

The utility cost coeffici ents A and B are charact eristic

of the con sidered utility and can be given eithe r by a

single number, as in the ca se of purchased electrici ty

(A

¼ 0.0001 3 an d B ¼ 0.01), or by a correl ation, as in

the case of compres sed air ( A

¼ 0.0000 5 q

0.3

ln p

and B

¼ 0.0009 ln p, where q and p are the total air-

plant capacit y and the delivered a ir pressur e, respect -

ively). Tabul ated data on the utilit y co st coeffici ents

are given by Ulrich [27,28]. The CE Ind ex in Equation

53.6 is the Plant Cost Index report ed monthl y in

Chemic al Eng ineering .

The varia ble maint enance cost, accordi ng to the

previous assum ption, is estimat ed toget her with a

fixed part in relation to FCI.

1975 1980 1985 1990 1995 2000

0

10

20

30

40

50

60

250

200

150

100

50

0

Gasoline

Crude oil

Bitum. Coal

Year

1 Barrel, petroleum (US) = 158.987 L

1 Gallon (US) = 3.785 L

1 Short Ton = 907.185 kg

US$ /Barrel

US /Gallon ; US$ /Short Ton

FIGURE 53.4 Average US first-purchase price of crude oil (1996 US$/barrel)—the right scale, gasoline price (1995 US /c/

gallon)—the left scale, and bituminous coal in 1996 US$/short ton—the left scale. (From US Energy Information Agency

(

ß

2006 by Taylor & Francis Group, LLC.

TABLE 53.4

Fuel Prices for the Years 2001–2006 (United States)

Year 2001 2002 2003 2004 2005 2006

Crude oil spot prices (FOB) ($/barrel) 21.2 (March) 22.5 (March) 26.5 (March) 31.1 (March) 47.6 (March)

Crude oil West Texas intermediate ($/barrel) 31.12 (year) 41.44 (year) 58.77 (year prediction) 63.46 (year prediction)

No. 2 heating oil, wholesale ($/gallon) 0.76 (year) 0.69 (year) 0.88 (year) 1.13 (year) 1.70 (year prediction) 1.76 (year prediction)

Natural gas, City Gate ($/thousand cubic feet) 5.72 (year) 4.12 (year) 5.8 (year) 6.6 (year) 7,18 (June)

Natural gas, average Wellhead ($/thousand cubic feet) 4.01 (year) 2.95 (year) 4.89 (year) 5.50 (year) 7.81 (year prediction) 7.64 (year prediction)

Natural gas residential average price ($/thousand cubic feet) 9.63 (year) 7.89 (year) 9.51 (year) 10.74 (year) 13.03 (year prediction) 15.33 (year prediction)

Electricity nominal industrial average retail prices ( /c/kWh) 5.04 (year) 4.88 (year) 5.13 (year) 5.11 (year) 5.71 (June)

Electricity residential average prices ( /c/kWh) 8.62 (year) 8.46 (year) 8.70 (year) 8.92 (year) 9.22 (year prediction) 9.37 (year prediction)

Imported coal average prices ($/short ton) 33.72 (year) 35.51 (year) 31.45 (year) 37.52 (year) 46.49 (June)

Coal (11,700 Btu, 0.8 lb SO

2

/mm Btu) spot price ($/t) 18 (September) 17 (September) 30 (September) 37 (September)

Coal for electric power sector ($/million Btu)

1.23 (year)

1.25 (year)

1.27 (year)

1.35 (year)

1.55 (year prediction)

1.62 (year prediction)

ß

2006

by

Taylor

&

Francis

Group,

LLC.

Servicing the working capital depends on the

credit value and its type, as well as on the interest

rate. It is reasonable to assume the credit to be equal

to the variable cost of a drying process. In developed

countries the interest charges on the working capital

can be estimated as 4 to 7% of the annual credit, but it

is strongly recommended to consider local conditions.

Royalties usually do not occur; but when a

profit is calculated on the basis of new technology,

royalties should be taken into consideration as a

cost item.

When comparing the competing drying technolo-

gies, it is recommended to relate the capital invest-

ment (FCI) and the annual drying costs to the annual

production rate. Usually, comparable estimates are

made on optimistic and pessimistic assumptions of

the level of costs (level of factors). With progress in

computer-aided design, a number of software pro-

grams have been custom-developed in order to provide

the engineers with an efficient tool for calculations

of approximate cost [29,30]. Although such software

programs are necessarily provided without warranty

of any kind, the reliability of the estimate of +30%

covers the majority of the cases tested. An implemen-

tation of a process simulator with a cost evaluator is

useful for the analysis of variants of a new plant,

especially for

.

Process calculation and equipment sizing

.

Estimating fixed investment cost

.

Performing a scheduling calculation, including

direct and indirect labor costs

.

Providing a detail evaluation of production cost

.

Evaluating project profitability

53.5 DRYING COST ESTIMATE:

A WORKED EXAMPLE

The following example of the cost-estimate procedure

made in the year 2005, for example, illustrates the

method of a preliminary cost evaluation for a drying

process.

Problem description: Based on the previously cal-

culated balance and one-parameter dryer sizing, the

‘‘factored estimate’’ for a cost of the laundry detergent

formulating and drying in a spray dryer is to be done.

The system will be located in Pennsylvania in the year

2006. The required capacity of the dryer is 4.9 t of the

product per hour (production period: 7,200 h/y; 35,280

t of dry product per annum) of which the moisture

content should be about 7% w/w. The feed moisture

content is 32.5% w/w, the feed temperature is 808C,

and the price of raw materials in the slurry in the year

2003 was US$1.48/kg (dry weight).

0

10

20

30

40

50

0

10

20

30

40

50

Coal: US$/short ton

Natural gas: US$/100 MJ

US total

New York

Michigan

Pennsylvania

Illinois

Kansas

Iowa

North Dakota

Nebraska

Oklahoma

Wisconsin

Indiana

Arkansas

New Jersey

Massachusetts

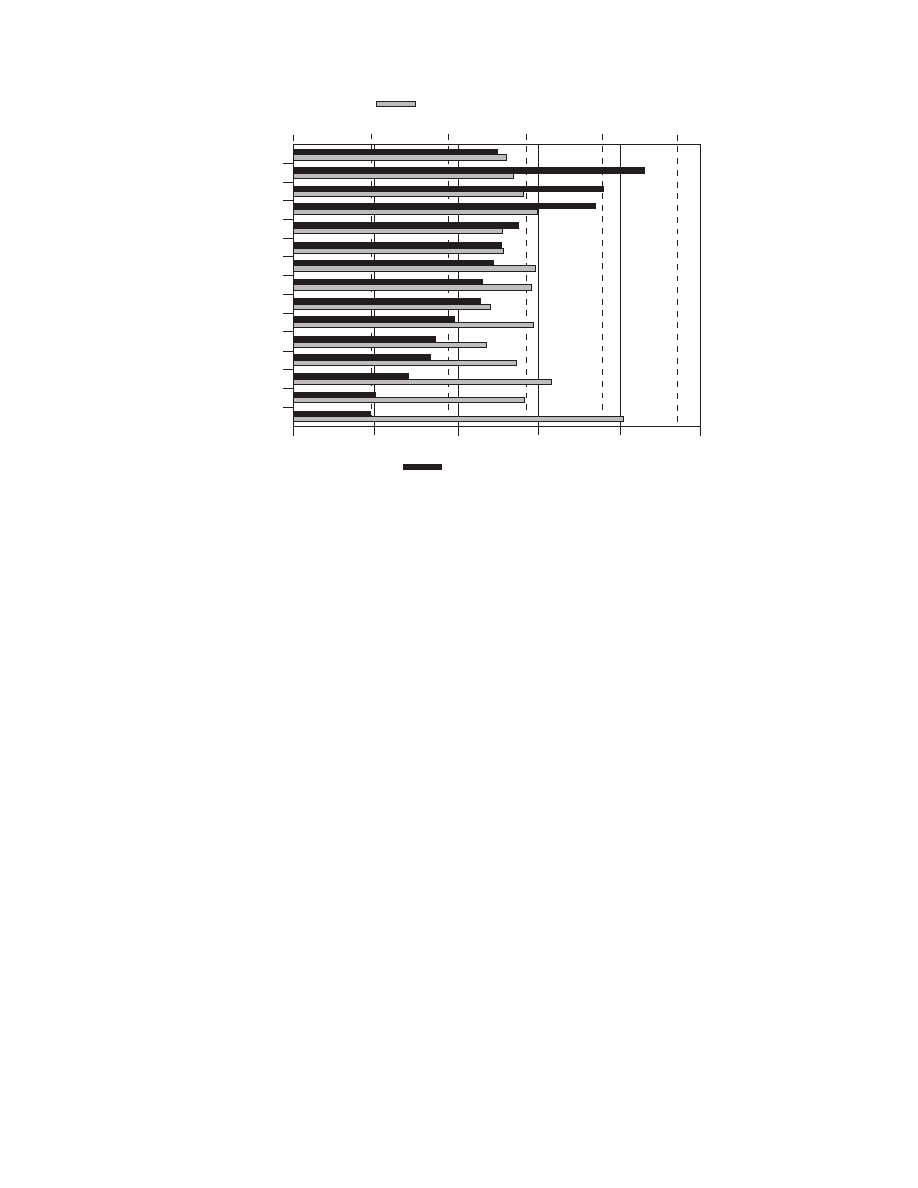

FIGURE 53.5 Average delivered cost of fossil fuel receipts at US Electric Utility Plants by state; coal: April–June 2000, US$/

short ton; gas: 1999, US$/100 MJ. (From Federal Energy Regulatory Commission, FERC Form 423, ‘‘Monthly Report of

Cost and Quality of Fuels for Electric Plants.’’)

ß

2006 by Taylor & Francis Group, LLC.

The task is to pr edict the cost of drying in a spray

system in the year 2006.

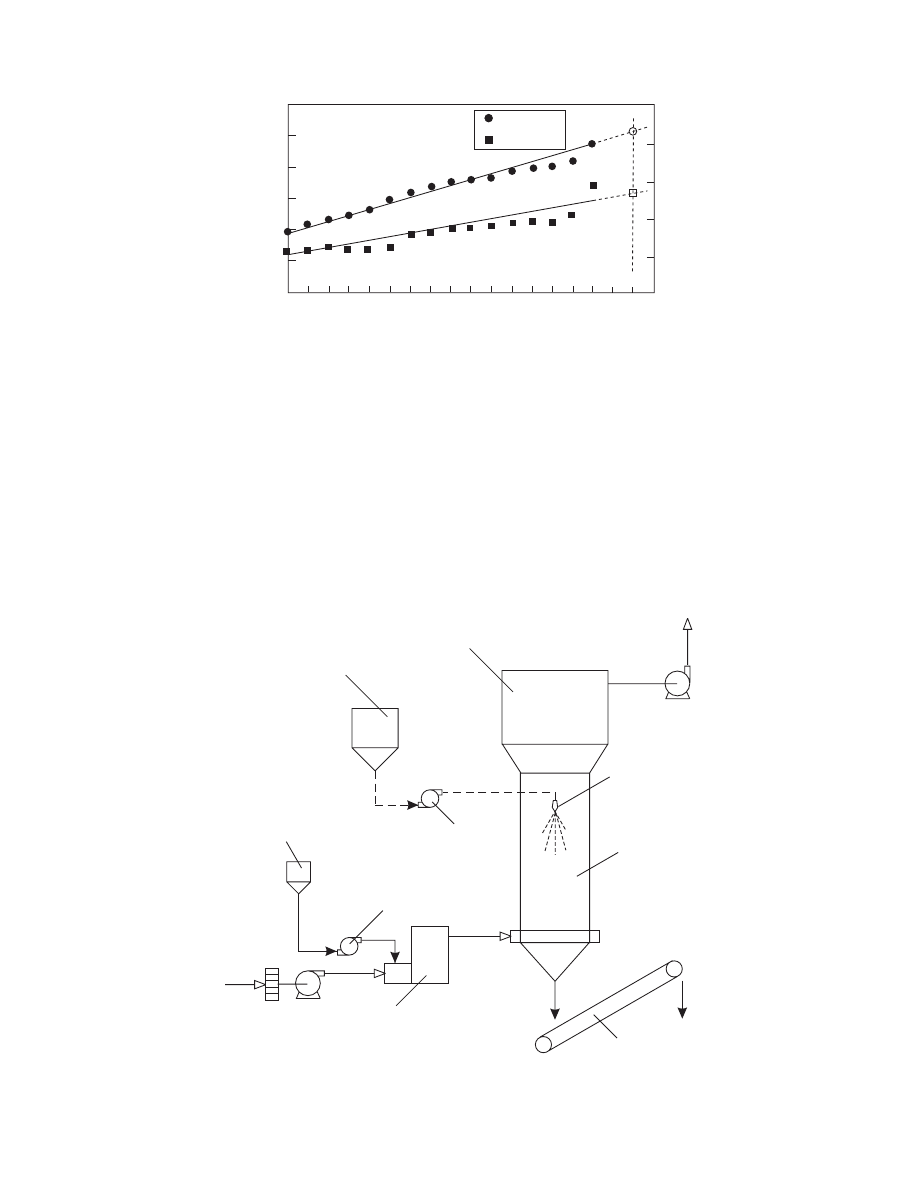

Solu tion: Based on the data presented in

, the M &S Index and the C E Index in the

year 2006 are predicted by linear extrapolation,

as shown in Figure 53.6. The values of the indices

are:

M&S Index

2006

¼ 1221.7

CE Index

2006

¼ 432.1

From previous experience, it is known that the

laundry detergent can effectively be formulated and

dried in a countercurrent spray dryer using combus-

tion gases at 240 and 1208C at the dryer inlet and

1989

1992

1995

2001

1998

2004

2007

Year

M&S Index

1200

1400

1100

1000

900

800

700

CE Index

300

350

400

450

550

500

M&S Index

CE Index

FIGURE 53.6 Trends in the M&S Index (left scale) and the CE Index (right scale) in the years 1989–2004 with extrapolation

to the year 2006.

Conveyor

Fuel

tank

Burner with a

mixing chamber

Air

Slurry tank

Feed pump

Fuel pump

Pressure

nozzle

Bag filter

Exhaust

Spray

dryer

Product

FIGURE 53.7 Flow sheet of the system for drying of the laundry detergent slurry.

ß

2006 by Taylor & Francis Group, LLC.

outlet, respectivel y. The volume tric evapo ration rate

under these condition s is 3.5 kg H

2

O/m

3

h.

For the prelimina ry c ost estimat e, an assump tion

is made that ambie nt air is heated by the co mbustion

of fuel oil; the flue gases a re then mixe d with fres h air

to ensure the requir ed gas tempe ratur e. Taking into

accoun t the specifics of the dr ying technol ogy, mois -

ture content of the feed, a s wel l a s fine s that are

likely to be entrai ned with the drying gas, the dry ing

plant sho uld co nsist of a slurry feedin g syst em, an oil

burner with a second ary air-mi xing ch amber, a dr yer

with pressur e nozzles, an d an exhaust -gas cleaning

system (

). As product co oling, mixing of

supplem ents, and pa ckaging are down stream pro -

cesses, they are outsi de of the ba ttery limits of the

consider ed pro ject. The basic material of constru ction

should be stainles s steel .

The following values a re known from the heat and

mass balances :

The mass flow rate of the flue gas–air mixtu re

enteri ng a dryer: 44,000 kg/h

The quantit y of fuel oil fed to the bur ner: 300 L/h

(inclu ding he at losse s)

The power of electrica l motor s: 190 kW

Accor ding to the specified values of the dryer

capacity and the v olumetric evap oration rate (3.5 kg

H

2

O/m

3

h), the dryer volume should be 570 m

3

.

Hence, the dryer FO B c ost in the year 2006 can be

calculated from

P

¼ 1221 :7 47 570

0 :52

¼ 1,554,000

(in the year 2006, US $)

Accor ding to the data present ed in

, the

above value includes the cost of a dryer, a fan, a filter ,

a heater , and the inst rument ation. The co st of the

remaining equ ipment calcul ated on the ba sis of the

past cost data is US$201,00 0 (in the year 2006). Then

the cost of the entire drying system is to be

US$1, 757,000 . The install ed cost of the syst em shou ld

contai n the co mponents present ed in Tabl e 53.5. As a

result of calcul ations, the fixed cost for drying of

35,280 t/y of the laun dry detergen t is predicted for

the year 2006 at the level of US$1,449,780 per annum,

resulting with US$41.09/t of dried product.

TABLE 53.5

Application of the Factor Method for Predicting Fixed Capital Investment and Fixed Cost of Drying (Data

for the Presented Example)

It.

Cost

Factor Range and Cost Basis

Estimate (US$)

A

FOB cost of equipment

Vendors’ data or actualized

previous data

1,757,000

B

Assembly, piping, wiring, instrumentation (1,757,000

0.4)

30–99% of FOB cost

702,000

C

Freight ([1,757,000

þ 702,000] 0.07)

Weight, distance, or 7% of (A

þ B)

172,200

D

Installed cost

(A

þ B þ C)

2,632,000

E

Building (2,632,000

0.3)

15–35% of installed cost

789,600

F

Utility facilities, site development (2,632,000

0.2)

20–35% of installed cost

526,400

G

Direct cost of plant

(D

þ E þ F)

3,948,000

H

Insurance, custom, taxes (3,948,000

0.07)

7% of direct cost

276,360

I

Contractor’s fee (3,948,000

0.2)

10–27% of direct cost

789,600

J

Contingencies (3,948,000

0.15)

10–30% of direct cost

592,200

K

Procurement, supervisory, administration,

and other owner expenses related to the plant (3,948,000

0.07)

5–15% of direct cost

276,360

L

Fixed capital investment

(G

þ H þ I þ J þ K)

5,882,520

1

Depreciation of drying system (2,632,000

0.09)

7–9% of installed cost

236,880

2

Depreciation of building, utility facilities and site improve

([789,600

þ 526,400] 0.05)

5% of building, utility facilities

and site improve costs

65,800

3

Interest charges on the investment (5,882,520

0.055)

3–5% of FCI

294,130

4

Constant taxes and rent (5,882,520

0.02)

2% of FCI

117,650

5

Plant protection, insurance (5,882,520

0.01)

1% of FCI

58,830

6

Maintenance (4,843,000

0.055)

5–10% of FCI

323,540

7

Executive salaries and other fixed costs (5,882,520

0.06)

6% of FCI

352,950

8

Fixed cost of drying (annual)

1,449,780

9

Unit fixed cost of drying

41.09/t

ß

2006 by Taylor & Francis Group, LLC.

According to the forecast for the year 2006, the

cost of fuel oil (loco system) will probably approxi-

mate 46.5 /c/L and the unit cost of electrical energy

will be of about 6 /c/kWh. The unit cost of raw

materials in the year 2006 predicted on the basis of

the price in the year 2003 as US$1.48/kg (dry weight)

as well as the values of the CE Index

2003

and the

predicted CE Index

2006

is

1:48

432:1

402:0

¼ $1:59=kg

The unit labor cost with insurance, tax, social, and

other personal expenses is expected at US$27/h and

the interest rate of about 4%. The variable cost items

for drying of the laundry detergent slurry calculated

according to the presented method are summarized in

Table 53.6. The predicted variable cost is about

US$1,685,699 per annum and US$47.78/t of dried

product. Then, the expected unit cost of drying of the

laundry detergent in the year 2006 will most likely be

US$41:09=t

þ US$47:78=t ¼ US$88,87=t

Because the fixed part of the unit cost includes the

variable part of the maintenance cost (as in the as-

sumption), the value to be compared with the costs of

alternative technologies for drying of the laundry

detergent should be the sum of both costs, i.e.,

US$0.089/kg.

SUMMARY

Very often, the published cost data (a primary re-

source is Chemical Engineering) refer to a specific

year and apply to a location of the plant in North

America. It is therefore necessary to correct the cost

estimate for the inflation index and also for different

geographical locations. Local cost of energy, as well

as the local regulations (environmental, taxes, cus-

tom) and legislative requirements, must be considered

carefully on a case-by-case basis to estimate the dry-

ing costs at different locations using the published

cost data for the United States. Also, no warranty

can be made concerning the accuracy of the published

correlations or data on costs of dryers, ancillary equip-

ment, as well as fuel and energy costs, but these data

are very useful for the shortcut methods of cost ana-

lyzing and for preliminary prediction of costs of a

drying process on optimistic and pessimistic levels.

ACRONYMS

CE Index

Chemical Engineering Plant Cost Index

FCI

Fixed capital investment

FOB

Free-on-board

M&S Index Marshall and Swift Index

w/w

Weight by weight

REFERENCES

1. J.S. Page. Conceptual Cost Estimating Manual. Hous-

ton, TX: Gulf Publishing Company Book Division,

1984.

2. M.S. Peters and K.D. Timmerhaus. Plant Design and

Economics

for

Chemical

Engineers.

New

York:

McGraw-Hill, 1980.

3. T. Peters and J. Timmerhaus. Chemical Plant Cost and

Designs. New York: McGraw-Hill, 1993.

4. C.H. Chilton (Ed.). Cost Engineering in the Process

Industries. New York: McGraw-Hill, 1960.

5. R.S. Hall, W.M. Vatavuk, and J. Matley. Chem. Eng.

95(17): 66–75, 1988.

6. A. Chauvel, P. Leprince, Y. Barthel, C. Raimbault, and

J.P. Arlie. Manual of Economic Analysis of Chemical

Process. New York: McGraw-Hill, 1981.

7. J.W. Hackney. Control and Management of Capital

Projects. New York: Wiley, 1965.

8. D. Noden. Chem. Proc. Eng. 50(10): 67–70, 1969.

9. J.J. McKetta, Ed. Unit Operations Handbook. New

York: Marcel Dekker, 1993.

TABLE 53.6

Predicted Variable Cost of Drying (Data for the Presented Example)

It.

Cost

Cost Basis

Estimate (Annual, US$)

A

Fuel

300 L/h

7200 h 46.5 /c/L

1,004,400

B

Electricity

190 kW

7200 h 6.3 /c/kWh

86,184

C

Labor

2 workers

8760 h $27/h

473,040

D

Royalties

Neglected

0

E

Lost of raw material

5 kg/h

7200 h $1.59/kg

57,240

F

Working capital servicing

(A

þ B þ C þ D þ E) 4%

64,835

G

Variable cost

1,685,699

H

Unit variable cost of drying

(G/35,280 t)

47.78/t

ß

2006 by Taylor & Francis Group, LLC.

10. Z.T. Sztabert. In: A.S. Mujumdar, Ed. Drying of Solids .

New Delhi: Sarita Prakashan, 1990, pp. 136–153.

11. Marshall and Swift Equipment Cost Index. Chem. Eng .

Last pages of every issue.

12. B. Plavsic. Chem. Eng . 100(8): 100–104, 1993.

13. R.H. Perry, D.W. Green, and J.O. Maloney. Perry’s

Chemical Engineers’ Handbook. New York: McGraw-

Hill, 1984.

14. L. Pintelon and F. Van Puyvelde. Chem. Eng . 104(8):

98–104, 1997.

15. A . V . B r i d ge w a t e r . Chem. Eng. 8 6( 24 ) : 1 19 – 12 1,

197 9.

16. J.T. Gallagher. Chem. Eng . 76(6): 196–202, 1969.

17. K.M. Guthrie. Chem. Eng . 76(6): 114–142, 1969.

18. I.V. Klumpar and S.T. Slavsky. Chem. Eng . 92(15):

73–75, 1985.

19. I.V. Klumpar and S.T. Slavsky. Chem. Eng . 92(17):

76–77, 1985.

20. C.A. Miller. Chem. Eng. 86(14): 89–93, 1979.

21. W.M. Vatavuk. Chem. Eng . 102(8): 68–71, 1995.

22. C.M. Van’t Land. Industrial Drying Equipment. New

York: Marcel Dekker, 1991.

23. S.F. Sapakie and T.A. Renshow. In: B. McKenna, Ed.

Engineering and Food: Processing Application , Vol. 2.

Amsterdam: Elsevier, 1984, pp. 927–937.

24. OilEnergy.com. Nymex Heating Oil Price.

25. U.S. Energy Information Administration.

26. Energy Shop.com. Brokers of Natural Gas & Electri-

http://www.energyshop.com/es/default.cfm

27. G.D. Ulrich. Chem. Eng. 79(2): 110, 1992.

28. G.D. Ulrich. A Guide to Chemical Engineering Process

Design and Economics. New York: Wiley, 1984.

29. N. Basta. Chem. Eng. 102(4): 151–154, 1995.

30. J.C. Kemp, N.J. Hallas, and D.E. Oakley. Develop-

ments

in

Aspen

Technology

Drying

Software.

Proc. IDS2004, Sao Paulo, Brazil, pp. 767–774,

2004.

ß

2006 by Taylor & Francis Group, LLC.

Document Outline

- Table of Contents

- Chapter 053: Cost-Estimation Methods for Drying

Wyszukiwarka

Podobne podstrony:

Semi Empirical Method for Estimating the Combustion Wave Transition through the Contact Surface in a

Free Energy Bedini Device And Method For Pulse Charging A Battery Patent Info 2004

Fibonacci Practical Fibonacci Methode For Forex Trading

Improvements in Fan Performance Rating Methods for Air and Sound

Combinatorial Methods for Polymer Science

Metallographic Methods for Revealing the Multiphase Microstructure of TRIP Assisted Steels TŁUMA

Methodology for Assessment Biodiversity

Influence of drying methods on drying of bell pepper (Tunde Akintunde, Afolabi, Akintunde)

FOREX Systems Research Practical Fibonacci Methods For Forex Trading 2005

Numerical Methods for Engineers and Scientists, 2nd Edition

Advanced Methods for Development of Wind turbine models for control designe

ASTM D638â99 (1999) [Standard Test Method for Tensile Properties of Plastics] [13p]

NACA TM 948 A Simple Approximation Method for Obtaining the Spanwise Lift Distribution

Gas chromatography–mass spectrometry method for determining

Checking methods for internal memory size of Galaxy S6 S6Edge Rev2 0

Ken Marshal Practical Fibonacci Methods For Forex Trading

Simple Method for Measuring Recognition Acuity

Cost Estimation Manual

MODELING OF THE ACOUSTO ELECTROMAGNETIC METHOD FOR IONOSPHERE MONITORING EP 32(0275)

więcej podobnych podstron