Classification Confidential

Doc Number

Date

May 25, 2007

Version

Draft v0.1

GSM RF Debug Tool Operating

Manual

ASUSTeK Computer Inc.

Mobile Communication Business Unit

R&D Div.1

Writer: YC Chang

Reviser:Aden Chang

1. Purpose & Scope

The purpose of this document is to describe the guidelines and main

building blocks for the ASUS Hermon repair tool. The document describes the

calibration process required for repairing and measuring the phone

functionality. These calibration processes consist of a set of independent

calibration procedures, however we need to initialize the IFL (Intelligence

Framework Libraries) first before we use them.

The document will focus on the GSM system and introduce how to use the

repair tool for repairing and measuring the phone functionality. The outcome of

the calibration process is a set of parameters that shall be loaded two

databases on the PC and on the phone.

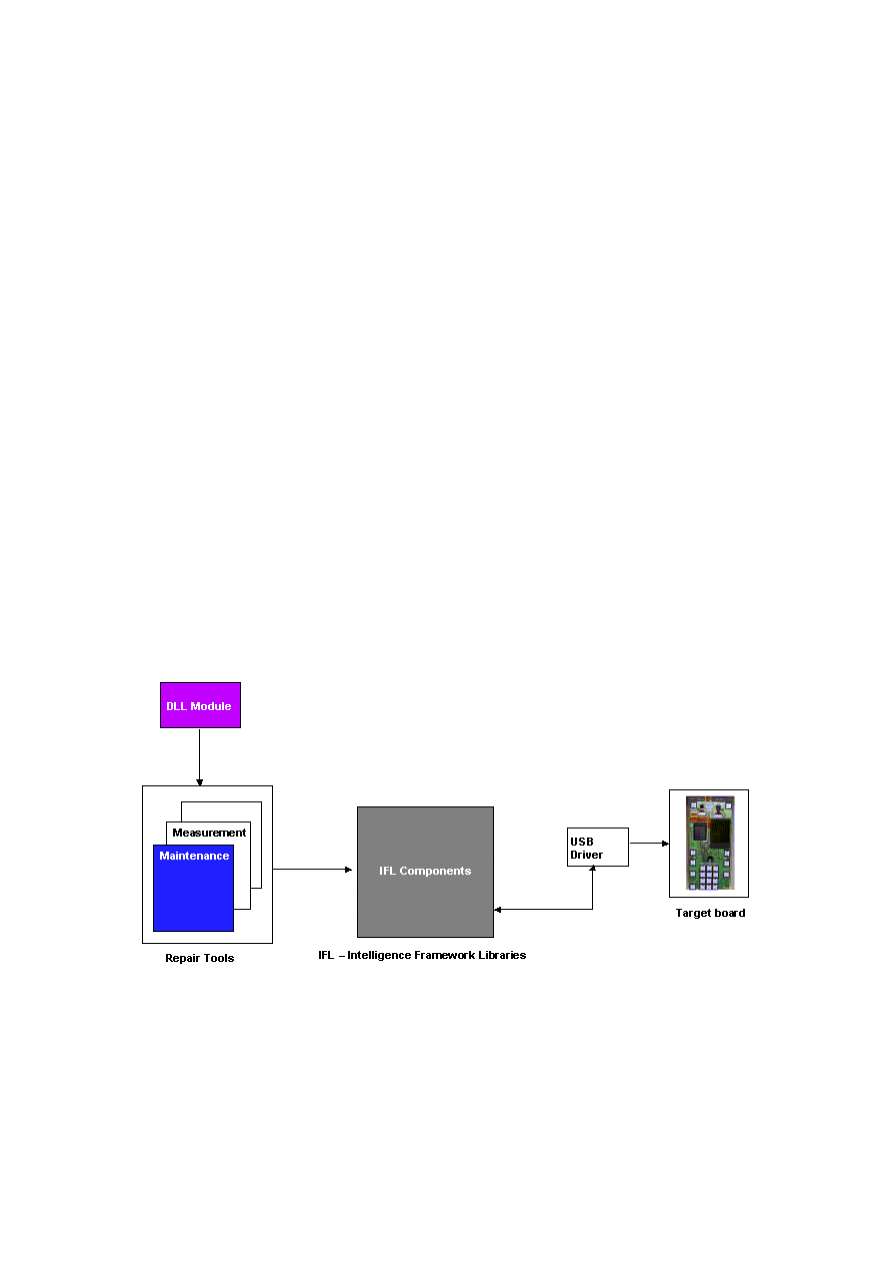

2. Hermon Repair Tool Hierarchy

DLL Module:(build with Visual C++)

Base on HMDSender.dll and reference Intel HTS 2.01 source code

Application Side:(create by C++ Builder)

User interface

Combine the export functions and test procedures

Show result and information

Hermon repair tool features the following capabilities:

Flexibility. (easy to add extended functions or create new method by

update DLL module)

Auto identifies USB connection between application tool and target

board.

Set and control UE in difference mode. (production mode/operational

mode)

GSM system – preliminary finish TX/RX debug functions.

Embedded other useful function in repair tool.

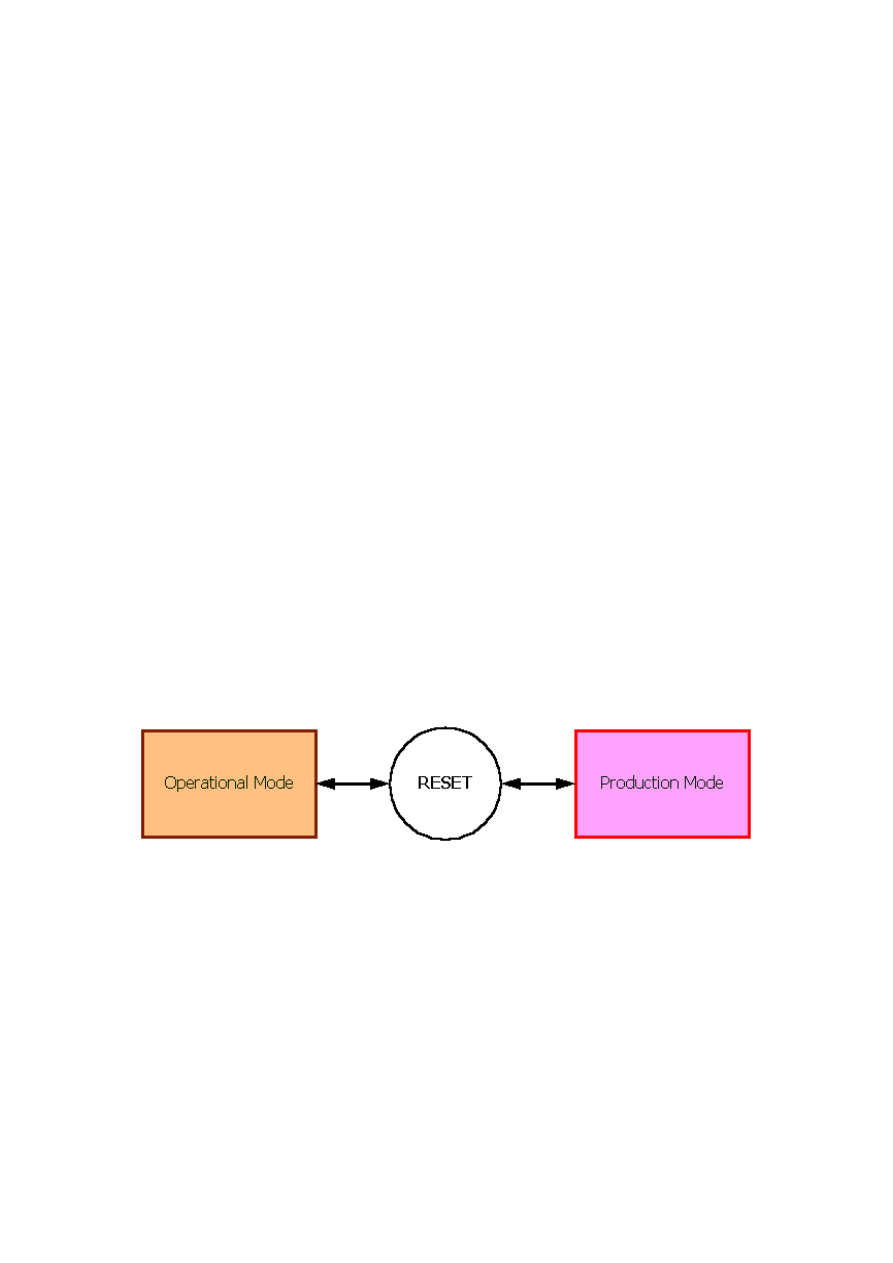

3. General Description

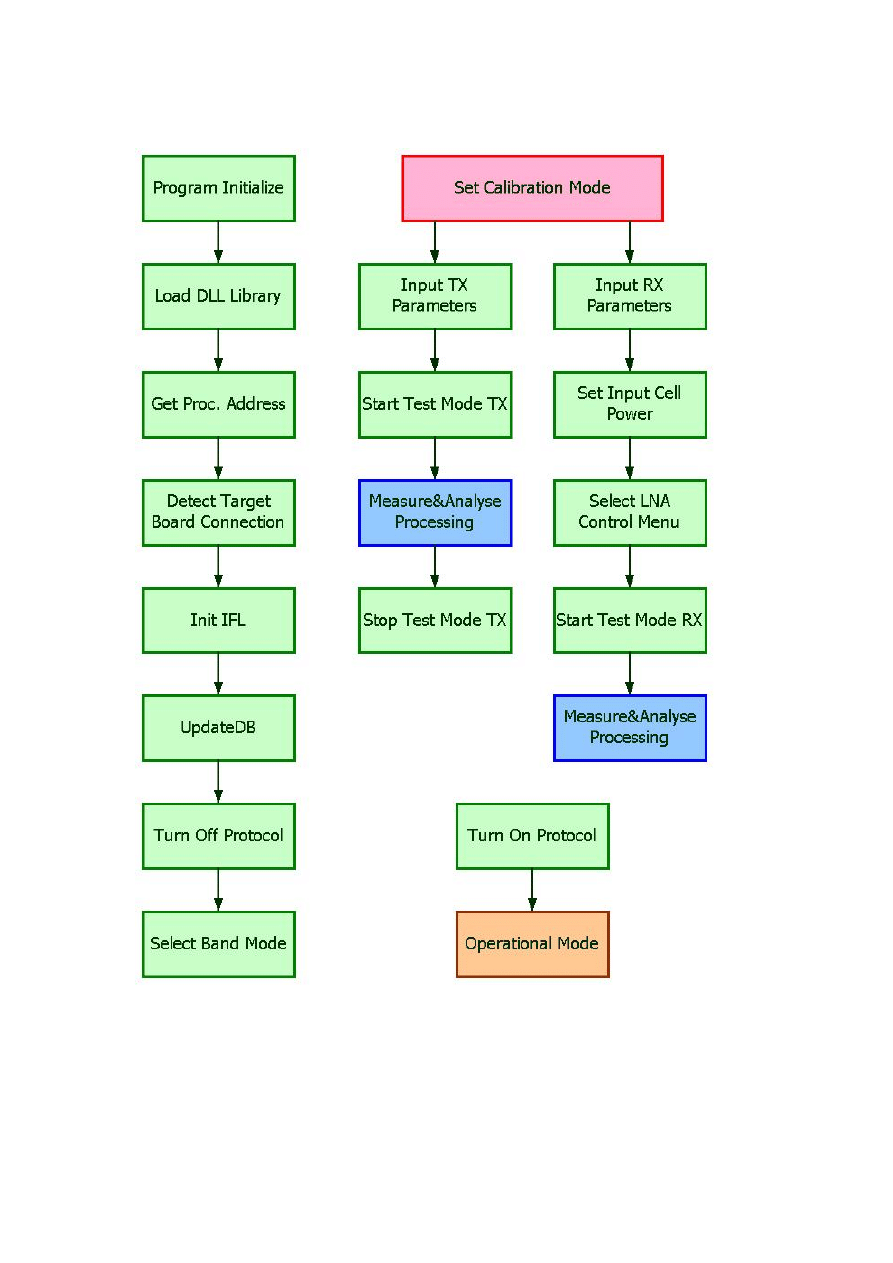

The Hermon software has two main states as shown in below.

There are two main operating modes,

Operational Mode

Default operating mode.

Normal operation of the system.

Production Mode (Calibration Mode)

Production mode is used mainly for calibration activities, thus no

call processing activities are required.

This mode can be entered only after reset (or wake-up).

This mode requires the system to disable the protocol stack that the

external control software (e.g. ICAT or Hermon Repair Tool) will

manage the system; it will communicate with the DIAG module.

4. System Block Diagram

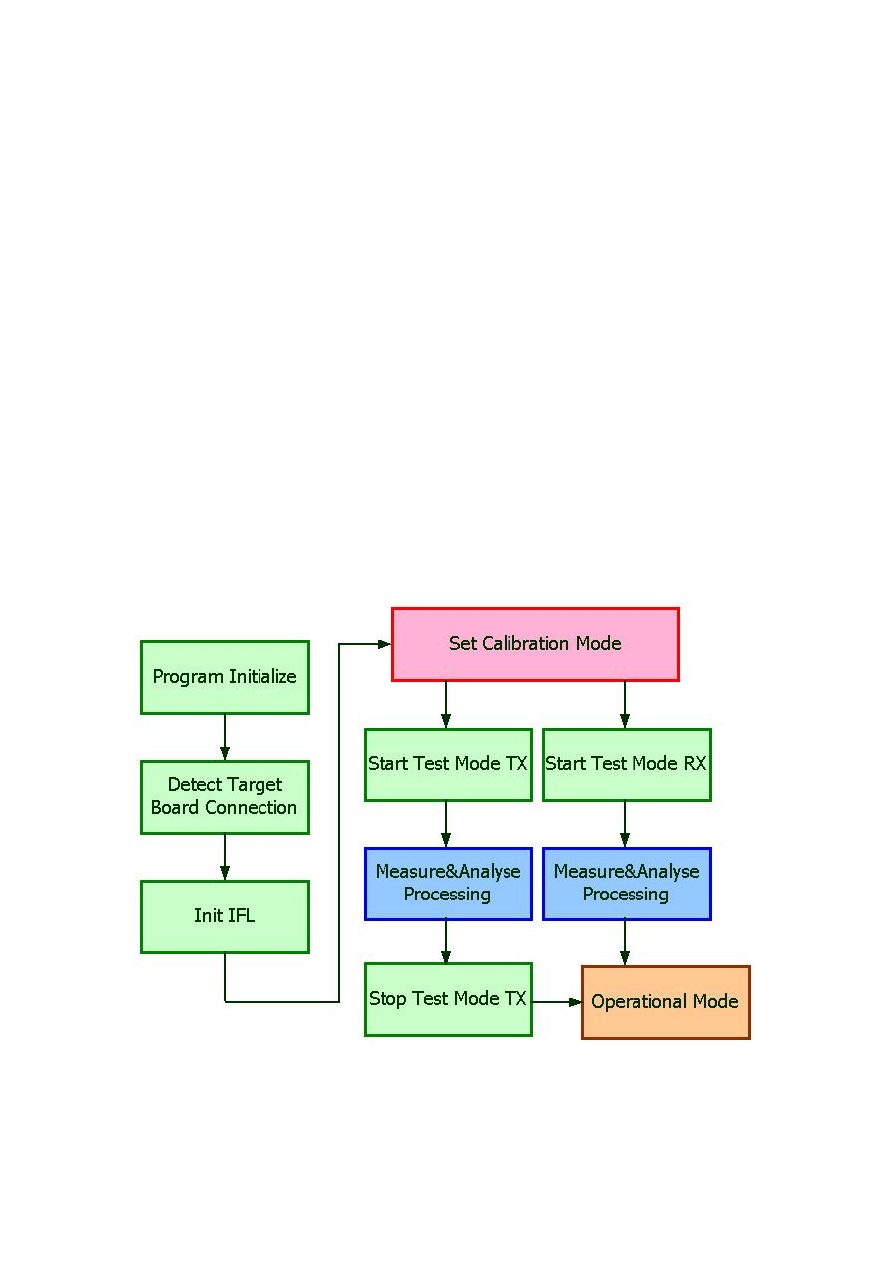

Following are the main test procedures:

System wakeup

Test equipment initialization

Scenario initialization

Acquisition

Application Side:

Following figures are the scenario of operating guidelines. You can refer to the

main building blocks in the below too.

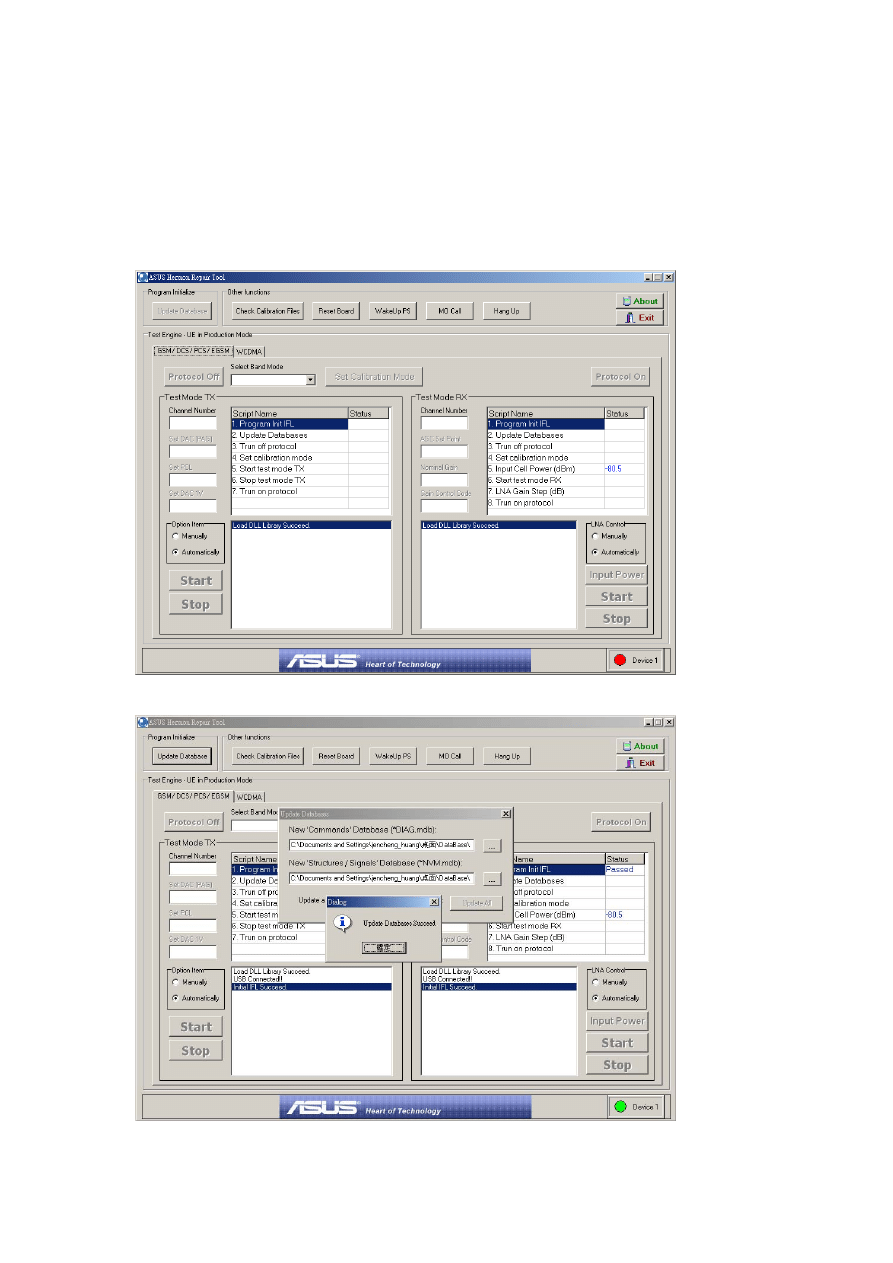

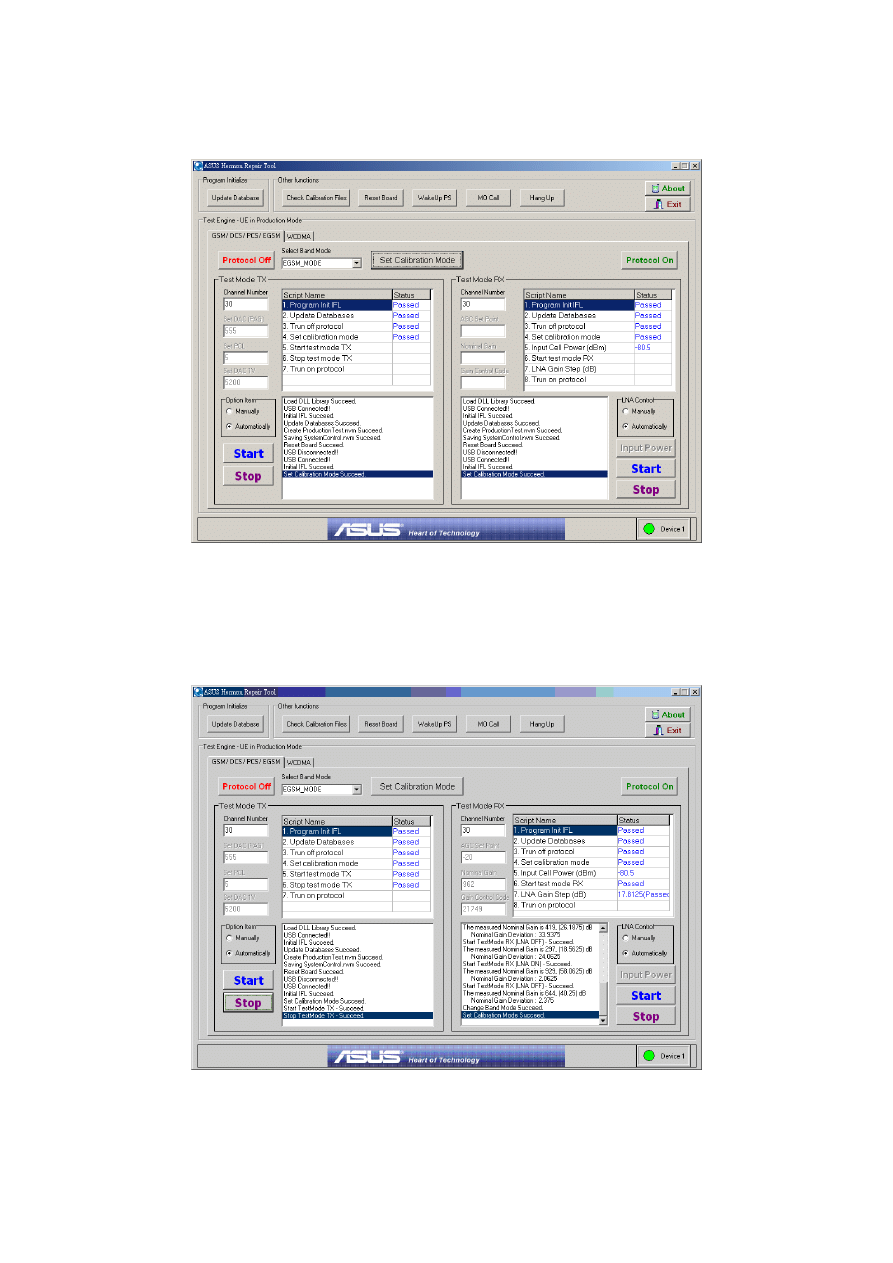

1. Start the program and power on the target then wait the device connection.

2. Update database

4. Fill out the data then press following button:turn off protocol

select band

mode

set calibration mode

5. Run the test scenario:

TX – Remember press STOP button when you finished TX.

RX – You can select LNA Control option before press START button.

The main building blocks:

Appendix

Other reference

:

ASUS Hermon Repair Tool V1.0

使用說明

.doc

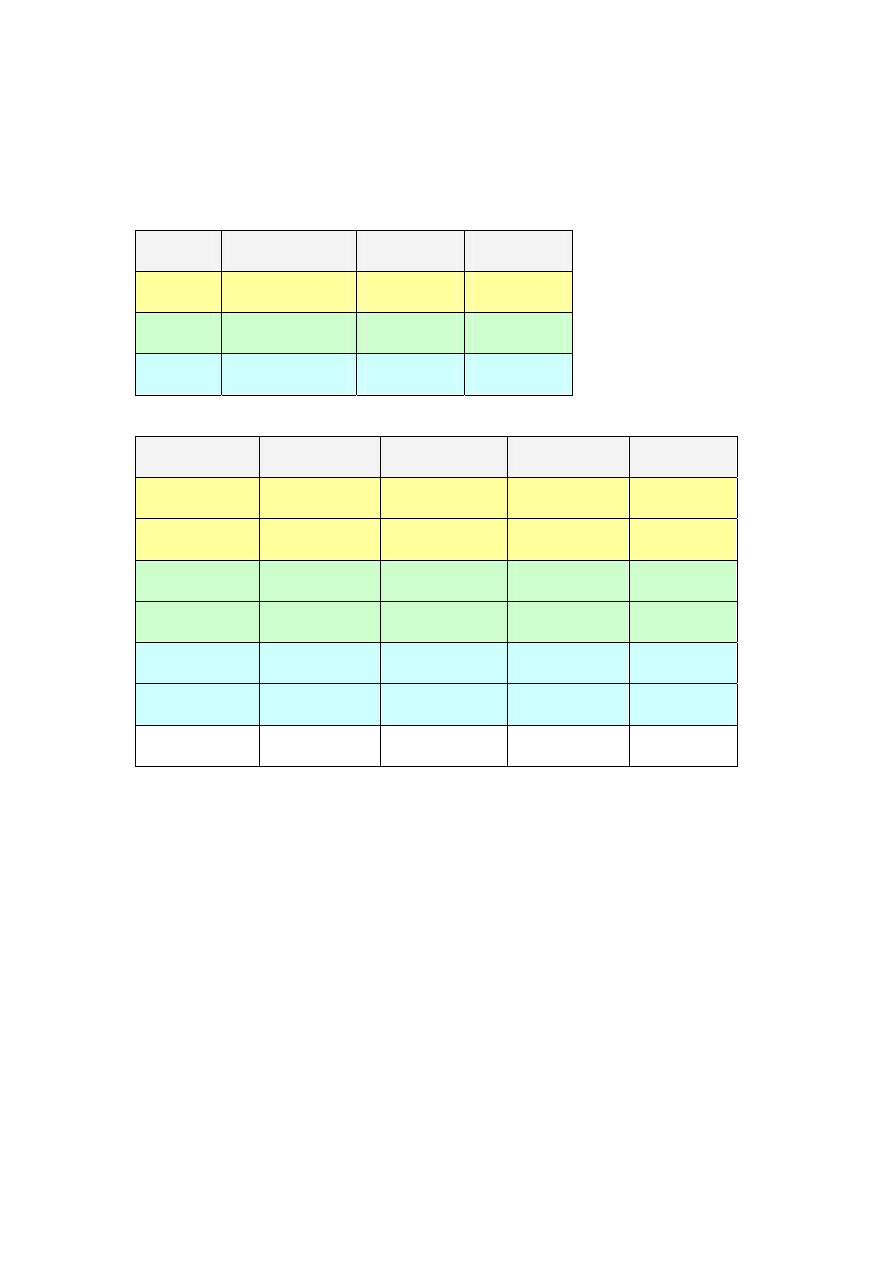

About automatically option parameters value

Test Mode TX

Band

PAG_Value

PCL

DAC1V

DCS

580

0

5200

PCS

550

0

5200

EGSM

555

5

5200

Test Mode RX

Band

PGA_Value

Input Power

GainCode

LNA State

DCS

960

-80dBm

0x73f4

ON

667

0x73f5

OFF

PCS

962

-80.125dBm

0x54f4

ON

682

0x54f5

OFF

EGSM

966

-80.375dBm

0x4f4

ON

697

0x4f5

OFF

Recommend

-80.5dBm

Wyszukiwarka

Podobne podstrony:

Halley Calibration Tool SOP

Halley WCDMADebug Tool SOP

Halley Pre RF Test Tool Beta

2 Planowanie produkcji SOP

93 1343 1362 Tool Failures Causes and Prevention

GSM

SYSTEM OCHRON PRAWNEJ Wykla 17[1].10.2009, Dokumenty STUDIA SKANY TEXT TESTY, ADMINISTRACJA UNIWEREK

GSM to system telefonii komórkowej

SOP opracownie

dpf doctor diagnostic tool for diesel cars function list

launch cresetter oil lamp reset tool introduction

original c68 retail diy auto diagnostic tool manual

16 197 208 Material Behaviour of Powder Metall Tool Steels in Tensile

SOP UE-II 19[1].12.2009, Dokumenty STUDIA SKANY TEXT TESTY, ADMINISTRACJA UNIWEREK WROCŁAW MAGISTER,

SOP 8

Spraw SOP

electric brake service tool ebs301

21 269 287 Effect of Niobium and Vanadium as an Alloying Elements in Tool Steels

więcej podobnych podstron