28

ENGINE MAINTENANCE

Before Engine Starts

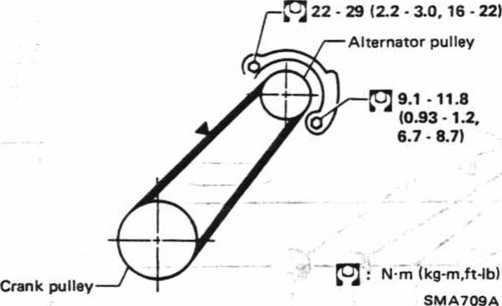

CHECKING DRIVE BELT

1. Inspect for cracks fraying, wear or oiliness. Replace if necessary.

The belts should not touch the bottom of the pulley groove.

2. Check drive belt deflections by pushing mid-way between pulleys.

Adjust if belt deflections exceed the limit.

Unit: mm (in)

|

Used belt deflection |

Set deflection of new belt | ||

|

Limit |

Adjust deflection | ||

|

Alternator |

19.0 (0.748) |

13.5-16.0 (0.531 - 0.630) |

12.5- 14.0 (0.492-0.551) |

Applied pushing force: 98 N (10 kg, 22 Ib)

Alternator belt

1. Loosen the upper and lower alternator securing bolts until the alternator can be moved slightly.

2. Move the alternator with a prying bar until the belt deflection is within the specified rangę. Then tighten the bolts securely.

i 5 5J j ś d i

£ Ł -

> -i

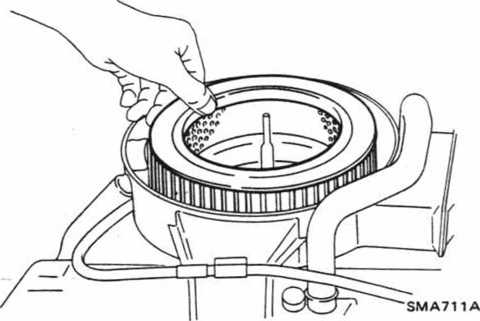

REPLACING AIR CLEANER FILTER

Air cleaner filter is a viscous paper type and does not require cleaning.

1. Remove air cleaner cover and remove air cleaner filter.

2. Install new air cleaner filter and install air

cleaner cover.

Align the mark on air cleaner cover to the mark on body.

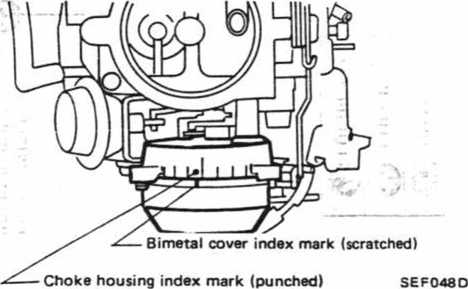

CHECKING CHOKE MECHANISM (Choke piąte and linkage)

1. Check choke valve and mechanism for free operation, and clean or replace if necessary. Binding can result from Petroleum gum forma-tion on choke shaft or from damage.

2. Before starting engine, fully open throttle valve and make surę that choke valve closes properly.

3. Push choke valve with your finger, and check for binding.

4. Check to be surę that the punched index mark on the bimetal cover meets the scratched index mark on the choke housing, as shown below.

Do not set the bimetal cover index mark at any other positions except the punched mark on the choke housing.

Wyszukiwarka

Podobne podstrony:

*ENGINE MAINTENANCEBefore Engine Starts (Cont d) REPLACING TIMING BELT Removal 1.

ENGINE MAINTENANCEBefore Engine Starts (Cont d) 1. To flush system, open drain cock at bottom of&nbs

ENGINE MAINTENANCEBefore Engine Starts (Cont d) 9. Refill engine with the appropriate new engine&nbs

ENGINE MAINTENANCEBefore Engine Starts (Cont d) Spark pług: Canada Standard type BPR5ES Hot

ENGINE MAINTENANCEBefore Engine Starts (Cont d) Installation 1. Confirm that No. 1 cylinder is at T.

46705 Suzuki RM250 PERIODIC MAINTENANCE 2-9TRANSMISSION OIL TRANSMISSION OIL LEVEL INSPECTION

89 TransAlp Manual General Specifications Service 3 3 MAINTENANCE MAINTENANCEMAINTENANCE SCHEDULE Pe

v/L/ T MAINTENANCEChecking Parking Brake Checking Tire Cor Puli lever with specified amount of force

CHASSIS AND BODY MAINTENANCE Wheel NutWheel Inspection For spare wheels only For Steel wheels

7n. Product maintenance 1. The lubrication After running belt is used for a period

5. Adjustment of drive belt Ali treadmills have a drive belt adjustment before deliyery, but after a

Page07 L-Jetronic 7Principle A pump supplies fuel to the engine and creates the pressure necessary f

Page07 L-Jetronic 7Principle A pump supplies fuel to the engine and creates the pressure necessary f

47916 Page05 The spark-ignition engine 5 Fig. 2 Stoichiometric air-fuel ratio for ideał combustion w

FRONT AXLE — Drive Shaft InspectionDisassembly (Cont d) • Remove snap ring, and withdraw inner race.

MATLABChallenges and perspectives in Engineering education Building a computational learning erwiron

FRONT DISC BRAKE (CL16) — Rotor__Inspection- SLIDING SURFACE Check rotor for cracks or chips. Repair

więcej podobnych podstron