32

ENGINE MAINTENANCE

Before Engine Starts (Cont'd)

Spark pług:

|

Canada | |

|

Standard type |

BPR5ES |

|

Hot type |

BPR4ES |

|

Cold type |

BPR6ES |

3. Check A.T.C. system for function by proceed-ing as follows:

Confirm that engine is cold before starting test. With engine turned off, check position of air contro! valve by hand or mirror.

5. Install new spark plugs. Reconnect high tension cables according to Nos. indicated on them.

[F] : Spark pług

20 - 29 N m

(2.0 - 3.0 kg-m, 14 - 22 ft-lb)

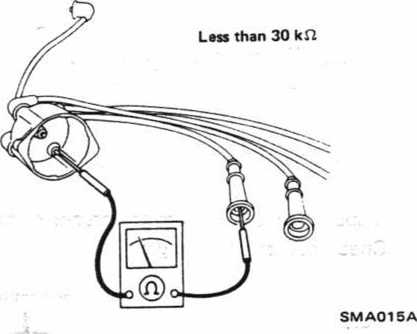

CHECKING IGNITION WIRES (HIGH-TENSION CABLES)

1. Check the high-tension cables for cracks, dam-age, burned terminals and proper fit.

Air control valve is in correct position if its cold air inlet is open and hot air inlet is closed.

4. Start engine and keep idling.

Immediately after starting engine, air control valve is in correct position if its cold air inlet is closed and hot air inlet is open.

5. Check that air control valve gradually opens to cold air inlet side as engine warms up. When environmental temperaturę around temperaturę sensor is Iow, allow morę time for engine warming up to facilitate smooth operation of air control valve.

If the above test reveals any problem in the operation of air control valve, carry out the further inspection described in Section EF.

2. Shake the high-tension cable while measuring resistance to check for intermittent breakes.

CHECKING AUTOMATIC TEMPERATURĘ

CONTROL (A.T.C.) AIR CLEANER

1. Check that vacuum hoses (Intake manifold to temperaturę sensor, idle compensator and vacuum motor) are securely connected in correct position.

2. Check each hose for cracks or distortion.

Wyszukiwarka

Podobne podstrony:

ENGINE MAINTENANCEBefore Engine Starts (Cont d) 1. To flush system, open drain cock at bottom of&nbs

ENGINE MAINTENANCEBefore Engine Starts (Cont d) 9. Refill engine with the appropriate new engine&nbs

*ENGINE MAINTENANCEBefore Engine Starts (Cont d) REPLACING TIMING BELT Removal 1.

ENGINE MAINTENANCEBefore Engine Starts (Cont d) Installation 1. Confirm that No. 1 cylinder is at T.

page2 CHAMPION SPARK PŁUG COMPANYS Modern Dynamometer Test Facilities VOLKSWAGEN ENGINEShave establi

565 types of engines types of engines types of engines spark pług bujiaF bougieFd allumageM exhaus

ENGINE MAINTENANCEBefore Engine Starts CHECKING DRIVE BELT 1. Inspect for cracks f

64002 Suzuki RM250B ENGINE DISMOUNTING AND MOUNTING 3-3 Disconnect the radiator hoses CD. Disconnect

engine ENGINE Borę and stroke Compression ratio Displacement Spark pług Standard For

ENGINE OVERHAULInspection (Cont d) PISTON RING GAP CRANKSHAFT INSPECTION 0.8(0.031) / Ring gap mm

ENGINE OVERHAULAssembly (Cont d) 2. Select suitable thickness of main bearing according to the follo

ENGINE OYERHAULAssembly (Cont d) 6. Measure connecting rod clearance. 5. Tighten bearing cap bolts t

54423 Suzuki RM250 2-6 PERIODIC MAINTENANCESPARK PŁUG Inspect the spark pług condition. electrode c

Suzuki RM250! PERIODIC MAINTENANCE 2-5INSPECTION BEFORE PRACTICE WHAT TOCHECK CHECK FOR Spark płu

więcej podobnych podstron