essentÊrving°55

C A R V E D M O U L D I N G S

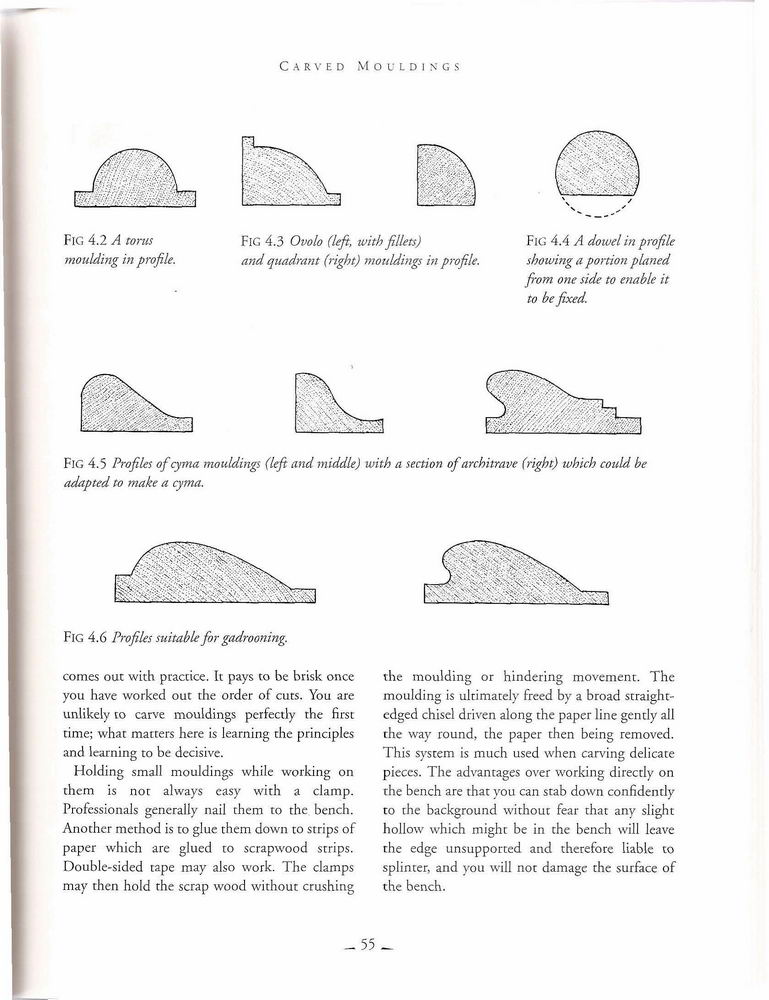

Fic, 4.2 A torus moulding in profile.

FlG 4.3 Ovolo (lefi, witb fillets) Fic. 4.4 A dowel in profile

and Ä…uadrant (right) mouldings in profile. showing a portion planed

firom one side to enable it to be fixed.

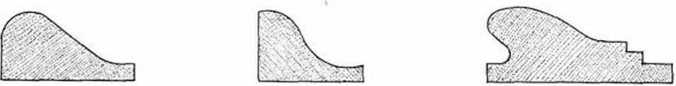

FlG 4.5 Profiles of cyma mouldings (lefi and tniddle) witb a section ofiarchhrave (right) which coitld be adapted to make a cyma.

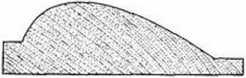

Fig 4.6 Profiles suitabU for gadrooning.

comes out with practice. It pays to be brisk once you have worked out the order of cuts. You are unlikely to carve mouldings pcrfectly the first tirne; what matters here is learning the principles and learning to be dccisivc.

Holding smali mouldings whilc working on thcm is not always casy with a clamp. Profcssionals gencrally nail thcm to the bench. Anothcr merhod is to glue them down to strips of paper which are glucd to scrapwood strips. Double-sided tape may also work. The clamps may thcn hołd the scrap wood without crushing the moulding or hindcring movcment. The moulding is ultimately freed by a broad straight-edged chiscl driven along the paper linę gently all the wav round, the paper then being removed. This system is much used when carving delicate picccs. The advantages over working direedy on the bench are that you can stab down confidently to the background without fear that any slight hollow which might be in the bench will lcave the edge unsupported and thcreforc liablc to splinter, and you will not damage the surface of the bench.

— 55 —

Wyszukiwarka

Podobne podstrony:

essent?rving?54 Essential Wo o d c a R VIN g Techniques Fic. 4.1 Various mouldings (from the top): a

essent?rving?69 F O I. I A G F. : COPYING A NATURAL LEAF IN W O O D Fic; 5.7 Thegr

Sikorsky S 16 (Great War Aircraft in Profile 1) i.mń Wii Klnitfl m. ivy.l. 1Sikorsky S-16 MłtM M.kKf

76 LES d£terminations essentielles habebit unde sustentetur, in hoc casu si non dat huic peccat mor-

essent?rving?06 E S S F. N T I A !. W O O D C A R V I X G T F. C H N I Q C E $ Fic, 9.22 A backbent

essent?rving?10 E S 5 E N T I A I. W O O I) C A R V I N (i T E C H N I Q U F. S Fic 10.5 Plasticine

essent?rving?12 E S S F. N T I A I. W O O r> C A R V I N G T E C H X I Q V E S Fic 10.12 The arra

essent?rving?16 E $ S E N T I A L W O O I) C A R V I N G T t C I ! N I Q V E S Fic. 10.20 Large syca

essent?rving?34 E $ S E N T I A I. W O O D C A R V I N G T H C H X I Q U F. S Fic; 12.16 The pine he

essent?rving?35 Fic 12.17 NotÄ™ the fullness of the brom and tbe eyebalis and the slope np from cheek

essent?rving?66 E $ S F. X T I A L W O O D C A R V 1 N G T E C H X I Q U E S Fic 15.10 A gouge with

Cim F 4077 0076 Mo aohittm royrjucirobatipld

essent?rving?61 C A R V E D MOULDIKCS Fic 4.17 Yarious examples of water leaf camed in limÄ™ wood, wi

essent?rving?32 E SS EN T I A L W O O D C A R V I N G T ECHN’!QUES FlG 2.8 Stripy figurę in a mahoga

essent?rving?40 Essen tial Woodcarying Techniques FlG 2.20 Arrow Crosstree (Dick Onians), carued in

essent?rving?56 Essential Woodcarvixc Techniques Critical factors in cutting mouldings are the sizes

więcej podobnych podstron