8589356384

V. Tuzhilkin. K. Urazbayeva. R. Alibekov. SEMICONTINUOS SUGAR CRYSTALLIZA TION

3. Reducing sugar losses and colour by rcducing the duration and temperaturę of boiling massecuite.

4. Creating of a favourable environment for automating of the crystals growing phase.

The disadvantage of this method is that a second vacuum apparatus before

filling of crystal mass it has unproductive downtime while this mass is being prepared.

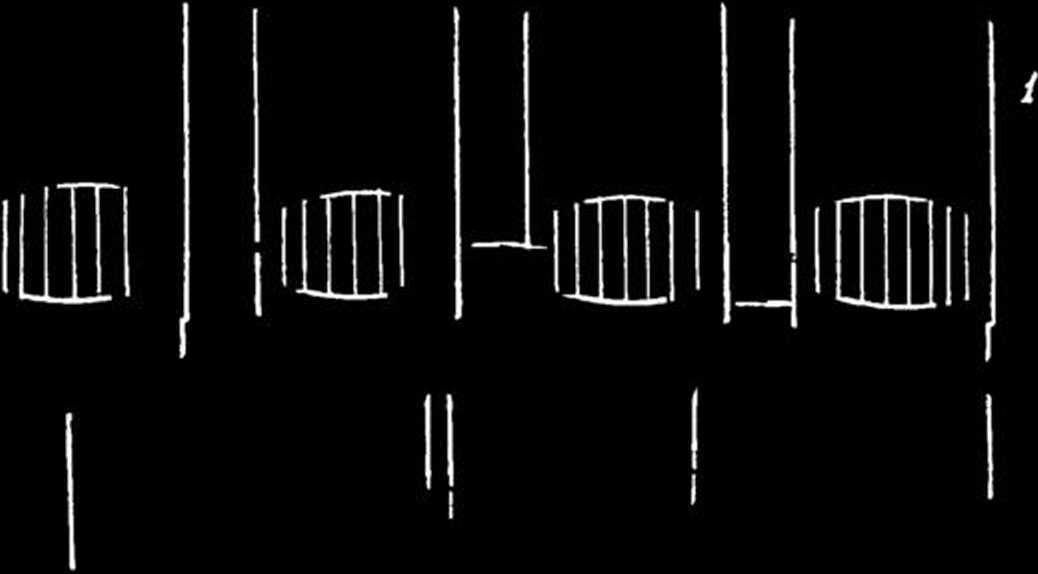

Morę rational organizational management of the product section by using the proposed method with floating vacuum apparatus is shown in figurę 2.

1- crystal oscillator;

2 - vacuum apparatuses;

3 - pipelines;

4,5 - crystallizers;

Fig. 2. The method of boiling with the generation of crystal mass

Journal of Industrial Technology and Engineering, 2012, 2(3): 11-18

The most suitable operation of productivity department by the proposed method is the generation of crystal base produces in the special dedicated crystal generator.

According to this method, the crystal base obtained in the crystal generator then direct to a special receiver mixer (Fig. 3). As reąuired the crystalline mass taken up in the vacuum apparatus in which the growing of crystals on the semi-continuous crystallization technology.

There is provided the variant of operation organization of product

14

separation, when the vacuum apparatus generate crystal mass in the amount of Ncr -2Ncr, steam-heated first or second housing evaporator, and the remaining vacuum units operating in a semi-continuous crystallization of sugar, steam heat one notch below than machinę - generator crystal mass.

Crystallization by using artificially prepared massecuite.

This crystallization method is based on a predetermined concentration of the massecuite preparation Substance Content = 87 88 % on the base of a mixture of

Wyszukiwarka

Podobne podstrony:

V. Tuzhilkin. K. Urazbayeva. R. Alibekov. SEMICONT1NUOS SUGAR CRYSTALUZA T/ON syrup, its heating to

V Tuzhilkin. K. Urazbayeva. R. Alibekov. SEMICONTINUOS SUGAR CRYSTALLIZA TIONCONCLUSION For study th

V Tuzhilkin. K Urazbayeva, R. Alibekov. SEMICONTINUOS SUGAR CR YSTALUZA TION •ellow sugar crystals o

V. Tuzhilkin, K. Urazbayeva, R. Alibekov. SEMICONTINUOSSUGAR CRYSTAU.1ZATJON CHEMICAL TECHNOLOGY AND

V. Tuzhilkin. K. Urazbayeva. R. Alibekov. SEMIC0NT1NU0S SUGAR CR YSTALUTA TION 1)

V. Tuzhilkin. K. Urazbayeva. R. A Ubeków SEMICONTINUOS SUGAR CR YSTALLIZA TION provide in the same d

Fragment nici RNA(1) Ribose 3 ud sugar t 0 « RNA Base (single-stranded) o><°

Hoch,?ward D The Sugar Train [EQMM 06 11] image002 The WorłcTs Leading Mystery Magazine NOYtMBCR

00175 Sf44c966c95fb915bf72191bd27e4aa 176 McWilliams To understand the wide rangę of cost penalties

This effect is known as "magnetoresist-ance.” Ohio Semiconductors, Inc. has de-vcloped a device

why your nexł speaker system shou/d beTHENEW Only Audax incorporates the Patented Parafie* Foam Susp

iI crystal, or magnetic—can be employed. Stereo or mono tape recordings can be madę using the monito

więcej podobnych podstron