Hardware and Engineering

PS 416-TCS-200

Telecontrol Card

08/97 AWB 27-1298 GB

1st published 1997, edition 08/97

© Moeller GmbH, Bonn

Author:

Thomas Dahmen

Editors:

Klaus Krüger, Thomas Kracht

Translators: Christopher Baker, Terence Osborn

1298u1g.fm Seite 1 Dienstag, 23. Februar 1999 12:54 12

Caution!

Dangerous electrical voltage!

Before commencing the installation

●

Disconnect the power supply of the

device.

●

Ensure that the device cannot be

accidentally restarted.

●

Verify isolation from the supply.

●

Earth and short circuit.

●

Cover or enclose neighbouring units that

are live.

●

Follow the engineering instructions

(AWA) of the device concerned.

●

Only suitably qualified personnel may

work on this device/system.

●

Before installation and before touching

the device ensure that you are free of

electrostatic charge.

●

Connecting cables and signal lines

should be installed so that inductive or

capacitive interference do not impair the

automation functions.

●

Install automation devices and related

operating elements in such a way that

they are well protected against

unintentional operation.

●

Suitable safety hardware and software

measures should be implemented for

the I/O interface so that a line or wire

breakage on the signal side does not

result in undefined states in the

automation devices.

●

Ensure a reliable electrical isolation of

the low voltage for the 24 volt supply.

Only use power supply units complying

with IEC 60 364-4-41 or HD 384.4.41 S2.

●

Deviations of the mains voltage from the

rated value must not exceed the

tolerance limits given in the

specifications, otherwise this may cause

malfunction and dangerous operation.

●

Emergency stop devices complying with

IEC/EN 60 204-1 must be effective in all

operating modes of the automation

devices. Unlatching the emergency-stop

devices must not cause uncontrolled

operation or restart.

●

Devices that are designed for mounting

in housings or control cabinets must only

be operated and controlled after they

have been installed with the housing

closed. Desktop or portable units must

only be operated and controlled in

enclosed housings.

●

Measures should be taken to ensure the

proper restart of programs interrupted

after a voltage dip or failure. This should

not cause dangerous operating states

even for a short time. If necessary,

emergency-stop devices should be

implemented.

IBM is a registered trademark of International

Business Machines Corporation.

All other brand and product names are

trademarks or registered trademarks of the

owner concerned.

All rights reserved, including those of the

translation.

No part of this manual may be reproduced in

any form (printed, photocopy, microfilm or

any otherprocess) or processed, duplicated

or distributed by means of electronic

systems without written permission of

Moeller GmbH, Bonn.

Subject to alterations without notice.

1

0

8

/97

AW

B

27

-1

29

8-

GB

Contents

Setting Up A Telecontrol Station With

The PS 416 Controller

Hardware and software requirements

Construction of the PS 416-TCS-200

Number of PS 416-TCS-200 cards in

the rack

Installing the PS 416-TCS-200 in the rack

2

0

8

/97

AW

B

27

-1

29

8-

GB

3

0

8

/97

AW

B

27

-1

29

8-

GB

About This Manual

This card has been developed for remote metering,

remote indication and remote control and supports

the data security protocols FT 1.2 and FT 3

(asynchronous) as per the IEC 870-5 standard for

telecontrol equipment and systems.

This manual describes the structure, planning,

configuration, installation, operation and also the

testing and diagnostics of the PS 416-TCS-200

communication processor. The PS 416-TCS-200 is a

communication processor for PS 416 programmable

logic controller. With the aid of the PS 416-TCS-200

communication processor the PS 416 can be

connected as telecontrol station to a telecontrol

network.

This documentation is intended for the project

planner, programmer and commissioning engineer.

This documentation will enable such users to

connect the PS 416 to a telecontrol system.

A general knowledge of control and communication

engineering is required for a good comprehension of

this technical documentation.

Other manuals (AWBs)

The fundamentals of remote control using compact

PLCs are described in a separate manual. Each of

the individual components also has its own manual.

Guide to telecontrol, AWB 27-1299-GB

ZB 4-501-TC1:

Hardware and engineering, telecontrol card

ZB 4-501-TC1, AWB 27-1297-GB

About This Manual

4

0

8

/97

AW

B

27

-1

29

8-

GB

PS 416-TCS-200:

Hardware and engineering, telecontrol card PS 416-

TCS-200, AWB 27-1298-GB

Leased line S 40-AM-TL:

Telecontrol via leased line, application module S 40-

AM-TL, AWB 27-1301-GB

Dial-up line S 40-AM-TD:

Telecontrol via dial-up line, application module

S 40-AM-TD, AWB 27-1300-GB

5

0

8

/97

AW

B

27

-1

29

8-

GB

1

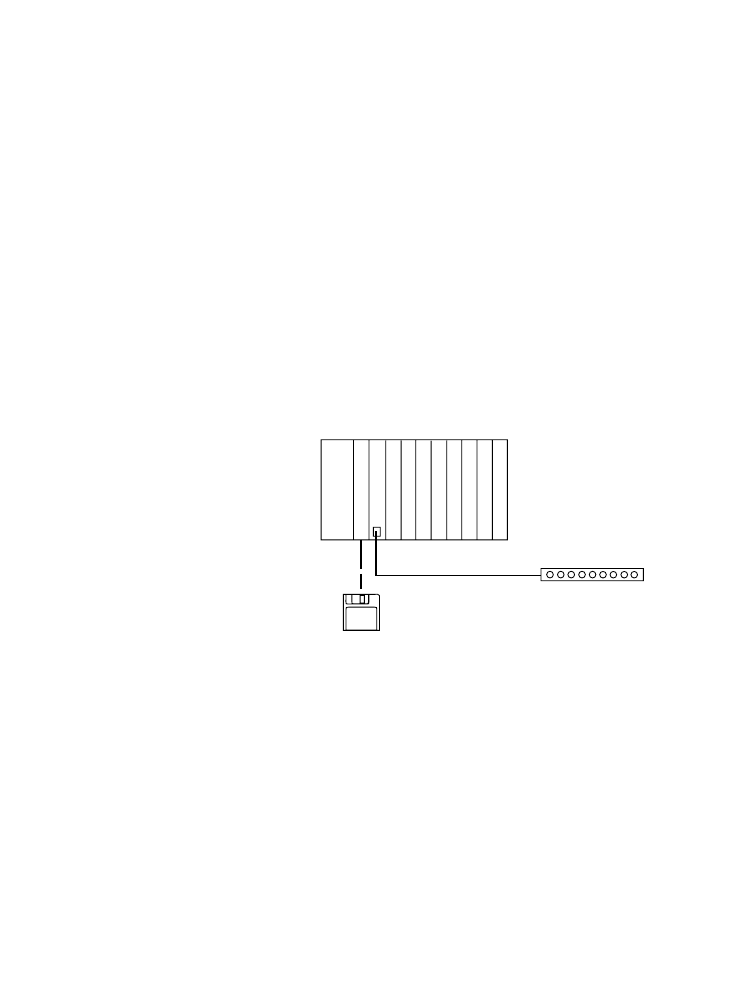

Setting Up A Telecontrol Station With

The PS 416 Controller

The PS 416-TCS-200 communication processor

forms part of the PS 416 modular control system.

With the PS 416-TCS-200 the individual controller

can be integrated into a telecontrol system. Here the

controller can be the central station or a substation.

Communication with the telecontrol network is

effected via modem and modem cable.

Communication is supported by task-specific

application modules (function blocks).

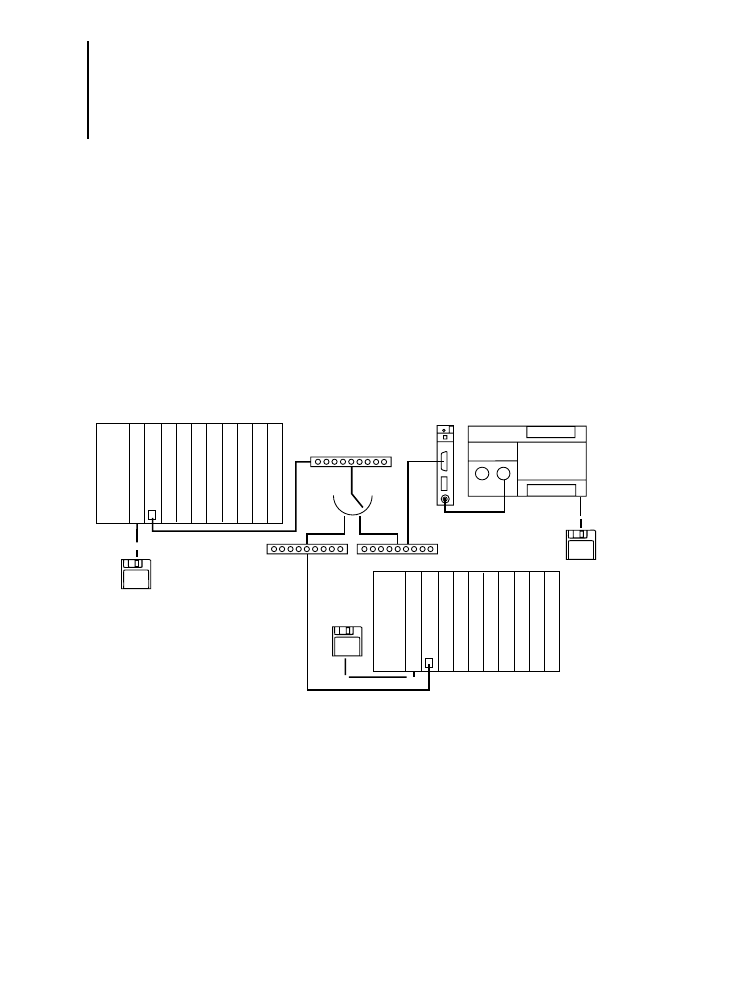

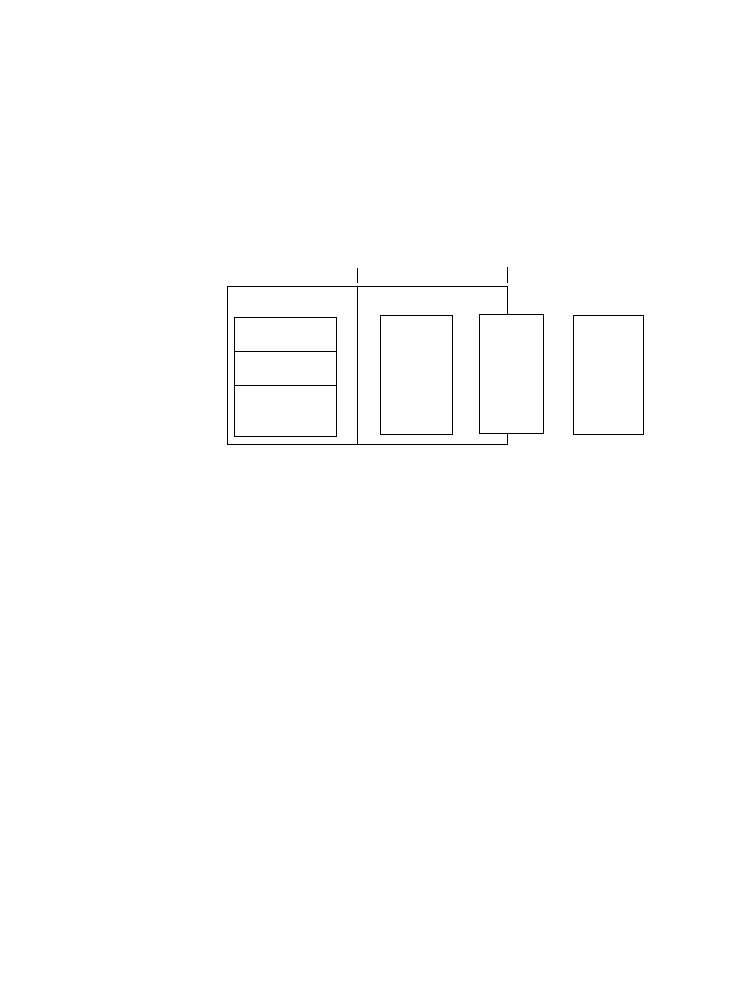

Figure 1: Layout of a telecontrol station with the PS 416

programmable controller

a Central station

b Modem

Either a dial-up line or a leased line can be used as the

transmission medium.

In the case of the dial-up line existing telephone

networks are used as transmission medium. All of the

modems in the central station and substations must

be modems with dialling capability. At the request of

S 40-AM-TD/TL

ZB 4-254-KB1

b

CPU PS 416

PS 416-TCS-200

a

Setting Up A Telecontrol

Station With The PS 416

Controller

6

0

8

/97

AW

B

27

-1

29

8-

GB

the central station or the substation the modems set

up a connection with a specified telephone number.

In the case of the dial-up line both the central and also

the substation can take over the function of a primary

station or the function of a secondary station:

Primary station:

Station which initiates data transport

Secondary station:

Station which replies to a data request

Communication of one station with several stations

simultaneously is not possible.

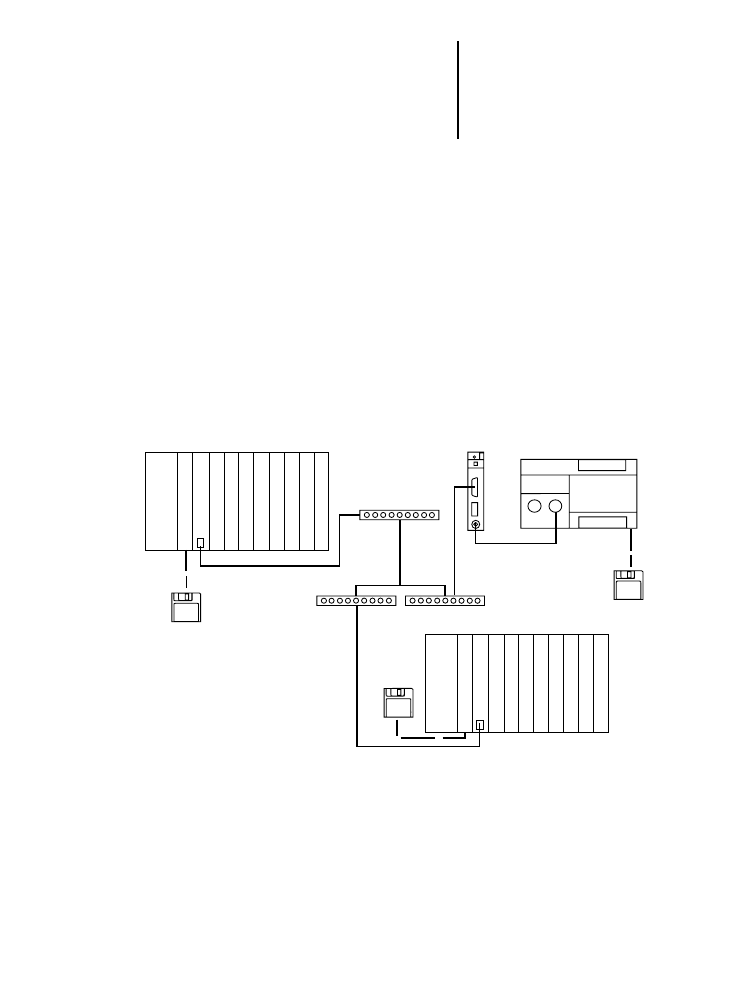

Figure 2: Telecontrol system with PS 416 components and

dial-up line configuration

a Central station – primary station / secondary station

b Dial-up modem

c Dial-up line

d Substation – primary station / secondary station

S 40-AM-TD

ZB 4-254-KB1

b

b

b

a

c

PS 4-200

d

ZB 4-501-TC1

S 40-AM-TD

S 40-AM-TD

CPU PS 416

PS 416-TCS-200

PS 416-CPU-400

PS 416-TCS-200

d

Other manuals (AWBs)

7

0

8

/97

AW

B

27

-1

29

8-

GB

In the case of the leased line all substations are

permanently connected to the central station.

If more than one secondary station is addressed via

the leased line only point-to-point leased modems

(party line) may be used. The central station will in

this case always be a primary station and the

substations always secondary stations. This makes it

possible for the central station to send messages to

all substations simultaneously.

Only the central station can initiate communication.

A substation cannot autonomously initiate

communication with the central station or with

another substation.

Figure 3: Telecontrol system with PS 416 components and

leased line configuration

a Central station – primary station

b Modem (party line)

c Substation – secondary station

S 40-AM-TL

b

b

b

a

PS 4-200

c

ZB 4-501-TC1

S 40-AM-TL

S 40-AM-TL

PS 416-TCS-200

CPU PS 416

PS 416-TCS-200

c

CPU PS 416

ZB 4-254-KB1

Setting Up A Telecontrol

Station With The PS 416

Controller

8

0

8

/97

AW

B

27

-1

29

8-

GB

Procedure

The following procedure is recommended for

connecting the PS 416 to a telecontrol system.

E Define all requirements made on the telecontrol

system – for example, data security, number of

stations, and so on. A detailed description will be

found in the “Guide to telecontrol” manual.

E Select the application module which matches

your requirements. Relevant factors here include:

station type (modular – compact), station class

(primary – secondary), number of stations.

E Configure the interface parameters for the

PS 416-TCS-200 in the application module. See

Chapter 4, Configuration.

E Adjust the transmission parameters where

necessary to match the requirements of the data

integrity class. See the “Guide to telecontrol”

manual.

E Install the card in the rack. See Chapter 5,

Installation

E Connect the PS 416-TCS-200 to the modem via

the ZB 4-254-KB1 modem cable. See Chapter 5,

Installation

The card is now installed, programmed, configured

and is ready for operation.

9

0

8

/97

AW

B

27

-1

29

8-

GB

2

About The Card

Task of the

PS 416-TCS-200

The PS 416-TCS-200 communication processor is

used for connecting the PS 416 programmable

controller via a modem to a telecontrol system. It

communicates with other telecontrol stations via a

point-to-point modem or dial-up modem.

The card has its own microcontroller. This means that

it handles the communication process autonomously

without taking up any of the capacity of the PS 416

central processing unit.

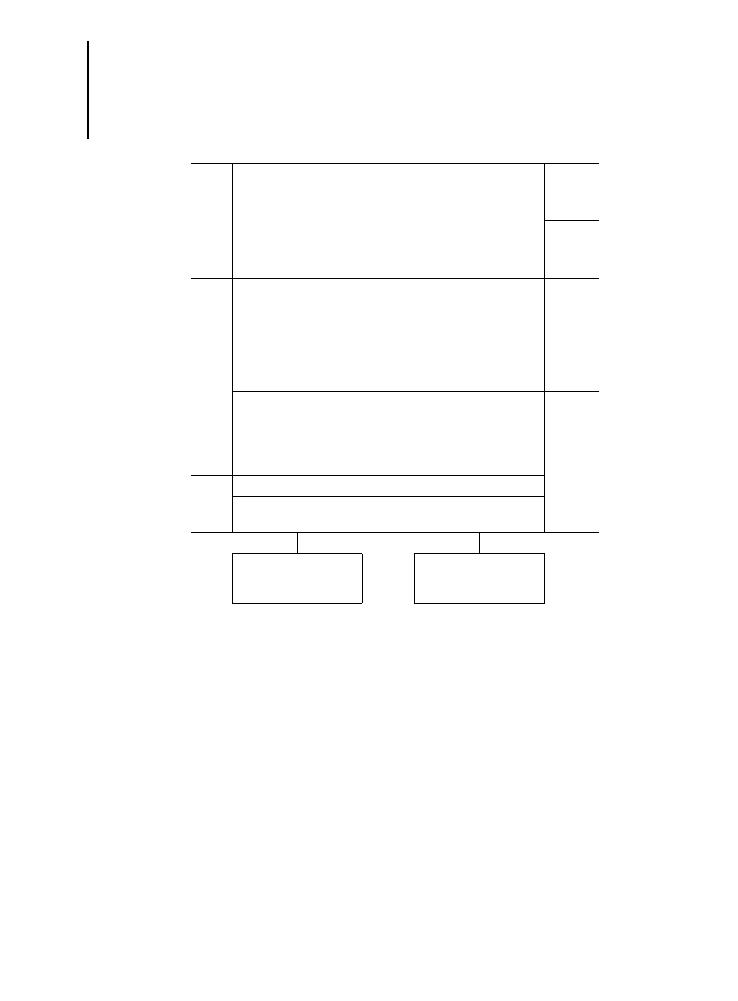

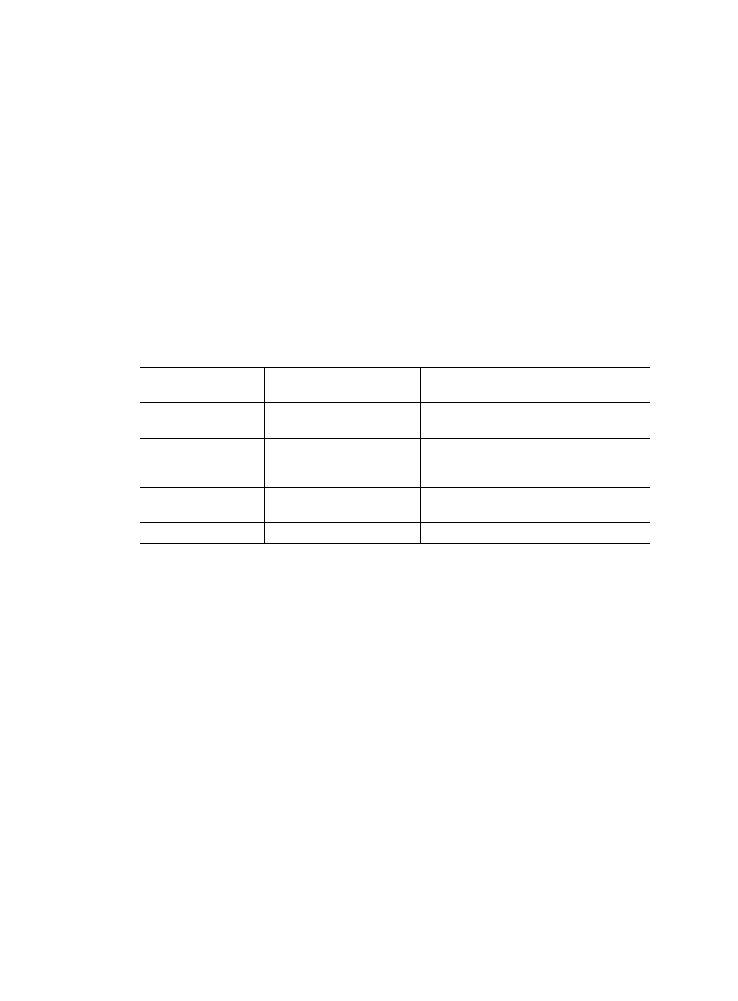

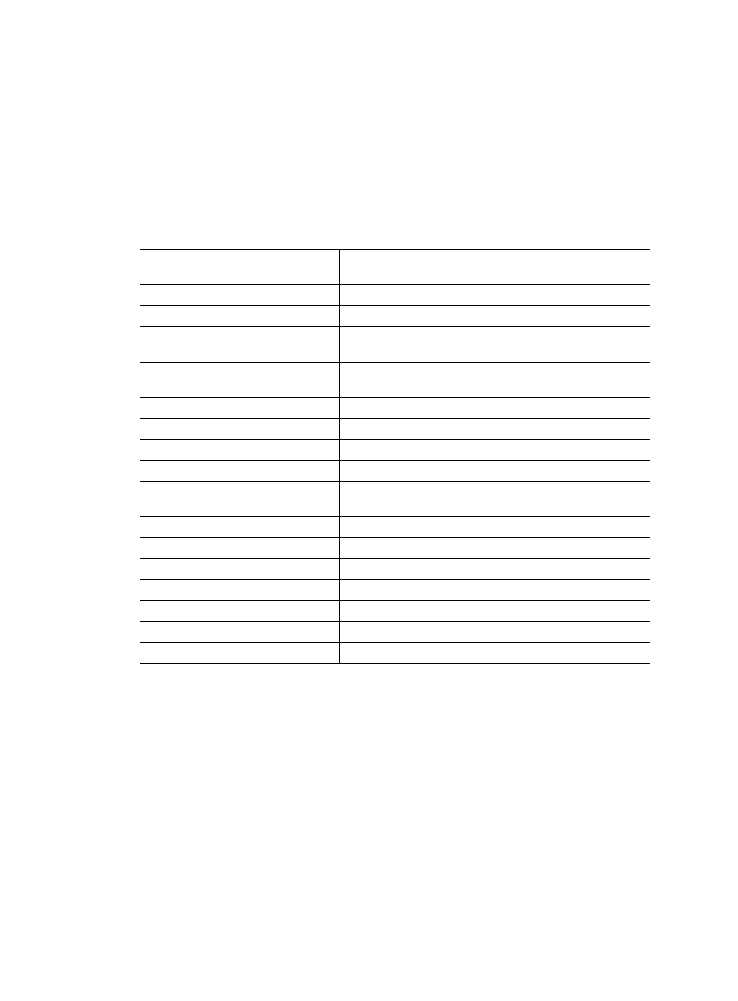

Hardware and software

requirements

Table 1 provides an overview of the hardware and

software requirements for running the

PS 416-TCS-200 within the PS 416 PLC system.

Table 1: Hardware and software requirements

Software

Programming software

Operating system

Application modules

Sucosoft S 40 Manager, Version 2.0 and

higher for PS 416-CPU-400 Version 1.13 and

higher

S 40-AM-TD Version 1.0 (dial-up line)

S 40-AM-TL Version 1.0 (leased line)

Hardware

Central processing unit

Power supply card:

Subrack

Modem cable

PS 416-CPU-400

PS 416-POW-400

PS 416-POW-410

PS 416-POW-420

PS 416-BGT-400/410/420 or 421 with

PS 416-ZBX-401/402/403 potential

equalisation rail

ZB 4-254-KB1

About The Card

10

0

8

/97

AW

B

27

-1

29

8-

GB

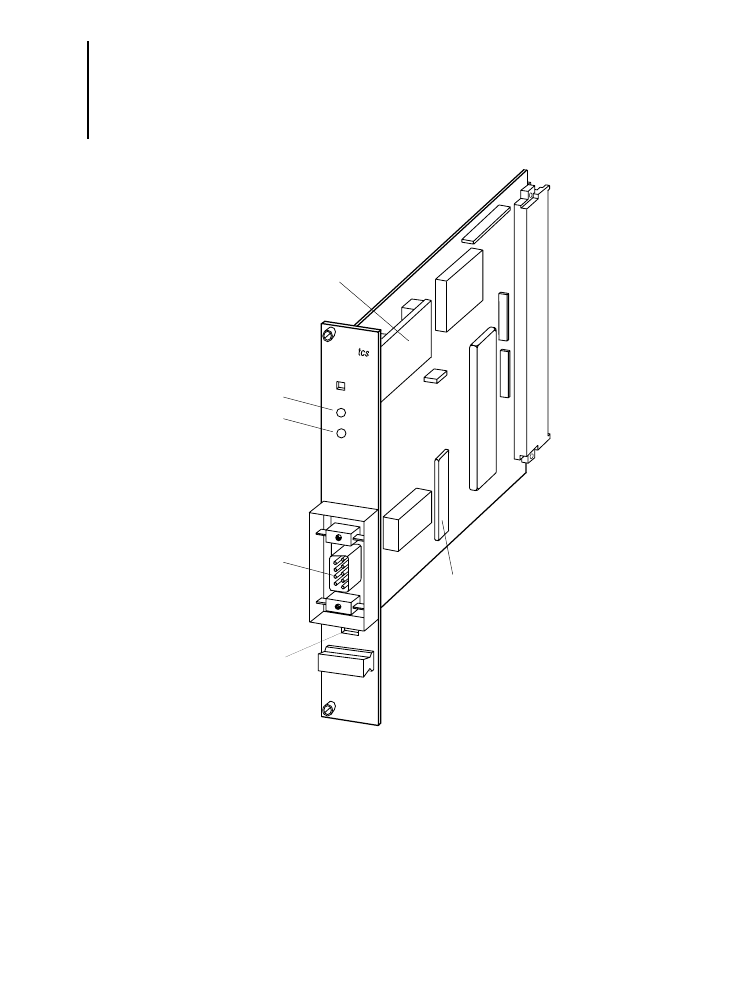

Construction of the

PS 416-TCS-200

Figure 4: Elements of the PS 416-TCS-200

a Switches S1 / S2

b RS 232 – modem port

c LED (error)

d LED (RxD / TxD)

e Interface module

f System EPROM

rxd/

txd

error

TCS-

a

200

d

c

b

e

f

Communication layers

model

11

0

8

/97

AW

B

27

-1

29

8-

GB

a

Switches S1 / S2

These switches must be left switched off at all times.

b

Port

The 9-pole Sub-D connector is used for connecting

the modem cable. The modem cable is not supplied.

Pin assignments are described in Chapter 3,

Engineering.

c

LED (error)

The LED indicates error messages. See Chapter 7,

Diagnostics

d

LED (RxD / TxD)

The LED indicates the operating status of the card.

See Chapter 7, Diagnostics

e

Interface

In order to ensure interference immunity the data

lines are optocoupled and the interface is supplied

with power via DC / DC converter with electrical

isolation.

Communication layers

model

The communication layers model describes the

relationships between programming software,

function blocks and the requisite hardware.

About The Card

12

0

8

/97

AW

B

27

-1

29

8-

GB

Figure 5: Communication layers model

Application layer

The program data are processed in the application

layer.

Link layer

This layer generates the line telegrams in accordance

with the IEC 870-5 standard and synchronises data

traffic between the station and the telecontrol system.

Physical layer

The electrical signals are formed in this layer in

accordance with the transmission medium used.

A

p

plica

tion layer

Sucosoft S 40

A

ppli

ca-

tion

Routing data

Event control

Data type conversion

Da

ta

modules

Li

nk layer

S 40-AM-TL

S 40-AM-TD

Te

lecont

rol function

blocks

A

ppl

ica

tion modules

Handling services

Address evaluation

Life control

Time-out monitoring

PS 416 programmable controller

PS 416-TCS-200 card

Card

IEC 870-5 primary station point-to-point modem

IEC 870-5 secondary station point-to-point modem

IEC 870-5 dial-up modem

Phys

ical

laye

r

Integrated RS-232 interface

SUB D, 9-pole

Dial-up modem

Primary / secondary

Type 1

Point-to-point modem

Primary

Secondary

Type 2

Type 3

13

0

8

/97

AW

B

27

-1

29

8-

GB

3

Engineering

Number of PS 416-

TCS-200 cards in the

rack

The communication processor works in all PS 416

basic units. The maximum number of

PS 416-TCS-200 cards which can be operated in a

single rack depends on the power consumption. For

this reason a power requirements calculation must

be made in all cases .

Power supply

The card is supplied internally with power at 5 V DC

from the PS 416-POW-400/410/420 power supply

card via the PS 416-rack. For further information

please refer to the Appendix, Technical data.

Terminal assignments

The communication processor is classed as data

terminal equipment (DTE).

The interface has full duplex capability – in other

words, data can be sent and received

simultaneously.

For the connection to the modem use the

ZB 4-254-KB1 modem cable.

Figure 6 shows:

interconnections and the pin assignments for the

9-pole Sub-D front connector

signal numbering as per CCITT recommendation

V24/V28

signal designations as per RS 232C

signal flow

Engineering

14

0

8

/97

AW

B

27

-1

29

8-

GB

Figure 6: Connections of the ZB 4-254-KB1 modem cable

Table 2: Meaning of the signals

Modem

D connector

25-pole plug

PS 416-TCS-200

D connector

9-pole plug

Pin

Pin

1

Protective ground (screening)

—

Not connected

8

DCD

(Data Carrier Detect)

R

1 DCD (Data

Carrier

Detect)

3

TxD

(Transmit Data)

R

2 RxD (Receive

Data)

2

RxD (Receive

Data)

r

3 TxD

(Transmit Data)

20 DSR (Data

Set

Ready)

r

4 DTR

(Data Terminal Ready)

7

SGND

(Signal Ground)

—

5 SGND

(Signal Ground)

6

DTR

(Data Terminal Ready)

R

6 DSR (Data

Set

Ready)

4

CTS

(Clear To Send)

r

7 RTS

(Request To Send)

5

RTS

(Request To Send)

R

8 CTS

(Clear To Send)

22 RI (Ring

Indicator)

R

9 (Signal not supported)

Signal

Meaning

TxD output

Transmit data, in idle state

m 3 V

RxD input

Receive data

SGND

Signal ground

RTS output

The modem is switched to the transmission state and remains in this

state for as long as the On state exists.

RTS is active M 3 V (Request To Send)

CTS input

The modem is ready to send data signals or to receive data for setting up

the connection.

CTS is active

M 3 V (Clear to send)

DTR output

The telecontrol card is ready for operation:

DTR is active

M +3 V, CPU in RUN MODE (Data Terminal Ready)

DSR input

The modem is ready for operation:

DSR is active

M +3 V (Data Set Ready)

DCD input

The modem reports that the transmission link is ready to receive data

(modem carrier frequency is stable).

DCD is active

M 3 V (Data Carrier Detection)

Selection of modem

15

0

8

/97

AW

B

27

-1

29

8-

GB

Selection of modem

You should select modems which have electrical

isolation between the RS 232 and the dial-up or

leased line. This prevents potential equalisation

currents occuring.

Electromagnetic

compatibility

You should note the following engineering

instructions in order to comply with the requirements

of EMC legislation:

E If the inductive and capacitive effects of

electromagnetic fields are to be reduced you will

need to fit the screen in a thorough and careful

manner.

E Connect the screen of the data line to the

protective ground by connecting each end of the

screen to a potential equalisation rail.

E Fit an RF ferrite ring of type PS 416-ZBX-405 to

the lead wire to the data line before the screen

connection.

The RF ferrite sleeve is not supplied with the card. It

can be ordered under type designation

PS 416-ZBX-405.

For the designation of the potential equalisation rail

appropriate for the rack please refer to

AWB 27-1208, PS 416 system.

The modems must also support the 11-bit

signalling format (8E1)

Engineering

16

0

8

/97

AW

B

27

-1

29

8-

GB

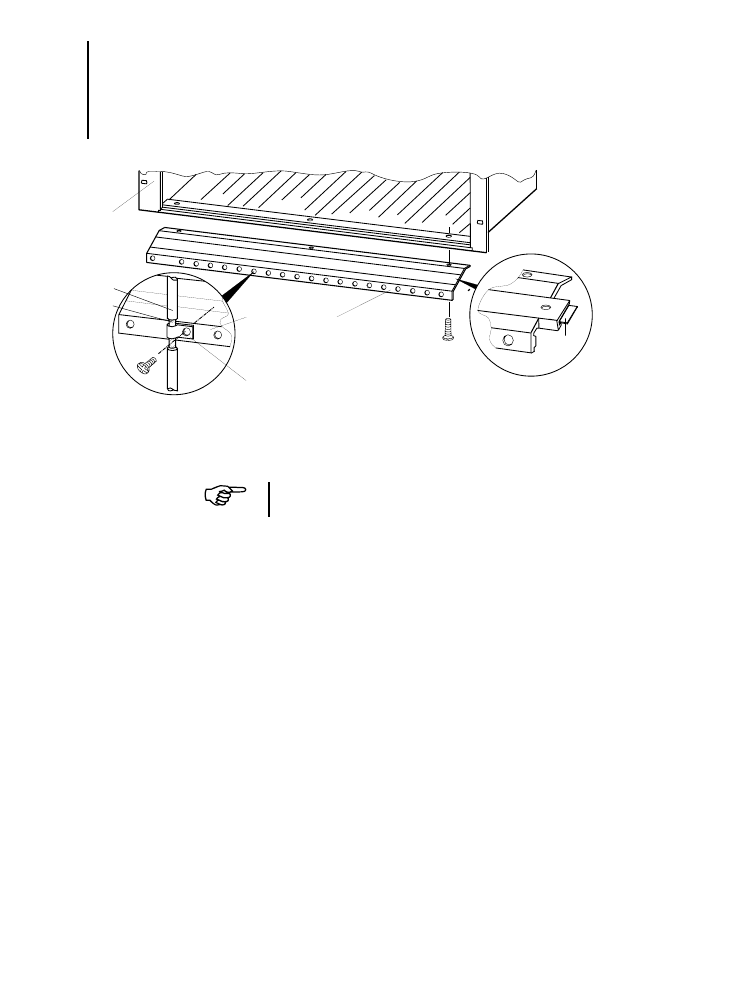

Figure 7: Grounding the signal line of the PS 416-TCS-200

a Signal line of the PS 416-TCS-200

b Screen

a

b

PS 416-BGT-4xx

PS 416-ZBX-40x

PS 416-ZBX-404

c

M4

×

12

M4

×

8

The screen braid must not be interrupted.

Electromagnetic

compatibility

17

0

8

/97

AW

B

27

-1

29

8-

GB

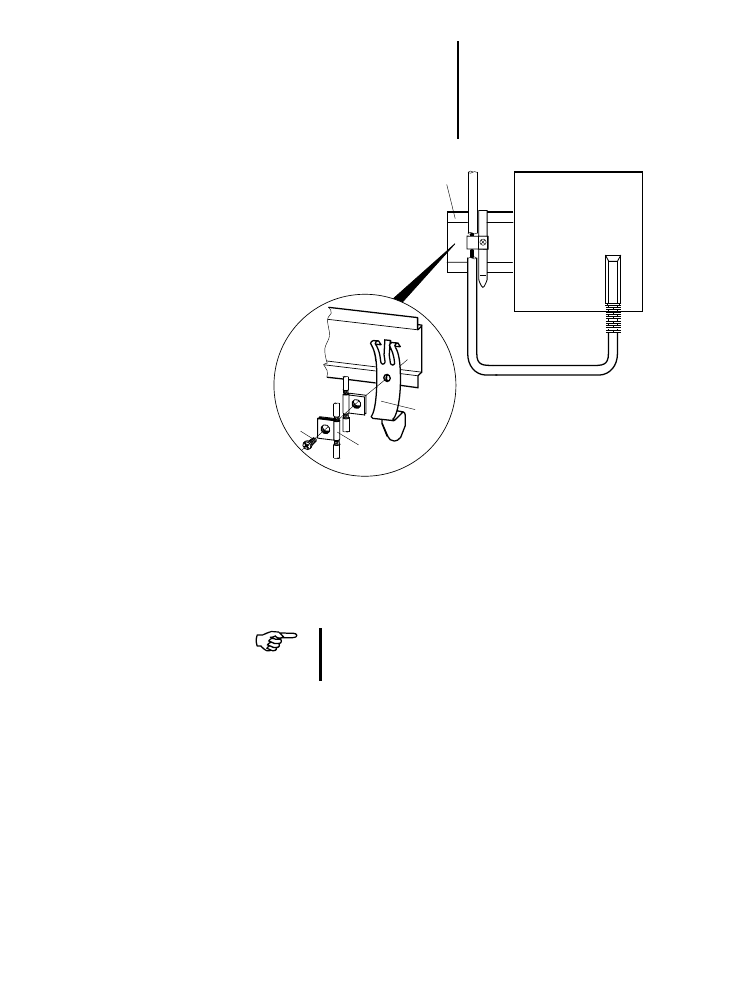

Figure 8: Grounding the signal lines of the modem

a Top-hat rail

b Snap fastener

c Contact clamp

d Screw

e Modem

a

b

d

c

M4

e

The screen braid must not be interrupted.

Items

b

,

c

, and

d

are constituent parts of the

ZB 4-102-KS1 screen earth kit.

18

0

8

/97

AW

B

27

-1

29

8-

GB

19

0

8

/97

AW

B

27

-1

29

8-

GB

4

Configuration

Before you can exchange data over the telecontrol

system for the first time with the PS 416 you will need

to configure each communication processor with the

aid of the device configurator.

E Access the Sucosoft S 40 Topology

Configurator.

E In order to configure the telecontrol card, key a

“0” into the boxes “Line” and “Rack / Station”

since the card can only be operated in the basic

unit of the PS 416.

E Next, in the “Slot / module” box you should

specify which slot the card is occupying.

E In the “Selectable Types” selection box you

should select the option “Card”. From the list of

available cards select the PS 416-TCS-200.

Interface parameters for data transmission

Parameter sets for communication have been

provided in the telecontrol card for the various

modes (leased or dial-up lines). When a service is

called via the application module the appropriate

parameters are used automatically. If these settings are

not the same as the parameters you want you can

change the settings via the application module.

The modified settings are saved in the controller and

when the controller is switched on they are

transferred automatically to the card.

Configuration

20

0

8

/97

AW

B

27

-1

29

8-

GB

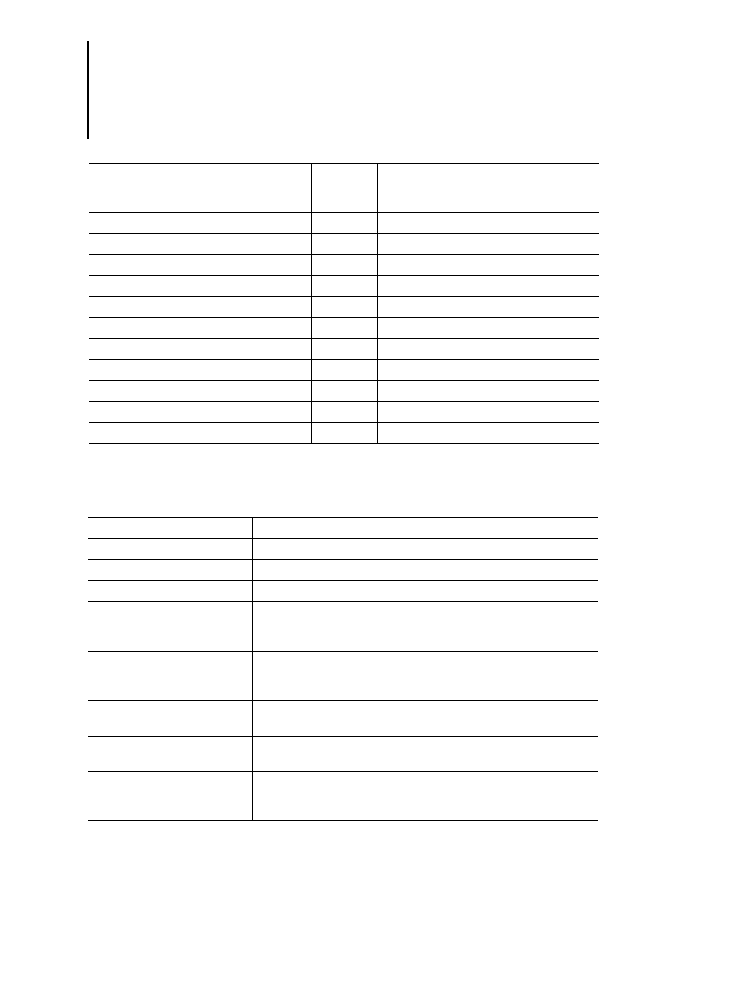

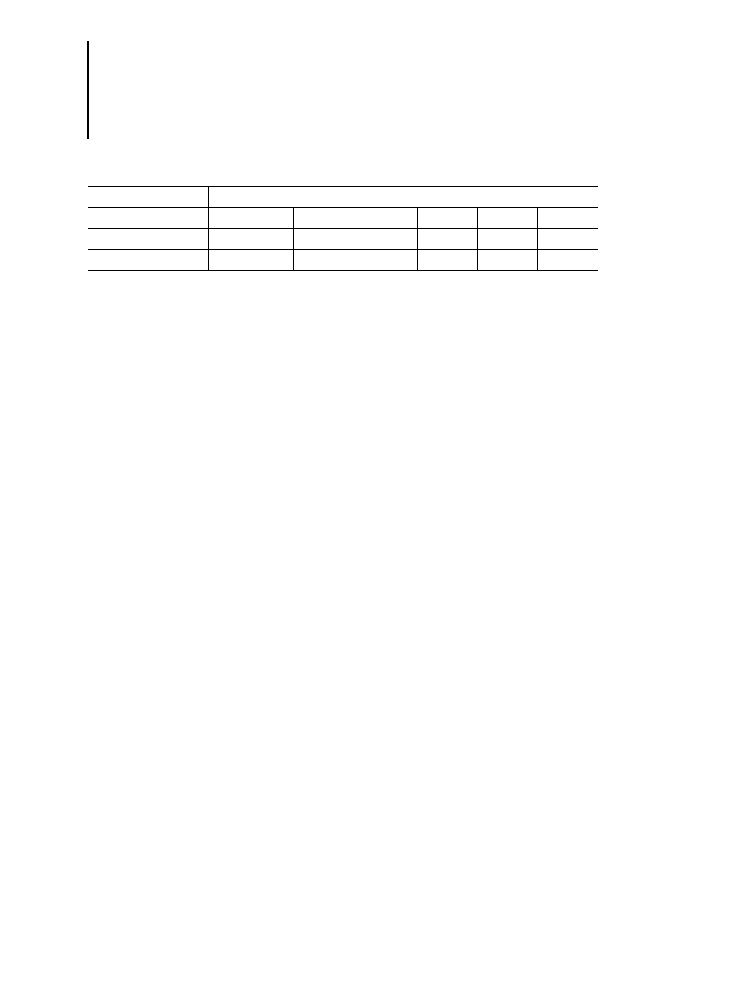

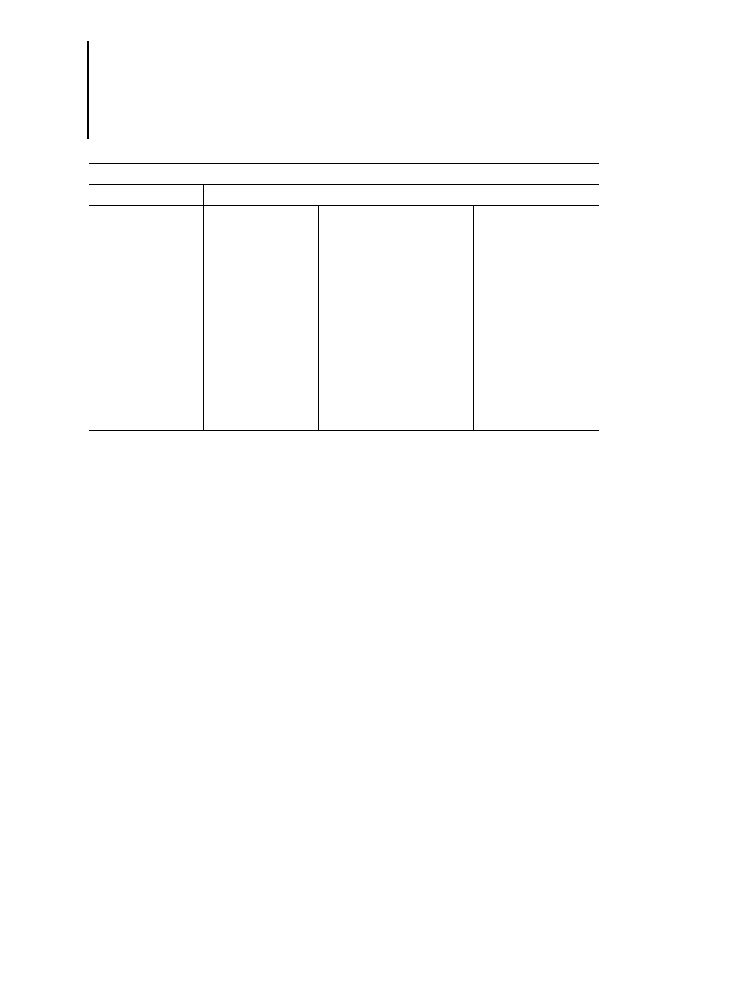

Table 3: Default settings for the various modes

Baud rate

You can select from the following baud rates:

300 baud

4800 baud

600 baud

9600 baud

1200 baud

19200 baud

2400 baud

The better the signal quality (the transmission link)

the higher the baud rate you can select for faster data

transmission.

Parity

For additional data security a parity bit can also be

transmitted. Here at the transmitting end it is

possible to expand the character to an even or odd

value. Agreement with the parity setting must be

aimed at with all stations. Note that here not every

combination of data format, number of stop bits and

parity bit is possible – see Table 4

Handshaking RTS/CTS/DSR/DTR/DCD

The handshake lines RTS/CTS/DSR/DTR/DCD are

supported in order to ensure trouble-free

communication between two telecontrol stations via

modem.

Interface parameters (default settings)

Mode

Baud rate

Start bit (fixed value)

Data bit

Parity bit

Stop bit

Dial-up modem

9600

1

8

even

1

Point-to-point modem

1200

1

8

even

1

21

0

8

/97

AW

B

27

-1

29

8-

GB

Data format

7 bit / 8 bit: With 7-bit selection 128 different bit

combinations are available. If you wish to transmit

the entire character set with 256 bit combinations

you will need to select the 8-bit format.

Stop bit

Character format combinations

The PS 416-TCS-200 carries out plausibility checks

and any incompatibilities arising from the character

format combinations will be signalled.

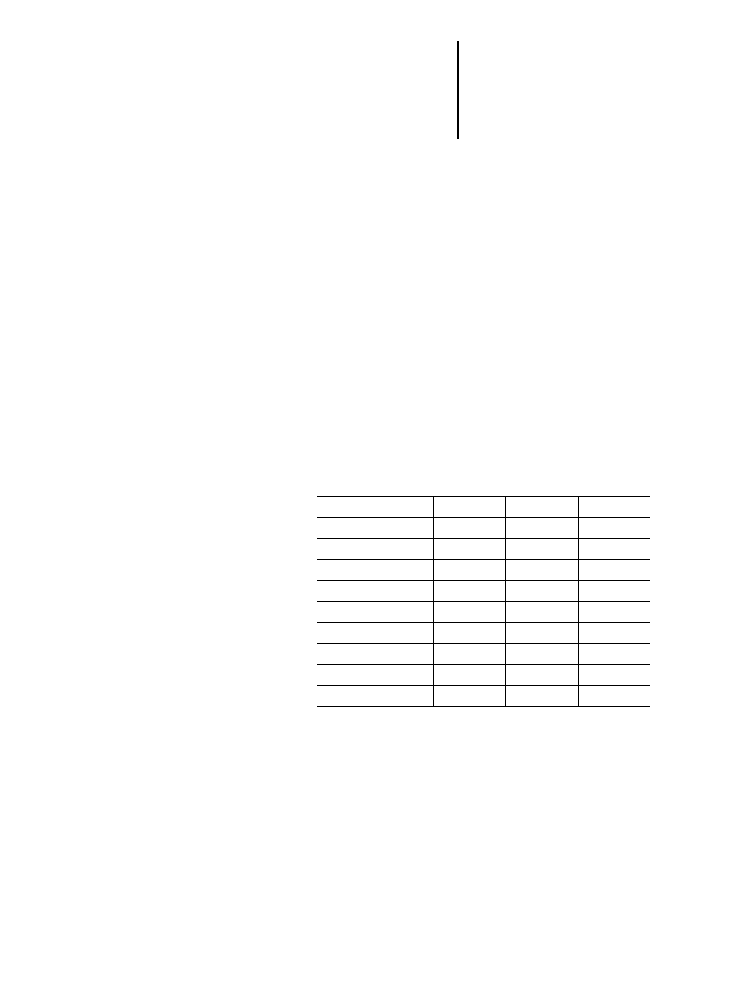

Table 4: Permissible character format combinations

* Default setting of the PS 416-TCS-200

Start bit (fixed value)

Data bit

Parity bit

Stop bit

1

7

none

2

1

7

even

1

1

7

even

1

1

7

even

2

1

7

even

2

1

8

none

1

1

8

none

2

1*

8*

even*

1*

1

8

odd

1

22

0

8

/97

AW

B

27

-1

29

8-

GB

23

0

8

/97

AW

B

27

-1

29

8-

GB

5

Installation

Installing the PS 416-

TCS-200 in the rack

E Make sure that the interface module is firmly

seated in the PS 416-TCS-200.

E Install the PS 416-TCS-200 in the basic unit from

slot 4 onwards.

E Connect the RS 232 interface on the front plate of

the card to the modem. You should use the

ZB 4-254-KB1 modem cable.

E Install the application module; in this regard see

AWB 27-1300-GB and AWB 27-1301-GB.

E Configure the PS 416-TCS-200 with the

application module; see Chapter 4, Configuration.

E Integrate the PC 416-TCS-200 into your

configuration with the aid of the Sucosoft S 40

Topology Configurator.

Operating instructions:

To protect the components from the discharge of

static electricity the operator must discharge

himself electrostatically before touching the

PS 416-TCS-200, its front plate components or

the card.

Warning!

The PS 416-TCS-200 must not be inserted or

removed unless the power supply has been

switched off.

24

0

8

/97

AW

B

27

-1

29

8-

GB

25

0

8

/97

AW

B

27

-1

29

8-

GB

6

Operation

Function of the

PS 416-TCS-200 card

Figure 9: Function of card in a telecontrol station

The card functions in a telecontrol system as a

protocol generator or protocol evaluator. The

application module prepares the user and control

data for the PS 416-TCS-200 communication

processor. The card packs this user data (a

maximum of 220 bytes) into the telecontrol protocol

and sends it to the modem via the integrated RS-232

interface.

The received data is evaluated according to the

telegram protocol used. The application module in

the central processing unit evaluates this data and

makes it available to the user for further processing.

Programmable controller

User program

Application module

PS 416-TCS-200

Protocol

Protocol

Data

generation

evaluation

interface

mission

equipment

PS 416

↔

↔

↔

Data trans-

(modem)

Data terminal equipment (DTE)

Operation

26

0

8

/97

AW

B

27

-1

29

8-

GB

Startup behaviour

Both cold starts and warm starts are possible.

Cold start

Once the PS 416 has been switched on or a cold

restart signal has been received from the PS 416, the

activities of the communication processor begin with

the self-test. Here the PS 416-TCS-200 checks the

functional readiness of the interface module and of

the RAM memory modules.

The operating system will enter an error message in

the DPRAM should one of the following errors occur:

faulty operating system EPROM (where

detectable)

faulty RAM

faulty DPRAM (where detectable)

interface module not plugged in

In the event of such an error the user will receive the

corresponding fault message via the red front panel

LED when the program starts.

If there is none such error, the program logic

assumes that a cold start has taken place and sets

up a configuration which corresponds to the

system’s own default parameters. This default

configuration (leased line) includes a transmission

rate of 1200 baud, a data format of 8 data bits, even

parity with one stop bit as well as the characteristics

of a secondary station with a FT 1.2 message format.

The PS 416-TCS-200 now waits for new parameters

or the command to exchange data using the existing

default parameters.

Shutdown behaviour

27

0

8

/97

AW

B

27

-1

29

8-

GB

Warm start

If the PS 416-TCS-200 receives a reset command

from the application card without a cold start signal

from the central processing unit of the PS 416, the

communication processor stops all jobs which have

started and re-initialises itself with the aid of the user

parameters.

If there is no parameter error, the operating system of

the PS 416-TCS-200 assumes a warm start.

Shutdown behaviour

A drop in the power supply is communicated to the

communication card via a control line. In this case

transmit and receive operation via the serial interface

is aborted. All data which still needs to be sent and

data which has already been received is discarded.

28

0

8

/97

AW

B

27

-1

29

8-

GB

29

0

8

/97

AW

B

27

-1

29

8-

GB

7

Diagnostics

Once the power supply has been switched on and

the self-test has run successfully the green front

panel LED “TxD / RxD” comes on and stays on.

The current operating status can be read off from the

two LEDs; see table.

Table 5: LED function during operation

Green data transfer LED

’TxD / RxD’

Red error LED ’ERR’

Card and bus interconnection status

On

Off

PS 416-TCS-200 is in coupled operation

No data exchange

Flashing

Off

PS 416-TCS-200 is exchanging data

The flashing mirrors the rhythm of the incoming

and outgoing characters.

Off

On

Hardware fault or defective initialization

No data exchange

Off

Flashes at a frequency of 2 Hz

Faulty or incorrectly initialised interface module

30

0

8

/97

AW

B

27

-1

29

8-

GB

31

0

8

/97

AW

B

27

-1

29

8-

GB

Appendix

Technical data

Data interface

RS 232, V24/V28

9-pole SUB-D connector for modem connection

Handshake lines

RTS, CTS, DCD, DTR, DSR

Data transmission protocol

FT 1.2, FT 3 asynchronous

Maximum amount of user data in the

telecontrol transmission protocol

220 bytes

Maximum amount of user data in the

telecontrol transmission protocol

250 bytes

Electromagnetic compatibility (EMC)

Transmission procedure

Asynchronous, choice of protocol

Data transmission rate

300, 600, 1200, 2400, 4800, 9600, 19 200 baud

Transmission link

RS 232, maximum cable length 2 m

Recommended cable

RS 232 with control lines: eight-conductor cable, screened;

max. cable length 2 m

Power consumption

0.83 A (5 V DC)

Power loss

Max. 4.2 W

Ambient temperature

0 to +55 °C

Transportation and storage temperature

–20 to +70 °C

Cards

4 space units (1 slot)

Format

Euroformat (160

u 100 mm)

Weight

approx. 180 g

Appendix

32

0

8

/97

AW

B

27

-1

29

8-

GB

Glossary

Application module

Application modules are programs or parts of

programs for the PLC or PC which support a function

in an application or which execute it entirely.

Application modules provide ready-made solutions

for the most varied applications.

Assymmetrical configuration

Configurations of telecontrol stations which consist

of primary and secondary stations are referred to as

asymmetrical configurations.

Asynchronous transmission

Each message character is synchronised

individually, usually by start and stop elements.

Central station

The station which remotely monitors substations

and / or remotely controls them.

Characters

Agreement regarding the data format, for example,

1 start bit, 8 data bits, 1 parity bit, 1 stop bit; i.e. 1

character = 11 bits.

General information on the electromagnetic compatibility (EMC) of programmable controllers

Emission

EN 55 011/22 Class A

Immunity

ESD

EN 61 000-4-2

Contact discharge

Air discharge

4 kV

8 kV

RFI

ENV 50 140

AM/PM

10 V/m

Burst

EN 61 000-4-4

Power supply/digital I/O

Analogue I/O, field bus

2 kV

1 kV

Surge

ENV 50 142

Digital I/O, assymmetrical

DC supply, assymmetrical

DC supply, symmetrical

AC supply, assymmetrical

AC supply, symmetrical

0.5 kV

1 kV

0.5 kV

2 kV

1 kV

Line-conducted

interference

ENV 50 141

AM

10 V

Glossary

33

0

8

/97

AW

B

27

-1

29

8-

GB

Dial-up line

A transmission line which can be used after dialling.

DTE

Data Terminal Equipment may include computers,

terminals or other input or output devices. A DTE

which transmits data is referred to as a data source.

A DTE which receives data is referred to as a data

sink.

DTE

Data transmission equipment; see also Modem

Handshake

Defined sequence of signals for setting up and

checking a connection.

ISO / OSI

The ISO / OSI model describes a model for

classifying data transmission and processing

between two computers.

Leased line

A non-switched transmission line.

Modem

Abbreviation for “modulator-demodulator”. Device

which converts digital signals into analog signals and

vice versa.

Parity

Method of providing security for data – a check bit is

attached to every character.

Party line configuration

A configuration whereby the central station is

connected to more than one substation via a shared

transmission path in such a way that only one

substation at a time can send data to the central

station. The central station can send data either to

one or more substations. General messages can be

sent to all substations simultaneously.

Appendix

34

0

8

/97

AW

B

27

-1

29

8-

GB

Primary station

Station which initiates data transportation.

Secondary station

A station which replies to a data request from a

primary station.

Substation

A station which is monitored or monitored and

controlled by a central station.

Symmetrical configuration

Configurations of telecontrol stations which consist

of stations with equal rights are referred to as

symmetrical configurations. The stations in these

configurations combine the properties of primary

and secondary stations.

Telecontrol

Telecontrol is the monitoring and control of spatially

widely distributed processes by means of coded bit-

serial data transmission.

Telecontrol configuration

The combination of telecontrol stations and the

transmission paths between the stations.

Telecontrol station

Central station or substation within a telecontrol

system.

Telecontrol station

A telecontrol system is used for controlling and

monitoring processes which are spatially widely

distributed.

The system includes all equipment and functions for

data acquisition, processing, transmission and

display of the requisite process information.

35

0

8

/97

AW

B

27

-1

29

8-

GB

Index

A

Application modules ........................................................ 9

B

Baud rate ....................................................................... 20

C

Central processing unit .................................................... 9

Character format combinations ..................................... 21

Cold restart .................................................................... 26

Communication layers model ........................................ 11

Configuration ................................................................. 19

CTS ................................................................................ 14

D

Data format .................................................................... 21

DCD ............................................................................... 14

Default settings .............................................................. 20

Diagnostics .................................................................... 29

Dial-up line ....................................................................... 5

DSR ................................................................................ 14

DTR ................................................................................ 14

E

Electromagnetic compatibility ....................................... 15

G

Glossary ......................................................................... 32

H

Handshaking .................................................................. 20

Hardware and software requirements ............................. 9

I

Installation ...................................................................... 23

Interface ......................................................................... 11

Interface parameters ...................................................... 19

Index

36

0

8

/97

AW

B

27

-1

29

8-

GB

L

Leased line ....................................................................... 7

LED (error) ...................................................................... 11

LED (RxD / TxD) ............................................................. 11

LED function ................................................................... 29

M

Modem ............................................................................. 5

Grounding the signal line ............................................ 17

Selection ..................................................................... 15

Modem cable ............................................................... 5, 9

O

Operating system ............................................................. 9

Operation ........................................................................ 25

P

Parity .............................................................................. 20

Party line ........................................................................... 7

Point-to-point dedicated modem ..................................... 7

Port ................................................................................. 11

Power supply .................................................................. 13

Power supply card ........................................................... 9

Primary station ................................................................. 6

Protective earth .............................................................. 14

PS 416-TCS-200

Construction ............................................................... 10

Function ...................................................................... 25

Installation in rack ....................................................... 23

Number in rack ........................................................... 13

S

Secondary station ............................................................ 6

SGND ............................................................................. 14

Shutdown behaviour ...................................................... 27

Signal line

Grounding ................................................................... 16

Startup behaviour ........................................................... 26

Index

37

0

8

/97

AW

B

27

-1

29

8-

GB

Stop bit .......................................................................... 21

Subrack ............................................................................ 9

Switches S1 / S2 ............................................................ 11

T

Technical data ................................................................ 31

Terminal assignments .................................................... 13

TxD ................................................................................. 14

U

User data ....................................................................... 25

W

Warm start ..................................................................... 27

Document Outline

- Hardware and Engineering

- Before commencing the installation

- Contents

- About This Manual

- 1 Setting Up A Telecontrol Station With ThePS416 Controller

- 2 About The Card

- 3 Engineering

- 4 Configuration

- 5 Installation

- 6 Operation

- 7 Diagnostics

- Appendix

- Index

Wyszukiwarka

Podobne podstrony:

PS4 PS 416 NET 440, Master h1330g

PS4 PS 4 271 MM1 h1364g

h1239g PLC PS4 416

h1239g PLC PS4 416

h1244g MODBUS PLC PS4 416

1 72 Short 330 200 Bobs Card Models 2007

PS VI

PS spolecznosc lokalna 3

PS 1 Psychologia społeczna wstep

200 Faszyzm 2id 21545 ppt

PS Organiz 11

PS Komunikacja 910

Semin 3 ST Ps kl Stres

PS IV

w2 ps poznawcza

43 Appl Phys Lett 88 013901 200 Nieznany (2)

EC08 FPC PS TIG FPC Outbrief (9May08)

więcej podobnych podstron