© 2013 Smithers Rapra Technology

T/15

Plasticheskie Massy, No. 4, 2012, pp. 57–59

Targeted control of the structure and properties of

polyethylene containing disperse fillers

O.V. Egorova, Yu.A. Kadykova, and S.E. Artemenko

Engels Technological Institute (Branch), Saratov State Technical University, Engels, Saratov Region, Russia

Selected from International Polymer Science and Technology, 39, No. 8, 2012, reference PM 12/04/57; transl. serial no. 17019

Translated by P. Curtis

SuMMaRy

A study was made of the possibility and effectiveness of

using disperse production waste as filler for polyethylene.

The obtained data demonstrate the expediency of using

phenolic plastic and basalt wool waste for the filling of

polyethylene, which makes it possible to increase the

properties of polyethylene, reduce the cost of the finished

articles, and reduce the ecological impact.

Polyolefins are the highest-tonnage polymers, the

production of which amounts to tens of millions of tons

(35% of the world volume of polymer production). In terms

of the scales of production and consumption, polyolefins

have been and remain the number-one polymeric

materials worldwide. The most important representative

of this class of polymers is polyethylene (PE).

Polyethylene possesses a valuable combination

of properties, providing articles with sufficiently high

strength, resistance to corrosive media and radiation,

non-toxicity, and high dielectric indices. In the vast

majority of cases in practice, even when not prompted

by technical necessity, it is not filled polymers that are

used, but “pure” polyethylene. However, the introduction

of an efficient quantity of mineral and other fillers makes

it possible to improve considerably the combination of

physicomechanical properties of the polymers, to lower

their cost, and to expand the raw material base.

Every year, 350 000420 000 t of industrial waste

is formed in Russia, the waste formed in the synthesis

and processing of polymeric materials amounting to

5-35 wt% of this figure.

At the Trolza OJSC (Engels, Saratov Region), a

different range of articles is produced from polymeric

materials, to be used in trolleybuses. Every year, up

to 5165 t of waste of different polymeric materials is

formed, 2435 t of which is sent to the dump.

Thus, it was of interest to conduct the filling of PE with

production waste in order to improve the properties and

reduce the cost of finished products. Phenolic plastic

waste, glass-fibre-reinforced plastic waste, and basalt

wool waste were chosen as the fillers.

Phenolic plastic waste is formed in the process

of manufacture of parts by compression moulding

of phenolic moulding material (GOST 28804-90) of

grade FF2O2 – general-purpose phenol-formaldehyde

novolac resin with improved electrical properties, filled

with carbon black. The phenolic plastic waste comprises

flash and substandard articles, which are carted off to

the dump.

The glass-fibre-reinforced plastic waste is formed

as a result of the manufacture of parts by the cutting of

sheets using templates and trimming in order to give

the articles the necessary shape. Glass-fibre-reinforced

plastic sheets are manufactured at Trolza by contact

moulding, using glass fibre, polyester resin, and gelcoat

as the raw materials.

Basalt wool waste is formed as a result of the service

life of the wool (7-10 years) as heat-insulation material for

piping coming to an end. The basalt wool is produced

by the Ivotsk Glass Factory, Bryansk Region, TU 21-23-

247-88 “Mats and wool of basalt staple supertonnage

fibre” specifications.

In earlier studies, chemical engineering personnel

at the Saratov State Technical University investigated

International Polymer Science and Technology, Vol. 40, No. 9, 2013

T/16

the degree of filling of PE with given compositions and

established that the optimum quantity of filler per 100

parts PE was as follows: 50 parts phenolic plastic, 5 parts

glass-fibre-reinforced plastic, and 30 parts basalt wool.

To determine the processing parameters of polymer

composites based on polyethylene and different fillers,

the processing equipment, and the processing schedules,

flow of the composite was assessed from the melt flow

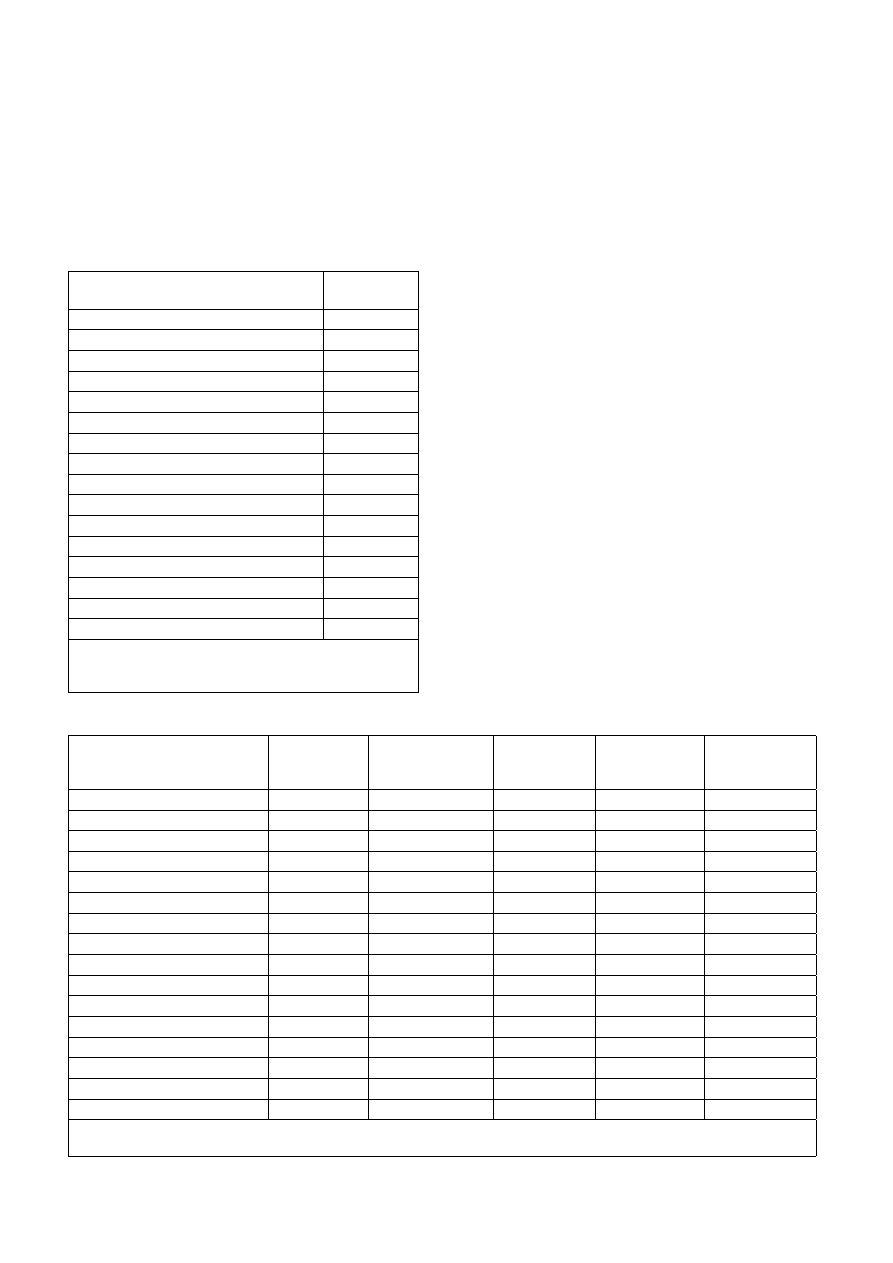

index (MFI). As can be seen from the data in Table 1,

polymer composites filled with different disperse fillers can

be processed by injection moulding, as thermoplastics

with a melt flow index of 1.2-15 g/10 min can be

processed by this method.

The physicomechanical properties of the developed

polymer composites (Table 2) indicate that the highest

values of bending stress, impact strength, and Brinell

hardness are observed when phenolic plastic and basalt

wool are introduced into polyethylene, including both

virgin and recycled low-density polyethylene (LDPE) and

high-density polyethylene (HDPE).

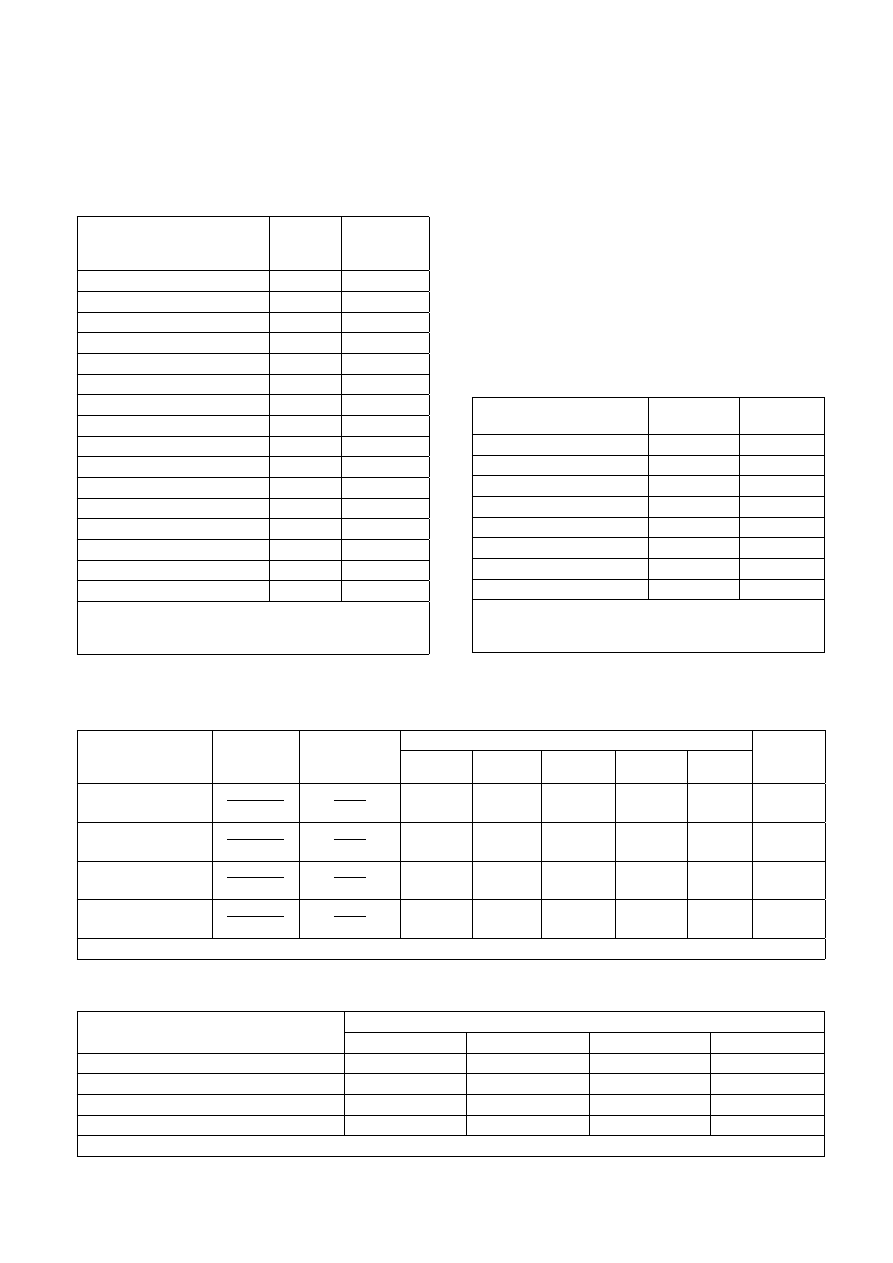

It is known that polyethylene is a flammable material,

and therefore the developed materials were investigated

for fire resistance by the “flame tube” method. As

shown by investigations (Table 3), polymer composites

containing 30 parts basalt wool and 50 parts phenolic

plastic waste possess practically twofold lower weight

losses. This indicates that PE with the given fillers is more

combustion resistant.

Confirmation of the denser and more crosslinked

structure of polymer composites is provided by data

on the heat stability of specimens, determined by

thermogravimetric analysis (Table 4). The increase in

coke residue, the lower weight loss up to 600°C, and the

increase in activation energy make it possible to assert

a more complete interaction of polyethylene with basalt

wool and phenolic plastic by comparison with unfilled

LDPE and LDPE filled with glass-fibre-reinforced plastic.

The degradation rate of filled specimens (Table 5) with

Table 1. Change in the melt flow index of the composite

at 200°C as a function of its composition and

temperature

Composition of composite

a

(parts per

100 parts PE)

MFI (g/10

min)

LDPE

5.30

Virgin LDPE + 5GFRP

5.20

Virgin LDPE + 30BW

3.21

Virgin LDPE + 50PP

2.53

Recycled LDPE

5.62

Recycled LDPE + 5GFRP

5.55

Recycled LDPE + 30BW

3.36

Recycled LDPE + 50PP

2.86

HDPE

6.50

Virgin HDPE + 5GFRP

6.35

Virgin HDPE + 30BW

5.04

Virgin HDPE + 50PP

3.87

Recycled HDPE

6.78

Recycled HDPE + 5GFRP

6.70

Recycled HDPE + 30BW

4.84

Recycled HDPE + 50PP

3.71

a

LDPE: low-density polyethylene; HDPE: high-density

polyethylene; GFRP: glass-fibre-reinforced plastic; BW: basalt

wool; PP: phenolic plastic

Table 2. Comparative characteristics of polymer composites based on PE and disperse fillers (particle size <0.14 mm)

Composition of composite

a

(parts per 100 parts PE)

Bending stress

(MPa)

Tensile stress

causing failure

(MPa)

Elongation at

break

(%)

Impact strength

(kJ/m

2

)

Brinell hardness

(MPa)

LDPE

25

28

167

34

38

Virgin LDPE + 5GFRP

26

26

152

38

42

Virgin LDPE + 30BW

33

27

111

59

64

Virgin LDPE + 50PP

32

20

102

46

64

Recycled LDPE

20

15

121

30

34

Recycled LDPE + 5GFRP

22

14

114

34

41

Recycled LDPE + 30BW

24

14

99

48

57

Recycled LDPE + 50PP

24

10

96

44

55

HDPE

20

17

215

24

25

Virgin HDPE + 5GFRP

22

15

204

27

41

Virgin HDPE + 30BW

29

12

182

42

59

Virgin HDPE + 50PP

30

10

175

44

57

Recycled HDPE

18

14

170

19

21

Recycled HDPE + 5GFRP

20

12

158

22

25

Recycled HDPE + 30BW

25

11

142

36

48

Recycled HDPE + 50PP

26

10

136

37

46

a

LDPE: low-density polyethylene; HDPE: high-density polyethylene; GFRP: glass-fibre-reinforced plastic; BW: basalt wool; PP:

phenolic plastic

© 2013 Smithers Rapra Technology

T/17

increase in temperature, starting at 400°C, decreases by

comparison with unfilled polyethylene, which indicates

the greater heat stability of polymer composites based

on basalt wool.

Table 3. Influence of the composition of the polymer

composite on the flammability indices

Composition of composite

a

(parts per 100 parts PE)

Ignition

time

(s)

Weight loss

(%)

LDPE

4

78

Virgin LDPE + 5GFRP

6

70

Virgin LDPE + 30BW

10

35

Virgin LDPE + 50PP

12

41

Recycled LDPE

4

74

Recycled LDPE + 5GFRP

6

68

Recycled LDPE + 30BW

12

33

Recycled LDPE + 50PP

14

35

HDPE

6

81

Virgin HDPE + 5GFRP

7

78

Virgin HDPE + 30BW

16

43

Virgin HDPE + 50PP

10

41

Recycled HDPE

6

79

Recycled HDPE + 5GFRP

7

73

Recycled HDPE + 30BW

14

40

Recycled HDPE + 50PP

12

37

a

LDPE: low-density polyethylene; HDPE: high-density

polyethylene; GFRP: glass-fibre-reinforced plastic; BW: basalt

wool; PP: phenolic plastic

Table 4. Thermogravimetric analysis of polymer composites based on polyethylene and glass-fibre-reinforced plastic,

basalt wool, and phenolic plastic

Composition of

material

a

(parts)

T

s

–T

f

/T

max

(°C)

m

s

–m

f

/m

max

(%)

Weight loss (%) at different temperatures

E

act

(kJ/mol)

100°C

300°C

400°C

500°C

600°C

LDPE

280–550

475

2–98

96

1

4

26

98

98

210

Virgin LDPE + 5GFRP

282–554

475

2–95

92

1

4

26

90

95

223

Virgin LDPE + 30BW

280–570

473

2–85

82

1

4

26

84

85

271

Virgin LDPE + 50PP

280–568

470

2–80

79

1

4

26

79

80

280

a

LDPE: low-density polyethylene; GFRP: glass-fibre-reinforced plastic; BW: basalt wool; PP: phenolic plastic

Table 5. Degradation rate of the developed polymer composites

Composition of material

a

(parts)

Degradation rate (mg/min) at different temperatures

200–300°C

300–400°C

400–500°C

500–600°C

LDPE

0.54

3.9

11.9

1.4

Virgin LDPE + 5GFRP

0.54

3.9

11.7

1.3

Virgin LDPE + 30BW

0.54

3.6

11.1

0.18

Virgin LDPE + 50PP

0.54

23.6

10.8

0.17

a

LDPE: low-density polyethylene; GFRP: glass-fibre-reinforced plastic; BW: basalt wool; PP: phenolic plastic

Table 6. Effect of fillers on the heat resistance of PE

Composition of composite

a

(parts per 100 parts PE)

T

flash

(°C)

OI (vol%)

LDPE

108

19

Virgin LDPE + 5GFRP

108

19

Virgin LDPE + 30BW

122

26

Virgin LDPE + 50PP

124

27

HDPE

100

19

Virgin HDPE + 5GFRP

100

20

Virgin HDPE + 30BW

118

26

Virgin HDPE + 50PP

123

26

a

LDPE: low-density polyethylene; HDPE: high-density

polyethylene; GFRP: glass-fibre-reinforced plastic; BW: basalt

wool; PP: phenolic plastic

Filling also affects the heat resistance and oxygen

index of PE: there is an increase in the OI and heat

resistance of LDPE and HDPE when they are filled with

phenolic plastic and basalt wool (Table 6).

Generalising the results of the investigations, it can

be concluded that the most promising fillers are phenolic

plastic and basalt wool waste. When the given fillers are

introduced, there is an increase in the bending stress,

impact strength, and Brinell hardness, an increase in

fire and alkali resistance, and a reduction in water

absorption. Here there is a reduction in the cost of the

finished article as a result of the introduction into the

polymer composite of production waste that previously

was sent to the dump.

Copyright of International Polymer Science & Technology is the property of Rapra

Technology and its content may not be copied or emailed to multiple sites or posted to a

listserv without the copyright holder's express written permission. However, users may print,

download, or email articles for individual use.

Wyszukiwarka

Podobne podstrony:

Struktury i właściwości zeliw, MBiM

zadania.prezen, Studia, SEMESTR 3, NOM, struktury i właściwości stopów miedzi - prezentacja

Struktury i właściwości zeliw

3 - Struktura I Właściwosci Stali Po Obróbce Cieplno-Chemicznej, ZiIP, Semestr 2, Nauka o Materiałac

mowa, Studia, SEMESTR 3, NOM, struktury i właściwości stopów miedzi - prezentacja, prezentacja sokol

Wpływ temperatury hartowania na strukturę i właściwości stali 40H, Nauka o materialach

12. STRUKTURA I WŁAŚCIWOŚCI PROCESU WYCHOWANIA, Przygotowanie Pedagogiczne, Teoria Wychowania

rozwiązanie, Studia, SEMESTR 3, NOM, struktury i właściwości stopów miedzi - prezentacja

METALOZNAWCZE PODSTAWY KSZTALTOWANIA STRUKTURY I WLASCIWOSCI BLACH ZE STALI DP W PROCESIE CIAGLEGO W

6. Wykorzystanie strukturotwórczych właściwości jaj w technologii gastronomicznej, Zastosowanie jaj

Tworzywo polimerowe - sciaga, Tworzywo polimerowe - materiał, którego głównym składnikiem determinuj

Struktura i właściwości stali w stanie dostawy – wykres Fe – Fe3C Sprawozdanie

Struktura i właściwości stali w stanie dostawy – wykres Fe – Fe3C Instrukcja

Struktura a wlasciwosci funkcjonalne bialek

Kontrola strukturalna Jak działa układ

Proces wychowania struktura, właściwości, metody i błędy

ANIZOTROPIA WŁAŚCIWOŚCI PLASTYCZNYCH Wyroby kształtowane obróbką plastyczną zwłaszcza na zimno mają

więcej podobnych podstron