Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 1 of 27

Author : TML

Dept : ERC-E&E

D

D

i

i

a

a

g

g

n

n

o

o

s

s

t

t

i

i

c

c

M

M

a

a

n

n

u

u

a

a

l

l

f

f

o

o

r

r

A

A

-

-

E

E

C

C

U

U

PURPOSE :

This document details the Diagnostic Procedure for the A-ECU used in Indica ,

Indigo, Marina Diesel BSII vehicles

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 2 of 27

Author : TML

Dept : ERC-E&E

NOTE : This document is subject to change based on the A-ECU Hardware & software

changes

R

R

e

e

v

v

i

i

s

s

i

i

o

o

n

n

H

H

i

i

s

s

t

t

o

o

r

r

y

y

Prepared By

Approved By

Date

Reason For Changes

Page No. for

Changes

Ver.

Mr. V.Ashok Kumar

Mr.Vaidya

20/06/07

New release

1.00

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 3 of 27

Author : TML

Dept : ERC-E&E

1. Scope …………………………………………………………… ………. 3

2. List of Fault Codes ……………………………………………………….. 4

3. Trouble-shooting with fault-codes ………………………………………..7

3.1 Fault Code 11 details …………………………………………………… 8

3.2 Fault Code 12 details ………………………………………………………. 9

3.3 Fault Code 13 details ………………………………………………………..10

3.4 Fault Code 14 details ………………………………………………………..11

3.5 Fault Code 15 details ………………………………………………………..12

3.6 Fault Code 16 details ………………………………………………………..13

3.7 Fault Code 17 details ………………………………………………………..14

3.8 Fault Code 18 details ………………………………………………………..15

3.9 Fault Code 21 details ………………………………………………………..16

3.10 Fault Code 22 details ………………………………………………………17

3.11 Fault Code 23 details ………………………………………………………18

3.12 Fault Code 24 details ……………………………………………………….19

3.13 Fault Code 27 details ………………………………………………………20

3.14 Fault Code 28 details ……………………………………………………….21

3.15 Fault Code 29 details ……………………………………………………….22

3.16 Table of Symptoms ……………………………………………………….23

Appendix A - ECU Pin Out ……………………………………………………...24

Appendix B – Circuit schematic ………………………………………………… 25

Appendix C – Diagnostic connector Location ……………………………………26

Contents. Page No.

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 4 of 27

Author : TML

Dept : ERC-E&E

1.0 Scope:

This manual is intended as a trouble-shooting aid for AECU based system to be used by service

technicians. Section 2 lists various fault codes issued by AECU and how they are to be read.

Section 3 explains in detail trouble-shooting flow charts for each of the fault codes. Appendices

at the end include AECU pin-out and schematic diagram along with diagnostic enable connector

location.

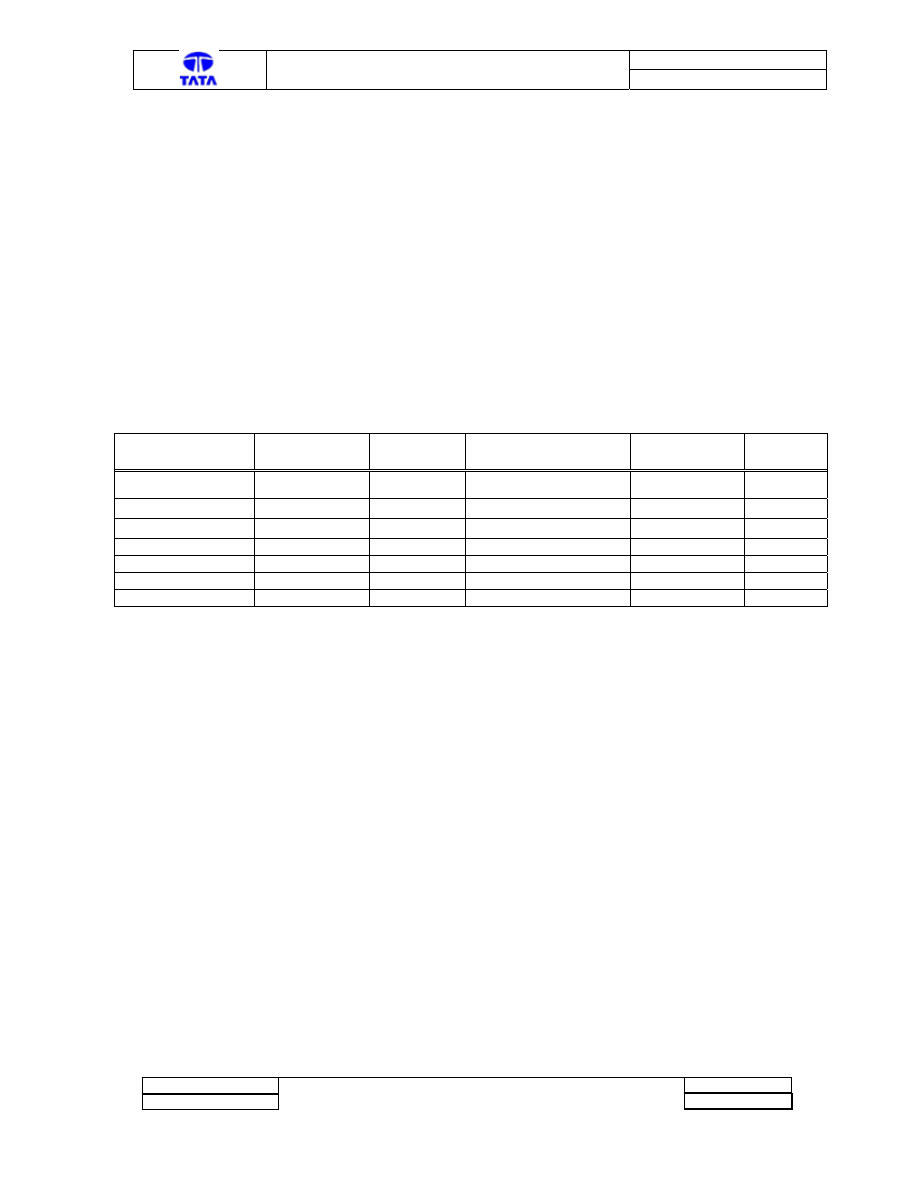

2.0 A ECU Fault codes:

Sr.

No.

Fault Description

Code

1 Temperature

Sensor

Open

11

2 Temperature

Sensor

Short

12

3

Throttle Lever Potentiometer

Centre/Supply point open

13

4

Throttle Lever Potentiometer Gnd

point open

14

5

Loss Of Engine Speed Signal

15

6

Glow Plug Unit/Glow Plugs Faulty

7

GP ON Command or F/B Wire Open

16

8 GPR

Relay

Stuck

17

9

GPR Command line shorted to

supply

18

10

GP ON Lamp Shorted to Supply

21

11

GP ON Lamp Open/Wire Open

22

12

AC Relay Coil Shorted to Supply

23

13

AC Relay Coil open/ Wire Open

24

14

Fan In Series Relay Shorted To

Supply

27

15

Fan In Series Relay Open/Wire Open

28

16

Throttle Pot Wrong connections/

Throttle Pressed

While cranking

29

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 5 of 27

Author : TML

Dept : ERC-E&E

2.1 Reading faults using flashing codes:

No diagnostic tool is required for reading the faults. Faults can be read by flashing codes

displayed on the check engine lamp mounted on the cluster.

Check engine lamp is lit when the ignition is switched on and remains on till crank is applied.

After crank, the check engine lamp goes off unless a fault is signalled by AECU. During a fault

condition, check engine lamp comes on continuously, signalling presence of a fault.

Specific fault code can be displayed on the check engine lamp by shorting the terminals of

“diagnostics enable” connector located at the connector side of AECU (See Appendix C)

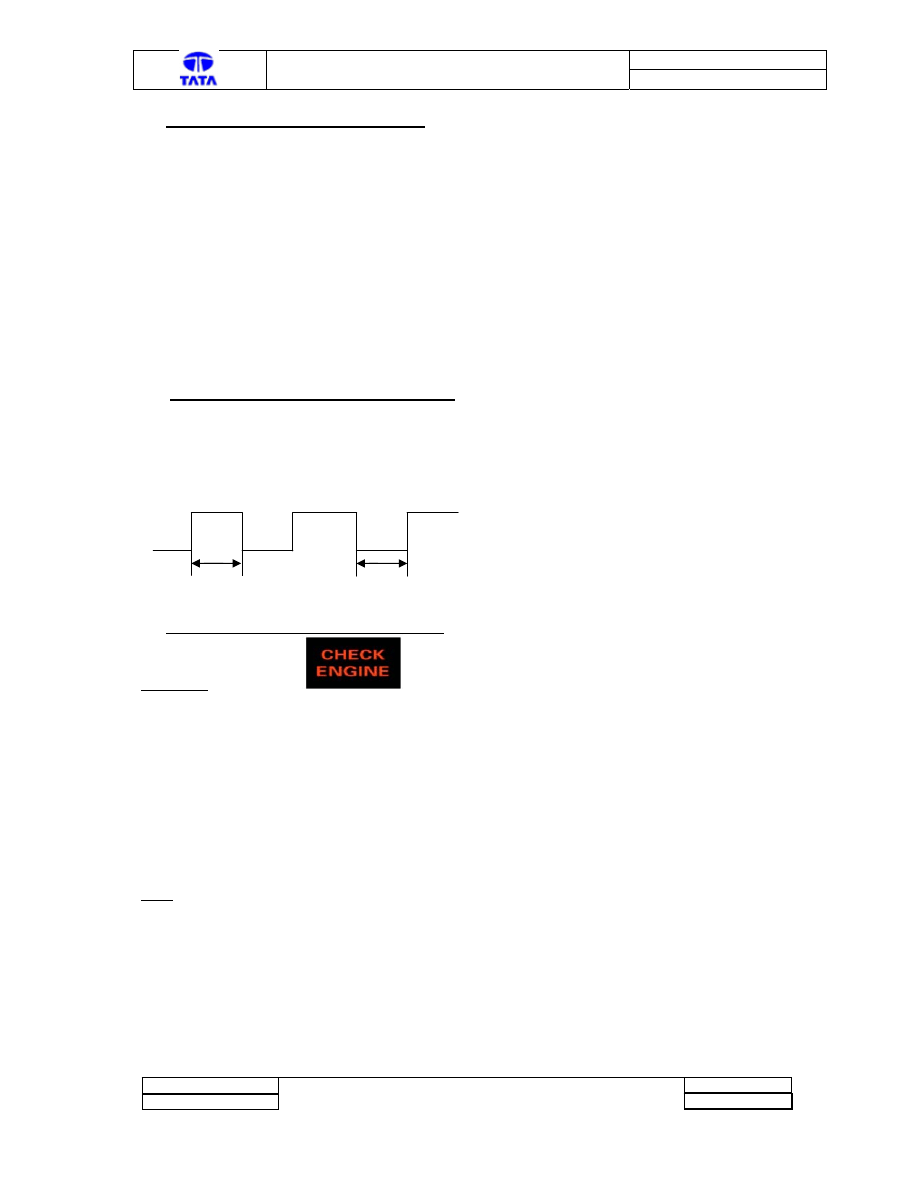

2.2 Operational mode : No fault indication

- CE lamp flashes as given below, if Diagnostics is enabled.

- CE lamp is OFF if Diagnostics is not enabled (See Fig 1)

Fig 1

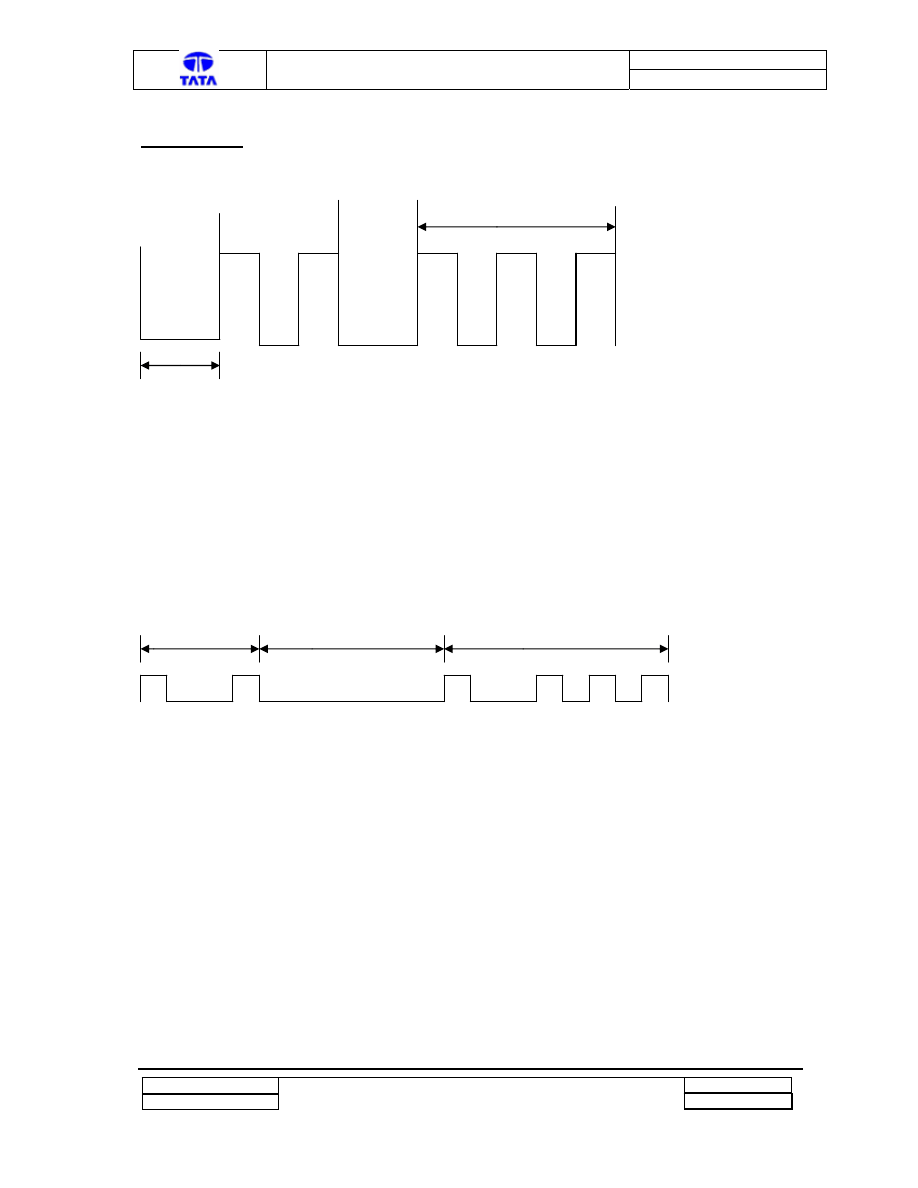

2.3 Operational mode : Fault indication

- This lamp is ON to indicate fault, if Diagnostics is not enabled.

- Fault code is indicated on CE lamp in pattern given below,

Corresponding to fault logged by controller. Each code consists

of 2 non- zero decimal digits (digit of ten & of one) ,if Diagnostics

is enabled.

- If there are more codes, then CE lamp remains off for 3 sec.

between each flashing code.

- Table a side indicates list of faults & flash codes.

- Fig 2. below indicates fault code = 23.

Note : In case of any fault switch Off and On Ignition

and if fault persists investigate further

Lamp ON

Lamp OFF

0.3s

0.3s

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 6 of 27

Author : TML

Dept : ERC-E&E

Flash Code 23.

Fig 2

2(tens)

3Seconds

2.4 Example of Two Simultaneous Faults

Two more faults can occur simultaneously. In that case each fault code is consecutively

displayed with a space of 3 seconds. Figure 3 shows a case where Fault code 11(Coolant sensor

open) and Fault code 13 Throttle pot open are present simultaneously. This sequence will repeat

till faults persist.

Fig 3

Fault code 11 3 Second Gap Fault Code 13

Lamp ON

Lamp OFF

3 (units)

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 7 of 27

Author : TML

Dept : ERC-E&E

3.0 Trouble-shooting with Fault Codes.

This section explains trouble-shooting procedure to be followed in response to each of the fault

code. This procedure is intended as guide-line only which cover most of the situations . However

depending on peculiarity of a given situation, the service technician will have to use his

judgement and discretion.

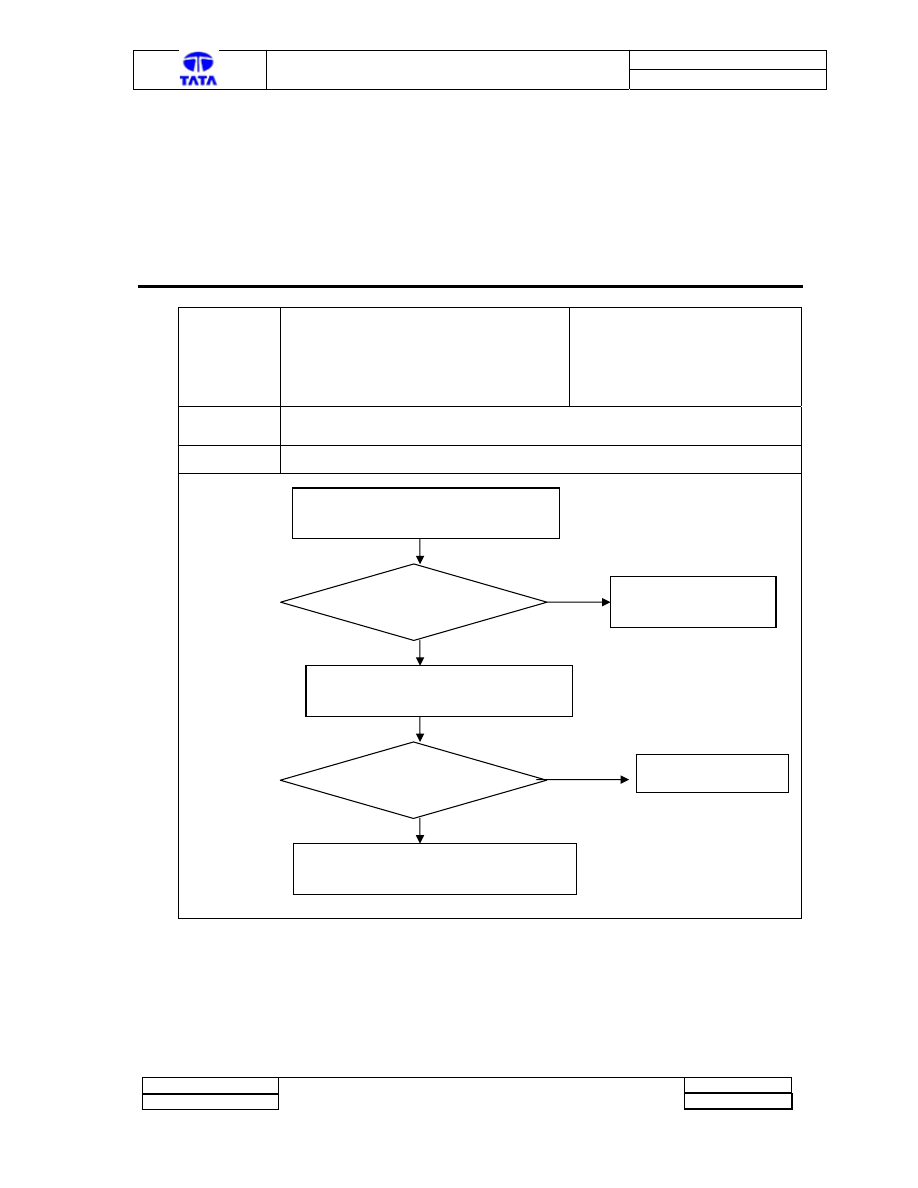

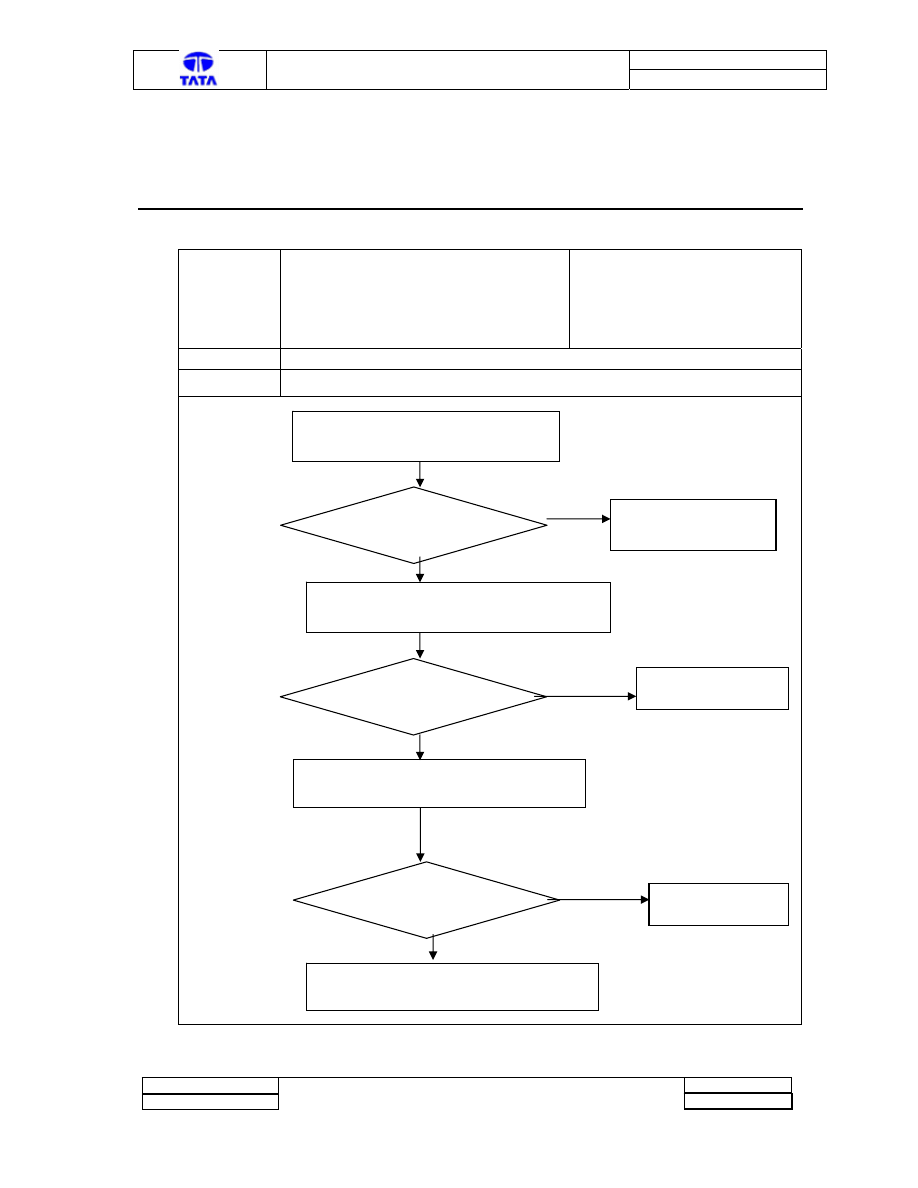

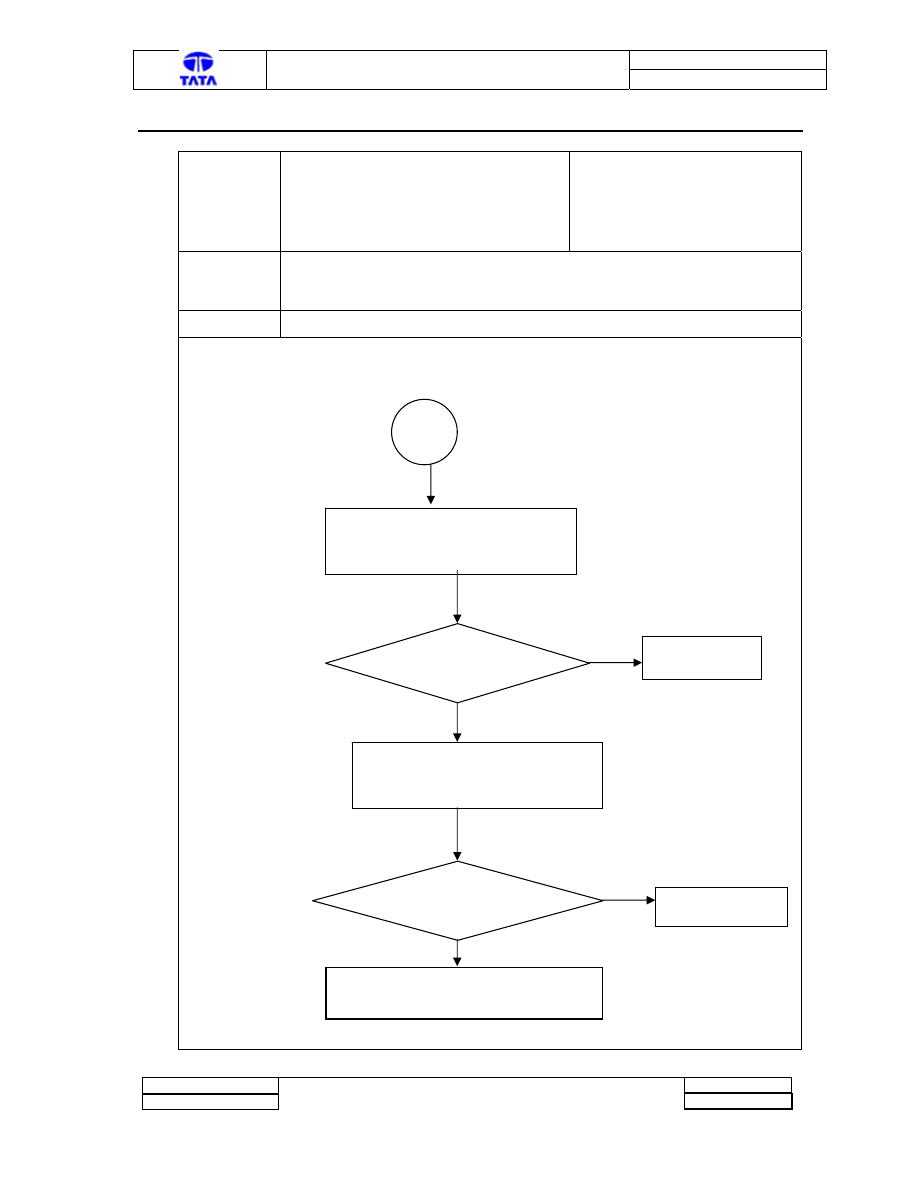

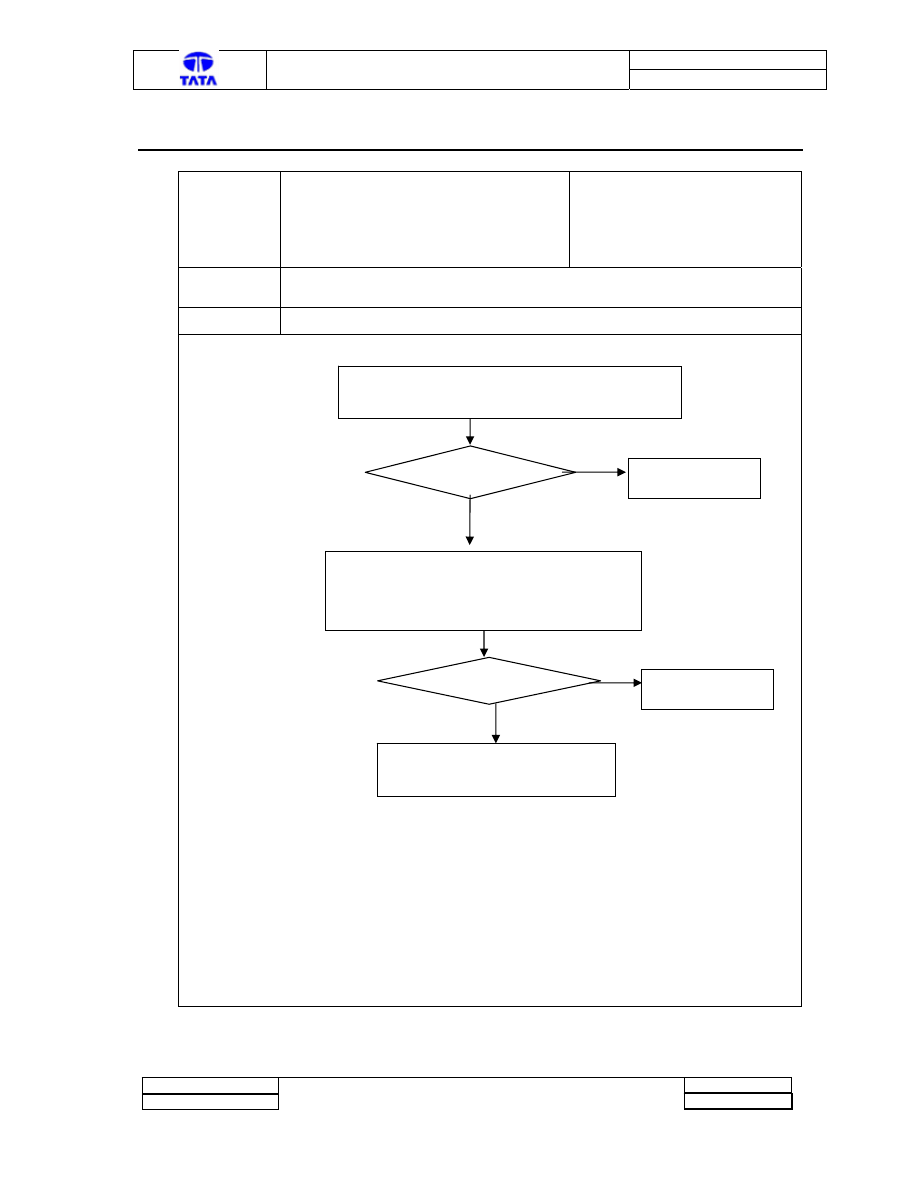

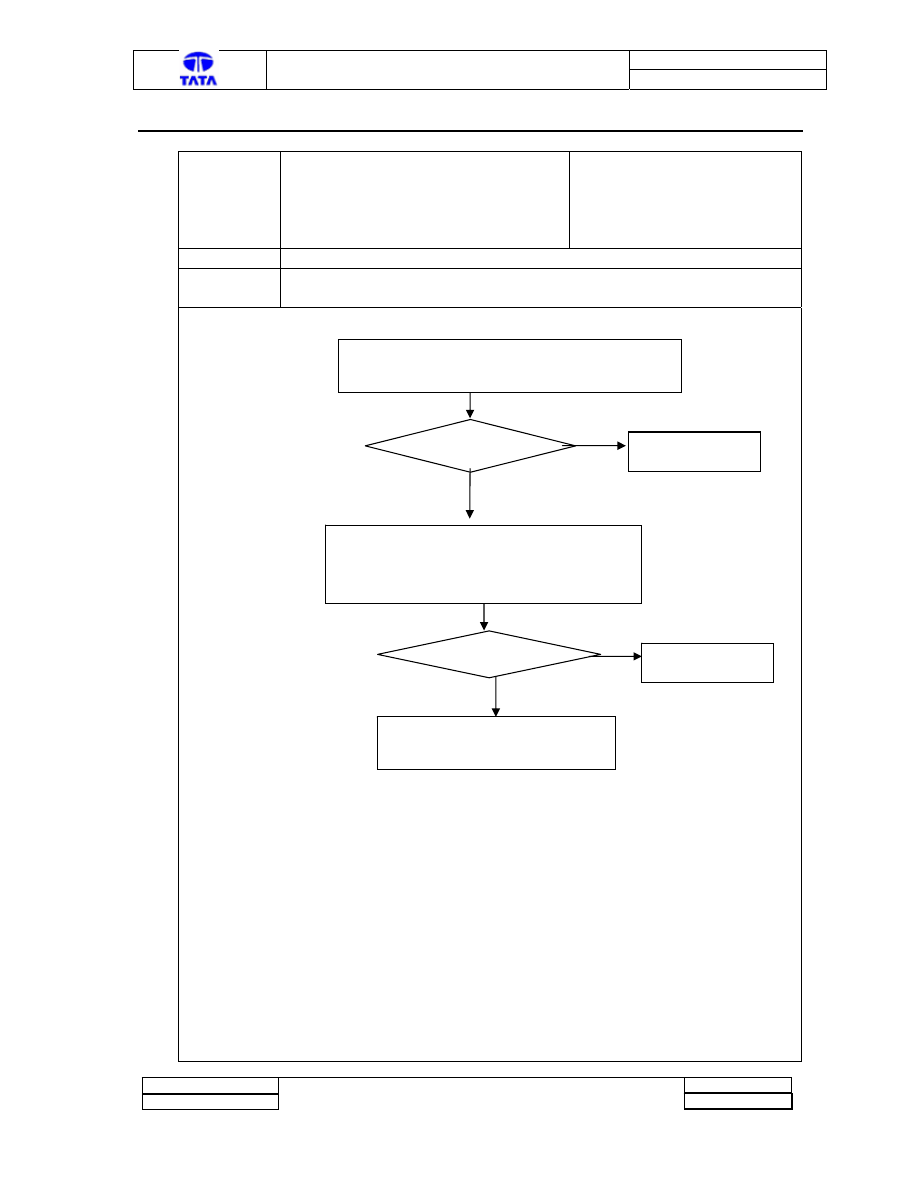

3.1 FAULT 11:

Fault code

11

Description

Coolant Temperature Sensor Open

Classification

Major

Detection

Value supplied by coolant temperature sensor is

Above allowable limit

Symptoms Emissions

(smoke).unsteady

idle

Checks:

Yes

No

Yes

Note 1: Resistance value varies as per coolant temperature. Generally this value should be few

kilo-ohms at temperatures above 40deg. At extreme low temperature this value reaches

100Kohm. Any value more than 100K and less than 500 ohms indicates resistance problem.

Connection

Problem

?

Check the sensor and AECU Connections

Rectify Connection

Problem

Measure Resistance between Sensor

Terminals

Resistance

Problem

?

Change the Sensor

Change AECU and re-confirm that the fault

does not persist.

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 8 of 27

Author : TML

Dept : ERC-E&E

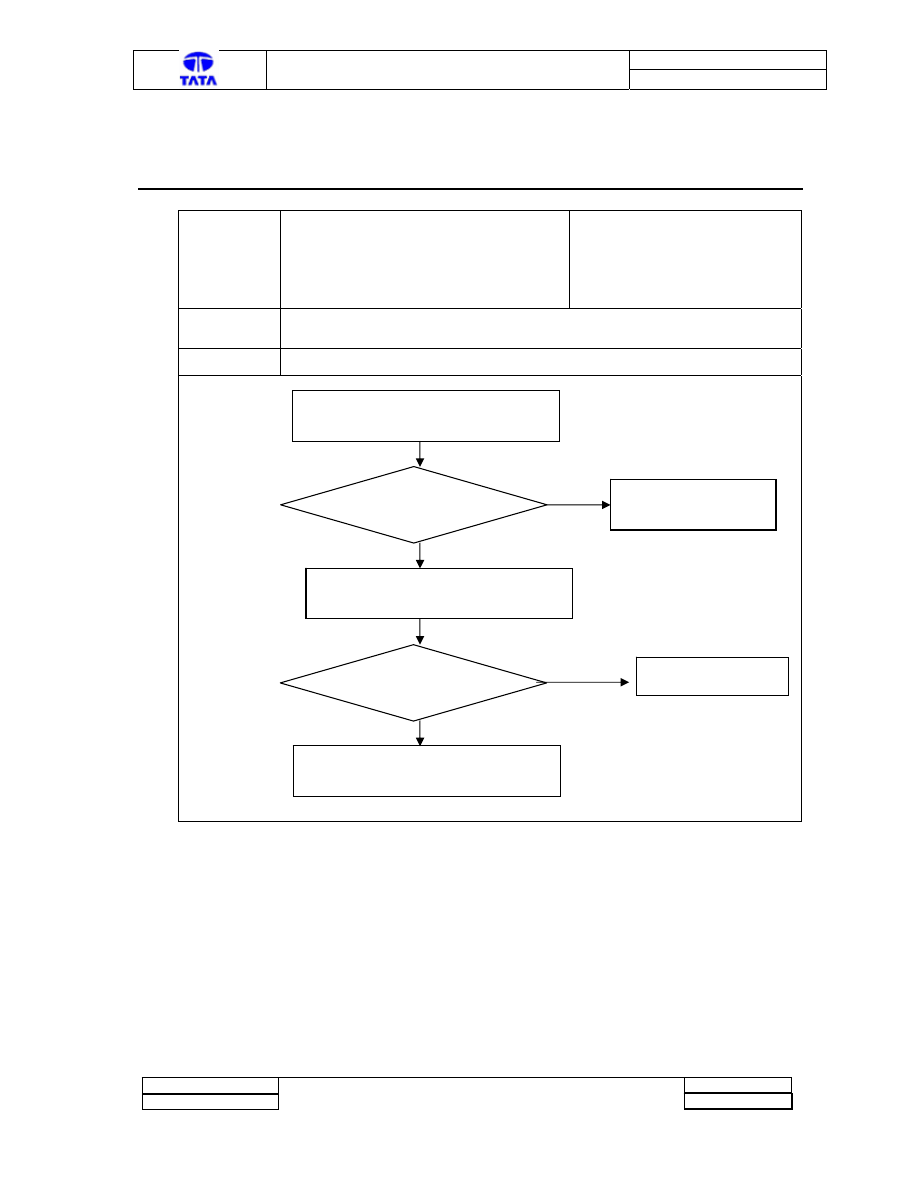

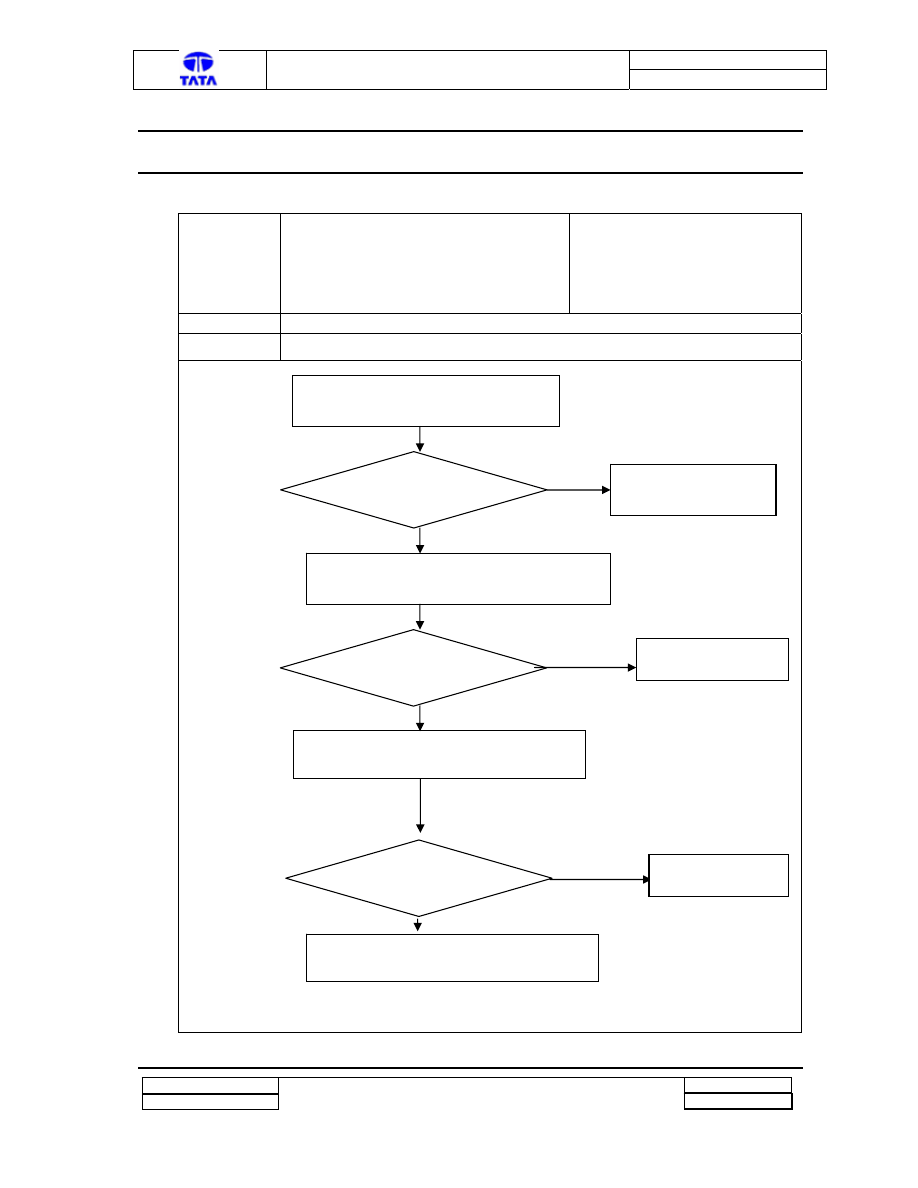

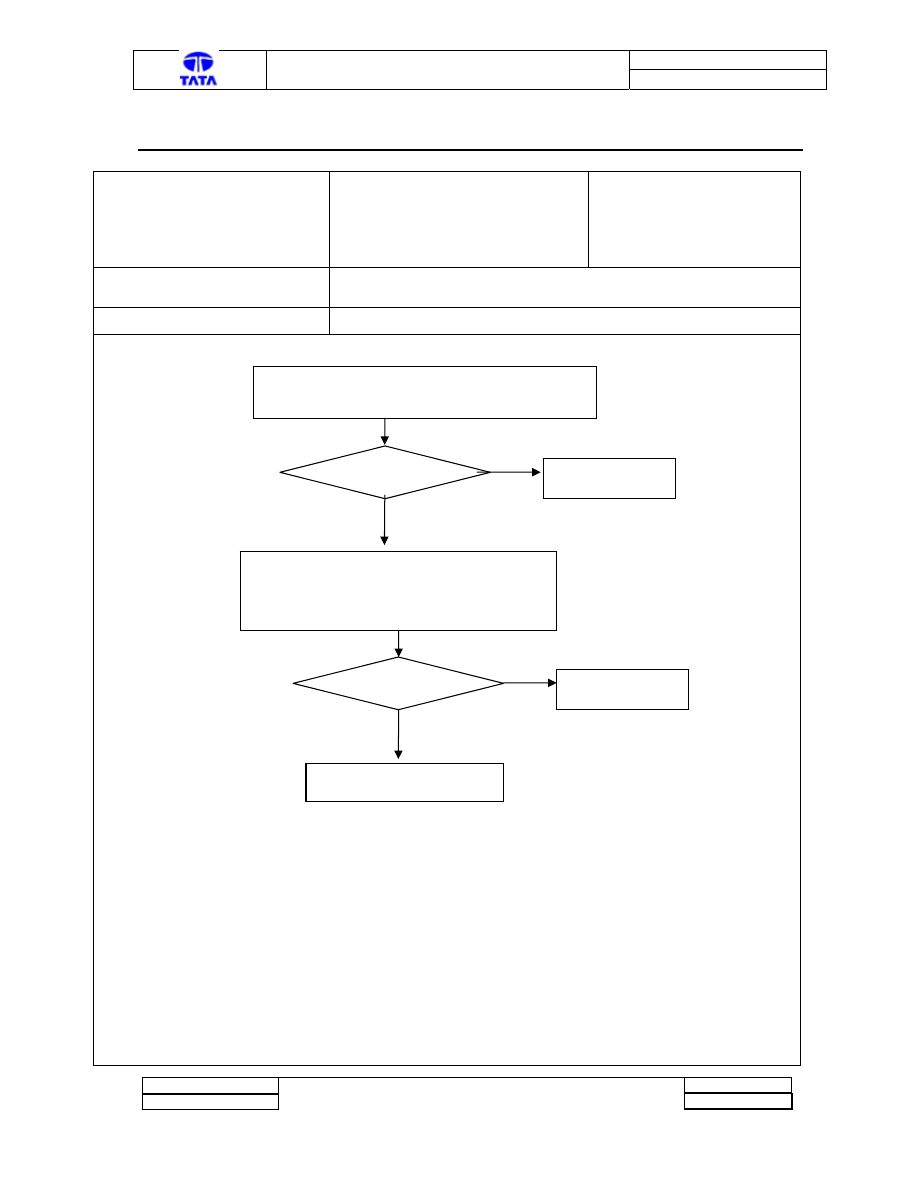

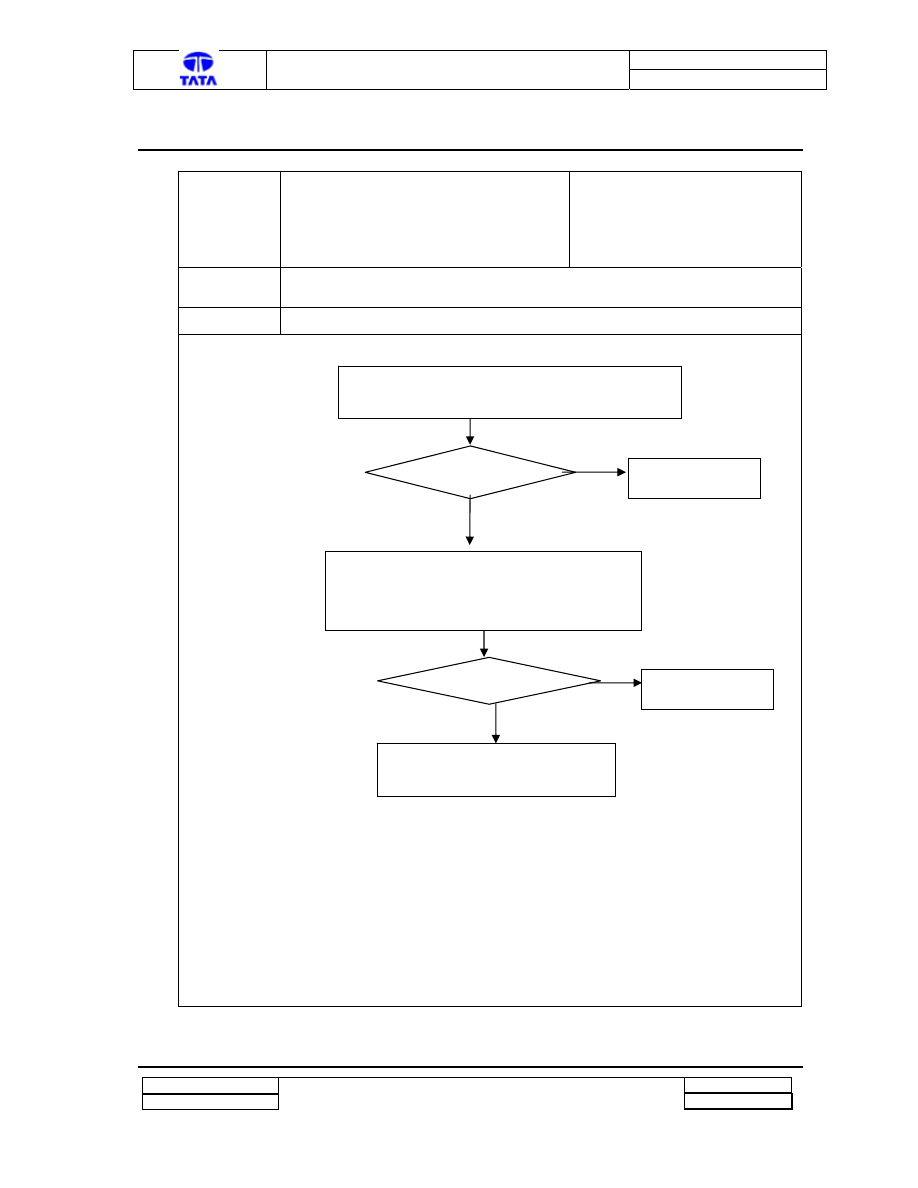

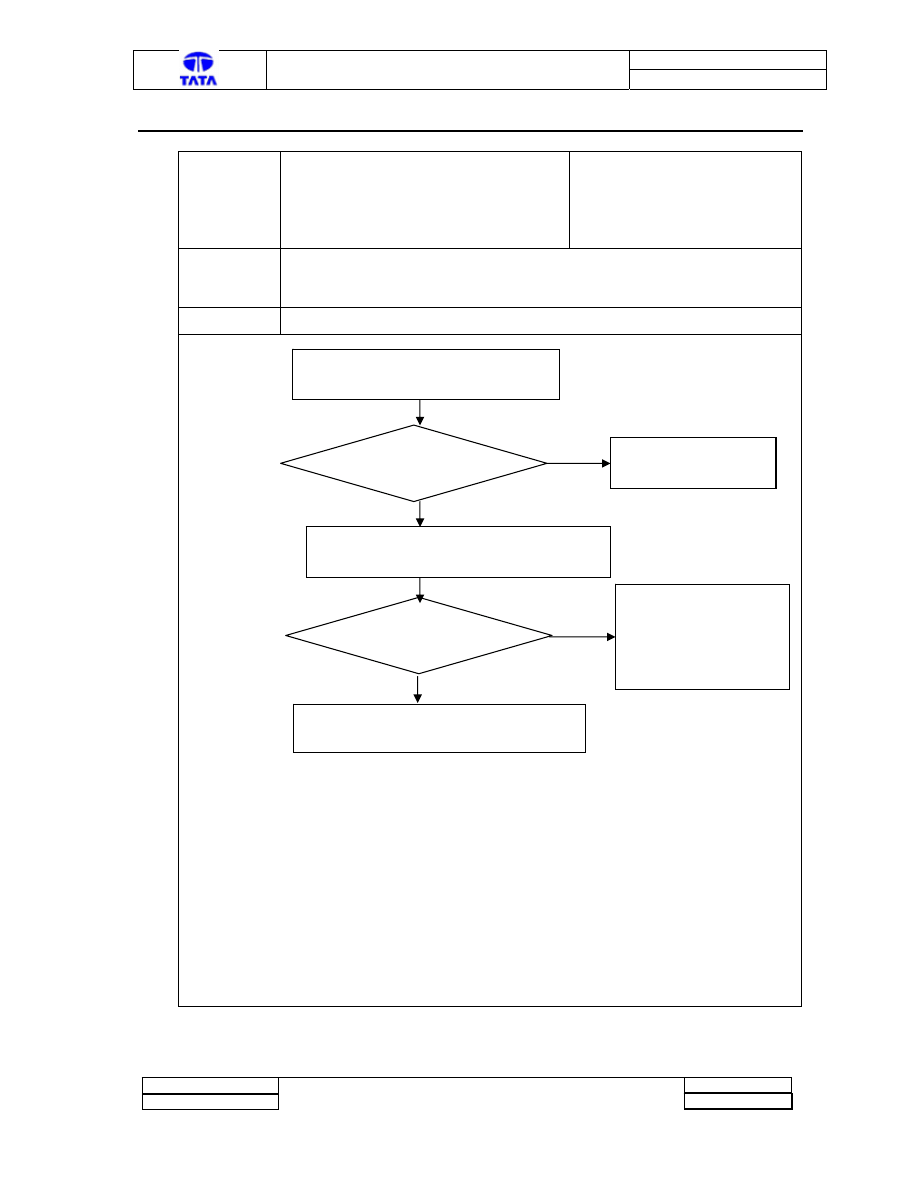

3.1 FAULT 12

Fault code

12

Description

Coolant Temperature Sensor Short

Classification

Major

Detection

Value supplied by coolant temperature sensor is

below allowable limit (See Note 1)

Symptoms Emissions

(smoke).unsteady

idle

Checks:

Yes

No

See Note 1

Yes

Note 1: Resistance value varies as per coolant temperature. Generally this value should be few kilo-ohms at temperatures above 40deg. At

extreme low temperature this value reaches 100Kohm. Any value more than 100K and less than 500 ohms indicates resistance problem

Connection

Problem

?

Check the sensor and AECU Connections

Rectify Connection

Problem

Measure Resistance between Sensor

Terminals

Resistance

Problem

?

Change the Sensor

Change AECU and re-confirm that the

fault does not persist

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 9 of 27

Author : TML

Dept : ERC-E&E

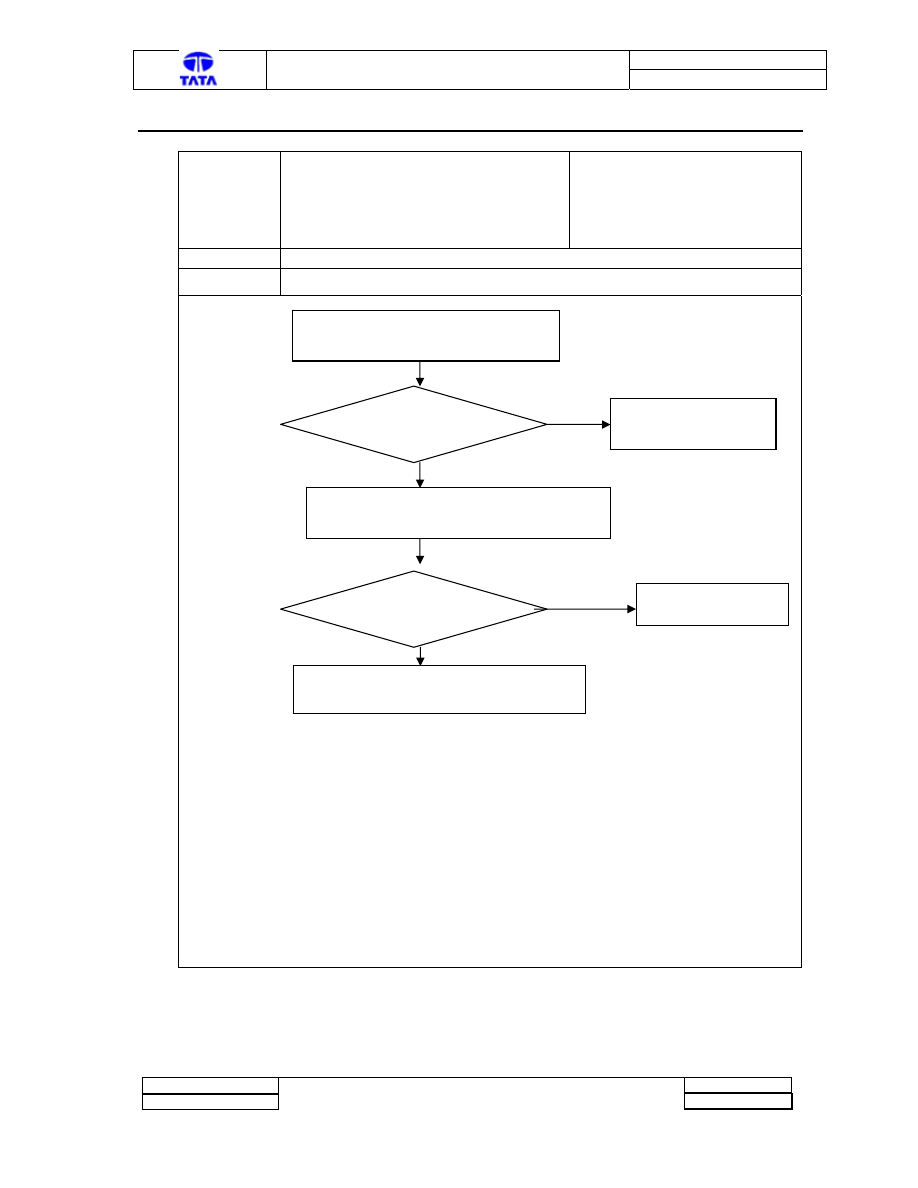

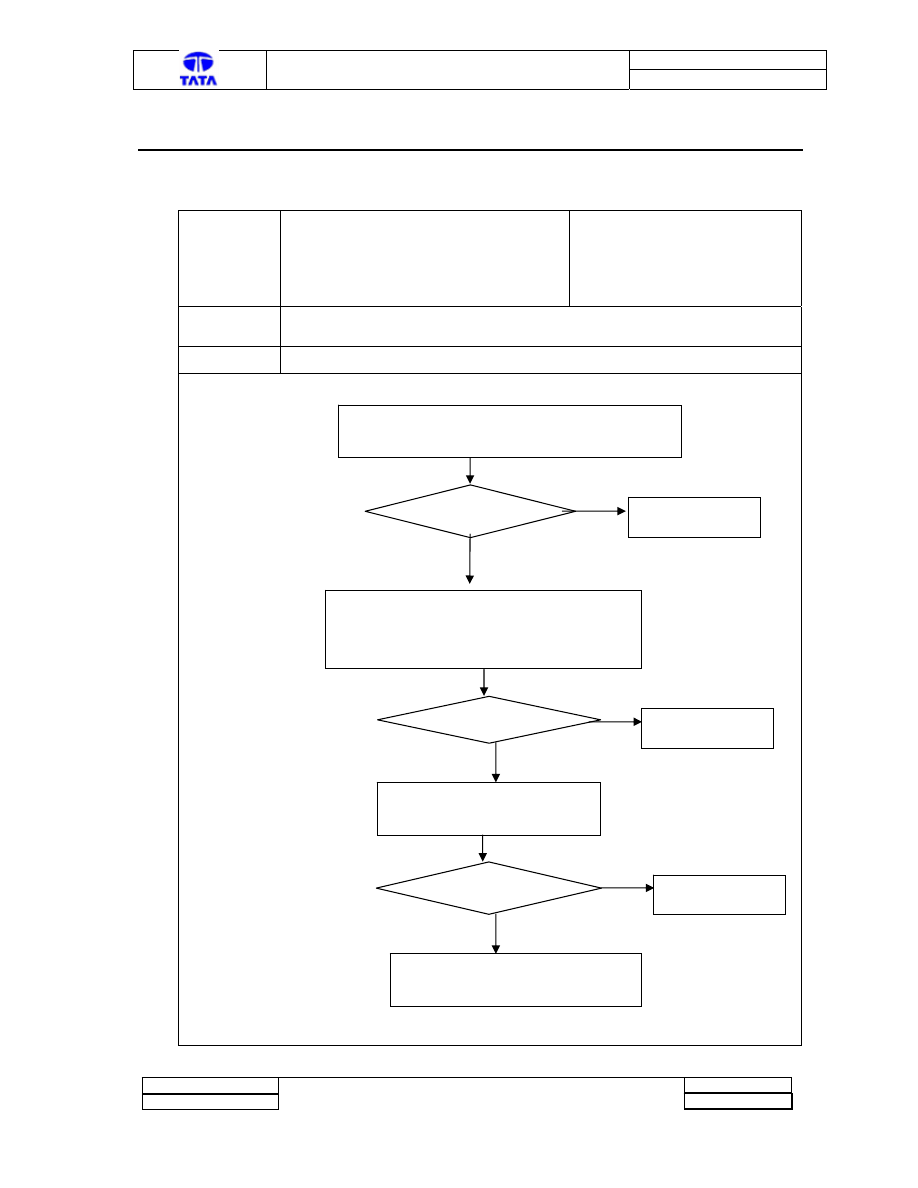

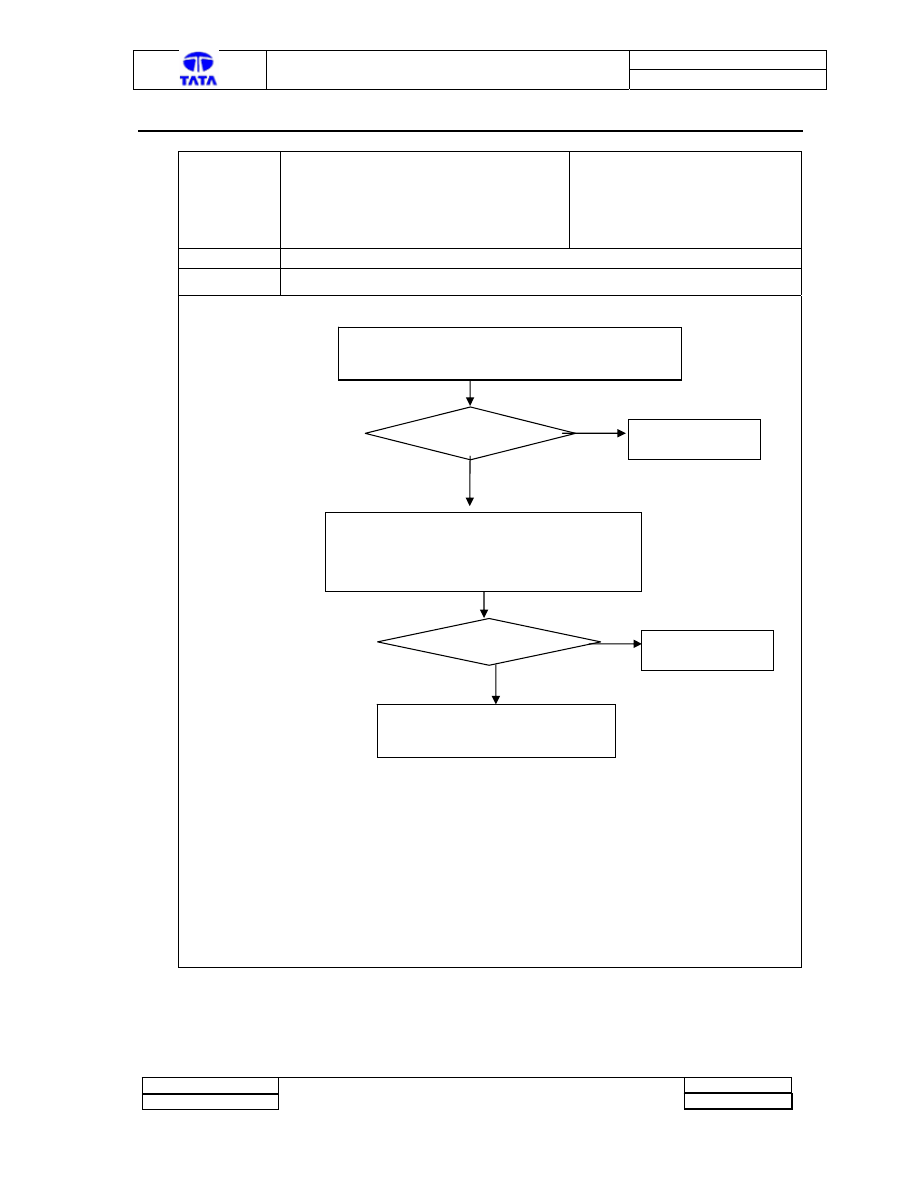

3.3 Fault Code 13

Fault code

13

Description

Throttle Lever Pot. Center/Supply point

open

Classification

Major

Detection

Throttle value read by AECU is below expected limit (See Note 1)

Symptoms

Emissions (smoke), Less pick-up during take-off with AC-on.

Checks:

See Note 1

Yes

No

Yes

No

Yes

No

Note 1: Resistance value depends on the throttle model used. Generally this value should be in the range of a few kilo-ohms

Resistance

Problem

?

Measure resistance between throttle

terminal 1 & 3 and 2 & 3

Change the throttle pot.

Measure voltage at AECU connector pins X1.13 to X1.12

Voltage should increase during acceleration (from 0.7 to 4.0

Volts)

Voltage

Problem?

Check the supply to

the sensor

Check AECU and Throttle Pot connections.

Connection

Problem?

Make necessary

repairs

Change AECU and re-confirm that

the fault does not persist

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 10 of 27

Author : TML

Dept : ERC-E&E

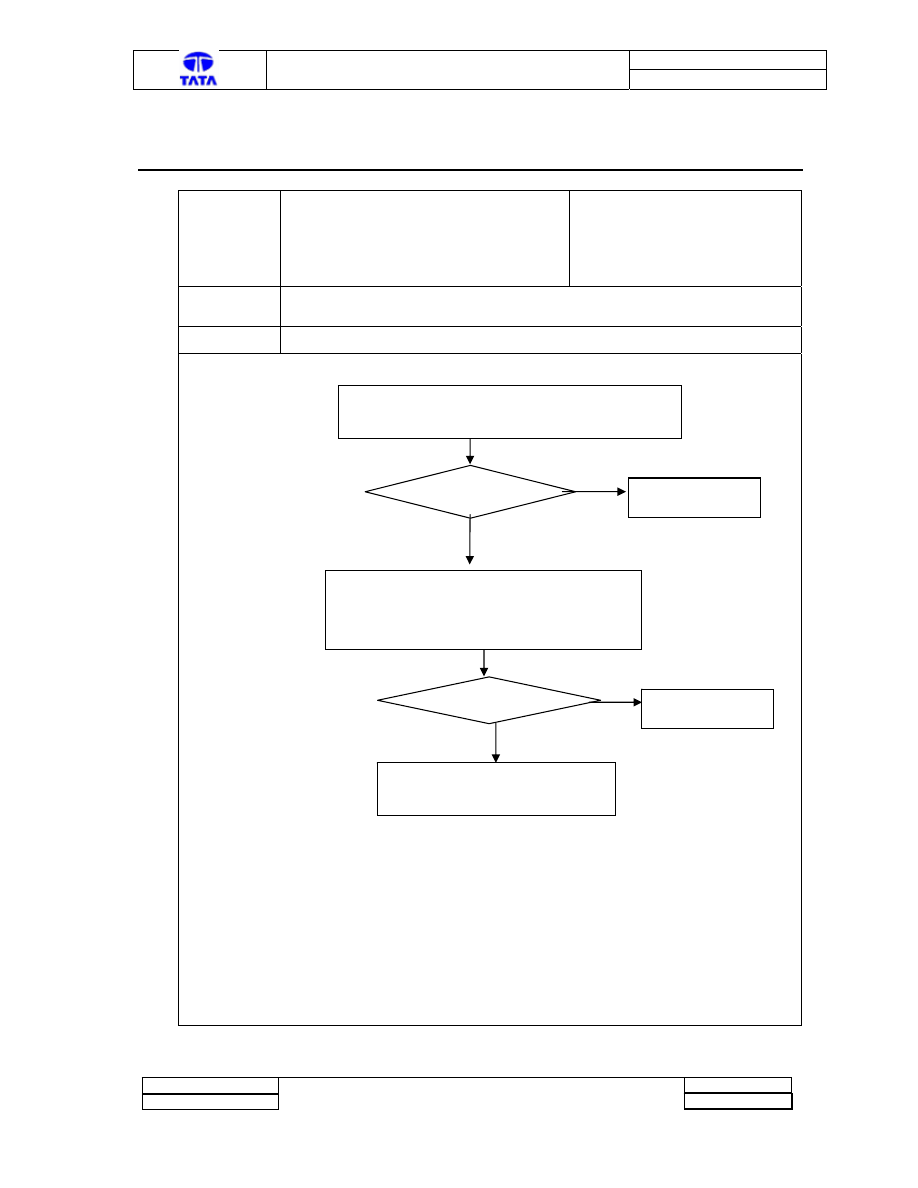

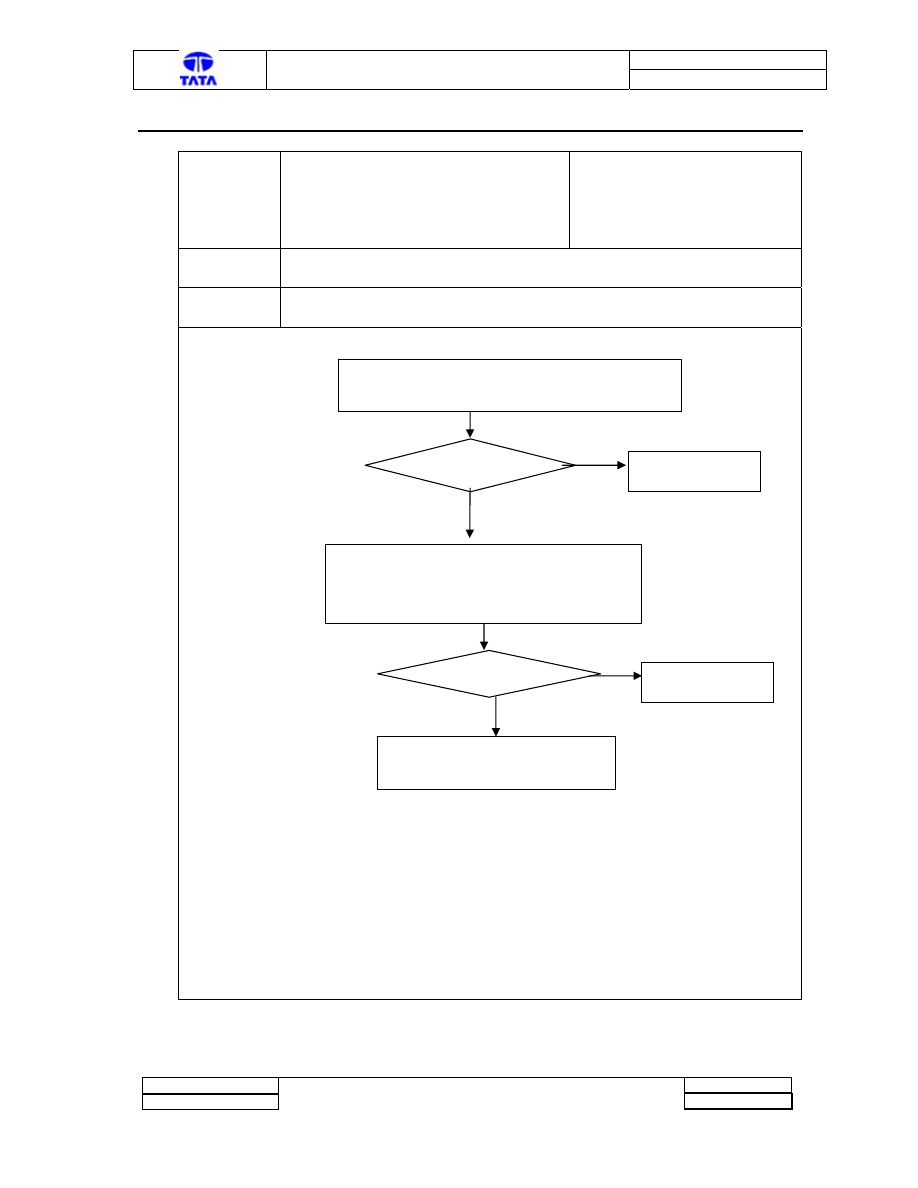

3.4 Fault Code 14

Fault code

14

Description

Throttle Lever Pot. Ground point open

Classification

Major

Detection

Throttle value read by AECU is above expected limit

Symptoms

Emissions (smoke), Less pick-up during take-off with AC-on.

Checks:

Yes

No

Yes

No

Yes

No

Note 1: Resistance value depends on the throttle model used. Generally this value should be in the range of a few kilo-ohms

Resistance

Problem

?

Measure resistance between throttle

terminal 1 & 3 and 2 & 3

Change the throttle pot.

Measure voltage at AECU connector pins X1.13 to X1.12

Voltage should increase during acceleration (from 0.7 to 3.8

Volts)

Voltage

Problem?

Check the supply to

the sensor

Check AECU and Throttle Pot connections.

Connection

Problem?

Make necessary

repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 11 of 27

Author : TML

Dept : ERC-E&E

3.5 Fault Code 15

Fault code

15

Description

Loss of RPM signal

Classification

Major

Detection

RPM signal not sensed by AECU after one minute from cranking

Symptoms

Emissions (smoke), Less pick-up during take-off with AC-on.

Checks:

Yes

No

Yes

No

Connection

Problem?

Check connections with alternator “W”

terminal

Make necessary repairs.

Measure the pulse waveform at AECU connector terminal

X1.7 (connector with black housing)

Alternator signal

problem

?

Change the Alternator

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 12 of 27

Author : TML

Dept : ERC-E&E

3.6 Fault Code 16

Fault code

16

Description

Glow-plug Interface Unit/Glow-plug faulty or

Glow-Plug On command or feedback wire

open

Classification

Major

Detection

1. Engine does not start after switching on glow-plugs.

2.AECU does not receive feedback for relay on after issuing “GP on

command”

Symptoms

Emissions (smoke), Starting trouble

Checks:

Yes

No

Yes

No

Voltage Problem?

Check voltage at AECU connector pin

X2.2 with ignition on. (<8Volt)

Measure Voltage appearing across Glow-plugs at ignition on

Glow-plug voltage =

Battery Voltage?

Change the Glow-plug if

engine is not cranking

This is due to connection problem.

Check connections from GPIU to glow-plug

A

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 13 of 27

Author : TML

Dept : ERC-E&E

3.6 Fault code 16 (contd..)

Fault code

16

(Contd..)

Description

Glow-plug Interface Unit/Glow-plug

faulty or GP On command or feedback

wire open

Classification

Major

Detection

1.0 Engine does not start after switching on glow-plugs.

2.0AECU does not receive feedback for relay on after issuing “GP on

command”

Symptoms

Emissions (smoke), Starting trouble

Checks: (Contd..)

Feedback Voltage from GPIU Not Ok

Yes

No

No

Yes

A

Voltage Ok?

Measure Voltage between pin 4

and Pin 2 of GPIU at ignition on

(It should be <0.8 Volts)

Change GPIU

Voltage Ok?

Measure Voltage At AECU

connector x2.13 at ignition on (It

should be <0.8 Volts)

Change AECU

This is a connection problem Check

Aecu to GPIU connection and rectify

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 14 of 27

Author : TML

Dept : ERC-E&E

3.7 Fault Code 17

Fault code

17

Description

Glow-plug Relay Stuck

Classification

Major

Detection

Detected if “Glow-Plug relay on “ feedback persists after removal

of command

Symptoms

Emission (Smoke), Battery Charge Balance Problems

Checks:

Yes

No

No

Yes

Check Voltage GP command signal from AECU (x2.13)

when the fault is flashing . Expected Voltage > 8Volt

Voltage Problem?

Measure voltage at AECU Gp-feedback input

(Expected Voltage <0.8 volts)

Change AECU

Voltage Problem?

Change GPIU

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 15 of 27

Author : TML

Dept : ERC-E&E

3.8 Fault Code 18

Fault code

18

Description

Glow-plug Relay Command Line

Shorted to Supply

Classification

Major

Detection

Detected if Glow-Plug Command Line is sensed as “shorted to supply” by

AECU

Symptoms

Emission(smoke), Starting Problems

Checks:

No

Yes

No

Yes

No

Yes

Check Voltage GP command signal from AECU (x2.13)

at ignition on. Expected Voltage <0. 8Volt

Voltage Problem?

Switch off ignition and Unplug GPIU

Carry out cold check of the harness connection at

AECU pin x2.13 to see if short to supply still exists

Change AECU

Still short to supply?

Unplug AECU x2 connector and

re-check if short to supply exists

Change GPIU

Still short to supply?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 16 of 27

Author : TML

Dept : ERC-E&E

3.9 Fault Code 21

Fault code

21

Description

Glow-plug Lamp (Pre-heat) shorted to

supply

Classification

Minor

Detection

Detected if Glow-plug Lamp (Pre-heat)output is sensed as “shorted to

supply” by AECU

Symptoms

Pre-heat lamp does not glow at “ignition on”

Checks:

Yes

No

No

Yes

Check pre-heat lamp for possible short-circuit

Lamp Short?

Switch off ignition and Unplug AECU connector

Carry out cold check of the harness connection at

AECU pin x2.11 to see if short to supply still exists

Change Lamp

Still short to supply?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 17 of 27

Author : TML

Dept : ERC-E&E

3.10 Fault code 22

Fault code

22

Description

Glow-plug Lamp (Pre-heat) Open/wire

open

Classification

Minor

Detection

Detected if Gp Lamp (Pre-heat)output is sensed as “open circuit” by

AECU

Symptoms

Pre-heat lamp does not glow at “ignition on”

Checks:

Yes

No

Yes

No.

Check pre-heat lamp for possible open circuit

Lamp Open?

Check harness connections from AECU pin x2.11

to the lamp for a possible open circuit

Change Lamp

Connections are ok?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 18 of 27

Author : TML

Dept : ERC-E&E

3.11 Fault Code 23

Fault code

23

Description

AC Relay coil shorted to Supply

Classification

Minor

Detection

Detected if AC relay coil output is sensed as “shorted to supply” by

AECU

Symptoms Air-conditioning

cannot

switch-on.

Checks:

Yes

No

No

Yes

Check AC relay coil for possible short circuit.

Relay coil Short?

Switch off ignition and Unplug AECU connector

Carry out cold check of the harness connection at

AECU pin x2.12 to see if short to supply still exists

Change AC relay

Still short to supply?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 19 of 27

Author : TML

Dept : ERC-E&E

3.12 FAULT CODE 24

Fault code

24

Description

AC Relay coil Open/wire open

Classification

Minor

Detection

Detected if AC relay coil output is sensed as “open circuit” by AECU

Symptoms

Air-conditioning cannot be switched on

Checks:

Yes

No

Yes

No.

Check AC relay coil for possible open circuit

Relay Open?

Check harness connections from AECU pin x2.12

to the AC relay coil for a possible open circuit

Change Relay

Connections are ok?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 20 of 27

Author : TML

Dept : ERC-E&E

3.13 FAULT CODE 27

Fault code

27

Description

“Fan-Series” Relay coil shorted to

Supply

Classification

Major

Detection

Detected if “Fan-Series” relay output is sensed as “shorted to supply” by

AECU

Symptoms

Low-speed Operation of Fans not possible. NVH may increase

accompanied with possible charge balance problems.

Checks:

Yes

No

No

Yes

Check “Fan-Series” relay for possible short circuit.

Relay coil Short?

Switch off ignition and Unplug AECU connector

Carry out cold check of the harness connection at

AECU pin x1.15 to see if short to supply still exists

Change the relay

Still short to supply?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 21 of 27

Author : TML

Dept : ERC-E&E

3.14 Fault Code 28

Fault code

28

Description

“Fan-series Relay” coil Open/wire open

Classification

Major

Detection

Detected if fan-series relay coil is sensed as “open circuit” by AECU

Symptoms

Low-speed Operation of Fans not possible. NVH may increase

accompanied with possible charge balance problems.

Checks:

Yes

No

Yes

No.

Check “Fan-Series” relay coil for possible open circuit

Relay Open?

Check harness connections from AECU pin x1.15

to the AC relay coil for a possible open circuit

Change Relay

Connections are ok?

This is a Harness connection problem.

Carry out necessary repairs

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 22 of 27

Author : TML

Dept : ERC-E&E

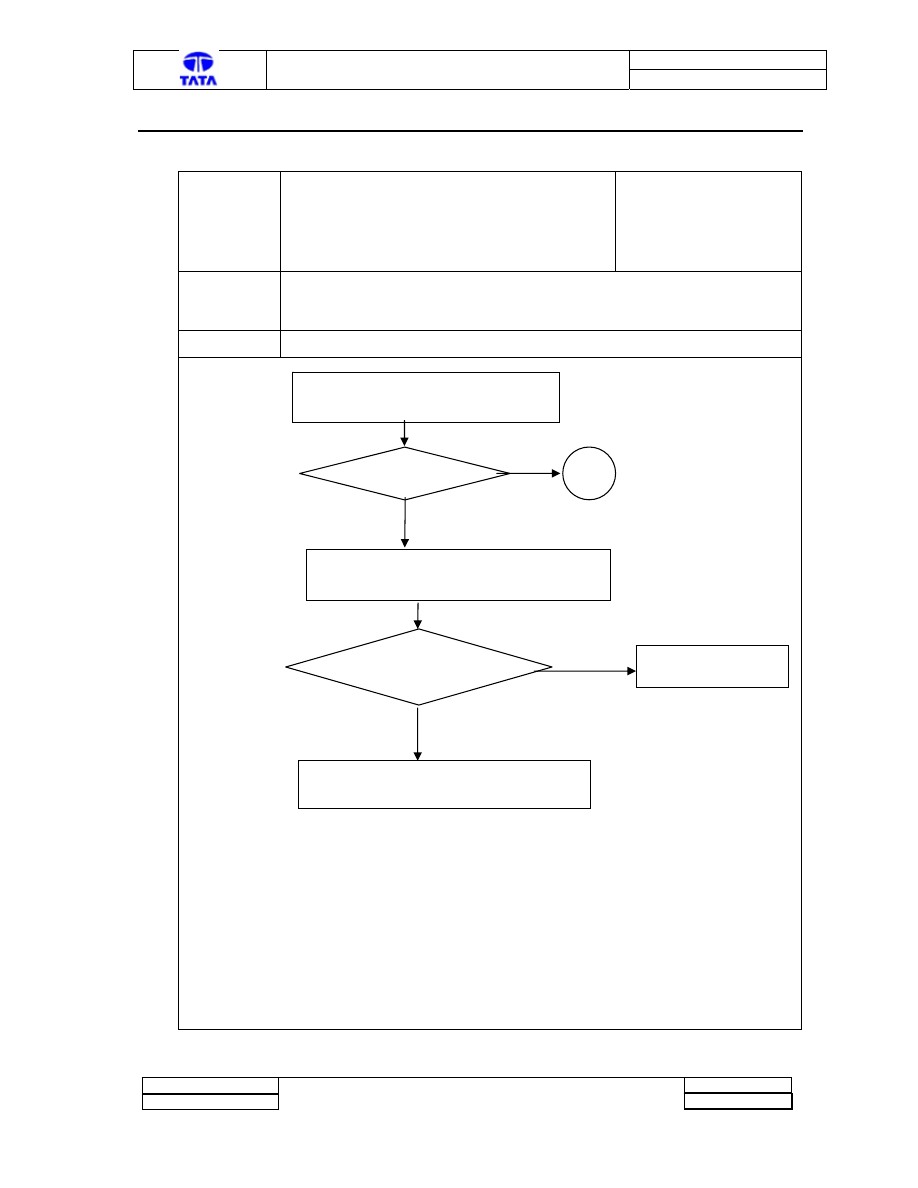

3.15 Fault code 29

Fault code

29

Description

Throttle Lever Pot. Wrong connections

Classification

Major

Detection

Throttle value read by AECU at ignition on is more than 2.5 Volt

(This also occurs if the throttle is pressed during cranking See Note 1

below)

Symptoms

Emissions (smoke), Less pick-up during take-off with AC-on.

Checks:

Yes

No

Yes

No

Note 1: The customer is not supposed to press throttle before and during cranking the engine. Otherwise

fault code number 29 will be issued. AECU based system uses mechanical fuel-injection system. Hence

fuel will be injected during cranking if throttle is pressed at the time of cranking causing smoke. HENCE

PRESSING THROTTLE DURING CRANKING IS NOT RECOMMENDED.

Resistance

Problem

?

Measure resistance between throttle

terminal 1 & 3 and 2 & 3

Change the throttle pot.

Measure voltage at AECU connector pins X1.13 to X1.12 at

the time of ignition on. Voltage should be less than 0.8 volt

Voltage

Problem?

This a connection

problem. Most probably

connections to throttle

supply and ground are

reversed. Make necessary

repairs.

Change AECU

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 23 of 27

Author : TML

Dept : ERC-E&E

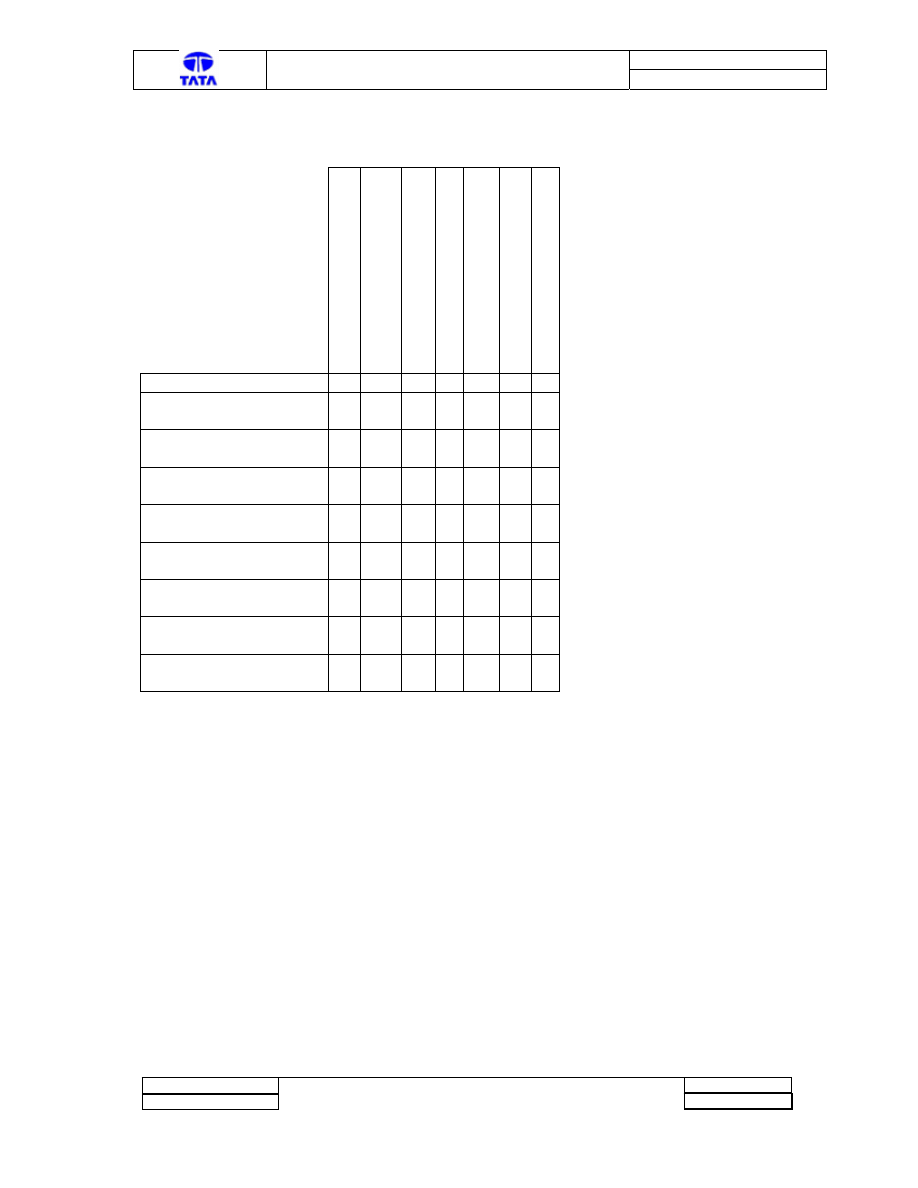

3.16 Table of Symptoms

Em

is

si

o

n

s

Slow To

Start/St

a

rting

Tro

uble

No

is

e

Air-c

o

n

d

ition

in

g off

Le

s

s

-P

ick

u

p

d

u

ring AC-on

B

a

tt

e

ry

Char

g

e

B

a

lanc

e

P

roblem

P

re

-H

eat Lamp Off

Fault

Coolant Sensor short/Open

x

Throttle Lever Potentiometer

Connections open/wrong

x

x

Loss of RPM signal

x

x

Glow-Plug/GPIU related

Problem

x

x

Glow-Plug Relay stuck

x

x

Glow-Plug Lamp short/Open

x

AC Relay coil short/open

x

Fan Series Relay open/short

x

x

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 24 of 27

Author : TML

Dept : ERC-E&E

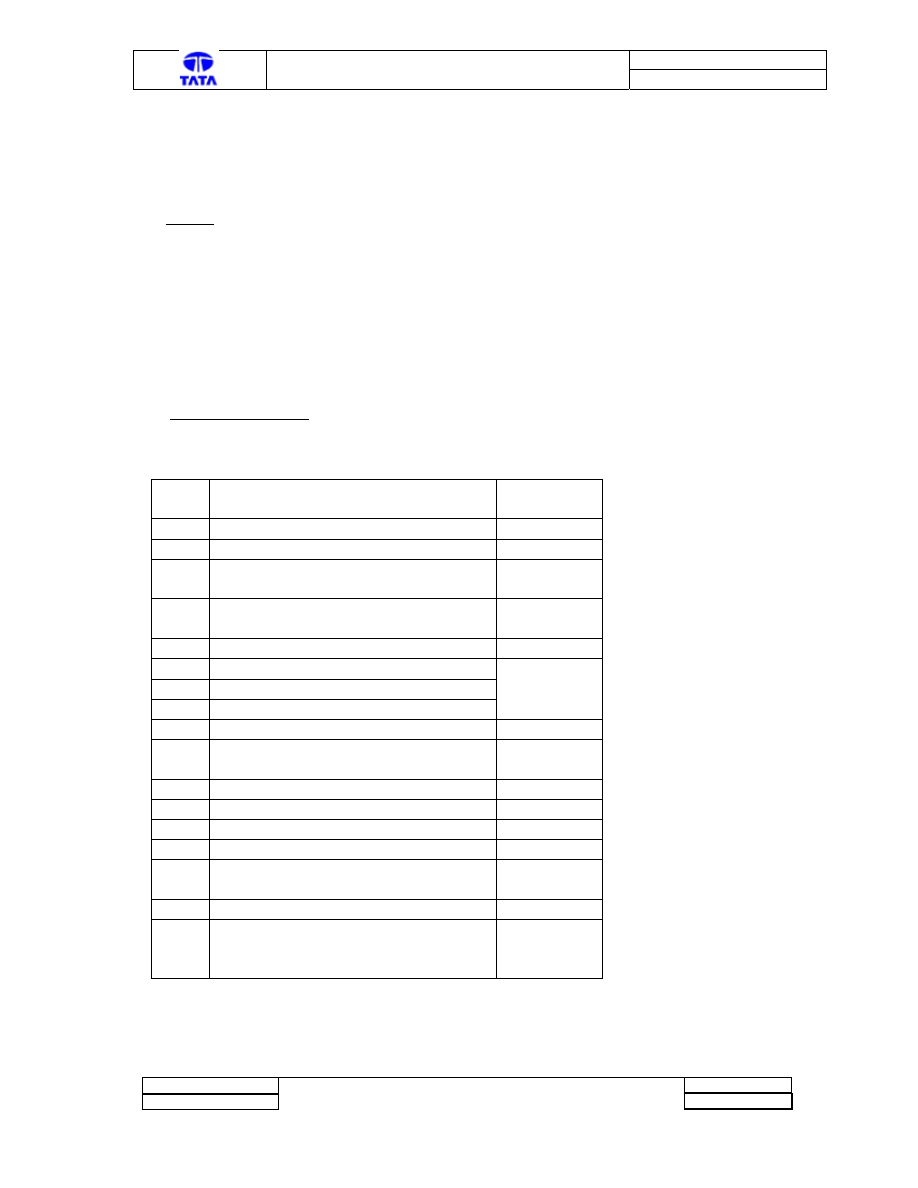

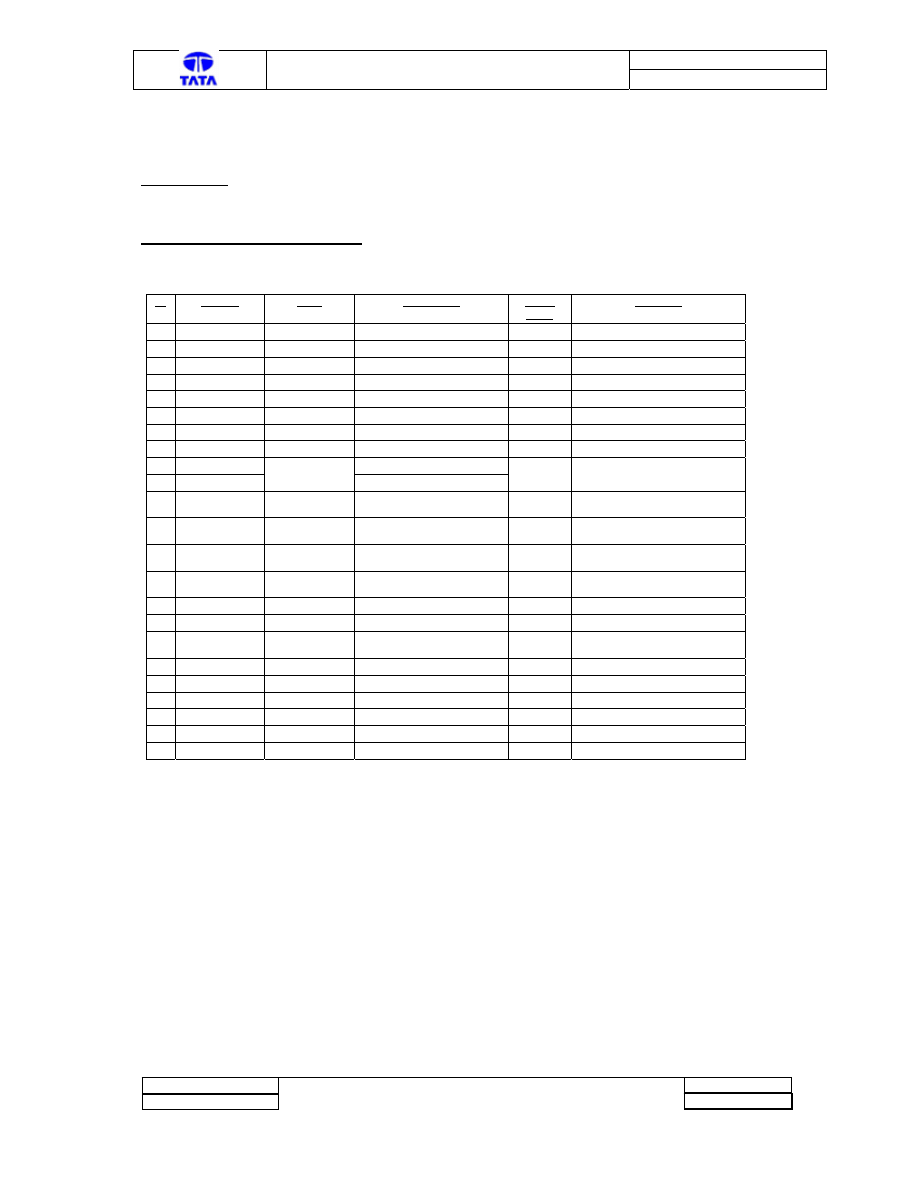

Appendix A

A-ECU Pin Out Configuration :

Sr Ter.

No Type Description Active

Level

Condition

1

X1.1, X 1.10

Supply

+ Supply for Controller

VCC

Permanent

2

X2.9, X2.18

Ground

- Supply for Controller

GND

Permanent

3 X2.1

Input

Crank

High

Engine

Cranked

4

X2.4

Input

Enable Diagnostics

Low

Enables Diag. Thro’ CE lamp

5

X2.7

Input

Air Conditioner ON

High

I/p from vehicle’s electrical ckt.

6

X2.2

Input

Glow Plug On Feedback

VCC

Glow Plug are ON

7

X2.5

Input

A/C present/absent

Low

Ac system absent

8

X1.4

Analogue I/p

Voltage=> GP Current

0-5Vdc

Voltage varies with Gpcurrent

9

X1.5

Coolant Temp. Sensor pin1

10 X2.9

Analogue I/p

Coolant Temp. Sensor pin2

11

X1.11

Output

Throttle position sensor

supply

5 V dc

Permanent

12

X1.12

Output

Throttle position sensor

Gnd

Gnd Permanent

13

X1.13

Analogue I/p

Throttle position sensor

Output

0-5 V dc

Voltage varies with throttle

position

14

X1.7

Input Pulses

Engine Speed signal from

alternator

High

Pulse

Pulses as per engine speed

15 X1.16

Output

Fans

In

Parallel

Low

Logical

condition

16 X1.15

Output

Fans

In

Series

Low

Logical

condition

17

X1.17

Output

EGR Solenoid

Low

Logical condition (A ECU

Temp. >-18

°C)

18 X1.18

Output

FICD

Solenoid

Low

Logical

condition

19

X2.11

Output

Pre-Heat Lamp

Low

Logical condition

20

X2.13

Output

Glow Plug On Command

Low

Logical condition

21

X2.10

Output

Check Engine Lamp

Low

Logical condition

22

X2.12

Output

Air Condition ON

Low

Logical condition

23 X2:17

Output

Cold

advance

Low

Logical

condition

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 25 of 27

Author : TML

Dept : ERC-E&E

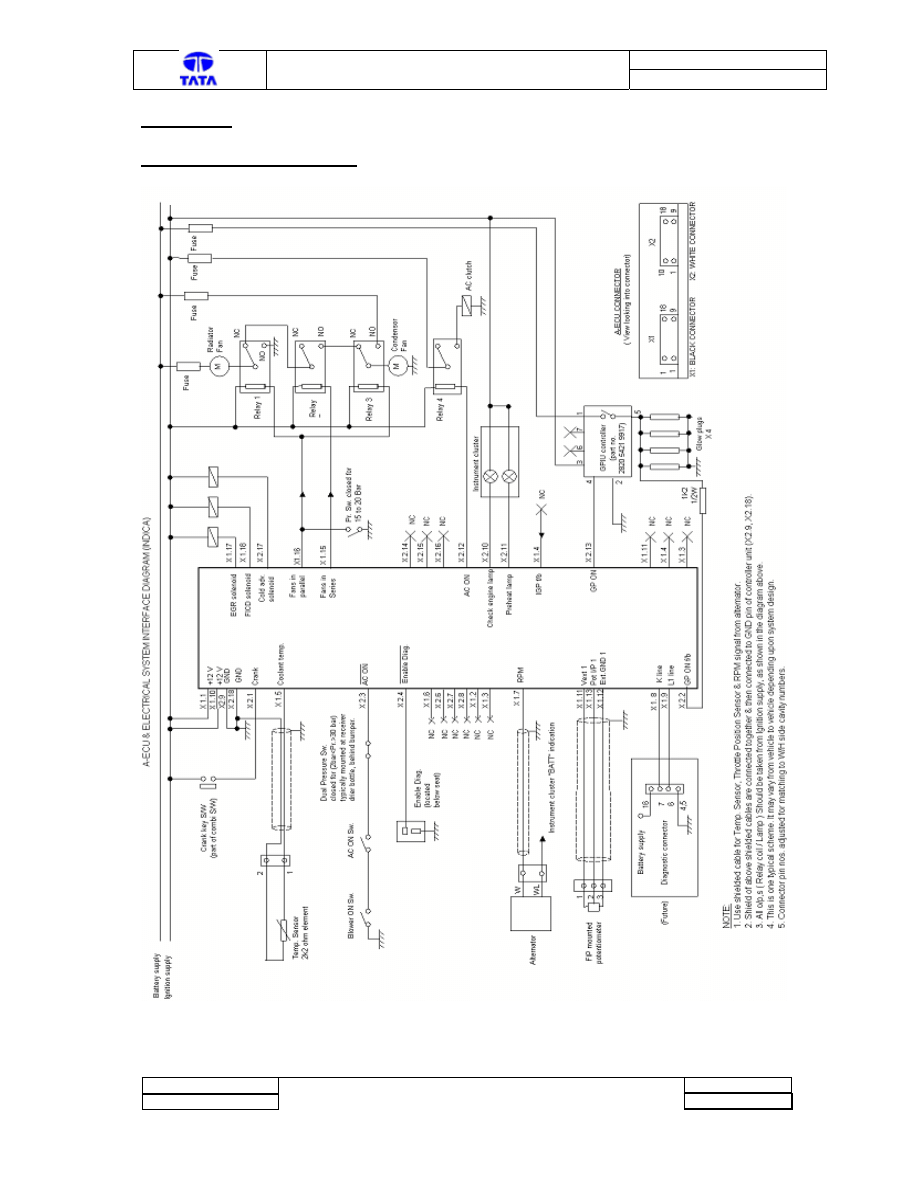

Appendix B:

Circuit schematic for A-ECU:

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 26 of 27

Author : TML

Dept : ERC-E&E

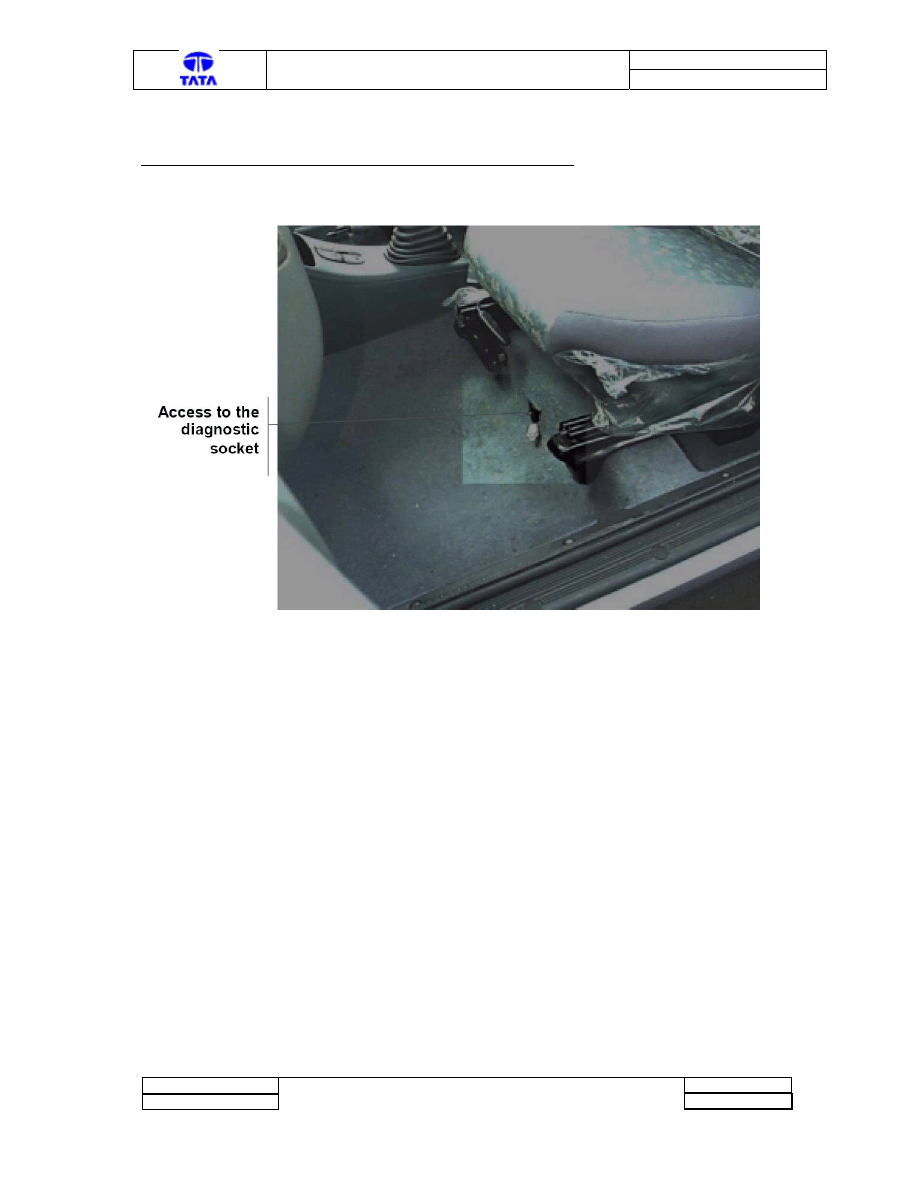

Appendix C

Location of Blink Code enable (2-Pole) Diagnostic Connector:

Doc. No. : 2101 2273 16 62

TML – Diagnostic Manual A-ECU

Version : 1

Project :

Copyright © with TATA MOTORS

This document must not be used in any way, such as copying and redistributing to third parties, without our consent

Page 27 of 27

Author : TML

Dept : ERC-E&E

END OF DOCUMENT

Wyszukiwarka

Podobne podstrony:

C5 (X7) D6AY01KAP0 9 23 07 2013 Pomoc w diagnostyce Manualna (mechaniczna) skrzynia biegów i sp

BCM Diagnosis Manual 0V2

CARPROG Opel ECU programmer user manual

Digital ECU Tuner III Manual

original c68 retail diy auto diagnostic tool manual

diagnostyka i techniki w terapii manualnej

zajęcia 1 techniki i diagnozy terapii manualnej-druk, terapia manualna

ECU Diagnostics

Techniki diagnozy i terapii manualnej

Diagnostyka usterek sprzęgła, - !!! SKRZYNIE BIIEGÓW AUTOMATYCZNE I MANUALNE !!! -

CARPROG Opel ECU programmer user manual

Digital ECU Tuner III Manual

original c68 retail diy auto diagnostic tool manual

The Merck Manual Objawy kliniczne Praktyczny przewodnik diagnost Kaminski Bogdan Klin Zuzanna Ksiad

Digital ECU Tuner II Manual(4)

Digital ECU Tuner III Manual

Digital ECU Tuner III FIT Manual

więcej podobnych podstron