!

"

#$%&'()(*%+%,

• -./

1

Index

35.0 Control Centre Fixed Type .................................................................................................... 2

35.1 General Characteristics......................................................................................................... 2

35.2 Arrangements........................................................................................................................ 3

35.3 Module Arrangements ........................................................................................................... 3

35.3.1 Module Fixed Type............................................................................................................. 3

35.3.2 Terminal Shield Cover with Moulded Case Circuit Breaker ............................................... 4

35.4 Rated current of main busbar system ................................................................................... 4

35.5 Vertical riser arrangements ................................................................................................... 5

35.5.1 Rated currents and short circuit strength ........................................................................... 5

35.5.2 Cross-sectional area of neutral conductor N...................................................................... 6

35.5.3 Cross-section of vertical protective conductor ................................................................... 7

35.5.4 De-ratings........................................................................................................................... 8

35.5.5 Power loss.......................................................................................................................... 8

35.6 Rigid busbar arrangement..................................................................................................... 9

35.6.1 Cross-sectional area of Rigid Busbars............................................................................... 9

35.6.2 Power Loss....................................................................................................................... 10

36.0 Standard configuration in Control Centre............................................................................ 11

36.1 Feeder Arrangement ........................................................................................................... 12

36.1.1 Feeder with Moulded Case Circuit Breaker ..................................................................... 12

36.1.3 Module sizes .................................................................................................................... 12

36.1.4 De-ratings......................................................................................................................... 13

36.1.5 Weights ............................................................................................................................ 13

36.1.6 Power Loss....................................................................................................................... 14

36.1.7 Arrangement for External Connections ............................................................................ 14

36.2. Motor-starter arrangements ............................................................................................... 15

36.2.1 Direct on line starter with protection fuse DIN type.......................................................... 15

36.2.2 Direct on line starter with protection fuse BS type ........................................................... 18

36.2.3 Direct on line starter with circuit breaker protection ......................................................... 19

36.2.4 Reverse motor-starter with protection fuse DIN type ....................................................... 22

36.2.5 Reverse motor-starter with protection fuse BS type ........................................................ 25

36.2.6 Reverse motor-starter with circuit breaker protection ...................................................... 26

2

35.0 Control Centre Fixed Type

35.1 General Characteristics

The principle of the Control Centre is similar to the Power Centre.

The Control Centre based on its functional units is:

Fixed Type Control Centre

– Cubicle Type C

For detail information see chapter 6.0 of base Technical Documentation 917180_00.

The Control Centre is subdivided in three functional zones:

Busbar zone

Equipment zone

Cable zone

The busbar zone is located at the rear of the column and contains the main horizontal and

vertical busbar system. Internal separation sheets are dividing the busbar zone from the

equipment and cable zone and are protecting the operator against contact with hazardous

parts. The standard equipment zone for the Fixed Type control centre is separated from the

cable zone by means of the Vertical Form Separation for complete section.

Busbar zone

The busbar zone can be equipped with maximal 2 main busbar systems. Standard positions are

the top and the middle position.

Provisions are taken as standard to couple the main busbar system to the main busbar system

in adjacent columns from the front.

Equipment zone – Fixed Type Control Centre

The effective stocking density in the equipment zone is 80E (1E=25mm). The standard

separation to the busbar zone is realised by means Mounting Plate used to mount the breaker

The standard way of mounting the electrical components in the equipment zone is by means of

steel carriers .The Fixed units can be combined currents up to 1900A can be fixed directly into

the vertical riser system by rigid bus bar connection.

Cabling Zone

The cable zone is designed for fast and comfortable cabling. The 400mm width cable zone (for

column 1000mm width) or 600mm width cable zone (for column 1200mm width) is situated on

the right hand side from the equipment zone. Cable trays for servicing of all cables are provided

as standard.

Cables can either enter through the top or from the bottom, without increasing the total depth of

the switchboard. This is due to position of the main busbar in the rear of the column.

Enclosure

The maximum degree of protection is up to IP54 (according to IEC 60529).

The maximum form of internal separation is up to Form 4a (according up to IEC 60439-1)

Doors and covers are made out 2mm sheet steel, epoxy powder coated in standard colour

RAL 7035. The column can be equipped with optional panel bottom plate with a removable

aluminium gland plate.

3

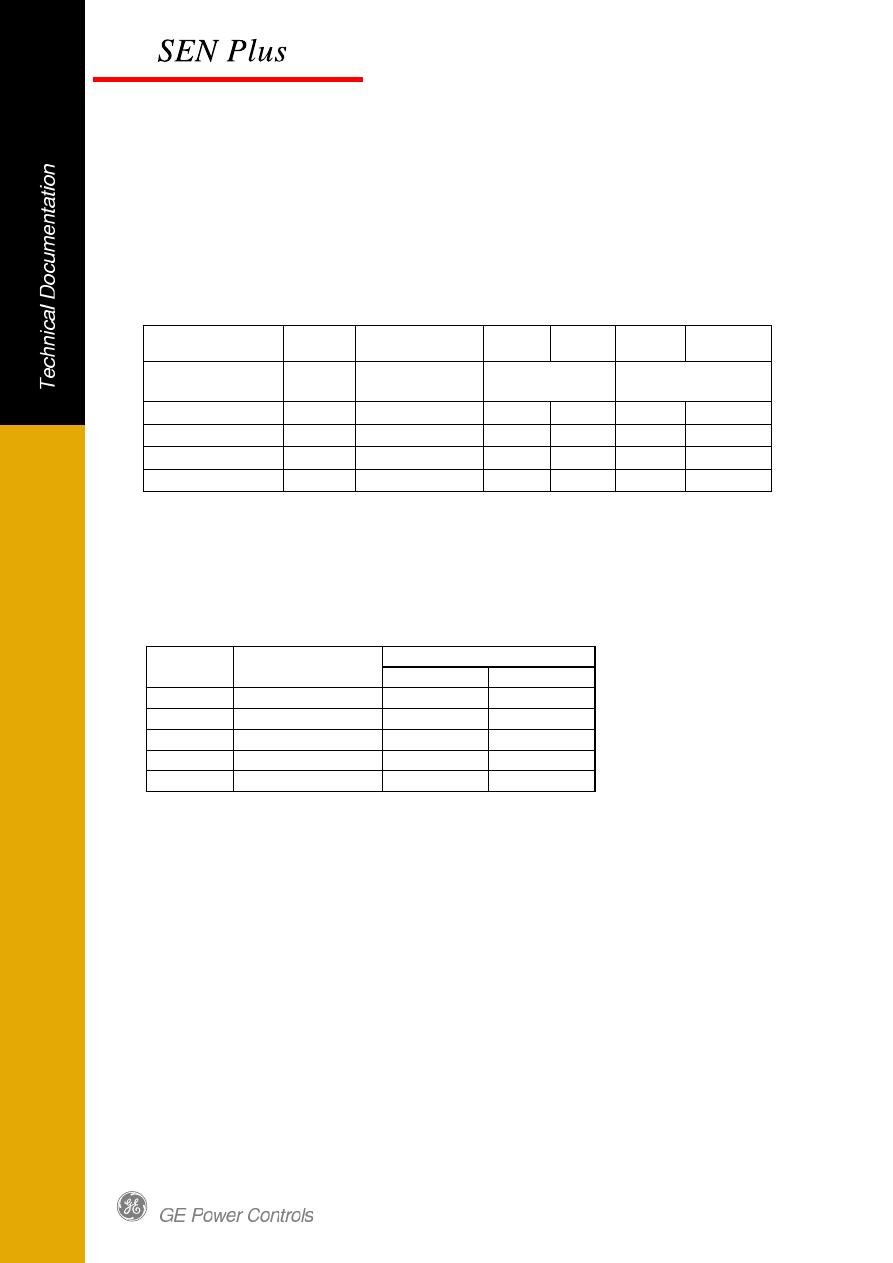

35.2 Arrangements

The height of the columns is 2200mm or 2000mm. Other dimensions could be supplied on

request.

Width

Depth

600 mm

Depth

800 mm

1000 mm

X

X

1200 mm

X

X

Fig. 1 Column arrangements Control Centre.

35.3 Module Arrangements

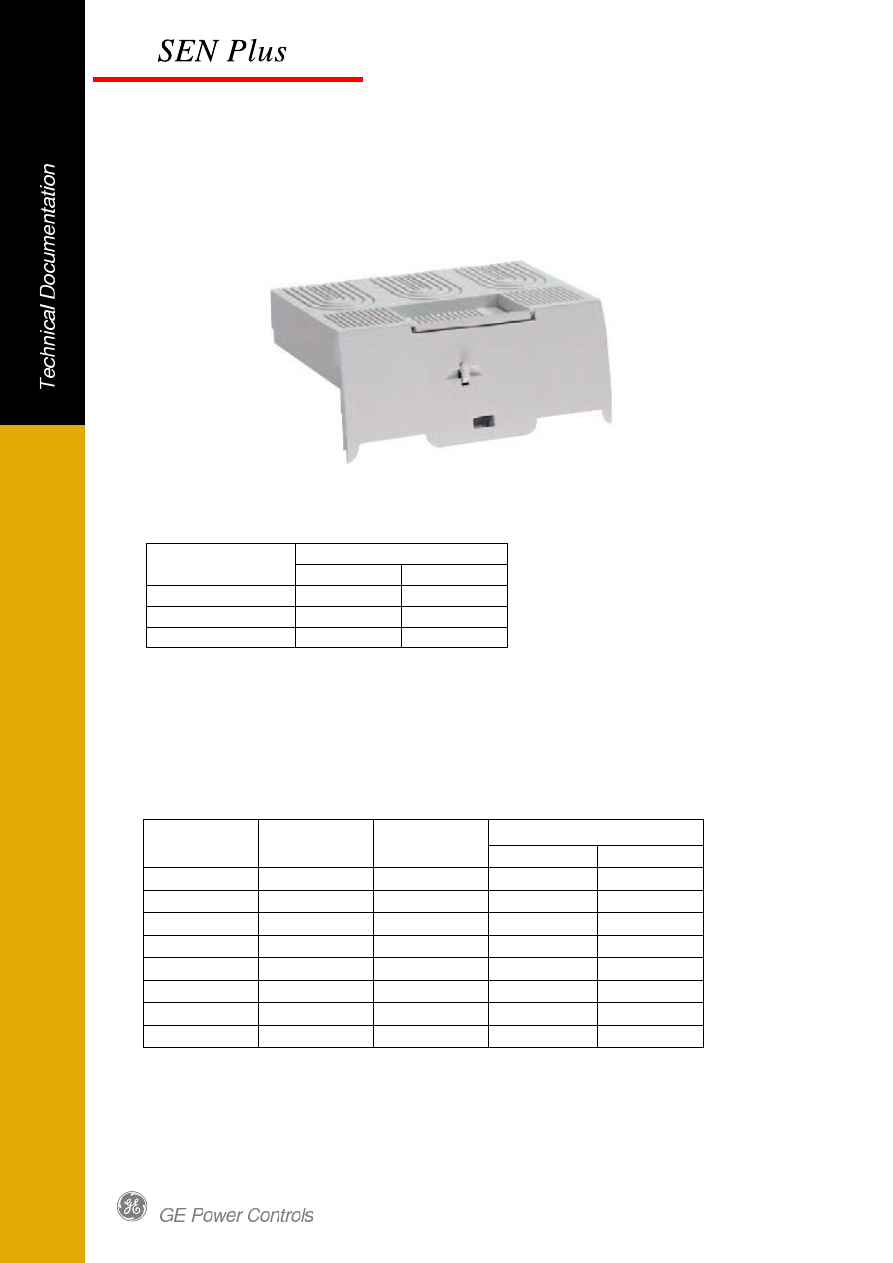

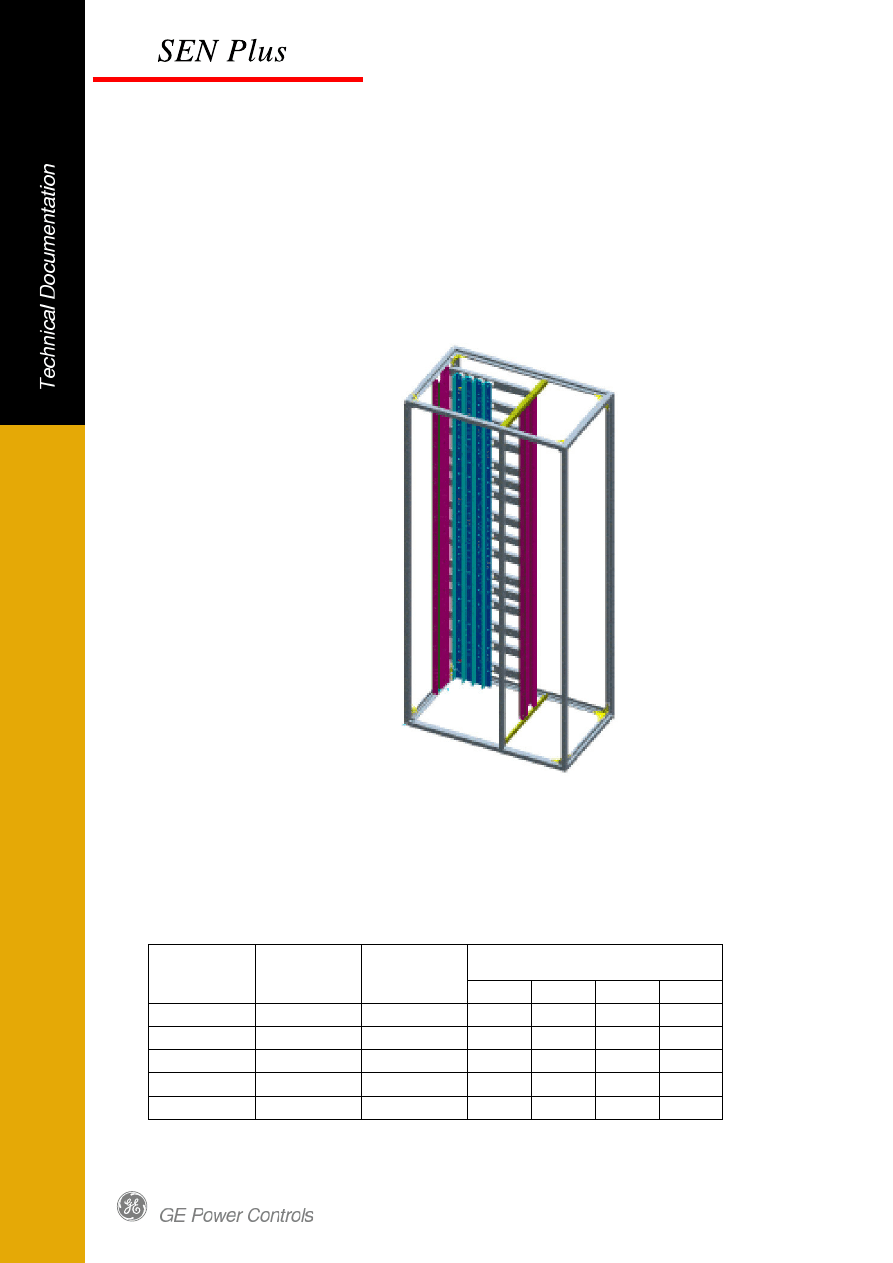

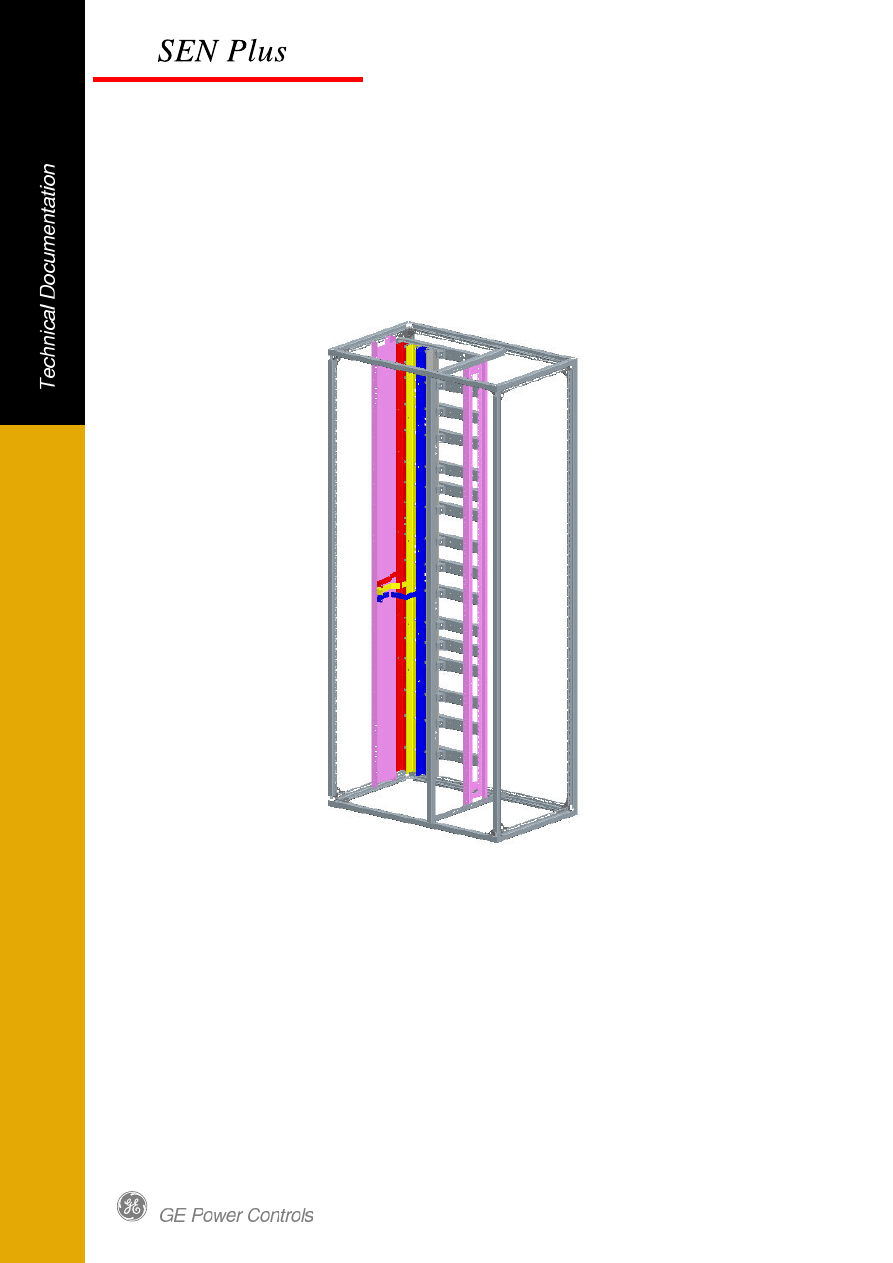

35.3.1 Module Fixed Type

The modules can be used for feeder (fuseless) applications. Modules are available to fix 3 and

4 pole version of MCCB type FD, FE and FG up to 630A. The line side of breaker to be

connected to VBB by mean of rigid copper or cables Customer is connecting the external

cables directly to the breakers terminals or to a specially provided busbars (as option).

The range of module sizes (height) varies from 6E up to 24E.

Fig.2 Module Fixed Type

4

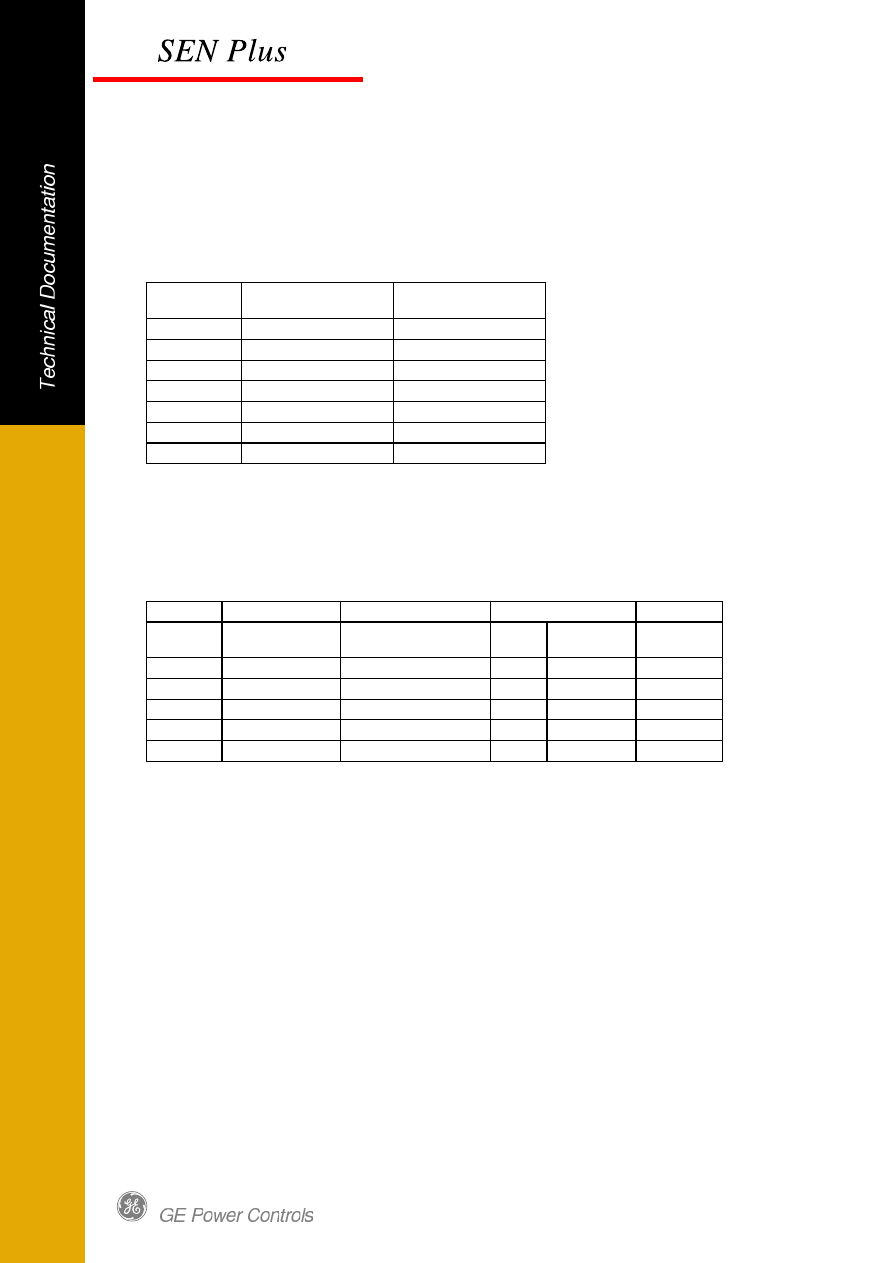

35.3.2 Terminal Shield Cover with Moulded Case Circuit Breaker

Use Breaker with Medium Terminal shields for FG and Long Terminal shields for FD and FE on

Load and Line Side.

Fig 3 Terminal Shield Cover

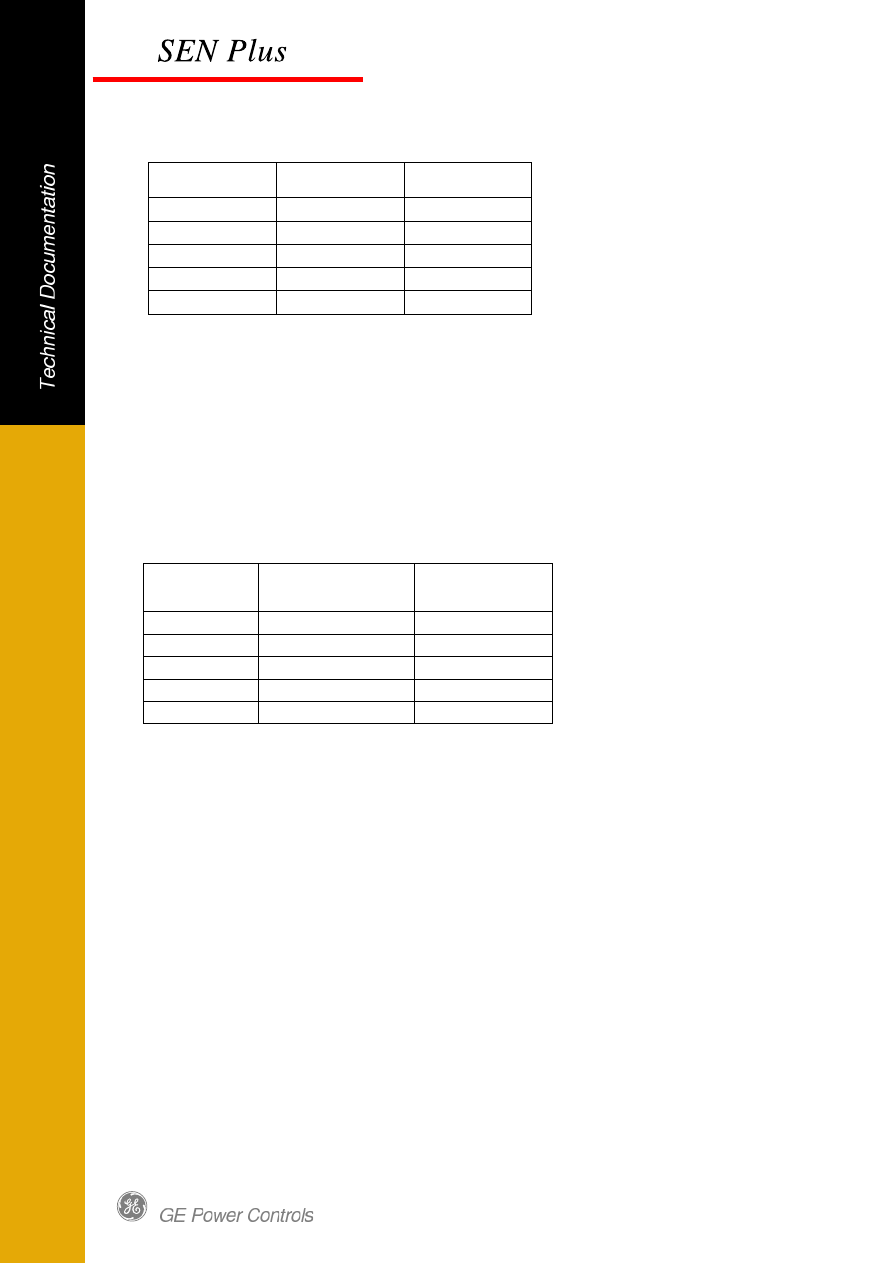

Ref No – Terminal Shields

Circuit breaker

3 pole

4 pole

Record Plus FD

430951

430954

Record Plus FE

432079

432082

Record Plus FG

432846

432849

Fig 4 Terminal Shield cover ref No

35.4 Rated current of main busbar system

The rated current of the main busbars varies from 1000A up to 4000 A and are based on blank

copper bars. Values for tinned copper on request.

Rated

Phases

Neutral

Depth of the panel

Current

600 mm

800 mm

A

mm

mm

1000

60x10

30x10

X

X

1250

60x10

30x10

X

X

1600

80x10

40x10

X

X

2000

100x10

40x10

X

X

2500

2/80x10

80x10

X

X

3200

2/100x10

80x10

X

X

4000

3/100x10

2/60x10

X

Fig. 5 Rated currents of the main horizontal busbars

5

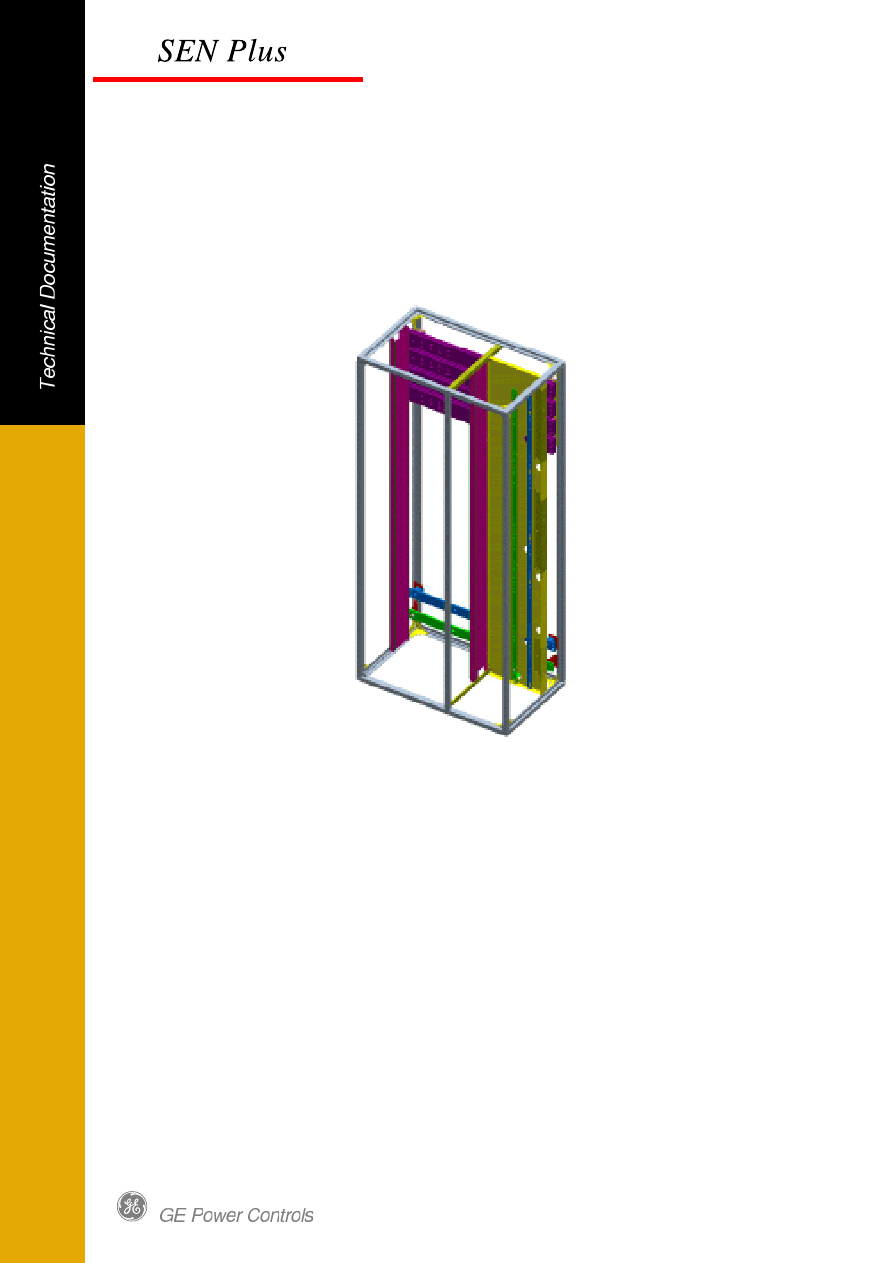

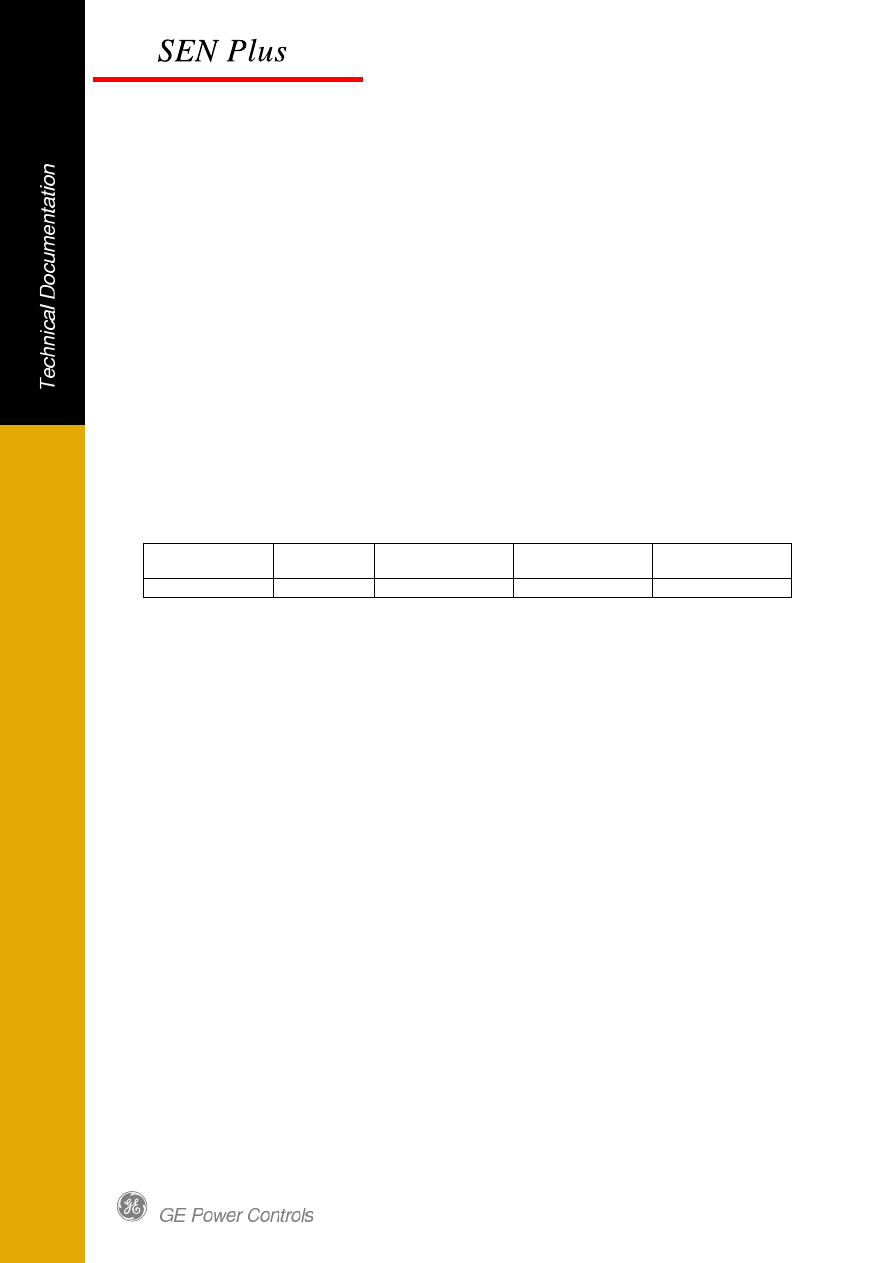

35.5 Vertical riser arrangements

The vertical riser system can be executed as a 3 or 4 pole design. The base is formed by an L

shape to which simply flat copper bus-bars can be added to upgrade the nominal current of the

system. For special environments the columns could be equipped with tinned copper bars as

option. The rated current is divided in 4 current steps variations from 850 up to 1900A.

The pole distance between the phases is 60mm.

The vertical busbar arrangements is Type C basically for feeder application in module technique

Fig. 6 Panel arrangement type C

35.5.1 Rated currents and short circuit strength

Short circuit strength of the neutral conductor 60% of the value of the three phase short-

circuit withstand test.

Other values i.e. tinned copper on request.

Short time Current 1 second

Rated current Performance

Cross-section

Phases

30

50

65

80

A

mm

2

mm

2

kA

kA

kA

kA

(850)

L profile

375

x

1200

+ 1 layer

525

x

x

1550

+ 2 layer

675

x

x

x

1900

+ 3 layer

825

x

x

x

x

Fig. 7 Rated currents and short circuit strength of the vertical riser.

6

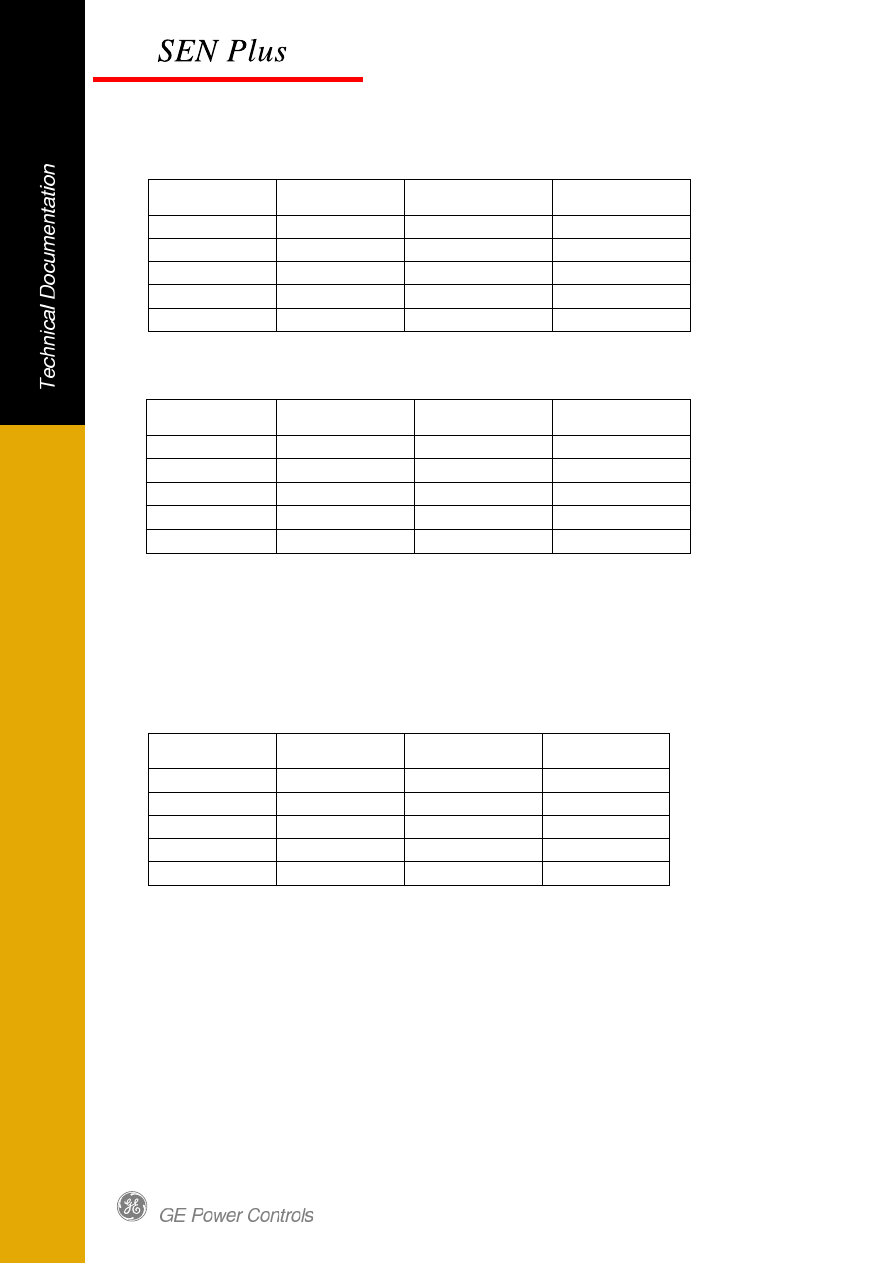

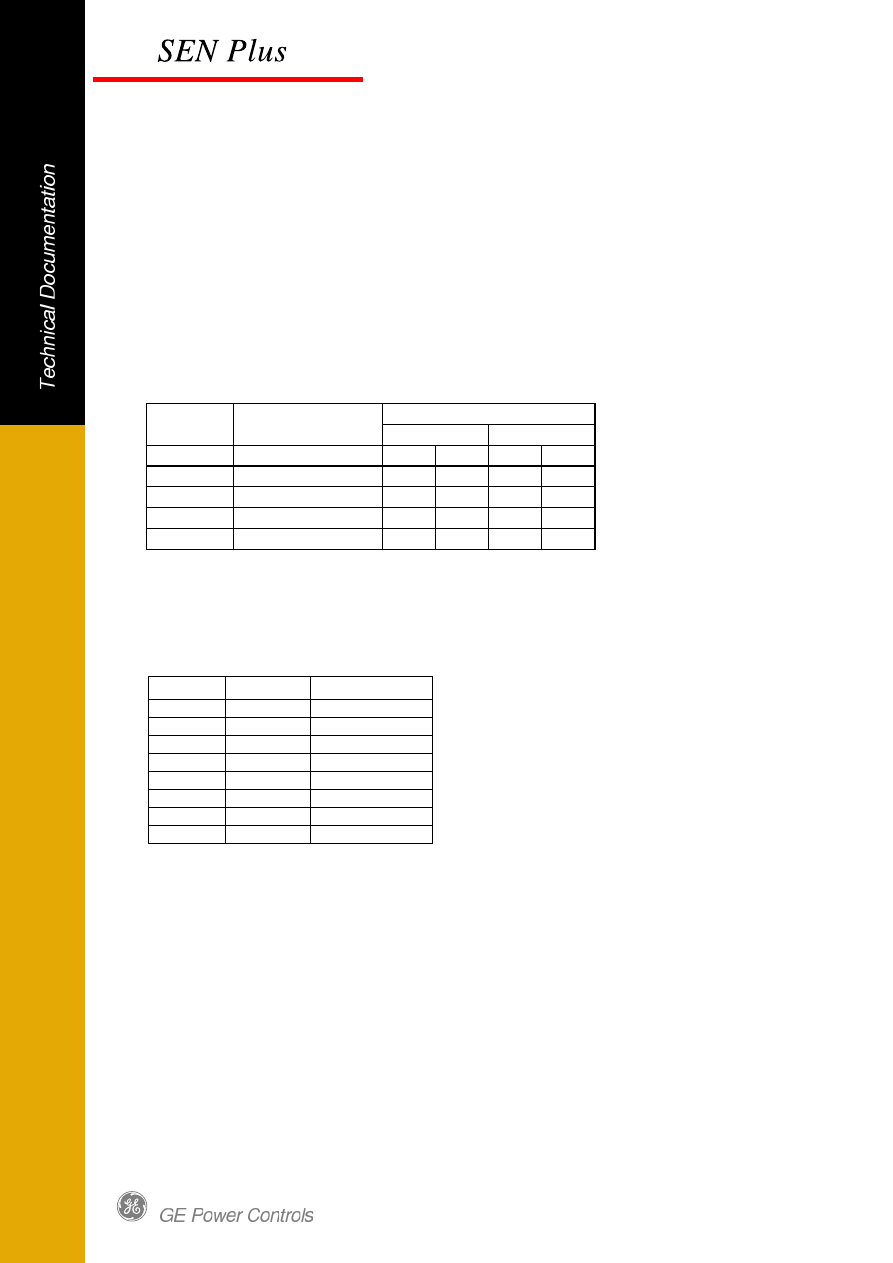

35.5.2 Cross-sectional area of neutral conductor N

The cross section of the neutral can be either half (standard) or full (optional) current carrying

capacity of the phases.

For 3 or 4 pole feeder applications in one column the cable compartment can be equipped with

an optional vertical neutral conductor

.

Fig. 8 Arrangement of N and PE vertical busbar (in cable compartment)

.

7

Figure 9 shows the cross section of the neutral conductor executed as separate conductor

positioned in cable compartment.

Rated current

Cross-section

Phases

Neutral Conductor

50%

Neutral Conductor

100% (optional)

A

mm

2

mm

mm

(850)

375

40x5

40x10

1200

525

40x5

50x10

1550

675

30x10

60x10

1900

825

40x10

80x10

Fig. 9 Cross section of neutral conductor

Figure 10 shows the cross section of the neutral as the 4th pole of the vertical riser system.

Rated current

Cross-section

Phases

Neutral Conductor

min. 50%

Neutral Conductor

100%

A

mm

2

mm

2

mm

2

(850)

375

375

375

1200

525

375

525

1550

675

375

675

1900

825

525

825

Fig.10 Cross section of neutral conductor

35.5.3 Cross-section of vertical protective conductor

The cross-section of protective conductors shall be determined in the following way:

in accordance to sub-clause 7.4.3.1.7a) of IEC standard 60439–1.

Cross sectional area of PE and PEN shall be not less than the value shown in the table

Rated current

Cross-section

Phases

Minimum Cross-

section of PE

Busbar

A

mm

2

mm²

mm

(850)

375

1/2

40x5

1200

525

200

40x5

1550

675

200

40x5

1900

825

1/4

30x10

Fig.11 Cross sections of the protective busbars as per IEC 60439-1 clause 7.4.3.1.7a.

Table is applicable for PEN-conductors, assumed the neutral currents do not exceed 30% of the

phase current

The standard arrangement of the PE conductor is at the rear side in the cable compartment

adjacent to the neutral conductor.

8

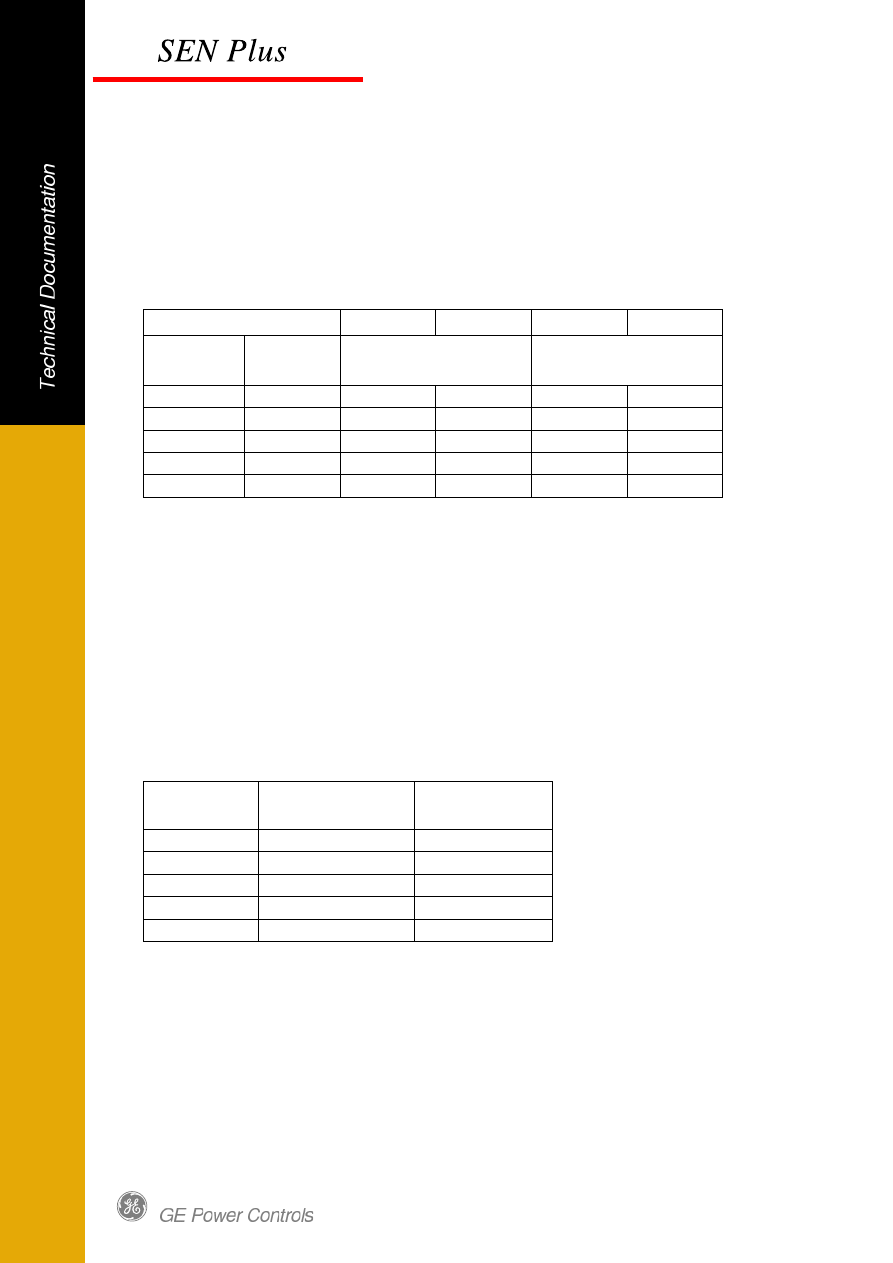

35.5.4 De-ratings

The maximum operation current of the vertical riser is related to

ambient temperature

protection degree of the enclosure

The copper bars are blank copper bars other values as tinned copper can be submitted on

request.

Ambient Temperature:

35°C

50°C

35°C

50°C

Rated

Current

Busbar

Degree of Protection

IP30

Degree of Protection

IP54

A

mm²

A

A

A

A

(850)

375

850

850

850

600

1200

525

1200

1000

850

650

1550

675

1550

1300

1150

800

1900

825

1900

1600

1350

900

Fig. 12 De-ratings of the vertical riser

Ambient temperature = temperature of the air surrounding the panels

35.5.5 Power loss

The power loss is based on the following

. dissipation at rated current

To enable the actual power loss the following formula is used

Actual Power Loss = (Actual Current / Rated Current)

2

x Rated Power Loss

Rated

Cross section

Power Loss

Current

Phases

at Rated Current

A

mm²

W

(850)

375

105

1200

525

160

1550

675

190

1900

825

233

Fig.13 Power losses of the vertical riser

.

9

35.6 Rigid busbar arrangement

The rigid busbar system can be executed as a 3 or 4 pole design. The rated current of the rigid

busbars are up to 630A and are based on blank copper bars. Busbar are insulated.

The rigid busbar arrangement is Type C basically for feeder application in module technique.

Fig. 14 Rigid Busbar arrangement

35.6.1 Cross-sectional area of Rigid Busbars

10

Cross-section area of rigid busbar are shown in fig 15

Rated current

Cross-section

Phases

Busbar

A

mm

2

mm

160

96

12x8

250

125

25x5

400

360

30x12

630

360

30x12

Fig.15 Cross sections of the rigid busbar

35.6.2 Power Loss

The power loss is based on the following

. dissipation at rated current

To enable the actual power loss the following formula is used

Actual Power Loss = (Actual Current / Rated Current)

2

x Rated Power Loss

Rated

Cross section

Power Loss

Current

Phases

at Rated Current

A

mm²

W

160

96

5

250

125

12

400

360

31

630

360

78

Fig.16 Power losses of the Rigid Busbar per meter

11

36.0 Standard configuration in Control Centre

A functional unit is a combination of electrical and mechanical components, which form together

an application. The standard functions of the control centre as of fixed type.

The Fixed modules units are fixed parts according to IEC standard 60439-1 sub clause 2.2.5:

The disconnections of fixed parts may require the disconnections of the complete ASSEMBLY

or parts of it.

In case of Fixed parts the connections of main circuits can only be established or broken when

the ASSEMBLY is dead. In general, removable and installation of Fixed parts required the use

of a tool.

GE advices always Switch off Mains while disconnection of Fixed Module

parts.

The electrical connections to the functional units are fixed or disconnectable as the table shows:

Connections:

Modules

type:

Disconnectable

Fixed

Withdrawable

Control circuits

Fixed Type

x

Fig.12 Standard connections

Disconnectable connection

a connection which is connected or disconnected by manual operation of the connected means

without a tool.

The supply side of the plug-in modules are executed with plug-in contacts.

Withdrawable connection

a connection which is connected or disconnected by bringing the functional unit into the

connected or disconnected situation.

Fixed connection

A connection, which is connected or disconnected by means of a tool.

Connections should be made either direct to the switchgear i.e. to the terminals of the thermal

overload relays (standard) or to a separate terminal strip (optional).

12

36.1 Feeder Arrangement

System integration is accomplished by using the new range of IEC 60947 designed and tested

rated industrial components of GE.

36.1.1 Feeder with Moulded Case Circuit Breaker

The arrangements are based on an operational voltage of 400V,500V and 690V and a breaking

capacity (Icu) of 50kA for the breakers.

Module size – Fixed Type

Current

Circuit breaker

3 pole

4 pole

A

type

mm

Height

mm

Height

up to 160

Record Plus FD160

200

8E

200

8E

up to 250

Record Plus FE250

250

10E

250

10E

up to 400

Record Plus FG400

250

10E

250

10E

up to 630

Record Plus FG630

250

10E

250

10E

Fig.17 Feeder arrangements with moulded case circuit breakers (400V,500V,690V)

36.1.3 Module sizes

The control centre fixed type modules sizes are specified in Table 18

Height

Fixed

Empty Module

5E

6E

x

8E

x

x

10E

x

x

12E

x

16E

18E

x

24E

x

Fig.18 Fixed Type Module size

13

36.1.4 De-ratings

The internal temperature of the columns and the derating is influenced by the following factors:

Power loss of the circuit breaker at service current

Panel dimensions

Type of erection (free standing or wall-mounted)

Protection degree of the enclosure

Internal partitions (hamper the free air circulation)

Ambient

Temperature:

Module

Ambient

Temperature:

35°C

50°C

35°C

50°C

Rated Current

Rated Current

With Ventilation

IP 30

Without Ventilation

A

A

A

A

A

A

FD-160

8E

160

144

122

122

80

FE-250

10E

250

225

175

175

125

FG-630

10E

630

567

441

441

315

Fig.19 Derating for module with Record Plus feeders for fully equipped tested panel configuration.

Free standing arrangement with main busbar system in the top position.

36.1.5 Weights

Module Weight – Fixed Type

Current

Circuit breaker

3 pole

4 pole

A

type

KG

KG

up to 160

Record Plus FD160

4.5

5.5

up to 250

Record Plus FE250

5.5

6.5

up to 400

Record Plus FG400

11.5

14.5

up to 630

Record Plus FG630

11.5

14.5

Fig.20 Weight of Module with Record Plus breaker

14

36.1.6 Power Loss

To enable the actual power loss the following formula is used

Actual Power Loss = (Actual Current / Rated Current)

2

x Rated Power Loss

Rated

Current

Circuit breaker

Power loss at rated

current

A

type

W

125

Record Plus FD160

18,8

160

Record Plus FD160

30,7

250

Record Plus FE250

45,0

400

Record Plus FG400

52,8

630

Record Plus FG630

119,1

800

Record Plus FK800

76,8

Fig. 21 Power loss standard feeders with MCCB.

36.1.7 Arrangement for External Connections

Current Circuit breaker

Cable Clamps

Bars or Cable lugs

Bars

Standard

connection

Bolt

Max. Width Thickness

A

type

mm

2

mm

mm

up to 160

FD160

1 x 2,5 - 95

M6

12

8

up to 250

FE250

1 x 16 -150

M8

25

5

up to 400

FG400

1 x 50 - 300

M10

32

12

up to 630

FG630

1 x 50 -300

M10

32

12

Fig. 22 Arrangement of external connections for Record Plus Breaker

15

36.2. Motor-starter arrangements

Full system integration is accomplished by using the new range of IEC 60947 designed and

tested range of industrial and control components of GE.

Customer uses empty modules 6E – 24E size, arranges and assembles apparatus by himself.

For detail information e.g. power loss, arrangement for external connections see

Base Technical Documentation - Chapter 6.0.

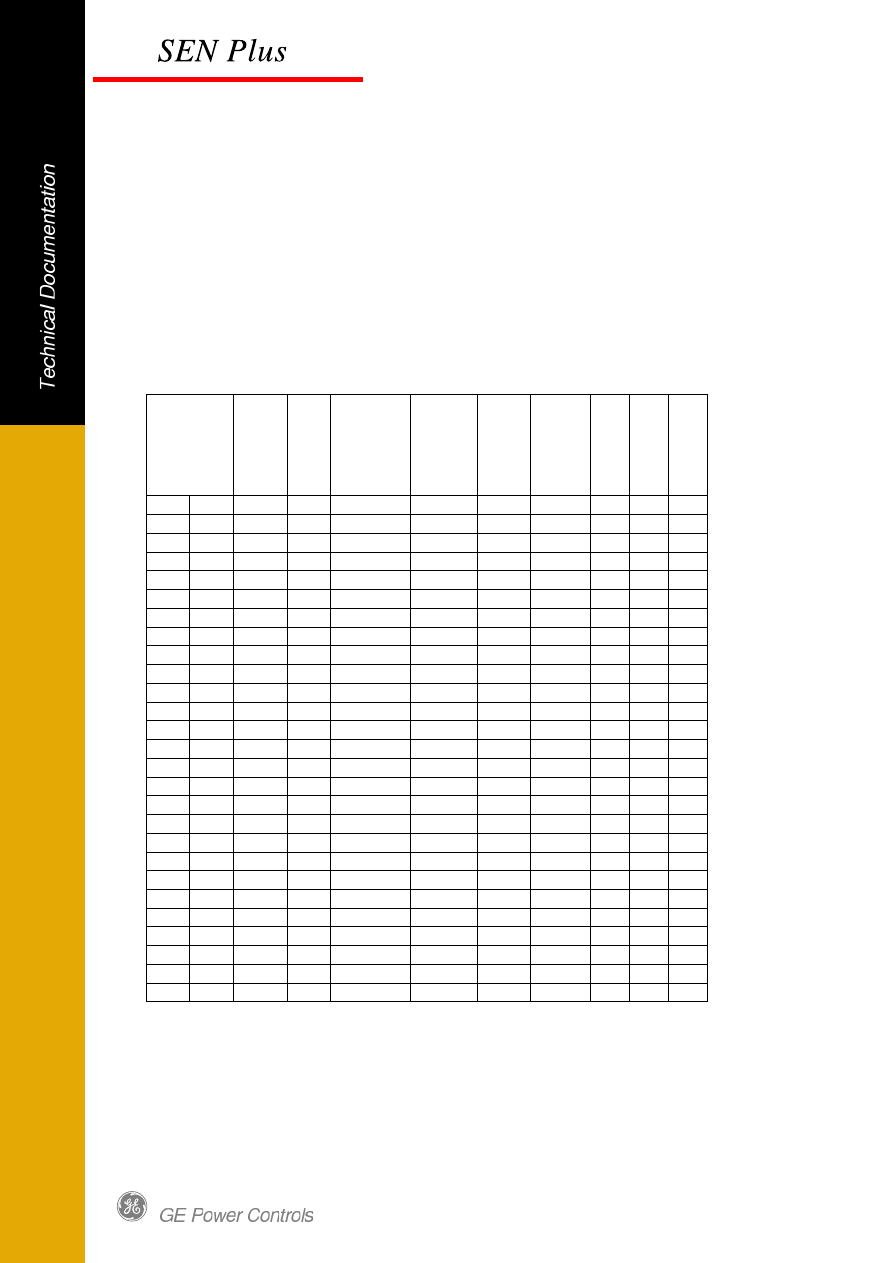

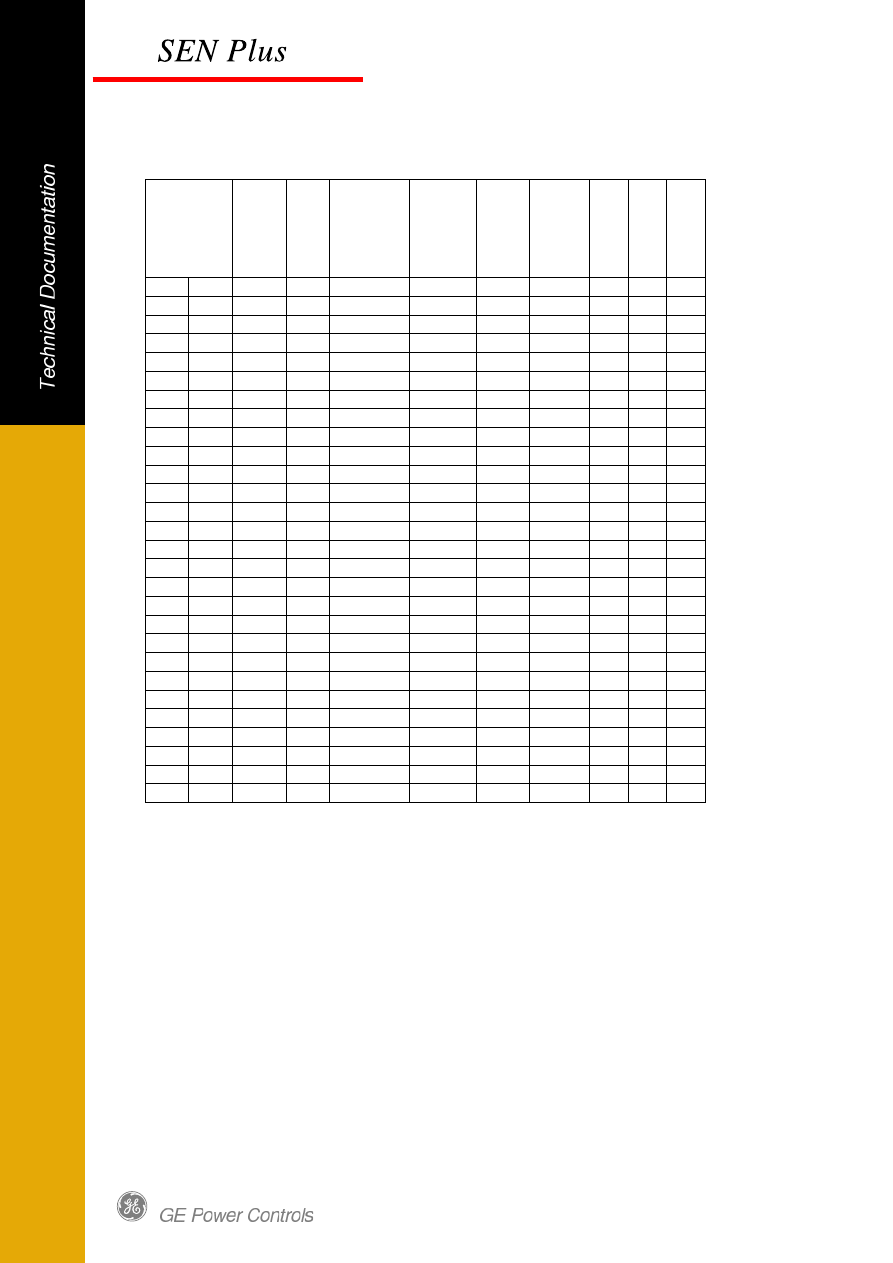

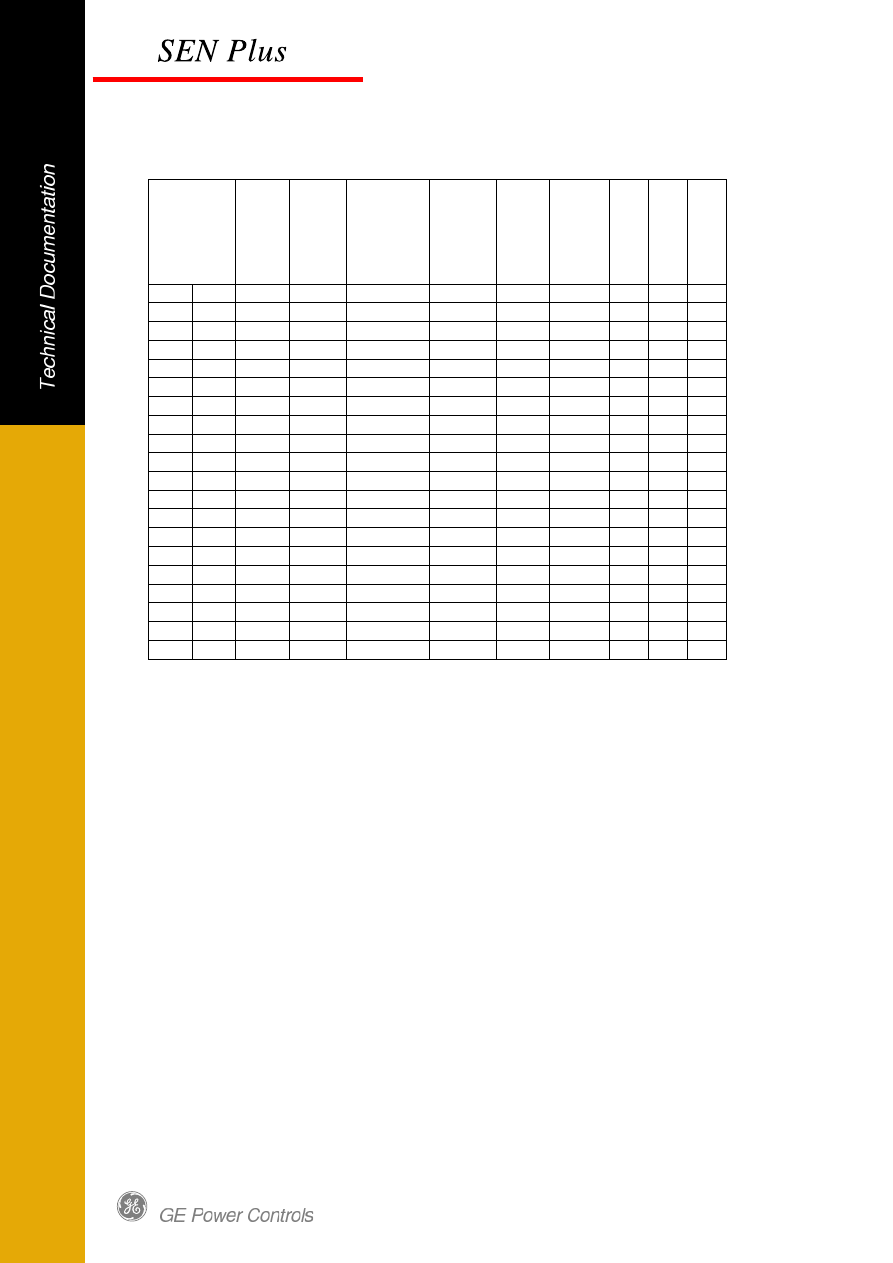

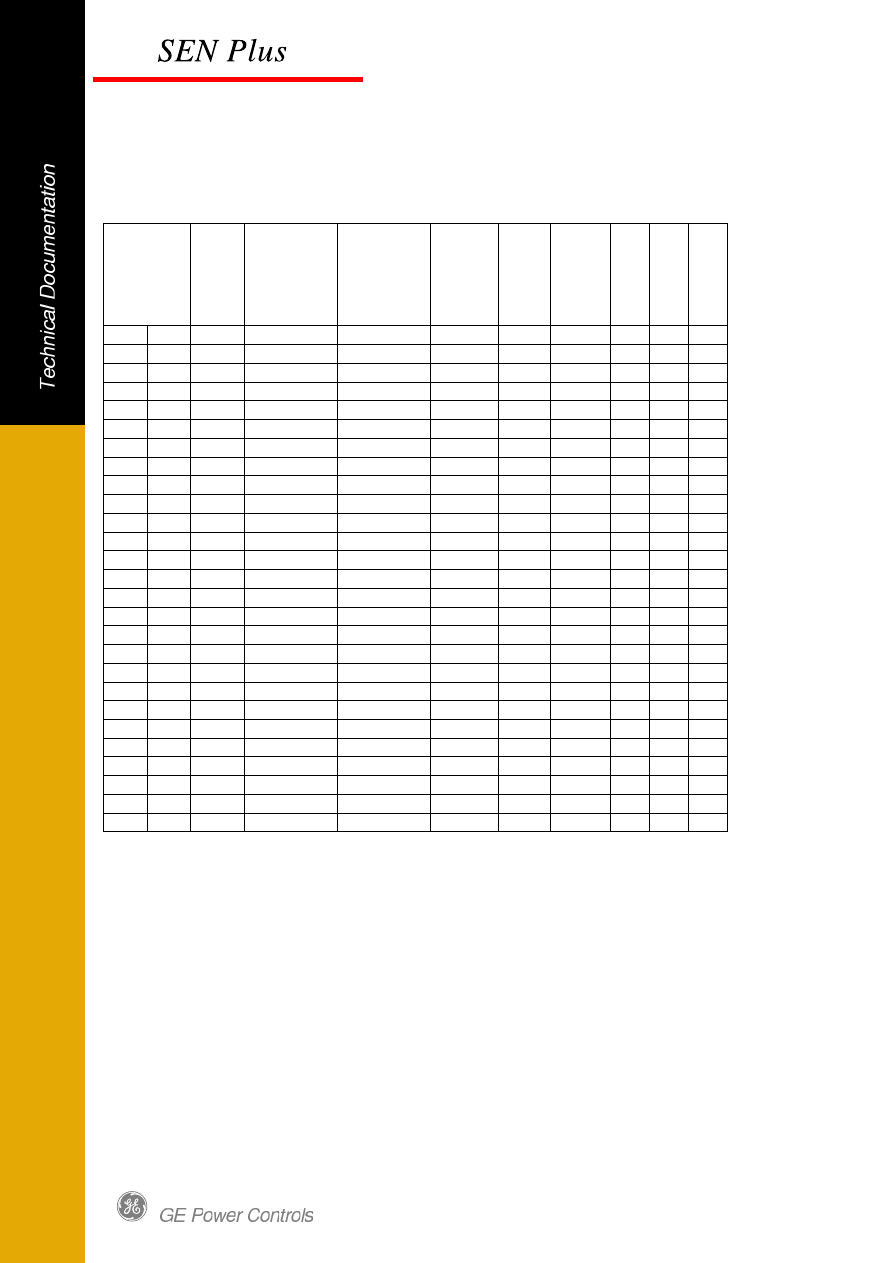

36.2.1 Direct on line starter with protection fuse DIN type

The motor-starters based on 3 pole arrangements at an operational voltage

of 400V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse

DIN

gL

Switch *) Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,9

2

DILOS 1

CL00

RT1F 0,65-1,1 150

6E

8E

0,37

0,5

1,13

4

DILOS 1

CL00

RT1G

1-1,5

150

6E

8E

0,55

0,75

1,6

4

DILOS 1

CL00

RT1H

1,3-1,9

150

6E

8E

0,75

1

2

4

DILOS 1

CL00

RT1J

1,8-2,7

150

6E

8E

1,1

1,5

2,6

4

DILOS 1

CL00

RT1K

2,5-4

150

6E

8E

1,5

2

3,5

6

DILOS 1

CL00

RT1K

2,5-4

150

6E

8E

2,2

3

5

10

DILOS 1

CL00

RT1L

4-6,3

150

6E

8E

3

4

7

16

DILOS 1

CL00

RT1N

8-12

150

6E

8E

4

5,5

9

20

DILOS 1

CL00

RT1N

8-12

150

6E

8E

5,5

7,5

12

25

DILOS 1

CL01

RT1N

8-12

150

6E

8E

7,5

10

16

35

DILOS 1

CL02

RT1P

10-16

150

6E

8E

11

15

22,5

35

DILOS 1

CL25

RT1U

21-26

150

6E

8E

15

20

30

50

DILOS 1

CL04

RT1V

25-32

150

6E

8E

18,5

25

37

63

DILOS 1

CL45

RT1W

30-40

150

6E

8E

22

30

44

63

DILOS 1

CL06

RT2G

42-55

200

8E

10E

30

40

60

80

FULOS 000

CL07

RT2H

54-65

250

10E

N/A

37

50

72

100 FULOS 000

CL08

RT2J

64-82

250

10E

N/A

45

60

85

125

FULOS 00

CL09

RT2L

78-97

300

12E

N/A

55

75

105

160

FULOS 1

CL10

RT2M

90-110

450 18E N/A

75

101

138

200

FULOS 1

CK75C

RT3E 110-140 600 24E N/A

90

121

170

200

FULOS 1

CK08C

RT3F 140-190 600 24E N/A

110

150

211

250

FULOS 2

CK85B

RT4P 175-280

N/A N/A

132

180

240

315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

160

220

309

400

FULOS 3

CK95B

RT4R 200-310

N/A N/A

200

270

370

500

FULOS 3

CK10C

RT5C 250-400

N/A N/A

220

300

408

500

FULOS 3

CK10C

RT5D 315-500

N/A N/A

Fig. 23 Standardized fused motor-starter arrangements DOL (400V)

*) DILOS1 plus fuse base size 000/00 160A

16

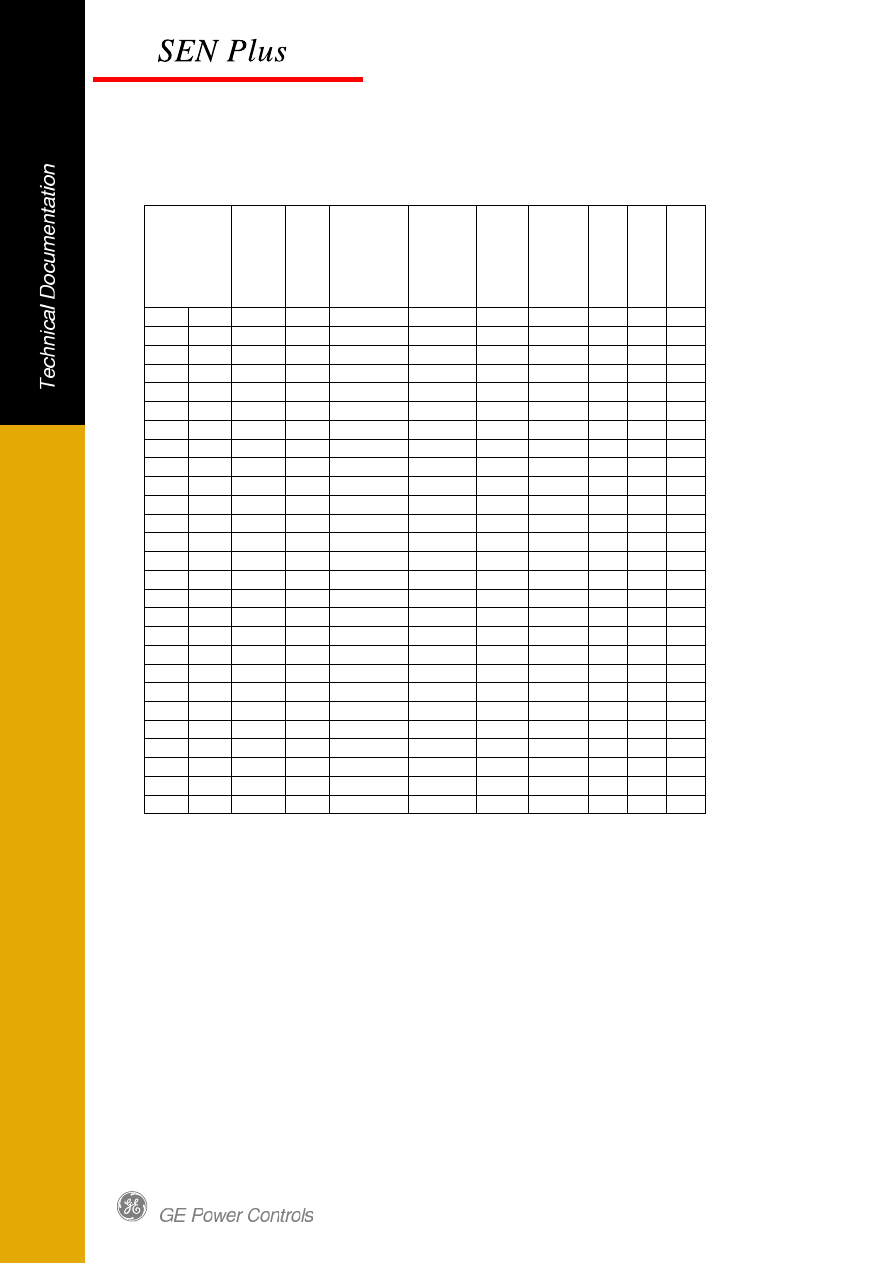

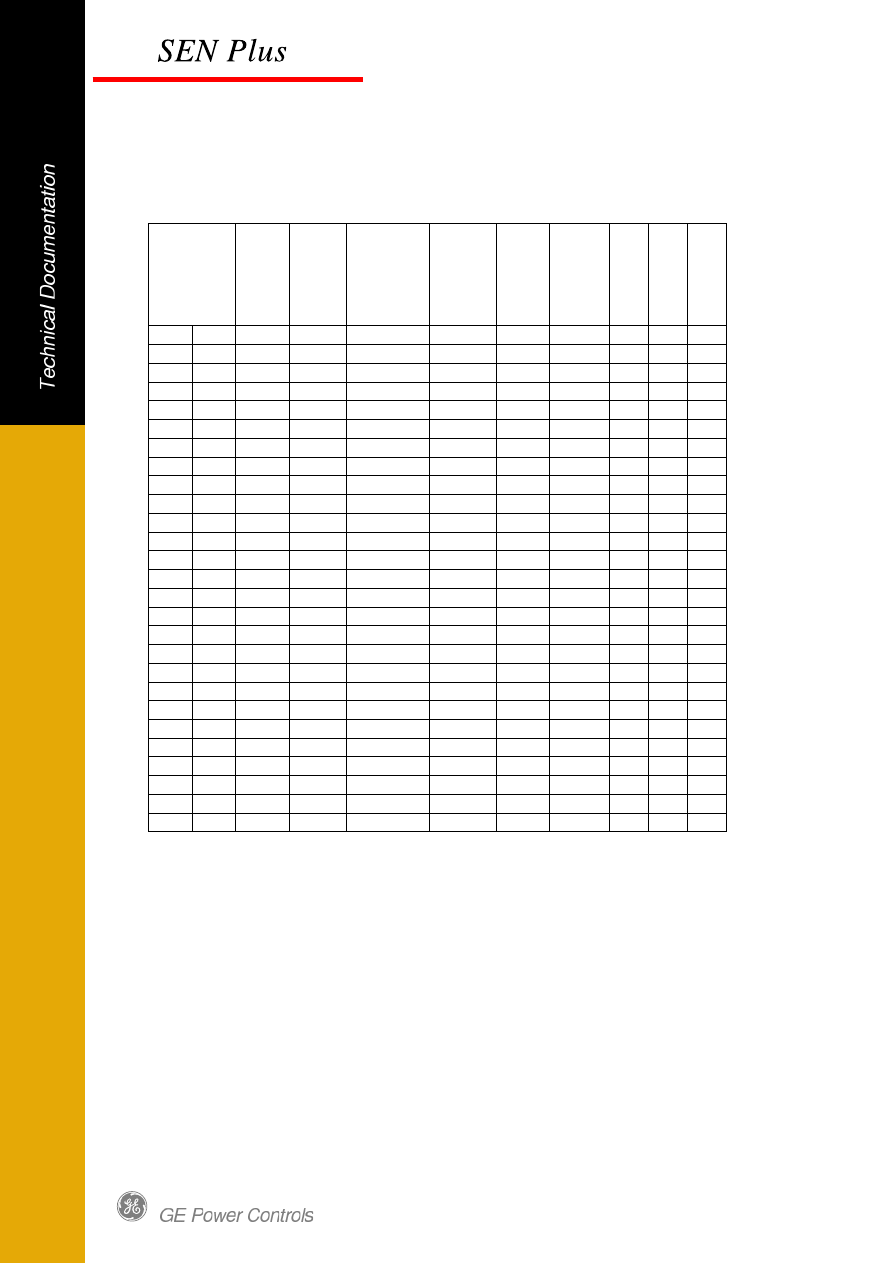

The motor-starters based on 3 pole arrangements at an operational voltage

of 500V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse

DIN

gL

Switch *) Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,66

4

DILOS 1

CL00

RT1D 0,4-0,65 150

6E

8E

0,37

0,5

0,9

4

DILOS 1

CL00

RT1F 0,65-1,1 150

6E

8E

0,55

0,75

1,2

4

DILOS 1

CL00

RT1G

1-1,5

150

6E

8E

0,75

1

1,5

6

DILOS 1

CL00

RT1H

1,3-1,9

150

6E

8E

1,1

1,5

2,1

6

DILOS 1

CL00

RT1J

1,8-2,7

150

6E

8E

1,5

2

2,6

6

DILOS 1

CL00

RT1K

2,5-4

150

6E

8E

2,2

3

3,8

10

DILOS 1

CL00

RT1K

2,5-4

150

6E

8E

3

4

5

16

DILOS 1

CL00

RT1L

4-6,3

150

6E

8E

4

5,5

6,5

25

DILOS 1

CL00

RT1N

8-12

150

6E

8E

5,5

7,5

9

25

DILOS 1

CL00

RT1N

8-12

150

6E

8E

7,5

10

12

25

DILOS 1

CL01

RT1N

8-12

150

6E

8E

11

15

17

40

DILOS 1

CL25

RT1S 14,5-18 150

6E

8E

15

20

23

50

DILOS 1

CL25

RT1U

21-26

150

6E

8E

18,5

25

28,5

50

DILOS 1

CL04

RT1V

25-32

150

6E

8E

22

30

33

80

DILOS 1

CL45

RT1W

30-40

150

6E

8E

30

40

45

100

DILOS 1

CL06

RT2G

42-55

200

8E

10E

37

50

55

125 FULOS 000

CL07

RT2H

54-65

250

10E

N/A

45

60

65

125 FULOS 000

CL08

RT2J

64-82

250

10E

N/A

55

75

80

200

FULOS 1

CL09

RT2L

78-97

450 18E N/A

75

101

105

200

FULOS 1

CK75C

RT3D

90-120

600 24E N/A

90

121

129

200

FULOS 1

CK75C

RT3E 110-140 600 24E N/A

110

150

156

250

FULOS 1

CK08C

RT3F 140-190 600 24E N/A

132

180

188

315

FULOS 2

CK85B

RT4P 175-280

N/A N/A

160

220

228

315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

200

270

281

400

FULOS 3

CK95B

RT4R 200-310

N/A N/A

220

300

310

500

FULOS 3

CK10C

RT5C 250-400

N/A N/A

250

340

348

500

FULOS 3

CK10C

RT5D 315-500

N/A N/A

Fig. 24 Standardized fused motor-starter arrangements DOL (500V)

*) DILOS1 plus fuse base size 000/00 160A

17

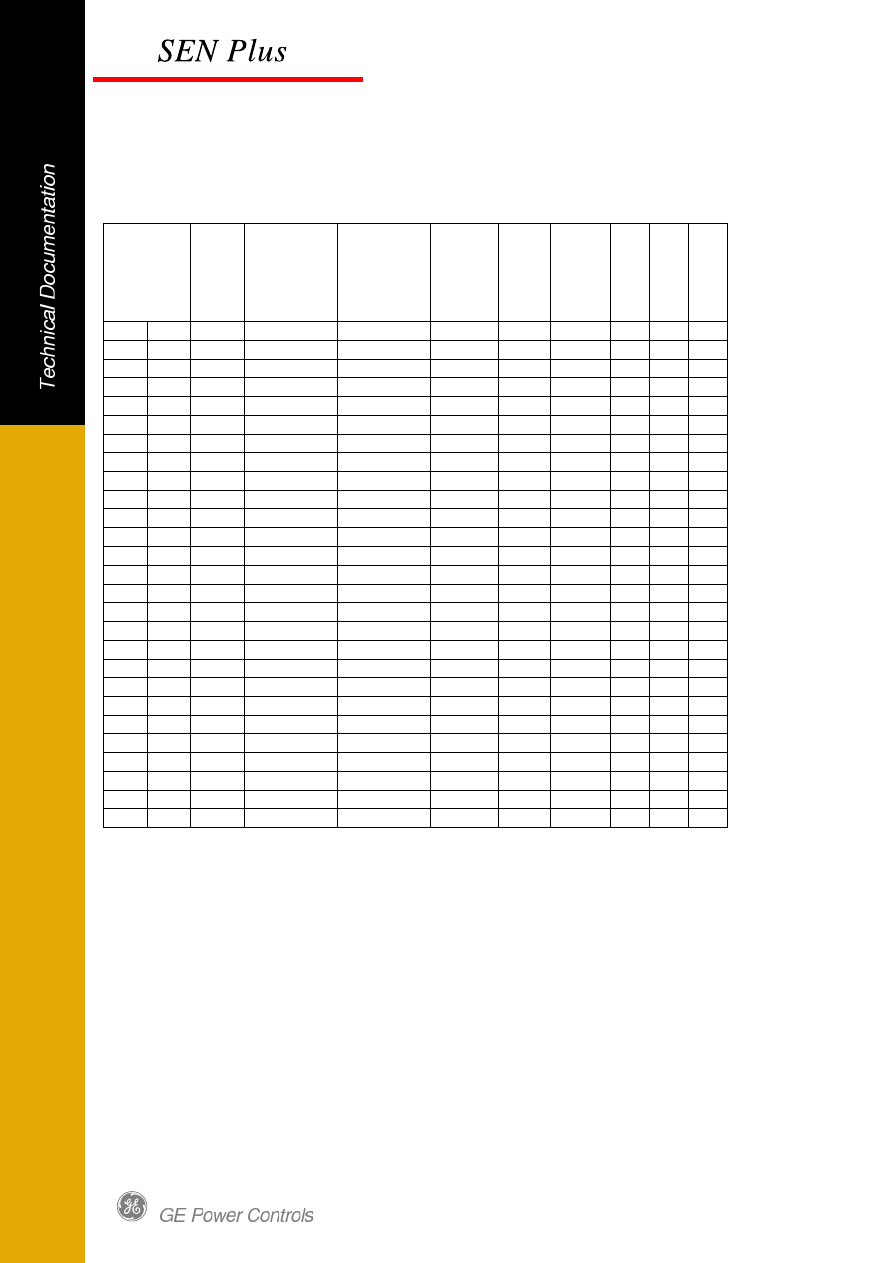

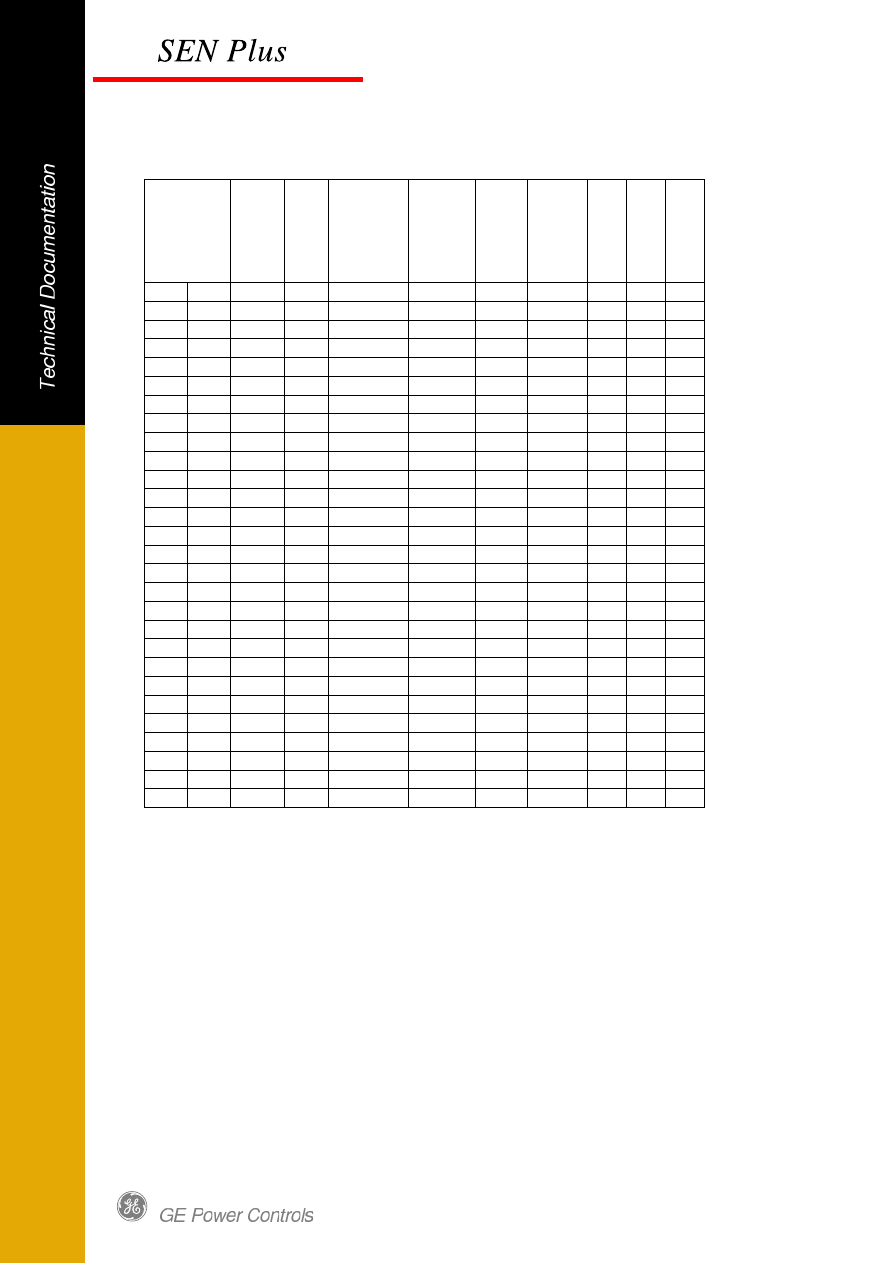

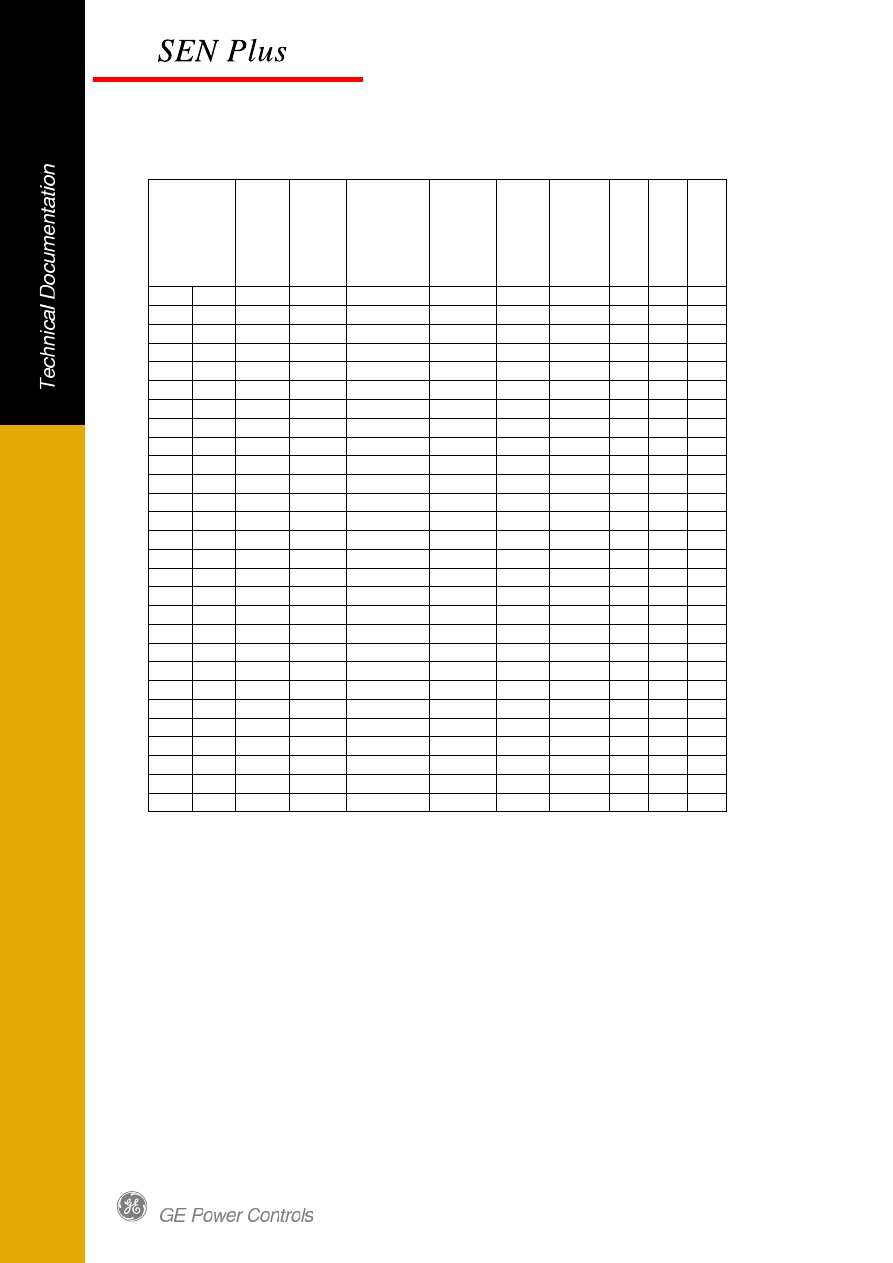

The motor-starters based on 3 pole arrangements at an operational voltage

of 690V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse

DIN

gL

Switch *) Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,46

4

DILOS 1

CL00

RT1D 0,4-0,65 150

6E

8E

0,37

0,5

0,7

4

DILOS 1

CL00

RT1F 0,65-1,1 150

6E

8E

0,55

0,75

0,8

4

DILOS 1

CL00

RT1F 0,65-1,1 150

6E

8E

0,75

1

1,1

4

DILOS 1

CL00

RT1G

1-1,5

150

6E

8E

1,1

1,5

1,6

6

DILOS 1

CL00

RT1H

1,3-1,9

150

6E

8E

1,5

2

2,2

6

DILOS 1

CL00

RT1J

1,8-2,7

150

6E

8E

2,2

3

3,1

6

DILOS 1

CL00

RT1K

2,5-4

150

6E

8E

3

4

4,2

10

DILOS 1

CL00

RT1L

4-6,3

150

6E

8E

4

5,5

4,9

16

DILOS 1

CL00

RT1L

4-6,3

150

6E

8E

5,5

7,5

6,7

20

DILOS 1

CL00

RT1M

5,5-8,5

150

6E

8E

7,5

10

9

25

DILOS 1

CL01

RT1N

8-12

150

6E

8E

11

15

13

40

DILOS 1

CL25

RT1P

10-16

150

6E

8E

15

20

17,5

50

DILOS 1

CL25

RT1S 14,5-18 150

6E

8E

18,5

25

23

50

DILOS 1

CL04

RT1U

21-26

150

6E

8E

22

30

25

63

DILOS 1

CL45

RT1V

25-32

150

6E

8E

30

40

33

63

DILOS 1

CL45

RT1W

30-40

150

6E

8E

37

50

42

80

DILOS 1

CL07

RT2E

30-43

200

8E

10E

45

60

49

100 FULOS 000

CL07

RT2G

42-55

250

10E

N/A

55

75

60

160

FULOS 00

CL09

RT2H

54-65

300

12E

N/A

75

101

82

200

FULOS 1

CK75C

RT3C

63-90

600

24E

N/A

90

121

98

160

FULOS 1

CK75C

RT3D

90-120

600

24E

N/A

110

150

118

200

FULOS 1

CK08C

RT3E 110-140 600

24E

N/A

132

180

140

250

FULOS 1

CK08C

RT3F 140-190

N/A N/A

160

220

175

250

FULOS 2

CK09B

RT4N 120-190

N/A N/A

200

270

214

315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

220

300

230

400

FULOS 2

CK95B

RT4P 175-280

N/A N/A

250

340

270

400

FULOS 2

CK95B

RT4P 175-280

N/A N/A

Fig. 25 Standardized fused motor-starter arrangements DOL (690V)

*) DILOS1 plus fuse base size 000/00 160A

18

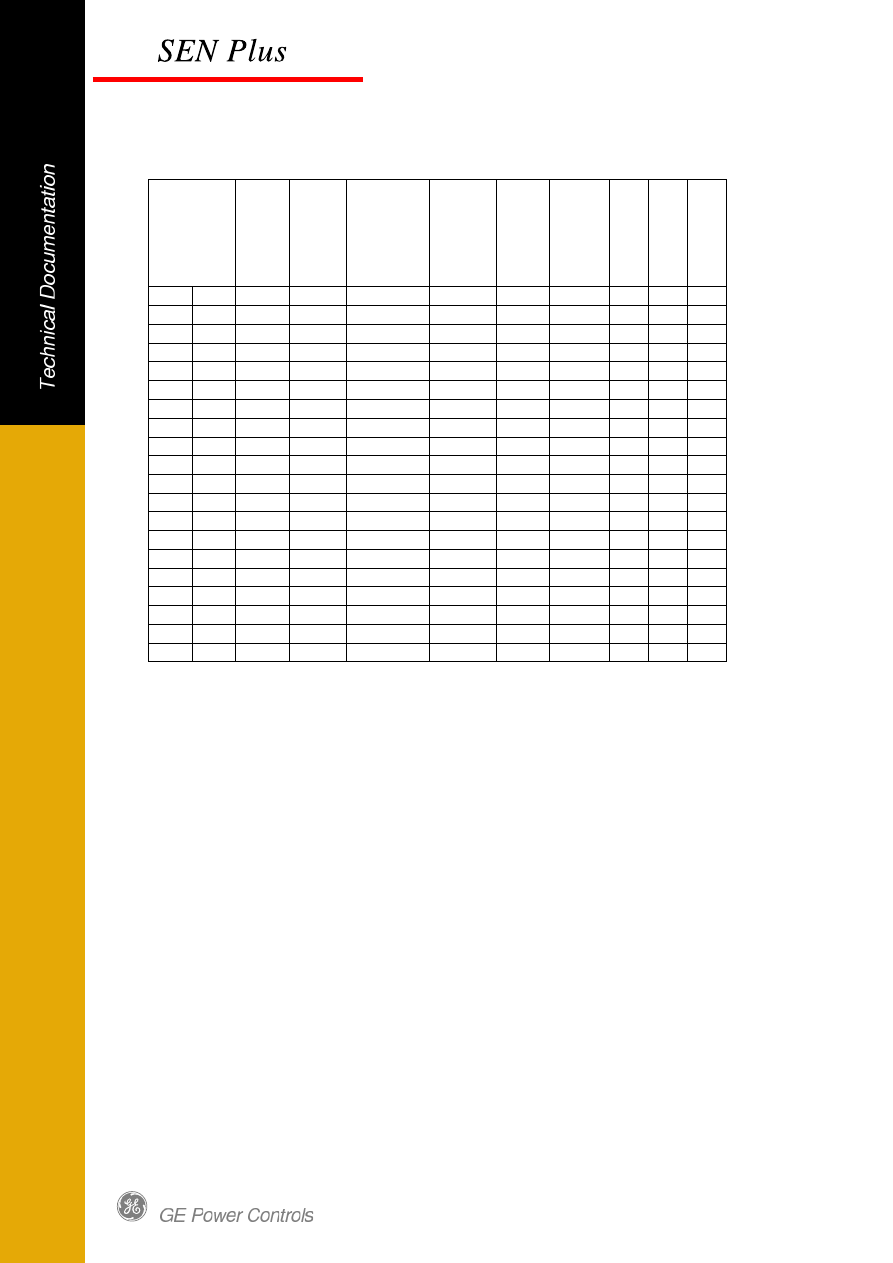

36.2.2 Direct on line starter with protection fuse BS type

The motor-starters based on 3 pole arrangements at an operational voltage

of 400V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse BS

Switch *)

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

type

type

type

type

A

mm

0,25

0,33

0,9

NIT4

DILOS 1

CL00

RT1F 0,65-1,1 150

6E

8E

0,37

0,5

1,13

NIT6

DILOS 1

CL00

RT1G

1-1,5

150

6E

8E

0,55

0,75

1,6

NIT6

DILOS 1

CL00

RT1H

1,3-1,9

150

6E

8E

0,75

1

2

NIT10

DILOS 1

CL00

RT1J

1,8-2,7

150

6E

8E

1,1

1,5

2,6

NIT10

DILOS 1

CL00

RT1J

1,8-2,7

150

6E

8E

1,5

2

3,5

NIT16

DILOS 1

CL00

RT1K

2,5-4

150

6E

8E

2,2

3

5

NIT16

DILOS 1

CL00

RT1L

4-6,3

150

6E

8E

3

4

7

NIT20

DILOS 1

CL00

RT1M

5,5-8,5

150

6E

8E

4

5,5

9

NIT20M25

DILOS 1

CL00

RT1N

8-12

150

6E

8E

5,5

7,5

12

TLA32M35

DILOS 1

CL01

RT1P

10-16

150

6E

8E

7,5

10

16

TLA32M40

DILOS 1

CL02

RT1S 14,5-18 150

6E

8E

11

15

22,5

TLA32M50

DILOS 1

CL25

RT1T 17,5-22 150

6E

8E

15

20

30

TIS63M80

DILOS 1

CL04

RT1V

25-32

150

6E

8E

18,5

25

37

TIS63M80

DILOS 1

CL45

RT1W

30-40

150

6E

8E

22

30

44

TIS63M80

DILOS 1

CL06

RT2G

42-55

200

8E

10E

30

40

60

OS100M125

FULOS 000

CL07

RT2H

54-65

250

10E N/A

37

50

72

OS100M125

FULOS 000

CL07

RT2J

64-82

250

10E N/A

45

60

85

TCP100M160

FULOS 00

CL08

RT2L

78-97

300

12E N/A

55

75

105

TCP100M160

FULOS 00

CL10

RT2M

90-110

300

12E N/A

75

101

135

TF200M250

FULOS 1

CK75C

RT3E 110-140 600

24E N/A

90

121

165

TF200M315

FULOS 1

CK08C

RT3F 140-190 600

24E N/A

110

150

211

TF200M315

FULOS 1

CK85B

RT4P 175-280

N/A N/A

132

180

240

TKF315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

160

220

309

TKF315M355

FULOS 2

CK95B

RT4R 200-310

N/A N/A

200

270

370

TM400

FULOS 3

CK10C

RT5C 250-400

N/A N/A

220

300

408

TM450

FULOS 3

CK10C

RT5D 315-500

N/A N/A

Fig. 26 Standardized fused motor-starter arrangements DOL (400V)

*) DILOS1 plus fuse base:

RS20H up to 4kW

RS32H 5,5 to 11kW

RS63H 15 to 22kW

19

36.2.3 Direct on line starter with circuit breaker protection

The motor-starters based on 3 pole arrangements at an operational voltage

of 400V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

T

h

e

rm

a

l

c

u

rr

e

n

t

b

re

a

k

e

r

ra

n

g

e

Circuit

breaker

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,9

0,63-1 GPS1BHAE

CL00

150

6E

8E

0,37

0,5

1,13

1-1,6

GPS1BHAF

CL00

150

6E

8E

0,55

0,75

1,6

1-1,7

GPS1BHAF

CL00

150

6E

8E

0,75

1

2

0,6-2,5 GPS1BHAG

CL00

150

6E

8E

1,1

1,5

2,6

2,5-4

GPS1BHAH

CL01

150

6E

8E

1,5

2

3,5

2,5-4

GPS1BHAH

CL01

150

6E

8E

2,2

3

5

4-6,3

GPS1BHAJ

CL02

150

6E

8E

3

4

7

6,3-10 GPS1BHAK

CL25

150

6E

8E

4

5,5

9

6,3-10 GPS1BHAK

CL25

150

6E

8E

5,5

7,5

12

9-13

GPS1BHAL

CL25

150

6E

8E

7,5

10

16

11-16 GPS1BHAM

CL25

150

6E

8E

11

15

22,5

19-25 GPS1BHAP

CL25

150

6E

8E

15

20

30

24-32 GPS2BHAR

CL04

150

6E

8E

18,5

25

37

28-40 GPS2BHAS

CL45

150

6E

8E

22

30

44

35-50 GPS2BHAT

CL06

150

6E

8E

30

40

60

45-63 GPS2BHAU

CL07

150

6E

8E

37

50

72

80

FDH160

CL08

RT2J

64-82

300 12E N/A

45

60

85

100

FDH160

CK85B

RT2L

78-97

450 18E N/A

55

75

105

125

FEH160

CK85B

RT2M

90-110

450 18E

N/A

75

101

138

160

FEH160

CK95B

RT3E 110-140 450 18E

N/A

90

121

170

250

FEH250

CK95B

RT4N 120-190 600 24E N/A

110

150

211

250

FEH250

CK10C

RT4R 200-310 600 24E N/A

132

180

240

250

FEH250

CK10C

RT4R 200-310 600 24E N/A

160

220

309

350

FGH400

CK10C

RT5C 250-400

N/A N/A

200

270

370

500

FGH630

CK10C

RT5D 315-500

N/A N/A

220

300

408

500

FGH630

CK10C

RT5D 315-500

N/A N/A

Fig. 27 Standardized fuseless motor-starter arrangements DOL (400V)

20

The motor-starters based on 3 pole arrangements at an operational voltage

of 500V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

T

h

e

rm

a

l

c

u

rr

e

n

t

b

re

a

k

e

r

ra

n

g

e

Circuit

breaker

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,66

0,63-1 GPS1BHAE

CL00

150

6E

8E

0,37

0,5

0,9

0,63-1 GPS1BHAE

CL00

150

6E

8E

0,55

0,75

1,2

1-1,6

GPS1BHAF

CL00

150

6E

8E

0,75

1

1,5

1-1,6

GPS1BHAF

CL00

150

6E

8E

1,1

1,5

2,1

1,6-2,5 GPS1BHAG

CL00

150

6E

8E

1,5

2

2,6

2,5-4

GPS1BHAH

CL25

150

6E

8E

2,2

3

3,8

2,5-4

GPS1BHAH

CL25

150

6E

8E

3

4

5

4-6,3

GPS1BHAJ

CL25

150

6E

8E

4

5,5

6,5

6,3-10 GPS1BHAK

CL25

150

6E

8E

5,5

7,5

9

6,3-10 GPS1BHAK

CL25

150

6E

8E

7,5

10

12

9-13

GPS1BHAL

CL25

150

6E

8E

11

15

17

14-20 GPS1BHAN

CL25

150

6E

8E

15

20

23

19-25 GPS1BHAP

CL04

150

6E

8E

18,5

25

28,5

24-32 GPS1BHAR

CL04

150

6E

8E

22

30

33

28-40 GPS2BHAS

CL06

150

6E

8E

30

40

45

35-50 GPS2BHAT

CL06

150

6E

8E

37

50

55

45-63 GPS2BHAU

CL07

150

6E

8E

45

60

65

80

FEH160

CL07

RT2J

64-82

300 12E N/A

55

75

80

100

FEH160

CK75C

RT2L

78-97

450 18E

N/A

75

101

105

100

FEH160

CK85B

RT2M

90-110

450 18E

N/A

90

121

129

125

FEH160

CK85B

RT3E 110-140 450 18E N/A

110

150

156

160

FEH160

CK95B

RT3F 140-190 450 18E N/A

132

180

188

250

FEH250

CK95B

RT4N 120-190 600 24E N/A

160

220

228

250

FEH250

CK10C

RT4R 200-310 600 24E N/A

200

270

281

250

FGH400

CK10C

RT4R 200-310

N/A N/A

220

300

310

400

FGH400

CK10C

RT5C 250-400

N/A N/A

250

340

348

400

FGH400

CK10C

RT5C 250-400

N/A N/A

Fig. 28 Standardized fuseless motor-starter arrangements DOL (500V)

21

The motor-starters based on 3 pole arrangements at an operational voltage

of 690V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

T

h

e

rm

a

l

c

u

rr

e

n

t

b

re

a

k

e

r

ra

n

g

e

Circuit

breaker

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

4

5,5

4,9

7

FEL160

CL03

RT12L

4-6.3

300 12E N/A

5,5

7,5

6,7

7

FEL160

CL03

RT1M

5.5-8.5

300 12E N/A

7,5

10

9

12,5

FEL160

CL07

RT2A

7.6-15

300 12E N/A

11

15

13

20

FEL160

CL07

RT2B 12.5-19 300 12E N/A

15

20

17,5

20

FEL160

CL07

RT2B 12.5-19 300 12E N/A

18,5

25

23

30

FEL160

CL09

RT2C 18.5-25 300 12E N/A

22

30

25

30

FEL160

CL09

RT2D

24-32

300 12E N/A

30

40

33

50

FEL160

CL09

RT2E

30-43

300 12E N/A

37

50

42

50

FEL160

CL09

RT2G

42-55

300 12E N/A

45

60

49

50

FEL160

CL09

RT2G

42-55

300 12E N/A

55

75

60

80

FEL160

CL09

RT2H

54-65

300 12E N/A

75

101

82

100

FEL160

CK75C

RT2L

78-97

450 18E N/A

90

121

98

100

FEL160

CK85B

RT2M

90-110

450 18E N/A

110

150

118

125

FEL160

CK85B

RT3E 110-140 450 18E N/A

132

180

140

160

FEL160

CK95B

RT3F 140-190 450 18E N/A

160

220

175

250

FEL250

CK95B

RT4N 120-190 600 24E N/A

200

270

214

250

FEL250

CK10C

RT4R 200-310 600 24E N/A

220

300

230

250

FEL250

CK10C

RT4R 200-310 600 24E N/A

250

340

270

400

FGL400

CK10C

RT5C 250-400

N/A N/A

Fig. 29 Standardized fuseless motor-starter arrangements DOL (690V)

22

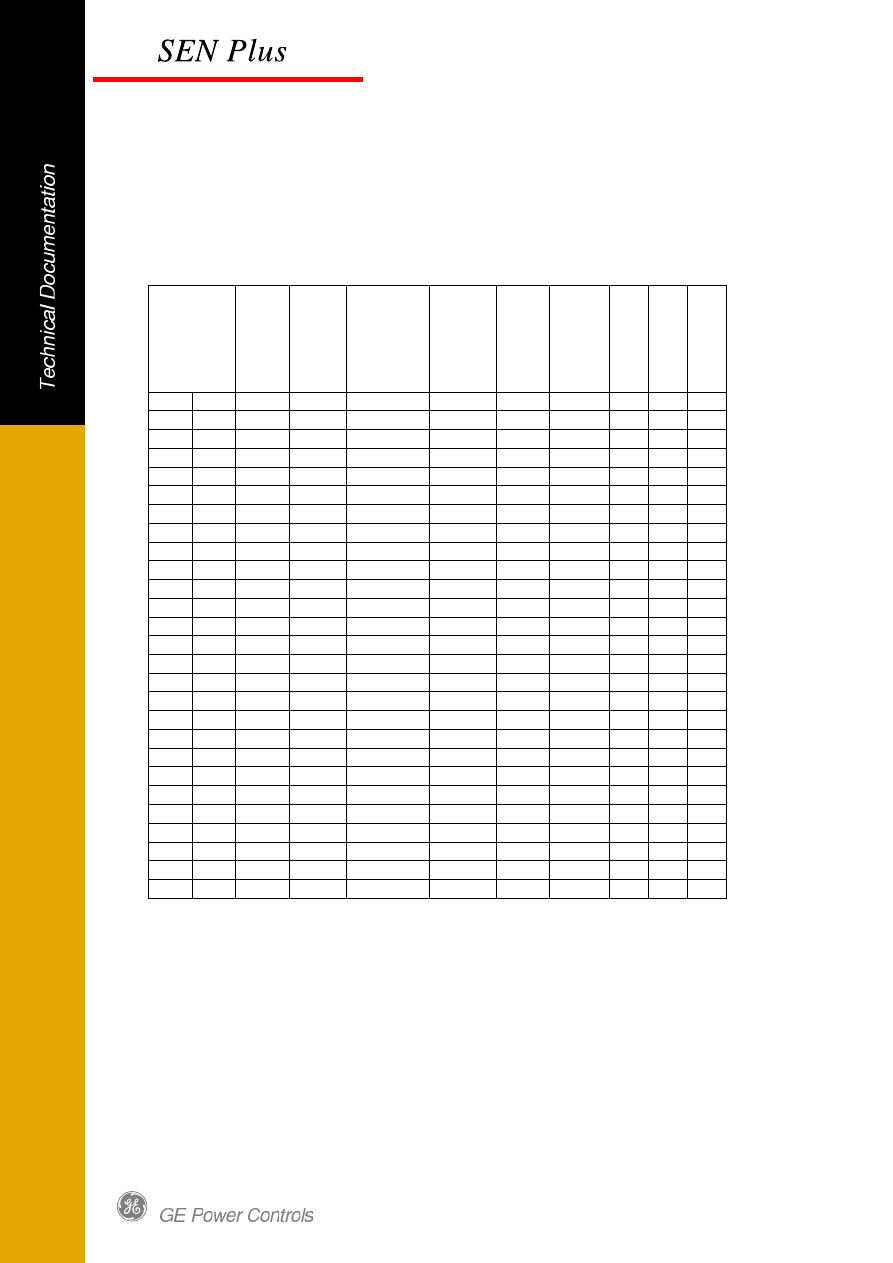

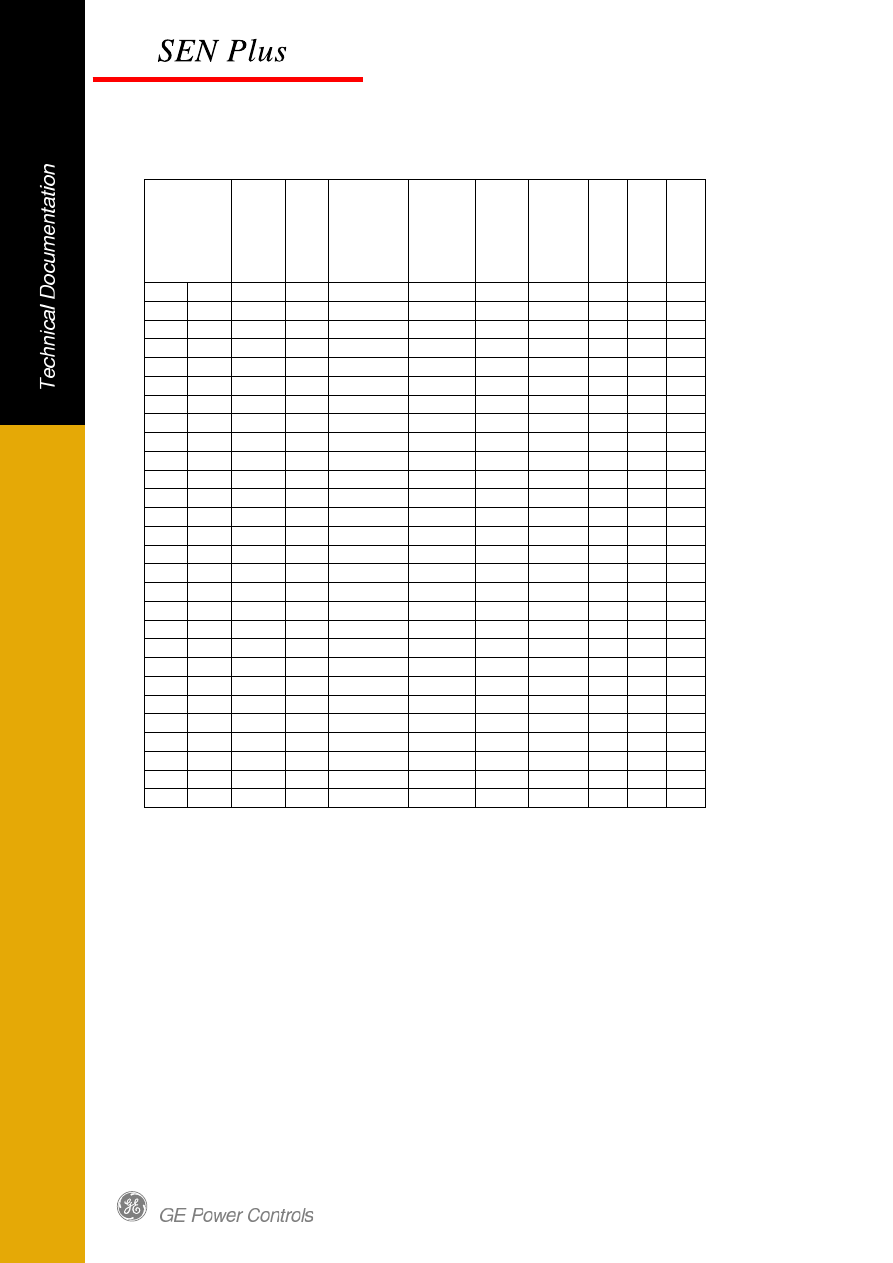

36.2.4 Reverse motor-starter with protection fuse DIN type

The motor-starters based on 3 pole arrangements at an operational voltage

of 400V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse

DIN

gL

Switch *) Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,9

2

DILOS 1

CL00

RT1F 0,65-1,1 200

8E

10E

0,37

0,5

1,13

4

DILOS 1

CL00

RT1G

1-1,5

200

8E

10E

0,55

0,75

1,6

4

DILOS 1

CL00

RT1H

1,3-1,9

200

8E

10E

0,75

1

2

4

DILOS 1

CL00

RT1J

1,8-2,7

200

8E

10E

1,1

1,5

2,6

4

DILOS 1

CL00

RT1K

2,5-4

200

8E

10E

1,5

2

3,5

6

DILOS 1

CL00

RT1K

2,5-4

200

8E

10E

2,2

3

5

10

DILOS 1

CL00

RT1L

4-6,3

200

8E

10E

3

4

7

16

DILOS 1

CL00

RT1N

8-12

200

8E

10E

4

5,5

9

20

DILOS 1

CL00

RT1N

8-12

200

8E

10E

5,5

7,5

12

25

DILOS 1

CL01

RT1N

8-12

200

8E

10E

7,5

10

16

35

DILOS 1

CL02

RT1P

10-16

200

8E

10E

11

15

22,5

35

DILOS 1

CL25

RT1U

21-26

200

8E

10E

15

20

30

50

DILOS 1

CL04

RT1V

25-32

200

8E

10E

18,5

25

37

63

DILOS 1

CL45

RT1W

30-40

200

8E

10E

22

30

44

63

DILOS 1

CL06

RT2G

42-55

250

10E

N/A

30

40

60

80

FULOS 000

CL07

RT2H

54-65

300

12E

N/A

37

50

72

100 FULOS 000

CL08

RT2J

64-82

300

12E

N/A

45

60

85

125

FULOS 00

CL09

RT2L

78-97

300

12E

N/A

55

75

105

160

FULOS 1

CL10

RT2M

90-110

600

24E

N/A

75

101

138

200

FULOS 1

CK75C

RT3E 110-140

N/A N/A

90

121

170

200

FULOS 1

CK08C

RT3F 140-190

N/A N/A

110

150

211

250

FULOS 2

CK85B

RT4P 175-280

N/A N/A

132

180

240

315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

160

220

309

400

FULOS 3

CK95B

RT4R 200-310

N/A N/A

200

270

370

500

FULOS 3

CK10C

RT5C 250-400

N/A N/A

220

300

408

500

FULOS 3

CK10C

RT5D 315-500

N/A N/A

Fig. 30 Standardized fused motor-starter arrangements reverse (400V)

*) DILOS1 plus fuse base size 000/00 160A

23

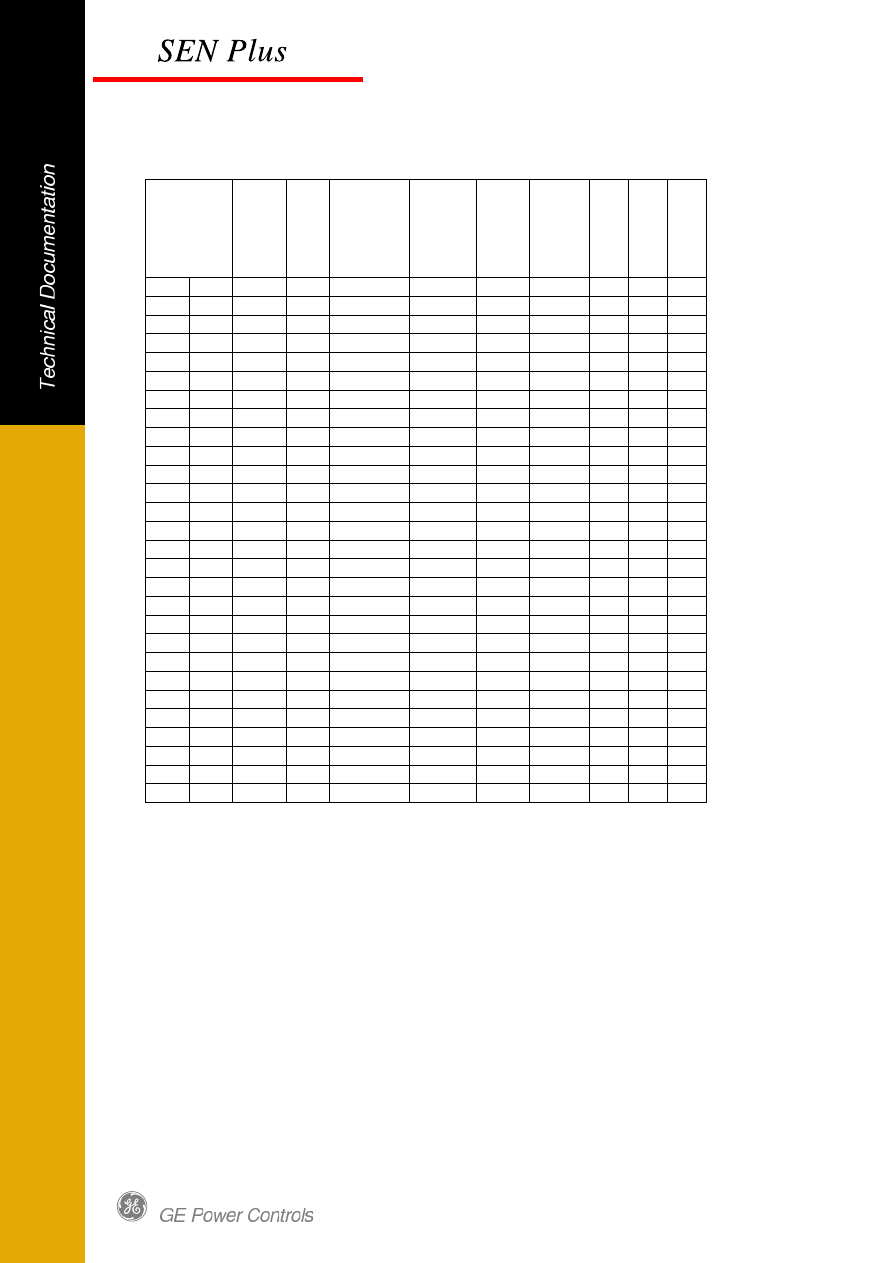

The motor-starters based on 3 pole arrangements at an operational voltage

of 500V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse

DIN

gL

Switch *) Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,66

4

DILOS 1

CL00

RT1D 0,4-0,65 200

8E

10E

0,37

0,5

0,9

4

DILOS 1

CL00

RT1F 0,65-1,1 200

8E

10E

0,55

0,75

1,2

4

DILOS 1

CL00

RT1G

1-1,5

200

8E

10E

0,75

1

1,5

6

DILOS 1

CL00

RT1H

1,3-1,9

200

8E

10E

1,1

1,5

2,1

6

DILOS 1

CL00

RT1J

1,8-2,7

200

8E

10E

1,5

2

2,6

6

DILOS 1

CL00

RT1K

2,5-4

200

8E

10E

2,2

3

3,8

10

DILOS 1

CL00

RT1K

2,5-4

200

8E

10E

3

4

5

16

DILOS 1

CL00

RT1L

4-6,3

200

8E

10E

4

5,5

6,5

25

DILOS 1

CL00

RT1N

8-12

200

8E

10E

5,5

7,5

9

25

DILOS 1

CL00

RT1N

8-12

200

8E

10E

7,5

10

12

25

DILOS 1

CL01

RT1N

8-12

200

8E

10E

11

15

17

40

DILOS 1

CL25

RT1S 14,5-18 200

8E

10E

15

20

23

50

DILOS 1

CL25

RT1U

21-26

200

8E

10E

18,5

25

28,5

50

DILOS 1

CL04

RT1V

25-32

200

8E

10E

22

30

33

80

DILOS 1

CL45

RT1W

30-40

200

8E

10E

30

40

45

100

DILOS 1

CL06

RT2G

42-55

250

10E

N/A

37

50

55

125 FULOS 000

CL07

RT2H

54-65

300

12E

N/A

45

60

65

125 FULOS 000

CL08

RT2J

64-82

300

12E

N/A

55

75

80

200

FULOS 1

CL09

RT2L

78-97

600

24E

N/A

75

101

105

200

FULOS 1

CK75C

RT3D

90-120

N/A N/A

90

121

129

200

FULOS 1

CK75C

RT3E 110-140

N/A N/A

110

150

156

250

FULOS 1

CK08C

RT3F 140-190

N/A N/A

132

180

188

315

FULOS 2

CK85B

RT4P 175-280

N/A N/A

160

220

228

315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

200

270

281

400

FULOS 3

CK95B

RT4R 200-310

N/A N/A

220

300

310

500

FULOS 3

CK10C

RT5C 250-400

N/A N/A

250

340

348

500

FULOS 3

CK10C

RT5D 315-500

N/A N/A

Fig. 31 Standardized fused motor-starter arrangements reverse (500V)

*) DILOS1 plus fuse base size 000/00 160A

24

The motor-starters based on 3 pole arrangements at an operational voltage

of 690V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse

DIN

gL

Switch *) Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,46

4

DILOS 1

CL00

RT1D 0,4-0,65 200

8E

10E

0,37

0,5

0,7

4

DILOS 1

CL00

RT1F 0,65-1,1 200

8E

10E

0,55

0,75

0,8

4

DILOS 1

CL00

RT1F 0,65-1,1 200

8E

10E

0,75

1

1,1

4

DILOS 1

CL00

RT1G

1-1,5

200

8E

10E

1,1

1,5

1,6

6

DILOS 1

CL00

RT1H

1,3-1,9

200

8E

10E

1,5

2

2,2

6

DILOS 1

CL00

RT1J

1,8-2,7

200

8E

10E

2,2

3

3,1

6

DILOS 1

CL00

RT1K

2,5-4

200

8E

10E

3

4

4,2

10

DILOS 1

CL00

RT1L

4-6,3

200

8E

10E

4

5,5

4,9

16

DILOS 1

CL00

RT1L

4-6,3

200

8E

10E

5,5

7,5

6,7

20

DILOS 1

CL00

RT1M

5,5-8,5

200

8E

10E

7,5

10

9

25

DILOS 1

CL01

RT1N

8-12

200

8E

10E

11

15

13

40

DILOS 1

CL25

RT1P

10-16

200

8E

10E

15

20

17,5

50

DILOS 1

CL25

RT1S 14,5-18 200

8E

10E

18,5

25

23

50

DILOS 1

CL04

RT1U

21-26

200

8E

10E

22

30

25

63

DILOS 1

CL45

RT1V

25-32

200

8E

10E

30

40

33

63

DILOS 1

CL45

RT1W

30-40

200

8E

10E

37

50

42

80

DILOS 1

CL07

RT2E

30-43

250

10E

N/A

45

60

49

100 FULOS 000

CL07

RT2G

42-55

300

12E

N/A

55

75

60

160

FULOS 00

CL09

RT2H

54-65

300

12E

N/A

75

101

82

200

FULOS 1

CK75C

RT3C

63-90

N/A N/A

90

121

98

160

FULOS 1

CK75C

RT3D

90-120

N/A N/A

110

150

118

200

FULOS 1

CK08C

RT3E 110-140

N/A N/A

132

180

140

250

FULOS 1

CK08C

RT3F 140-190

N/A N/A

160

220

175

250

FULOS 2

CK09B

RT4N 120-190

N/A N/A

200

270

214

315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

220

300

230

400

FULOS 2

CK95B

RT4P 175-280

N/A N/A

250

340

270

400

FULOS 2

CK95B

RT4P 175-280

N/A N/A

Fig. 32 Standardized fused motor-starter arrangements reverse (690V)

*) DILOS1 plus fuse base size 000/00 160A

25

36.2.5 Reverse motor-starter with protection fuse BS type

The motor-starters based on 3 pole arrangements at an operational voltage

of 400V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

Fuse BS

Switch *)

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

type

type

type

type

A

mm

0,25

0,33

0,9

NIT4

DILOS 1

CL00

RT1F 0,65-1,1 200

8E

10E

0,37

0,5

1,13

NIT6

DILOS 1

CL00

RT1G

1-1,5

200

8E

10E

0,55

0,75

1,6

NIT6

DILOS 1

CL00

RT1H

1,3-1,9

200

8E

10E

0,75

1

2

NIT10

DILOS 1

CL00

RT1J

1,8-2,7

200

8E

10E

1,1

1,5

2,6

NIT10

DILOS 1

CL00

RT1J

1,8-2,7

200

8E

10E

1,5

2

3,5

NIT16

DILOS 1

CL00

RT1K

2,5-4

200

8E

10E

2,2

3

5

NIT16

DILOS 1

CL00

RT1L

4-6,3

200

8E

10E

3

4

7

NIT20

DILOS 1

CL00

RT1M

5,5-8,5

200

8E

10E

4

5,5

9

NIT20M25

DILOS 1

CL00

RT1N

8-12

200

8E

10E

5,5

7,5

12

TLA32M35

DILOS 1

CL01

RT1P

10-16

200

8E

10E

7,5

10

16

TLA32M40

DILOS 1

CL02

RT1S 14,5-18 200

8E

10E

11

15

22,5

TLA32M50

DILOS 1

CL25

RT1T 17,5-22 200

8E

10E

15

20

30

TIS63M80

DILOS 1

CL04

RT1V

25-32

200

8E

10E

18,5

25

37

TIS63M80

DILOS 1

CL45

RT1W

30-40

200

8E

10E

22

30

44

TIS63M80

DILOS 1

CL06

RT2G

42-55

250

10E

N/A

30

40

60

OS100M125

FULOS 000

CL07

RT2H

54-65

300

12E

N/A

37

50

72

OS100M125

FULOS 000

CL07

RT2J

64-82

300

12E

N/A

45

60

85

TCP100M160

FULOS 00

CL08

RT2L

78-97

300

12E

N/A

55

75

105

TCP100M160

FULOS 00

CL10

RT2M

90-110

300

12E

N/A

75

101

135

TF200M250

FULOS 1

CK75C

RT3E 110-140

N/A N/A

90

121

165

TF200M315

FULOS 1

CK08C

RT3F 140-190

N/A N/A

110

150

211

TF200M315

FULOS 1

CK85B

RT4P 175-280

N/A N/A

132

180

240

TKF315

FULOS 2

CK09B

RT4P 175-280

N/A N/A

160

220

309

TKF315M355

FULOS 2

CK95B

RT4R 200-310

N/A N/A

200

270

370

TM400

FULOS 3

CK10C

RT5C 250-400

N/A N/A

220

300

408

TM450

FULOS 3

CK10C

RT5D 315-500

N/A N/A

Fig. 33 Standardized fused motor-starter arrangements reverse (400V)

*) DILOS1 plus fuse base:

RS20H up to 4kW

RS32H 5,5 to 11kW

RS63H 15 to 22kW

26

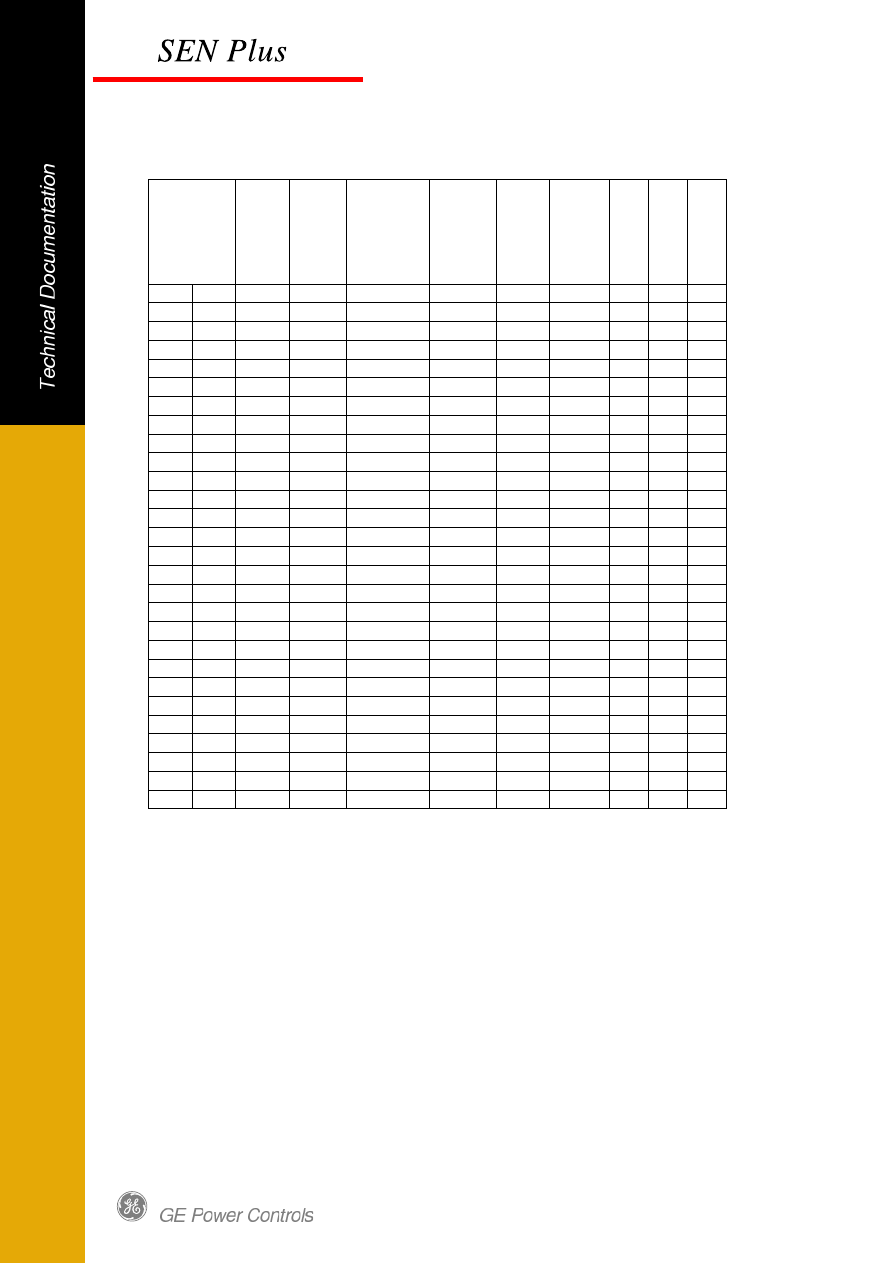

36.2.6 Reverse motor-starter with circuit breaker protection

The motor-starters based on 3 pole arrangements at an operational voltage

of 400V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

T

h

e

rm

a

l

c

u

rr

e

n

t

b

re

a

k

e

r

ra

n

g

e

Circuit

breaker

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,9

0,63-1 GPS1BHAE

CL00

150

6E

8E

0,37

0,5

1,13

1-1,6

GPS1BHAF

CL00

150

6E

8E

0,55

0,75

1,6

1-1,7

GPS1BHAF

CL00

150

6E

8E

0,75

1

2

0,6-2,5 GPS1BHAG

CL00

150

6E

8E

1,1

1,5

2,6

2,5-4

GPS1BHAH

CL01

150

6E

8E

1,5

2

3,5

2,5-4

GPS1BHAH

CL01

150

6E

8E

2,2

3

5

4-6,3

GPS1BHAJ

CL02

150

6E

8E

3

4

7

6,3-10 GPS1BHAK

CL25

150

6E

8E

4

5,5

9

6,3-10 GPS1BHAK

CL25

150

6E

8E

5,5

7,5

12

9-13

GPS1BHAL

CL25

150

6E

8E

7,5

10

16

11-16 GPS1BHAM

CL25

150

6E

8E

11

15

22,5

19-25 GPS1BHAP

CL25

150

6E

8E

15

20

30

24-32 GPS2BHAR

CL04

150

6E

8E

18,5

25

37

28-40 GPS2BHAS

CL45

200

8E

10E

22

30

44

35-50 GPS2BHAT

CL06

200

8E

10E

30

40

60

45-63 GPS2BHAU

CL07

200

8E

10E

37

50

72

80

FDH160

CL07

RT2J

64-82

300 12E

N/A

45

60

85

100

FDH160

CK85B

RT2L

78-97

600 24E

N/A

55

75

105

125

FEH160

CK85B

RT2M

90-110

600

24E

N/A

75

101

138

160

FEH160

CK95B

RT3E 110-140 600

24E

N/A

90

121

170

250

FEH250

CK95B

RT4N 120-190

N/A

N/A

110

150

211

250

FEH250

CK10C

RT4R 200-310

N/A

N/A

132

180

240

250

FEH250

CK10C

RT4R 200-310

N/A

N/A

160

220

309

350

FGH400

CK10C

RT5C 250-400

N/A

N/A

200

270

370

500

FGH630

CK10C

RT5D 315-500

N/A

N/A

220

300

408

500

FGH630

CK10C

RT5D 315-500

N/A

N/A

Fig. 34 Standardized fuseless motor-starter arrangements reverse (400V)

27

The motor-starters based on 3 pole arrangements at an operational voltage

of 500V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

T

h

e

rm

a

l

c

u

rr

e

n

t

b

re

a

k

e

r

ra

n

g

e

Circuit

breaker

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

0,25

0,33

0,66

0,63-1 GPS1BHAE

CL00

150

6E

8E

0,37

0,5

0,9

0,63-1 GPS1BHAE

CL00

150

6E

8E

0,55

0,75

1,2

1-1,6

GPS1BHAF

CL00

150

6E

8E

0,75

1

1,5

1-1,6

GPS1BHAF

CL00

150

6E

8E

1,1

1,5

2,1

1,6-2,5 GPS1BHAG

CL00

150

6E

8E

1,5

2

2,6

2,5-4

GPS1BHAH

CL25

150

6E

8E

2,2

3

3,8

2,5-4

GPS1BHAH

CL25

150

6E

8E

3

4

5

4-6,3

GPS1BHAJ

CL25

150

6E

8E

4

5,5

6,5

6,3-10 GPS1BHAK

CL25

150

6E

8E

5,5

7,5

9

6,3-10 GPS1BHAK

CL25

150

6E

8E

7,5

10

12

9-13

GPS1BHAL

CL25

150

6E

8E

11

15

17

14-20 GPS1BHAN

CL25

150

6E

8E

15

20

23

19-25 GPS1BHAP

CL04

150

6E

8E

18,5

25

28,5

24-32 GPS1BHAR

CL04

150

6E

8E

22

30

33

28-40 GPS2BHAS

CL06

150

6E

8E

30

40

45

35-50 GPS2BHAT

CL06

200

8E

10E

37

50

55

45-63 GPS2BHAU

CL07

200

8E

10E

45

60

65

80

FEH160

CL07

RT2J

64-82

300 12E N/A

55

75

80

100

FEH160

CK75C

RT2L

78-97

600 24E N/A

75

101

105

100

FEH160

CK85B

RT2M

90-110

600 24E N/A

90

121

129

125

FEH160

CK85B

RT3E 110-140 600 24E N/A

110

150

156

160

FEH160

CK95B

RT3F 140-190 600 24E N/A

132

180

188

250

FEH250

CK95B

RT4N 120-190

N/A N/A

160

220

228

250

FEH250

CK10C

RT4R 200-310

N/A N/A

200

270

281

250

FGH400

CK10C

RT4R 200-310

N/A N/A

220

300

310

400

FGH400

CK10C

RT5C 250-400

N/A N/A

250

340

348

400

FGH400

CK10C

RT5C 250-400

N/A N/A

Fig. 35 Standardized fuseless motor-starter arrangements reverse (500V)

28

The motor-starters based on 3 pole arrangements at an operational voltage

of 690V 50 Hz. Type 2 Coordination (acc. IEC 60947-4-1) / AC3 category 50kA.

Motor load Current

T

h

e

rm

a

l

c

u

rr

e

n

t

b

re

a

k

e

r

ra

n

g

e

Circuit

breaker

Contactor TOR

TOR

range

U

n

it

h

e

ig

h

t

M

o

d

u

le

s

iz

e

E

x

tr

a

M

o

d

u

le

s

iz

e

kW

HP

A

A

type

type

type

A

mm

4

5,5

4,9

7

FEL160

CL03

RT12L

4-6.3

300 12E N/A

5,5

7,5

6,7

7

FEL160

CL03

RT1M

5.5-8.5

300 12E N/A

7,5

10

9

12,5

FEL160

CL07

RT2A

7.6-15

450 18E N/A

11

15

13

20

FEL160

CL07

RT2B 12.5-19 450

18E N/A

15

20

17,5

20

FEL160

CL07

RT2B 12.5-19 450

18E N/A

18,5

25

23

30

FEL160

CL09

RT2C 18.5-25 450

18E N/A

22

30

25

30

FEL160

CL09

RT2D

24-32

450

18E N/A

30

40

33

50

FEL160

CL09

RT2E

30-43

450

18E N/A

37

50

42

50

FEL160

CL09

RT2G

42-55

450

18E N/A

45

60

49

50

FEL160

CL09

RT2G

42-55

450

18E N/A

55

75

60

80

FEL160

CL09

RT2H

54-65

450

18E N/A

75

101

82

100

FEL160

CK75C

RT2L

78-97

600 24E N/A

90

121

98

100

FEL160

CK85B

RT2M

90-110

600

24E N/A

110

150

118

125

FEL160

CK85B

RT3E 110-140 600

24E N/A

132

180

140

160

FEL160

CK95B

RT3F 140-190 600

24E N/A

160

220

175

250

FEL250

CK95B

RT4N 120-190

N/A N/A

200

270

214

250

FEL250

CK10C

RT4R 200-310

N/A N/A

220

300

230

250

FEL250

CK10C

RT4R 200-310

N/A N/A

250

340

270

400

FGL400

CK10C

RT5C 250-400

N/A N/A

Fig. 36 Standardized fuseless motor-starter arrangements reverse (690V)

Document Outline

- 35.0 Control Centre Fixed Type

- 35.1 General Characteristics

- 36.1 Feeder Arrangement

- 36.1.1 Feeder with Moulded Case Circuit Breaker

- 36.1.3 Module sizes

- 36.1.4 De-ratings

- 36.1.5 Weights

- 36.1.6 Power Loss

- 36.1.7 Arrangement for External Connections

- 36.2 Motor-starter arrangements

- 36.2.1 Direct on line starter with protection fuse DIN type

- 36.2.2 Direct on line starter with protection fuse BS type

- 36.2.3 Direct on line starter with circuit breaker protection

- 36.2.4 Reverse motor-starter with protection fuse DIN type

- 36.2.5 Reverse motor-starter with protection fuse BS type

- 36.2.6 Reverse motor-starter with circuit breaker protection

Wyszukiwarka

Podobne podstrony:

19 05 2012 Techniczne bezpieczeństwo pracyid 18228

05 Stosowanie technik graficznych i multimedialnych

2 Rzutowanie 11str, 05 RYSUNEK techniczny, 2 Rzutowanie

05 Zastosowanie technik kompute Nieznany

Ekonomia miedzynarodowa postep techniczny doc

Sprawdzian 26.05, masaz, technik masazysta, Gmail

12 05 2012 Techniczne bezpieczeństwo pracyid 13359

~$sunki na egzamin z techniki doc

OPIS TECHNICZNY DOC

Specyfikacja techniczna doc

~$is techniczny doc

02 OPIS TECHNICZNY DOC

OPIS TECHNICZNYnasz doc

05 Zastosowanie technik komputerowych

D elementow techniki doc

Podkłady kolejowe, szyny dane techniczne doc

Pomiary rezystancji i mocy prądu stałego metodą techniczną doc

Piotr Pietrzak I KBI Opis Techniczny doc

więcej podobnych podstron