1. Structural sketch of the examined shaft-bearing system.

2. Records of measurements and juxtaposition of calculations and plots of measured relationships ![]()

for P=const.

a) ![]()

Lp. |

v[obr/s] |

u[mV] |

U[V] |

∆U[V] |

n[obr/min] |

2*Mt[N*m] |

∆(2Mt)[Nm] |

µ srednie |

∆µ srednie |

błąd + |

błąd - |

1 |

10 |

8,5 |

0,425 |

0,0135 |

600 |

0,304371 |

0,009668 |

0,006442 |

0,001815 |

0,008257 |

0,004627 |

2 |

20 |

9,5 |

0,475 |

0,0145 |

1200 |

0,340179 |

0,010384 |

0,0072 |

0,00202 |

0,009219 |

0,00518 |

3 |

30 |

9 |

0,45 |

0,014 |

1800 |

0,322275 |

0,010026 |

0,006821 |

0,001917 |

0,008738 |

0,004903 |

4 |

40 |

9 |

0,45 |

0,014 |

2400 |

0,322275 |

0,010026 |

0,006821 |

0,001917 |

0,008738 |

0,004903 |

5 |

50 |

9,5 |

0,475 |

0,0145 |

3000 |

0,340179 |

0,010384 |

0,0072 |

0,00202 |

0,009219 |

0,00518 |

b) ![]()

Lp. |

v[obr/s] |

u[mV] |

U[V] |

∆U[V] |

n[obr/min] |

2*Mt[N*m] |

|

µ srednie |

∆µ srednie |

błąd + |

błąd - |

1 |

10 |

11 |

0,55 |

0,016 |

600 |

0,393892 |

0,011459 |

0,004168 |

0,000642 |

0,00481 |

0,003526 |

2 |

20 |

11,5 |

0,575 |

0,0165 |

1200 |

0,411796 |

0,011817 |

0,004358 |

0,00067 |

0,005027 |

0,003688 |

3 |

30 |

11 |

0,55 |

0,016 |

1800 |

0,393892 |

0,011459 |

0,004168 |

0,000642 |

0,00481 |

0,003526 |

4 |

40 |

11 |

0,55 |

0,016 |

2400 |

0,393892 |

0,011459 |

0,004168 |

0,000642 |

0,00481 |

0,003526 |

5 |

50 |

11,5 |

0,575 |

0,0165 |

3000 |

0,411796 |

0,011817 |

0,004358 |

0,00067 |

0,005027 |

0,003688 |

c) ![]()

Lp. |

v[obr/s] |

u[mV] |

U[V] |

∆U[V] |

n[obr/min] |

2*Mt[N*m] |

∆(2Mt)[Nm] |

µ srednie |

∆µ srednie |

błąd + |

błąd - |

1 |

10 |

11,5 |

0,575 |

0,0165 |

600 |

0,411796 |

0,011817 |

0,002905 |

0,000325 |

0,003231 |

0,00258 |

2 |

20 |

11,5 |

0,575 |

0,0165 |

1200 |

0,411796 |

0,011817 |

0,002905 |

0,000325 |

0,003231 |

0,00258 |

3 |

30 |

11,5 |

0,575 |

0,0165 |

1800 |

0,411796 |

0,011817 |

0,002905 |

0,000325 |

0,003231 |

0,00258 |

4 |

40 |

11 |

0,55 |

0,016 |

2400 |

0,393892 |

0,011459 |

0,002779 |

0,000312 |

0,003091 |

0,002466 |

5 |

50 |

12 |

0,6 |

0,017 |

3000 |

0,4297 |

0,012175 |

0,003031 |

0,000339 |

0,00337 |

0,002693 |

d) ![]()

Lp. |

v[obr/s] |

u[mV] |

U[V] |

∆U[V] |

n[obr/min] |

2*Mt[N*m] |

∆(2Mt)[Nm] |

µ srednie |

∆µ srednie |

błąd + |

błąd - |

1 |

10 |

12 |

0,6 |

0,017 |

600 |

0,4297 |

0,012175 |

0,002274 |

0,000207 |

0,00248 |

0,002067 |

2 |

20 |

12 |

0,6 |

0,017 |

1200 |

0,4297 |

0,012175 |

0,002274 |

0,000207 |

0,00248 |

0,002067 |

3 |

30 |

11,5 |

0,575 |

0,0165 |

1800 |

0,411796 |

0,011817 |

0,002179 |

0,000199 |

0,002378 |

0,00198 |

4 |

40 |

11,5 |

0,575 |

0,0165 |

2400 |

0,411796 |

0,011817 |

0,002179 |

0,000199 |

0,002378 |

0,00198 |

5 |

50 |

12,5 |

0,625 |

0,0175 |

3000 |

0,447604 |

0,012533 |

0,002368 |

0,000214 |

0,002583 |

0,002154 |

e) ![]()

Lp. |

v[obr/s] |

u[mV] |

U[V] |

∆U[V] |

n[obr/min] |

2*Mt[N*m] |

∆(2Mt)[Nm] |

µ srednie |

∆µ srednie |

błąd + |

błąd - |

1 |

10 |

12 |

0,6 |

0,017 |

600 |

0,4297 |

0,012175 |

0,001819 |

0,000142 |

0,001961 |

0,001676 |

2 |

20 |

12 |

0,6 |

0,017 |

1200 |

0,4297 |

0,012175 |

0,001819 |

0,000142 |

0,001961 |

0,001676 |

3 |

30 |

12 |

0,6 |

0,017 |

1800 |

0,4297 |

0,012175 |

0,001819 |

0,000142 |

0,001961 |

0,001676 |

4 |

40 |

11,5 |

0,575 |

0,0165 |

2400 |

0,411796 |

0,011817 |

0,001743 |

0,000137 |

0,00188 |

0,001606 |

5 |

50 |

12,5 |

0,625 |

0,0175 |

3000 |

0,447604 |

0,012533 |

0,001895 |

0,000148 |

0,002042 |

0,001747 |

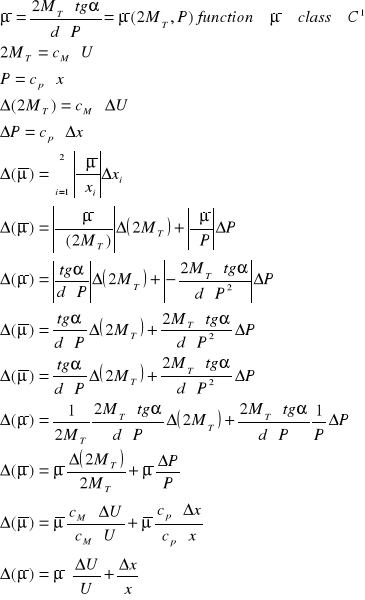

3. Derive of formula

4. Plots of measured relationships ![]()

for n=const; in the graphs, indicate error intervals.

n=600

n=1200

n=1800

n=2400

n=3000

5. Observations concerning measuring setup structure, measuring methods, and final conclusions.

The preload and the total moment acting on the bearing were measured directly. Knowing appropriate formulas and the parameters of the system we can calculate the friction coefficient in the bearings.

The error of deflection depends mainly on the scaling error (due to inaccuracy of the millimeter scale and hysteresis of the spring) and the read-out error. The voltage measurement error is arising due to nonlinearity and hysteresis of mechanical characteristics of the transducer, as well as instability of amplifier circuits and its reference voltage. Vibrations generated by the rotating shaft also influenced our measurements and caused some errors.

Angular bearings can carry transverse loads only if they are simultaneously subjected to axial (thrust) force. Otherwise they don't work properly and failure can occur.

The value of preload has a big influence on the friction coefficient - contrarily to the value of rotations per minute. With the increase of preload the value of friction coefficient decreases.

Experiment 2 - Support of axles and shafts in angular bearings

Page -12-

Wyszukiwarka

Podobne podstrony:

lab pkm 4

lab pkm 5

W2K3-15-raport, WAT, SEMESTR VII, Systemy operacyjne windows, Systemy operacyjne windows, sow, W2K3-

lab pkm 3

lab 3 gradkowski- kolos, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 4, Gradko

lab pkm 6new

ściąga pkm lab i projekt

pytaniawela11-20(beta version), Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 4,

lab pkm 7

jadzia, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 6

jadzia poprawiona, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 6

pkm1, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 6

odp PKM Lozysko, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 4, Gradkowski, la

Lab. 7 - wnioski, Polibuda MBM PWR 2012-2016, Sem. V, PKM I, Lab

lab pkm 1

pytaniawela1-10(beta version), Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 4,

potoczny, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab 2, Potoczny

16 GD, lab pkm

Pkm lab lepiarczyk, Domumenty, Studia, Studia, 2 rok, PKM, PKM-różne laboratoria, lab3 - lepiarczyk

więcej podobnych podstron