essentÊrving°42

Essential \Voodcarving Techkiques

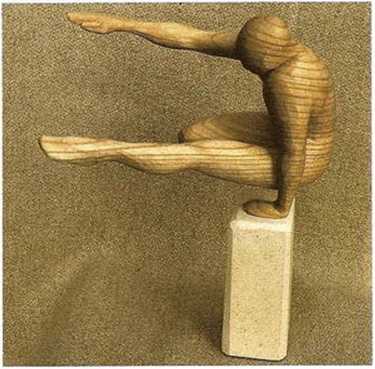

Fig 2.24 Vaulter carued in cauilpa by Dick Oniatis. The strong markings of this ring-porous timber accentuate the movement. The strength of the grain rum along the potential weak arem ofleg and arm. The short grain in the supporting arm is confined to a smali area which is strengthened by the fixing pin that rum through it into the stone base.

poisoning of plants and unplcasanrness of application. However, the colour even of crcaied wood left cxposed to the weather gradually changes to a silvery grey. Varnishcs arc of only short lifc, and as the wood moves moisture generally gers trapped under them and rot or mould staining occurs. Paint hidcs the figurÄ™ of wood and can trap moisture in the same way. Danish and tung oils are besc for keeping colour but necd rccoating cvcry fcw years. Linsccd oil, whether raw or boiled, tends to attraci grimc when uscd out of doors and will go black.

Choosing Wood with Appropriate Strengths

When selecting timber for particular work the strengths have to be taken into account. Brittle or

crumbly woods are undesirable wherc sharp edges or chin forms are needed. A tough wood like ash is appropriate wherc thin forms have short grain in them {see Chapter 13). It is best to arrange for slcndcr forms to have long grain, that is, to have the grain running along them. It is not always possiblc to ensure this for all parts of a carving and risks may have to be taken (Fig 2.24), but the design can often be adjusted. It is sometimes necessary to add long, weak limbs, such as arms, not only for strength but also to make a sculpture larger than the availablc błock. When this is done a wood with either no figurę, like limę, or one with a wild figurę, such as walnut, makes the join less obvious. The same is truć when you laminate pieces to make a large błock (Fig 2.25). Fudging joins with fillcrs can spoił a carving. Care has to be taken in the planning of any joints, as well as in the making of them, if they are not to be unsighdy.

Tf.sting Wood for its Suitability

Almost all woods are carvable, and your choice will be affected by the timc you are prepared to spend on a piece, the tools you have, the finished texture you want and the woods available. If you are in doubt the simplest test is to try a sharp knife or chisel on different aspects of the grain. Most woods work well along the grain. If wood is intrinsically soft or is diseased it will tear or crumblc when cut across the side grain. Cutting across the end grain is the best test. You should beware if it plueks and crumbles. Rotary machines and sandpaper may be the only way to carvc such wood. If you necd great effort to cut across end grain you will have to be prepared to spend a long time on carving. One consolation is that if you want to sand it, it will take far less time than a soft wood. It will also last better.

-42 -

Wyszukiwarka

Podobne podstrony:

essent?rving?36 E S S E N T I A L W o O D C A R V ! N G T E C H X i .. Fig 12.19 Edward Greene (khay

essent?rving?43 S T V L I Z 1 X G THE F I G U R E Fig 13.12 Essays in stylization. followed too clos

essent?rving?54 FlG 14.10 A sculpture on the theme of Compression in cedar of Lebanon by Zena Micha

image045 Fig. 21. Wolgast - a plan from about 1760 (a siraplified copy). The stronghold and St Peter

essent?rving?70 Essential Woodcaryinc Techntiques Fig 5.11 The top surface of the leaffinished, with

essent?rving?14 pp Essential Woodcarvixg Techniques W Fig 1.17 Ttoo grounders. Very narrow old Engli

essent?rving?18 Essen tul Woodcarning Techniques Fig 1.29 A bench holdfast in use. Fig 1.28 A univer

essent?rving?22 ESSENTIAL W O O D C A R VIN G T E C H N IQ U E S Fig 1.36 It is possible to use the

essent?rving?31 S K L K C T lG AND B l Y I N G Sl l T A B I E W O O D Fig 2.7 The tiuisted bark on t

essent?rving?40 Essen tial Woodcarying Techniques FlG 2.20 Arrow Crosstree (Dick Onians), carued in

essent?rving?47 First C i t s: Chip C a r v i n c, Fig 3.3 The depth of the stab cut. exercise. Cut

essent?rving?52 Essen’ tial W o o d c a r v i n g Techniques Fig 3.18 A No. 3 fishtail being used to

essent?rving?77 C A R VI X G T RADITIONAL F O L 1 A G E Fig 6.8 Rococo frame showing leafedges to un

essent?rving?82 ESSENTIAL W o O D C A R VIXG T E C H N1Q U E S Fig 7.3 Drawings ofa linenfoldpatiem

essent?rving?84 Essential Woodcarving Techniques Fig 7.7 This is how a piece of card would look if f

essent?rving?92 Essentiai. Voodcarving T e c h n i q u f. s che ground then began crcating the relat

essent?rving?98 Essential Woodcarving Techniques Fig 9.1 Various lines. The one on the left Incks in

essent?rving?24 E S ii E Nil A L W O O O C A R V l N O, T E C H X I Q L F. S Fig 11.14 The left sic

essent?rving?29 C A R v I N O. Tl-IF. H l* M A N F I C, f R F. Fig 12.5 Finished małe figurę. (Notę

więcej podobnych podstron