6837092899

14 Diagnostyka’ 4(48)/2008

KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pressure in Compression Ignition Engine ...

°CA

fuzzy system for engine work modeling, 3) development of methodology for "timing" tliis model for other fuels.

2. TEST STAND

Experimental research was madę on the test stand (presented in Part 1) built of diesel engine Perkins AD3.152UR, water brake and control cubicle. The cylinder pressure was measured by piezoelectric transducers. Measured values were recorded in function of cranksliaft angle degrees (°CA). The engine was fueled by FAMĘ. Measurements were done when engine operated in extemal speed cliaracteristic regime with the crankshaft speeds 1000. 1200, 1400, 1600, 1800 and 2000 rpm. Cylinder pressure values were recorded eveiy 1.4 °CA (exactly 512 measurements for one working cycle of 4-stroke engine). At each measurement point. values of parameters were recorded. for 50 consecutive working cycles. Indicator diagrams. acquired in tliis way, were averaged.

3. RESULTS OF EXPERIMENTAL

RESEARCH AND MODELING OF

PRESSURE CURVE

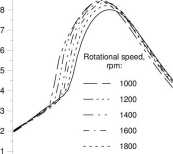

Fig. 1 shows acquircd indicator diagrams of cylinder pressure. for engine work at different rotational speeds and for ranges 180-540 and 340-390 °CA. For the latter rangę, the differences between pressure curves for different rotational speeds are noticeable. Fast pressure increase (for FAMĘ fuel) starts at 3.3 to 3.9 MPa. and 351° to 357° CA. When rotational speed increases, maximum cylinder pressure decreases, but the cranksliaft angle. at which it appears. increases. Maximum value of slope of the tangent linę to tlie pressure curve decreases with increase of rotational speed from 1400 to 2000 rpm [4]. Knowledge of first and second derivative of pressure curie with respect to crankshaft angle allows detennining the start of self-ignition.

The calculations were madę by means of GFSm system [4], proposed by the authors. which can be described as a method of generation of fuzzy models by means of genetic algoritlun [2, 3], GFSm creates Mamdani fuzzy' model (Fig. 2) or Takagi-Sugeno fuzzy model. The model describes relations between input \ ariables and output \ariable. which describe given phenomena or process. Model produced by GFSm predicts cylinder pressure for all possible rotational speeds in AD3.152UR engine fueled by diesel oil - this was presented in Part 1 of paper. In order to predict pressure for another fuel (like FAMĘ), we added two scaling functions: one for input scaling and one for output scaling (Fig. 2).

a)

pc, MPa 9

b)

pc, MPa

- 2000

0

340 350 360 370 380 390

°CA

Fig. 1. Indication diagram of cylinder pressure in diesel engine working at extemal speed cliaracteristic and fueled by FAMĘ. in function of crankshaft angle. for several CA speeds: a) in the rangę 180° - 540°. b) in the rangę 340° - 390°

Parameters of these functions are different for each fuel. In order to find these values, we measured cylinder pressure curve for one rotational speed (1200 rpm) when engine was fueled by FAMĘ. Later. we used this curve to obtain parameters of scaling functions.

Fig. 2. Mamdani-type fuzzy model (with scaling functions). which has two input variables xt and x2, and one output \ ariable y

Wyszukiwarka

Podobne podstrony:

10 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

16 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI. Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pres surę in Compression

12 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 11 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 13 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 15 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 DYBAŁA, GAŁĘZIĄ, MĄCZAK, Verification Of Doppler EffectRemovalMethodFor The

Diagnostyka’ 4(48)/2008 DYBAŁA, GALĘZIA, MĄCZAK, I erificalion Of Doppler Effect Removal AleihodFor

Diagnostyka’ 4(48)/2008 DYBA!A, GALĘZIA, MĄCZAK, 1 erification Of Doppler Effect ReniovalMełhodFor T

14 Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

17 Diagnostyka 4(48)/2008 BARSZCZ, MASKA, Application of Hardware-In-Loop for 11irtualPower

Diagnostyka’ 4(48)/2008 BARSZCZ, MAŃKA, Application ofHardware-In-Loop for 1 irlual Power Piani •

Diagnostyka 4(48)/2008 Spis treści / Contents Jubileuszprof. Lesława BĘDKOWSKIEGO / Jubilee of Profe

Diagnostyka 4(48)/2008 Spis treści/ Contents Jędrzej MĄCZAK - Politechnika

Diagnostyka’ 4(48)/2008 Jubileusz prof. Lesława BĘDKOWSKIEGO / Jubilee of Profesor Lesław

Diagnostyka’ 4(48)/2008 7 DYBAŁA, GALĘZIA, MĄC7.AK, Yerification Of Doppler Effect

14 Diagnostyka’ 3(47)/2008 ENGEL: Wkład Profesora Czesława CEMPELA w rozwój wibroakustyki Rys. 1.

Diagnostyka’ l(45)/2008 RYBCZYŃSKI, Maps offolerable Misalignments of Bearings Applicable...MAPS OF

więcej podobnych podstron