6837092900

Diagnostyka’ 4(48)/2008 15

KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pres surę in Compression Ignition Engine ...

Table 2. Parameters of output scaling function

|

Para meter |

Yalue | |

|

a° |

p,.fora whenfd2pĄ |

for diesel oil |

|

“l |

WL |

for a new fuel (e.g. FAMĘ) |

|

for diesel oil | ||

|

*3 |

for a new fuel (e.g. FAMĘ) | |

The output scaling function y'= f(y) has the form given by the eąuation:

y —— for y <a0

y=| a a° (i)

(y-ao)'°3_fl2'+g2 foryŁao

where a0,ax,a2,a2 values are calculated in the way given in Table 2.

The idea of calculation of a0,aha2,a3 parameters is shown in Fig. 3. After the calculation of output scaling parameters, we also calculate aA parameter value for input scaling, which "moves” pressurc curve along with horizontal axis. We select a value of “move” for which mean indicated pressure is calculated with highest accuracy.

The results are quite good: we acquired Takagi-Sugeno model for diesel oil, which has good accuracy (mean indicated pressure error less than 3.9% and maximum pressure error less than 2.1%, for all rotational speeds). Later, we measured cylinder pressure curve for FAMĘ fliel, at 1200 rpm and calculated parameters of input and output scaling functions. The resulting model (Fig. 4) had also good accuracy (mean indicated pressure error less than 4.1% and maximum pressure error less tlian 2.6%, for all rotational speeds).

4. CONCLUDING REMARKS

During experimental research the cylinder pressure curves in function of crankshaft angle were recorded while engine was fueled with diesel oil and FAMĘ. The results of measurements for diesel oil allowed building of model of engine work by means of GFSm system. The acquired model was later “tuned” for FAMĘ fuel, by using input and output scaling in fuzzy model. The resulting model has good accuracy for both diesel oil and FAMĘ (mean indicated pressure error less than 4.1% and maximuin pressure error less than 2.6%).

4. CONCLUDING REMARKS

During experiinental research the cylinder pressure curves in function of crankshaft angle were recorded winie engine was fueled with diesel oil and

FAMĘ. The results of measurements for diesel oil allowed building of model of engine work by means of GFSm system. The acquired model was later luned” for FAMĘ fuel, by using input and output scaling in fuzzy model. The resulting model has good accuracy for both diesel oil and FAMĘ (mean indicated pressure error less than 4.1% and maximum pressure error less than 2.6%).

c) d)

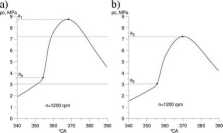

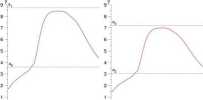

Fig. 3. Idea of calculation of parameters and work of output scaling function: a) experimental cylinder pressure curve pc when engine operated in extemal speed characteristic regiine at 1200 rpm and was fueled by diesel oil and idea of calculation of a0 and ax values, b) experiinental cylinder pressure curve pc when engine operated in extemal speed characteristic regime at 1200 rpm and was fueled by a new fuel (e.g. FAMĘ) and idea of calculation of a2 and values, c) modeled cylinder pressure curve pc for any given rotational speed, without output scaling (for diesel oil) d) modeled cylinder pressure curve pc for any given rotational speed, with output scaling (for new fuel, e.g. FAMĘ)

Wyszukiwarka

Podobne podstrony:

Diagnostyka’ 4(48)/2008 11 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 13 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pres surę in Compression

12 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

10 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

14 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI, Modeling of Cylinder Pre

16 Diagnostyka’ 4(48)/2008 KEKEZ, AMBROZIK, RADZISZEWSKI. Modeling of Cylinder Pre

Diagnostyka’ 4(48)/2008 Jubileusz prof. Lesława BĘDKOWSKIEGO / Jubilee of Profesor Lesław

Diagnostyka’ 4(48)/2008 7 DYBAŁA, GALĘZIA, MĄC7.AK, Yerification Of Doppler Effect

Diagnostyka’ l(45)/2008 15 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

Diagnostyka’ 4(48)/2008 DYBAŁA, GAŁĘZIĄ, MĄCZAK, Verification Of Doppler EffectRemovalMethodFor The

17 Diagnostyka 4(48)/2008 BARSZCZ, MASKA, Application of Hardware-In-Loop for 11irtualPower

Diagnostyka’ 4(48)/2008 BARSZCZ, MAŃKA, Application ofHardware-In-Loop for 1 irlual Power Piani •

Diagnostyka 4(48)/2008 Spis treści / Contents Jubileuszprof. Lesława BĘDKOWSKIEGO / Jubilee of Profe

Diagnostyka 4(48)/2008 Spis treści/ Contents Jędrzej MĄCZAK - Politechnika

Diagnostyka’ 4(48)/2008 DYBAŁA, GALĘZIA, MĄCZAK, I erificalion Of Doppler Effect Removal AleihodFor

Diagnostyka’ 4(48)/2008 DYBA!A, GALĘZIA, MĄCZAK, 1 erification Of Doppler Effect ReniovalMełhodFor T

Diagnostyka’ l(45)/2008 13 RYBCZYŃSKI, Maps ofTolerable Misalignments of Bearings

Diagnostyka’ l(45)/2008 17 RYBCZYŃSKI, Maps ofTolerable Misalignmenls of Bearings

więcej podobnych podstron