Translation from Polish

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-169

EDITION

1

DFME

DAMEL S.A.

INDUCTION MINING MOTORS

2SGS 355L-8/4

PAGE

1/6

File no: 125 250 kW, 2SGS 355L-8 4.doc/2006

APPLICATION

The two-speed motors of 2SGS type and mechanical series of 355 are intended for driving mining machines and

equipment, especially for belt conveyors and scraper belt conveyors.

The motors can be used in underground parts of mines and surface installations of the mines, where there are

possible explosion conditions for methane and/or coal dust.

There is also possible to operate the motors in the surroundings where the explosion-proof equipment is not

required.

CHARACTERISTIC FEATURES OF MOTORS

•

Induction 3-phase motors with squirrel-cage rotor, with two independent windings: for synchronous speed of

750 r.p.m. – so called “slow speed” (2p=8) and for synchronous speed of 1500 r.p.m. – so called “fast speed”

(2p=4).

•

Explosion-proof construction with flame-proof casing of motor “d” - mark

I M2 Exd I, equipment ranked

as group I of category M2 according to Directive 94/9/CE.

•

Degree of protection IP 55 acc. to PN-EN 60034-5:2004.

•

The motors are cooled by water flowing through the water channels in body and a channel of bearing’s disk

P connected in series with the body.

•

Form of execution: flanged execution – IM 3001 (B5); flanged FF740.

•

Basic voltage execution: 1000; 1140V – 50Hz .

After settlement it is possible to execute the motors for other voltage and frequency of 60Hz.

•

Class of insulation: class H – basic execution, class H + reinforced wound insulation – execution against

order.

•

Thermal protection of motors: bimetal sensors (NC) or posistor PTC sensors in winding and bearing nodes –

two identical circuits: basic and stand-by.

•

Temperature control: thermometric resistors Pt 100 in winding and bearing nodes (execution against order).

•

Two-inlet terminal box with one or two cable inlets with rubber gaskets selected to the outer diameters of

conductors, type Wk3u/d... produced by DAMEL (Catalogue Card K4-15-136).

•

The motor is equipped with the final link of protection conductor continuity control circuit, mounted in the

terminal box – primary execution: the final link CK-OA.

After settlement the assembly of final unit CK of other type is possible (e.g. diode+resistor, reverse polarity,

etc.) produced by DAMEL (Catalogue card K4-15-121).

•

Feeding and start-up: the motors are intended for feeding from the power network – start-up by direct

switching on the voltage.

•

The motors adapted for work in temperate climate.

After settlement the adaptation for work in tropical climate TA or TH is possible.

COMPATIBILITY WITH REQUIREMENTS OF STANDARDS

The motors meet requirements of Directive 94/9/CE (ATEX), European harmonized norms and domestic norms:

- norms for electrical equipment in areas of explosion hazard:

-

EN 60079-0:2004 – Polish equivalent PN-EN 60079-0:2004(U),

-

EN 60079-1:2004 – Polish equivalent PN- EN 60079-1:2004(U),

-

EN 60079-7:2003 – Polish equivalent PN-EN 60079-7:2004(U),

- norms for rotational electric machines:

-

EN 60034-1:2004 – Polish equivalent PN-EN 60034-1:2005(U)

-

domestic norms for induction motors for mining machines:

-

PN G-38010:1997 (domestic norm).

CERTIFICATES

The motors have the certificates:

-

certificate CE (ATEX) issued by notified Testing Station GIG KD “BARBARA”, valid on the area of

European Union.

Translated by: PTU -DAMAR- Sosnowiec

Translation from Polish

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-169

EDITION

1

DFME

DAMEL S.A.

INDUCTION MINING MOTORS

2SGS 355L-8/4

PAGE

2/6

File no: 125 250 kW, 2SGS 355L-8 4.doc/2006

Translated by: PTU -DAMAR- Sosnowiec

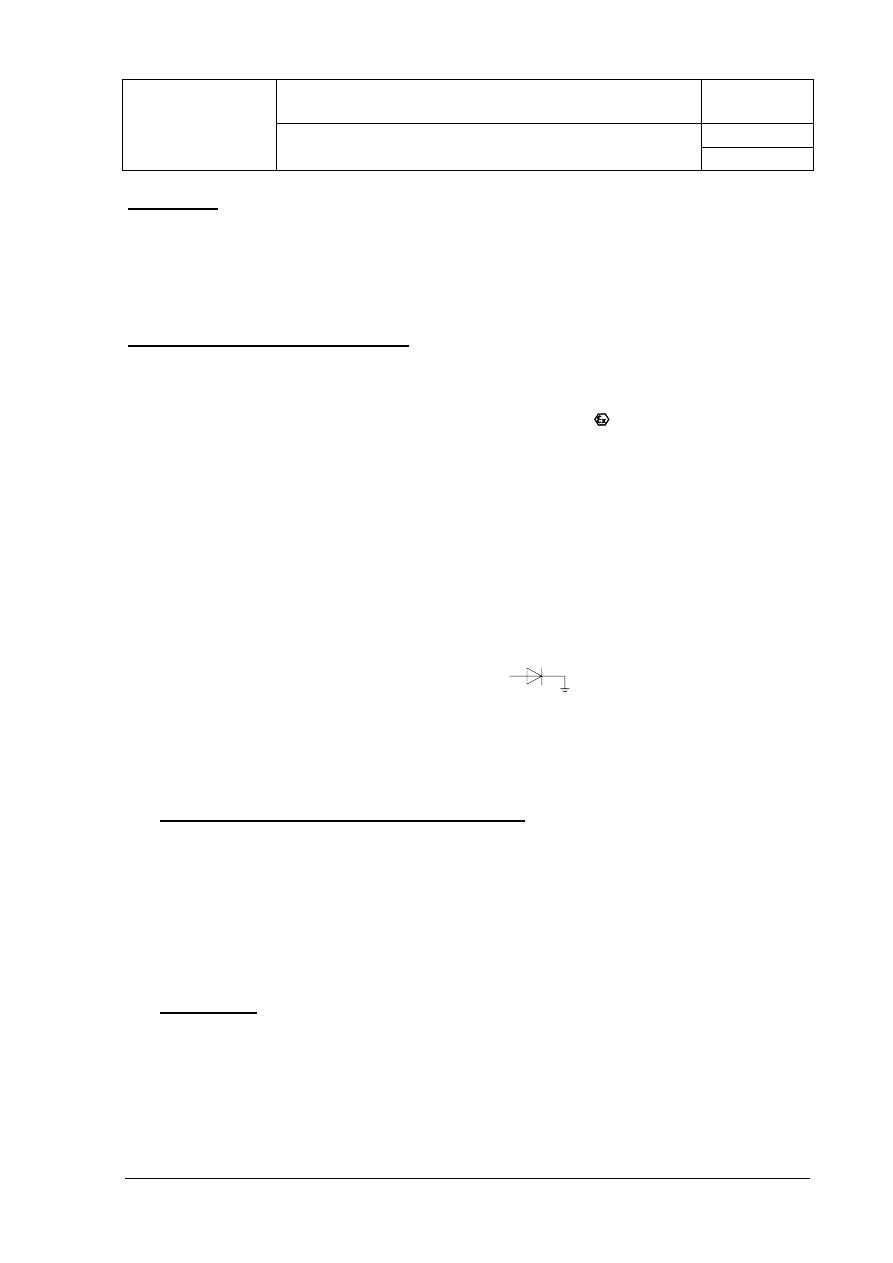

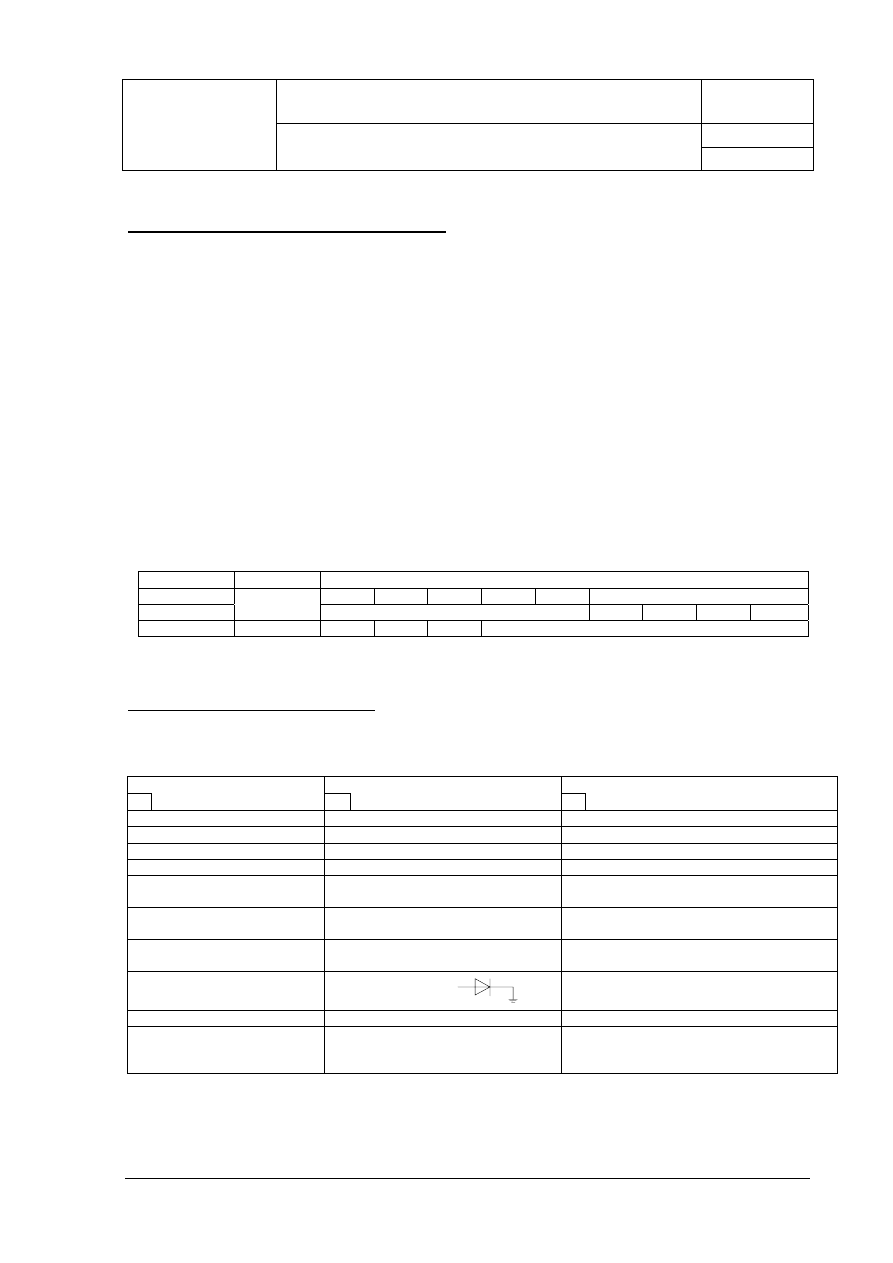

TECHNICAL DATA

Table 1

Parameters

2SGS

355L-8/4

Rated power P

N

[kW] 125/250

Current at rated voltage

I

N

[A]

1000V

I

N

[A]

1140V

105/172

92/151

Power factor cos

ϕ

0,74/0,88

Efficiency

η

[%] 93/95,5

Rotational speed n

[min

-1

] 739/1485

Rated moment M

N

[Nm] 1615/1608

Multiplicity of start-up current I

K

/I

N

5,1/6,8

Multiplicity of start-up moment M

K

/M

N

2,7/2,5

Multiplicity of critical moment M

Max

/M

N

2,7/2,6

Minimal flow of cooling water

[dm

3

/min]

12

Mode of operation

S1;

S4-60%, 75c/h, J

ext

/J

M

=0,6

Rotor moment of inertia J

M

[kgm

2

]

13

Mass of motor

[kg]

2400

1. The parameters of motor: rated current, efficiency, power factor, rotational speed and rated moment

relate to rated load at rated feeding conditions – 50Hz.

2. Multiplicities of start-up current , start-up moment and critical moment refer to direct connection of the

motor to the supply network (mains).

3. J

ext

– inertia moment of motor load referred to the axis of shaft .

Translation from Polish

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-169

EDITION

1

DFME

DAMEL S.A.

INDUCTION MINING MOTORS

2SGS 355L-8/4

PAGE

3/6

File no: 125 250 kW, 2SGS 355L-8 4.doc/2006

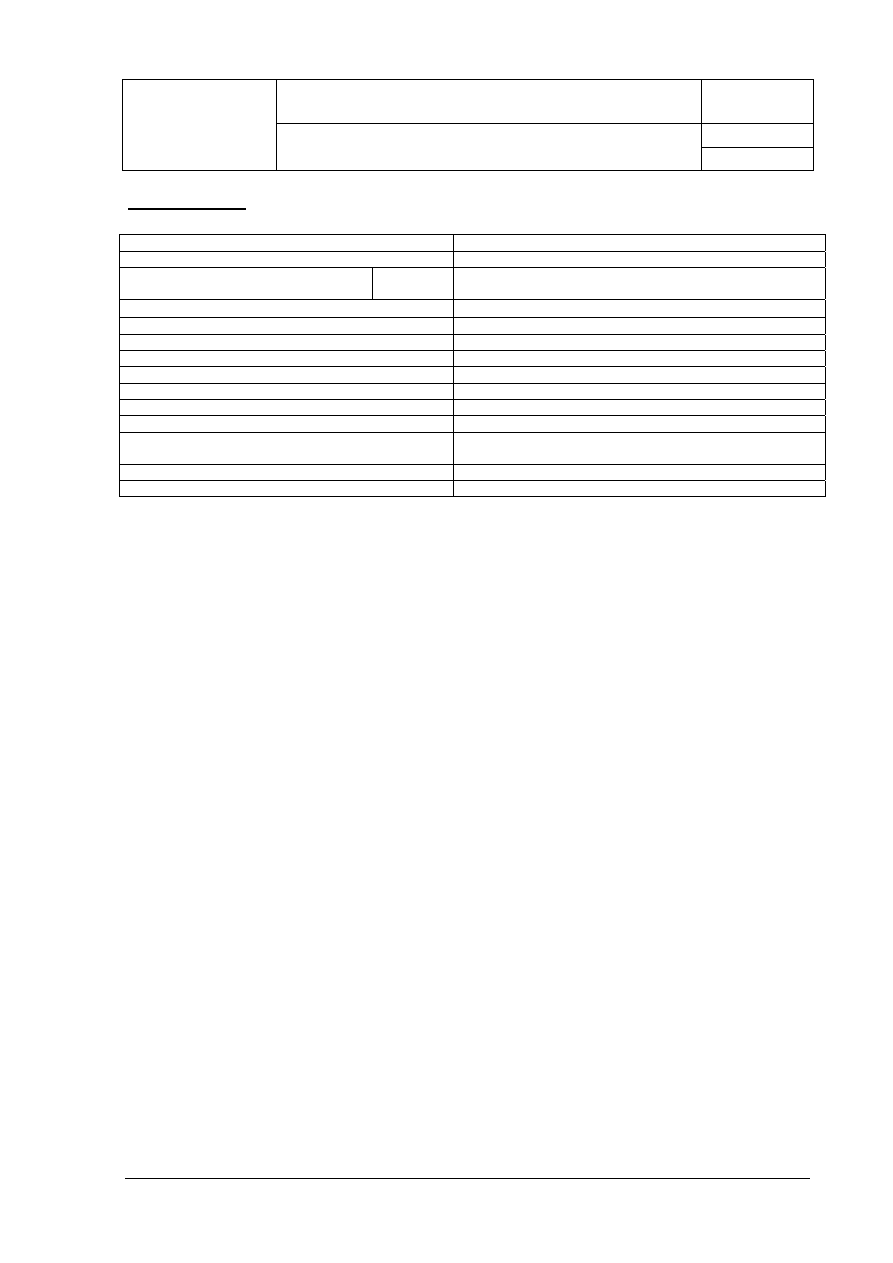

bearing

winding

NC bimetals

or PTC

posistors

version without thermometric resistors Pt 100

NC bimetals

or PTC

posistors

thermometric resistors

Pt 100

version with thermometric resistors Pt 100

Fig. 1 Diagram of motor connections

-

winding, protective terminals, thermal protection.

High pressure hose

Water outlet

Water inlet

Body

Disk P

Fig. 2 Diagram of cooling system

Translated by: PTU -DAMAR- Sosnowiec

Translation from Polish

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-169

EDITION

1

DFME

DAMEL S.A.

INDUCTION MINING MOTORS

2SGS 355L-8/4

PAGE

4/6

File no: 125 250 kW, 2SGS 355L-8 4.doc/2006

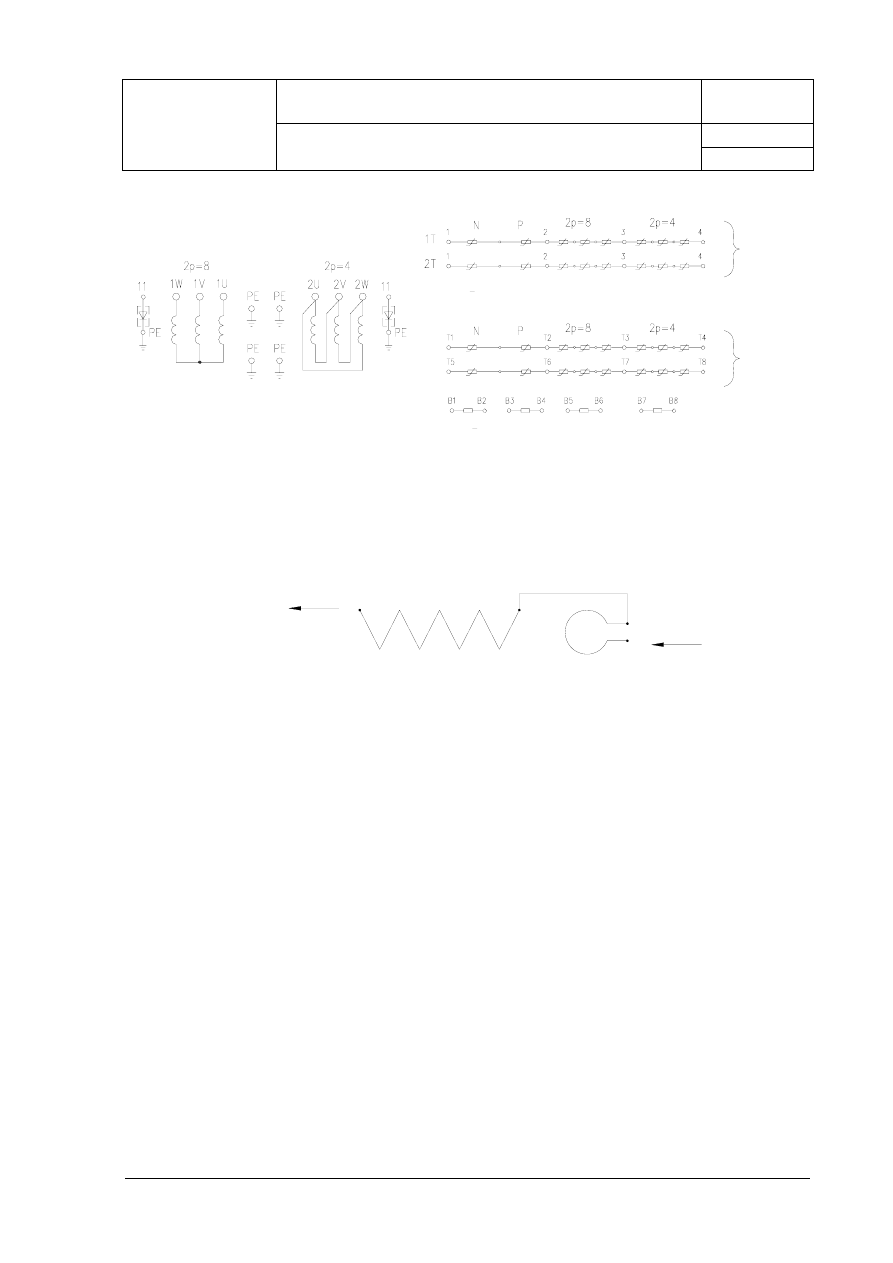

Water inlet

Water outlet

Centre hole

M20

View W

View P

Cable inlet

or stopper

Cable inlet

Water inlet

Water outlet

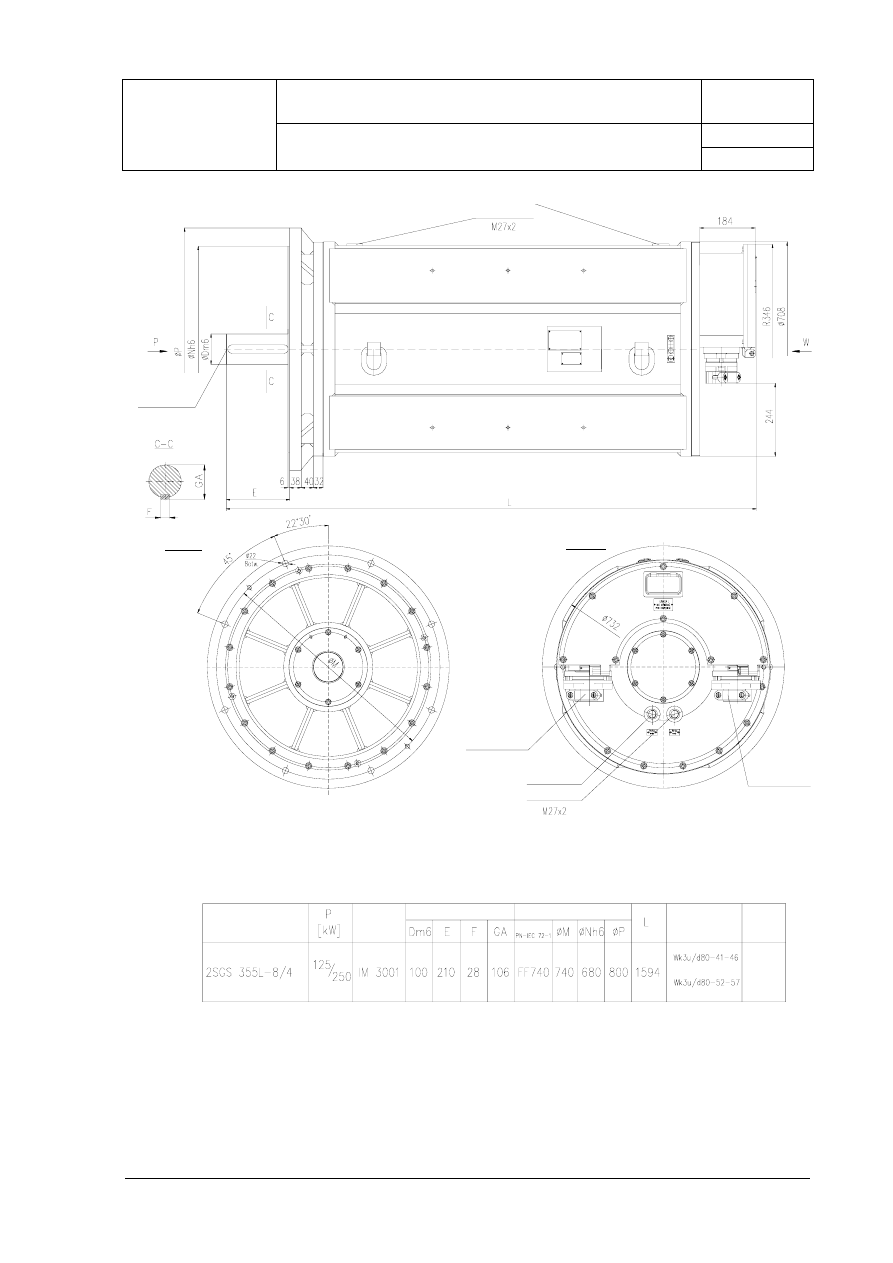

Table 2

Flange

The shaft of

Diagram

of cooling

system

Cable inlets

(basic

execution)

Form of

executio

Type of

motor

acc. to

acc. to

Fig. 2

Fig. 3 Assembly and overall dimensions of motors.

Translated by: PTU -DAMAR- Sosnowiec

Translation from Polish

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-169

EDITION

1

DFME

DAMEL S.A.

INDUCTION MINING MOTORS

2SGS 355L-8/4

PAGE

5/6

File no: 125 250 kW, 2SGS 355L-8 4.doc/2006

CONDITIONS OF OPERATION AND APPLICATION

• Ambient

temperature

0÷40

o

C

•

Relative humidity at temperature of 35

o

C 97÷100%

•

Height above the sea level

≤ 1000m

•

Degree of corrosive aggressiveness C acc. to PN-71/H-04651

•

Admissible inclination of the shaft axis to level

< 30

o

•

Parameters of cooling water at inlet of cooling system

-

maximum temperature

+30

o

C

-

maximum static pressure

3MPa

• Supply

voltage

(0,95÷1,05)U

N

•

Electrical terminal

Power supply connection – mining armour conductor with rubber armour and insulation, multicore, screened

for voltage of 0,6/1kV, with section area of cores selected to operating conditions.

Connection of auxiliary circuits of temperature sensors and temperature control thermometric elements –

auxiliary cores of feeder armour conductor or multicore armoured (control) conductor with section area of

wires up to 4mm

2

.

When connecting the motor with one conductor the other inlet hole of the terminal box is stopped FLP by

stopper Zk3u.

•

Leading the flexible conductors to terminal box through cable inlets selected according to the outer

diameter of conductors acc. to table 3.

Table 3

Type of inlet

Conductor

The range of diameters of conductors for cable inlets

Wk3u/d80

40÷44 41÷46 44÷49 48÷53 52÷57

Wk3u/d100

Feeding

55÷61

59÷65

62÷68

68÷74

Wk3u/d47

Control

19÷21

20÷24

22÷26

In case the Orderer does not state the type of cable inlet (outer diameter of conductor ) the motor is delivered

with cable inlet and stopper determined acc. to Table 2.

OFFER FOR DELIVERIES OF MOTORS

The producer offers motors in primary execution and in options executed against the order from offeree

(additional, diversified equipment).

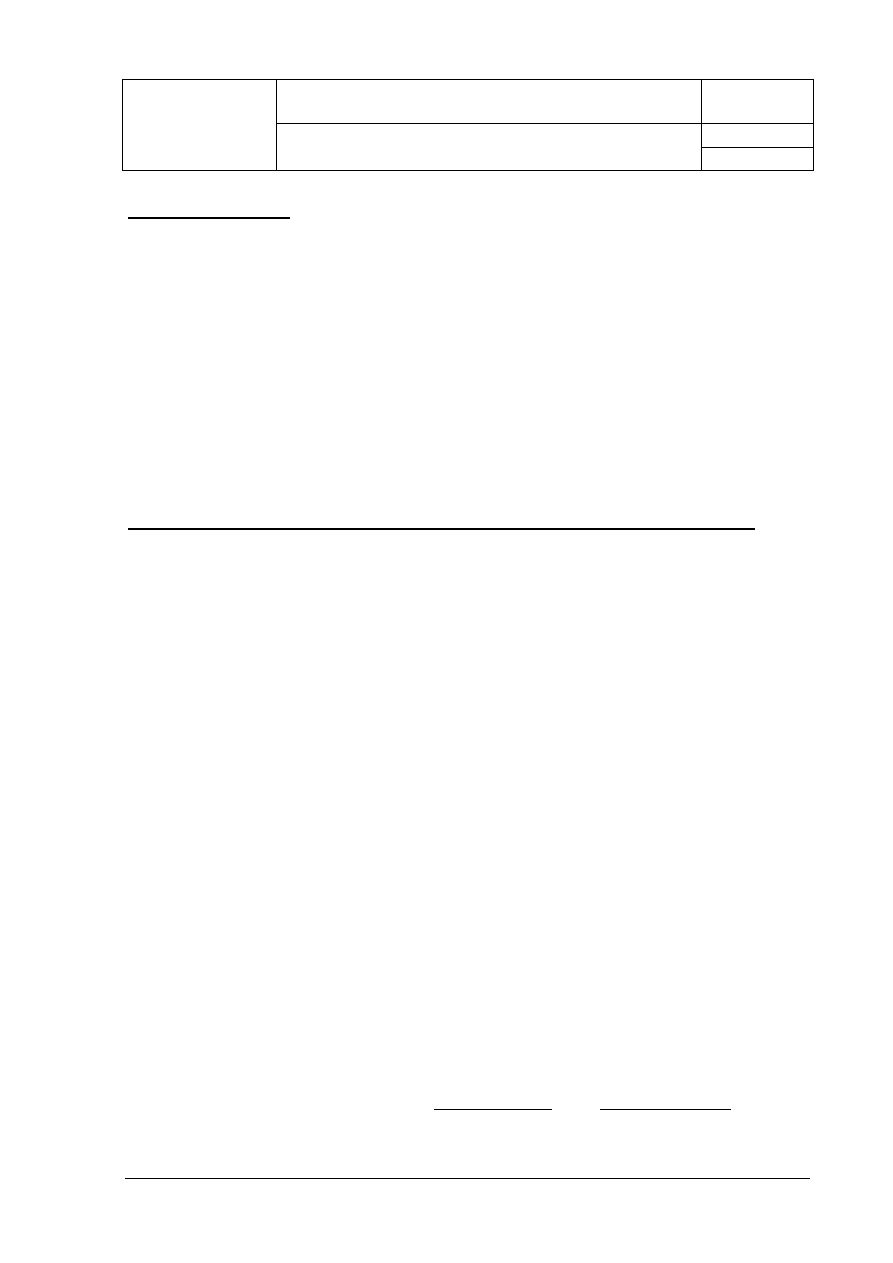

Table 4

1

Constructional

characteristic of motor

2

Primary execution

3

Execution against order

rated voltage

1000; 1140V other

voltage

frequency 50Hz

60Hz

form of execution

Flanged IM 3001(B5)

–

class of insulation

H

H + reinforced wound insulation

thermal protection

– type of sensors

bimetal NC

posistor PTC

Temperature control

- thermometric elements

–

thermometric resistors Pt100

cable inlets

two cable inlets Wk3u/d80…

-see table 2

one or two cable inlets Wk3u

- see table 3, or conductor connection

final link of control circuit

CK-0A

CK … appointed by Orderer

(acc. to catalogue card K4-15-121)

climatic execution

for temperate climate

for tropical climate TH or TA

constructional characteristic

other than above mentioned

–

acc. to settlements, it can require

acceptance of the unit certifying the

product

The following items are included to the delivered motors by producer:

- service manual,

- declaration of conformity CE.

Translated by: PTU -DAMAR- Sosnowiec

Translation from Polish

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-169

EDITION

1

DFME

DAMEL S.A.

INDUCTION MINING MOTORS

2SGS 355L-8/4

PAGE

6/6

File no: 125 250 kW, 2SGS 355L-8 4.doc/2006

Translated by: PTU -DAMAR- Sosnowiec

ORDERING PROCEDURE

The following data should be stated in the order directed to the address of

manufacturer given below:

-

type of motor, power

-

rated voltage and frequency

-

motor execution: preliminary – see table 4 column 2 or execution against order, for which required

equipment and constructional characteristic should be determined acc. to table 4 column 3.

When ordering we recommend to fill up the questionnaire „Statement of technical data of the motor...” –

accessible at internet (web) sites and in Marketing Department of DFME DAMEL.

The producer offers additionally:

- guarantee and after guarantee service of motors,

- delivery of spare parts,

- training of employees in the range of correct maintenance and operating the motor.

Producer reserves the right to implement to the motor changes resulting from technical progress.

Dąbrowska Fabryka Maszyn Elektrycznych DAMEL S. A.

Aleja Józefa Piłsudskiego 2, 41-300 Dąbrowa Górnicza, POLSKA, tel: (32) 262-32-30 do 39

Faks (32) 264-34-26, 264-10-12, http: www.damel.com.pl, email: office@damel.com.pl

Elaboration: “DAMEL” – TK/PG/01/2006

Document Outline

- APPLICATION

- CHARACTERISTIC FEATURES OF MOTORS

- COMPATIBILITY WITH REQUIREMENTS OF STANDARDS

- CERTIFICATES

- TECHNICAL DATA

- 1. The parameters of motor: rated current, efficiency, power factor, rotational speed and rated moment relate to rated load at rated feeding conditions – 50Hz.

- 2. Multiplicities of start-up current , start-up moment and critical moment refer to direct connection of the motor to the supply network (mains).

- CONDITIONS OF OPERATION AND APPLICATION

- OFFER FOR DELIVERIES OF MOTORS

- ORDERING PROCEDURE

Wyszukiwarka

Podobne podstrony:

85 250, 105 315 kW, 2SGS 355L 12 4, 2SGS 400S 12 4

Katalog Części Jawa CZ Typ 473 04 125 ccm 470 04 175 ccm 475 04 250 ccm Rok 1966

kw żółciowe

KW o sukcesji państw

125 szuttaid 14026 Nieznany (2)

125

125 SC DS300 R TOYOTA AVENSIS A 03 XX

pair sala 125

125 Ośrodki informacji Iid 14023

125 pytanid 14024 Nieznany

ARKUSZ DIAGNOSTYCZNY GM M4 125 Nieznany (2)

Nowe prawo Praktyka z 23 grudnia 08 (nr 250)

StacjonarneBAT pytania egzamin2013-KW, Uczelnia PWR Technologia Chemiczna, Semestr 6, BAT-y egzamin

250

Domy Olgi Tokarczuk-KW, tokarczuk

Kw szczawiowy, WNOŻCiK wieczorowe, semestr V, toksykologia

Kataster nieruchomosci KW, EGiB

Wykaz KW

więcej podobnych podstron