"SHAPE YOUR SUSTAINABILITY TOOLS

- and let your tools shape you"

Uppsala, Sweden 23-24.9.2009

Scenario analysis of fuel-pellet production

– the influence of torrefaction on material

flows and energy balances

Wihersaari M

1,2

, Agar D

1

, Kallio M

2

1

University of Jyväskylä

2

VTT

"SHAPE YOUR SUSTAINABILITY TOOLS

- and let your tools shape you"

Uppsala, Sweden 23-24.9.2009

OUTLINE

- "Traditional" pellet production (2005)

- Trends & visions

- Pellets in Eforwood

- Introducing new process: Torrefraction

- Torrefraction affect material and energy balances of

pellet production - how?

"SHAPE YOUR SUSTAINABILITY TOOLS

- and let your tools shape you"

Uppsala, Sweden 23-24.9.2009

Pellet production in Europe 2005

2-3 million tonnes produced (10-15 TWh)

~200 pellet plants

~1-2 % of harvested wood ended up in pellets

present raw material: saw dust (by product)

branch depencence!

"SHAPE YOUR SUSTAINABILITY TOOLS

- and let your tools shape you"

Uppsala, Sweden 23-24.9.2009

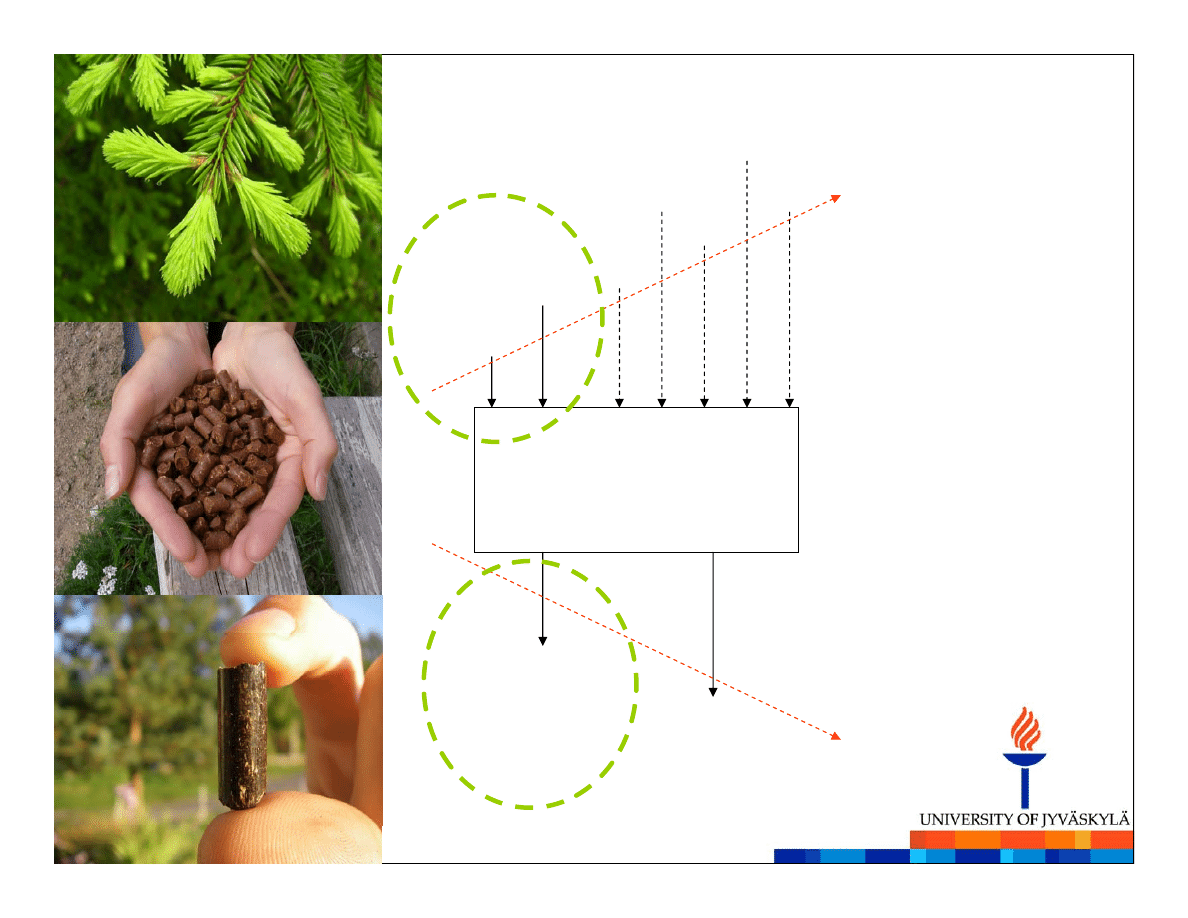

Traditional pellet raw material

Chip to P&P

Stem

wood

Bark

Saw dust and cutter

- particle board

- drying agent (for animals)

- pellet production

- solid biofuel (no upgrading)

Energy

Wooden

products

Saw mill

"SHAPE YOUR SUSTAINABILITY TOOLS

- and let your tools shape you"

Uppsala, Sweden 23-24.9.2009

2005 -> 2008 rapid changes

Germany: production capacity 2005 & 2008

Danmark and Netherlands: pellet production

capacity expands - despite limited forest biomass

resources!

Scenarious: Even a moderate growth (10 %/a?)

until 2025…10-12 % of harvested wood would end up

in pellets!

New raw materials needed!

"SHAPE YOUR SUSTAINABILITY TOOLS

- and let your tools shape you"

Uppsala, Sweden 23-24.9.2009

SAW MILL VISION

(prof. Usenius, VTT)

eg. TECH scenario (Eforwood, Scandinavian case):

new or improved technologies

increased efficiency of raw material use

sawn wood share in output products 50

55 %

share of saw dust decrease from 15 13 %,

producing 1 t of sawn timber:

present technology 0,30 t saw dust

TECH scenario 0,24 t

20 % less saw dust!

But also forest industry is changing…

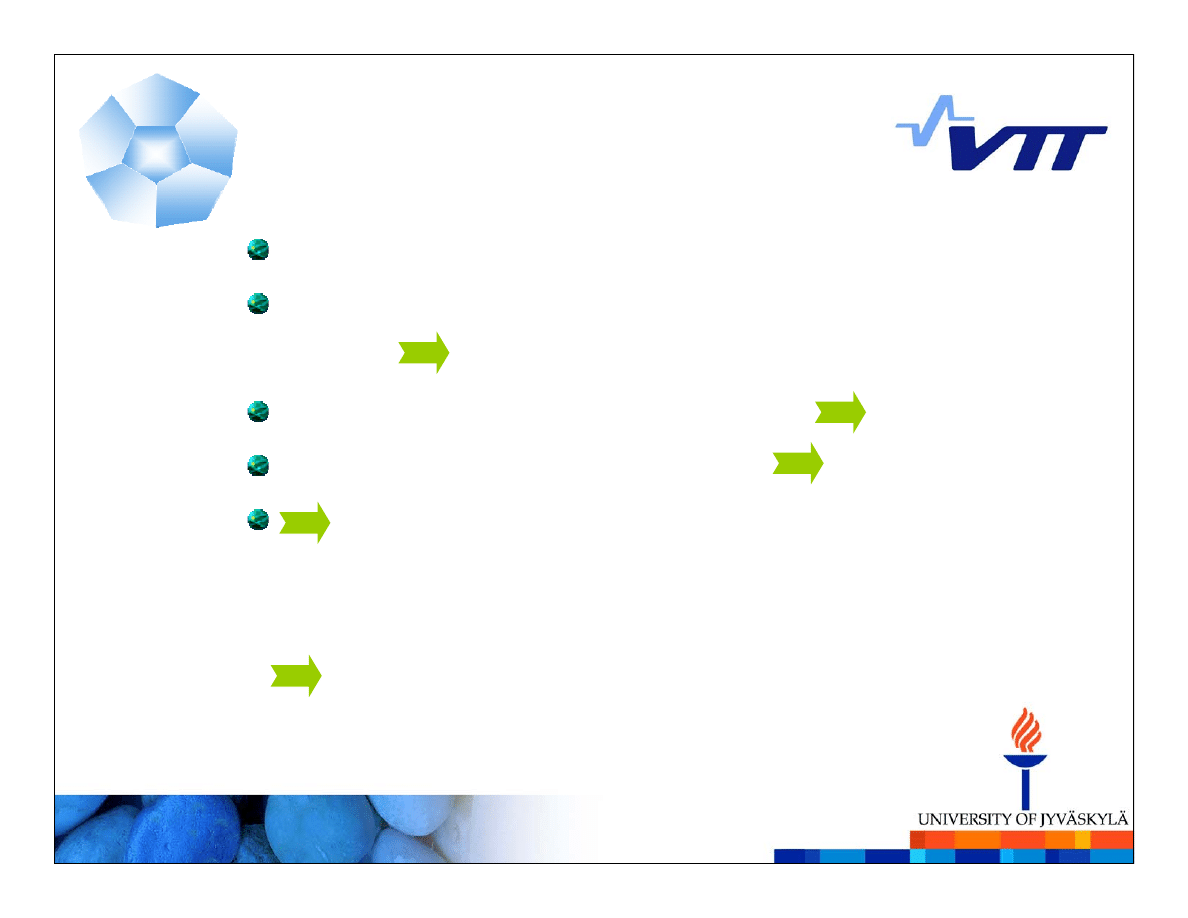

.

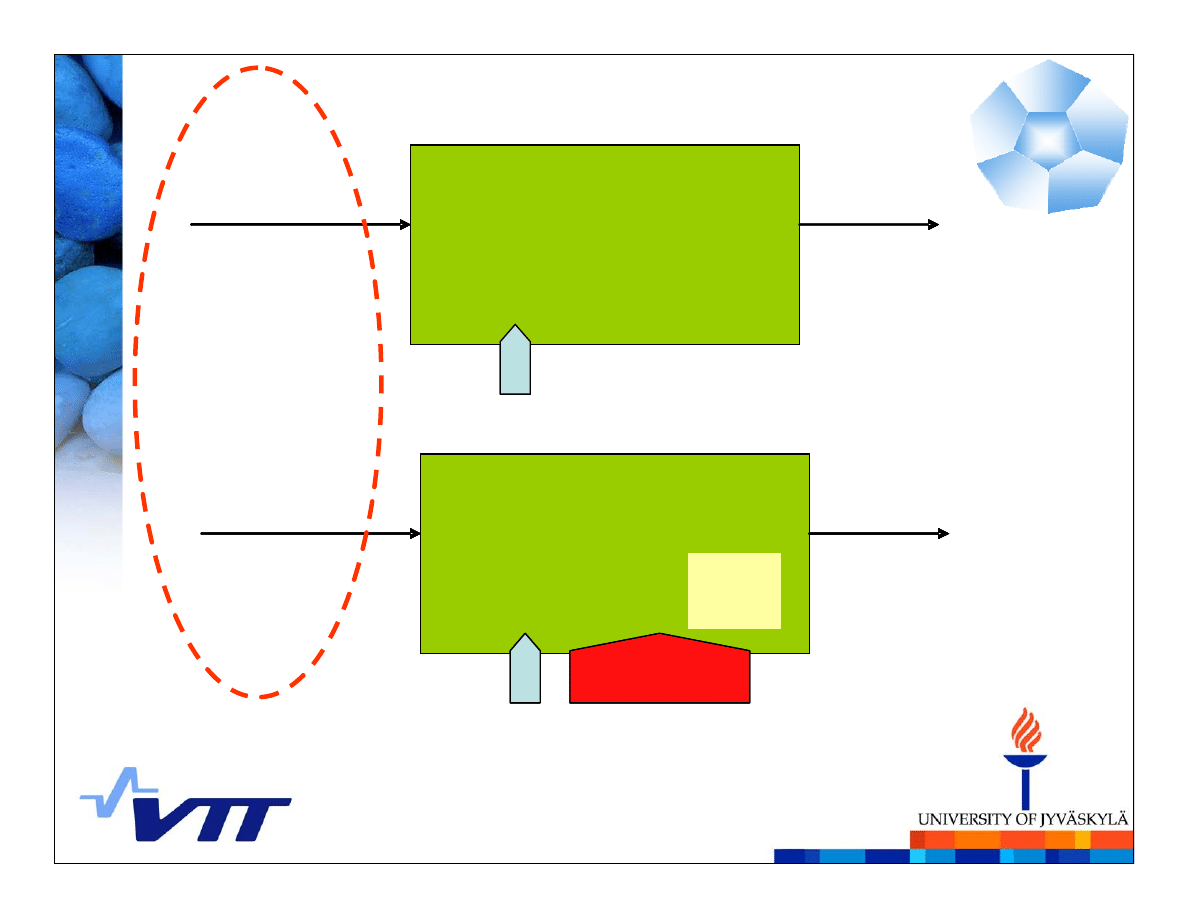

Mixing raw

materials is a

problem for

traditional pellet

production!

Pellet

production

Low ash

pellets

0,2…0,5 %

High ash

pellets

1..5 %

Dry saw

dust

Wet saw

dust

P&P

chip

Forest

residue

Fuel

chip

Quality!

More

demanding

raw materials

Bark

Stumps

Agrobiomass

…

Photos: Agar 2009

Rather

homogenous!

Torrefraction?

Pre-treatment process (~pyrolysis)

- heterogenous input -> more

homogenous output

-

mixing

raw materials possible (?)

- improves energy

density

of biomass

- treated material very dry and

hydrofobic

, less

storage emissions(?) & resistance to

biodegradation

=> Better durability, handling and storage

properties

Process can be situated separately!

Pictures from: Kiel, J.H.A. et al., BO2-

technology for biomass upgrading into

solid fuel

- pilot-scale testing and market

implementation, 16th European

Biomass

Conference & Exhibition, Valencia,

Spain, June (2008).

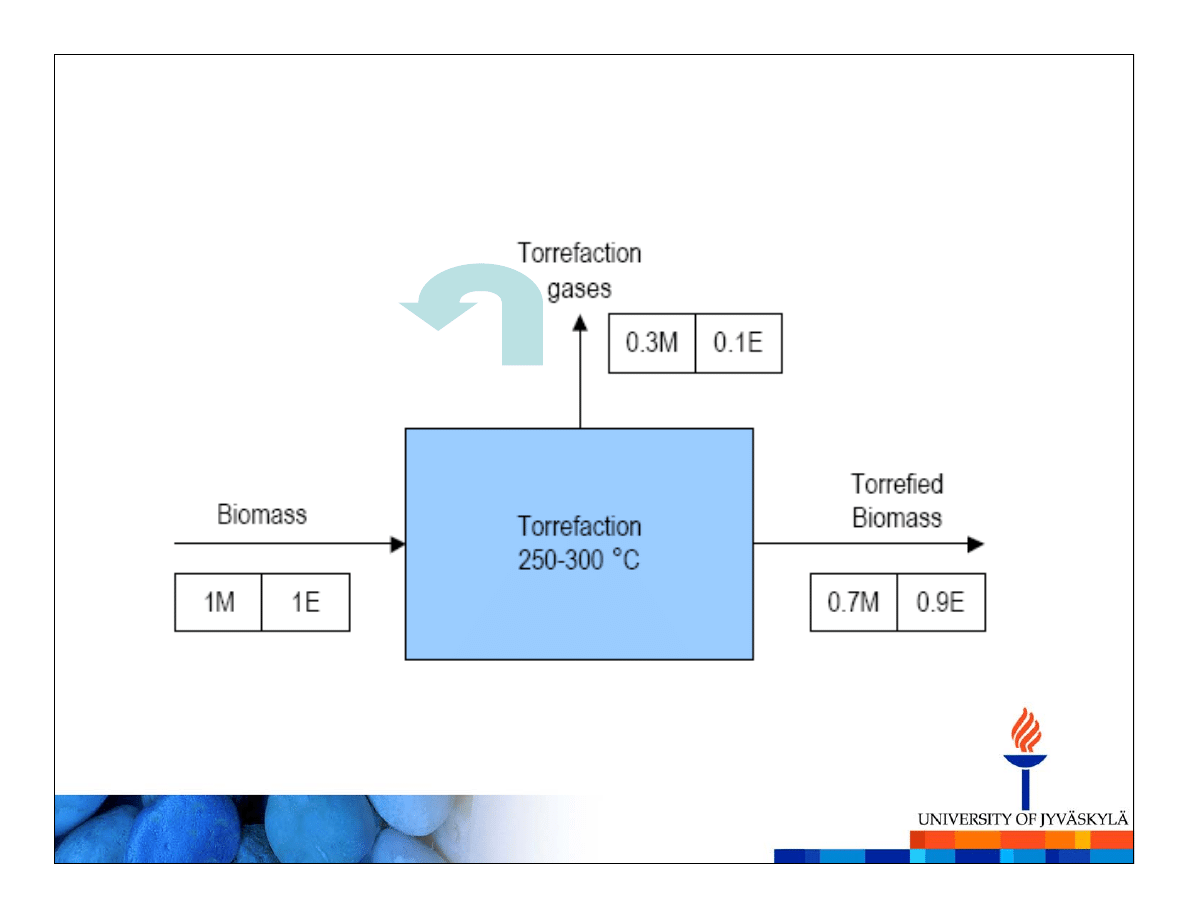

Torrefraction

mass and energy balances in general

From: Bergman P.C.A. (2005): Combined torrefraction

and pelletisation. The TOP process

Incinerated

and used as

heat the

process

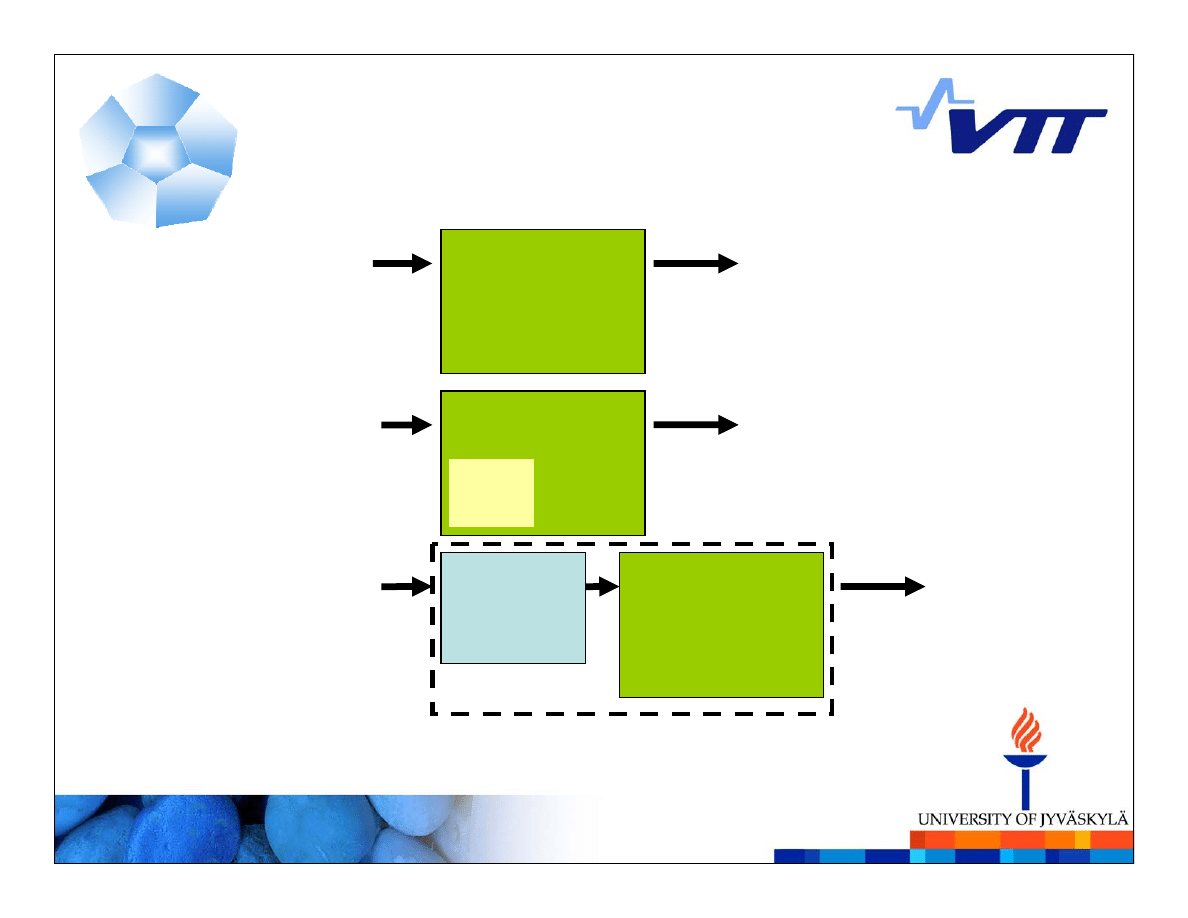

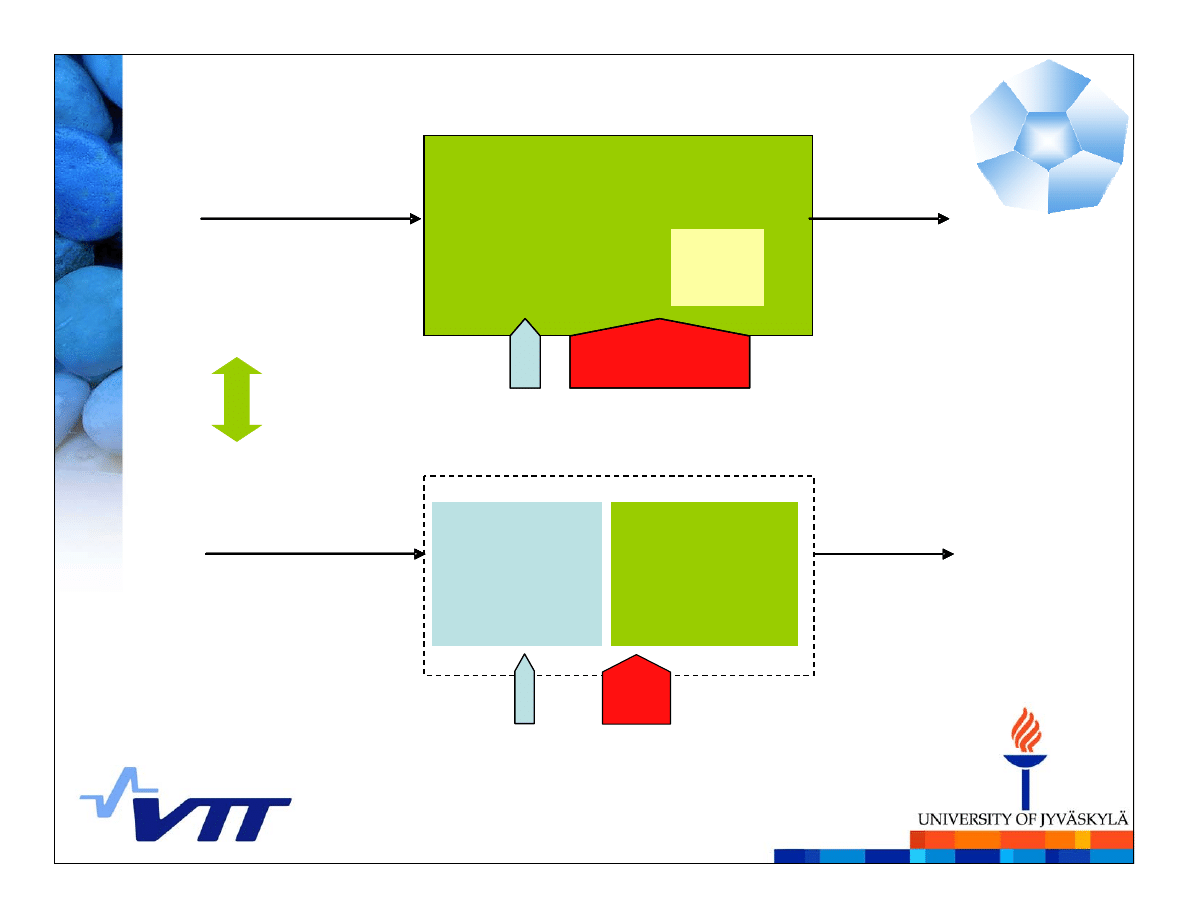

Pellet production "process"

Dry saw dust

Process:

Pellet

production

"Universal"

pellet with

low ash

content

How does this new process (or sub-process)

affect sustainability?

Wet saw dust

Drying

unit

New raw

materials

Torrefration

unit

Pellet

with

new

properties

saw dust (15 %)

Pellet (10 %)

Production process (dry)

85 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

150-200 kWh

e

/t

saw dust (15 %)

Pellet (10 %)

Production process (dry)

85 000 t

80 000 t

saw dust (15 %)

Pellet (10 %)

Production process (dry)

85 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

700-1000 kWh

h

/t

150-200 kWh

e

/t

heat

el

el

0,36 TWh

0,36 TWh

Double mass

to transport!

Drying

stage

~ 0,07 - 0,1 TWh

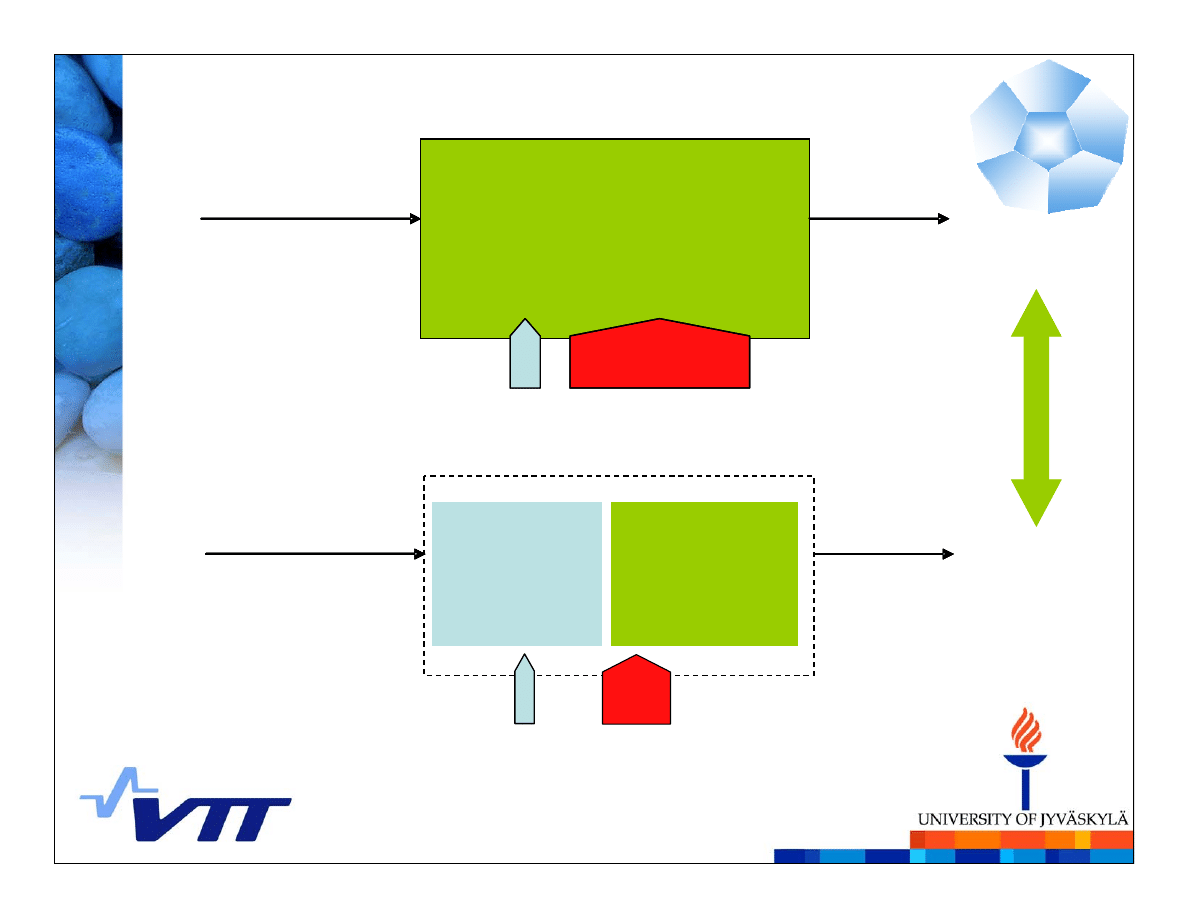

Material flow and energy balances: Eforwood

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

130 kWh

e

/t

Pellet (3 %)

saw dust (57 %)

Production process

55 000 t

167 000 t

0,32 TWh

0,36 TWh

375 kWh

h

/t

~ 0,07 - 0,1 TWh

~ 0,03 TWh

Torre-

fraction

Drying

stage

Introducing a new process, what changes?

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

saw dust (57%)

Pellet (10 %)

Production process (wet)

167 000 t

80 000 t

Pellet (3 %)

saw dust (57 %)

Production process

62 000 t

184 000 t

(+10 %)

0,36 TWh

0,36 TWh

~ 0,033 TWh

~ 0,07 - 0,1 TWh

Torre-

fraction

This presentation focused on

- material balances

- energy balances

Quality

…

.of raw material (more flexible)

…

.pellets for large scale use (substituting eg. coal)

Economy…

…

…

needs probably improvements…

Focus for research approaches

- at least in Finland!

Traditional production or

combined with torrefraction ?

=> seem to be in order!

Presentation based on results

from:

- Eforwood project (2005-2009)

- OSKE project: Pellet R&D

(2009)

- literature

Thank you!

Wyszukiwarka

Podobne podstrony:

TorrefactionForBiogasification George Richards NETL DOE PR

PR CYW PR ROP WYKLAD 26

Stany nagle w położnictwie PR

Pr UE Zródła prawa (IV 2013)

PR CYW PR ROP WYKLAD 28

PR CYW PR ROP WYKLAD 6

Z Pr 1

Pr dewizowe(2)

2013 01 15 ustawa o srodkach pr Nieznany

2008 klucz pr próbna

Cwi 6a PR Lesiu

Odpowiedzi Test przed probna matura 2008 Arkusz PR Wos

fizyka termodynamika pr klucz

chemia3 pr p2012

więcej podobnych podstron