Co-gasification: an introduction, October 23,

2008

Co-gasification: an introduction

Opportunities and issues

National Energy Technology Laboratory

The following NETL employees

and research associates are

recognized for contributions to this

webinar presentation:

Larry Shadle

James Bennett

Cindy Powell

Chris Guenther

Tom Tarka

John Wimer

Bryan Morreale

Sridhar Seetharaman (NETL-IAES)

Massood Ramezon (SAIC)

2

Why “Co-gasification”?

• Gasifiers historically focused on a single fuel (coal,

biomass, petcoke, etc.)

• Blends of fuel offer opportunities:

– Limited A + Limited B = Enough

– Adequate A + Limited Renewable = carbon credit

– Economies of scale

3

CH

coal

biomass

CH

x

CH

n

e

-

CO

2

to sequestration

n=2 for transportation

n=4 for natural gas

O

2

CO

2

H

2

O

CO

2

H

2

O

O

2

O

2

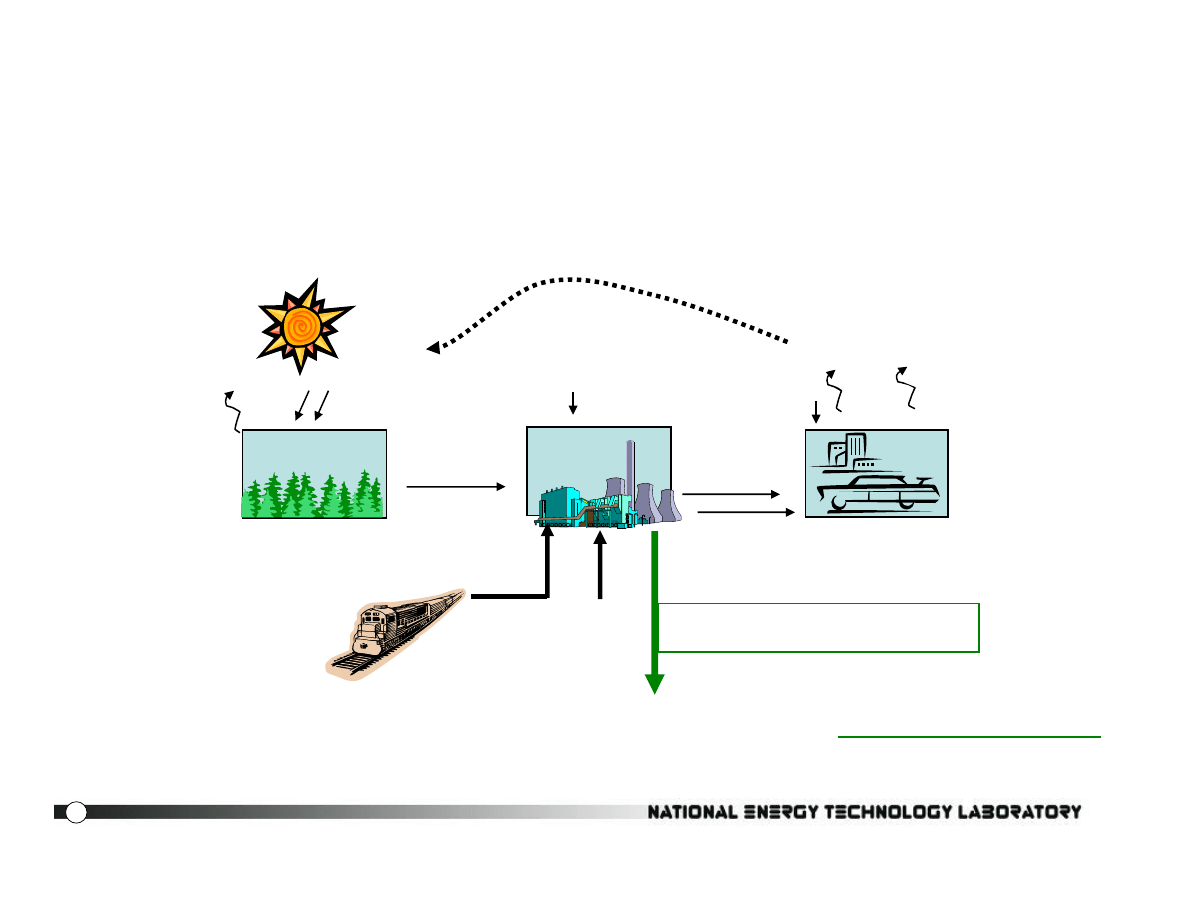

•

Combining CO

2

sequestration with co-gasification.

•

Coal energy used to “reform” renewable carbon.

•

Details? See “Affordable, Low-Carbon Diesel Fuel from Domestic Coal and Biomass”

DOE/NETL-2009/1349 January 14, 2009, available www.netl.doe.gov

A Future Option to Consider?

This idea has been described by the Princeton Environmental Institute, Energy Group

http://web.princeton.edu/sites/pei

Williams, R. H., Larson, E., Jin, H.(2006). Synthetic fuels in a world with high oil and carbon prices, 8th International

Conference on Greenhouse Gas Control Technologies, Trondheim, Norway, 19-22 June 2006

4

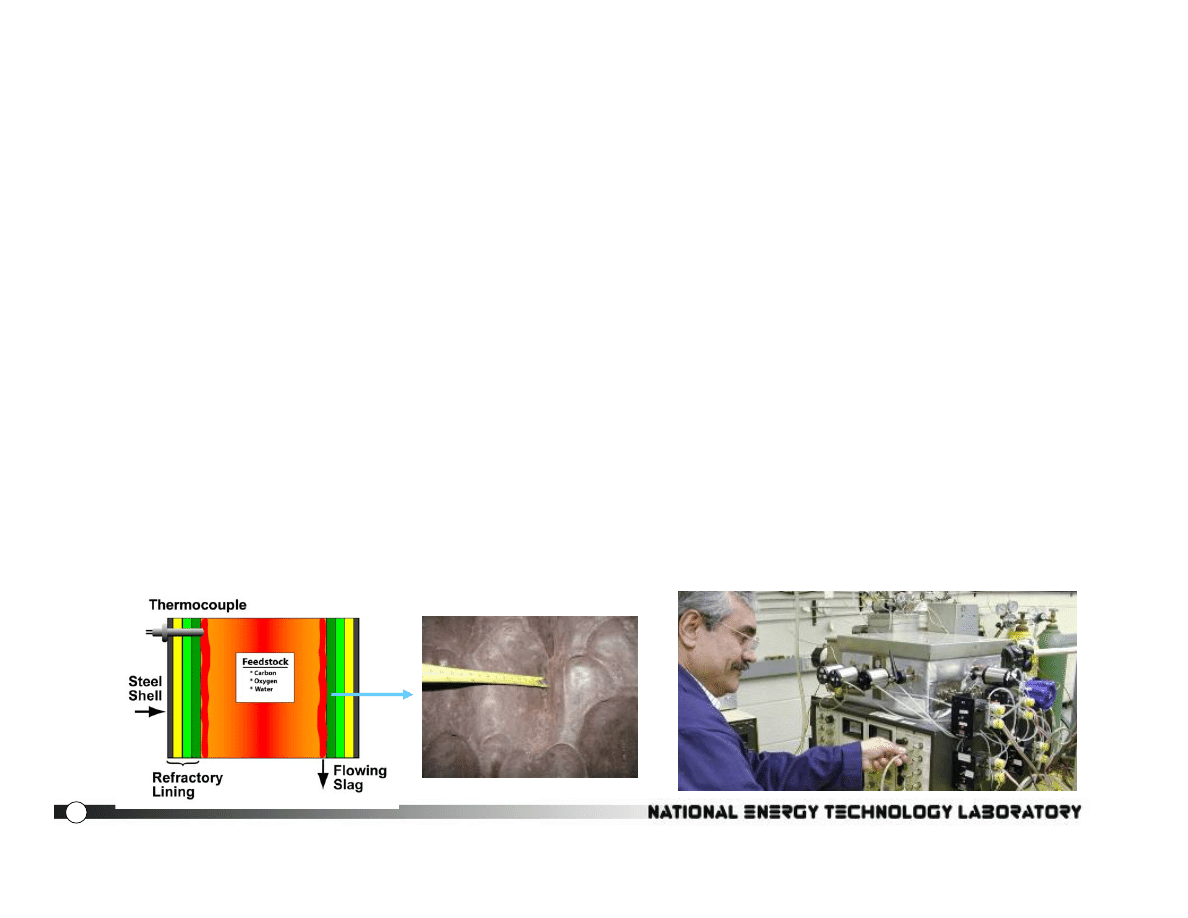

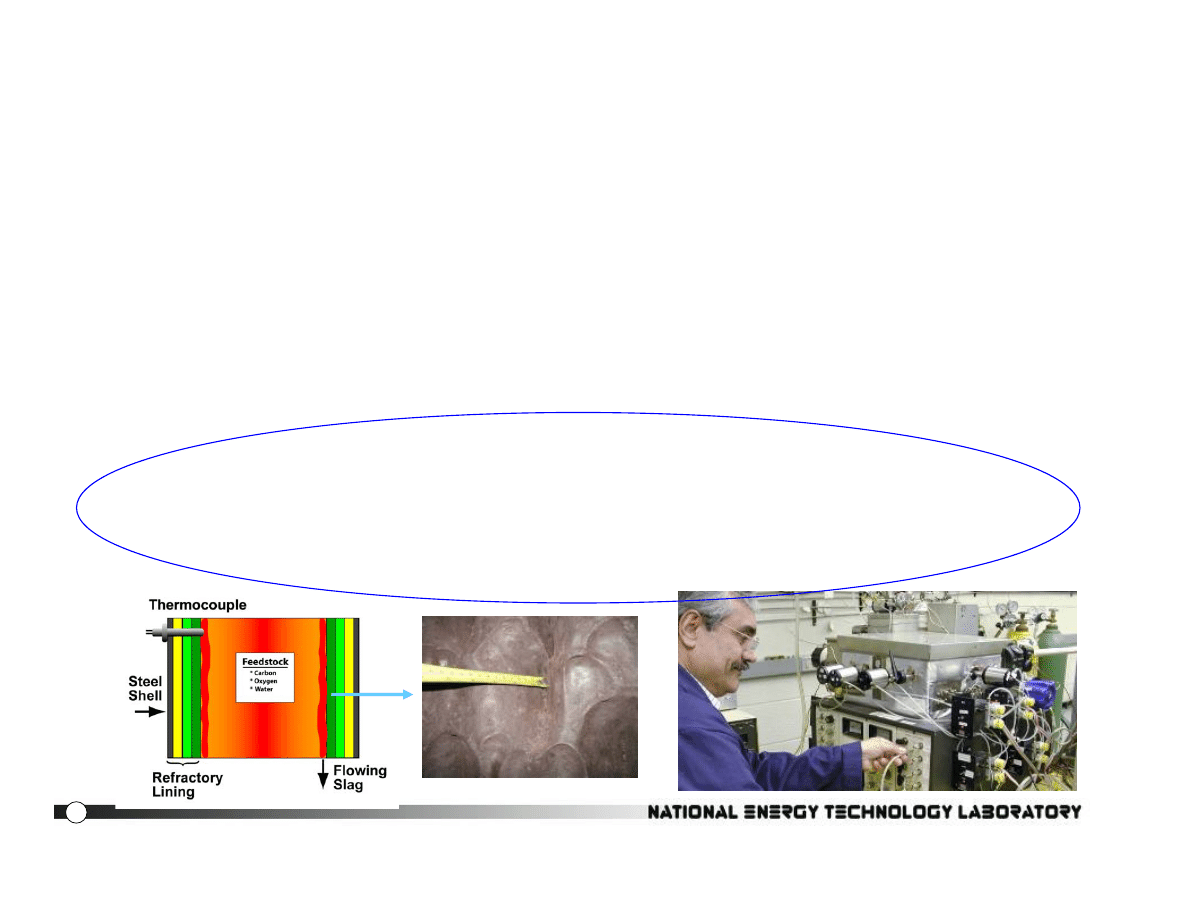

Research areas for co-gasification

Material Interactions: Alternative Fuel versus Coal Ash

Alternative fuel ash behavior can affect slagging

Ash chemistry can affect refractory life

Specific questions about impurity effects on chemical production being addressed

Numeric Models for Predicting Fuel Blend Effects

Models are increasingly used to predict gasifier behavior/design

Specific kinetic models for co-gasification are needed.

Feeding Biomass Into a Pressurized Gasifier

Grinding raw biomass to feed sizes (for entrained) can require significant energy

Pre-treatment options are possible, tradeoff with needed size for reactive biomass

Feeding techniques are being developed/investigated

5

Research areas for co-gasification

Material Interactions: Alternative Fuel versus Coal Ash

Alternative fuel ash behavior can affect slagging

Ash chemistry can affect refractory life

Specific questions about impurity effects on chemical production being addressed

Numeric Models for Predicting Fuel Blend Effects

Models are increasingly used to predict gasifier behavior/design

Specific kinetic models for co-gasification are needed.

Feeding Biomass Into a Pressurized Gasifier

Grinding raw biomass to feed sizes (for entrained) can require significant energy

Pre-treatment options are possible, tradeoff with needed size for reactive biomass

Feeding techniques are being developed/investigated

Discussed today

6

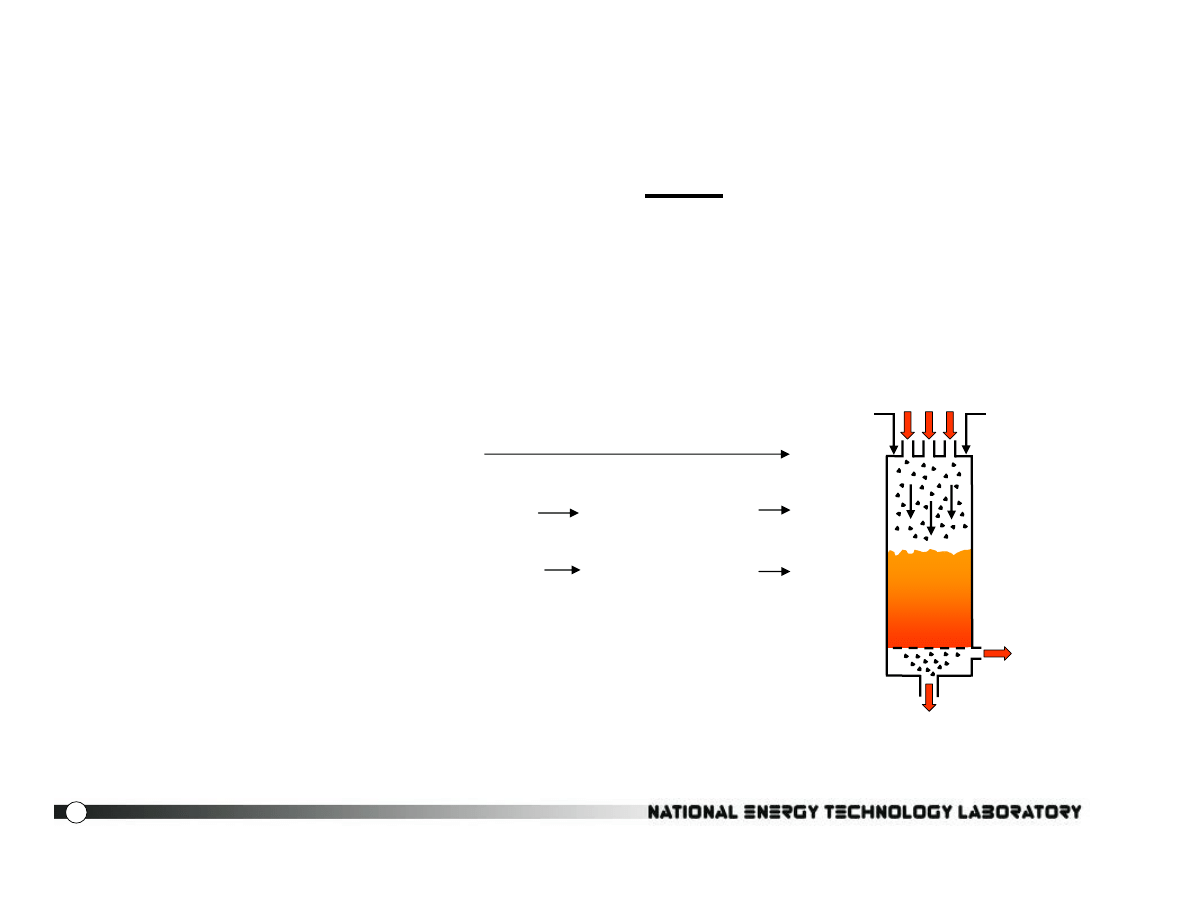

Feeding Biomass into Entrained Flow Gasifiers

• Different feed approaches for pure biomass studied

*

:

• Take advantage of better reactivity of biomass versus coal: mill to

(just) 1000

μm biomass particles (versus ~100μm coal, typ.)

• Torrefaction: make the feedstock brittle like coal, grind like coal.

• Flash pyrolize and make a char/oil slurry.

*

van der Drift et al. (2004). Entrained Flow Gasification of Biomass, ECN-C—04-039

1000 um grind

Torrefaction (~300°C)

“usual” grinding, etc.

Flash pyrolysis (400-600°C)

Oil + char slurry

Slag

Product

Gas

Steam

Oxygen or Air

80-84%

74-75%

76%

Efficiency to syngas**

**Efficiency = (LHV syngas + [Net Electric]/0.4) / (LHV wood)

7

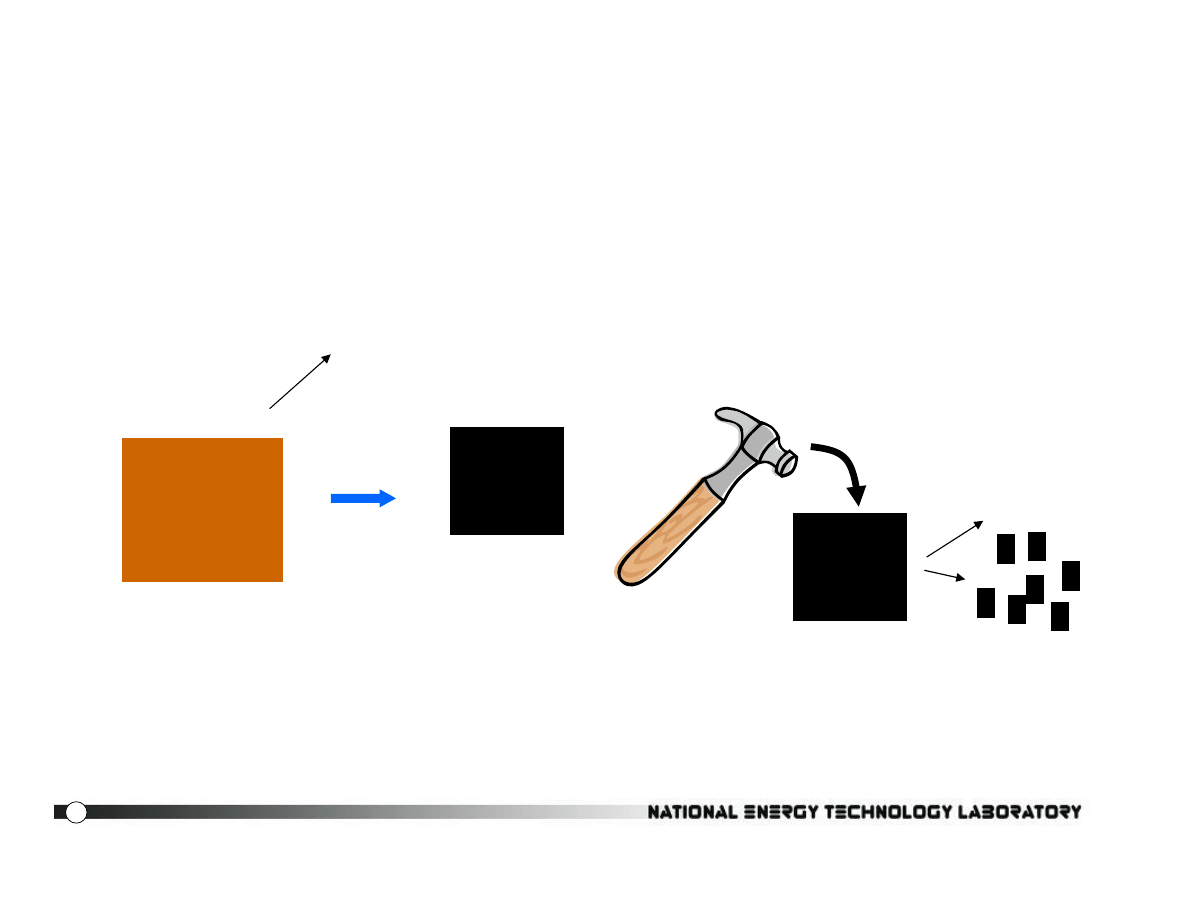

Torrefaction: A Method to Prepare Biomass?

•

Typical process: 200-300°C heating, less than 60 minutes

•

Chief attributes for use in feed preparation:

– Densify the energy content in biomass solids

– Makes the biomass brittle (more like coal)

Biomass

30% mass loss

10% energy out as volatiles (may be used for heat?)

Retains ~90%

of the original

fuel energy

Torrefaction

Bergman, P.C.A, Boersma, A. R., Zwart, R. W. R., Kiel, J.H.A (2005)

Torrefaction for Biomass in Existing Coal-Fired Power Stations, ECN-C—0513, www.ecn.nl

Bergman, P. C. A., Boersma, A. R., Kiel, J. H. A., Prins, M. J., Ptasinski, K. J., Janssen, F. J. J. G. (2005).

Torrefaction For Entrained-Flow Gasification of Biomass, ECN-C05-067, www.ecn.nl/biomass.

8

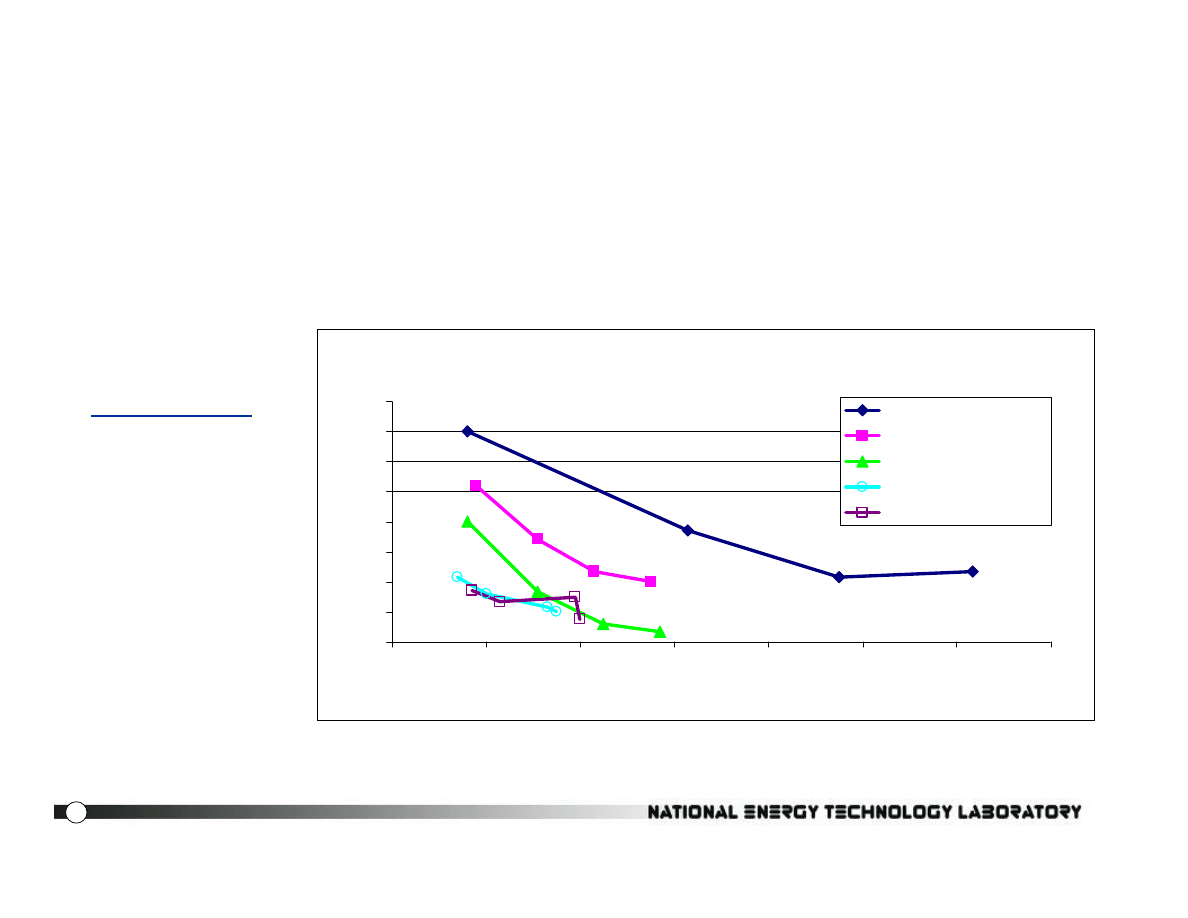

Net Power Consumption Curves

3

0

100

200

300

400

500

600

700

800

0

0.2

0.4

0.6

0.8

1

1.2

1.4

average particle size (mm, volume based)

P

o

w

e

r C

o

ns

um

pt

io

n

(k

J

/k

g

)

Willow (10-13% moist)

Willow (<1% moist)

AU Bituminous coal

W (290°C, 24mins)

W (260°C, 24mins)

Torrefaction Benefits to Grinding Energy

• Auxiliary power need to run PC coal grinding and auxiliary is typically less than 1%

of the fuel energy input to the boiler

1

• Untreated biomass grinding can require significant energy: may be 7% (or more?) of

the energy value of the biomass

2,3

• Torrefaction can reduce grinding energy to levels comparable to coal.

[1] Steam, 41

st

ed, Babcock and Wilcox, pp. 13-11

[2] Zwart, R. W.R., Boerrigter, H., van der Drift, (2006). The Impact of Biomass Pretreatment on the Feasibility of Overseas Biomass Conversion to Fisher-Tropsch

Products, Energy and Fuels, Vol. 20, pp. 2192-2197

[3] Bergman, P.C.A, Boersma, A. R., Zwart, R. W. R., Kiel, J.H.A (2005) Torrefaction for Biomass in Existing Coal-Fired Power Stations, ECN-C—0513, www.ecn.nl

From [3]

Power to grind:

Willow

Australian Bit Coal

Torrefied Willow

9

Some Comments on Feeding and Reactivity

•

Mixture of coal + biomass could change feed reliability:

– Some gasification lab studies have demonstrated benefits to feed/flow

for particular mixtures

1

– Consistent with basic studies/theoretical models of mixed dry feed

2

(Beware: better/worse depends on details!)

•

Because biomass is (typically) more reactive than coal:

– For conversion, required biomass particle size larger than coal.

– May need less preparation…how much less is a research issue.

[1] McClendon, T. R., Lui, A. P., Pineault, R. L., Beer, S. K., Richardson, S. W. (2004). High-Pressure Co-Gasification of Coal and Biomass in a Fluidized

Bed, Biomass and Bioenergy, Vol. 26, pp. 377- 388.

[2] Zulfiqar, M., Moghtaderi, B., Wall, T. F., (2006). Flow Properties of Biomass and Coal Blends, Fuel Processing Technology, Vol. 87, pp. 281-288.

“…Transport (rheological) properties of coal/ biomass… are

greatly improved… .Plugging is greatly reduced…”

1

Flow performance depends on the

size and shape of mixed particles

2

Earlier NETL Studies on co-gasification (circa 2002)

10

Experience with Co-feed

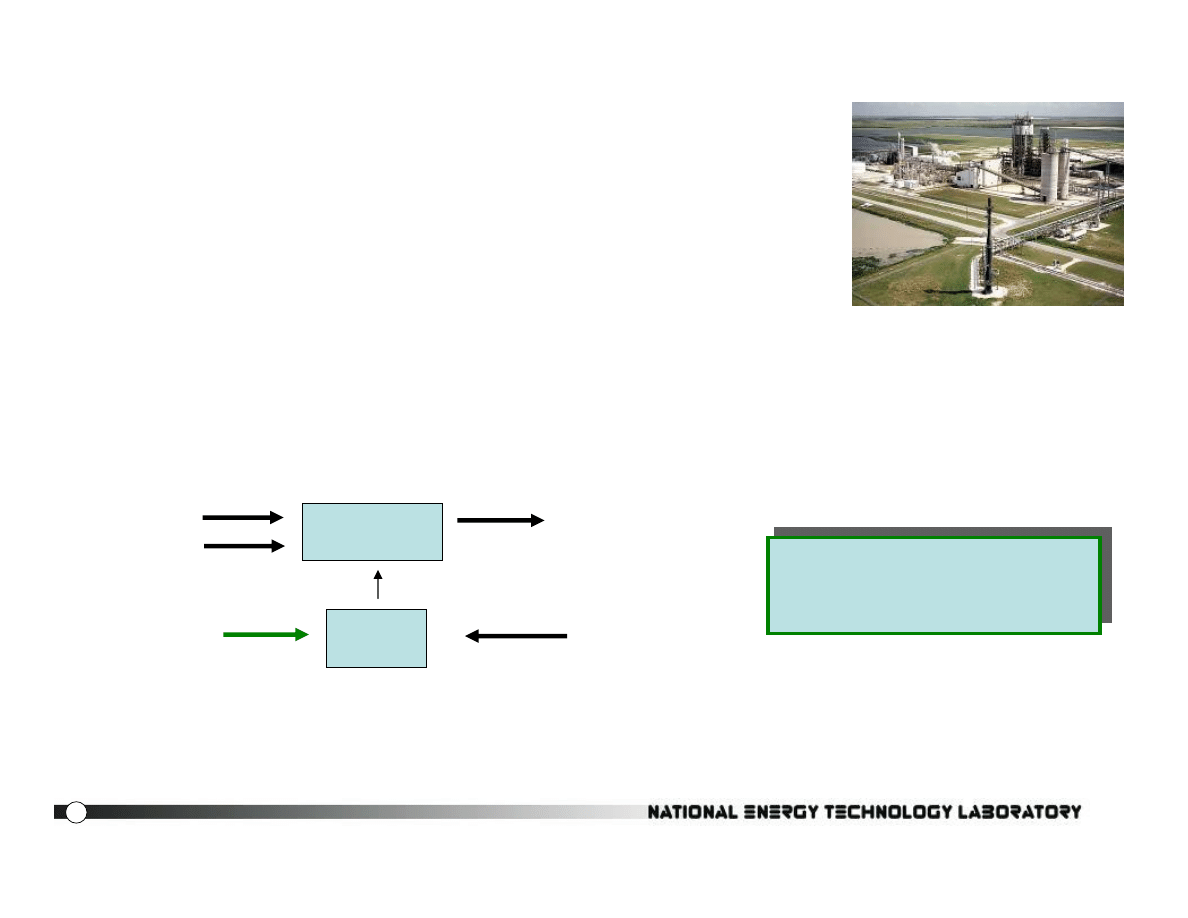

• Tampa Electric Polk Power Station*

– 1.2% of the fuel input (mass) was biomass:

• That is 0.4% of energy input.

• Eucalyptus trees (46% moisture), processed by portable

commercial hammer mill, five passes through mill – screen.

• Added to existing coal-water slurry system

* Tampa Electric Polk Power Station Integrated Gasification Combined Cycle Project Final Technical Report, August 2002, DOE Cooperative Agreement

DE-FC-21-91MC27363 Available www.netl.doe.gov

Slurry

preparation

Recycle

tank

Make-up water

Coal + petcoke

Biomass

Slurry to gasifier

Recycled solids

from syngas

coolers/scrubbers

Operation for 8.5 hours

“statistically indistinguishable

…from….. base fuel”

11

• Nuon IGCC Plant

Buggenum, The Netherlands,

253 MW Power

• Recent reports: up to 20%

energy input from biomass

1

Experience with Co-feed (Continued)

[1] Zwart, R. (2007). Large-scale Fischer Tropsch Diesel Production, 2

nd

Frieberg Conference on IGCC &XtL Technologies, (8-12 may 2007) Available

www.ecn.nl

[2] Babu, S. (2006). Perspectives on Biomass Gasification, IEA Bioenergy Agreement, Task 33, Available www.gastechnology.org

Entrained flow gasifier

Dry feed, using lockhopppers

Non-coal feed includes wood,

wastewater sludge, chicken litter

2

12

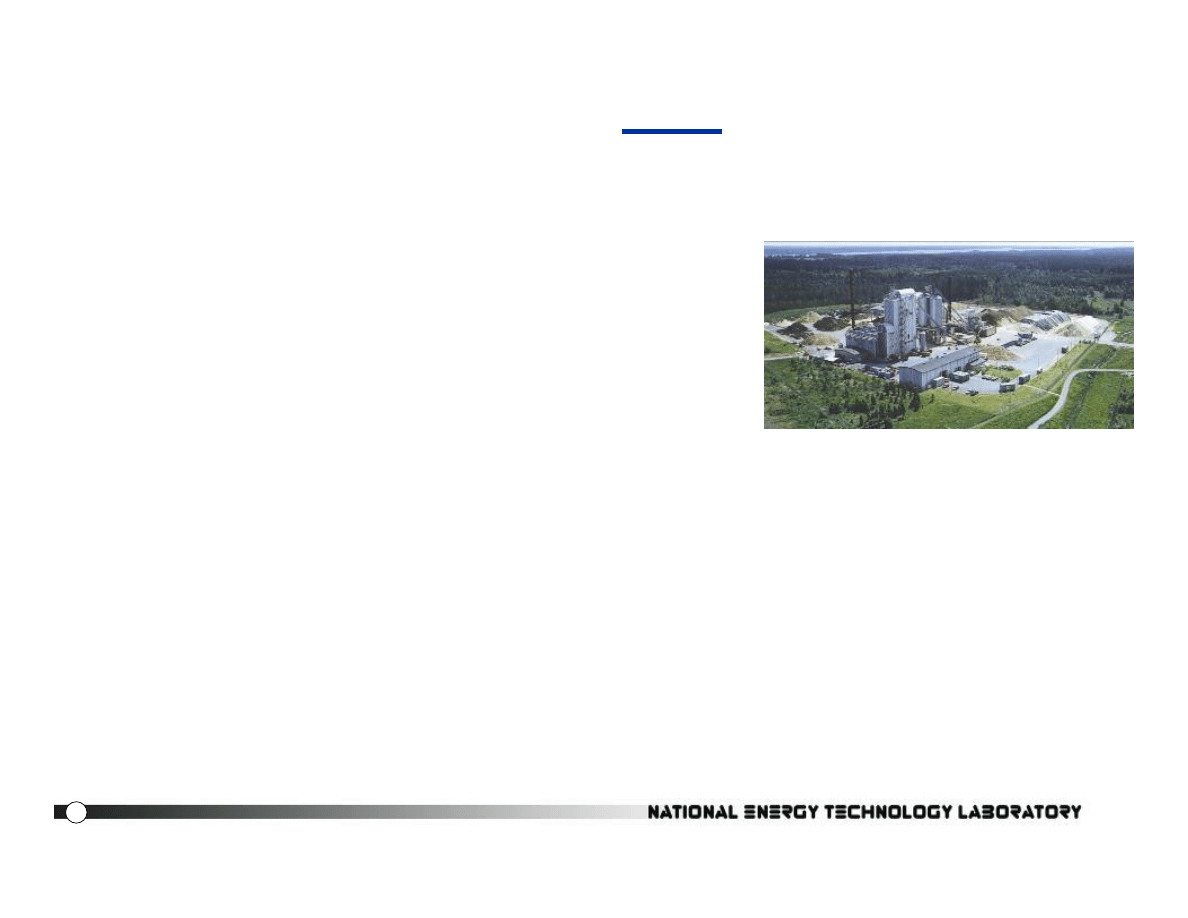

Experience with Pure Biomass

•

Pure biomass operation in IGCC has been

demonstrated.

– Värnamo, Sweden: Pressurized CFB,

syngas operating 4.2 MWe gas turbine

1

– 3600 hours of turbine operation

2

– Not economical for commercial operation

“The plant was shut down in 2000 after the test program had been

completed as revenues from the sales of power and heat did not

cover the operating costs.”

1

– Project re-activated under “Chrisgas”: focus

on hydrogen fuel production.

• Development will include “piston feeder” for

biomass

1

Past Turbine testing:

Wood fuel dried with flue gas.

Lockhopper and screw feeder

[1] www.chrisgas.com

[2] Babu, S. (2006). Perspectives on Biomass Gasification, IEA Bioenergy Agreement, Task 33, Available www.gastechnology.org

13

More to Come on Biomass Feed Preparation

• Recently announced Department of Energy

research projects address this issue

1

– GE Global Research/GE Energy and Idaho National Laboratory (INL)

– Southern Research Institute and its partner, TK Energi A/S

…pump to handle mixtures of coal and biomass that encompass the relevant

range of coal rank… and biomass type… at biomass loadings up to at least 50

percent by weight.

…demonstrate a biomass pretreatment system and a coal/biomass co-feed

system…

• System Studies and basic data (NETL) – in progress

[1] www.netl.doe.gov

[1] www.netl.doe.gov

Visit the web-site for more details

14

Summary

Co-gasification is an avenue for:

•

Using opportunity fuel feedstocks with a stable coal supply

•

Renewable credits and low carbon fuel production

Research and development for co-gasification:

•

Ash behavior and material interactions with refractory liners

•

Development of fuel flexible numeric models

•

Feeding biomass into a pressurized vessel

+

Wyszukiwarka

Podobne podstrony:

Margareta Wihersaari Torrefaction PR

From MajorJordan s Diaries The Truth About The US And USSR George R Jordan & Richard L Stokes

PR CYW PR ROP WYKLAD 26

Stany nagle w położnictwie PR

Pr UE Zródła prawa (IV 2013)

PR CYW PR ROP WYKLAD 28

PR CYW PR ROP WYKLAD 6

Z Pr 1

Pr dewizowe(2)

2013 01 15 ustawa o srodkach pr Nieznany

2008 klucz pr próbna

Cwi 6a PR Lesiu

Odpowiedzi Test przed probna matura 2008 Arkusz PR Wos

fizyka termodynamika pr klucz

chemia3 pr p2012

więcej podobnych podstron