Journal of Basic Microbiology 2007, 47, 417 – 425

417

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Research Paper

Alpha-amylase production by Bacillus subtilis CM3

in solid state fermentation using cassava fibrous residue

M.R. Swain and R.C. Ray

Central Tuber Crops Research Institute (Regional Centre), Dumuduma Housing Board,

Bhubaneswar – 751019, India

In extraction of starch from cassava (Manihot esculenta Crantz), one of the major solid waste

released is fibrous residues which constitute 15 – 20% by weight of the cassava chips/tuber

processed. Production of

α-amylase under solid state fermentation by Bacillus subtilis CM3 has

been investigated using cassava fibrous residue. Response surface methodology (RSM) was used

to evaluate the effect of the main variables, i.e. incubation period, initial medium pH, moisture

holding capacity and temperature on enzyme production. A full factorial Central Composite

Design (CCD) was applied to study these main factors that affected

α-amylase production. The

experimental results showed that the optimum incubation period, initial medium pH,

moisture holding capacity and temperature were 6 days, 8.0, 70% and 50 °C, respectively.

Keywords:

α-Amylase / Bacillus subtilis CM3 / Cassava fibrous residue / Response surface methodology /

Solid state fermentation

Received: April 23, 2007; returned for modification: May 21, 2007; accepted: June 01, 2007

DOI 10.1002/jobm.200710132

Introduction

*

Cassava (Manihot esculanta Cranz.) is a starchy tropical

tuber crop having 20 – 30% extractable starch. In India,

more than 1500 cottage and small industries crush over

5000 tonnes of cassava per day during harvest season

(October – February) (Edison et al. 2006). Industrial pro-

cessing of cassava is done mainly to produce flour and

starch, and in the process generates huge solid wastes

in form of peels and fibrous residue with high moisture

content (85%). These solid wastes are generally dis-

carded in the landfill with out treatment. Cassava fi-

brous residue (CFR) contains about 10 – 15% crude fibre,

55 – 65% starch and very low ash content (1 – 1.2%) (on

dry weight basis) (Jyothi et al. 2005). Because of its low

ash content, CFR could offer numerous advantages in

comparison to other crop residues such as rice straw

and wheat straw, which have 17.5% and 11.0% ash

contents, respectively, for uses in bioconversion pro-

cesses using microbial cultures (Pandey et al. 2000a, b).

The CFR has been successfully put to use under SSF for

Correspondence: R.C. Ray, Central Tuber Crops Research Institute

(Regional Centre), Dumuduma Housing Board, Bhubaneswar – 751019,

India

E-mail: rc_ray@rediffmail.com

Fax: 91-674-2470528

various end products such as animal feed after enrich-

ing the protein content using fungi (Ray et al. 2006),

enzymes (Pandey et al. 2000b); organic acids (Kolichsky

et al. 1995); aroma compounds (Christen et al. 1997,

Bramorski et al. 1989), gibberllic acid (Tomasini et al.

1997), etc.

Approximately 90% of all industrial enzymes are

produced in submerged fermentation (SmF), frequently

using specifically optimized and genetically manipu-

lated microorganisms. However, SSF constitutes an

interesting alternative since the metabolites so pro-

duced are concentrated and purification process costs

less over SmF (Nigam and Singh 1995, Pandey et al.

2000a). SSF is defined as the cultivation of microorgan-

isms on moist solid support, either on inert carriers or

insoluble substrates that can, in addition be used as

carbon and energy source. SSF takes place in the ab-

sence and near absence of free water, thus being close

to the natural environment to which microorganisms

are adapted (Holker et al. 2004). The aim of SSF is to

bring the cultivated microorganisms into tight contact

with the insoluble substrate and thus to achieve the

highest substrate concentration during fermentation.

Response surface methodology (RSM) is an experi-

mental strategy for seeking the optimum conditions for

a multivariable system (He et al. 2004) and is used for

418

M. R. Swain and R. C. Ray

Journal of Basic Microbiology 2007, 47, 417 – 425

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

optimization of culture conditions (Rao et al. 1993). RSM

consists of a group of mathematical and statistical pro-

cedures that can be used to study relationships between

one or more responses and a number of independent

variables. In addition to analyzing the effect of inde-

pendent variables, this experimental methodology gen-

erates a mathematical model that accurately describes

the over all process (Senanayake and Shahidi 2002,

He et al. 2004). Statistical optimization not only allows

quick screening of large experimental domain, but also

reflects the role of each of the components. RSM has

already been successfully applied for optimization of

the media and culture conditions in many cultivation

processes for the production of primary and secondary

metabolites (Shirai et al. 2001, Boyaci 2005) i.e., amino

acid (Xiong et al. 2005), ethanol (Carvalho et al. 2003),

flavouring compound (acetoin) (Xian et al. 2007) and

enzymes (Rao and Satyanarayana 2003).

In our earlier study it was found that Bacillus subtilis

strains were one of the predominant groups of bac-

teria isolated from the culturable cowdung microflora

(Swain and Ray 2007). These strains exhibit several

beneficial agricultural activities like biocontrol against

Fusarium oxysporum and Botryodiplodia theobromae (Swain

and Ray 2007), production of indole-3-acetic acid in

enhancing sprouting of yam minisetts (Swain et al.

2007) and thermostable enzyme (

α-amylase) in sub-

merged fermentation (Swain et al. 2006). The present

study was carried out to investigate the

α-amylase pro-

duction by B. subtilis strain CM3 isolated from cowdung

microflora in SSF using CFR as the substrate and opti-

mization of the fermentation parameters (incubation

period, medium initial pH, moisture holding capacity

(MHC) and temperature) by applying RSM.

Materials and methods

Bacillus subtilis strain

Bacillus subtilis strain CM3 earlier isolated from cultur-

able cowdung microflora (Swain and Ray 2007) was

found to produce thermostable (

≈60 °C) α-amylase in

submerged fermentation (Swain et al. 2006). In SSF

study, this strain (CM3) was used. The culture was

maintained on NA (nutrient agar) slants at 4 °C.

Cassava fibrous residue (CFR): CFR [(g/100 g dry resi-

due); moisture: 11.2; starch: 63.0; crude fibre: 10.8;

crude protein: 0.9 and total ash: 1.2] was used as solid

substrate (support and nutrient source) for SSF. CFR

was collected during starch extraction (October –

November, 2006) from cassava using the mobile starch

extraction plant, developed by our institute (Edison

et al. 2006). Because of its high water content (70–80%)

and presence of high quantity of starch (63% on dry

weight basis), the residues were de-watered, sun-dried

for 6 – 8 days and then oven – dried at 80 °C for 24 h to

prevent microbial deterioration. The dried CFR was

stored in air-tight container until required.

Optimization of incubation period, initial medium pH,

MHC and temperature by applying RSM

The characterization of different factors for

α-amylase

production was optimized by applying RSM. The statis-

tical model was obtained using Central Composite De-

sign (CCD) with four independent variables [incubation

period (A), initial medium pH (B), moisture holding

capacity (C) and temperature (D)]. Each factor in this

design was studied at five different levels (Table 1).

A set of 30 experiments was performed. All variables

were taken at a central coded value considered as zero.

The minimum and maximum ranges of variables were

used and the full experimental plan with respect to

their values in coded form is listed in Table 2. Upon

completion of the experiments, the average of

α-amy-

lase production was taken as the dependent variable or

response.

Statistical analysis and modeling

The data obtained from RSM on

α-amylase production

were subjected to the analysis of variance (ANOVA). The

results of RSM were used to fit a second order polyno-

mial equation (1) as it represents the behaviour of such

a system more appropriately.

Y= β

0

+

β

1

A + β

2

B + β

3

C + β

4

D + β

1

β

1

A

2

+

β

2

β

2

B

2

+

β

3

β

3

C

2

+

β

4

β

4

D

2

+

β

1

β

2

AB + β

1

β

3

AC + β

2

β

3

BC

+

β

1

β

4

AD + β

2

β

4

BD + β

3

β

4

CD (1)

where Y is response variable,

β

0

is intercept,

β

1

,

β

2

,

β

3

and

β

4

are linear coefficients,

β

1,1

,

β

2,2

,

β

3,3

and

β

4,4

are

squared coefficient,

β

1,2

,

β

1,3

,

β

2,3

,

β

1,4

,

β

2,4

and

β

3,4

are

interaction coefficient and A, B, C, D, A

2

, B

2

, C

2

, D

2

, AB,

AC, BC, AD, BD and CD are level of independent vari-

ables. Statistical significance of the model equation was

Table 1. Range of the values for the response surface metho-

dology.

Levels

Independent

variables

–

α

–1

0 +1 +

α

Incubation period

(Days)

– 2

2

6

10

14

Initial medium pH

3

5

7

9

11

Moisture holding

capacity (%)

20

40

60

80

100

Temperature (°C)

0

20

40

60

80

Journal of Basic Microbiology 2007, 47, 417 – 425

Alpha-amylase production by B. subtilis 419

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Table 2. Experimental design and result of CCD of response surface methodology.

Std.

A: Incubation period

(h)

B: pH

C: Moisture holding apacity

(%)

D: Temperature

(°C)

Enzyme production

(U/gds)

Predicted

Experimental

1

–1

–1

–1

–1

3232

3039

2

1

–1

–1

–1

3375

2992

3

–1

1

–1

–1

3610

3613

4

1

1

–1

–1

3785

3613

5

–1

–1

1

–1

3500

3340

6

1

–1

1

–1

3631

3293

7

–1

1

1

–1

3890

3962

8

1

1

1

–1

4033

3915

9

–1

–1

–1

1

3716

3502

10

1

–1

–1

1

3847

3455

11

–1

1

–1

1

4106

4123

12

1

1

–1

1

4248

4076

13

–1

–1

1

1

3972

3803

14

1

–1

1

1

4091

3756

15

–1

1

1

1

4374

4425

16

1

1

1

1

4505

4378

17 –

α

0

0

0

2812

2543

18

α

0

0

0

3630

3529

19

0

–

α

0

0

4980

5809

20

0

α

0

0

5702

5722

21

0

0

–

α

0

5402

5254

22

0

0

α

0

5398

5598

23

0

0

0

–

α 2150

2057

24

0

0

0

α 3328

3052

25

0

0

0

0

6386

6462

26

0

0

0

0

6386

6430

27

0

0

0

0

6386

6380

28

0

0

0

0

6386

6480

29

0

0

0

0

6386

6256

30

0

0

0

0

6386

6311

determined by Fisher’s test value, and the production

of variance explained by the model was given by the

multiple coefficient of determination, R squared (R

2

)

value. Design Expert (ver, 7.1; Statease Inc. Minneapo-

lis, MN, USA) was used in this investigation.

Effect of incubation period on enzyme production

The inoculum was prepared in soluble starch-peptone

broth (soluble starch: 2%; peptone: 1%; MgSO

4

: 0.05%;

NaCl: 0.05%, pH: 7.0) (Swain et al. 2006) by transferring

a loop full of organism (B. subtilis CM3) from a stock

culture and incubating at 50 °C and 120 rpm for 24 h in

an orbital incubator shaker (Remi Pvt. Ltd, Bombay,

India). The inoculum contained 1

× 10

7

CFU/ml.

CFR (20

g) was taken in Roux bottles (132

mm

× 275 mm), moistened with 27 ml of distilled water

containing 1% peptone to provide 70% moisture hold-

ing capacity (MHC) and were mixed thoroughly. The

bottles were autoclaved at 15 lb pressure for 30 min.

After autoclaving the bottles were taken out and cooled

at room temperature, 30

± 2 °C and inoculated with

15% (w/v) inoculum (1

× 10

7

CFU/ml). Then the inocu-

lated substrates were incubated under static condition

at 50 °C for 10 days in an incubator (Beautex Instru-

ments, New Delhi, India). Triplicate flasks were main-

tained for each treatment. The contents in the bottle

were periodically mixed by gentle tapping. At interval

of two days, the bottles were taken out and the enzyme

was extracted with 25 ml of distilled water [1 : 2 (CFR:

Water) ratio] and squeezed through wet cheesecloth.

The pooled enzyme extract was centrifuged at 8000 g

for 20 min in a refrigerated centrifuge (Remi India Pvt

Ltd, Bombay, India) and the clear supernatant (volume

made up to 25 ml) was used for enzyme assay.

Effect of MHC and initial medium pH

on enzyme production

The influence of MHC on the enzyme titre was evalu-

ated by varying the moisture content of the substrate

from 40 to 80% MHC, and initial medium pHs were

adjusted to 5 – 9 by using 0.1 N HCl or NaOH. The sam-

ples (n = 3) were incubated for six days at 50 °C.

420

M. R. Swain and R. C. Ray

Journal of Basic Microbiology 2007, 47, 417 – 425

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

Effect of temperature on enzyme production

The effect of temperature was studied by evaluating the

organism at different temperatures (20 – 60 °C) main-

tained in an incubator.

Amylase assay

The amylase assay was based on the reduction in blue

colour intensity resulting from enzymatic hydrolysis of

starch and formation of starch-iodine complex (Swain

et al. 2006). The reaction mixture consisted of 0.2 ml

enzyme (cell free supernatant), 0.25 ml of 0.1% starch

solution and 0.5 ml of phosphate buffer (0.1 M, pH 6.0)

incubated at 50 °C for 10 min. The reaction was stopped

by adding 0.25 ml of 0.1 N HCl and the colour was de-

veloped by adding 0.25 ml of I/KI solution (2% KI in

0.2% I). The optical density (OD) of the blue colour solu-

tion was determined using a UV-Vis Spectrophotometer

(Model no CE 7250, Cecil Instrument, UK) at 690 nm.

One unit of enzyme activity is defined as the quantity

of enzyme that causes 0.01% reduction of blue colour

intensity of starch iodine solution at 50 °C in one min-

ute per ml (Swain et al. 2006). In SSF, units of enzyme

activity are calculated as units per gram of dry sub-

strate (gds).

Determination of moisture of the substrate

The moisture content of the substrate was analyzed by

a Mettler LP16 Infra – Red analyzer.

Rate of hydrolysis of starch

A 2% (w/v) solution of soluble starch and cassava starch

were incubated with 2 – 4 ml of B. subtilis crude enzyme

at 50 °C in an incubator. The degradation of starch was

evaluated at one-hour interval up to 5 h.

Results

Optimization of incubation period, initial medium pH,

MHC and temperature by applying RSM

The results of CCD experiments for studying the effect

of four independent fermentation variables (incubation

period, initial medium pH, MHC and temperature) are

presented along with the mean predicted and observed

responses in Table 2. The regression equations obtained

after the ANOVA gave the level of

α-amylase production

as a function of the initial values of incubation period,

pH, MHC and temperature. The final response equation

that represented a suitable model for

α-amylase pro-

duction is given below:

Y = 79.91

+

0.64

× A + 1.64 × B + 1.04 × C + 2.11

× D – 6.74 × A

2

– 2.05

× B

2

– 2.05

× C

2

– 7.89

× D

2

+ 0.033

× AB – 0.020 × AC + 0.026

× BC – 0.018

× AD – 0.056 × BD – 0.064 × CD

where Y is enzyme production, A is incubation period

(days), B is initial medium pH, C is MHC (%) and D is

temperature (°C).

The coefficient of determination (R

2

) was calculated

as 0.9587 for

α-amylase production (Table 3), indicating

that the statistical model can explain 95.87% of vari-

ability in the response. The R

2

value is always between

0 and 1. The closer the R

2

is to 1.0, the stronger the

model and the better it predicts the response (Rao and

Satyanarayana 2003). An adequate precision of 17.850

for

α-amylase production was recorded. The predicted

R

2

(0.7646) is in reasonable agreement with the adjusted

R

2

(0.9202). This indicated a good agreement between

the experimental and predicted value for

α-amylase

production.

The

model

F-value of 24.89 and values of “prob > F”

less than 0.05 indicated that the model terms are sig-

nificant. For

α-amylase production B, D, A

2

, B

2

, C

2

and D

2

are significant model. The “lack of fit F-value” of 38.78

implied that the “lack of fit” is significant.

Response surface was generated by plotting the re-

sponse (

α-amylase production) on the z-axis against any

two independent variables while keeping the other

independent variables at zero level. Therefore, six re-

sponse surfaces were obtained by considering all the

possible combinations. Fig. 1A depicts three dimen-

sional diagram and a contour plot of calculated re-

sponse surface from the interaction between incuba-

tion period and pH while keeping the other two vari-

ables (MHC and temperature) at ‘0’ level. A linear in-

crease in

α-amylase production was observed when

Table 3. ANOVA for

α-amylase production in solid state fermentation.

Source

Sum of Squares

Degree of freedom

Mean Square

F-Value

p-value

Model 1387.73 14

200.15 24.89 0.0001

Pure error

1.54

5

0.31

Total 2922.65 29

R

2

= 0.9587, Adjusted

R

2

= 0.9202, Predicted

R

2

= 0.7646, Adequate precision = 17.850, Lack of Fit

F-value = 38.78.

Journal of Basic Microbiology 2007, 47, 417 – 425

Alpha-amylase production by B. subtilis 421

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

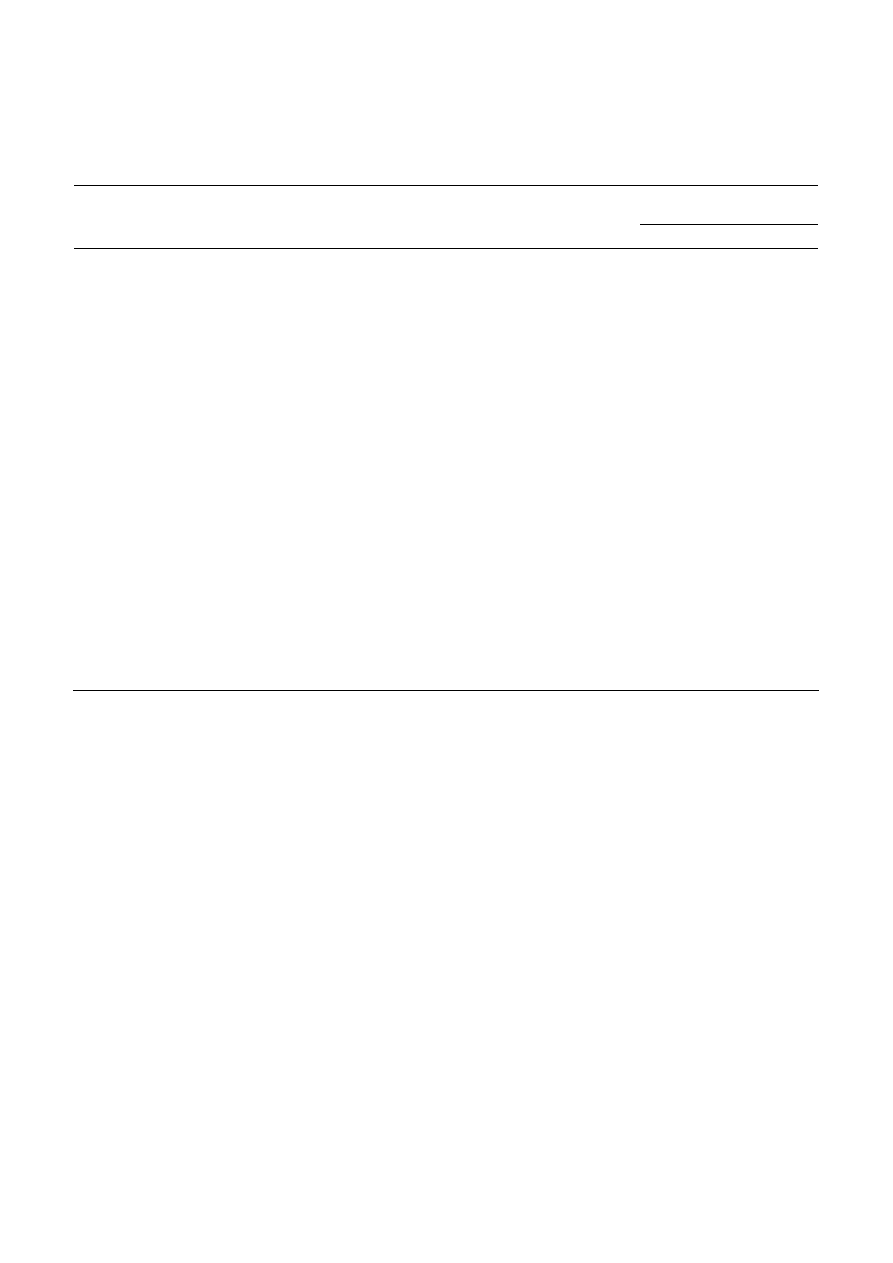

Figure 1. Statistical optimization of enzyme production using RSM. A: incubation period; B: pH; C: moisture holding capacity and

D: temperature holding capacity.

A

B

C

D

E

F

422

M. R. Swain and R. C. Ray

Journal of Basic Microbiology 2007, 47, 417 – 425

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

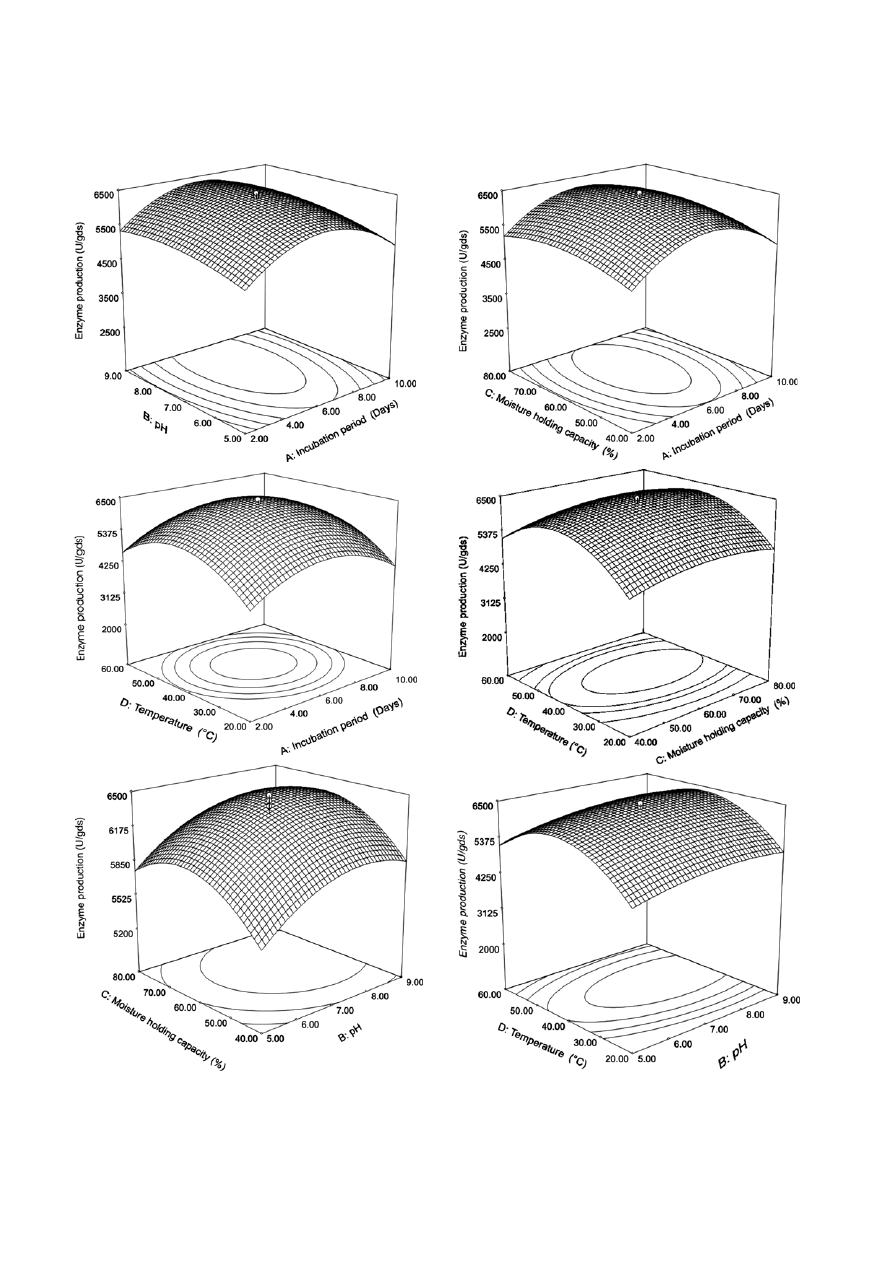

Figure 2.

Contour plot of the effect of A: pH and incubation period; B: incubation period and moisture holding capacity; C: incubation

period and temperature; D: pH and moisture holding capacity; E: pH and temperature and F: temperature and moisture holding.

A

B

C

D

E

F

Journal of Basic Microbiology 2007, 47, 417 – 425

Alpha-amylase production by B. subtilis 423

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

incubation period was increased up to 6 days, and there

after, it declined. In case of medium pH,

α-amylase

production was increased up to pH 8.0 and then de-

clined. When the level of MHC (%) was increased from

40 to 70%, a linear increase in

α-amylase production

was recorded up to day 6 and declined there after

(Fig. 1B). The response between incubation period and

temperature indicated that temperature at 50 °C was

optimum with 6 days incubation period for

α-amylase

production (Fig. 1C). The response surface was mainly

used to find out the optima of the variables for which

the response was maximized. An interaction between

the remaining two parameters (MHC and temperature)

(Fig. 1D) suggested a little difference with the earlier

responses. Fig. 1E and F represented the three dimen-

sional diagram and contour plots of calculated re-

sponse surface from the interaction between MHC and

pH, and temperature and pH, respectively. The six con-

tour plots proved the significance of earlier response

i.e. incubation period with pH, incubation period with

MHC, Incubation period with temperature, MHC with

temperature, pH with MHC, pH with temperature, and

MHC with temperature (Fig. 2A, B, C, D, E and F). Thus

Incubation period (6 days), initial medium pH (8.0),

MHC (70%) and temperature (50 °C) were adequate for

attaining maximum enzyme titre (6462 U/gds) as shown

in Table 2.

Validation of model

Validation was carried out in shake flasks under condi-

tions predicted by the model. The experimental values

were found to be very close to the predicted values and

hence, the model was successfully validated. Validation

of the statistical model and regression equation were

performed by taking A (6 days), B (8.0), C (70%) and D

(50 °C) in the experiment. The predicted response for

α-amylase production was 6362 U/gds, while the actual

(experimental) response was 6462 U/gds, thus proving

the validity.

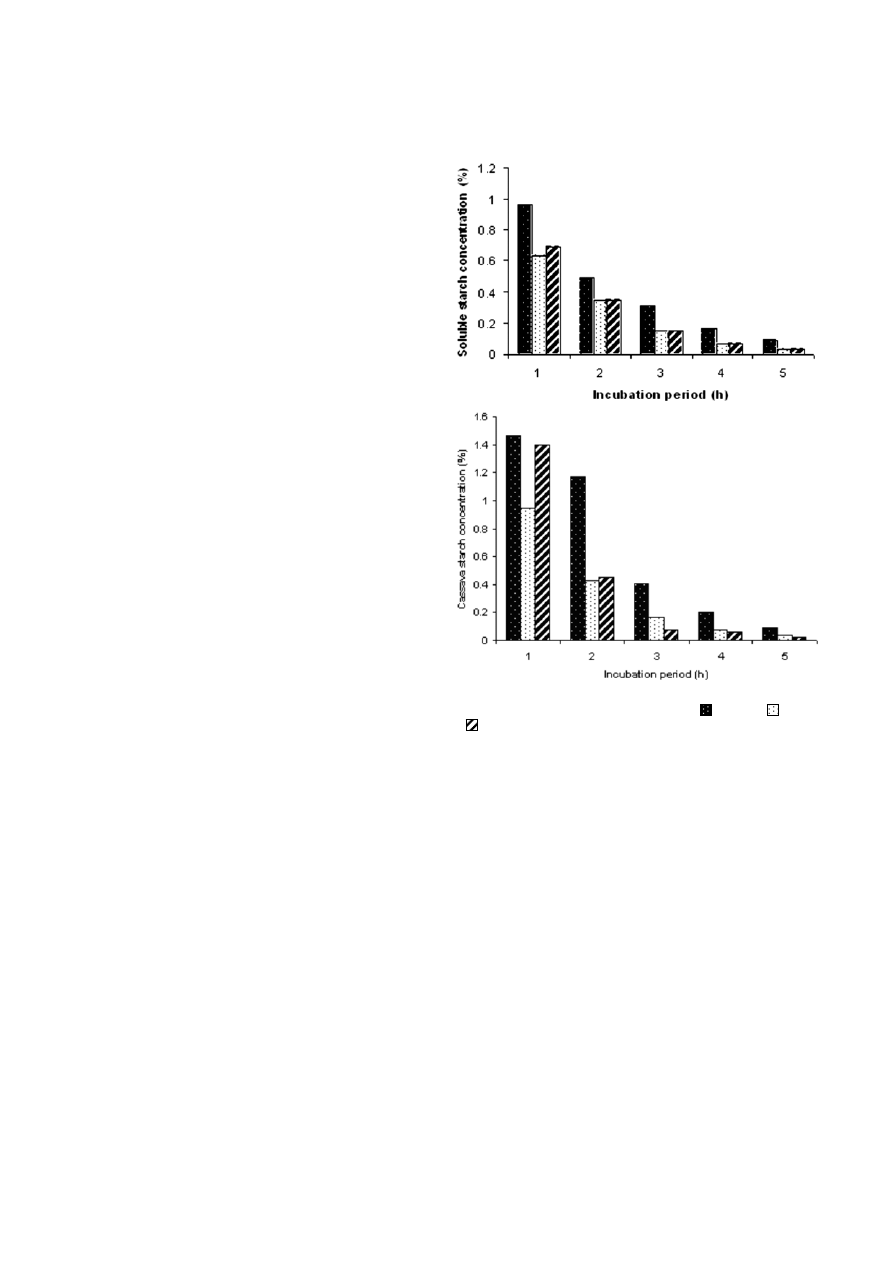

Rate of hydrolysis of starch

The rate of hydrolysis of 2% (w/v) soluble starch and

cassava starch by

B. subtilis CM3 α-amylase is shown in

Fig. 3. There was a gradual hydrolysis of starches with

increase in incubation period from 1 to 5 h and the rate

of hydrolysis also increased with the increase in en-

zyme concentration. With application of 4 ml crude

enzyme (

≈24,800 U/gds) there was 99% hydrolysis of

soluble as well as cassava starch.

Figure 3. Hydrolysis of commercial starch (A) and cassava starch

(B) by different

α-amylase concentrations (– – 2 ml, – – 3 ml,

– – 4 ml) from B. subtilis.

Discussion

B. subtilis is one of the best characterized organisms in

gram positive bacteria. It is safe, stable and widely used

in industrial fermentation process (Schallmey

et al.

2004). CFR is widely used as solid substrate for produc-

tion of several industrially important enzymes, i.e.,

amylase, cellulase, protease, lipases, etc. (Pandey

et al.

2000a) and other value added products (Ray

et al. 2006,

Ray and Moorthy 2007). In our previous study,

B. sub-

tilis strain CM3 was chosen as the best α-amylase pro-

ducer in SmF among five selected strains (CM1 – CM5)

isolated from cowdung microflora (Swain

et al. 2006).

The optimum temperature, pH and incubation

temperature for

α-amylase production by B. subtilis

CM3 were 50 – 70%, 5 – 9 and 36 h, respectively, in SmF.

The purified enzyme was in two forms with mole-

cular mass of 18.0 and 43.0 kDa in native SDS-PAGE.

However, optimization of culture parameters in

A

B

424

M. R. Swain and R. C. Ray

Journal of Basic Microbiology 2007, 47, 417 – 425

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

SSF often vary from SmF due to several physiologi-

cal factors (mainly water potential) (Durand

et al.

1997, Pandey

et al. 2000b), as evident from this

study.

RSM used in this investigation suggested the impor-

tance of various fermentation parameters at different

levels. The methodology employed will be successful to

any process, where an analysis of the effects and inter-

action of many experimental factors are required. CCD

maximizes the amount of information that can be ob-

tained, while limiting the numbers of individual ex-

periments (Kunamneni and Singh 2005). Thus, smaller

and less time consuming experimental designs could

generally suffice for the optimization of many fermen-

tation processes. The results of this study endorse this

viewpoint. In this study, a high similarity was observed

between the predicted and experimental results, which

reflected the accuracy and applicability of RSM to op-

timize the process for enzyme production in SSF. In

this study, an incubation period of 6 days, initial me-

dium pH of 8.0, moisture-holding capacity of 70%

and temperature at 50°C were the major factors that

influenced the enzyme titre. The decrease in enzyme

production above 50% MHC was probably due to inacti-

vation of the enzyme at higher (>50 °C) temperature

(Baysal

et al. 2003). Moisture holding capacity is another

important factor in SSF that influence the growth

of the microorganisms and there by enzyme production

(Durand

et al. 1997, Yang and Wang 1999). In general,

MHC between 50 to 70% is found suitable for

α-amylase

production by various microorganisms (Pandey

et al.

2000b, Ray

et al. 2006). In this context, our results

corroborated with these reports. Beyond 70% MHC,

the enzyme activity by

B. subtilis CM3 in this study

declined. The decline of enzyme activity might be

attributed to poor porosity, lower oxygen transfer, poor

aeration and adsorption of enzyme to the substrate

particle (Pandey

et al. 2000a, b). When the applicability

of the

B. subtilis amylase in liquefying starch was

studied at its optimum temperature of 50 °C, the crude

enzyme (4 ml) could hydrolyze starch (

≈99%) after

5 h of incubation. Further study is in progress in our

laboratory to utilize the

B. subtilis crude enzyme

for liquefaction of cassava starch for production of

ethanol.

References

Bramorski, A., Soccol, C.R., Christen, P. and Revah. S., 1989.

Fruity aroma production by Ceratacystis fimbriata in solid

culture from agro-industrial wastes. Rev. Microbiol.,

29,

208 – 212.

Baysal, Z., Uyar, F. and Aytekin, C., 2003. Solid-state fermenta-

tion for production of

α-amylase by a thermotolerant Bacil-

lus subtilis from hot spring water. Process Biochem.,

38,

1665 – 1668.

Boyaci, I.H., 2005. A new approach of determination of enzy-

me kinetic constants using response surface methodology.

Biochem. Eng. J.,

25, 55–62.

Carvalho, J.C.M., Vitolo, M., Sato, S. and Aquarone, E., 2003.

Ethanol production by Saccharomyces cerevisiae grown in su-

garcane blackstrap molasses through a feed batch process:

optimization by response surface methodology. Appl. Bio-

chem. Biotechnol.,

110, 151–164.

Christen, P., Meza, J.C. and Revah, S., 1997. Fruity aroma

production in solid state fermentation by Ceratacystis fimbri-

ata: influence of the substrate type and the presence of pre-

cursors. Mycol. Res.,

101, 911–919.

Durand, A., Almanzaa, S., Renaud, R. and Maratray, J., 1997.

Solid state fermentation: attractive alternative to sub-

merged liquid fermentations. Agro Food Ind. Hi-Tech.,

8,

39 – 42.

Edison, S., Anantharaman, M. and Srinivas, T., 2006. Status of

cassava in India – an overall view. Tech. Bull. Ser. 46, Cent-

ral Tuber Crops Research Institute, Thiruvanathapuram,

India, p. 79.

He, G.Q., Kong, Q. and Dingm, L.X., 2004. Response surface

methodology for optimizing the fermentation medium of

Clostridium butyricum. Lett. Appl. Microbiol.,

39, 363–368.

Holker, U., Hofer, M. and Lenz, J. 2004. Biotechnological ad-

vantages of laboratory-scale solid state fermentation with

fungi. Appl. Microbiol. Biotechnol.,

64, 175–186.

Jyothi, A.N., Sasikiran, K., Nambisan, B. and Balagopalan, C.,

2005. Optimization of glutamic acid production from cas-

sava starch factory residues using Brevibacterium divaricatum.

Process Biochem.,

40, 3576–3579.

Kolicheski, M.B., Soccal, C.R., Marin, B., Medeiros, E. and

Raimbault, M., 1995. Citric acid production on three cellu-

losic support in solid state fermentation. In: Advance in

Solid State Fermentation (S. Roussas, B.K. Lonsane, M. Rai-

mabult, G. Viniegra-Gonzalez, eds.), pp. 447 – 460. Kluwer

Academic Publisher Dordrecht.

Kunamneni, A. and Singh, S., 2005. Response surface optimi-

zation of enzymatic hydrolysis of maize starch for higher

glucose production. Biochem. Eng. J.,

27, 179–190.

Nigam, P. and Singh, D., 1995. Enzyme and microbial systems

involved in starch processing. Enz. Microb. Technol.,

17,

770 – 778.

Pandey, A., Soccol, C.R. and Mitchell, W., 2000a. New deve-

lopment in solid state fermentation: I. Bioprocess and pro-

ducts. Process Biochem.,

35, 1153–1169.

Pandey, A., Soccol, C.R., Nigam, P., Soccol, V.T., Vandenberg-

he, L.P.S. and Mohan, R., 2000b. Biotechnological potential

of agro-individual residues. II. Cassava bagasse. Biores.

Technol.,

74, 81–87.

Rao, J.L.M. and Satyanarayana, T., 2003. Statistical optimiza-

tion of a high maltose-forming, hyperthermostable and

Ca

2+

-independent

α-amylase production by an extreme ther-

mophile Geobacillus thermoleovorans using response surface

methodology. J. Appl. Microbiol.,

95, 712–718.

Rao, P.V. Jayaraman, K. and Lakshmanan, C.M., 1993. Produc-

tion of lipase by Candida rugosa in solid-state fermentation,

Journal of Basic Microbiology 2007, 47, 417 – 425

Alpha-amylase production by B. subtilis 425

© 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jbm-journal.com

medium optimization and effect of aeration. Process Bio-

chem.,

28, 391–395.

Ray, R.C. and Moorthy, S.N., 2007. Exopolysaccharide (pull-

ulan) production from cassava starch residue by Aureobasi-

dium pullulans strain MTTC 1991. J. Sci. Ind. Res.,

66, 252–

255.

Ray, R.C., Sahoo A.K., Asana, K. and Tomita, F., 2006. Micro-

bial processing of agricultural residues for production of

food, feed and food-additives. In: Microbial Biotechnology

in Agriculture and Aquaculture Vol. II (R.C. Ray, ed.),

pp. 511 – 552. Science Publishers Inc. Enfield, New Hamp-

shire.

Schallmey, M., Singh, A. and Ward, O.P., 2004. Developments

in the use of Bacillus species for industrial production.

Can.

J. Microbiol.,

50, 1–17.

Senanayake, S.P.J.N and Shahidi, F., 2002. Lipase catalysed

incorporation of docosahexaenoic acid (DHA) in to borage

oil: optimization using response surface methodology. Food

Chem.,

77, 115–123.

Shirai, K., Guerrero, I., Huerta, S., Saucedo, G., Castillo, A.,

Gorzalez, R.O. and Hall, G.M., 2001. Effect of initial glucose

concentration and inoculum level of lactic acid bacteria in

shrimp waste ensilation. Enz. Microb. Technol.,

28, 446–

452.

Swain, M.R. and Ray, R.C., 2007. Biocontrol and other benefi-

cial activities of Bacillus subtilis isolated from cowdung mi-

croflora. Microbiol. Res., doi:10.1016/j.micres.2006.10.009.

Swain, M.R., Naskar, S.K. and Ray, R.C., 2007. Indole-3-acetic

acid production and effect on sprouting of yam (Dioscorea

rotundata L.) minisetts by Bacillus subtilis isolated from cul-

turable cowdung microflora. Polish J. Microbiol.,

56, 103–

110.

Swain, M.R., Kar, S., Padmaja, G. and Ray, R.C., 2006. Partial

characterization and optimization of production of ex-

tracellular

α-amylase from Bacillus subtilis isolated from cul-

turable cowdung microflora. Polish J. Microbiol.,

55, 289–

296.

Tomasini, A., Fajardo, C. and Barrios-Gonzalez, J., 1997. Gib-

berllic acid production using different solid state fermenta-

tions. Process Biochem.,

37, 637–641.

Xian, J.Z., Lin, P.H., Qin, J.Y. and Xu, P., 2007. Statistical opti-

mization of medium composition for enhanced acetoin

production from molasses and soybean meal hydrolysate

Appl. Microbiol Biotechnol.,

74, 61–68.

Xiong, C., Shouwen, C., Ming, S. and Ziniu, Y., 2005. Medium

optimization by response surface methodology for poly-y-

glutamic acid production using dairy manure as the basis

of a solid substrate. Appl. Microbiol. Biotechnol.,

69, 390–

396.

Yang, S.S and Wang, J.Y., 1999. Protease and amylase produc-

tion of Streptomyces rimosus in submerged and solid state

cultivations. Bot. Bull. Acad. Sin.,

40, 259–265.

Wyszukiwarka

Podobne podstrony:

jobm 200710325

jobm 200710320

jobm 200710313

jobm 200710333

jobm 200710111

jobm 200710341

jobm 200710318

jobm 200710317

jobm 200710310

jobm 200710337

jobm 3620260101

200710s11 OgarnijTemat comid 26410 (2)

20071010

20071002CV PL Prof Grudzewski, a

20071002CV PL Prof Grudzewski, a

200710311013330 Coatedproductsu Nieznany (2)

jobm 3620250801

20071031

jobm 3620260805

więcej podobnych podstron