A typical endo-xylanase from Streptomyces rameus L2001 and its unique

characteristics in xylooligosaccharide production

Xiuting Li

, E. Li

, Yunping Zhu

, Chao Teng

, Baoguo Sun

, Huanlu Song

, Ran Yang

a

Department of Food Science, School of Food and Chemical Engineering, Beijing Technology and Business University, No. 33 Fucheng Road, Beijing 100048, PR China

b

Beijing Higher Institution Engineering Research Center of Food Additives and Ingredients, No. 33 Fucheng Road, Beijing 100048, PR China

c

Beijing Key Laboratory of Flavor Chemistry, No. 33, Fucheng Road, Beijing 100048, PR China

a r t i c l e

i n f o

Article history:

Received 12 March 2012

Received in revised form 2 May 2012

Accepted 3 May 2012

Available online 11 May 2012

Keywords:

Streptomyces rameus

endo-Xylanase

Agro-industrial residues

Enzymatic hydrolysis

Xylooligosaccharides

a b s t r a c t

The activity of the extracellular xylanase produced by Streptomyces rameus L2001 against different xylans

and xylooligosaccharides (XOS) was investigated. The main products of hydrolysis of birchwood xylan and

oat-spelt xylan by the S. rameus L2001 xylanase were xylobiose (X2) and xylotriose (X3), suggesting that

this is an endo-acting xylanase. This was confirmed by analysis of XOS degradation products. The enzyme

hardly hydrolyzed X2 and X3, but hydrolyzed xylotetraose (X4) and xylopentaose (X5) producing mainly

X2 and X3 through transglycosylation. Depending on the substrate, different quantities of reducing sugars

were produced by the xylanase: 150 mg/g from corncob, 105 mg/g from bean culms, and 133 mg/g from

bagasse. With the bagasse substrate, the xylanase yielded 2.36, 2.76, 2.03, and 2.17 mg/mL of X2, X3, X4,

and X5, respectively. The structure of xylobiose and xylotriose from the hydrolysis of corncob xylan was

identified by MS and NMR. The production of XOS from various agricultural wastes has potential industrial

applications. This is the first report of XOS production by S. rameus L2001.

Ó 2012 Elsevier Ltd. All rights reserved.

1. Introduction

There is increasing interest in the use of xylooligosaccharides

(XOS) as ingredients in functional foods, because prebiotic oligosac-

charides (OS) have various beneficial health effects. These include

their selective metabolism by Bifidobacteria, their ability to increase

production of volatile fatty acids, and their ability to diminish ulcer

lesions in the stomach. They are associated with a decreased risk of

colon cancer, and they are stable over a wide range of pH and

temperatures.

XOS have stimulatory effects on the selective

growth of human intestinal Bifidobacteria, which lower blood sugar

levels and blood pressure.

XOS can be produced by xylanases

(1,4-b-

D

-xylan xylanohydrolase, EC3.2.1.8) that hydrolyze lignocel-

lulosic materials containing substituted xylan as the major

hemicellulose component.

Xylanis a polysaccharide with a back-

bone consisting of b-1,4-linked xylopyranose with branches of

other residues such as arabinofuranosyl, acetyl, and glucuronosyl.

Complete hydrolysis of xylan requires the orchestrated actions of

various

enzymes

including

endo-xylanase,

b

-

D

-xylosidase,

a

-glucuronidase, acetyl esterase, and

a

-

L

-arabinofuranosidase;

endo-xylanases are the crucial enzyme components of microbial

xylanolytic systems.

Enzymes with high endo-xylanase but low

exo-xylanase and/or b-xylosidase activity are desirable for

enzymatic XOS production.

In recent years, xylanases have at-

tracted considerable research interest because of their potential

industrial applications. Fungal xylanases from Aspergillus sp. and

Trichoderma sp., and bacterial xylanases from Bacillus sp.,

Streptomyces sp., and Clostridium sp. have been intensively studied.

However, for economical production of XOS, it is important to find

highly efficient endo-xylanases. Nowadays, many researchers

working on xylanase spend considerable time and energy obtaining

XOS. The increasing number of industrial applications encourages a

search for renewable and cheap xylan sources for the preparation of

XOS. Agricultural wastes of a lignocellulosic nature are widely

available in China, and contain 15–25% xylan.

Some widely distrib-

uted and abundant agricultural wastes are corncobs, cottonseed

hulls, oat bran, bean culms, and bagasse. These could potentially

be appropriate substrates for the production of XOS. In addition,

since they are usually left to rot or are burned in the field after

harvesting, utilization of these materials for industrial purposes

provides a suitable disposal method, and some additional income

and employment for farmers.

In our previous paper, we described

the selection of Streptomyces rameus L2001 as a strain that pro-

duced high levels of xylan-degrading enzymes. The endo-xylanase

was purified from the strain and comparatively characterized.

However, its enzymatic activity against XOS and various xylans

had not been studied in detail. The S. rameus L2001 xylanase dis-

cussed here is a typical endo-xylanase. This is the first report of

its ability to produce XOS. Furthermore, this enzyme was able to

0008-6215/$ - see front matter Ó 2012 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.carres.2012.05.005

⇑

Corresponding author. Tel.: +86 10 68985378; fax: +86 10 68985456.

E-mail addresses:

(X. Li).

Carbohydrate Research 359 (2012) 30–36

Contents lists available at

Carbohydrate Research

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / c a r r e s

hydrolyze several kinds of agricultural wastes. Therefore, we eval-

uated the potential use of this endo-xylanase to produce XOS via

hydrolysis of xylan from agricultural wastes that are cheap and

abundant biomass resources in China.

2. Material and methods

2.1. Production of xylanase by S. rameus L2001 and enzyme

assay

Xylanase was produced by S. rameus L2001 under submerged

fermentation conditions using a corncob xylan preparation (2.5%,

w/v) as the inducer. The culture was incubated at 140 rpm for

7 days at 40 °C. The crude enzyme solution was recovered by cen-

trifuging the culture broth at 8000g for 10 min at 4 °C. The super-

natant was stored at 4 °C for further purification. The pure xylanase

used for enzymatic hydrolysis was produced as described previ-

ously.

The dialyzed culture supernatant was loaded on a DEAE-

52 column (1.0 10 cm) using a loading buffer (20 mM Tris–HCl,

pH 7.0) at a flow rate of 1.0 mL/min. The xylanase eluted from

the DEAE-52 column was further purified on a CM Sepharose Fast

Flow column (1.0 10 cm). The bound proteins were eluted with a

0–0.05 M NaCl gradient at a flow rate of 1.0 mL/min. The homoge-

neity of the active xylanase fraction was checked by SDS–poly-

acrylamide gel electrophoresis. The xylanase activity was assayed

using birch xylan as the substrate, as described previously.

2.2. Main reagents

Xylose, xylobiose, xylotriose, xylotetraose, and xylopentaose

(X1, X2, X3, X4, and X5, respectively) were purchased from Mega-

zyme (Megazyme International Ireland Ltd, Ireland). Birchwood

xylan, oat-spelt xylan were purchased from Sigma (Sigma–Aldrich

Co. Ltd, Germany). Xylans were obtained from the alkali extraction

of corncob. Water-soluble and water-insoluble xylans from corn-

cobs, and whole soluble xylans from corncobs, cottonseed hulls,

oat bran, bean culms, and bagasse, were obtained from the alkali

extraction of agricultural wastes as described elsewhere,

with

minor modifications. Locally obtained corncob, cottonseed hulls,

oat bran, bean culms, and bagasse were chopped and milled into

fine powders. The powders were treated with 10% NaOH with a so-

lid–liquid ratio of 1:15 (w/v) at 100 °C for 60 min. The resultant

soluble fraction was recovered by filtration and adjusted to pH

7.0 with dilute hydrochloric acid. Then, three volumes of 95% eth-

anol were added and the resultant mixture was incubated for

60 min at room temperature. Xylans were obtained from the

recovered precipitate. All other chemicals were of analytical grade

and were obtained locally.

2.3. Enzymatic hydrolysis of xylans and xylooligosaccharides as

substrates

For enzymatic hydrolysis of xylan, the reaction mixture con-

sisted of 2% of each xylan in 50 mM of acetic acid buffer with

4 U/mL of the enzyme. The mixture was incubated at 50 °C for

12 h. For enzymatic hydrolysis of different XOS, 2% of each xylool-

igosaccharide was incubated at 50 °C for 24 h, with 2 U/mL of

xylanase.

At selected time intervals, samples were analyzed for hydro-

lyzed products using thin layer chromatography (TLC) and silica

gel plates. The plates were developed with butanol, acetic acid,

and water (2:1:1), followed by heating for few minutes at 105 °C;

the plates were then sprayed with a methanol and sulfuric acid

mixture (20:1). A XOS mixture consisting of X1, X2, X3, X4, and

X5 was used as the standard.

2.4. Enzymatic hydrolysis of other xylans from different kinds

of agricultural waste

For enzymatic hydrolysis of xylans from different kinds of agri-

cultural waste, the reaction mixture consisted of 2% of each xylan

in 50 mM acetic acid buffer with 20 U/mL of the enzyme. The mix-

ture was incubated at 50 °C for 2 h. Reducing sugars were quanti-

fied using the 3,5-dinitrosalicylic acid(DNS) method,

with xylose

as a standard. XOS were separated by chromatography using a

Waters 1525 HPLC system equipped with a refractive index detec-

tor (Waters 2707) and a column oven (Waters 1500). The hydro-

lyzed products were separated by HPLC on a Shodex KS-800

column (8 300 mm, 6

l

m) after hydrolysis. The column oven

was set at 60 °C, the temperature of the refractive index detector

was 40 °C, the flow rate was 0.6 mL/min, and the injection volume

was 10

l

L.

2.5. Purification of xylobiose and xylotriose

The enzymatic hydrolysis products of corncob xylan were puri-

fied by column chromatography. After the hydrolysis reaction, the

reaction mixture was separated by column chromatography on a

silica gel column with butanol, acetic acid, and water (2:1:1) as

eluent. The xylobiose and xylotriose were collected and evaporated

in vacuum and lyophilized for further analysis.

2.6. Identification of the structure of xylobiose and xylotriose

2.6.1. Positive mass spectrometry (MS)

ESI-MS was performed (LTQ XL ion trap MS; Thermo Scientific,

San Jose, CA) on lyophilized xylobiose and xylotriose. Samples

were dissolved in milliQ water (100

l

g/mL) and applied to a Ther-

mo

Accela

UHPLC

system

equipped

with

a

Hypercarb

(100 2.1 mm, 3 lm) column (Thermo Scientific). Elution was per-

formed with a gradient of deionized water/acetonitrile and 0.2%

trifluoroacetic acid (0.4 mL/min; 70 °C). MS detection was per-

formed in the positive mode using a spray voltage of 4.5 kV and

a capillary temperature of 260 °C and auto-tuned on glucohexaose.

2.6.2. The nuclear magnetic resonance (NMR) spectrometry

The structures of xylobiose and xylotriose were also analyzed

by the proton nuclear magnetic resonance (

1

H NMR). Spectra were

recorded at 22 °C with a Bruker Advance DPX300 MHz spectrome-

ter operating at 300.13 MHz for

1

H and are referenced to the sol-

vent peak (D

2

O, 4.7 ppm).

3. Results and discussion

3.1. Enzymatic hydrolysis of xylans

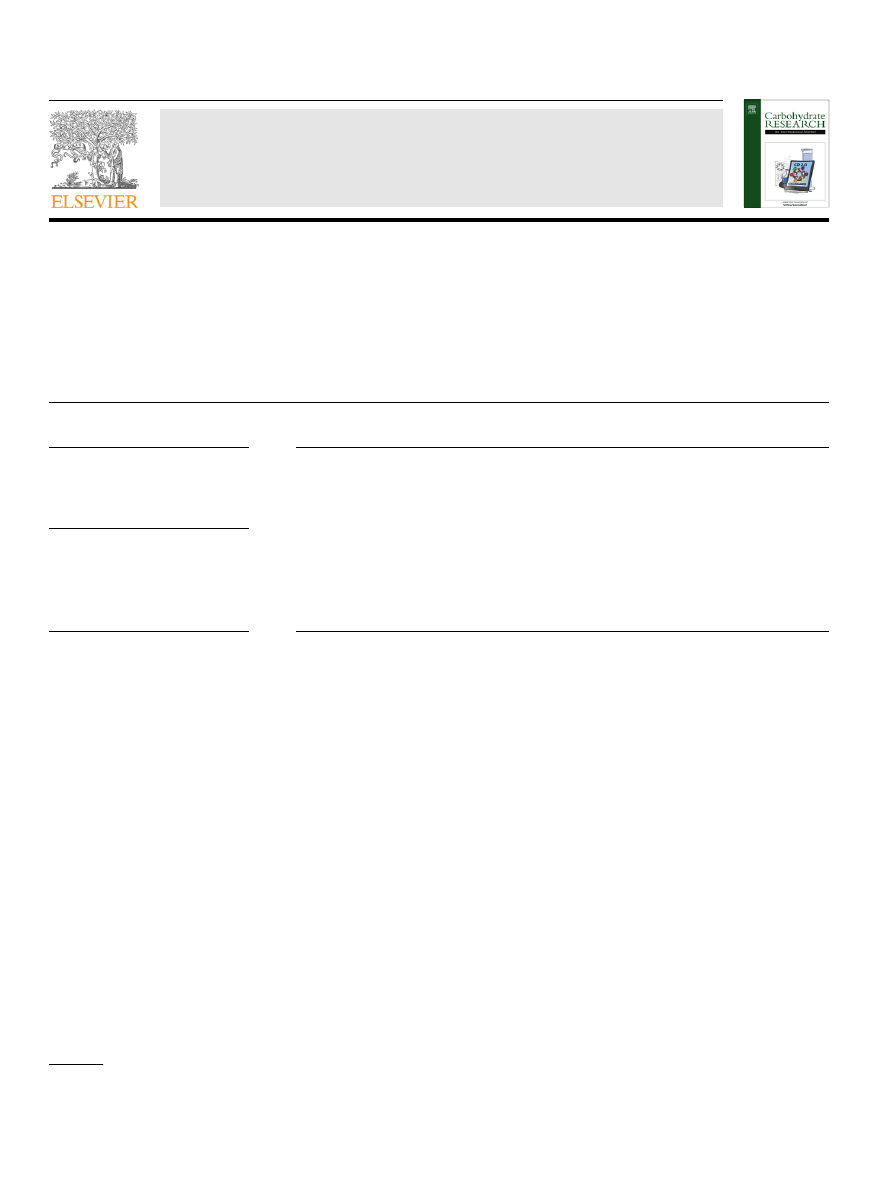

To test whether the xylanase was an endo-xylanase, TLC was

used to analyze the products of hydrolysis of birchwood xylan,

oat-spelt xylan, and water-soluble and water-insoluble xylans.

Analysis of the degradation products of birchwood xylan (

a)

showed that X2 and X3 were the main end products. Xylose was

not detected as an end product of the enzymatic hydrolysis reac-

tion. As the reaction time increased, both X4 and X5 were readily

degraded. Production of X3 was greater than that of X2. This pat-

tern of hydrolysis differs from that of xylanases from other bacte-

ria. For example, the xylanase of Thermotoga maritima exclusively

liberated X2 from birchwood xylan.

X2 and trace amounts of xy-

lose were liberated from birchwood xylan by the purified xylanase

from strains SSBP after 24 h of incubation.

The enzyme from

Talaromyces thermophilus released mainly X2; the major product

of xylan degradation.

X. Li et al. / Carbohydrate Research 359 (2012) 30–36

31

The degradation products of oat-spelt xylan (

b) were a

variety of XOS, including X2, X3, X4, and X5. Within 12 h, there

were increased concentrations of all XOS. With longer hydrolysis

time, the levels of X4 and X5 decreased gradually. Hydrolysis of

X4 and X5 slowed after 12 h of incubation, indicating that endo-

xylanase activity decreased because of inhibition by the end

products.

Analysis of different water-soluble xylans (

c and d) as sub-

strates for enzymatic hydrolysis showed that product composition

and production trends showed few differences; the main

difference was in the quantity of hydrolysis. When the same sub-

strate concentration, enzyme concentration, and time were used,

greater quantities of XOS were produced with water-soluble xylan

as the substrate than water-insoluble xylan, which indicated that

the water-soluble xylan was degraded more easily than the

water-insoluble xylan.

This indicated that the xylanase was a true endo-b-1,4-xylanase

that only cleaves internal b-1,4-xylosidic linkages on the backbone

of various xylosic compounds consisting of three or more b-

D

-xylopyranoside units.

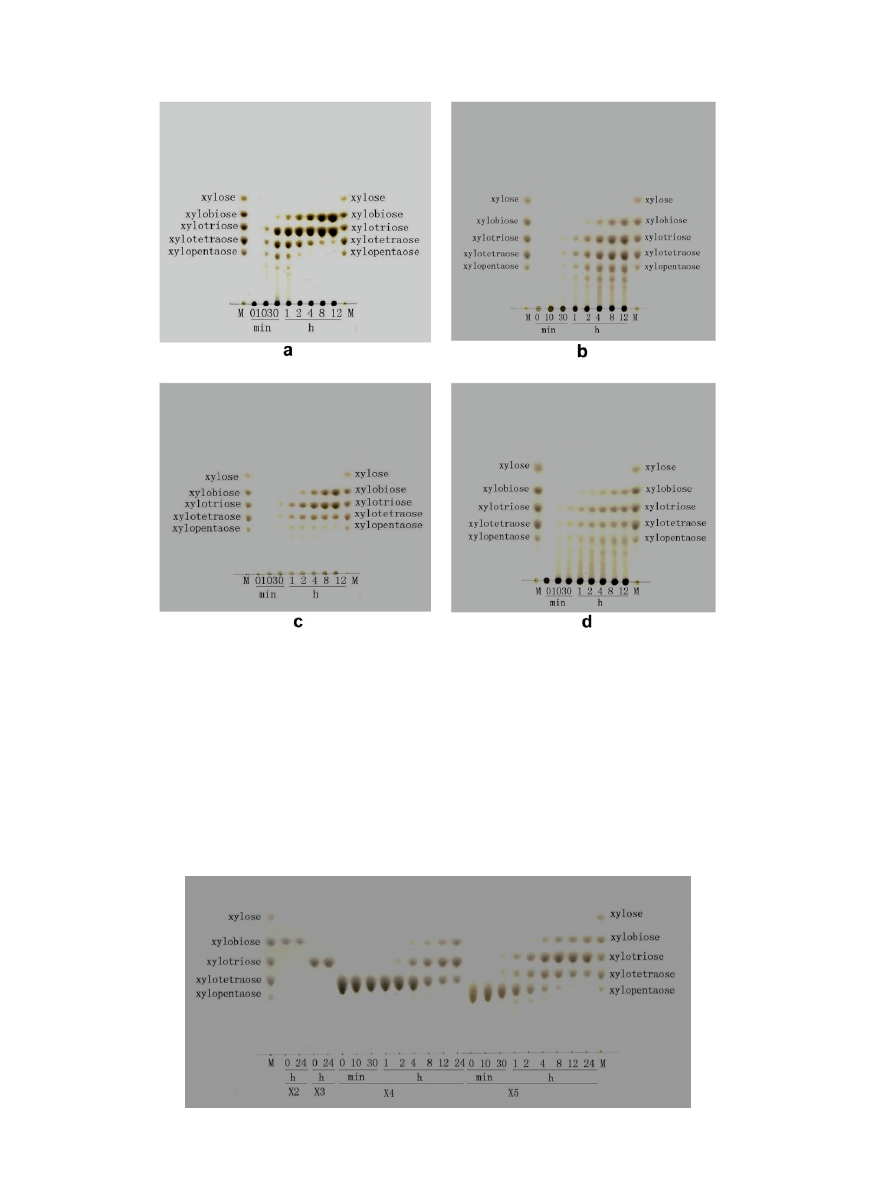

Figure 2. Thin layer chromatography (TLC) analysis of hydrolyzed products of xylooligosaccharides by xylanase from Streptomyces rameus L2001.

Figure 1. Thin layer chromatography (TLC) analysis of hydrolyzed products of different xylans by xylanase from Streptomyces rameus L2001. (a) Birchwood xylan; (b) oat-

spelt xylan; (c) water-insoluble xylan form corncobs; (d) water-soluble xylan from corncobs.

32

X. Li et al. / Carbohydrate Research 359 (2012) 30–36

3.2. Enzymatic hydrolysis of XOS

The mode of action of the xylanase was determined using X2,

X3, X4, and X5 as substrates (

). The Streptomyces L2001 en-

zyme could not hydrolyze X2 or X3, but it could hydrolyze X4

and X5. During the early course of hydrolysis of X5, the main prod-

ucts formed were X2, X3, and X4. A small amount of XOS with

higher degree of polymerization (DP >5) was observed at 1 h

(

). As the incubation time increased, X4 and higher xylooligo-

saccharides were further hydrolyzed into X2 and X3. Although X4

was slowly hydrolyzed by the Streptomyces L2001 xylanase, it was

ultimately hydrolyzed to X2 and X3. The high production of X2 and

X3 in the X4 and X5 reaction mixtures confirmed that the Strepto-

myces L2001 xylanase was a typical endo-b-1,4-xylanase that only

cleaves internal b-1,4-xylosidic linkages on the backbone of

various xylosic compounds consisting of four or more b-

D

-xylopyranoside units.

Similar production of X2 and X3 has been obtained from xylan

hydrolysis with the endo-acting xylanase from Chaetomium sp.

CQ31.

An enzyme from Streptomyces matensis DW67 converted

X4 to X5.

It has been reported that xylose and X2 were the end

products obtained from hydrolysis of X3, X4, and X5, via a transgly-

cosylation mechanism. Kumar et al. found that xylose and X2 were

the main end products, and that the conversion of X3 to X2 might

have occurred through a glycosyl transfer reaction.

Previously, it

was reported that the L. sulphureus xylanase is an endo-xylanase

that hydrolyzes X3, X4, and X5, but not X2.

Li et al. found that

X2 and a small amount of xylose and X3 were the main products

when X3 and X4 were converted to X2.

3.3. Enzymatic hydrolysis of xylans from various agricultural

wastes

A sample of pretreated xylan (2%) was hydrolyzed by the xylan-

ase (20 U/mL) at pH 7.0, 50 °C for 2 h. The products of the hydroly-

sis (X1, X2, X3, X4, and X5) were analyzed by HPLC.

Different xylans from various agricultural residues hydrolyzed

by the xylanase from S. rameus L2001 gave different quantities of

reducing sugars: 150 mg/g from corncobs, 105 mg/g from bean

culms, and 133 mg/g from bagasse (

). These quantities are

similar to those produced from birchwood xylan by the

T. thermophilus xylanase.

shows the quantities of oligosaccharides produced from

each xylan. Akpinar et al. reported that the Aspergillus niger xylan-

ase can hydrolyze several kinds of agricultural wastes, but the

quantities of X2, X3, X4, and X5 obtained were lower than those

obtained in the present study.

As shown in

, X2, X3 or both

of them could be detected in the hydrolysis of all the agricultural

residues tested. The highest amount of X2 and X3 was 87.2% of

sugars, obtained from hydrolysis of the birchwood xylan bought

from Sigma Ltd. Among all the other agricultural residues, hydroly-

sis of water-insoluble xylan from corncob exhibited high amount

of X2 and X3 (76.7% of sugars). In addition, the amount of X2

and X3 in hydrolysis of whole soluble xylan from bagasse and

water-soluble xylan from corncob also accounted for 63.6% and

56.2%, respectively. To the best of our knowledge, this is the first

report of enzymatic hydrolysis of bagasse xylan by S. rameus xylan-

ase producing XOS.

Xylobiose and xylotriose have been found to have a stimulatory

effect on the selective growth of human intestinal Bifidobacteria,

Table 2

Hydrolysis products from different xylans produced by S. rameus L2001 xylanase

Substrates

Total sugar (peak area)

X2–5 (peak area)

X1/total sugars (%)

X2/total sugars (%)

X3/total sugars (%)

Birchwood xylan

8.9 10

5

8.8 10

5

0

40.2

47.0

Water-soluble xylan from corncob

3.4 10

5

2.6 10

5

0

24.3

31.9

Water-insoluble xylan from corncob

3.4 10

5

3.3 10

5

0

32.8

43.9

Whole soluble xylan from corncob

2.5 10

5

4.2 10

4

0

—

10.4

Whole soluble xylan from cottonseed hulls

4.3 10

5

4.0 10

4

0

—

6.3

Whole soluble xylan from oat bran

—

—

0

—

—

Whole soluble xylan from bean culm

1.0 10

5

1.0 10

5

0

—

48.4

Whole soluble xylan from bagasse

2.8 10

5

2.7 10

5

0

24.7

38.9

0

20

40

60

80

100

120

140

160

180

1

2

3

4

5

6

7

Reducing sugars (mg/g)

Different xylans of agricultural wastes

Figure 3. Reducing sugars from enzymatic hydrolysis of various agricultural

wastes. (1) Water-soluble xylan from corncobs; (2) water-insoluble xylan from

corncobs; (3) whole soluble xylan from corncobs; (4) whole soluble xylan from

cottonseed hulls; (5) whole soluble xylan from oat bran; (6) whole soluble xylan

from bean culms; (7) whole soluble xylan from bagasse.

Table 1

HPLC analysis of XOS produced by xylanase of S. rameus L2001 from various agricultural wastes

Different xylans from agricultural wastes

Oligosaccharides (mg/mL)

X2

X3

X4

X5

Water-soluble xylan from corncob

2.50

2.76

1.92

2.08

Water-insoluble xylan from corncob

2.79

3.17

2.02

1.97

Whole soluble xylan from corncob

—

1.92

1.83

—

Whole soluble xylan from cottonseed hulls

—

1.94

1.80

—

Whole soluble xylan from oat bran

—

—

—

—

Whole soluble xylan from bean culm

—

2.15

2.03

1.82

Whole soluble xylan from bagasse

2.36

2.76

2.03

2.17

X2: xylobiose; X3: xylotriose; X4: xylotetraose; X5: xylopentaose.

X. Li et al. / Carbohydrate Research 359 (2012) 30–36

33

which are important for the maintenance of a healthy intestinal

microflora. But, the production of analytical grade xylobiose and

xylotriose is a time consuming and expensive process. The current

results suggest that the enzyme from S. rameus L2001 is a highly

efficient endo-xylanase to convert agro-industrial residues to xylo-

biose and xylotriose. Actually, the materials tested as substrates in

the present study are cheap, renewable, and readily available

sources of sugars. Therefore, the production cost of XOS could be

hopefully reduced significantly if agricultural residues could be

used instead of xylan. The high yield of xylobiose and xylotriose

in the hydrolysis of agricultural residues by xylanase from S. ram-

eus indicates the application prosperity in functional food industry.

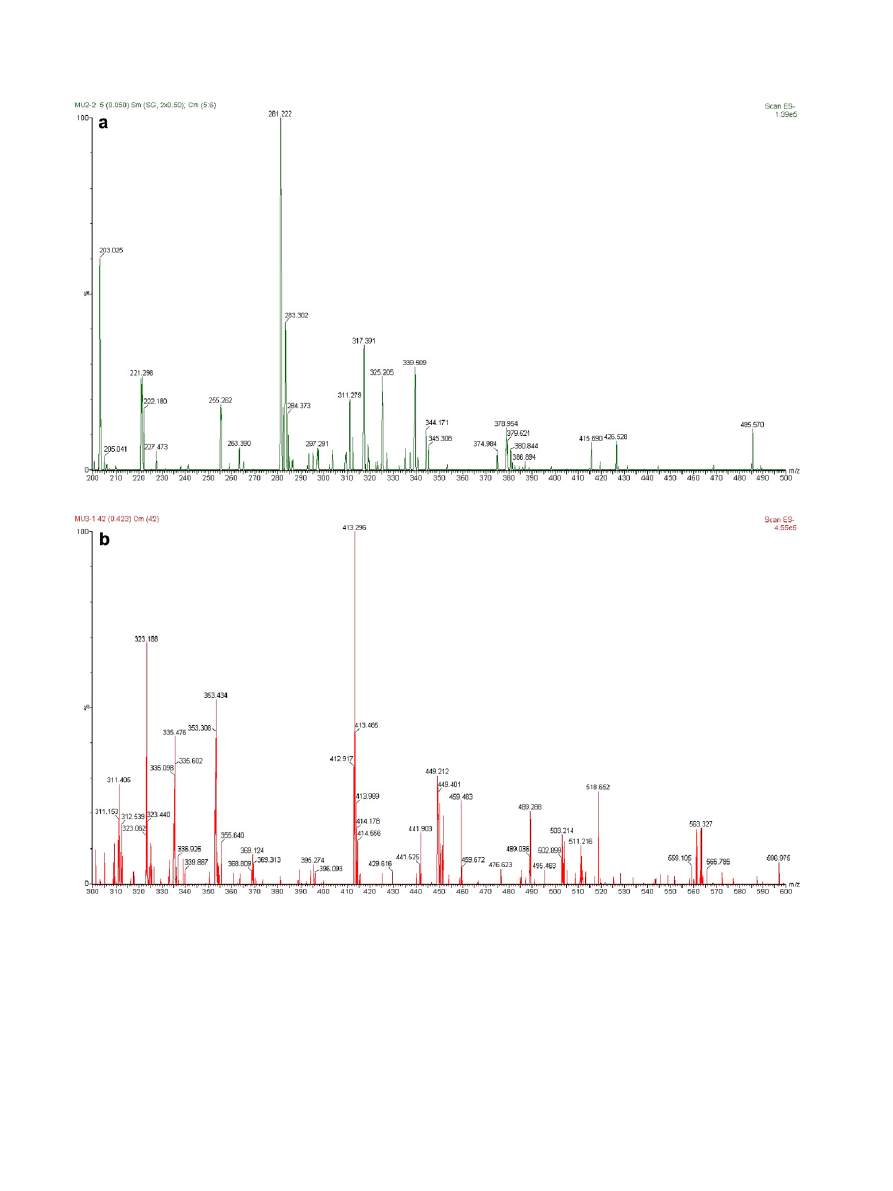

In order to confirm that the main products of the hydrolysis of

corncob xlyan were X2 and X3, the hydrolysis products from corn-

cob xylan were purified by preparative TLC and analyzed by MS

and

1

H NMR. In the full-scan MS spectrum, a main peak at m/z

283.3 (M

+

+1) was shown in

a and a main peak at m/z

413.3 (M

+

+1) was shown in

b. The chemical shifts of

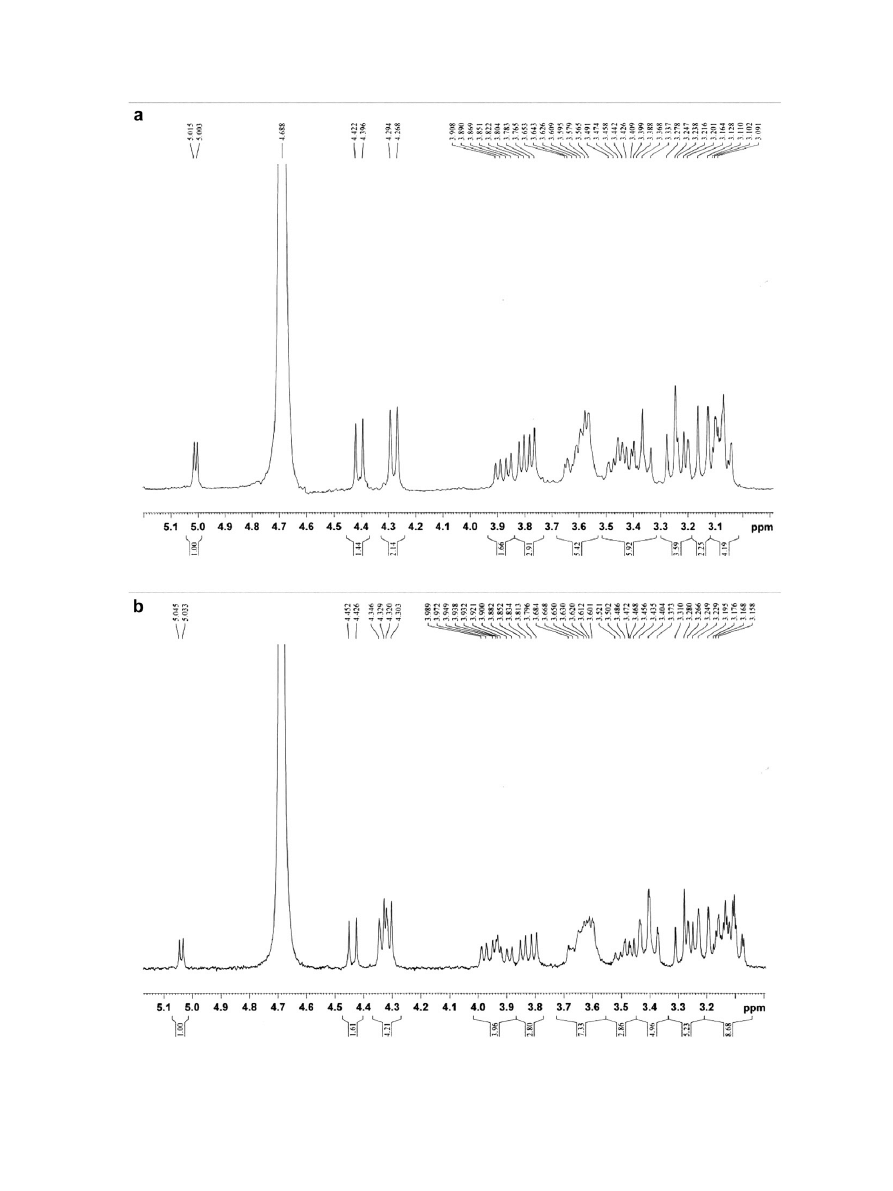

1

H

NMR are shown in

. For both xylobiose and xylotriose,

the signals of H-2, H-3, and H-4 occurred at 3.25, 3.6, and 3.8,

respectively, which are accordant with the report of Haffman.

Apart from these signals, the spectra showed signals at 5.0 (H-1),

4.4 (H-2), 4.3 (H-4), and 3.4 (H-5) indicating both the X2 and X3

product were anomeric mixtures (5.05 ppm, alpha; 4.45 ppm,

Figure 4. Mass spectra of purified xylooligosaccharides: (a) xylobiose; (b) xylotriose.

34

X. Li et al. / Carbohydrate Research 359 (2012) 30–36

beta), which are in agreement with those reported by Drouet

et al.

and Li et al.

Several other xylanases including from Thermoascus auranti-

acu,

Trichoderma longibrachiatum,

Aspergillus oryzae MTCC

Figure 5.

1

H NMR spectra of purified xylooligosaccharides: (a) xylobiose; (b) xylotriose.

X. Li et al. / Carbohydrate Research 359 (2012) 30–36

35

Pichia stipitis,

and Geobacillus thermoleovorans

have

been previously demonstrated the capability of converting xylan

to xylose, and XOS with DPs of three or higher.

Meanwhile,

several few strains of Streptomyces sp. have been reported to pro-

duction of xylooligosaccharides. For an instant, hydrolysis of birch-

wood xylan by the xylanase from Streptomyces matensis DW67

yielded xylobiose and xylotriose as the principal products.

In

the hydrolysis of xylan by the xylanase from Streptomyces olivaceo-

viridis E-86, the xylobiose was the main products and the xylose,

xylotriose were the minor products.

In current study, xylanase

of S. rameus is the first report that hydrolyzed xylan producing

xylobiose and xylotriose.

4. Conclusions

The xylanase from S. rameus L2001 can convert X4 and X5 to X2

and X3 by transglycosation reaction. X2 and X3 are the principle

products in the hydrolysis of birchwood xylan, oat-spelt xylan,

and other xylans from agricultural residues by xylanase from S.

rameus L2001, the highest yield reached to 87.2%. We first report

how to obtain xylobiose and xylotriose using bagasse xylan as

the substrate of xylanase from S. rameus. The high yield of xylobi-

ose and xylotriose in the hydrolysis of agricultural residues by

xylanase from S. rameus indicates the application prosperity in

functional food industry. Further detailed studies on this enzyme

and its products are underway.

Acknowledgements

This research was financially supported by the Program for the

National Natural Science Foundation of China (No. 31071511), and

the Funding Project for Academic Human Resources Development

in Institutions of Higher Learning under the Jurisdiction of Beijing

Municipality (No. PHR20110872).

Supplementary data

Supplementary data associated with this article can be found, in

the online version, at

http://dx.doi.org/10.1016/j.carres.2012.05.

.

References

1. Hsu, C. K.; Liao, J. W.; Chung, Y. C.; Hsieh, C. P.; Chan, Y. C. J. Nutr. 2004, 134,

1523–1528.

2. Adsul, M. G.; Bastawde, K. B.; Gokhale, D. V. Bioresour. Technol. 2009, 100, 6488–

6495.

3. Vázquez, M. J.; Alonso, J. L.; Domínguez, H.; Parajó, J. C. Trends Food Sci. Technol.

2000, 11, 387–393.

4. Biely, P. Trends Biotechnol. 1985, 3, 286–290.

5. Beg, Q. K.; Kapoor, M.; Mahajan, L.; Hoondal, G. S. Appl. Microbiol. Biotechnol.

2001, 56, 326–338.

6. Subramaniyan, S.; Prema, P. Crit. Rev. Biotechnol. 2002, 22, 33–64.

7. Akpinar, O.; Erdogan, K.; Bostanci, S. Food Bioprod. Process. 2009, 87, 145–151.

8. Li, X. T.; She, Y. L.; Sun, B. G.; Song, H. L.; Zhu, Y. P.; Lv, Y. G.; Song, H. X. Biochem.

Eng. J. 2010, 52, 71–78.

9. Zilliox, C.; Debeire, P. Enzyme Microb. Technol. 1998, 22, 58–63.

10. Miller, G. L. Anal. Chem. 1959, 31, 426–428.

11. Jiang, Z. Q.; Deng, W.; Zhu, Y. P.; Li, L. T.; Sheng, Y. J.; Hayashi, K. J. Mol. Catal. B:

Enzym. 2004, 27, 207–213.

12. Lin, J.; Ndlovu, L. M.; Singh, S.; Pillay, B. Biotechnol. Appl. Biochem. 1999, 30, 73–

79.

13. Jiang, Z. Q.; Cong, Q. Q.; Yan, Q. J.; Kumar, N.; Du, X. D. Food Chem. 2010, 120,

457–462.

14. Yan, Q. J.; Hao, S. S.; Jiang, Z. Q.; Zhai, Q.; Chen, W. W. J. Mol. Catal. B: Enzym.

2009, 58, 72–77.

15. Kumar, K. S.; Manimaran, A.; Permaul, K.; Singh, S. J. Biosci. Bioeng. 2009, 107,

494–498.

16. Lee, J. W.; Park, J. Y.; Kwon, M.; Choi, I. G. J. Biosci. Bioeng. 2009, 107, 33–37.

17. Li, X. T.; Jiang, Z. Q.; Li, L. T.; Feng, W. Y.; Fan, J. Y.; Kusakabe, I. Bioresour.

Technol. 2005, 96, 1370–1379.

18. Maalej-Achouri, I.; Guerfali, M.; Gargouri, A.; Belghith, H. J. Mol. Catal. B: Enzym.

2009, 59, 145–152.

19. Haffmann, R. A.; Leeflang, B. R.; de Barse, M. M. J.; Kamerling, J. P.; Vliegenthart,

J. F. G. Carbonhydr. Res. 1991, 221, 63–81.

20. Drouet, P.; Zhang, M.; Legoy, M. D. Biotechnol. Bioeng. 1994, 43, 1075–1080.

21. Li, Y. K.; Yao, H. J.; Cho, Y. Biotechnol. Appl. Biochem. 2000, 31, 119–125.

22. Kalogeris, E.; Christakopoulos, P.; Vršanská, M.; Kekos, D.; Biely, P. J. Mol. Catal.

B: Enzym. 2001, 11, 491–501.

23. Kadi, N.; Belloy, L.; Chalier, P.; Crouzet, P. C. J. Agric. Food Chem. 2002, 50, 5552–

5557.

24. Aachary, A. A.; Prapulla, S. G. Bioresour. Technol. 2009, 100, 991–995.

25. Yang, H.; Wang, K.; Song, X.; Xu, F. Bioresour. Technol. 2011, 102, 7171–7176.

26. Verma, D.; Satyanarayana, T. Bioresour. Technol. 2012, 107, 333–338.

27. Cheng, H. L.; Wang, P. M.; Chen, Y. C.; Yang, S. S.; Chen, Y. C. Bioresour. Technol.

2008, 99, 227–231.

28. Ninawe, S.; Kapoor, M.; Kuhad, R. C. Bioresour. Technol. 2008, 99, 1252–1258.

29. Yan, Q. J.; Hao, S.; Jiang, Z. Q.; Zhai, Q.; Chen, W. W. J. Mol. Catal. B: Enzym. 2009,

58, 72–77.

30. Ding, C. H.; Jiang, Z. Q.; Li, X. T.; Li, L. T.; Kusakabe, I. World J. Microbiol.

Biotechnol. 2004, 20, 7–10.

36

X. Li et al. / Carbohydrate Research 359 (2012) 30–36

Document Outline

- A typical endo-xylanase from Streptomyces rameus L2001 and its unique characteristics in xylooligosaccharide production

- 1 Introduction

- 2 Material and methods

- 2.1 Production of xylanase by S. rameus L2001 and enzyme assay

- 2.2 Main reagents

- 2.3 Enzymatic hydrolysis of xylans and xylooligosaccharides as substrates

- 2.4 Enzymatic hydrolysis of other xylans from different kinds of agricultural waste

- 2.5 Purification of xylobiose and xylotriose

- 2.6 Identification of the structure of xylobiose and xylotriose

- 3 Results and discussion

- 4 Conclusions

- Acknowledgements

- Supplementary data

- References

Wyszukiwarka

Podobne podstrony:

Production of xylooligosaccharides using immobilized endo xylanase of Bacillus

planta endo beta 1,4 xylanase activity

7 materiały endo

An%20Analysis%20of%20the%20Data%20Obtained%20from%20Ventilat

Biomass Fired Superheater for more Efficient Electr Generation From WasteIncinerationPlants025bm 422

Bleaching Water Stains from Furniture

O'Reilly How To Build A FreeBSD STABLE Firewall With IPFILTER From The O'Reilly Anthology

Estimation of Dietary Pb and Cd Intake from Pb and Cd in blood and urine

pages from xm 754sx 3

Cw 2 Gin endo endokryn

Does the number of rescuers affect the survival rate from out-of-hospital cardiac arrests, MEDYCYNA,

Test 3 notes from 'Techniques for Clasroom Interaction' by Donn Byrne Longman

06 TETRACYKLINY STREPTOGRAMINY

How to draw Donkey from Shrek

big profits from a very dirty business

Progressing from imitative to creative exercises

12 Werntges controling KNX from Linux and USB

On the Actuarial Gaze From Abu Grahib to 9 11

więcej podobnych podstron