5441336658

HALDOR TOPSDE [T

17/20

Latest developments in ammonia production technology

7.2 ATR Scheme - 5000 MTPD

Process steam Superheated HP steam

product

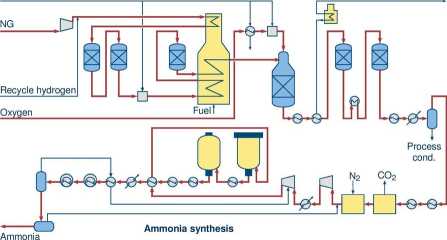

Figurę 13. ATR scheme for 5000 MTPD plant

When very high ammonia plant capacity is desired, the technology used for the reforming section may change to an autothermal reformer based reforming unit, to utilise the benefit of the ATR for very large plants as a result of economy of scalę considerations. The ATR scheme is illustrated in Figurę 13.

The ATR is fired with oxygen produced in a dedicated air separation unit (ASU), and a hydrogen-rich synthesis gas is produced. This synthesis gas is passing through the two shift reactors before the C02 is removed. Nitrogen for the ammonia synthesis is produced in the ASU and added in a nitrogen wash unit (NWU) located just upstream of the synthesis compressor. In this way the gas flow through the front-end is kept at a minimum. The steam to carbon ratio can in principle be very Iow in the ATR, often below 1 in synthesis gas plants, but in ammonia plants, due to the shift reaction and heat input requirement for the C02 section, the steam to carbon ratio is kept at a relative high level - around 2.2 - 2.3 depending upon actual gas conditions.

After the NWU the synthesis gas contains only hydrogen and nitrogen in the desired ratio, and the ammonia synthesis can be operated under inert-free conditions. This results in minimum flow in the ammonia synthesis loop, and the converter size is minimised as well due to the very reactive synthesis gas.

RESEARCH | TECHNOLOGY | CATALYSTS

Wyszukiwarka

Podobne podstrony:

HALDOR TOPSDE U 10/20 Latest developments in ammonia production technology The RCF, Trombay V revamp

HALDOR TOPSDE U 11/20 Latest developments in ammonia production technology Figurę 7. HTER internat b

HALDOR TOPSDE U 12/20 Latest developments in ammonia production technology During the test-run, it w

HALDOR TOPSDE [T 13/20 Latest developments in ammonia production technology Figurę 10. NH3 plant ref

HALDOR TOPSDE U 15/20 Latest developments in ammonia production technology Figurę 11. Layout of ammo

HALDOR TOPSDE U 16/20 Latest developments in ammonia production technology Figurę 12. Corwentional s

HALDOR TOPSDE U 18/20 Latest developments in ammonia production technology 7.3 Autothermal reformer

HALDOR TOPSDE U 9/20 Latest developments in ammonia production technology 4.1.3 IFFCO, Kalol energy

HALDOR TOPSDE U 2/20 Latest developments in ammonia production technology 2 Latest developments in a

HALDOR TOPSDE U 3/20 Latest developments in ammonia production technology 3 New developments Two mai

HALDOR TOPSDE [T 4/20 Latest developments in ammonia production technology installed as shown in Fig

HALDOR TOPSDE U 5/20 Latest developments in ammonia production technology The HTER-p is heated by th

HALDOR TORSOE U 1 / 20 Latest developments in ammonia production technology by Svend Erik Nielsen Ha

HALDOR TOPSOE CE 19/20 Latest developments in ammonia production technology importance. For further

HALDOR TORSOE U 7/20 Latest developments in ammonia production technology Figurę 5. Layout of synthe

HALDOR TORSOE U 8/20 Latest developments in ammonia production technology The S-50 converter consist

HALDOR TOPSDE U Latest developments in ammonia production technology

Theoretical and practical skills of a wide rangę of technologies in food production - technolog

więcej podobnych podstron